Micro-space combustion test measuring table based on modular design

A modular design, combustion test technology, applied in the direction of measuring devices, engine testing, machine/structural component testing, etc., can solve the difficult observation and measurement of internal flow field parameters, difficult to obtain the entire field parameters, impossible to provide space and other issues, to achieve the effect of strong adjustability, strong versatility, and strong observability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

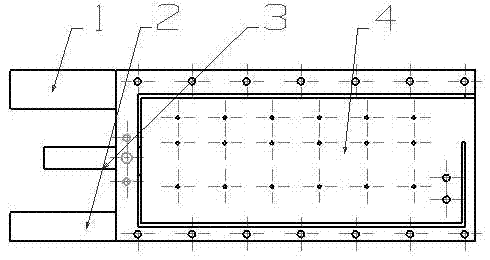

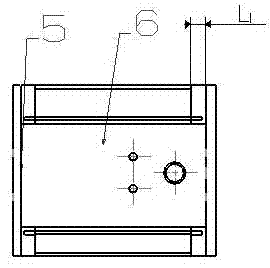

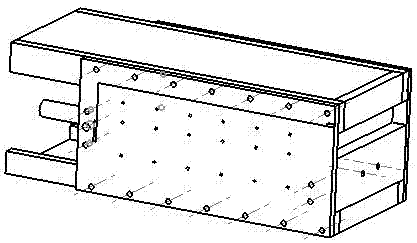

[0011] Referring to the accompanying drawings, its structure includes 4 mutually independent material transport channel modules, 3 of which are air supply channel modules and 1 fuel channel module, and the 3 air supply channel modules are respectively designed above the combustion test measuring platform. The upper channel air supply module 1 used to supply air to the jet holes on the outer wall, the lower channel air supply module 2 used to supply air to the jet holes on the outer wall under the combustion test measurement table, and the air supply channel module where a stream of air directly enters the evaporation tube , 1 fuel channel module is the fuel channel module from which fuel enters the evaporation tube from the fuel channel. It is used to fix the evaporation tube and is the front-end module 3 of the combustion table. When using optical glass and a metal plate with a measuring hole to cut off 4.

[0012] The width of the jet orifice on the inner and outer walls is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com