Micro-combustion thermoelectric generator based on porous medium micro-combustion

A technology of thermoelectric generators and porous media, applied in gas fuel burners, burners, combustion methods, etc., can solve problems such as high cost, high production requirements, and damage to thermoelectric modules, and achieve easy processing and manufacturing and solve ignition difficulties , Guarantee the effect of timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

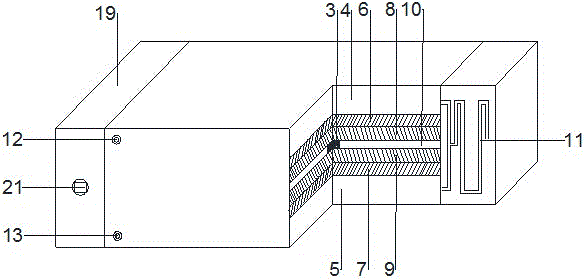

[0022] It is difficult to carry out combustion in a small volume, so it is necessary to ensure the stable and continuous combustion from many aspects. Such as figure 1 As shown, this device uses porous media to fill the combustion chamber, uses the sheet-like structure and the specially designed heat-conducting oil heat insulation layer to form a temperature gradient, and uses the heat exchange between layers to ensure the progress of combustion and reduce heat loss. From top to bottom: fuel storage layer 4, upper thermoelectric power generation piece 6, upper heat insulation layer 8, combustion module 10, lower heat insulation layer 9, lower thermoelectric power generation piece 7, combustion aid storage layer 5, that is, the combustion chamber is located The hot end of the thermoelectric sheet, the storage layer of fuel and oxidant is located at the cold end of the therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com