Micro-combustion equipment controlling air flow by using ionic wind

A micro-burner, ion wind technology, applied in the directions of gas fuel burners, burners, combustion methods, etc., can solve the problems of low energy consumption rate and low heat dissipation, achieve less heat dissipation, reduce wall heat loss, combustion good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

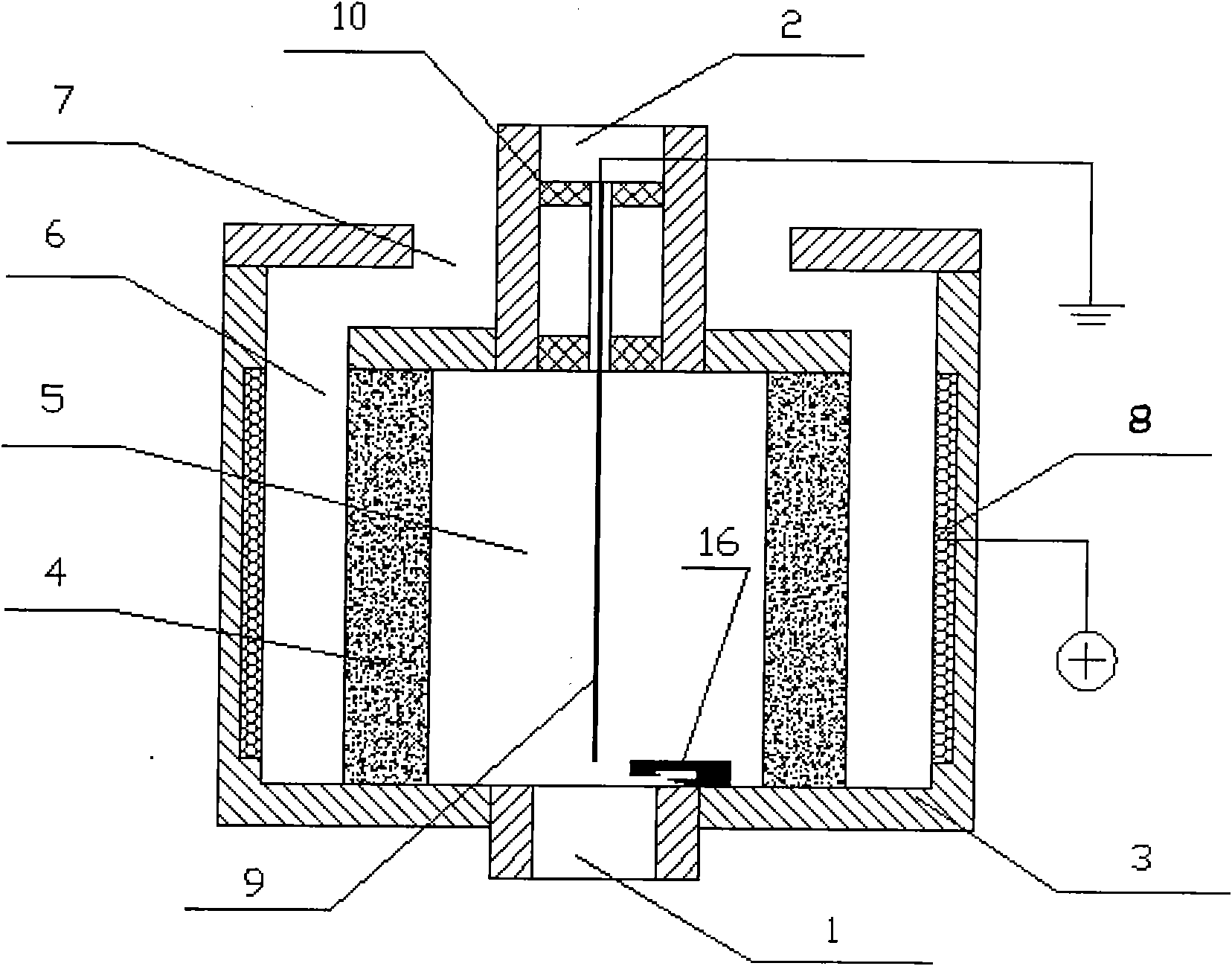

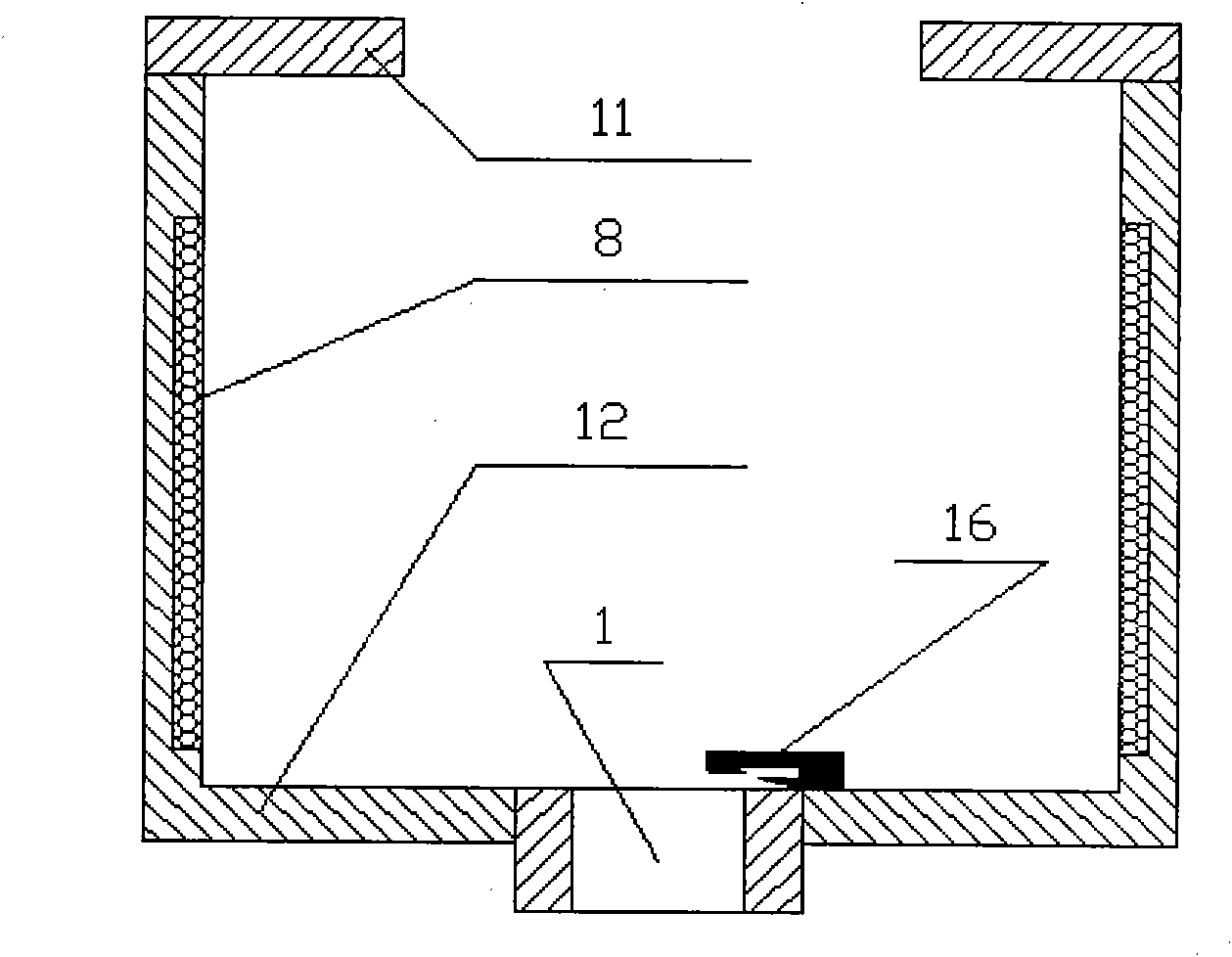

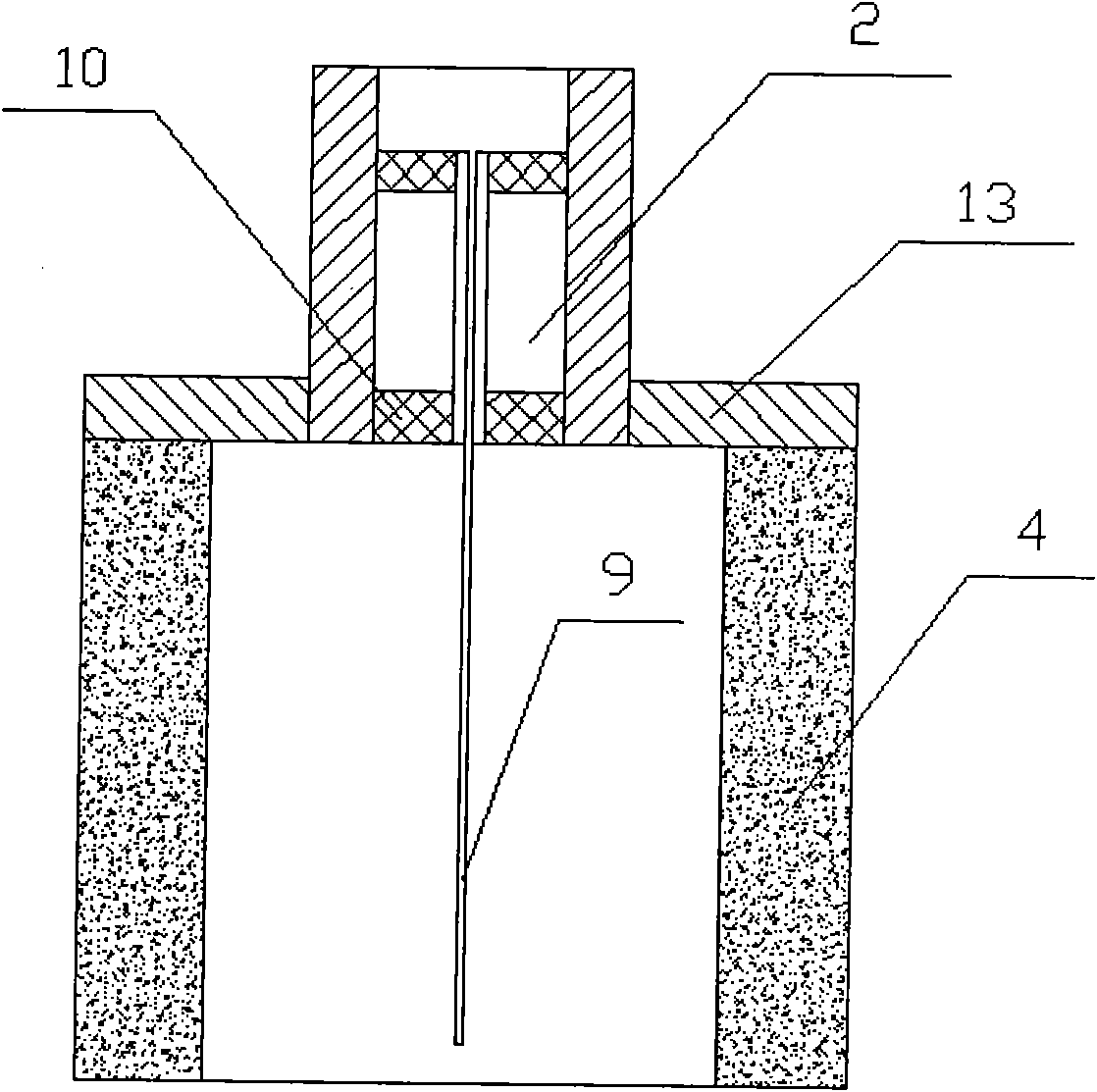

[0033] Such as figure 1 Shown, the micro-combustor of the present invention comprises outer casing wall 3, inner casing wall 4, fuel inlet hole 1, exhaust hole 2, air inlet hole 7 and electronic ignition device 16; Fuel inlet hole 1 and exhaust hole 2 are respectively located at both ends of the inner sleeve wall 4 in the axial direction. The side of the inner sleeve wall 4 is a porous material formed by sintering ceramic powder, with a thickness of 1mm and an air permeability of 30%. The outer sleeve wall 3 is made of ceramic material. The casing wall 4 forms an interlayer space 6, the sections of the fuel inlet hole 1, the exhaust hole 2, the inner casing wall 4 and the outer casing wall 3 are all circular, and the air intake hole 7 is formed between the outer casing wall 3 and the exhaust hole 2 In the annular gap, the micro burner is provided with an electrode device.

[0034] The electrode device consists of an electrode anode 8 and an electrode cathode 9, such as figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electric field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com