Novel power device for generating electric energy and thrust based on micro-combustion

A power plant, micro-combustion technology, applied in jet propulsion, piezoelectric effect/electrostrictive or magnetostrictive motor, generator/motor, etc., can solve the problem of short residence time of mixture and overall conversion efficiency of the system Not high, not enough combustion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

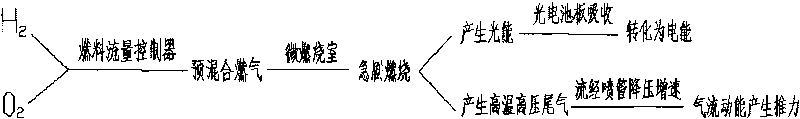

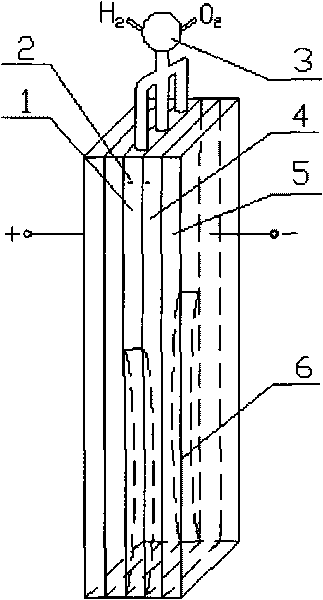

[0018] As attached to the manual figure 1 As shown, the hydrogen-oxygen fuel is mixed in a certain proportion through the gas mixer 3, enters the micro-parallel plate combustion chamber 1, and burns after being ignited by the electronic ignition electrode 2. The photons released at high temperature pass through the vacuum quartz heat insulation layer 4 and hit the external photovoltaic system. On the battery, it is converted into electrical energy output. In addition, the high-temperature and high-pressure exhaust gas is decompressed and accelerated through the tail nozzle 6, and the internal energy is converted into kinetic energy to generate thrust. Corresponding to different voltage / current and thrust requirements, it can be realized by adjusting the combustion flow and connecting multiple micro burners in series. The fuel used should be preferably hydrogen, and the tail gas generated is non-polluting high-temperature water vapor. Biomass biogas produced by composting of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com