Method for preparing porous metal oxide by cold plasma-induced combustion

A cold plasma, porous metal technology, applied in the fields of energy science and material science, can solve the problems of long reaction time, not green and environmental protection, difficult to control, etc., and achieves the effect of fast processing rate, environmental friendliness, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] ZrO 2 The colloidal solution is impregnated on the activated carbon pellets, and the atomic mass of Zr accounts for 20% of the total mass. The loaded solid C77Zr is directly spread on the quartz glass plasma reaction chamber, and it is induced at room temperature. The average input voltage is 14000V, and the input current It is 0.3~0.8A, and the treatment time is 2 minutes each time, 8 minutes in total for 4 times. The discharge atmosphere used is an oxygen atmosphere, and the oxygen flow rate is 30mL min -1 . At the end of the discharge, the temperature of the quartz kettle is still at room temperature.

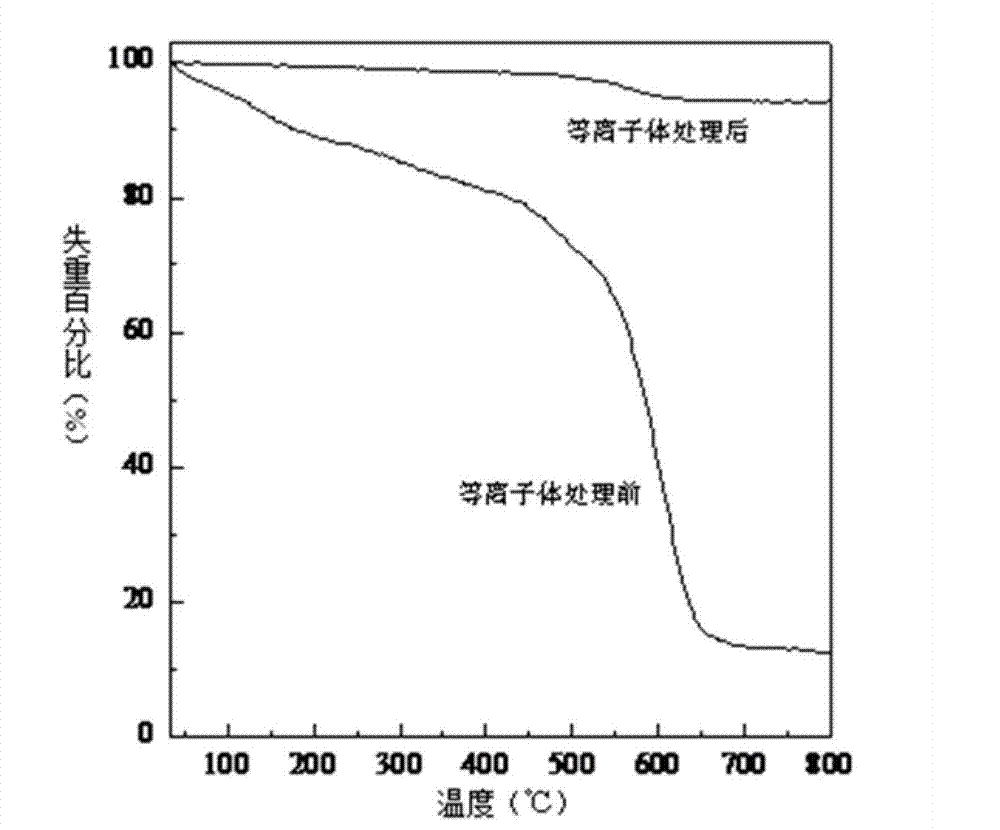

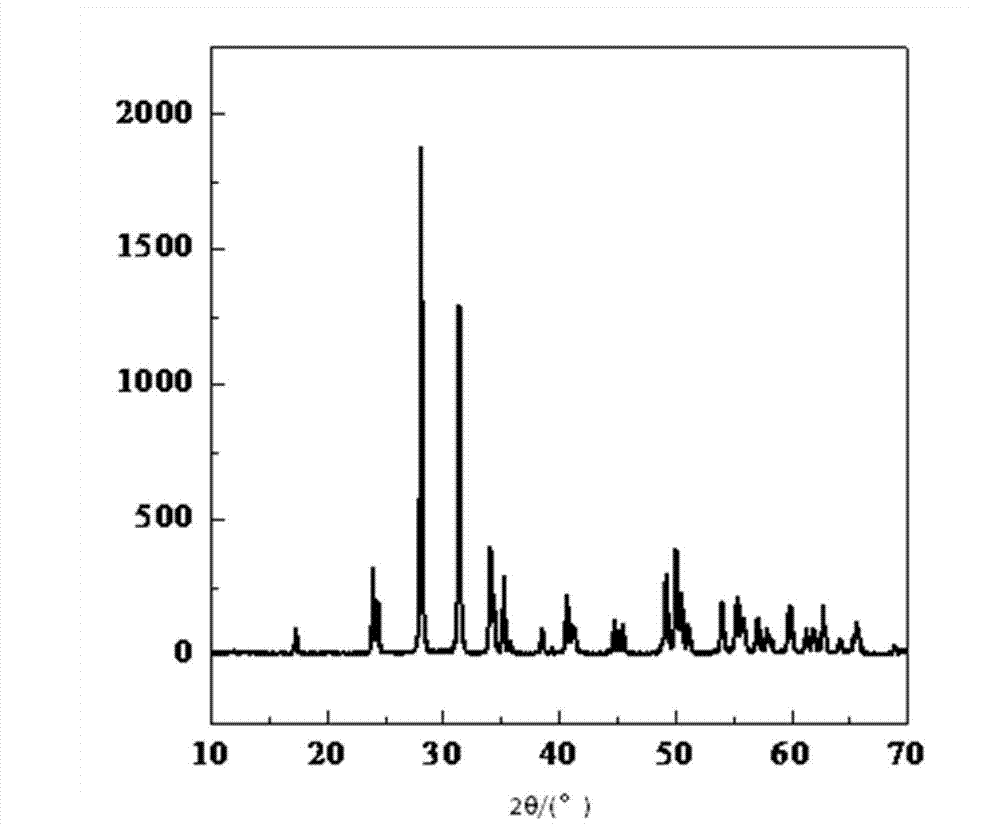

[0033] The prepared ZrO 2 After surface color observation, thermogravimetric analysis, X-ray diffraction and nitrogen adsorption and desorption analysis, the following analysis results were obtained:

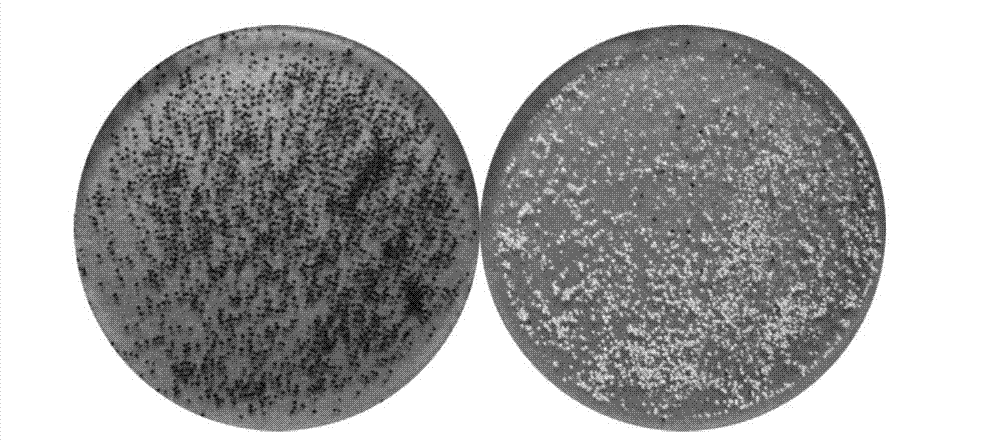

[0034] like figure 1 As shown in the photo comparison of the samples before and after plasma treatment, it can be observed that the color of the sample changes sig...

Embodiment 2

[0039] NiCl 2 The equal volume is impregnated on the coal powder, the atomic mass of Ni accounts for 25% of the total mass, and the moisture is removed by drying after impregnation. The loaded solid is directly spread on the quartz glass plasma reaction chamber, and it is induced at room temperature. The average input voltage is 10000V, the input current is 0.5-01.0A, and the treatment time is 3 minutes each time, 12 minutes in total for 4 times. The discharge atmosphere used is an oxygen atmosphere, and the oxygen flow rate is 30mL min -1 . The plasma treatment process is accompanied by electric sparks, and the treated sample is mesoporous NiO with a pore size distribution of 5-20nm.

Embodiment 3

[0041] Zn(NO 3 ) 2 The equal volume is impregnated on the activated carbon particles, the atomic mass of Zn accounts for 40% of the total mass, and the moisture is removed by drying after impregnation. The loaded solid is directly spread on the quartz glass plasma reaction chamber, and it is induced at room temperature. The average input voltage is 14000V, the input current is 0.3-1.2A, and the treatment time is 3 minutes each time, 30 minutes in total for 10 times. The discharge atmosphere used is an oxygen atmosphere, and the oxygen flow rate is 30mL min -1 . After plasma treatment, the sample turns from black to white, and electric sparks appear during the treatment.

[0042] like Figure 5 The shown nitrogen adsorption-desorption isotherm of the sample after plasma treatment, after calculation, the specific surface area of the sample is 92.04m 2 g -1 , the pore size distribution is mainly concentrated around 1.68nm, it can be seen that the sample is microporous ZnO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com