Micro-combustion thermal-photovoltaic generating device with regeneration function

A thermal photovoltaic power generation and micro-combustion technology, applied in photovoltaic power generation, photovoltaic power stations, burners, etc., can solve the problems of short continuous working time and low energy density, and achieve convenient refueling, high energy density and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

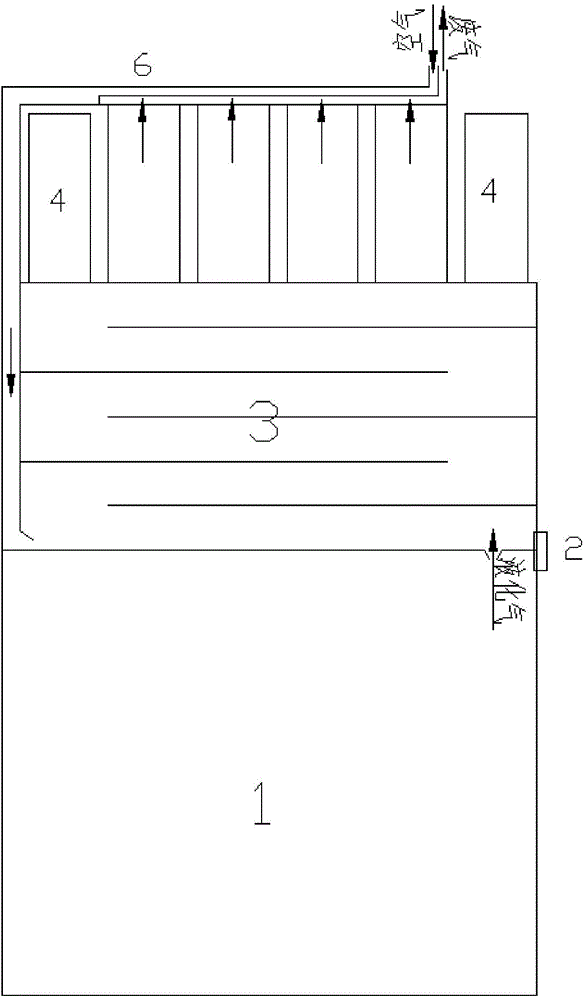

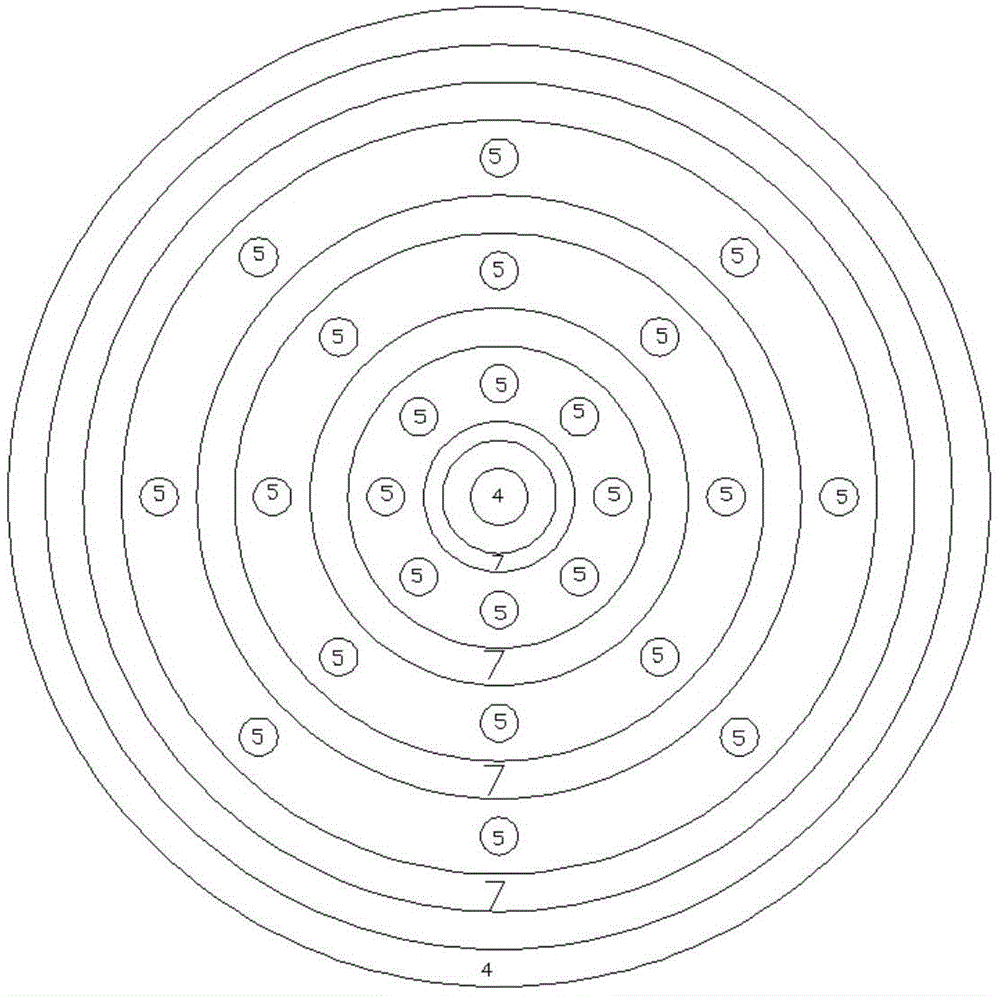

[0031] refer to figure 1 , image 3 , to illustrate the specific technical solutions of the present invention. A micro-combustion thermal photovoltaic power generation device with heat recovery function, comprising: a housing, and placed in the housing: a fuel tank 1 for storing fuel, and the fuel can be liquefied hydrogen, methane, n-butane or these substances The fuel flow regulating valve 2 controls the flow of fuel after gasification; the mixing chamber 3; the igniter 4 adopts piezoelectric material and uses piezoelectric effect to ignite; 12 micro burners 5 are arranged side by side;

[0032] The thermal photovoltaic panel 7 absorbs the thermal radiation energy on the wall of the micro burner and converts it into electrical energy, using gallium antimonide GaSb or a material based on it;

[0033] Composite two-way gas channel 6, one of which is an exhaust gas discharge pipeline, connected to the exhaust port of the combusted gas of the micro-burner; the other is connect...

Embodiment 2

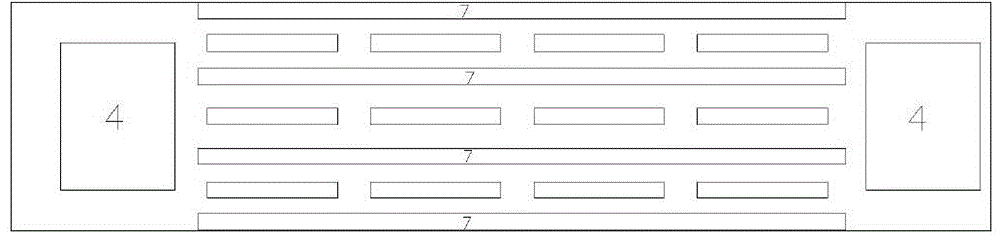

[0040] control figure 2 , to illustrate the specific technical solutions of the present invention. A micro-combustion thermal photovoltaic power generation device with heat recovery function, including: a casing, and placed in the casing: a fuel tank 1 for storing fuel, and the fuel can be selected from liquefied hydrogen, methane, and n-butane, which can also be used A mixture of several substances; a fuel flow regulating valve 2, which controls the flow of gasified fuel; a mixing chamber 3; an igniter 4, which uses piezoelectric materials to ignite by piezoelectric effect; 24 micro burners 5 arranged in parallel;

[0041] The thermo-photovoltaic panel 7 absorbs the thermal radiation energy of the wall surface of the micro-combustor and converts it into electric energy, using gallium antimonide GaSb or a material based on it.

[0042] Composite two-way gas channel 6, one of which is an exhaust gas discharge pipeline, connected to the exhaust outlet of the micro-burner; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com