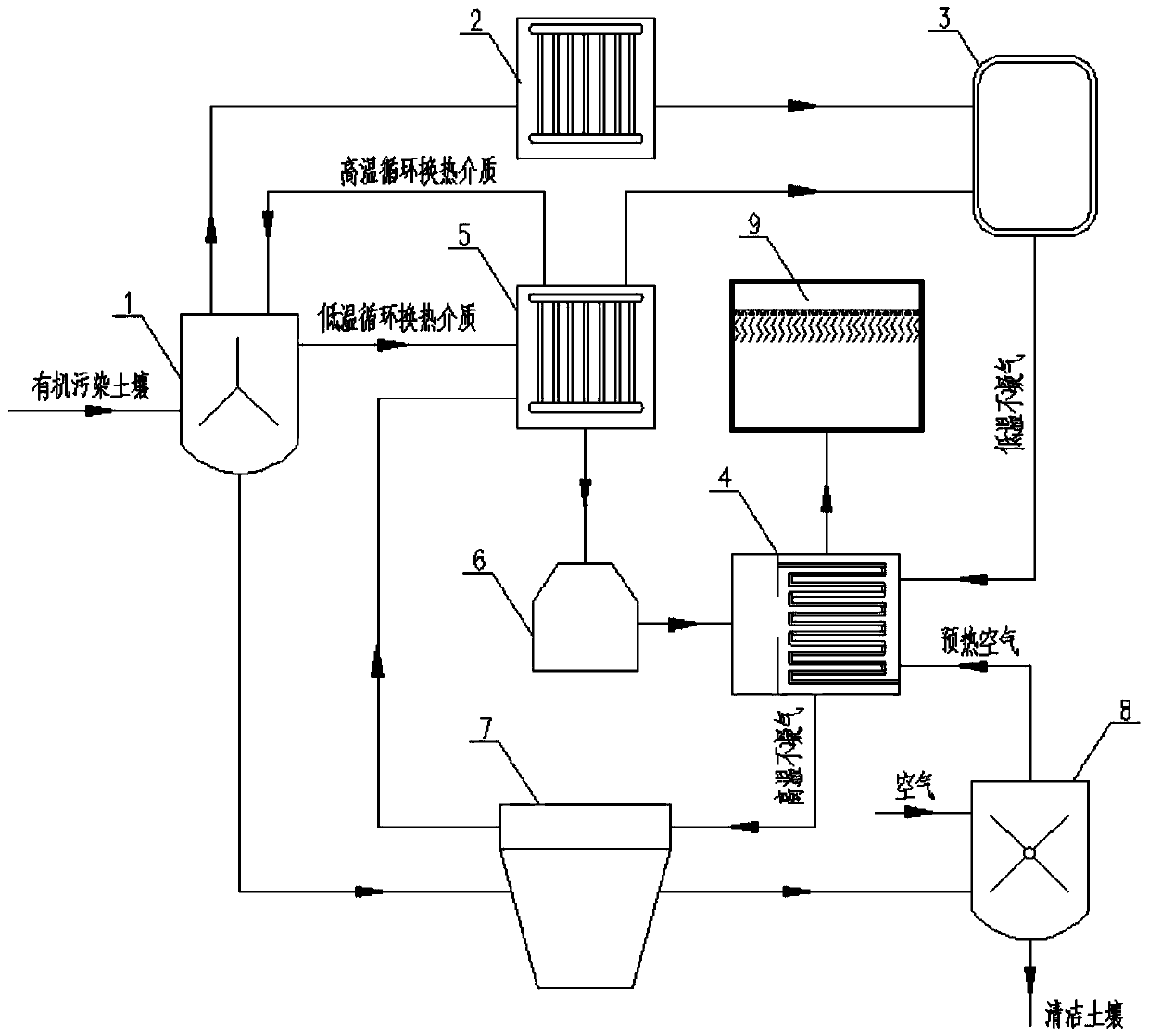

Device and method for sectional type thermal remediation of organic contaminated soil

An organic pollution and thermal remediation technology, applied in the field of soil remediation, can solve the problems of high process energy consumption, low heat exchange efficiency, large land occupation, etc., to achieve the effect of ensuring fertility and reducing volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] The organic polluted soil to be treated is sent to the agitating preheating device 1 for indirect heat exchange with the high-temperature circulating heat exchange medium from the condensing device B5. The organic polluted soil is continuously stirred and heated. Condensation device A2 condenses and sends it to the non-condensable gas storage tank 3 for storage, and the high-temperature circulating heat exchange medium after heat exchange is sent to the condensation device B5 for heat storage; the preheated soil is sent to the thermal analysis device 7, and the heat from the combustion The high-temperature non-condensable gas in the heat exchanger 4 performs direct contact heat exchange, the organic polluted soil is heated again and undergoes a thermal analysis reaction, and the analytical gas products inside the organic contaminated soil are continuously precipitated and sent to the condensation device B5. After the thermal analysis reaction is completed, The high-tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com