Patents

Literature

183results about How to "Reduce wall temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

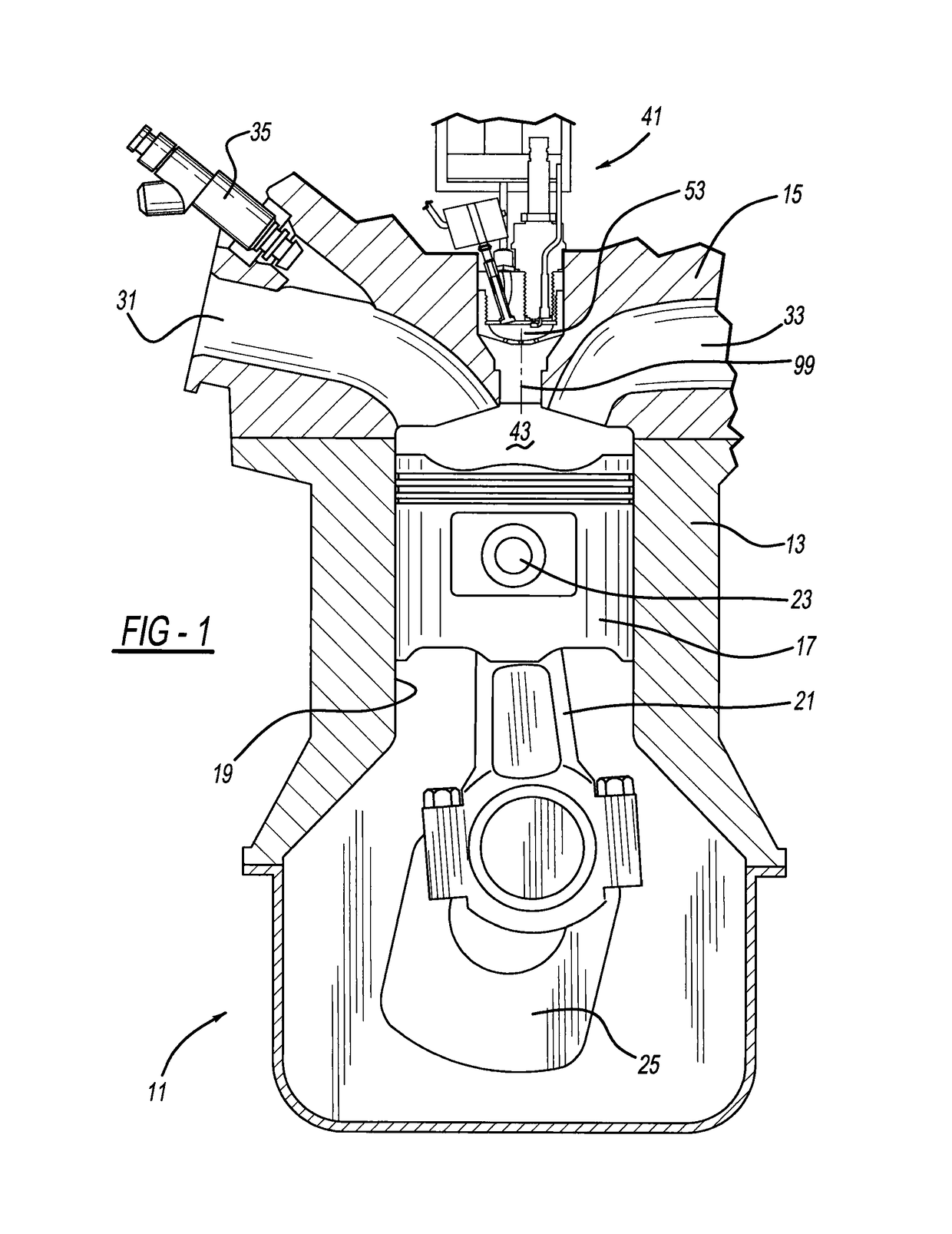

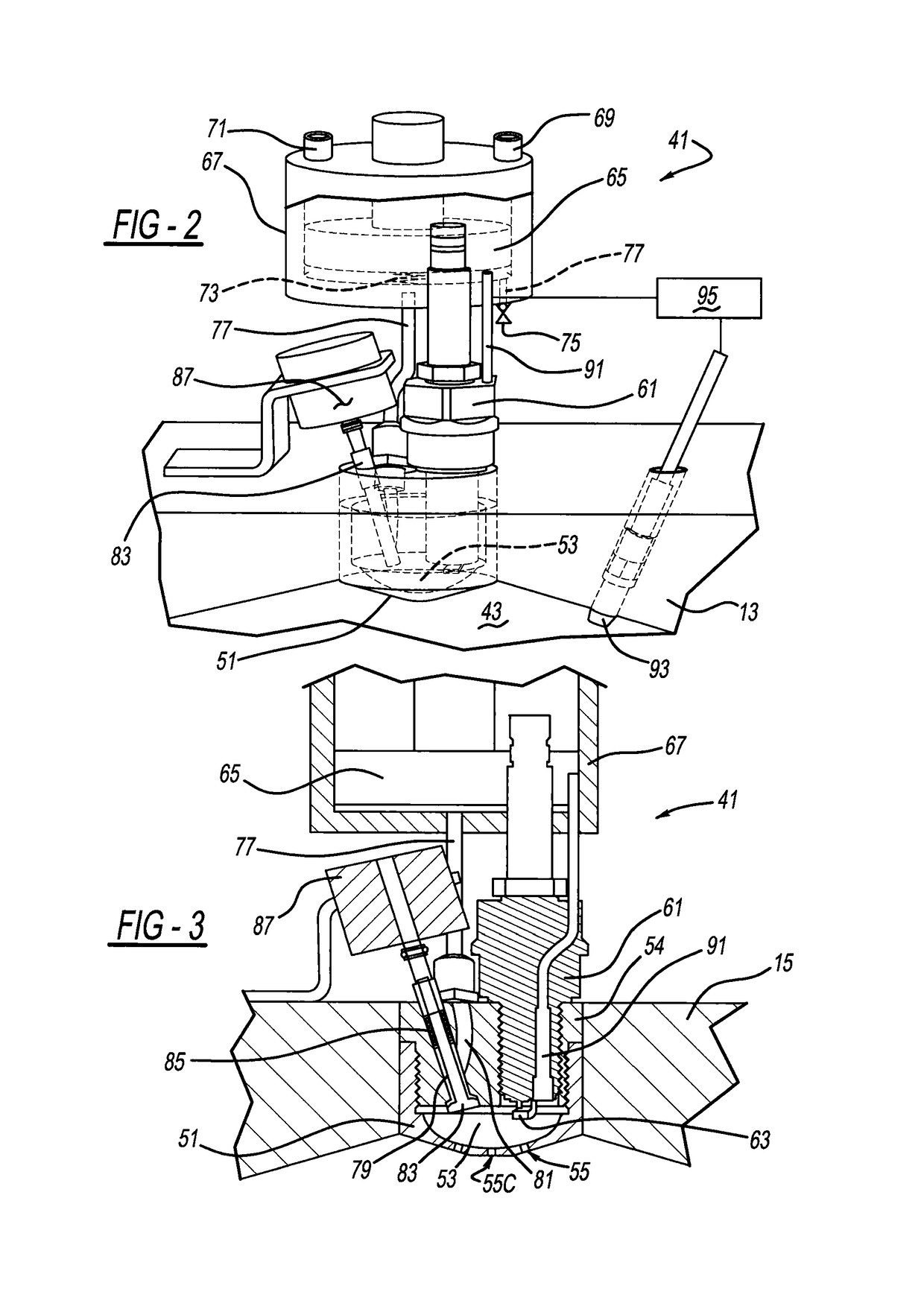

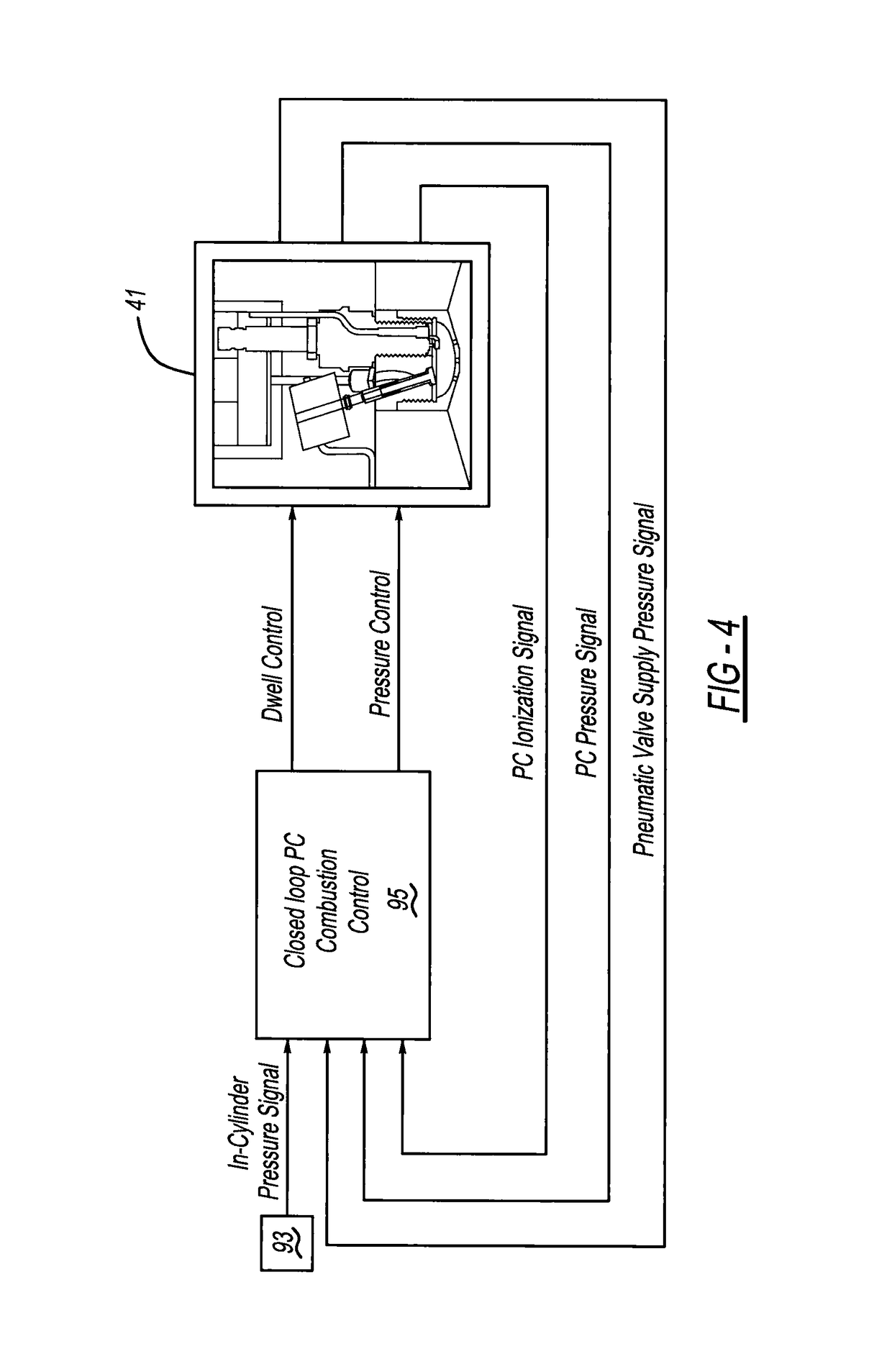

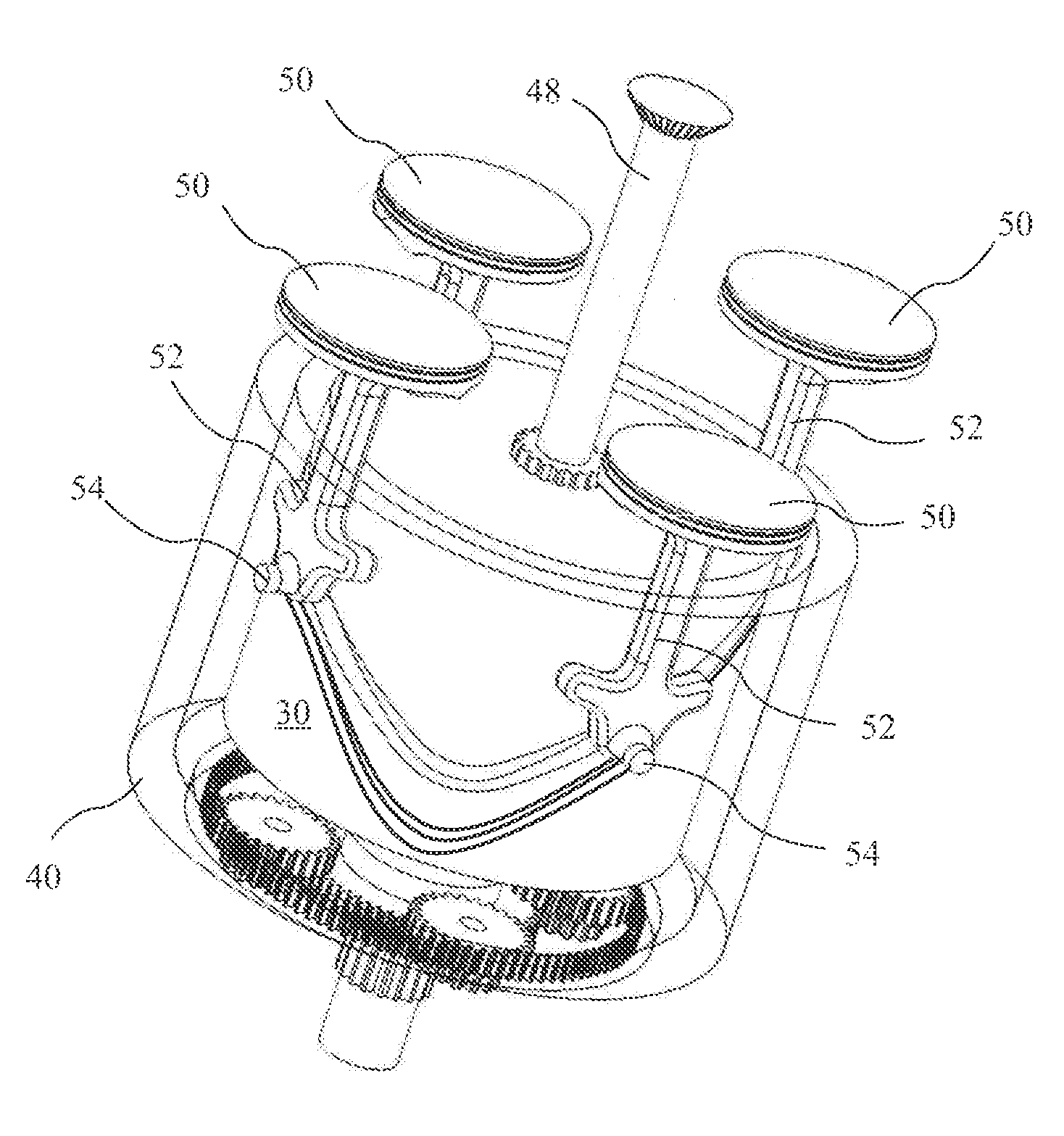

Internal combustion engine

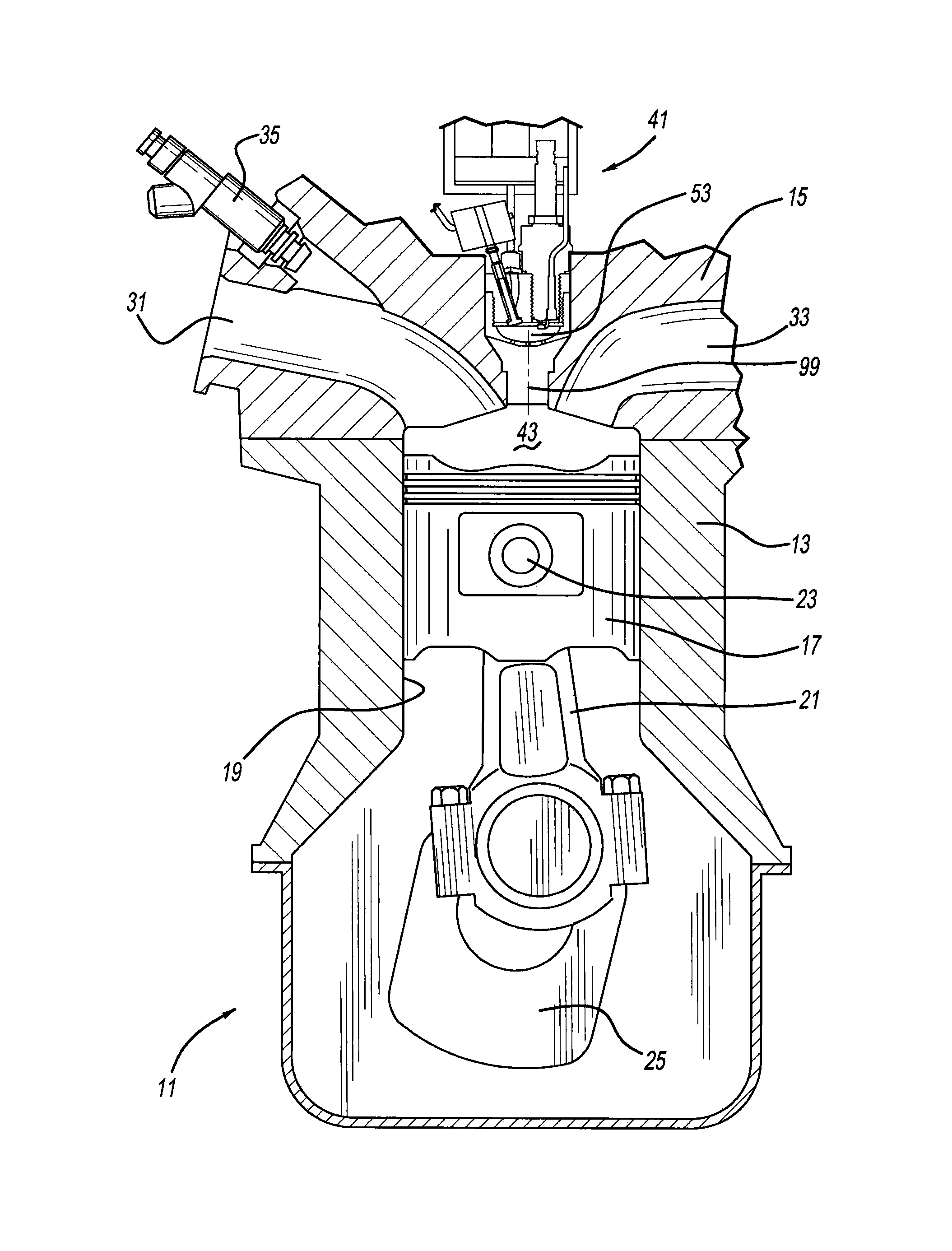

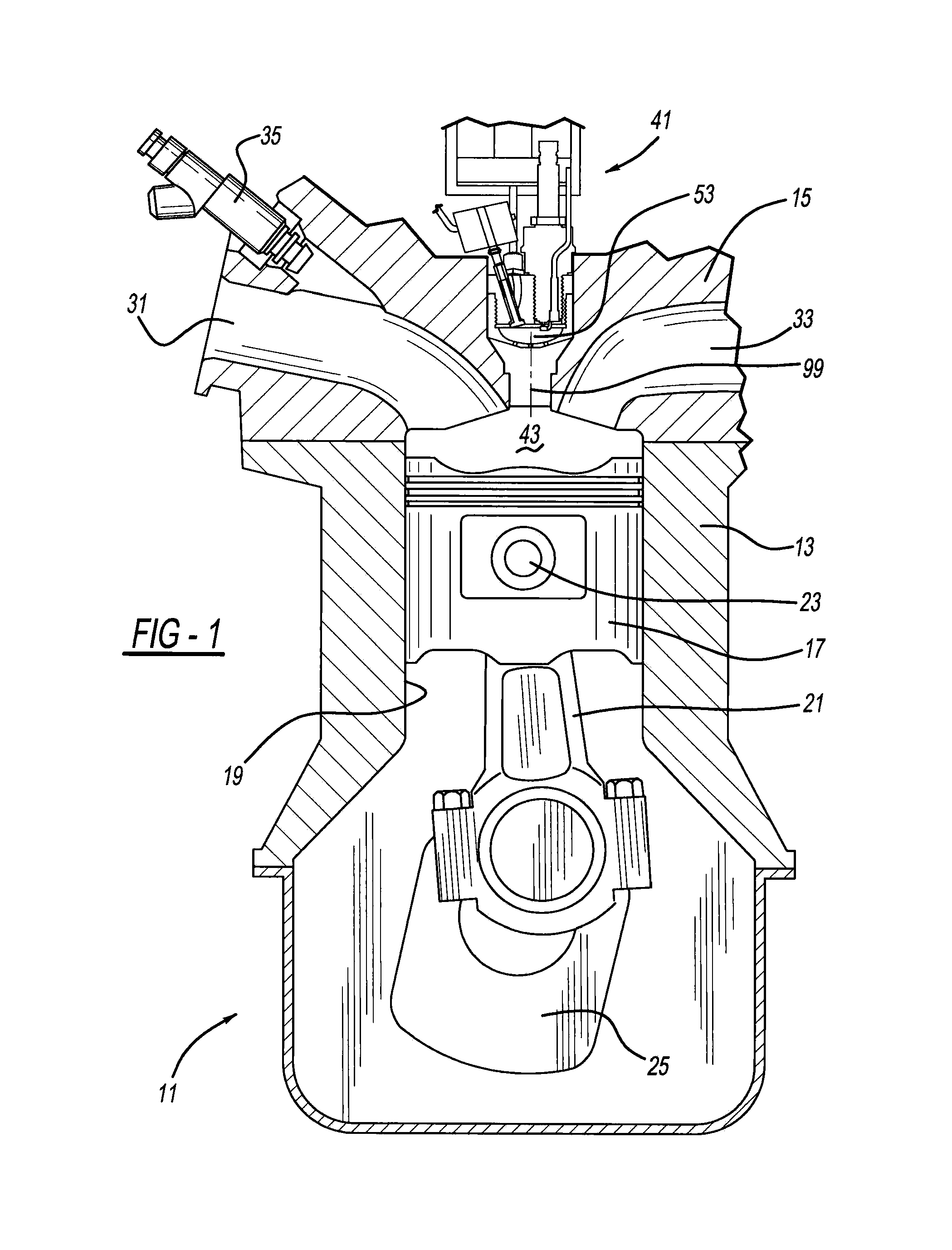

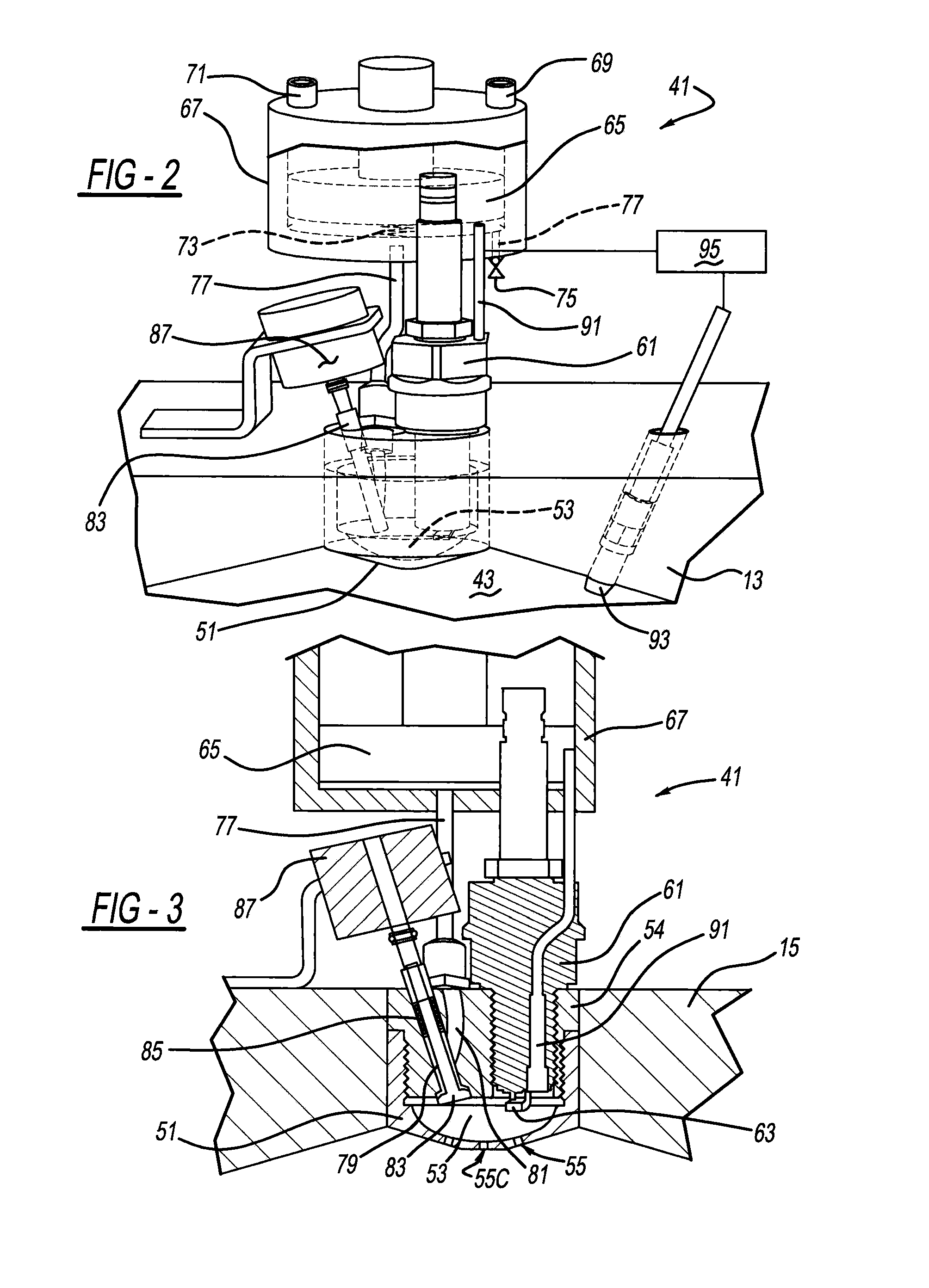

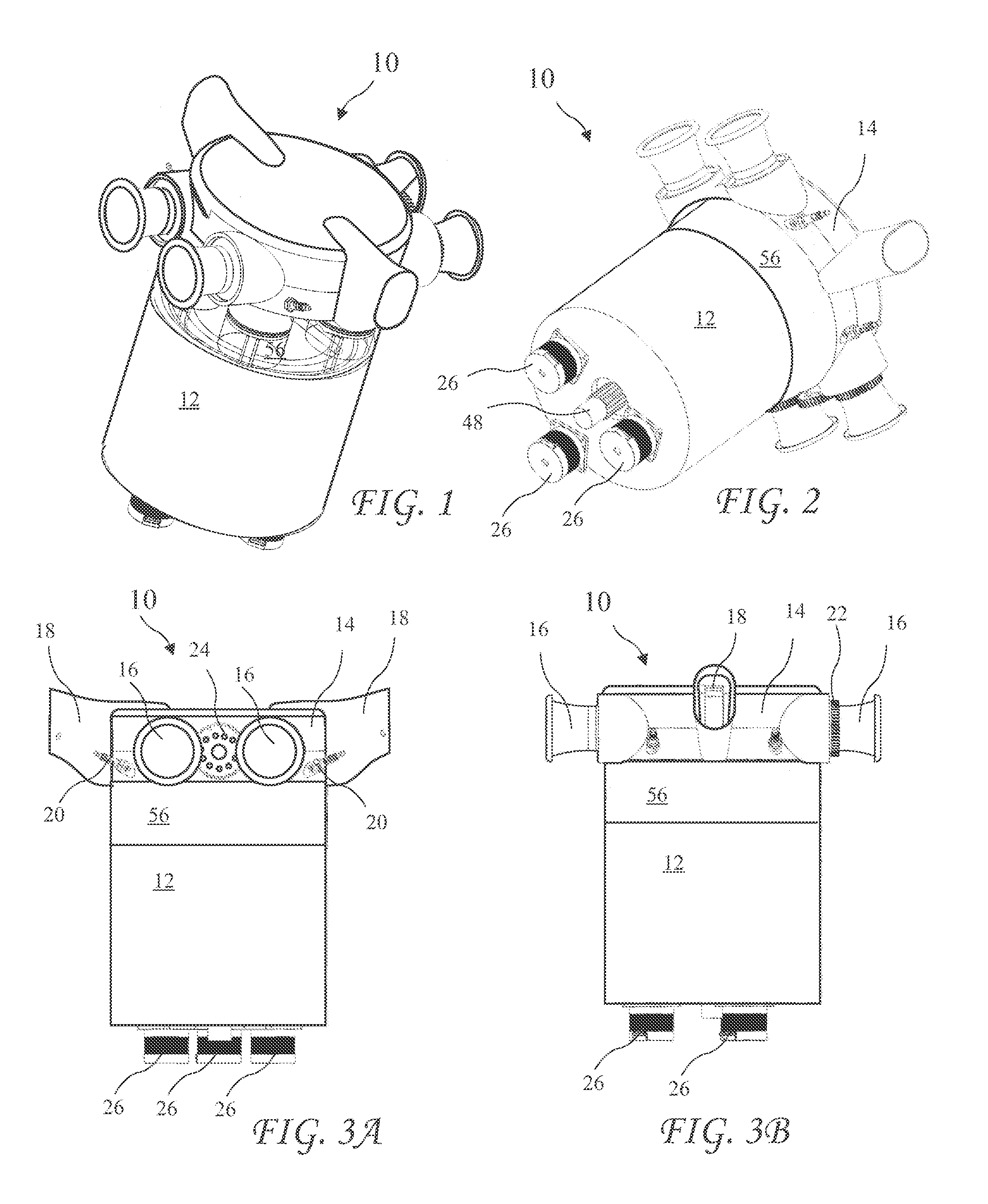

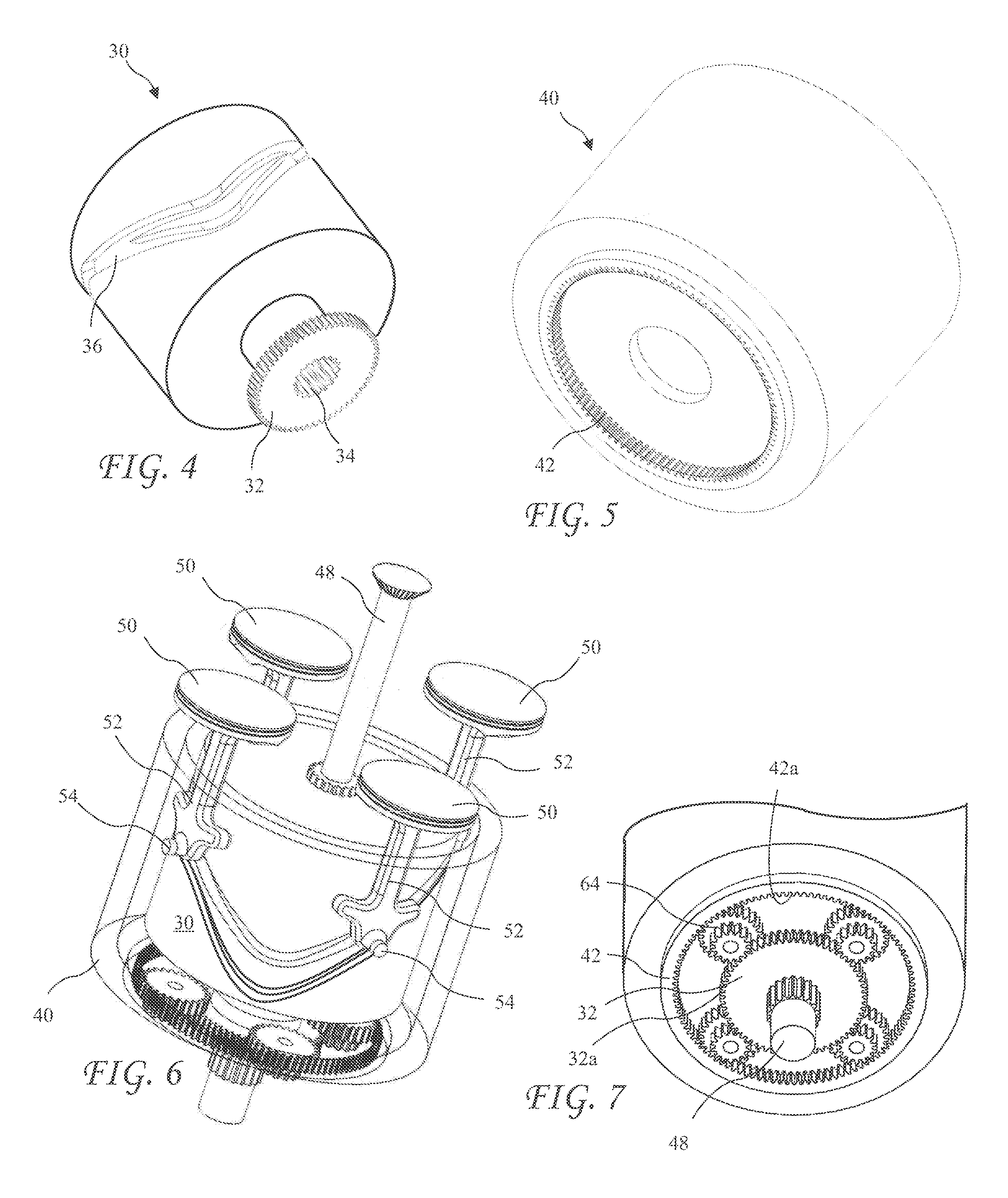

ActiveUS20160230645A1Lower overall cycle average pre-chamber wall temperatureReduce heat transfer lossInternal combustion piston enginesCylinder headsPistonInjector

An internal combustion engine includes a pre-chamber. In another aspect, pressure within a pre-chamber is equal to or greater than pressure within a main combustion chamber at least prior to ignition in the main combustion chamber. A further aspect provides a supplemental piston creating pressure and supplying a fuel-air mixture into a pre-chamber, and a spark or glow plug has an end located within the pre-chamber for ignition of the mixture therein. In yet another aspect, internal combustion engine control software automatically controls pressure within a turbulent jet ignition pre-chamber, controls a valve-actuator to admit a fuel-air charge into the pre-chamber, and causes an ignitor to initiate combustion in the pressurized pre-chamber. This also permits the rate of combustion to be controlled in the primary chamber regardless of the air-fuel ratio or the diluent fraction in the main chamber. Another aspect employs a pre-chamber purge pump with separate air and fuel injection. Moreover, an additional aspect separately supplies unmixed air and fuel into a turbulent jet ignition pre-chamber through a dual-mode, single injector unit.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

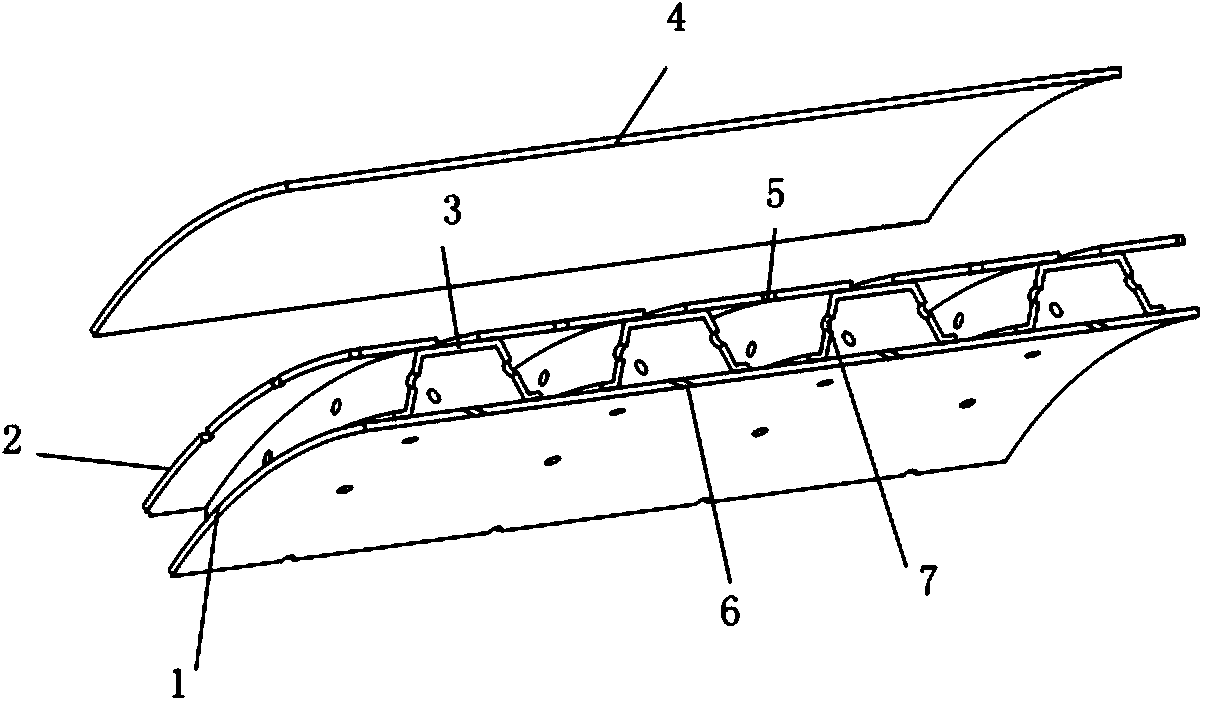

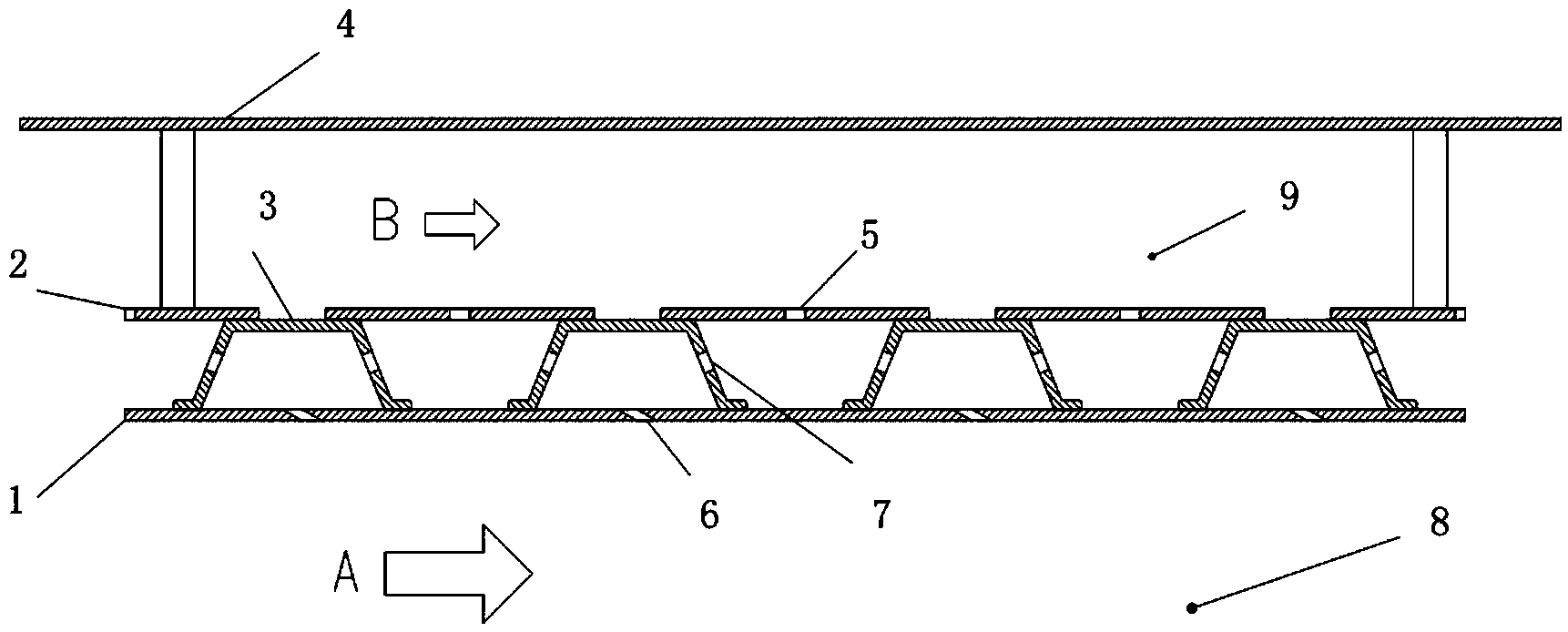

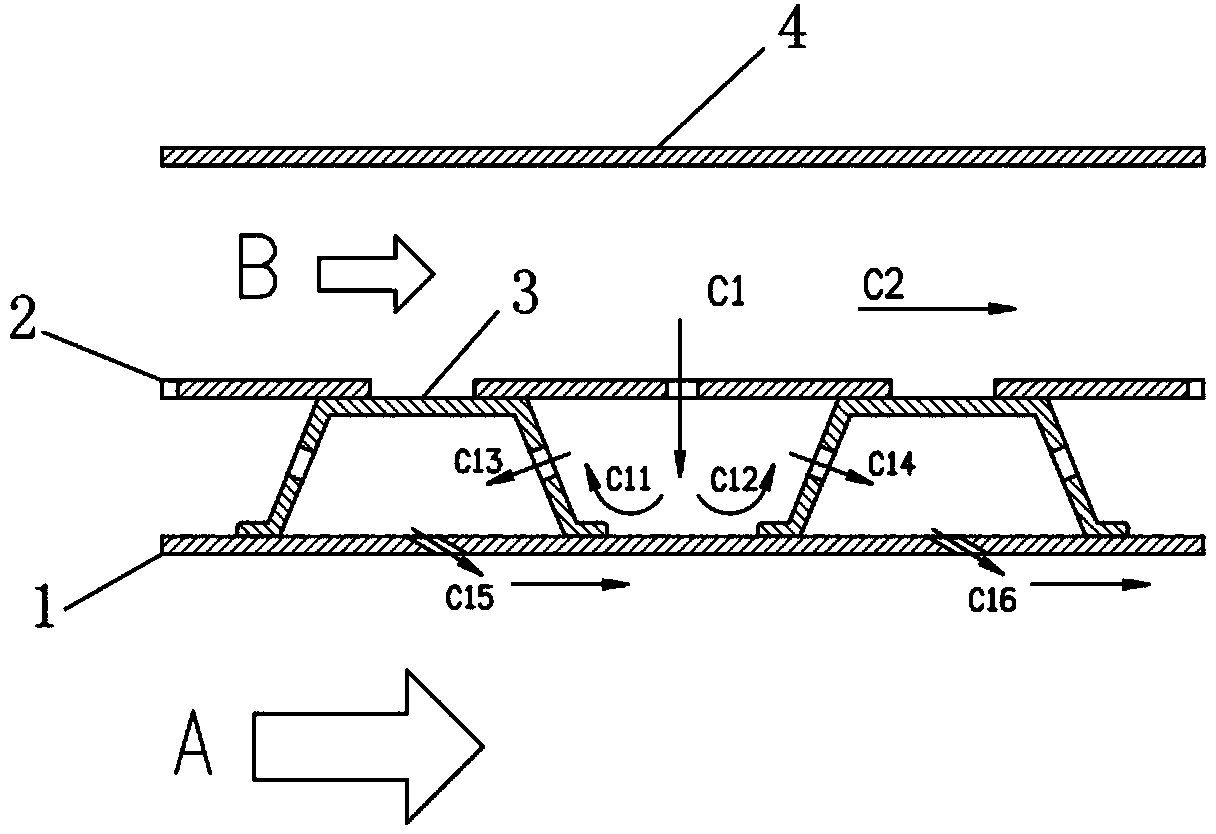

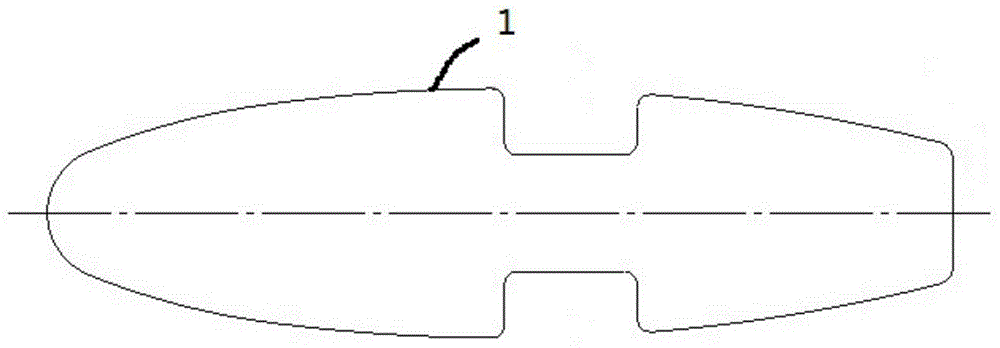

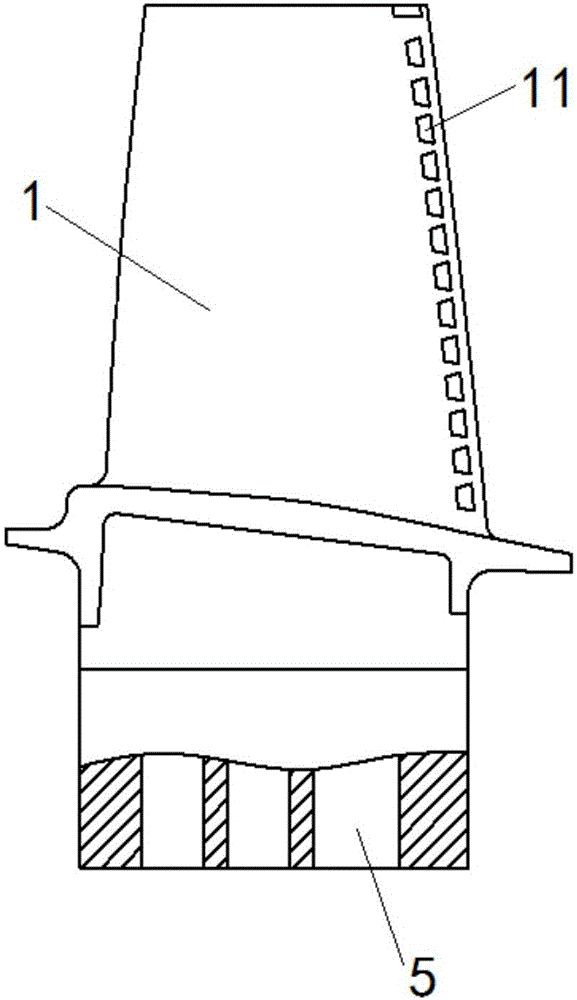

Double-layer-wall heat insulation screen used for afterburner

InactiveCN103968418AReduce heat load and gas flow lossReduce wall temperatureContinuous combustion chamberCombustion chamberEngineering

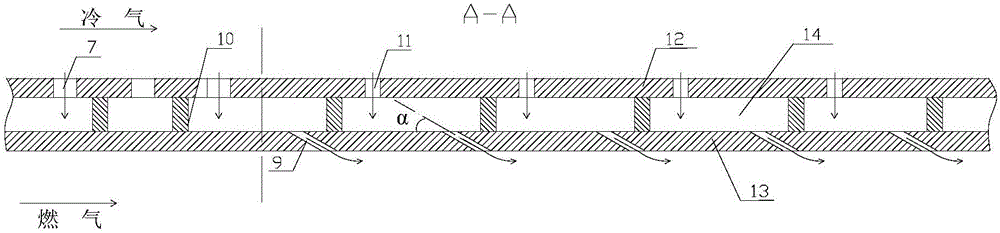

The invention discloses a double-layer-wall heat insulation screen used for an afterburner. Cooling protection is formed for the wall surface of the afterburner by using an inner convection cooling mode and a gas side air film cooling mode. The double-layer-wall heat insulation screen comprises a gas side gas film hole plate, a cool air side impacting plate and a trapezoidal reinforcing frame. The gas side air film hole plate serves as the inner wall of a cylinder body of the afterburner, the inner side of the gas side air film hole plate is provided with a main gas duct of the afterburner, the cool air side impacting plate and an outer wall surface form a cool air duct, and the trapezoidal reinforcing frame is arranged between the impacting plate and the air film hole plate. The double-layer-wall heat insulation screen is formed by the impacting plate, the air film hole plate and the trapezoidal reinforcing frame. Cooling air is made to form an air film on the gas side inner wall of the heat insulation screen, and heat load and gas flow losses are reduced. In addition, composite cooling is formed through inner convection cooling and outer air film cooling of a double-layer wall, incoming heat is brought away through convection heat exchange, and the cool air utilization rate is increased. Reduction is achieved after reflection, the effect of vibration prevention is achieved, the service life of the afterburner is prolonged, and the reliability of the afterburner is enhanced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

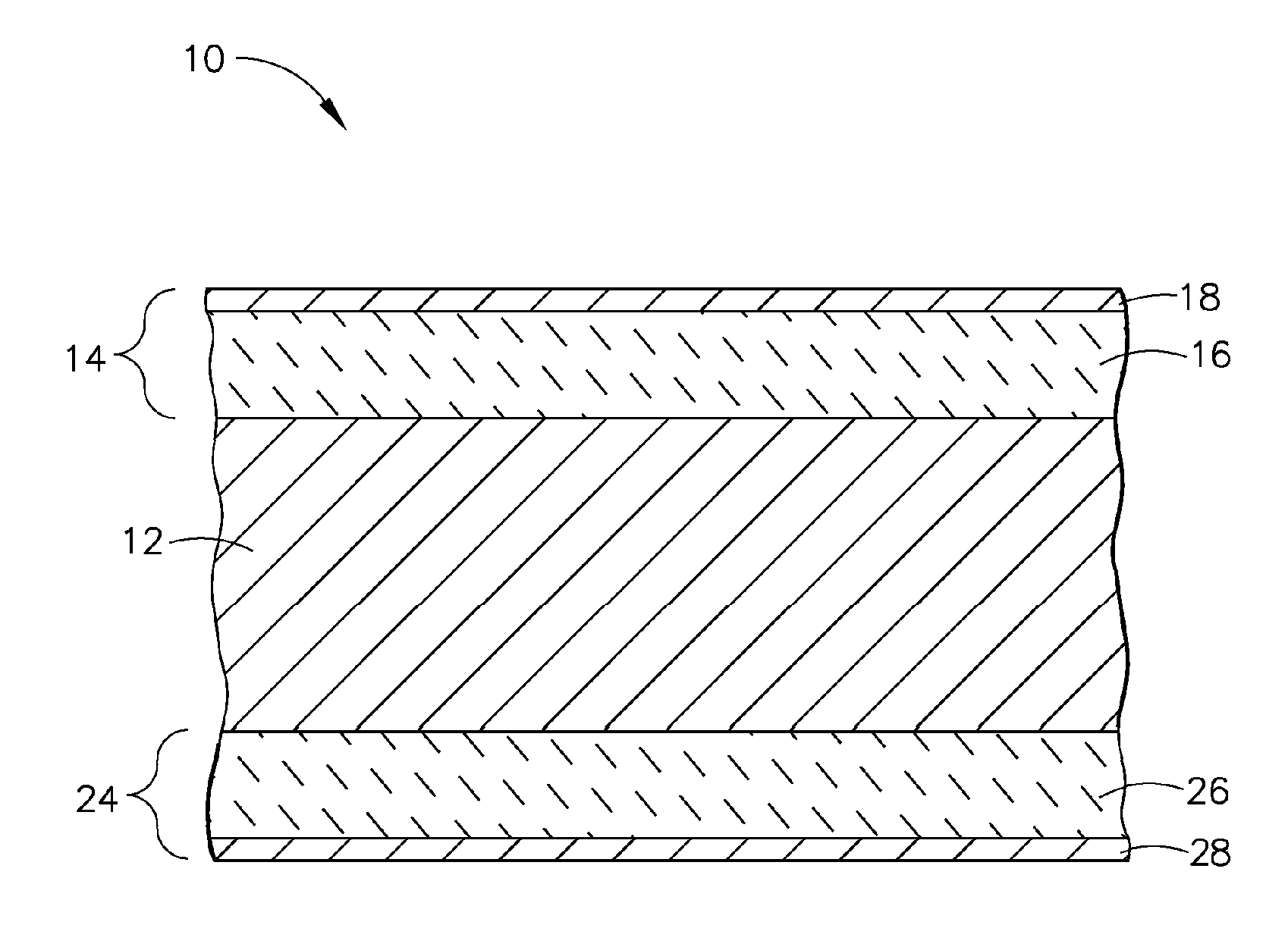

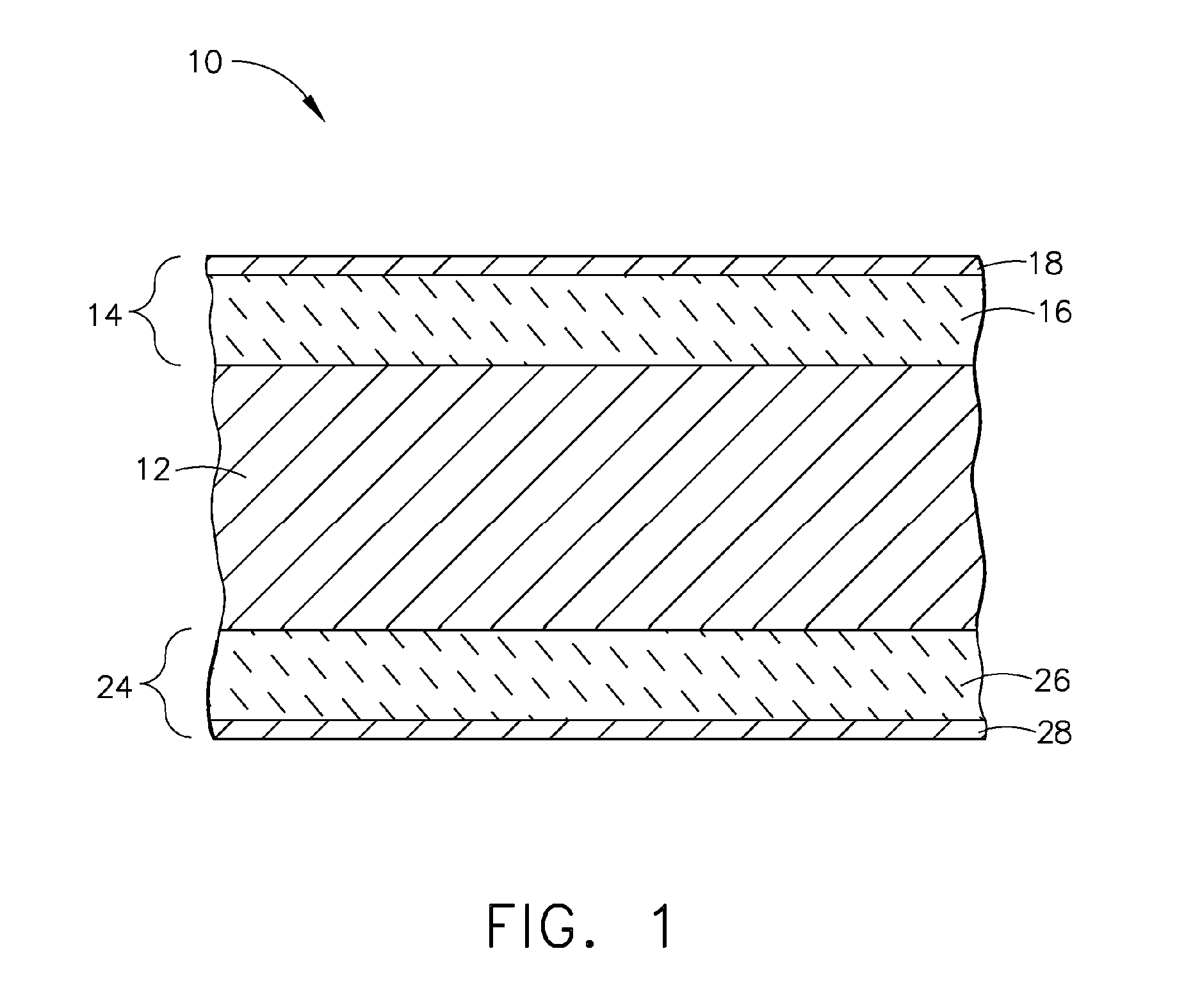

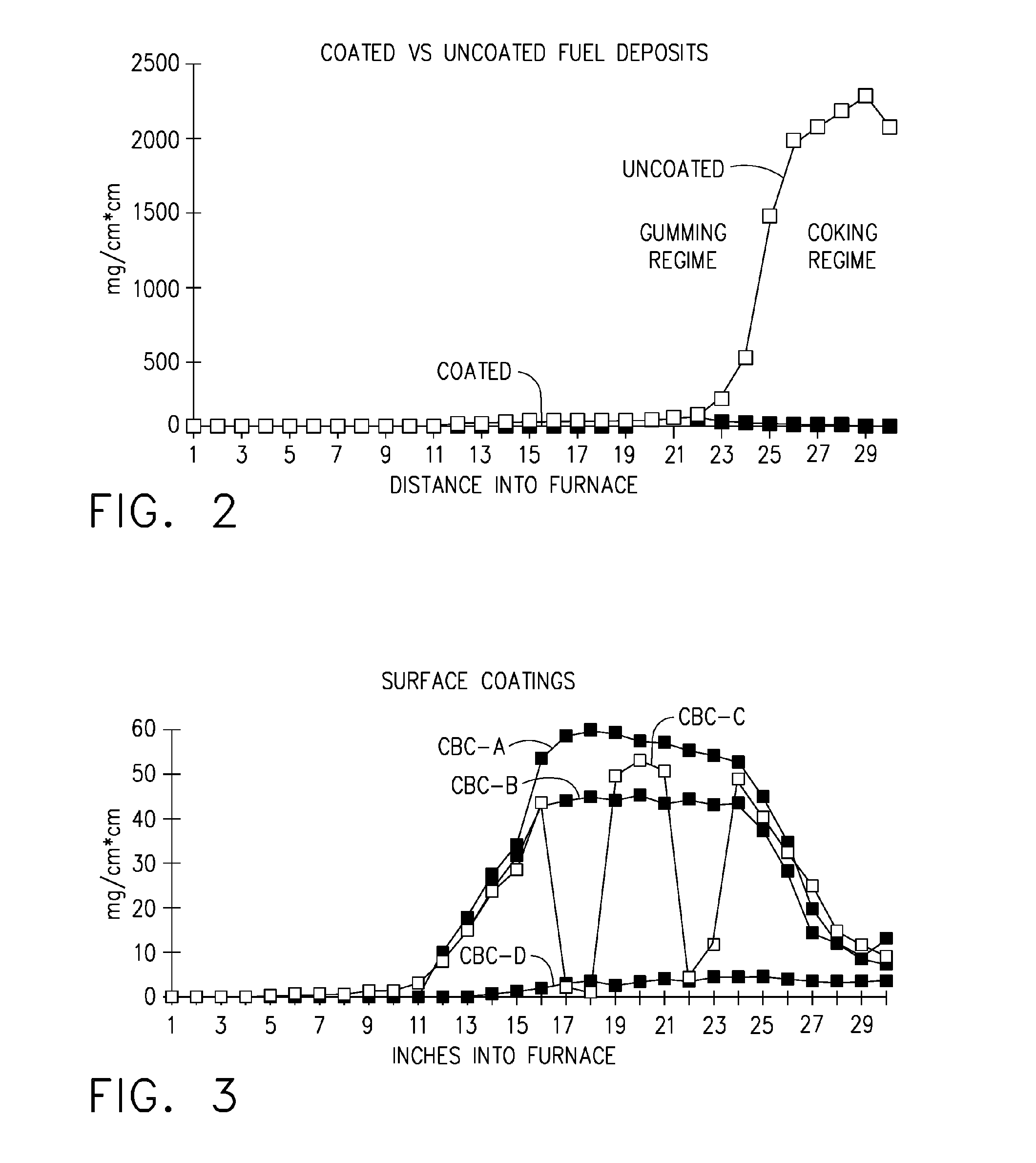

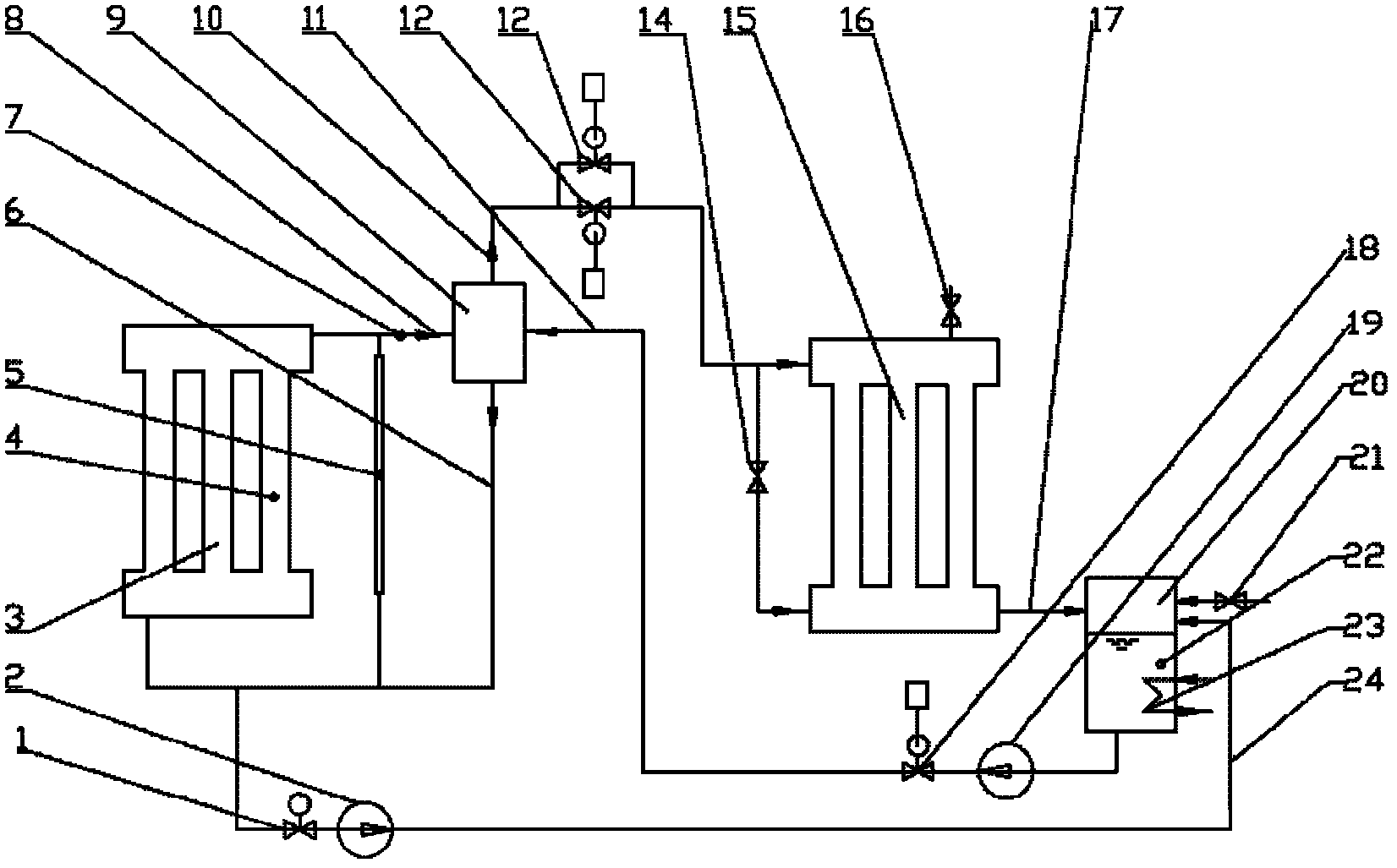

Method and coating system for reducing carbonaceous deposits on surfaces exposed to hydrocarbon fuels at elevated temperatures

InactiveUS20050019593A1Reduce formationReduce adhesionPropellersRecord information storagePlatinumCoating system

A coating system and method for reducing the tendency for hydrocarbon fluids, such as fuels and oils, to form carbonaceous deposits that adhere to a wall of a containment article. Of particular concern are carbonaceous deposits that form at temperatures below about 650° F. (about 345° C.). The coating system combines an outermost layer of platinum with a ceramic barrier layer. The coating system significantly reduces the formation of carbonaceous deposits and the adhesion of such deposits. To further reduce wall and hydrocarbon fluid temperatures and formation of carbonaceous deposits, the coating system is preferably applied to the surface of the wall wetted by the fluid, as well as the opposite surface of the wall exposed to a surrounding environment. The outermost layers serve as radiation shields to reduce heat transfer from the surrounding environment to the wall, and from the wall to the hydrocarbon fluid.

Owner:GENERAL ELECTRIC CO

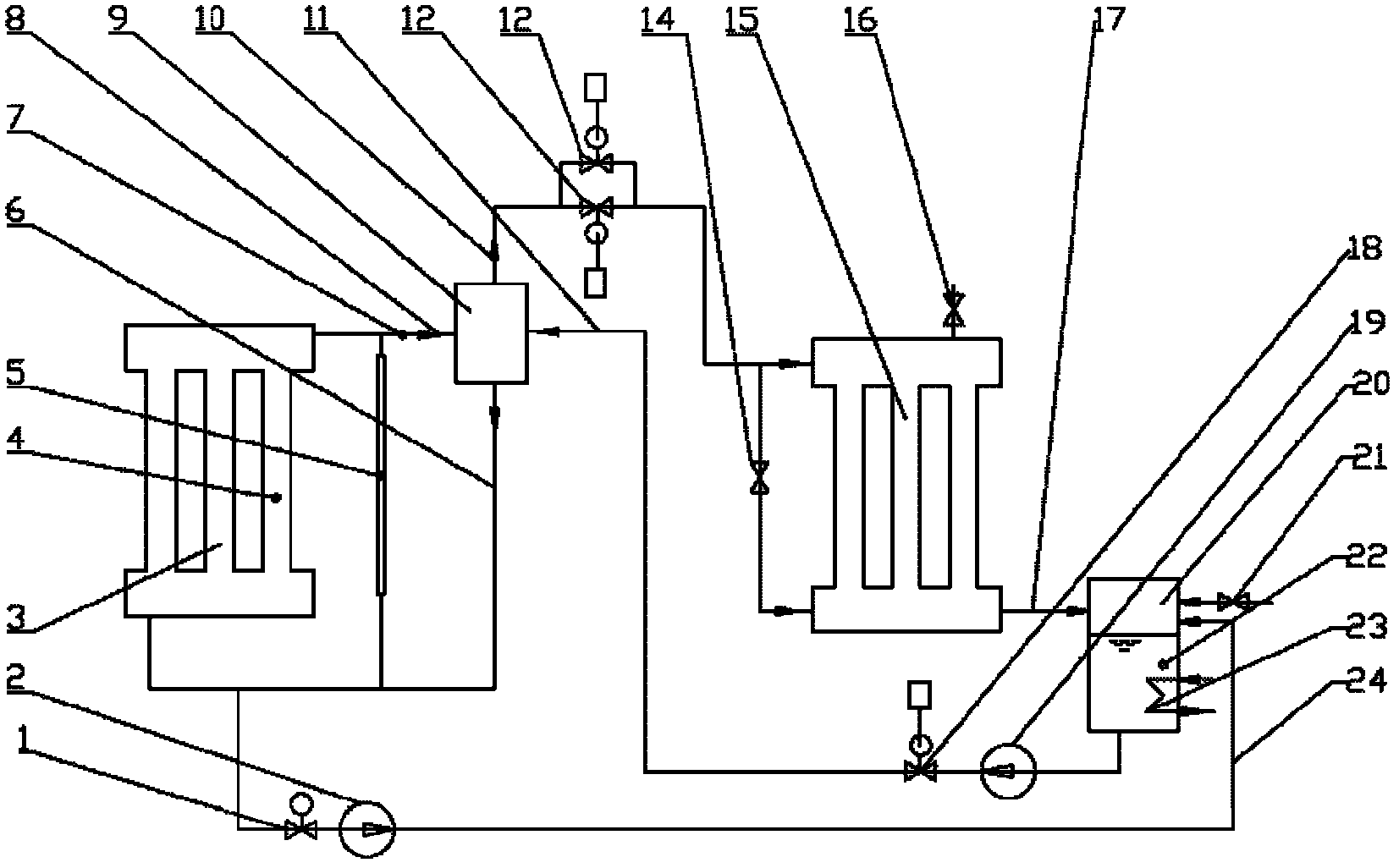

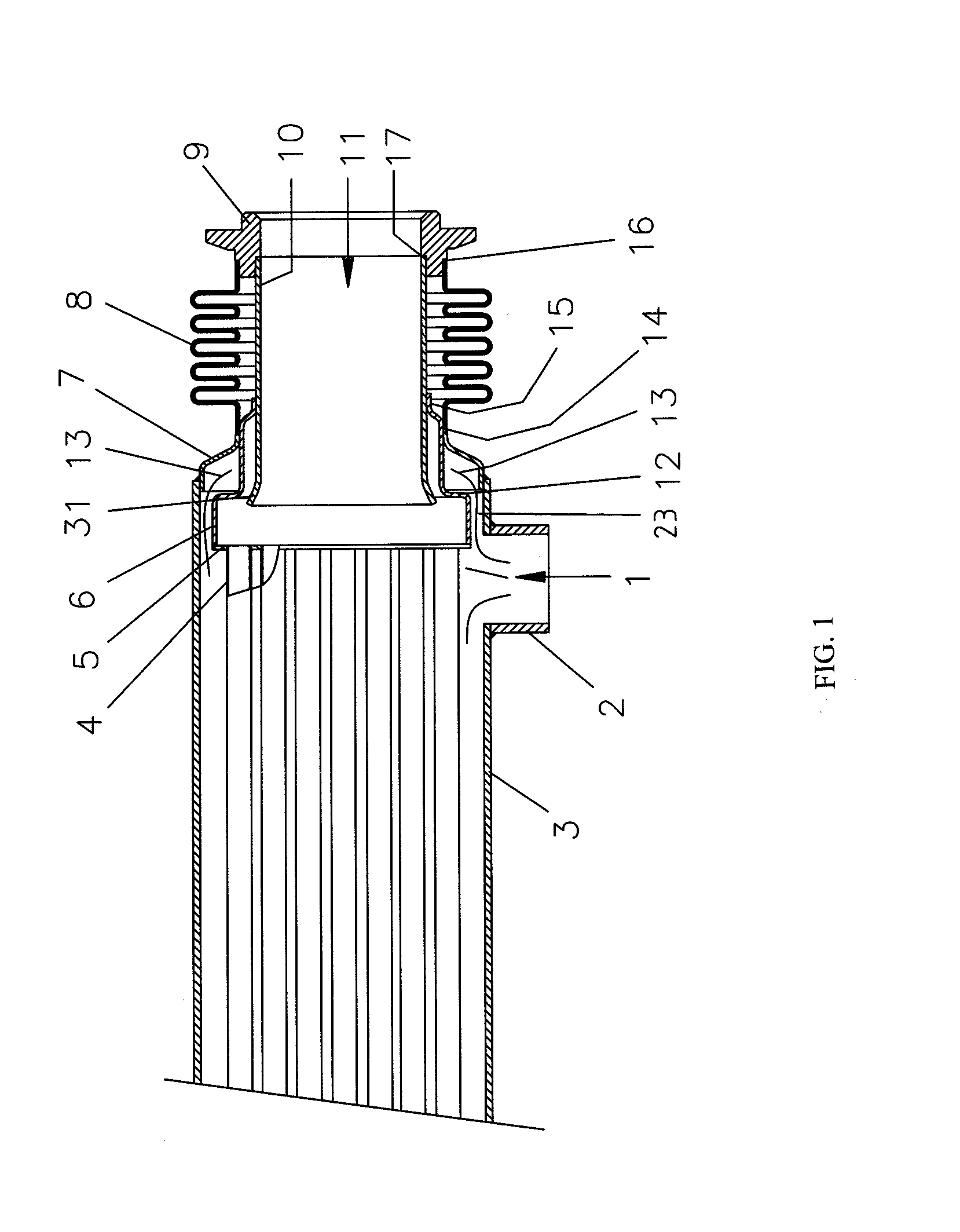

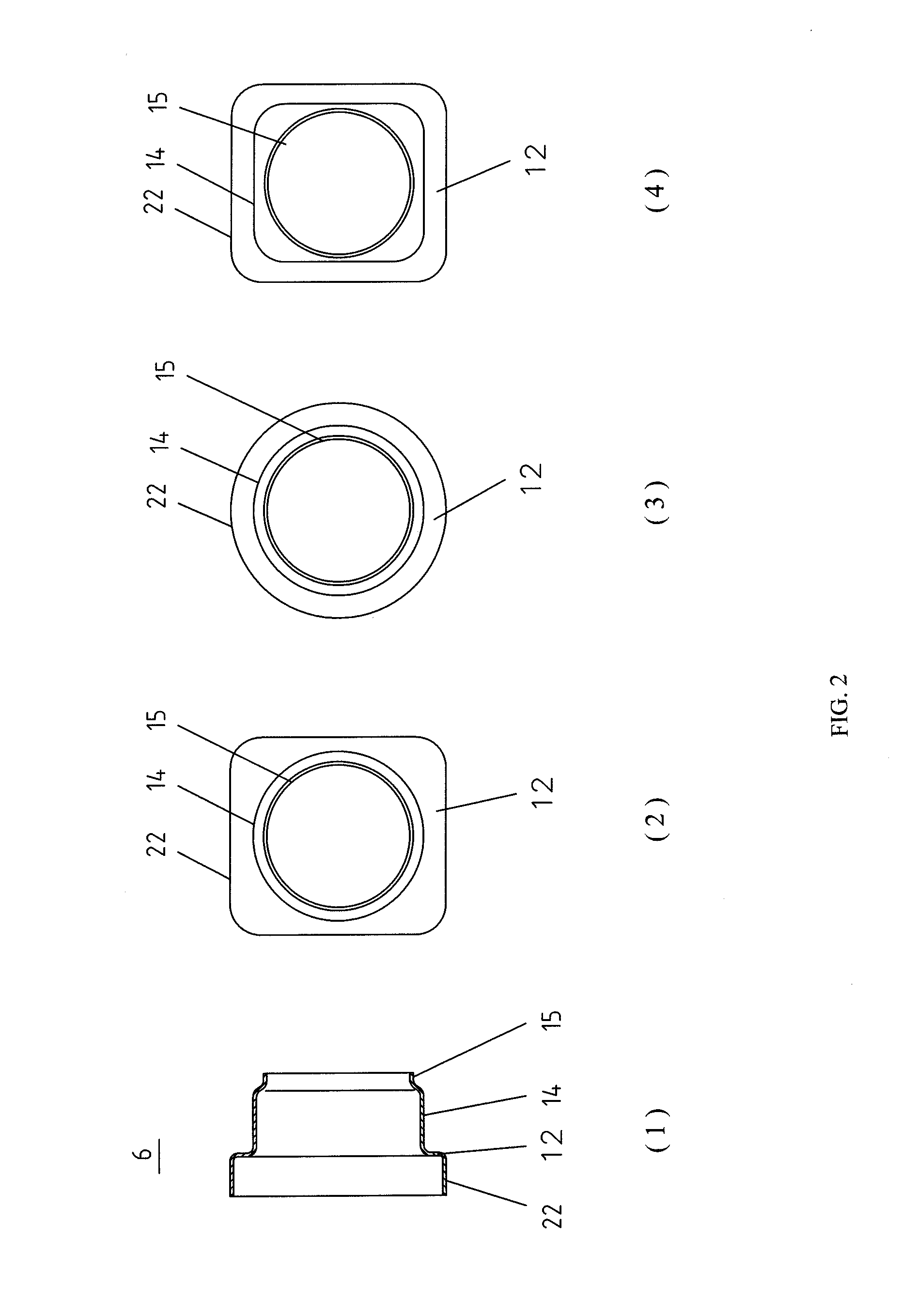

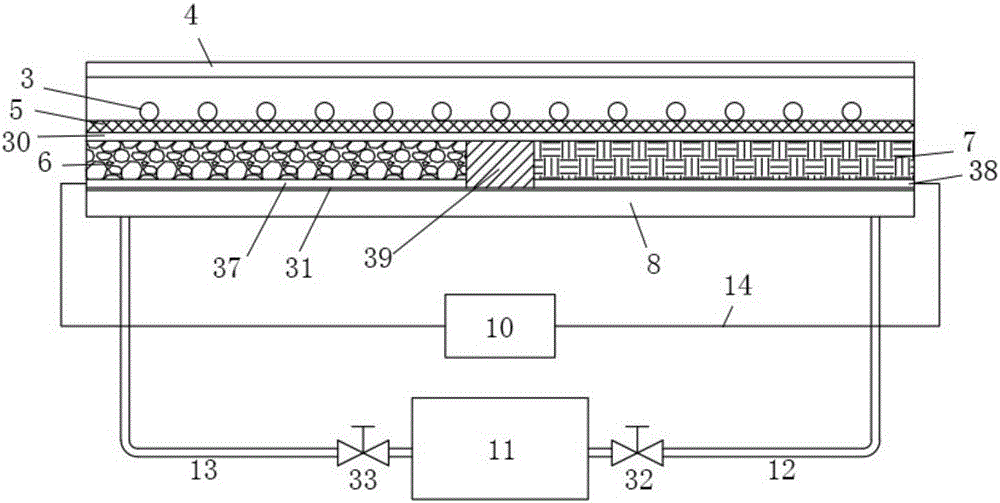

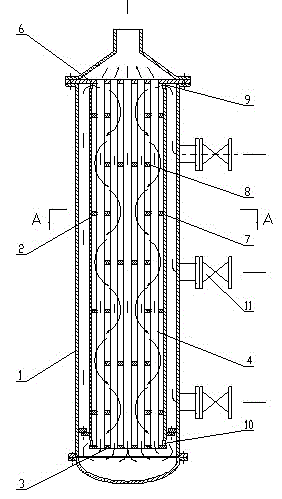

Branch control phase inversion heat exchange system and method based on vapor-liquid heat exchanger

ActiveCN102252543AWall temperature is not affectedReduce the chance of low temperature corrosionIndirect heat exchangersEngineeringLiquid storage tank

The invention relates to a branch control phase inversion heat exchange system and a branch control phase inversion heat exchange method based on a vapor-liquid heat exchanger. The system comprises a liquid storage tank (20), a heat source heat exchanger (3), a cold source heat exchanger (15) and a vapor-liquid heat exchanger (9); an upper collection tank of the heat source heat exchanger (3) is communicated with the vapor-liquid heat exchanger (9) through a heat exchanger inlet steam pipe (8); a vapor-liquid heat exchanger outlet steam pipe (10) which is arranged on the vapor-liquid heat exchanger (9) is divided into two branches which are communicated with an upper collection tank and a lower collection tank of the cold source heat exchanger (15); the lower collection tank of the cold source heat exchanger (15) is communicated with the upper part of the liquid storage tank (20) through a cold source heat exchanger liquid outlet pipe (17); the bottom of the liquid storage tank (20) is communicated with the vapor-liquid heat exchanger (9) through a heat exchanger inlet condensation liquid pipe (11); and the vapor-liquid heat exchanger (9) is communicated with a lower collection tank of the heat source heat exchanger (3) through a heat exchanger outlet condensation liquid pipe (6). The branch control phase inversion heat exchange system can solve the phenomena of overcooling and overheating and improve heat exchanging efficiency.

Owner:SHANXI SANHESHENG IND TECH

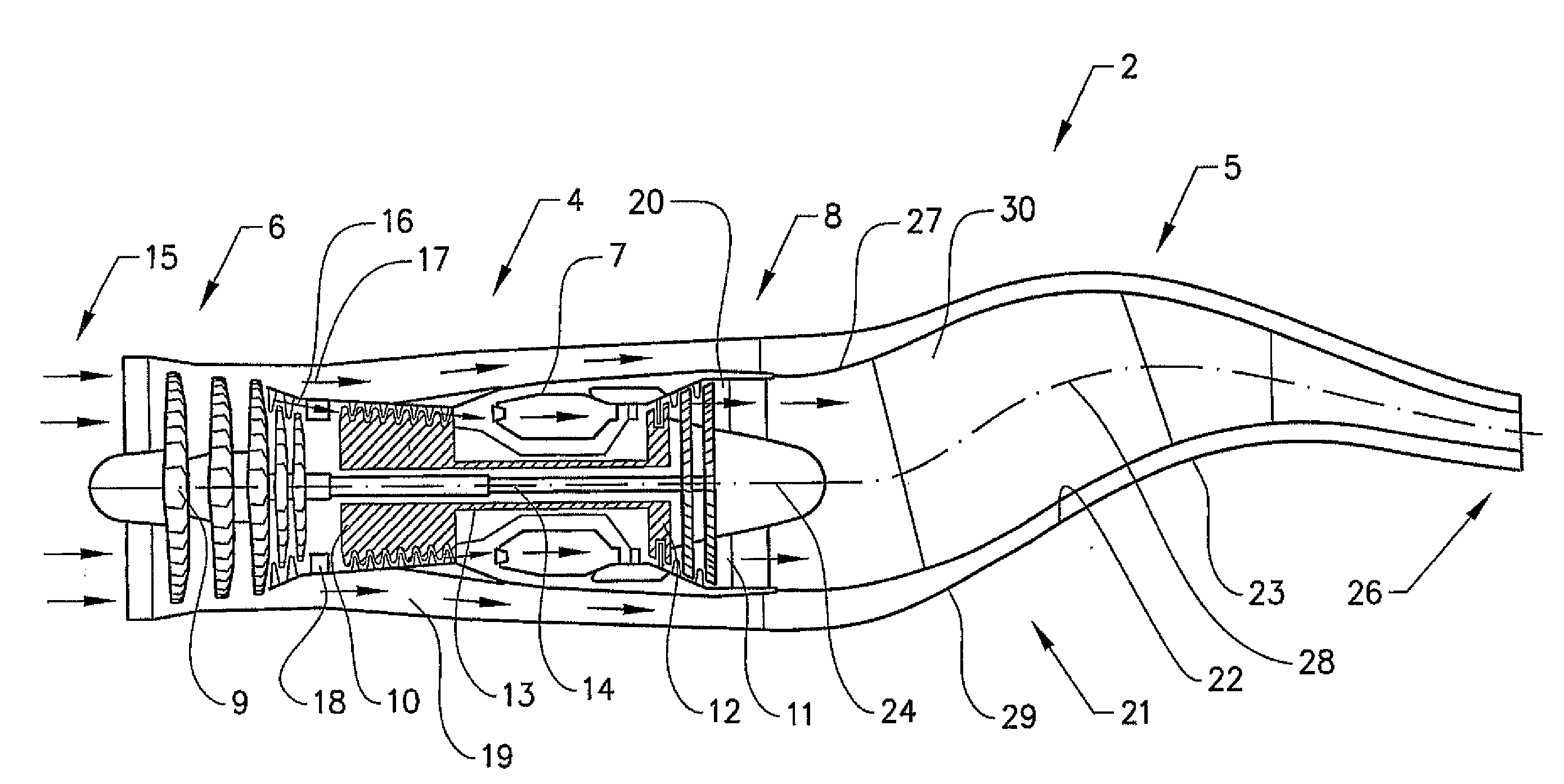

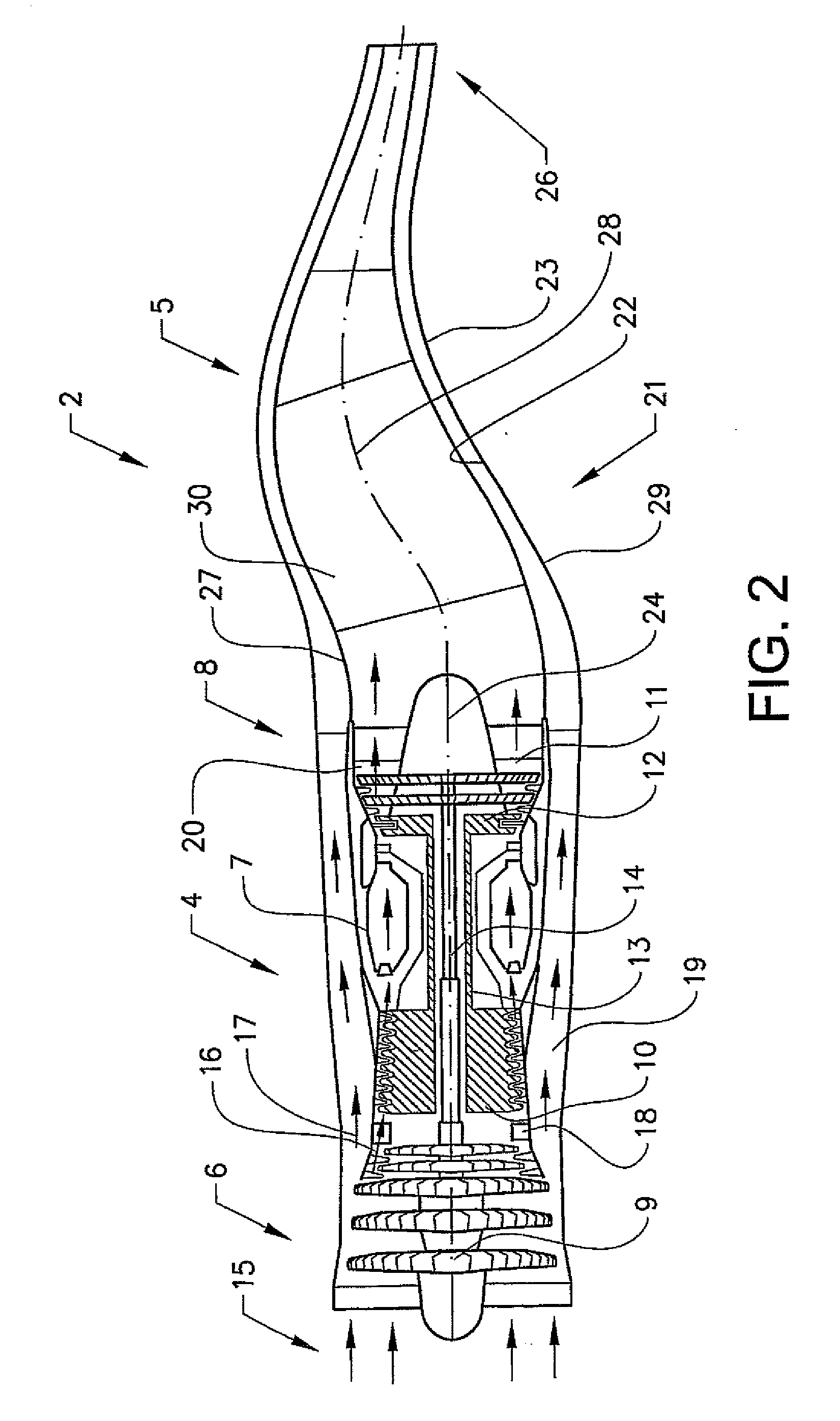

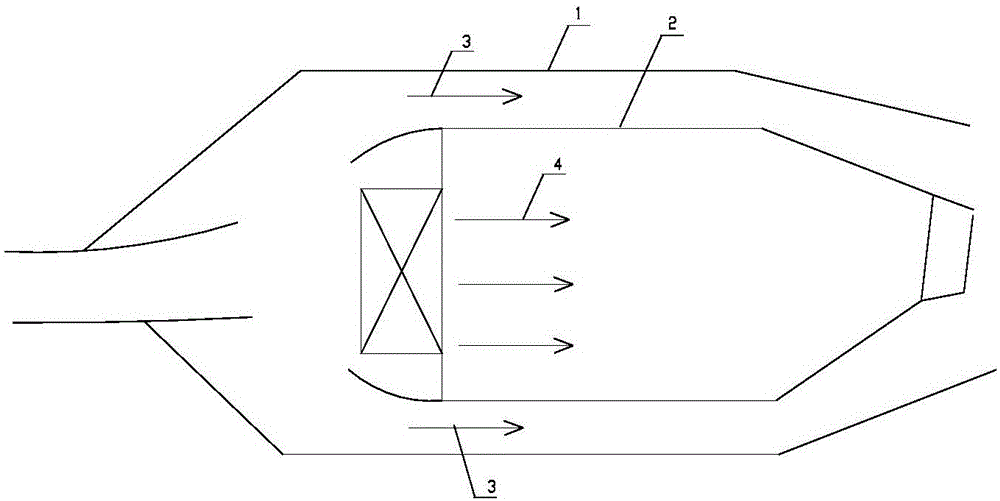

Arrangement for Propelling an Aircraft, Aircraft and Outlet Nozzle for a Jet Engine

InactiveUS20080236138A1Reduce wall temperatureReduce the temperaturePower plant exhaust arrangementsEngine manufactureJet engineAirplane

The invention relates to an arrangement for propelling an aircraft comprising a jet engine and an outlet nozzle arranged downstream of the jet engine. The jet engine is of a type which generates an internal core flow and an external fan flow. A part of the outlet nozzle has an internal surface which defines a gas duct for the fan flow. The aforementioned part of the outlet nozzle includes a wall structure that is arranged at a distance from the internal surface such that it separates the gas duct for the fan flow from an internal gas duct for the core flow.

Owner:VOLVO AERO CORP

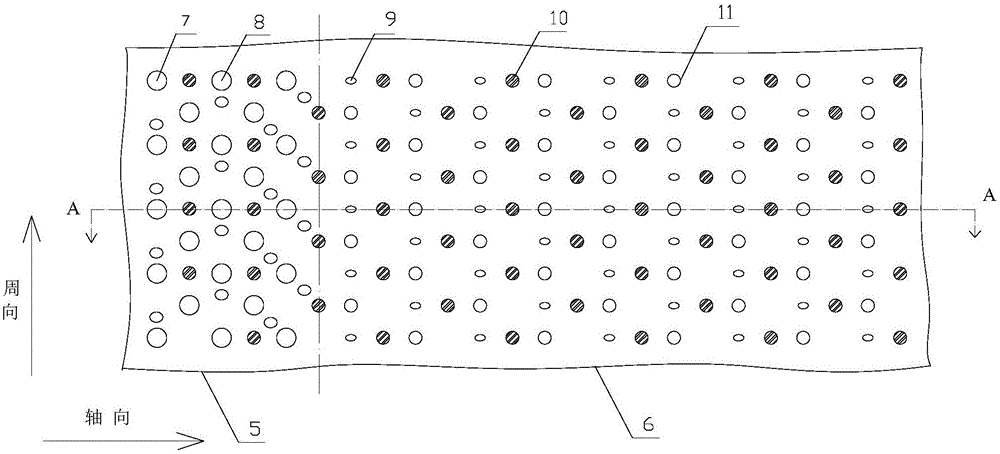

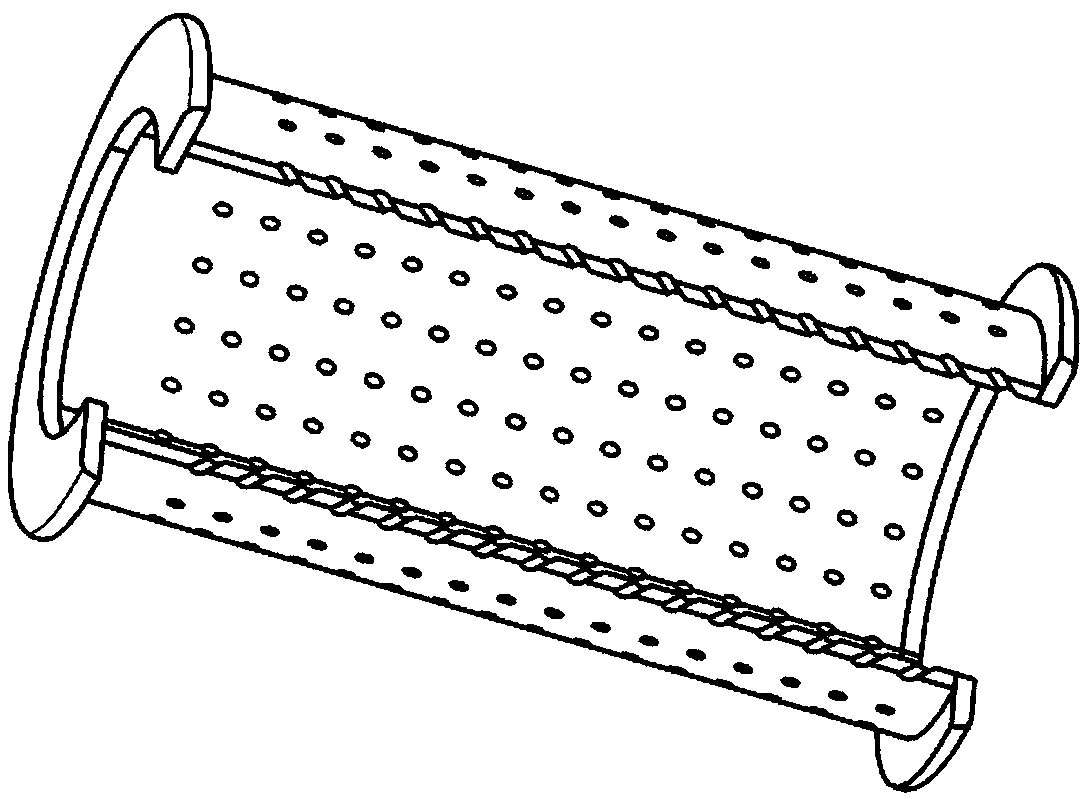

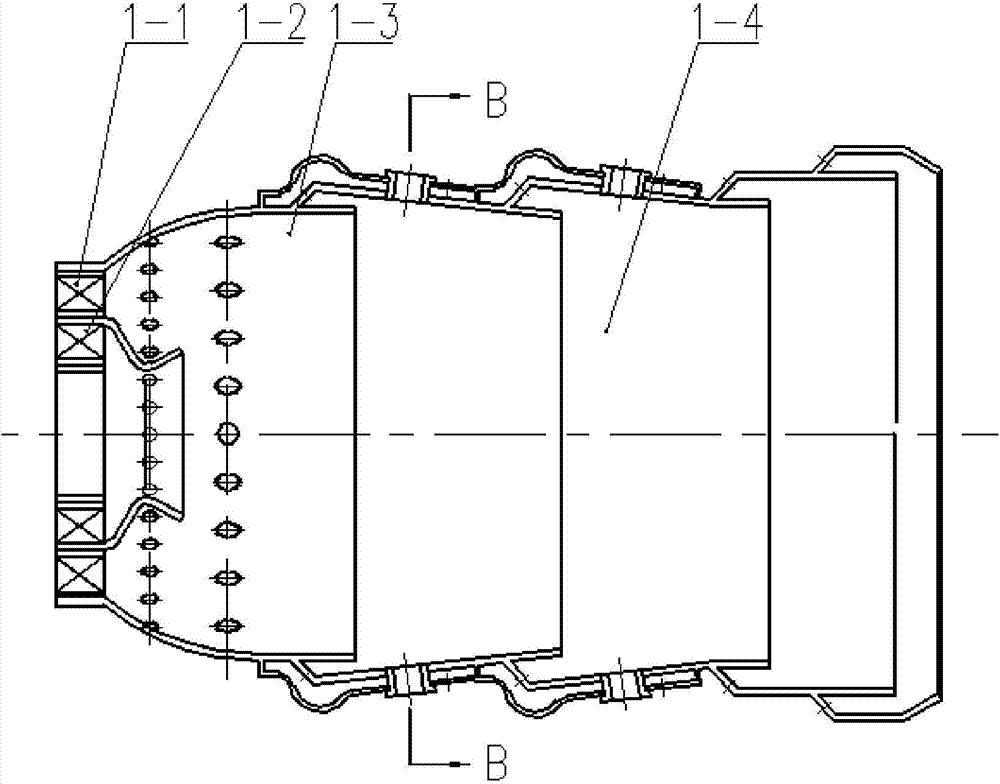

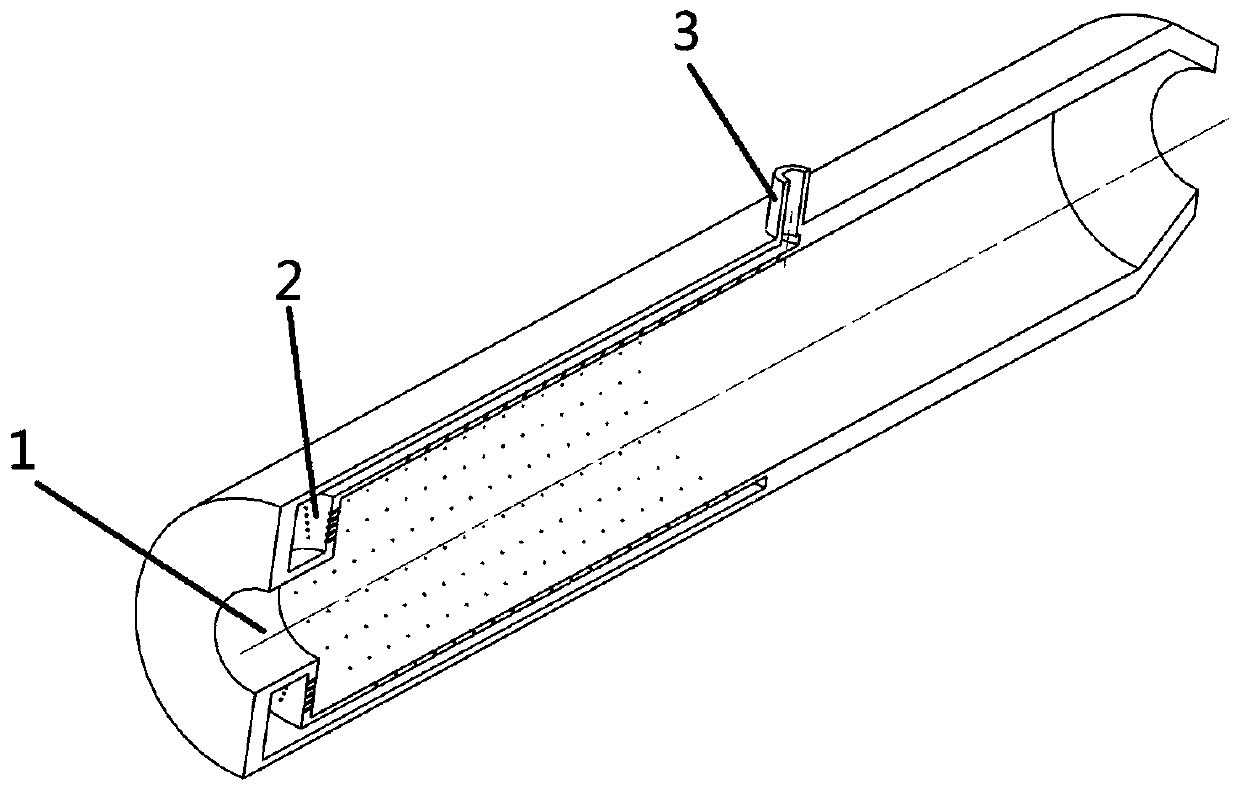

Cooling structure of flame tube of aero-engine combustor

InactiveCN105042640AReduce temperature gradientReduce wall temperatureContinuous combustion chamberCombustion chamberEngineering

The invention discloses a cooling structure of a flame tube of an aero-engine combustor. The cooling structure comprises a flame tube wallboard. The flame tube wallboard comprises an outer wallboard body and an inner wallboard body. The inner wallboard body is provided with a plurality of diffusion holes, the outer wallboard body is provided with a plurality of impact holes, and all the diffusion holes and impact holes are distributed in a crossing mode. Meanwhile, the inner wallboard body and the outer wallboard body are connected through a plurality of pin fins. The flame tube wallboard is divided into two parts in the axial direction, namely, a front flame tube wallboard segment close to a high-temperature area of the combustor and a rear flame tube wallboard segment far away from the high-temperature area of the combustor. The aperture of the front-segment impact holes in the front flame tube wallboard segment is larger than that of the rear-segment impact holes in the rear flame tube wallboard segment, and meanwhile the aperture of the front-segment diffusion holes in the front flame tube wallboard segment is larger than that of the rear-segment diffusion holes in the rear flame tube wallboard segment. Therefore, a traditional flame tube wall cooling structure is improved, and on the premise of not increasing cold capacity, the cooling potential of the cooling structure is fully tapped, and cooling efficiency is improved. Meanwhile, too large heat stress caused by the excess temperature and uneven temperature distribution of the wall of the flame tube is avoided.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

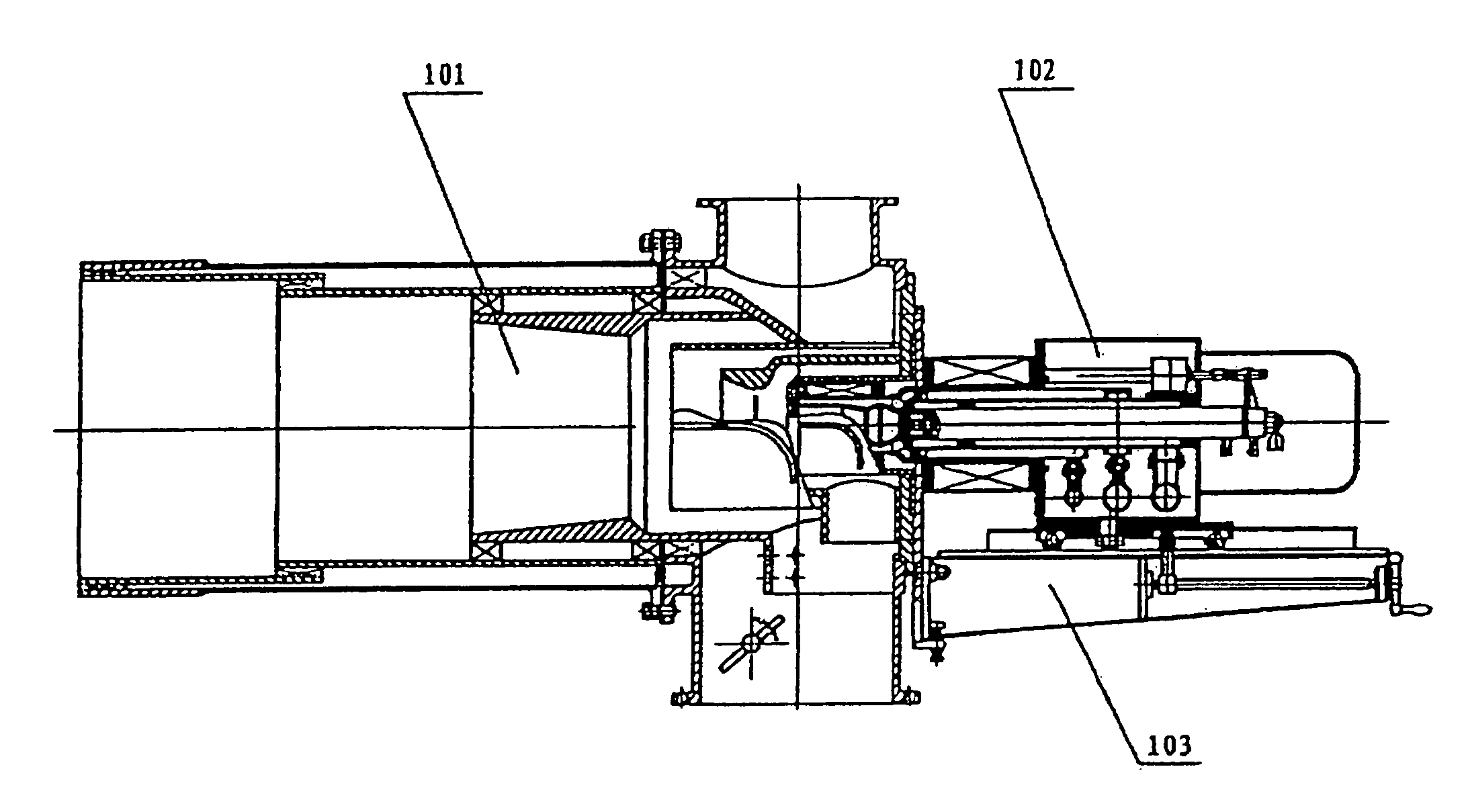

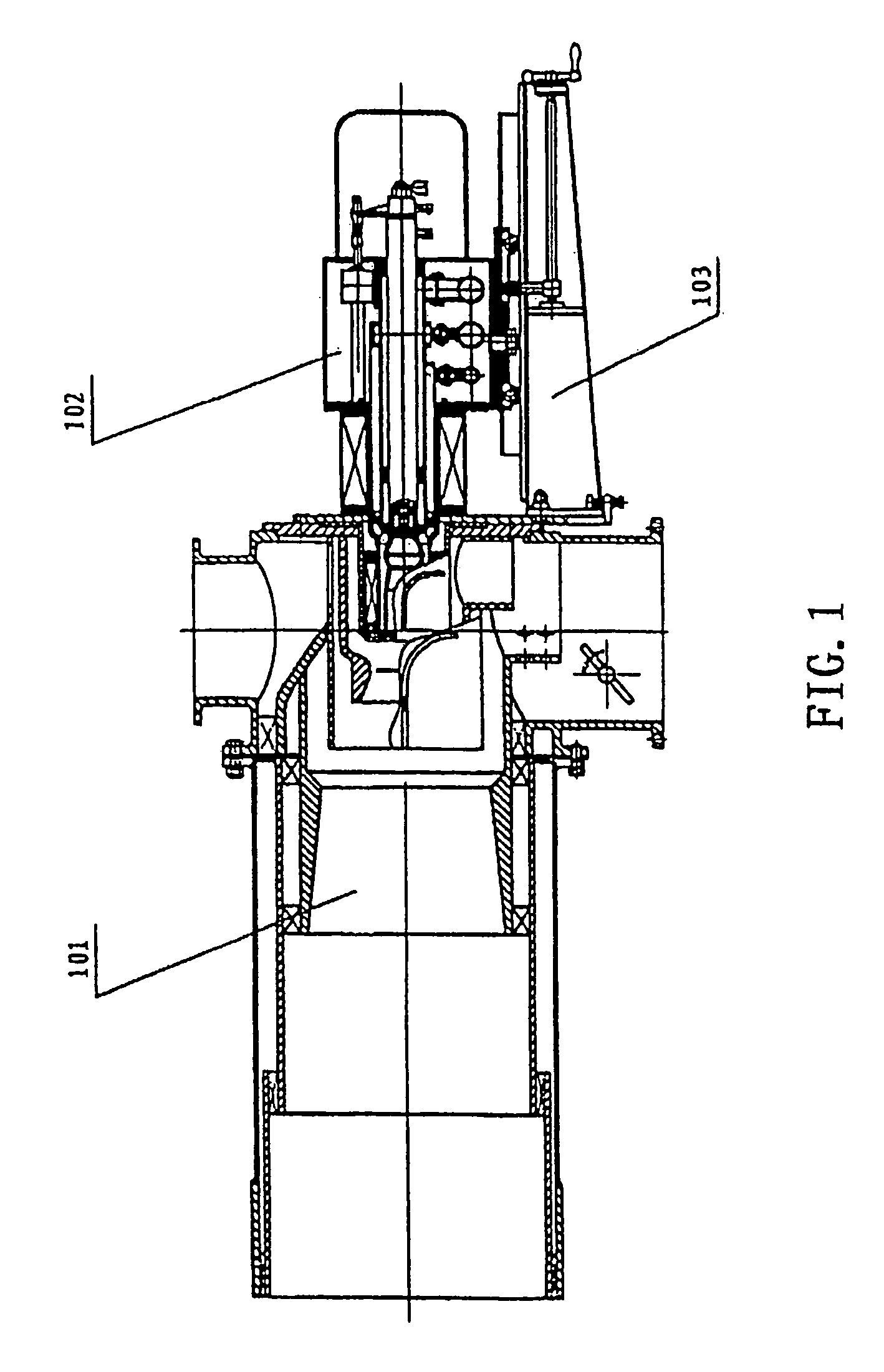

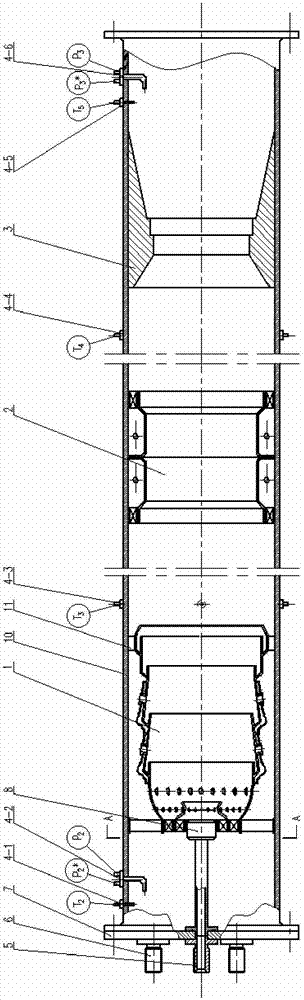

Coal-fired hot blast furnace with pre-combustion hearth and smoke circulating device

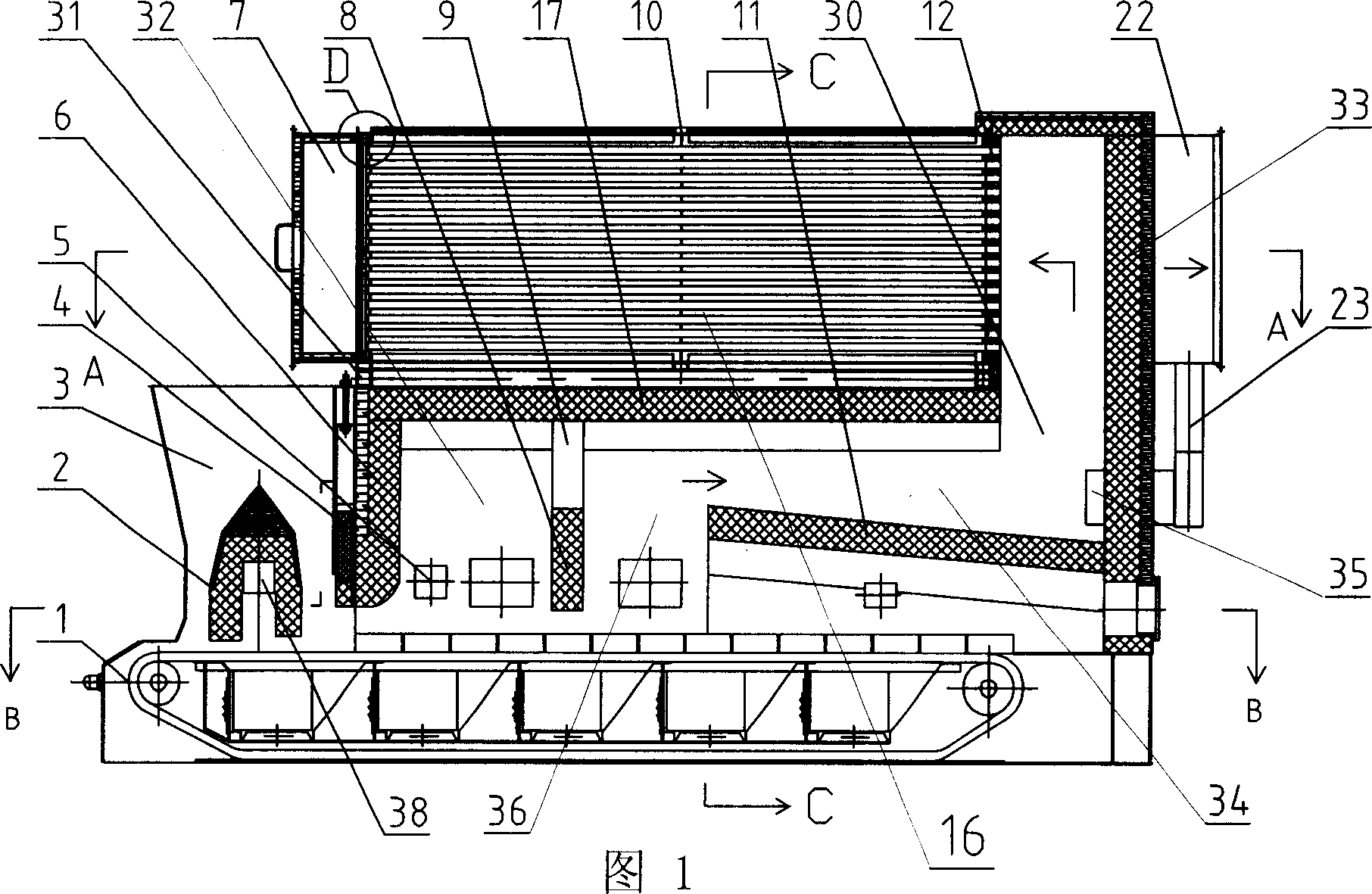

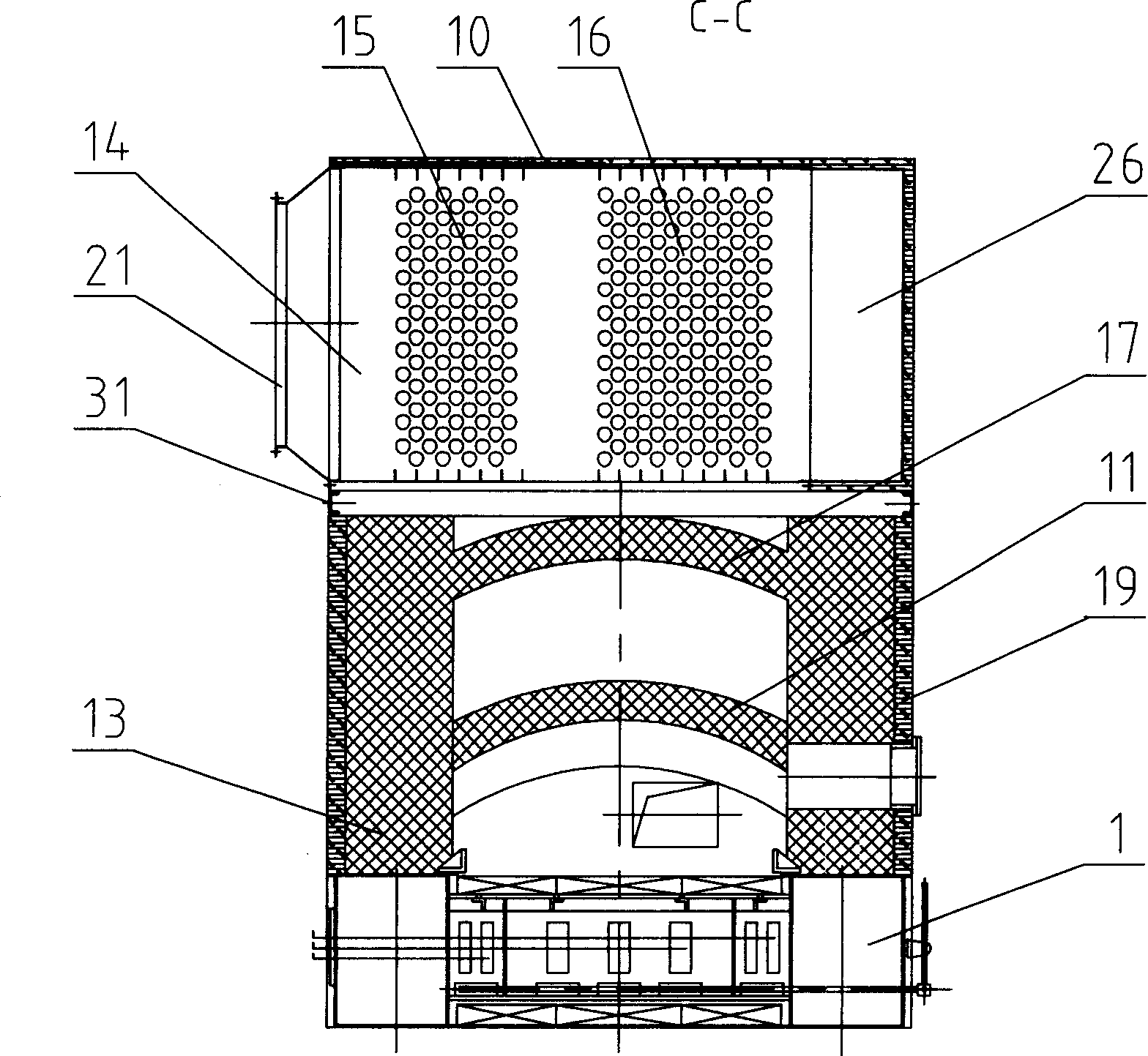

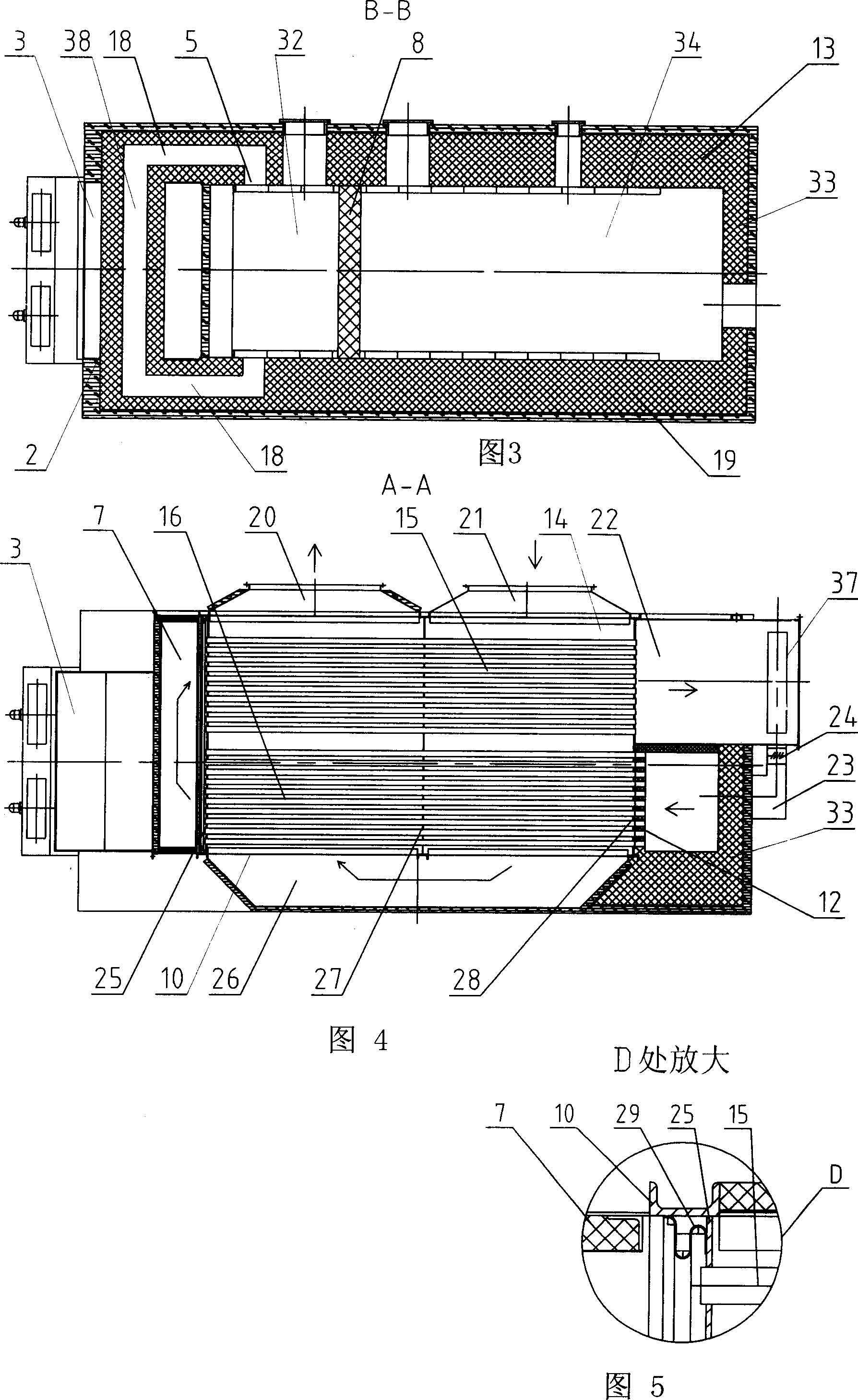

The invention discloses a coal air heater with a preignition hearth and a smoke recycler, which can solve the problems of present product with short service life, lower heating efficiency and worse environment pollution. Wherein, the wind inlet of cycle fan (24) via the cycle smoke channel (23) is through to the side opening (37) of smoke outlet channel (22)); the wind outlet of cycle fan (24) via the outlet (35) of cycle smoke channel (23) is through to the smoke channel (30); the preignition hearth (2) is fixed on the lower pat of coal hopper (3) between the left and right side walls (13). The inventive preignition hearth is thermal-insulated, with higher burning strength, and high application to variable coals. At the back of furnace row, the burnt coke can make the fire bed in open fire condition, to burn the gas fully; said air heater can avoid black smoke to reduce environment pollution; the cycle smoke channel can reduce the temperature of heat exchanger, to improve the service life and efficiency of air heater.

Owner:HARBIN INST OF TECH

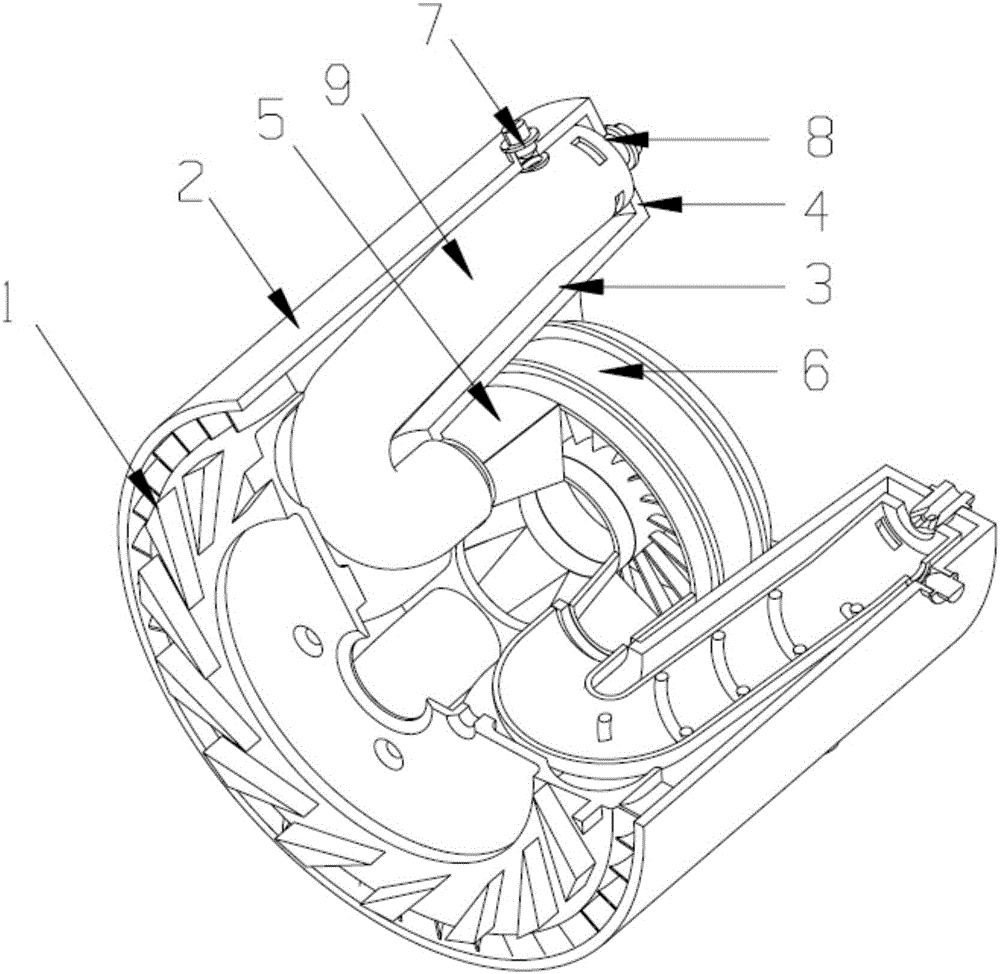

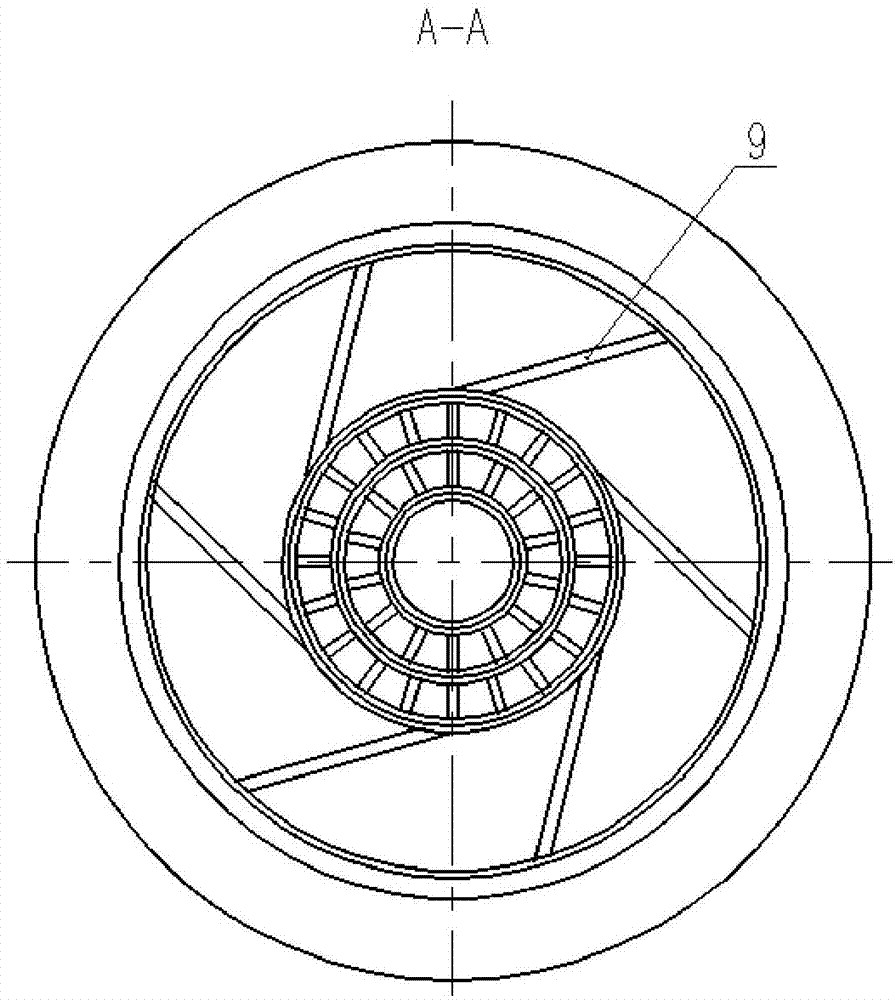

Assembled cathode and plasma igniter with such cathode

InactiveUS7281478B2Lengthen lifeLife of cathode be improveMake-and-break ignitionIncandescent ignitionElectric arcPetroleum

This invention relates to a plasma igniter for directly igniting the pulverized coal burner. Said plasma igniter consists of a plasma generator which includes a composite anode, an combined type cathode, an electromagnetic coil and a transmitting coil; a pulverized coal burner which comprises multi-stage chambers for conveying igniting coal, an equipment for adjusting concentration of coal powder and a four-stage burner canister; and a generator brace. Said combined type cathode consists of a cathode plate, a fixation nut, a conductive pipe, an inflowing pipe, an inflowing guiding pipe, a cathode lid and a sealing spacer. The lining for generating electric arc is assembled with the front of cathode. An alloy plate is used as the cathode plate. The nozzle that used for cooling the cathode is first convergent and then expansive, and is placed in the middle of the conductive pipe. The plasma igniter has the advantage of stable burning. It can be used as not only a main burner for the boiler but also an igniting burner. Since oil is not used, lots of petroleum source is saved.

Owner:YANTAI LONGYUAN POWER TECH

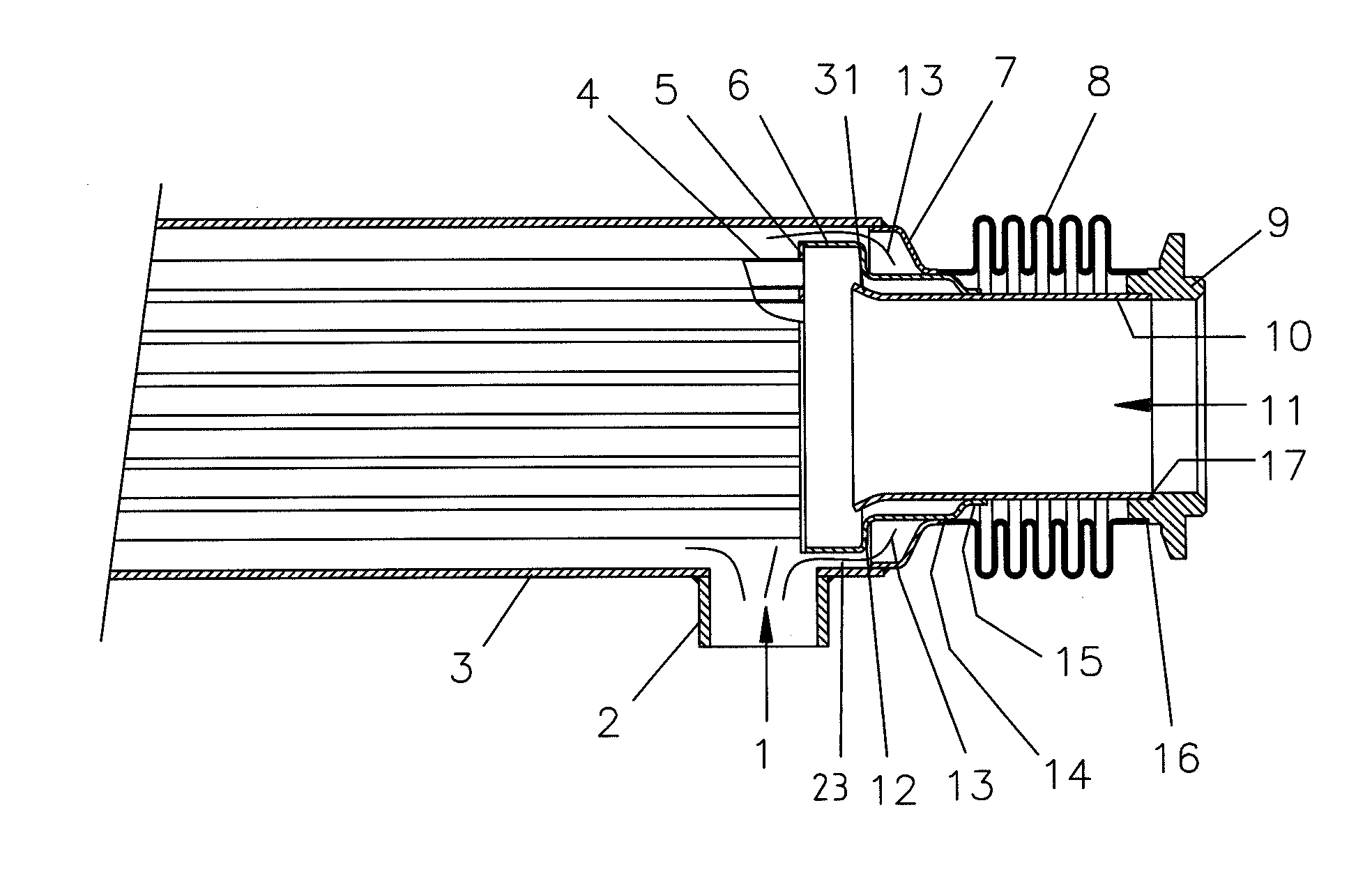

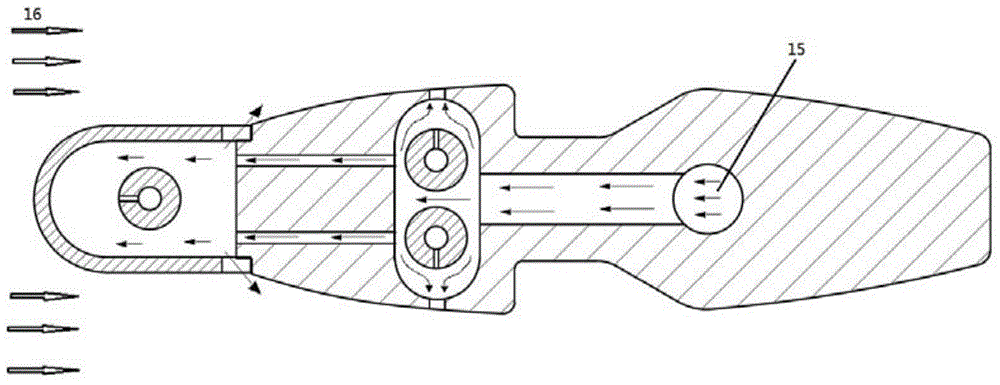

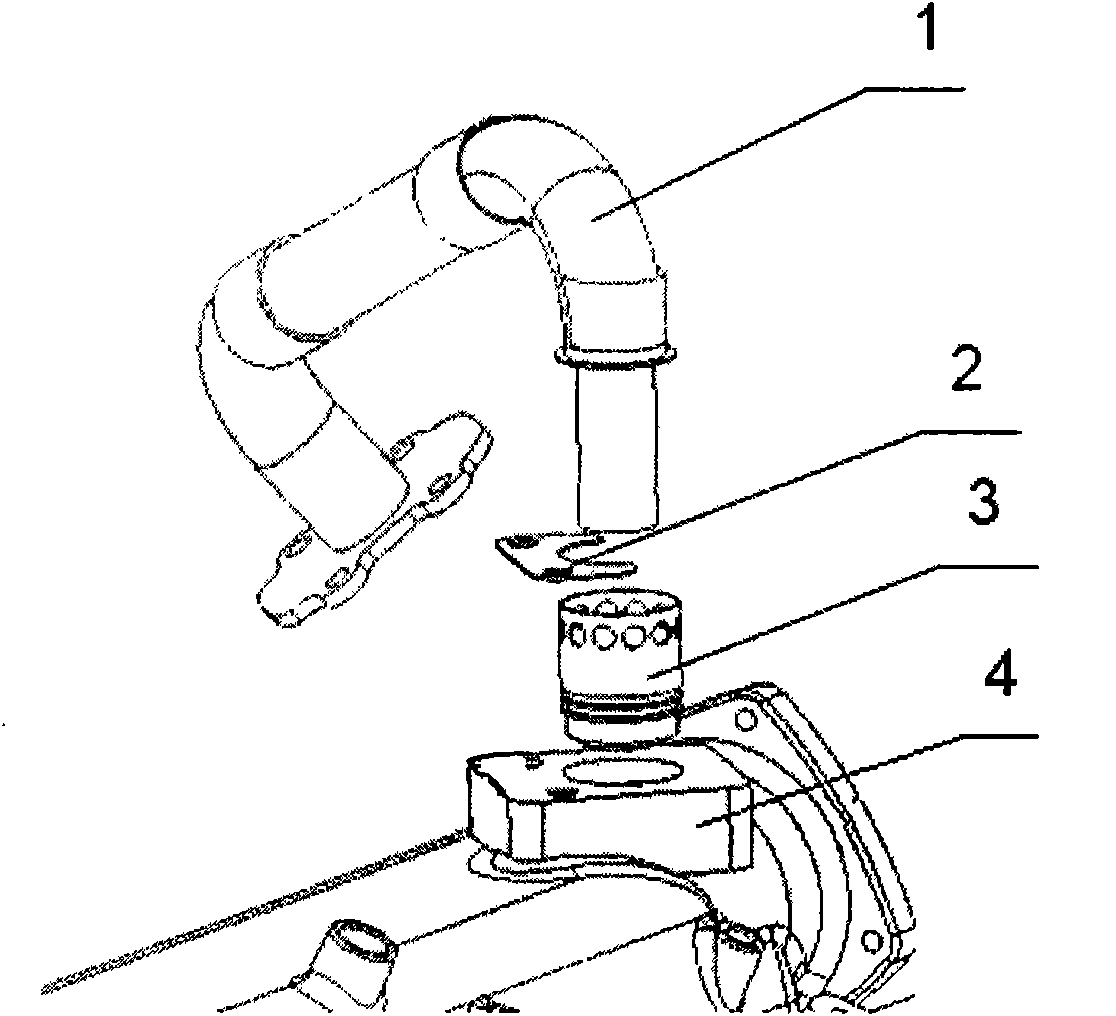

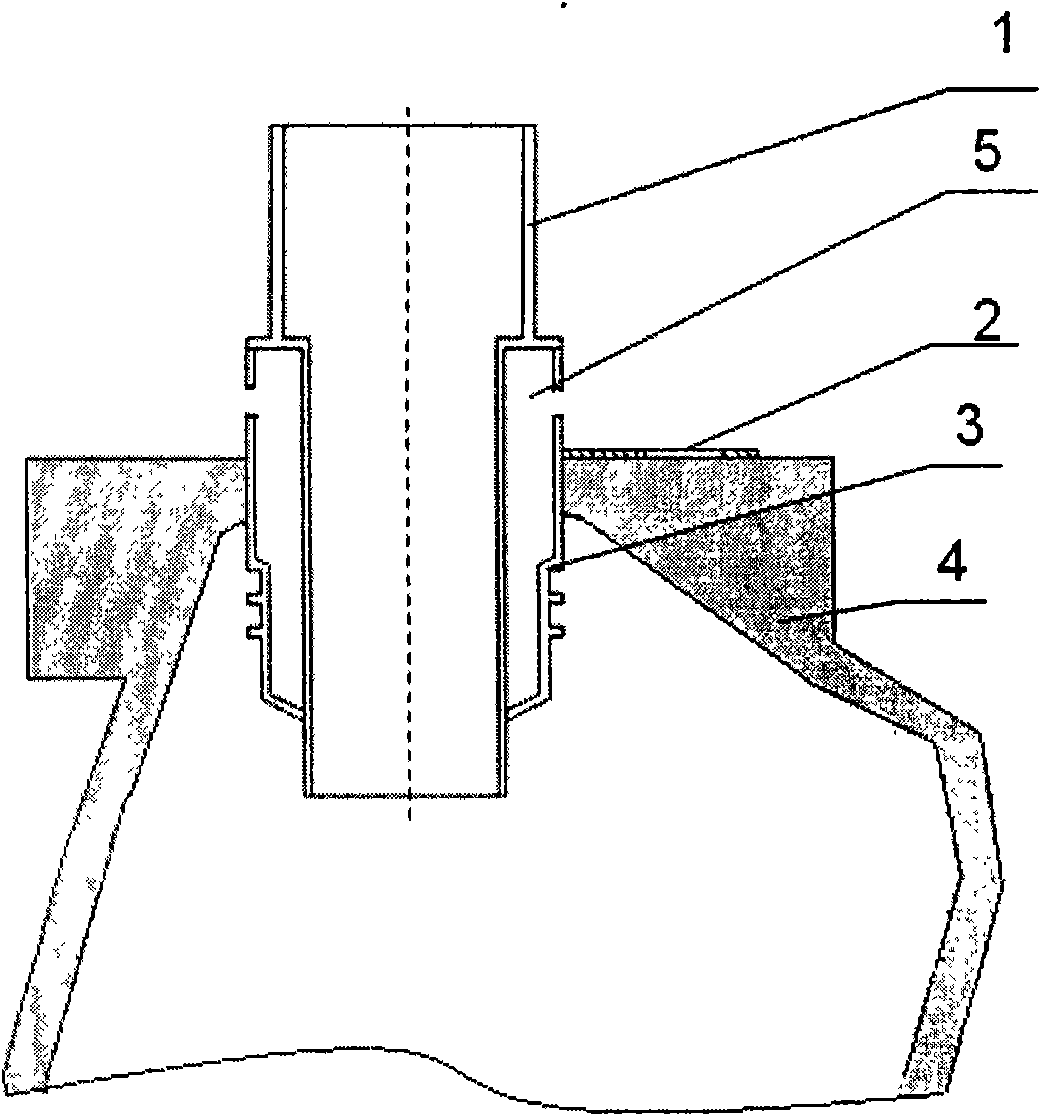

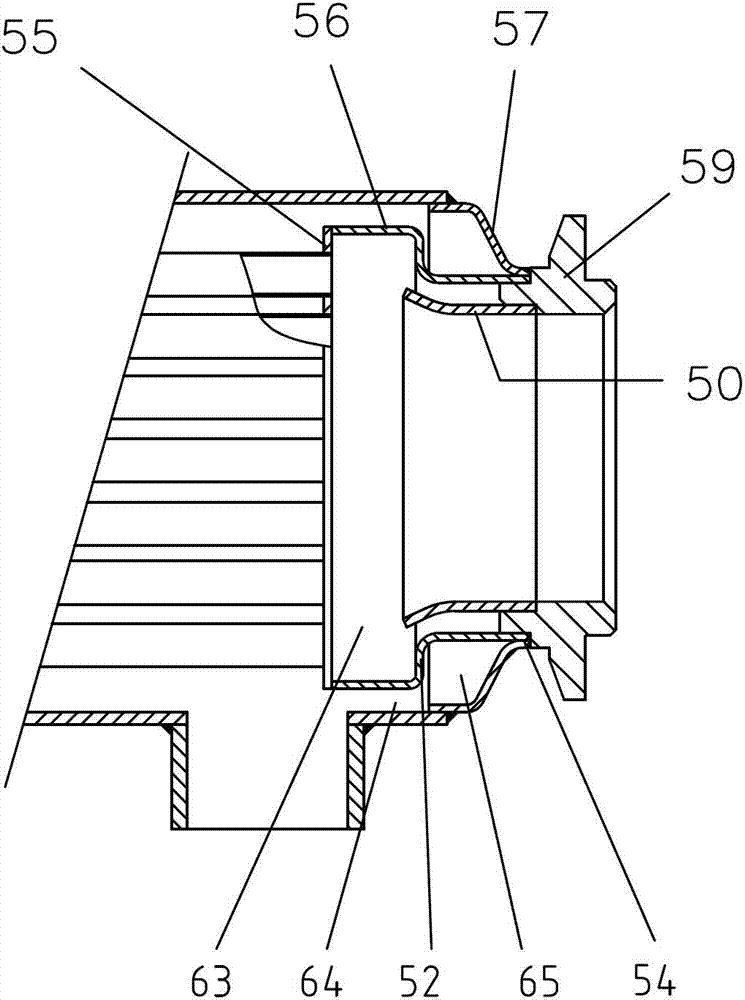

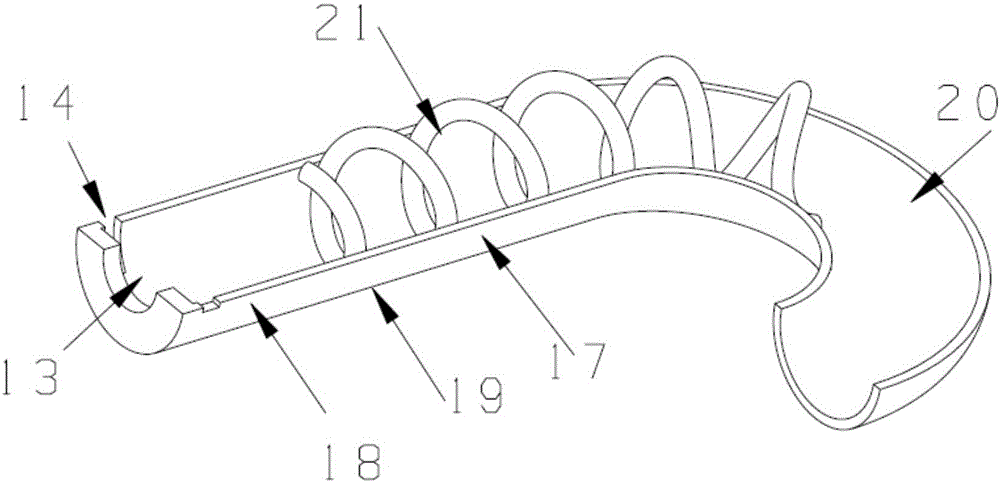

Exhaust gas inlet structure of an exhaust gas recirculation cooler

ActiveUS20140299115A1Reduce wall temperatureImprove vibration resistanceInternal combustion piston enginesNon-fuel substance addition to fuelAxial displacementExhaust fumes

The present invention discloses an exhaust gas inlet structure of an exhaust gas recirculation (EGR) Cooler which includes a water shell, a gas inlet pipe, a bellow, an insulated pipe, an inlet chamber, a pre-cooling water chamber and a main board. The water shell is equipped with a water inlet pipe. Its main feature is the insulated pipe is placed within the bellow and connected with the gas inlet pipe at one end while the other end is suspended. The large-bore end of the inlet chamber is connected with the main board to form a gas inlet cavity while leaving a space to form a coolant channel between the joining part and the water shell. An external surface of a middle pipe body connects to the bellow to form a pre-cooling cavity connected to the coolant channel. The advantages of the present invention are as follow: newly-added pre-cooling water chamber reduces the wall temperature of the main board and the inlet chamber; newly-added supporting in the middle part of the insulated pipe improves the vibration-proof function of the insulated pipe; the special structure of the inlet chamber increases the ability of the axial displacement compensation. The above-mentioned improvement of the present invention significantly improves the reliability of the EGR cooler.

Owner:ZHEJIANG YINLUN MACHINERY

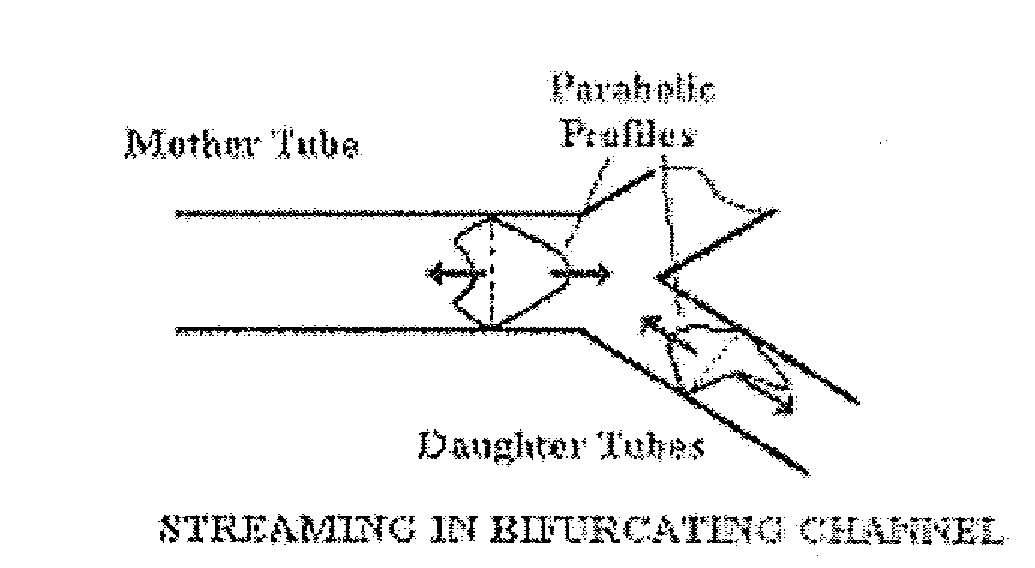

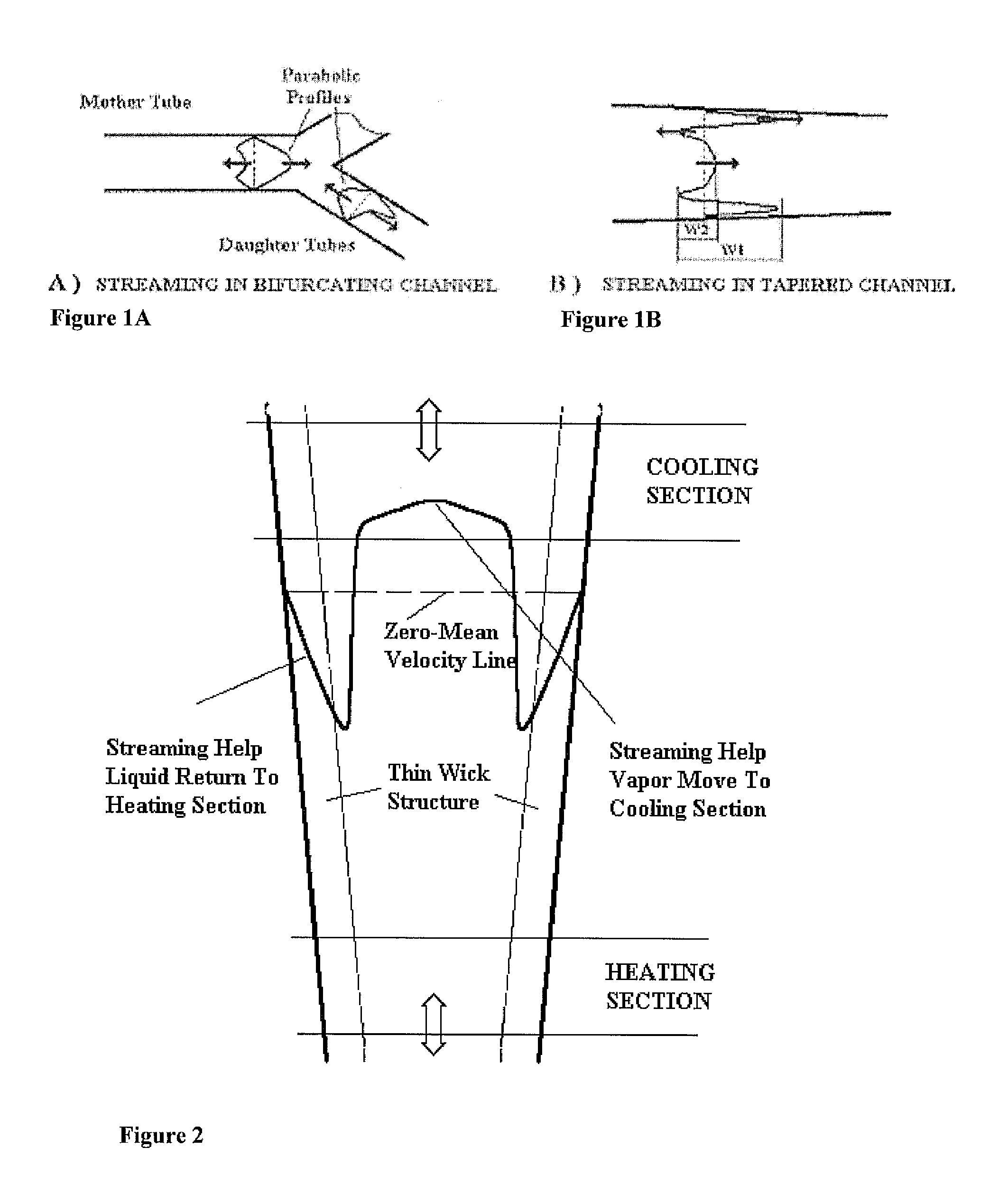

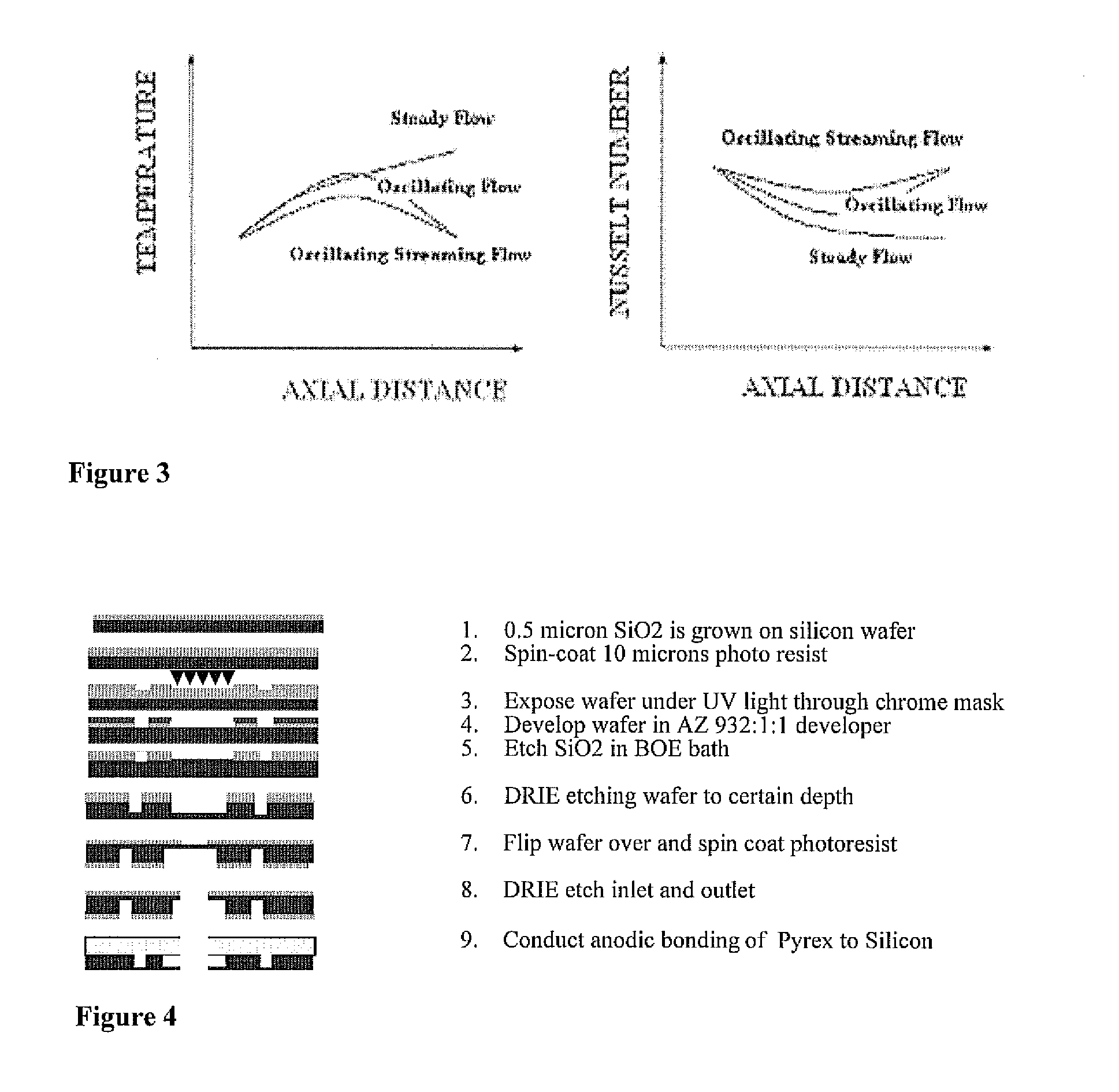

Streaming-based micro/mini channel electronic cooling techniques

InactiveUS20100091459A1Easy to createEfficient transportWave amplification devicesSemiconductor/solid-state device detailsHigh densityElectronics cooling

Micro-cooling technology for thermal control in the fabrication and operation of micro- and nano-scale such as high speed, high density micro scale electronic devices, micro sensors and micro machines Micro / mini heat exchangers and heat pipes have at least one channel through which the streaming flow is passed therethrough. The oscillating flow can be generated by diaphragms, vibrators, electrokinenatic force and thermal acoustic force.

Owner:BOARD OF GOVERNORS FOR HIGHER EDUCATION STATE OF RHODE ISLAND & PROVIDENCE

Internal combustion engine

ActiveUS10161296B2Easy to packReduce wall temperatureInternal combustion piston enginesCylinder headsCombustion chamberValve actuator

An internal combustion engine includes a pre-chamber. In another aspect, pressure within a pre-chamber is equal to or greater than pressure within a main combustion chamber at least prior to ignition in the main combustion chamber. In yet another aspect, internal combustion engine control software automatically controls pressure within a turbulent jet ignition pre-chamber, controls a valve-actuator to admit a fuel-air charge into the pre-chamber, and causes an igniter to initiate combustion in the pressurized pre-chamber. This also permits the rate of combustion to be controlled in the primary chamber regardless of the air-fuel ratio or the diluent fraction in the main chamber. Another aspect employs a pre-chamber purge pump with separate air and fuel injection.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

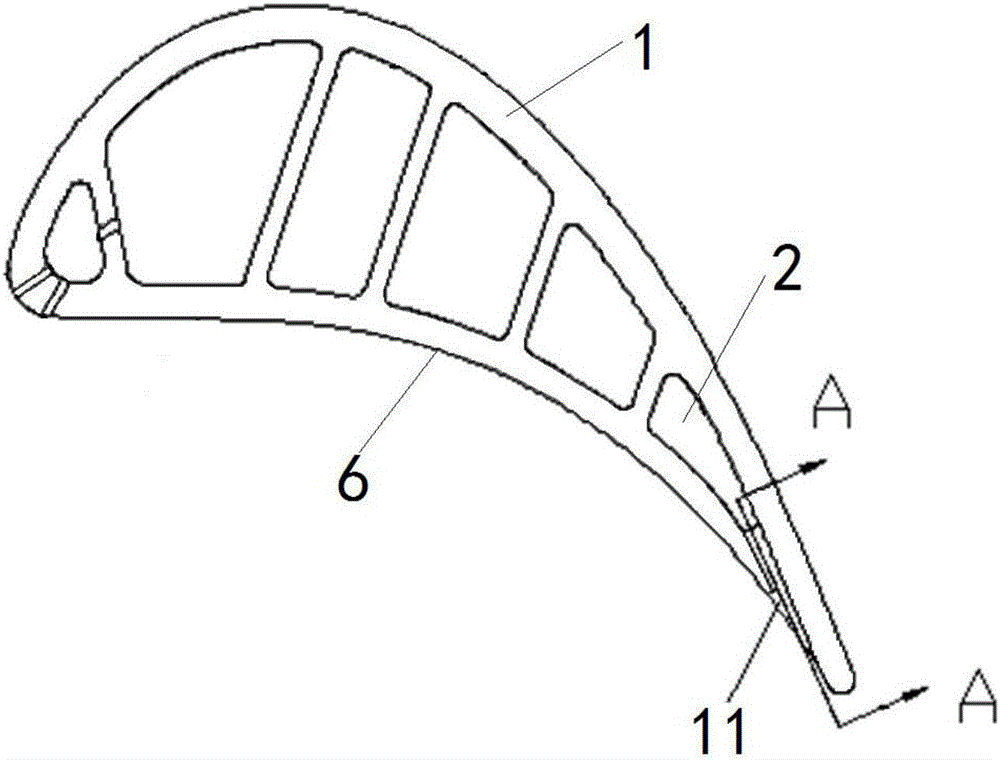

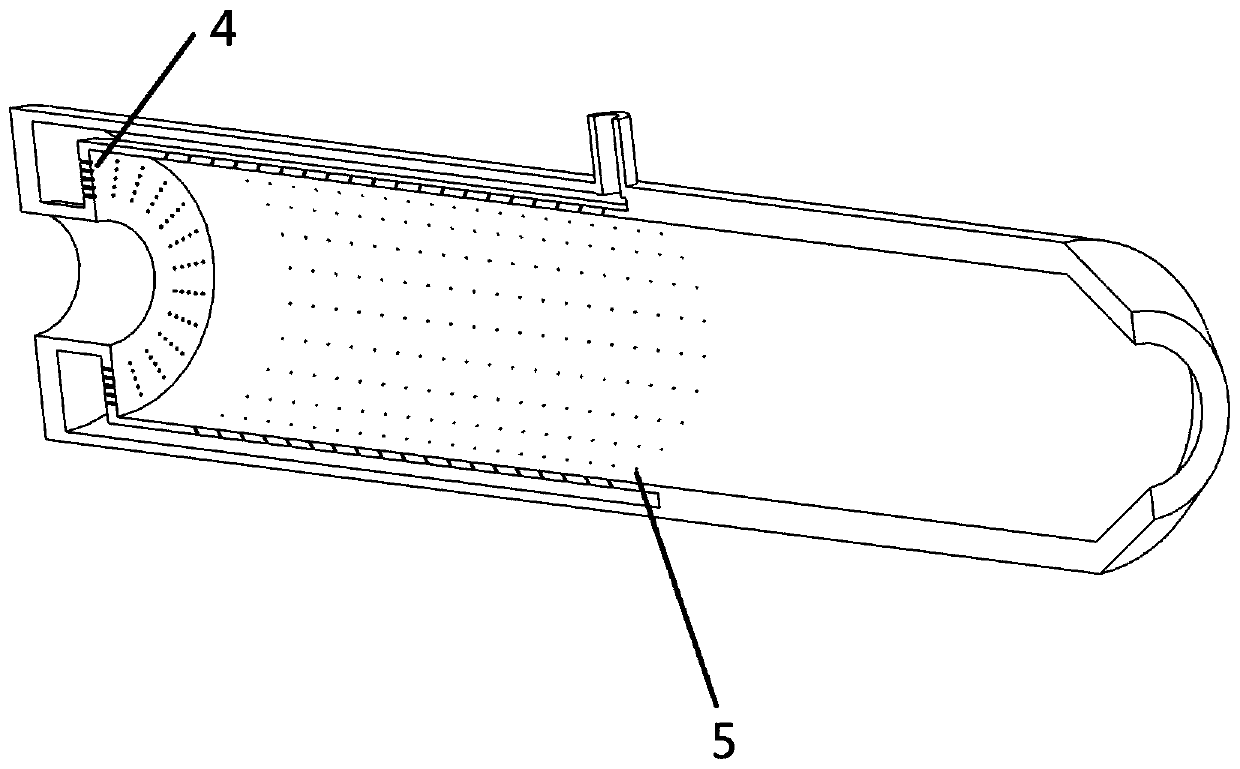

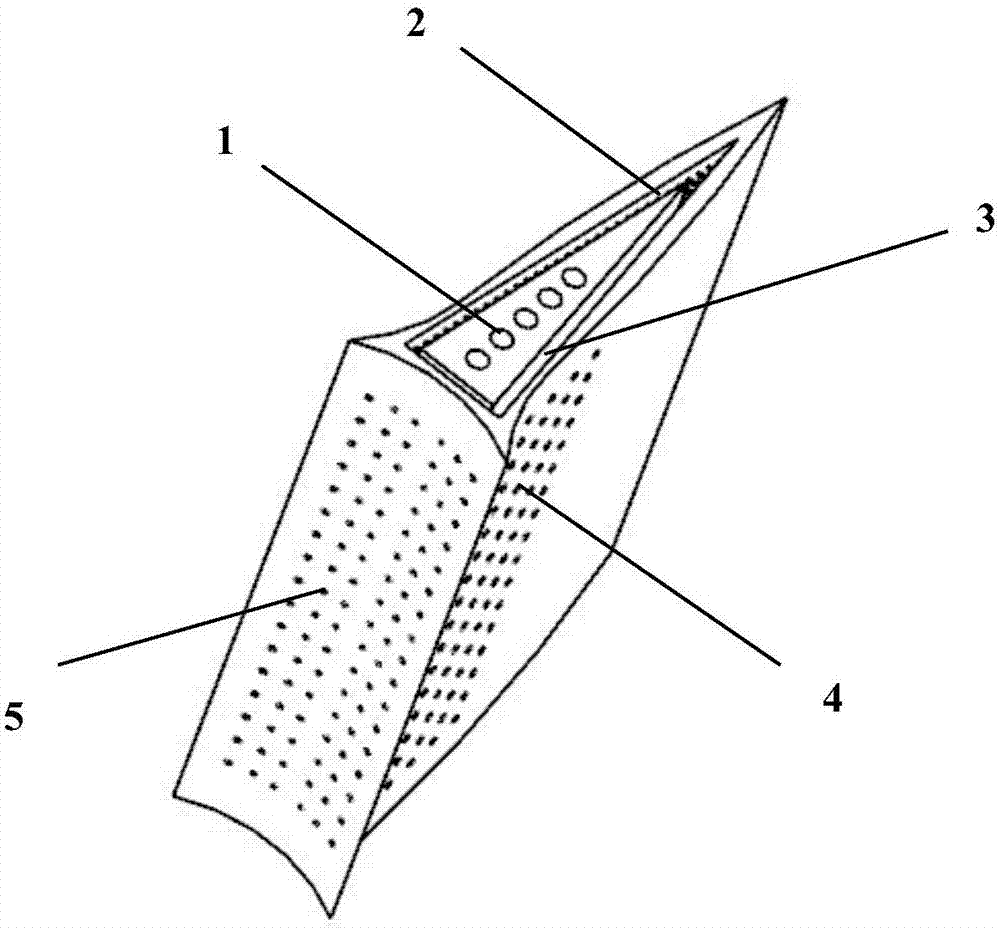

Cavity supporting plate flame stabilizer with built-in oil rod

InactiveCN104373964AReduce wall temperatureImprove stealth performanceContinuous combustion chamberIntegrated designPetroleum engineering

The invention provides an integrated design scheme of an oil injection system and a cavity supporting plate flame stabilization device, and discloses a cavity supporting plate flame stabilizer with a built-in oil rod. An oil injection rod is arranged in an inner cavity of a cavity supporting plate in a built-in mode, in this way, the number of components of an afterburner can be decreased, flow losses caused by the components are lowered, and the overall performance of the afterburner is improved. Meanwhile, the built-in oil injection rod can be subjected to pneumatic nebulization through cooling airflow which flows past the inside of the cavity supporting plate. Compared with a traditional direct-injection type oil injection mode, the atomization effect is better, and the organization burning capacity of the flame stabilizer and the combustion efficiency of the afterburner are further improved.

Owner:BEIHANG UNIV

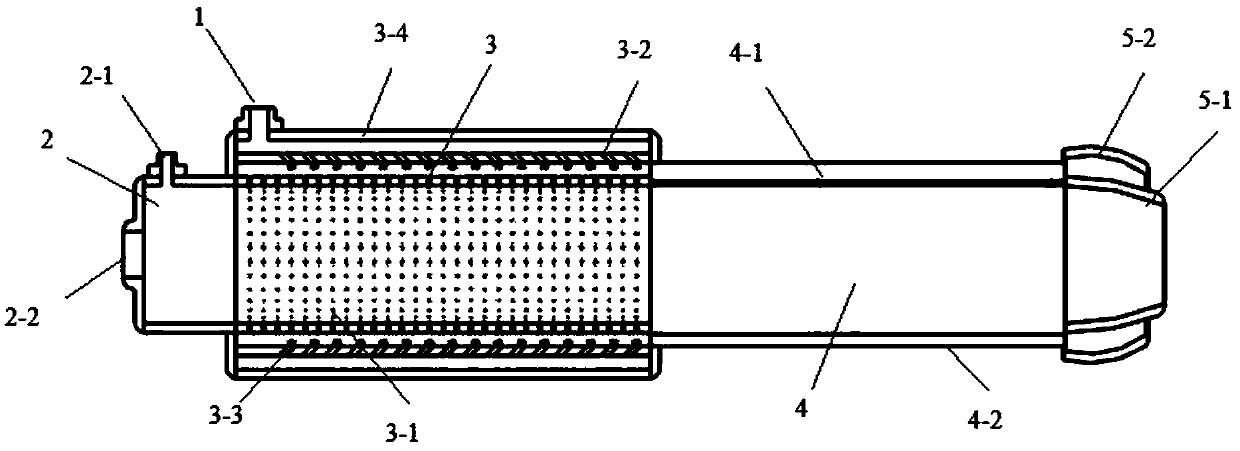

Cooling scheme for combustion chamber wall surface of aspirated type pulse detonation engine

InactiveCN109578168AReduce heat loadSafe and reliable workRocket engine plantsCombustion chamberInlet channel

The invention provides a cooling scheme for the combustion chamber wall surface of an aspirated type pulse detonation engine. Low-temperature gas of a gas inlet channel is used as a medium, and according to the characteristics of the different temperature of a DDT section and a detonation propagation section of the pulse detonation engine, a zonal cooling method is adopted to cool the combustion chamber wall surface of the aspirated type pulse detonation engine. A shock / sweat combined type cooling method is provided to cool the DDT section with higher temperature in the combustion chamber, thedetonation propagation section with relatively lower temperature is cooled through a method of convective heat exchanging in a channel, and the method of convective heat exchanging in the channel issimple in structure. The thrust of the engine can be improved by making full use of the cooling medium while without carrying an additional cold source. According to the cooling scheme for the combustion chamber wall surface of the aspirated type pulse detonation engine, the problem of uneven temperature distribution caused by existing cooling methods is solved, and the combustion chamber wall surface temperature of the pulse detonation engine is significantly reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Connection structure of engine exhaust gas reclrculation pipe and plastic intake manifold

ActiveCN101832201AImprove protectionReduce wall temperatureInternal combustion piston enginesNon-fuel substance addition to fuelEngineeringExhaust gas recirculation

The invention discloses a connection structure of an engine exhaust gas reclrculation pipe and a plastic inlet manifold, comprising an exhaust gas recirculation inlet pipe and a plastic inlet manifold, a thermal sleeve pipe is arranged on the connection part of the exhaust gas recirculation inlet pipe and the plastic inlet manifold, the thermal sleeve pipe is arranged in an entrance of a connection lug boss of the plastic inlet manifold, a connecting head of the exhaust gas recirculation inlet pipe is inserted into the thermal sleeve pipe, and the exhaust gas recirculation inlet pipe and the plastic inlet manifold are connected and mutually separated by the thermal sleeve pipe. The connection structure can avoid the direct contact of the exhaust gas recirculation inlet pipe and the plastic inlet manifold, directly conducts high temperature to the plastic inlet manifold, reduces the wall surface temperature of the inlet manifold of the connection of the EGR (Exhaust Gas Recirculation) pipe and the plastic inlet manifold, better protects the inlet manifold, and improves the reliability of the plastic inlet manifold with the EGR system.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

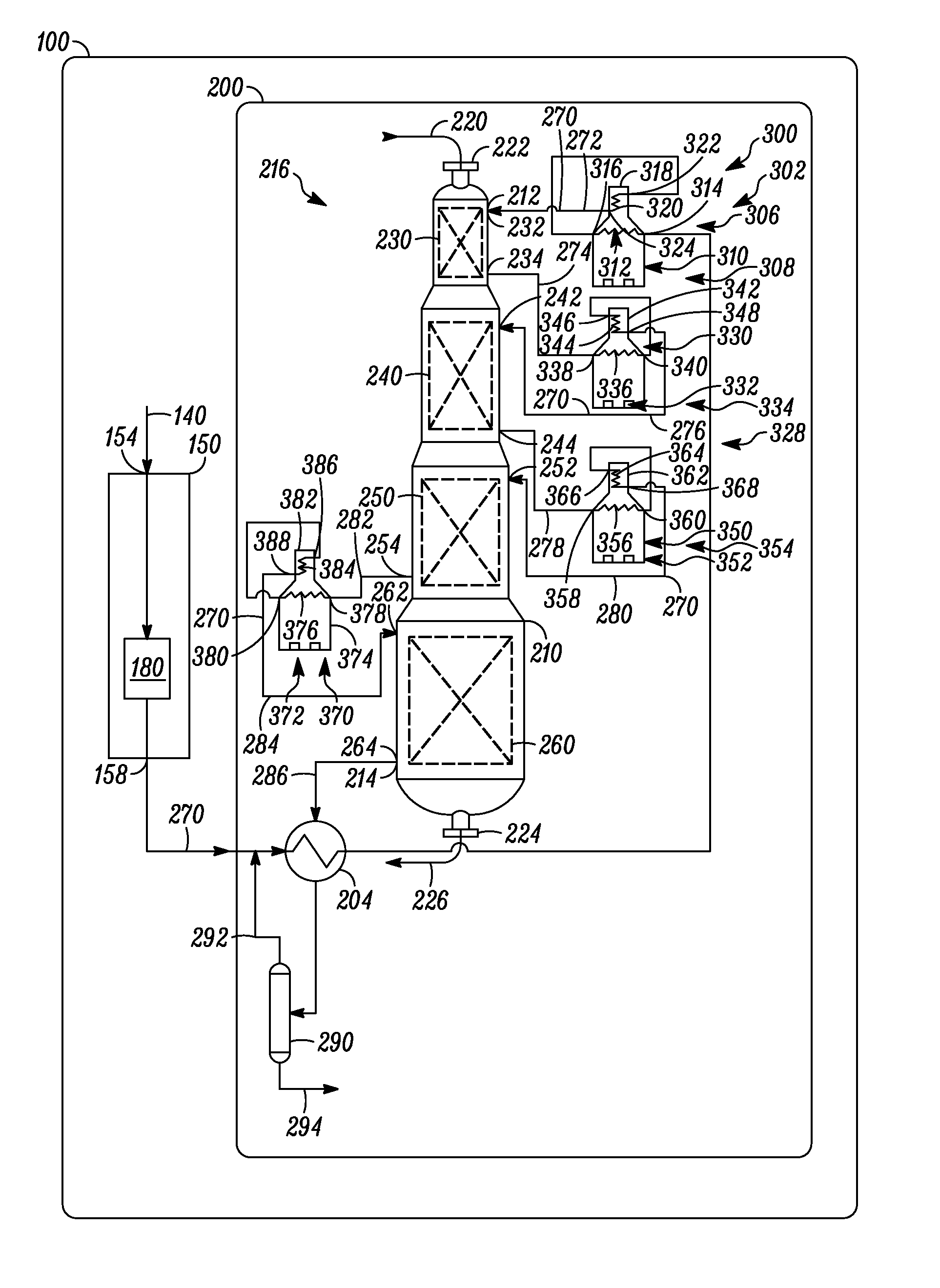

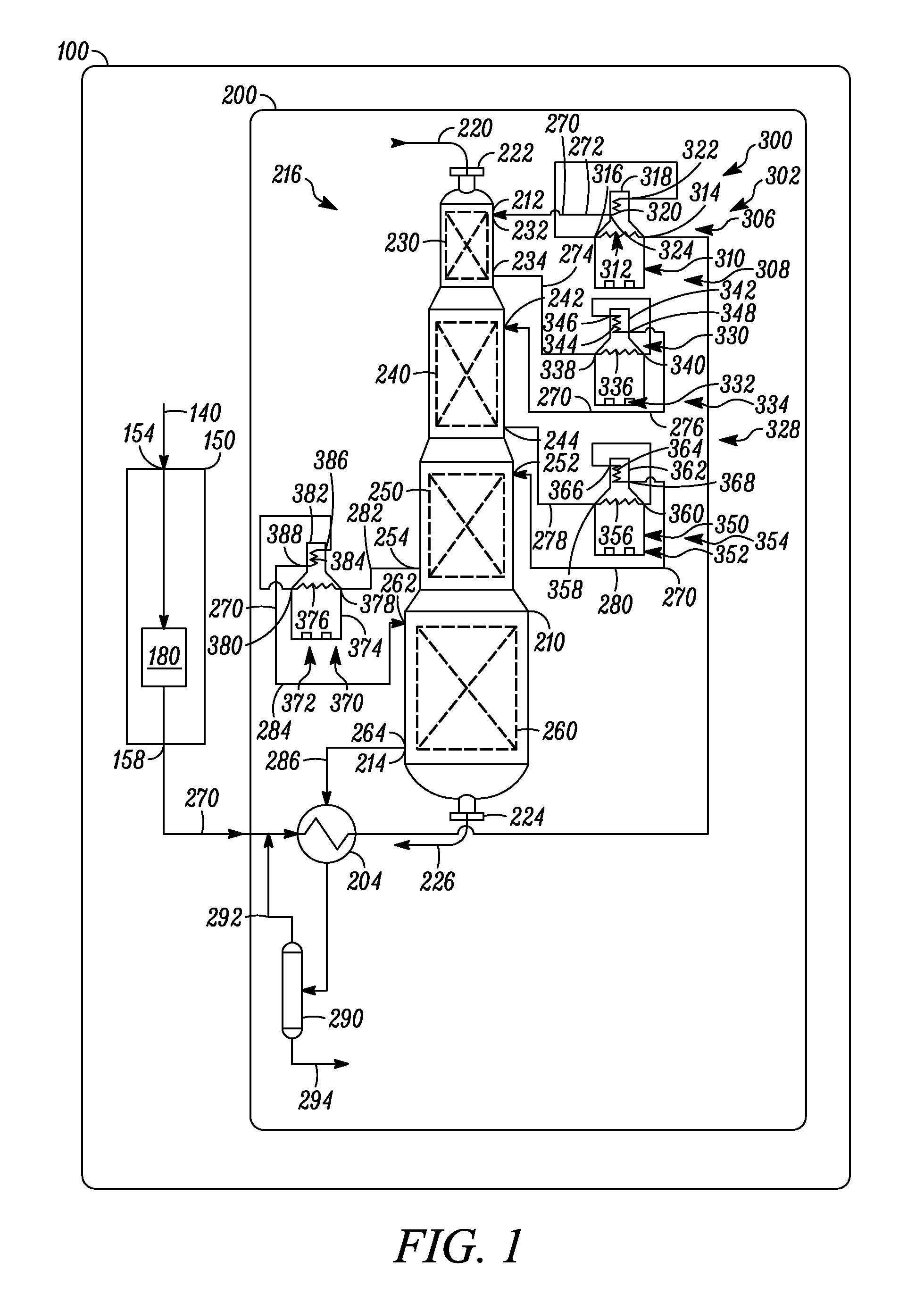

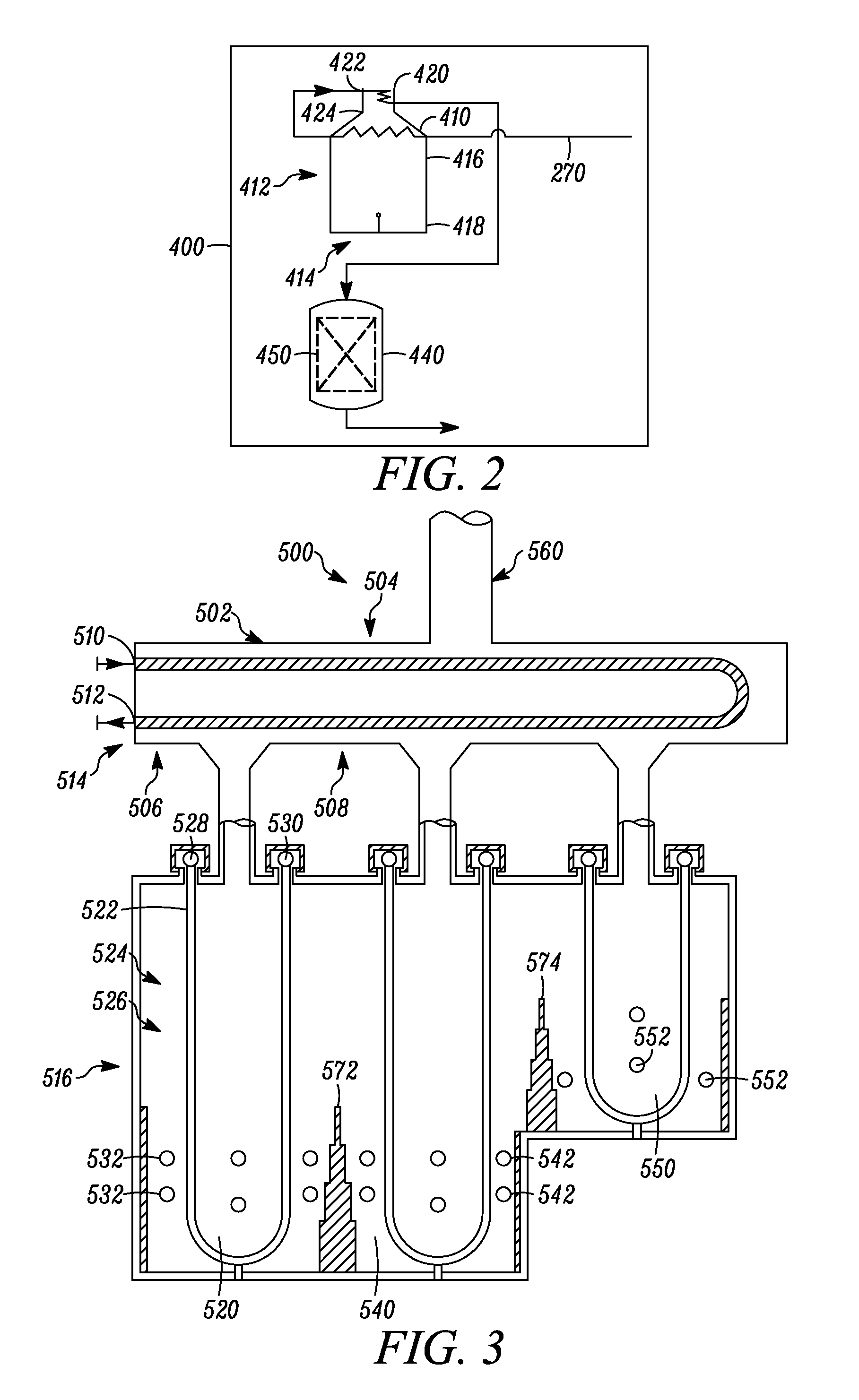

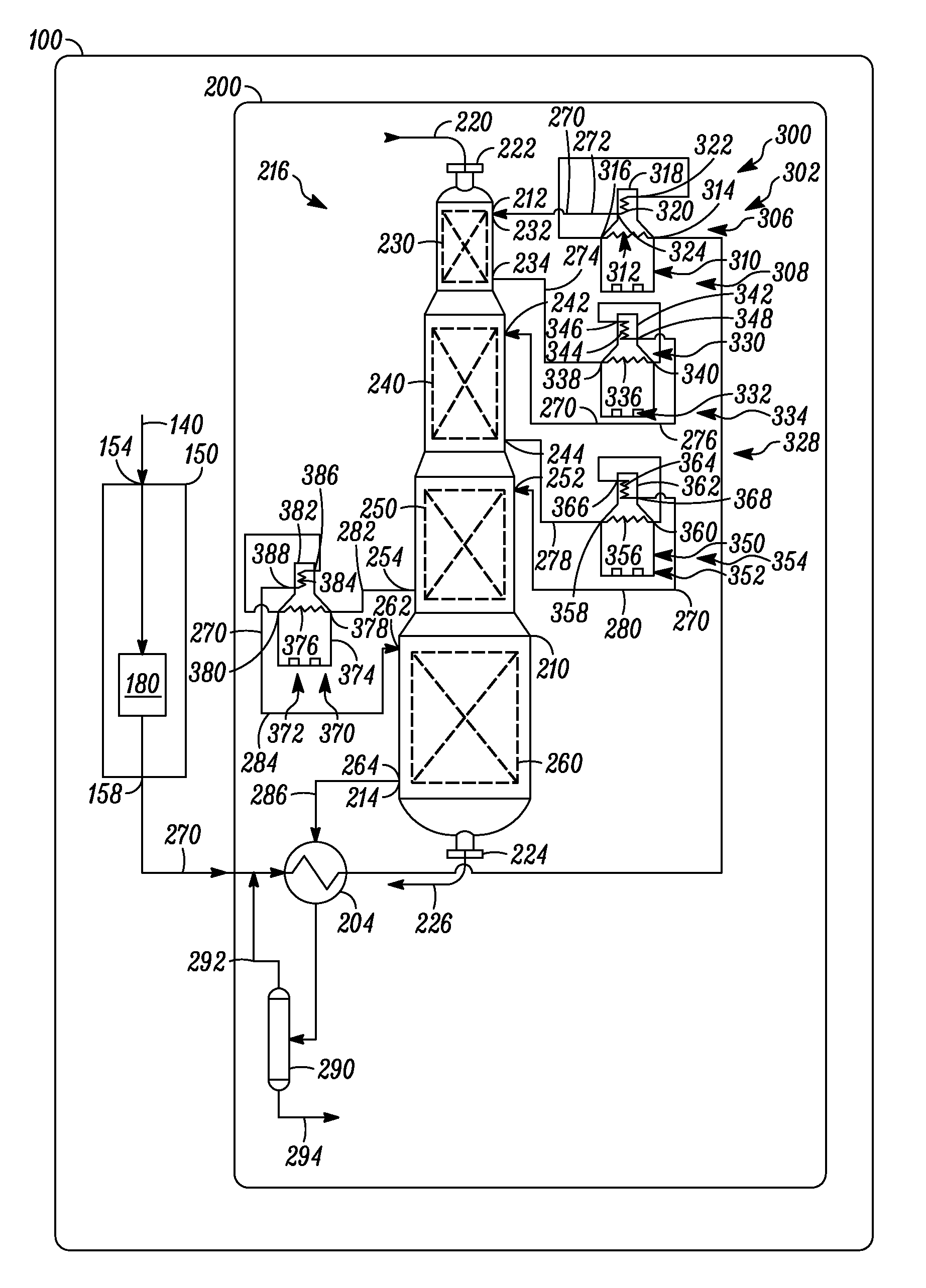

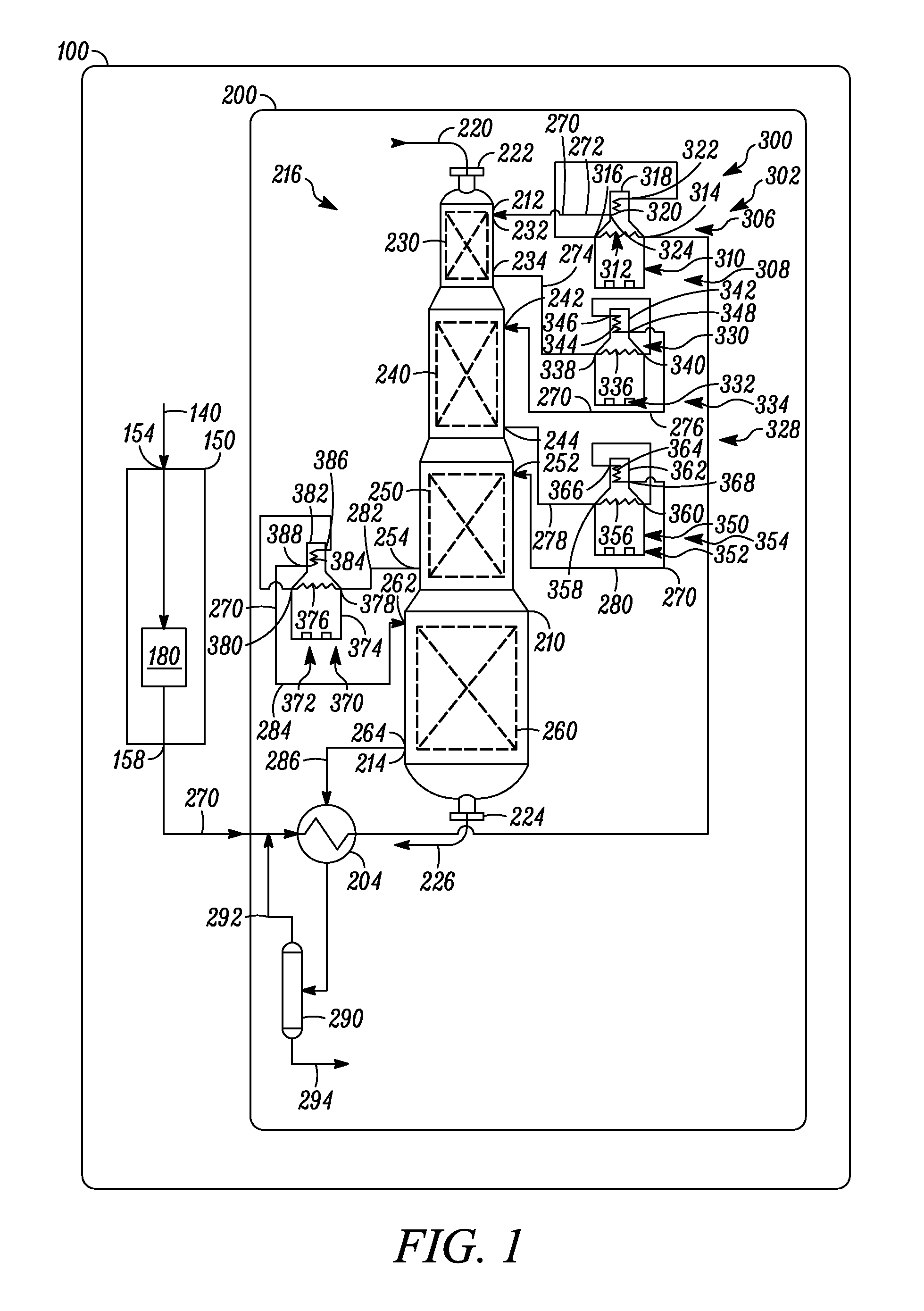

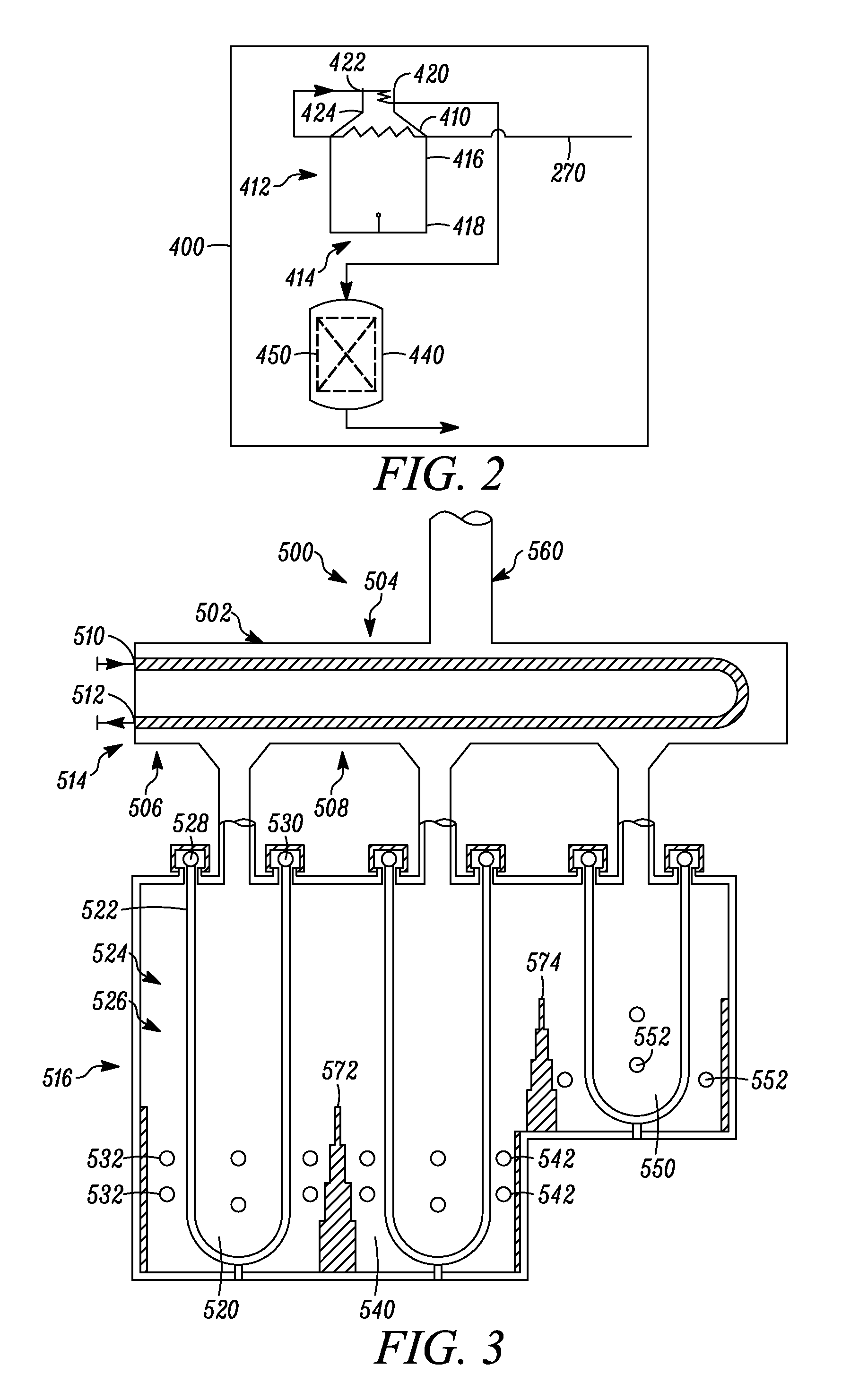

Process for heating a stream for a hydrocarbon conversion process

ActiveUS7740751B2Increase feed rateReduce wall temperatureCatalytic naphtha reformingThermal naphtha reformingThermodynamicsProcess engineering

One exemplary embodiment of the present invention can be a hydrocarbon conversion process. The process may include passing a hydrocarbon stream through at least one heater including at least one burner, a radiant section, and a convection section. Generally, the stream passes through the radiant section and then through the convection section before exiting the heater. Desirably, the hydrocarbon stream includes, in percent or parts by weight based on the total weight of hydrocarbons in the stream:C4 or less: less than about 0.5%,sulfur or sulfur containing compounds: less than about 1 ppm, andnitrogen or nitrogen containing compounds: less than about 1 ppm.Preferably, the sulfur or sulfur containing compounds and the nitrogen or nitrogen containing compounds are measured as, respectively, elemental sulfur or nitrogen.

Owner:UOP LLC

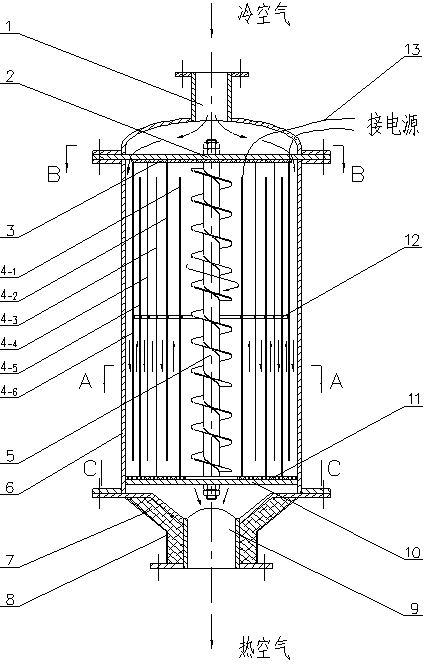

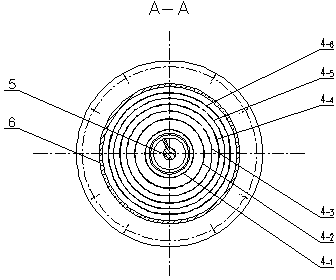

Sleeve-type electric heating device for high-temperature and high-pressure gas

ActiveCN104110838ASolve both withstand high temperatureSolve the technical difficulties of bearing high pressureAir heatersLow emissivityEngineering

The invention discloses a sleeve-type electric heating device for a high-temperature and high-pressure gas, and relates to an electric heating gas device. The sleeve-type electric heating device comprises a heating core body composed of metal sleeves which are coaxial and with different diameters, and a central ceramic spiral rod, wherein the heating core body is used as a resistor heat release body for releasing heat, and also forms a channel for the gas flowing while being heated; the quantity of inner barrels, and the wall thickness and the material of each inner barrel are changeable to adapt the differences of heating powers and heating final temperatures, and a layer of a low-emissivity material is capable of being selectively plated or coated on the inner surface and the outer surface of each inner barrel so as to reduce the mutual radiation heat exchange between the wall surfaces of the inner barrel; the outer-layer heat release power of the heating core body is low, and the wall temperature of the inner barrel is low. According to the sleeve-type electric heating device disclosed by the invention, the wall temperature of a housing and the wall temperature of the resistor electric heating body are effectively lowered, the consumption of precious metal materials is saved, and the manufacturing cost is reduced; moreover, the service life and the heat efficiency of the device are prolonged and increased, and the device is especially suitable for occasions with high gas pressures and high temperature rises.

Owner:CYBROG SHENYANG ENERGY & INTELLIGENCE EQUIPCO

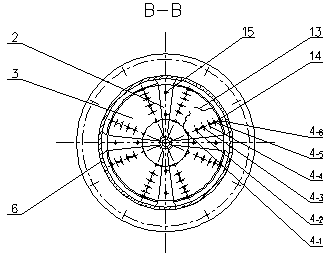

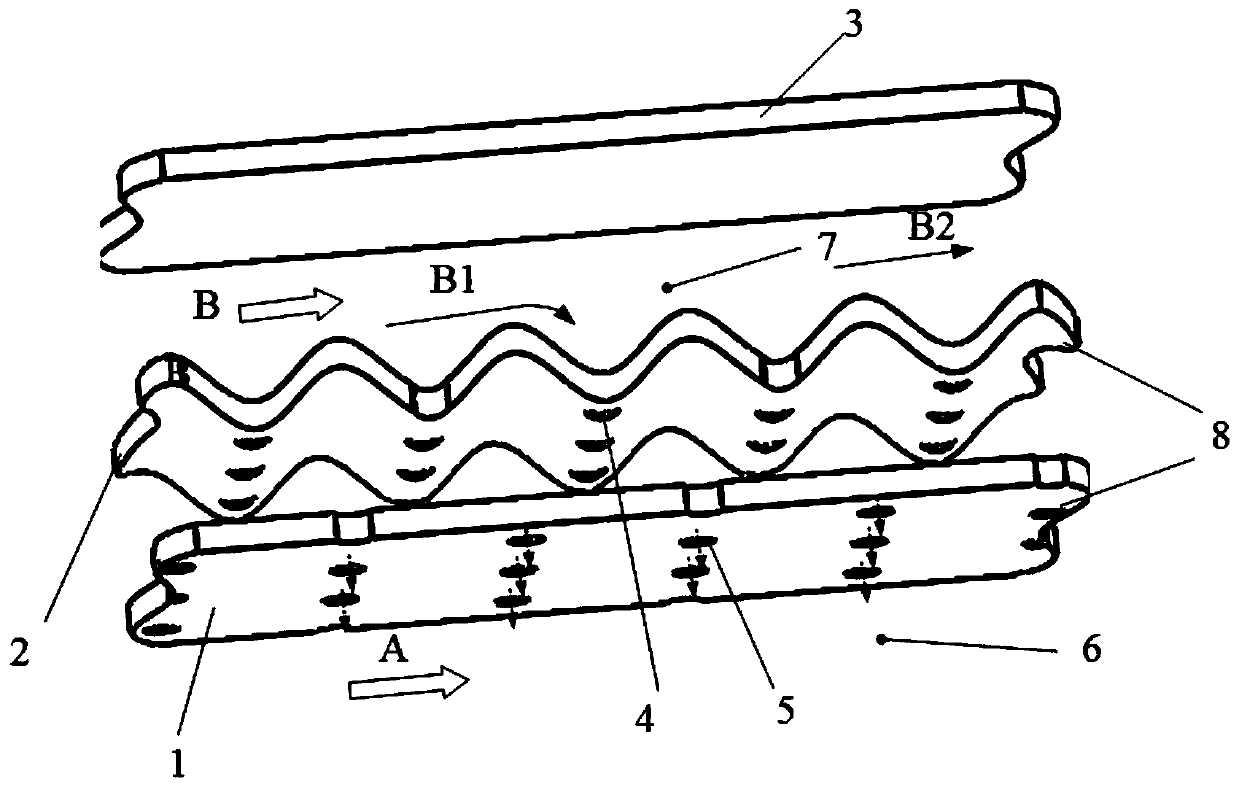

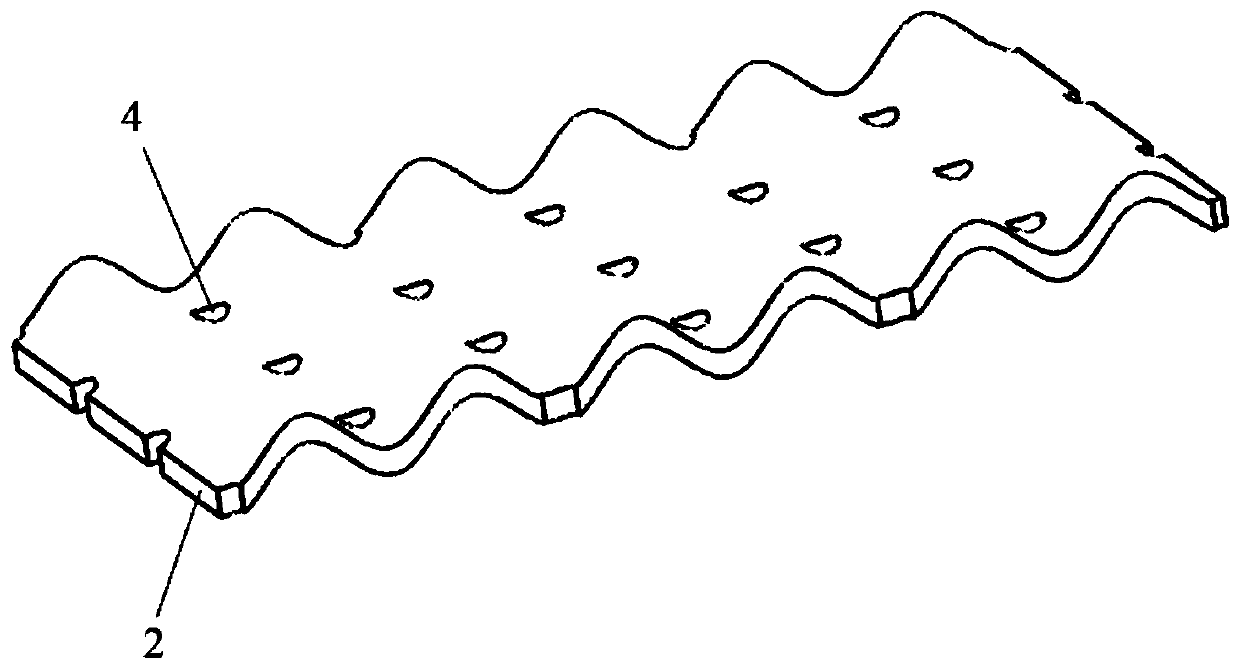

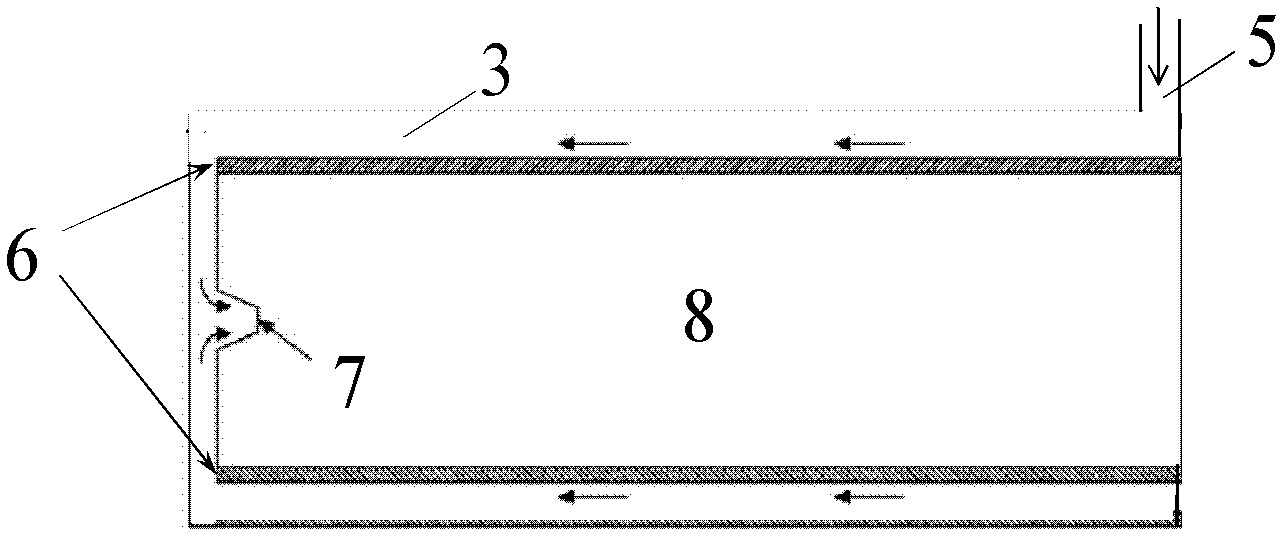

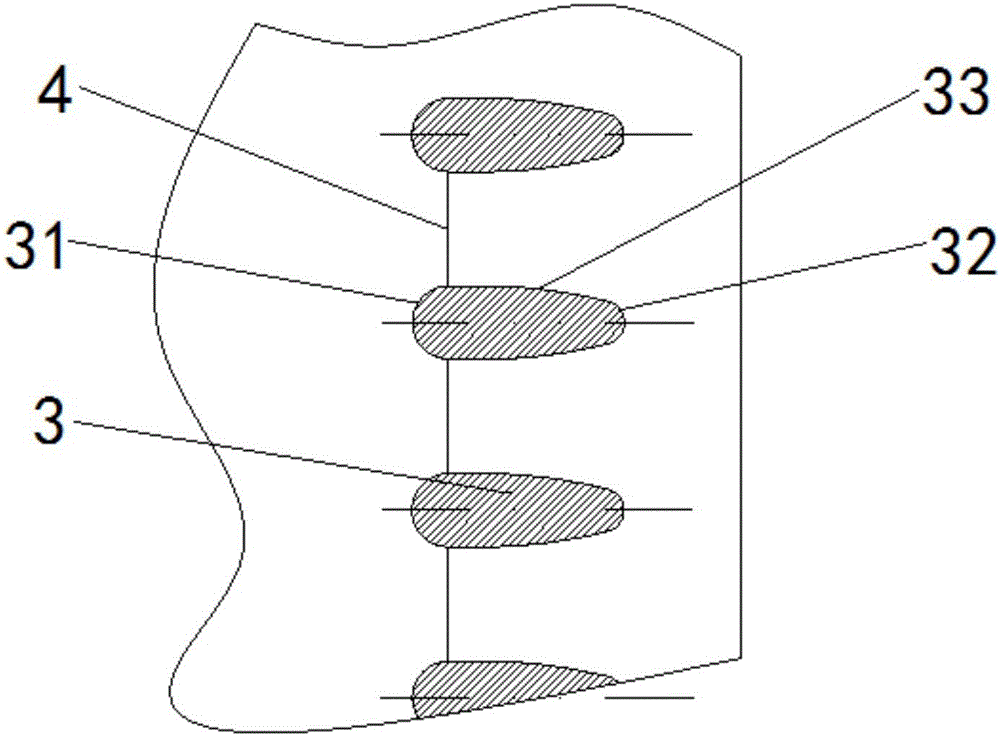

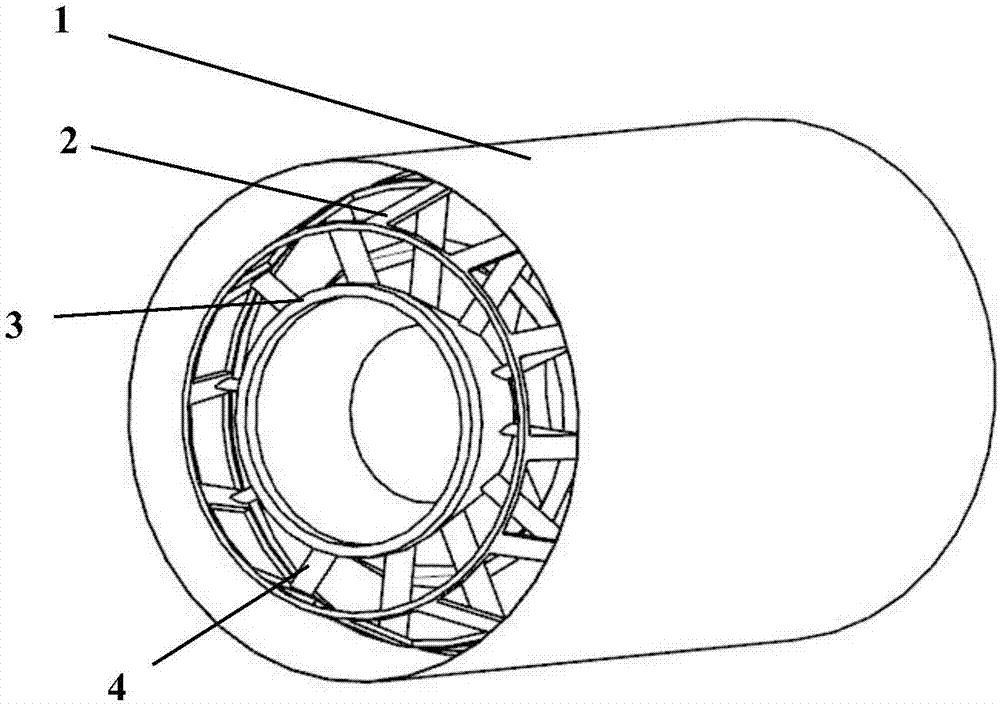

Double-wall cooling structure having longitudinal corrugated impact hole plate for thrust-vectoring nozzle

In the invention, a longitudinal corrugated impact pore plate and a flat plate type air film plate are used to constitute a double-wall cooling structure. Impact holes and air film holes are distributed in a staggered manner respectively; impact holes are formed in wave troughs of the corrugated impact hole plate and air film holes in the air film hole plate directly face wave peaks of the corrugated impact hole plate; and each of the corrugated impact pore plate and the air film hole plate is a plurality of unit period structures in the axial direction. A relatively small impact distance is formed between the wave trough and the air film hole plate, so that the heat exchange by impact may be increased; a relatively larger space may be formed between the wave peak and the air film hole plate, full development of cool air flowing is facilitated, outflowing is facilitated, the flow resistance may be reduced, the utilization ratio of cold air is increased and the contradiction between themethod of impact distance reduction for heat exchange enhancement and the method of impact distance increase for flow resistance reduction is solved; and meanwhile, the air film plate is a flat plate, so that air film attachment is facilitated to form effective heat protection, heat stress is reduced and the problem of uneven heat stress of a corrugated heat shield is solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

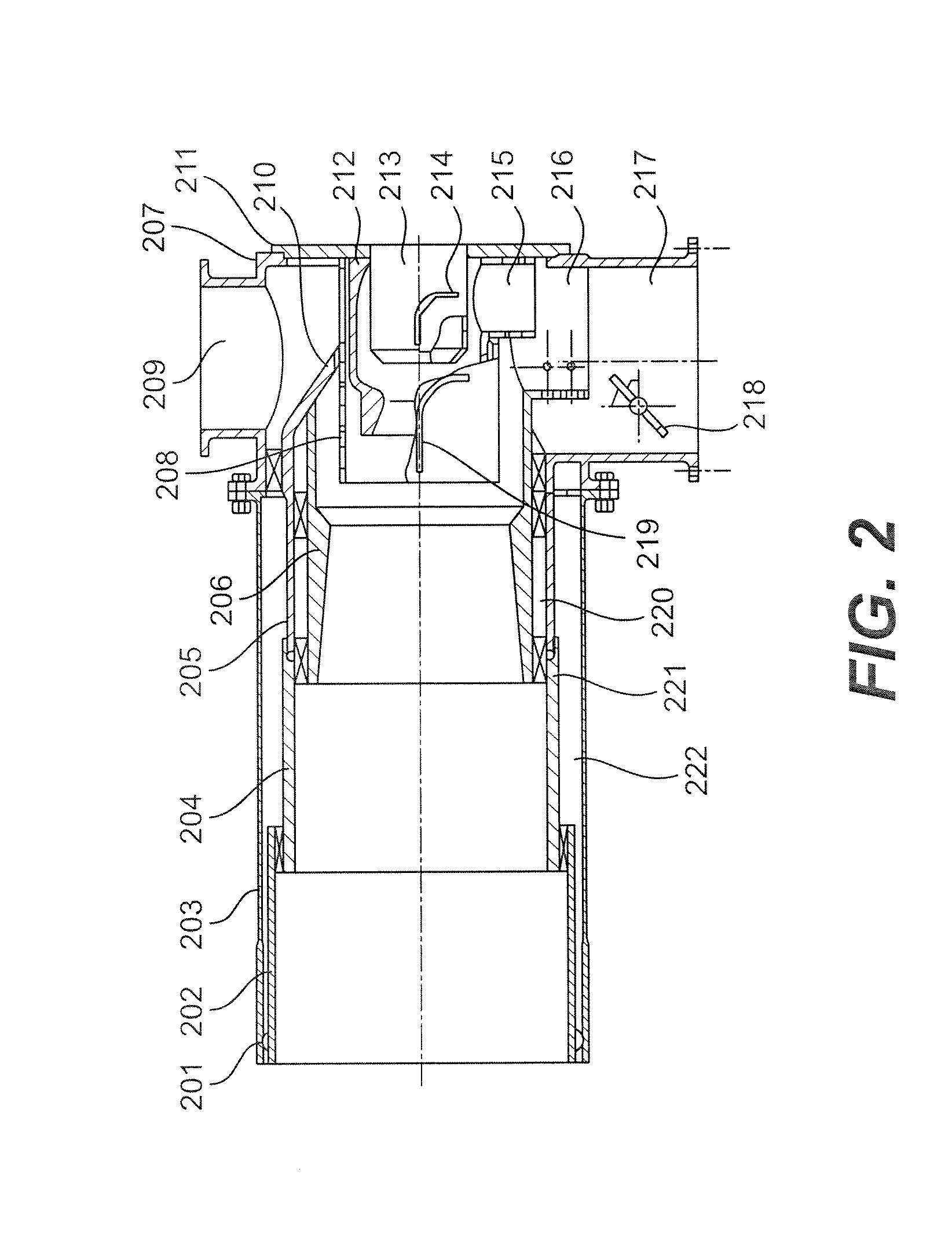

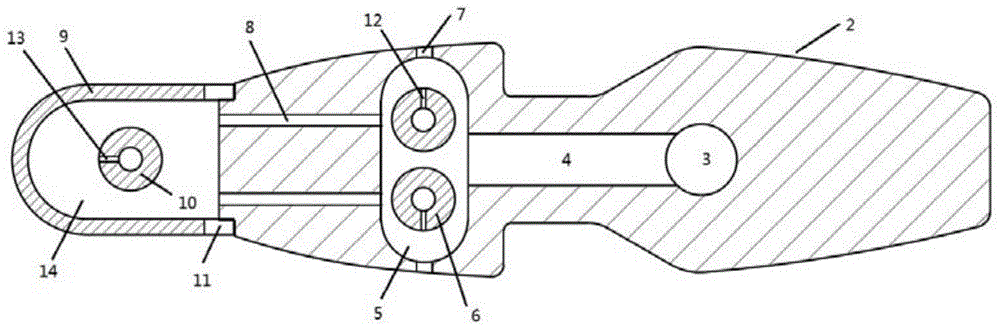

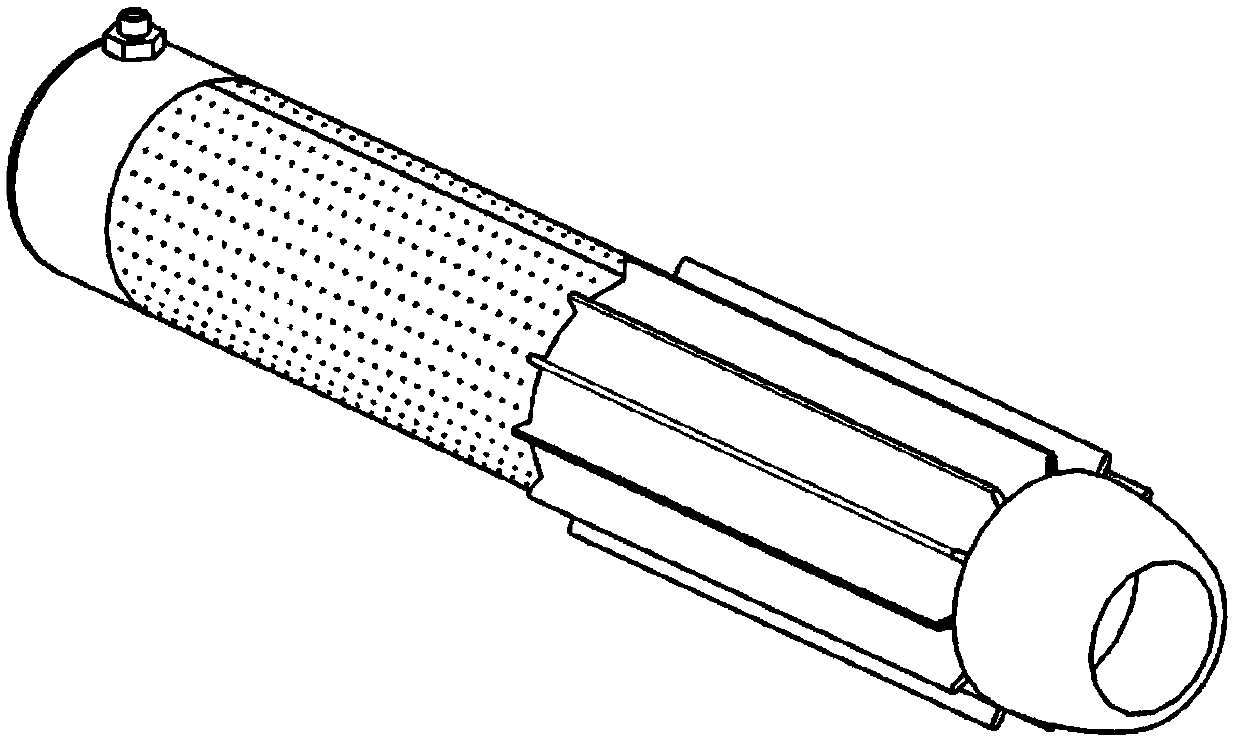

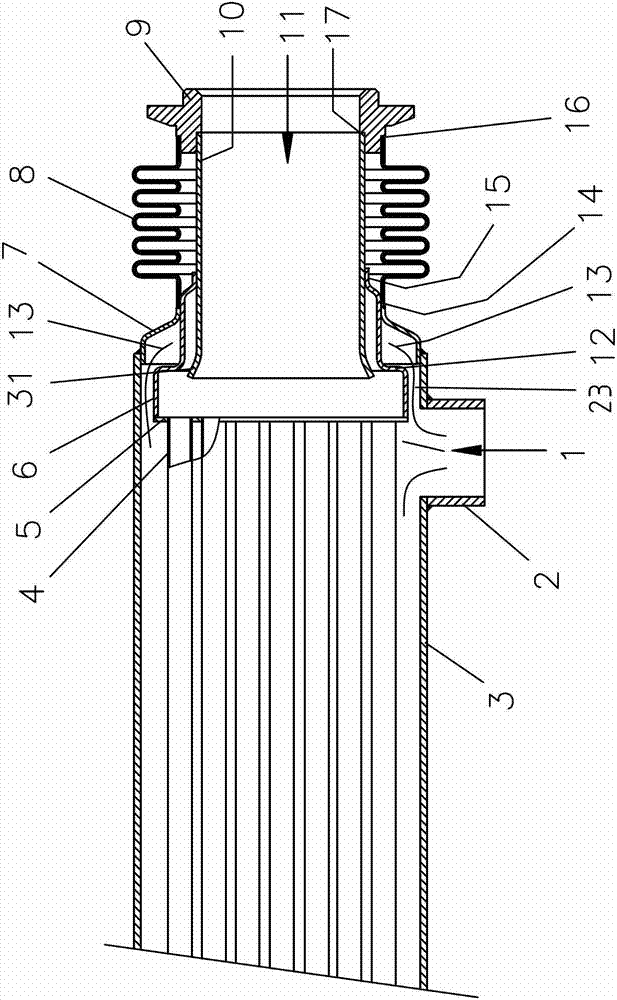

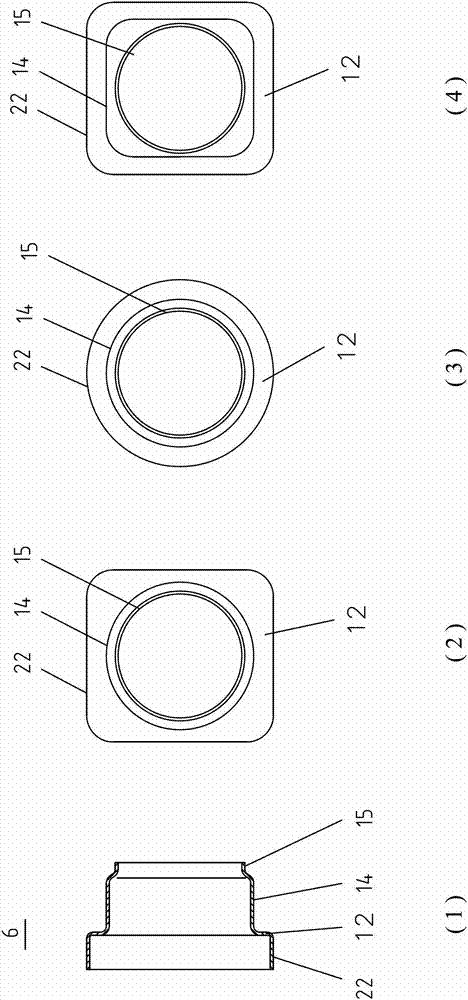

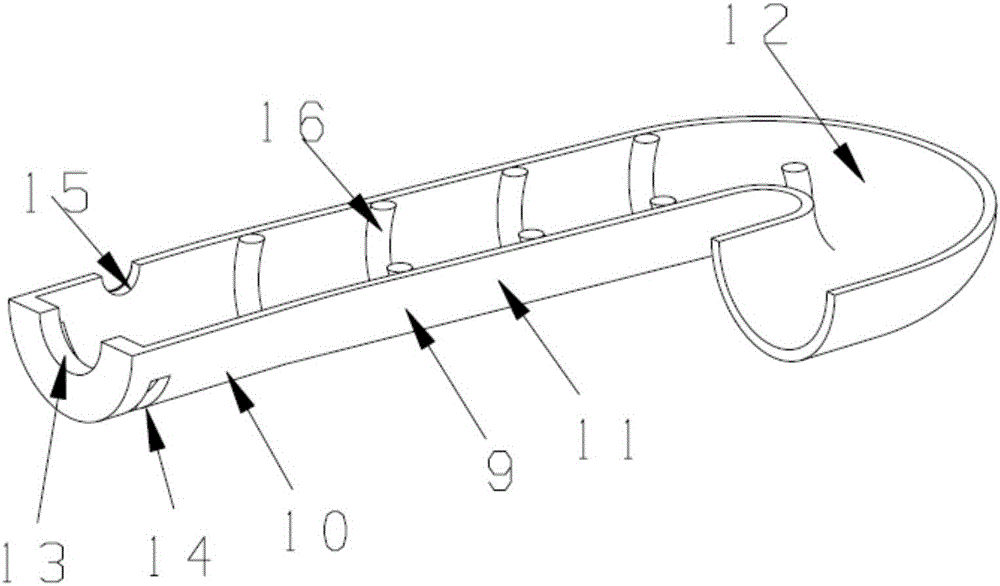

Waste gas inlet end structure of EGR (Exhaust Gas Recirculation) cooler

InactiveCN102734004ATo meet the needs of lateral thermal expansion releaseImprove vibration resistanceInternal combustion piston enginesNon-fuel substance addition to fuelEngineeringExhaust gas recirculation

The invention discloses a waste gas inlet end structure of an EGR (Exhaust Gas Recirculation) cooler. The waste gas inlet end structure comprises a water shell, a gas inlet pipe, a corrugated pipe, an gas inlet chamber of a heat insulation pipe, a pre-cooling water chamber and a main plate, wherein the water shell is provided with the water inlet pipe. The waste gas inlet end structure is characterized in that the heat insulation pipe is arranged in the corrugated pipe; one end of the corrugated pipe is connected with the gas inlet pipe and the other end of the corrugated pipe is suspended; the large-diameter end of the gas inlet chamber is connected with the main plate to form the gas inlet chamber, and a cooling liquid channel is formed between the water shell and a jointing part between the gas inlet chamber and the main plate; the outer surface of a middle pipe body is connected with the end part of the corrugated pipe to form the pre-cooling water chamber; and the small-diameter end of the gas inlet chamber is contacted with the outer surface of the middle part of the heat insulation pipe. The waste gas inlet end structure of the EGR cooler has the advantages that by virtue of the added pre-cooling water chamber, temperatures of the wall faces of the main plate and the gas inlet chamber are reduced; a support is additionally arranged in the middle of the heat insulation pipe, so that the anti-vibration performance of the heat insulation pipe is improved; and by virtue of a special structure of the gas inlet chamber, an inner axial heat expansion displacement compensation capability of the EGR cooler is improved. By virtue of the improvement, the reliability of the EGR cooler is obviously improved.

Owner:ZHEJIANG YINLUN MACHINERY

Process For Heating A Stream For A Hydrocarbon Conversion Process

ActiveUS20080110800A1Increase feed rateReduce pipe wall temperatureCatalytic naphtha reformingThermal naphtha reformingCombustorNitrogen

One exemplary embodiment of the present invention can be a hydrocarbon conversion process. The process may include passing a hydrocarbon stream through at least one heater including at least one burner, a radiant section, and a convection section. Generally, the stream passes through the radiant section and then through the convection section before exiting the heater. Desirably, the hydrocarbon stream includes, in percent or parts by weight based on the total weight of hydrocarbons in the stream:C4 or less: less than about 0.5%,sulfur or sulfur containing compounds: less than about 1 ppm, andnitrogen or nitrogen containing compounds: less than about 1 ppm. Preferably, the sulfur or sulfur containing compounds and the nitrogen or nitrogen containing compounds are measured as, respectively, elemental sulfur or nitrogen.

Owner:UOP LLC

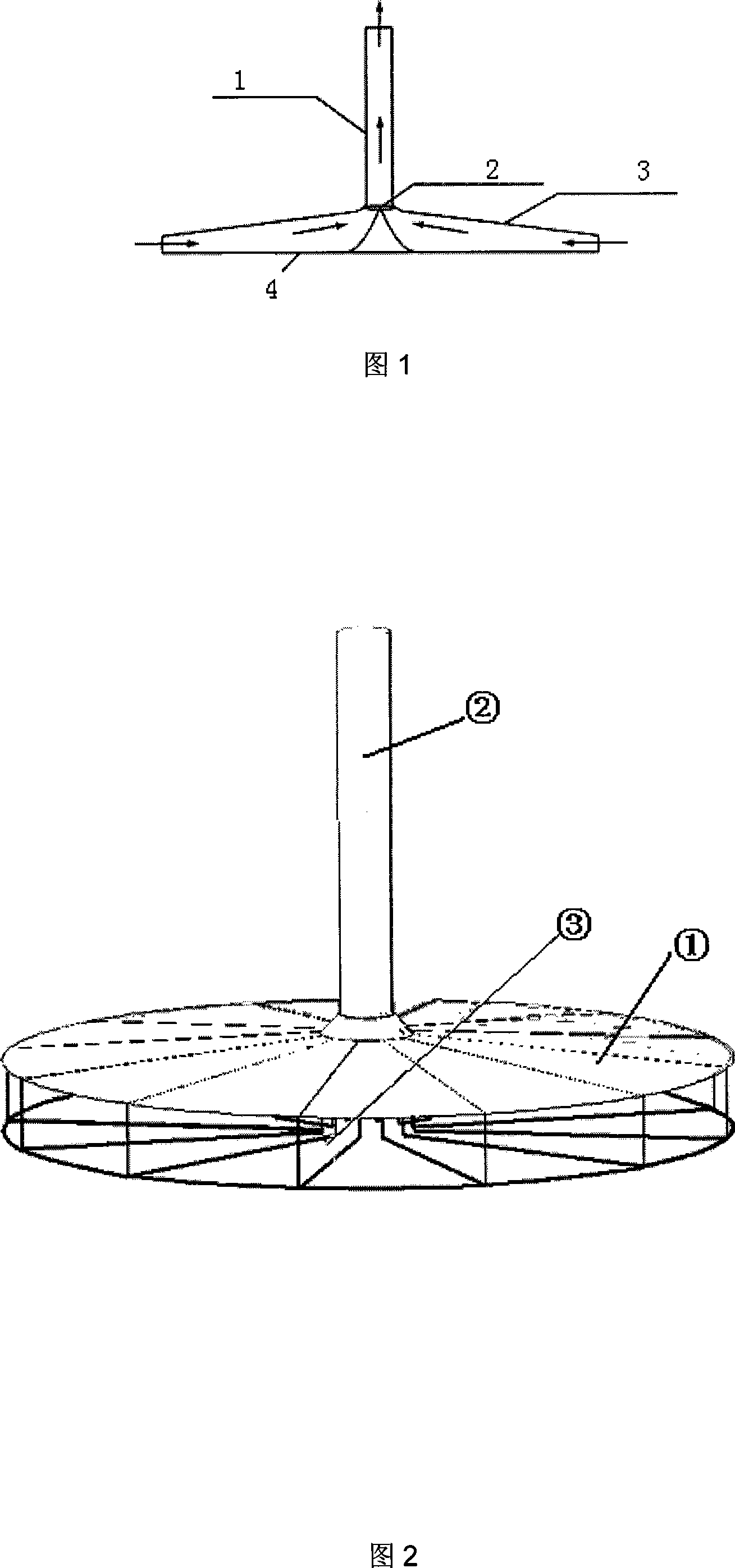

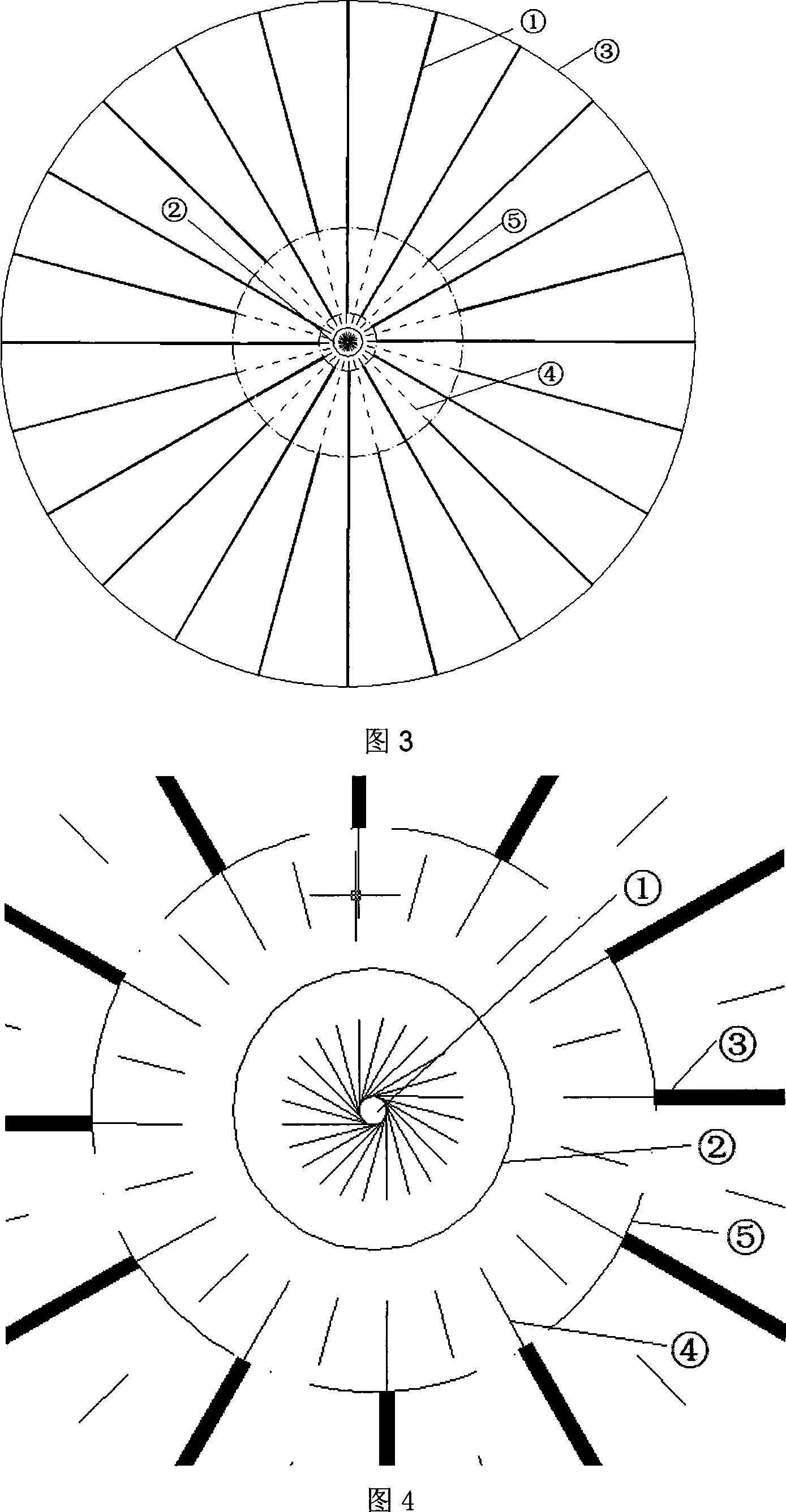

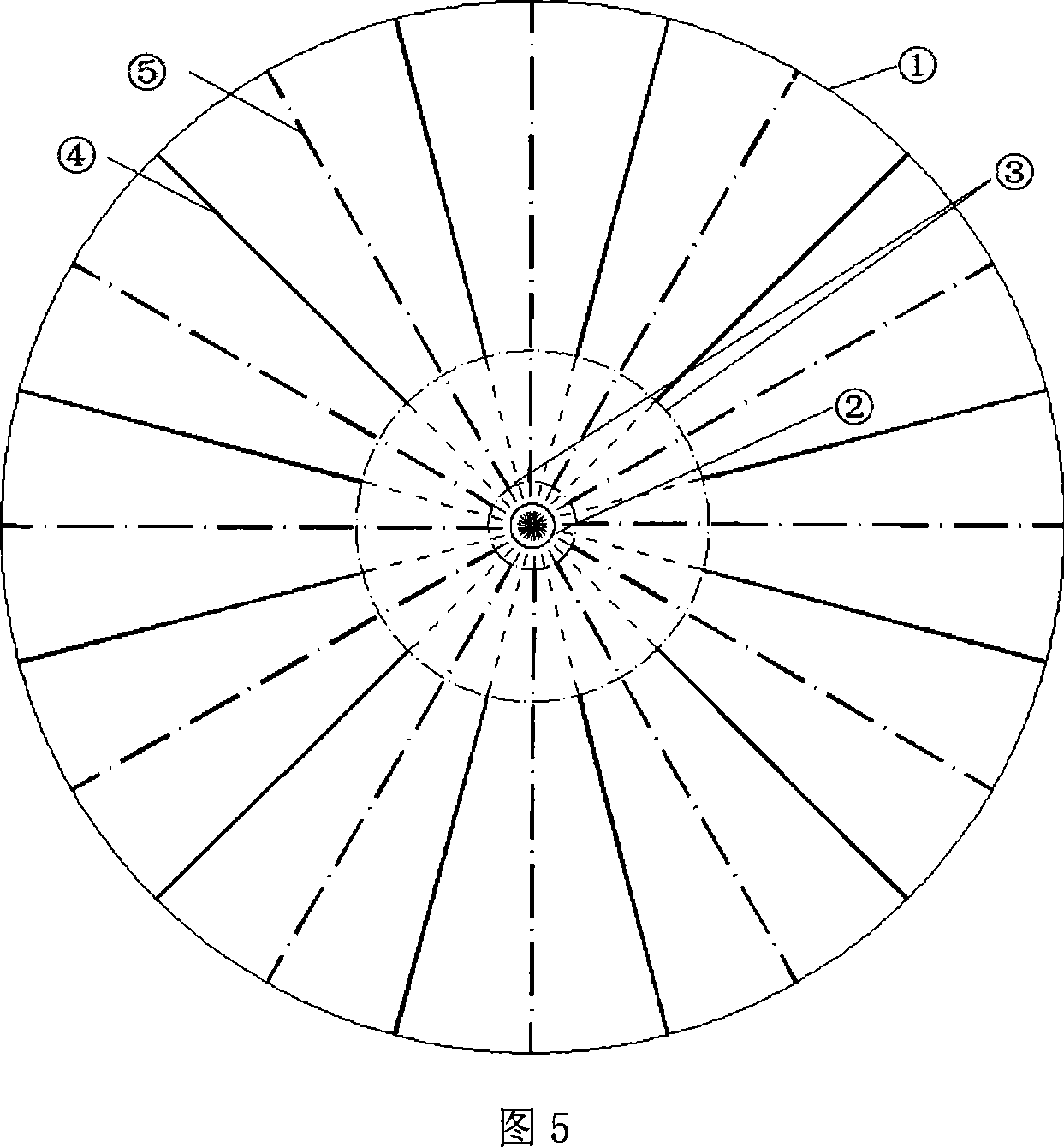

Heat collectors for solar energy hot blast power generation system

InactiveCN101240779AImprove heat collection efficiencyIncrease the heating areaWind motor combinationsMachines/enginesFlat glassCollector device

The present invention relates to a heat collector for solar hot air power generation system, includes solar chimney, heat collectors, transparent material spacing plate disposed vertically along circular tangential direction with 0.8-2 m which is the same center of circle of heat collectors, lower edge of transparent material spacing plate clings to floor of heat collectors, upper edge clings to ceiling of heat collectors; the apparent material spacing plate divides heat collectors into at least 24 regions equally along circumference; outer edge of apparent material spacing plate through to outer margin of heat collectors, and its length is 60-110m. The present invention improves Plate solar energy collector heat collecting stripe heat-collecting efficiency of solar hot air power generation system heat collectors, thereby improving its generating efficiency. Because of increasing heat collectors heating surface, so reducing heat dissipation losses of heat collectors; guiding function of plate glass to air current reaches airflow request when reaches air arriving turbine generator entrance, flowing loss of airflow is decreased.

Owner:DONGHUA UNIV

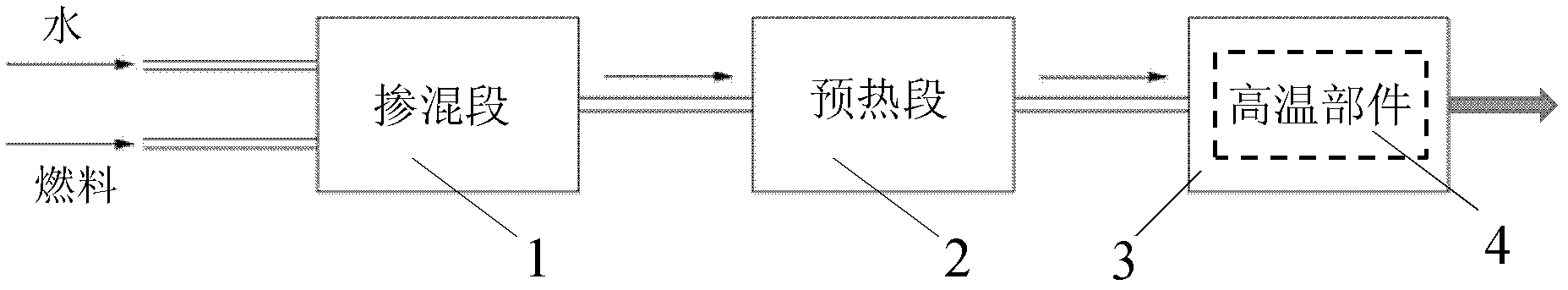

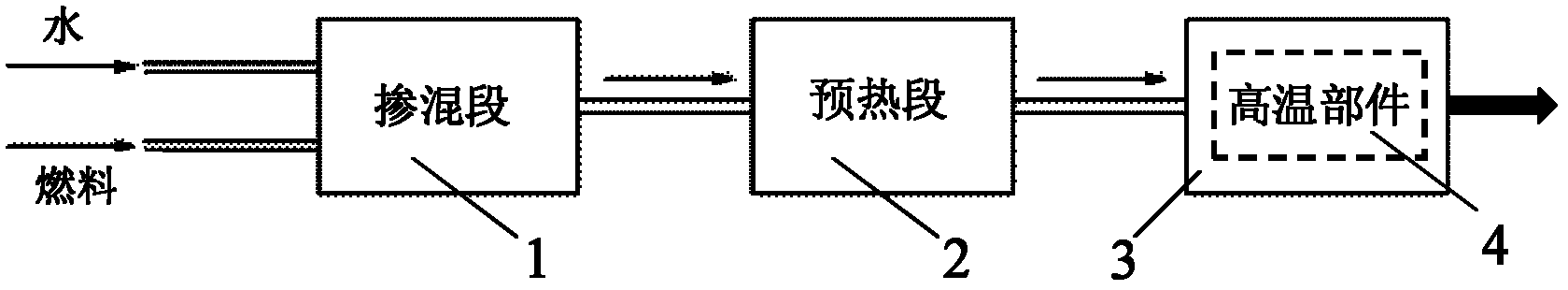

Method for cooling high temperature parts through catalytic reforming of liquid hydrocarbon fuel

The invention discloses a method for cooling high temperature parts through catalytic reforming of a liquid hydrocarbon fuel, and in particular relates to a process method for cooling high temperature parts. The liquid hydrocarbon fuel and water are blended and preheated to be vaporized into mixed vapor of hydrocarbon fuel vapor and water vapor, the mixed vapor enters a catalytic reforming reaction cooling section on the surface of a high temperature part, a reforming endothermic reaction is generated on the surface of a catalyst, and the surface temperature of the high temperature part is reduced; meanwhile, combustible gas rich in hydrogen is generated and is sprayed through a fuel nozzle or a convergent nozzle to form a combustible gaseous mixed fuel required by combustion. By the method, the cooling amount is great, the surface temperature of the high temperature part is effectively reduced, the coking of a cooling channel is relieved, and an effect of cooling the high temperaturepart and the characteristics of the fuel are improved.

Owner:TSINGHUA UNIV

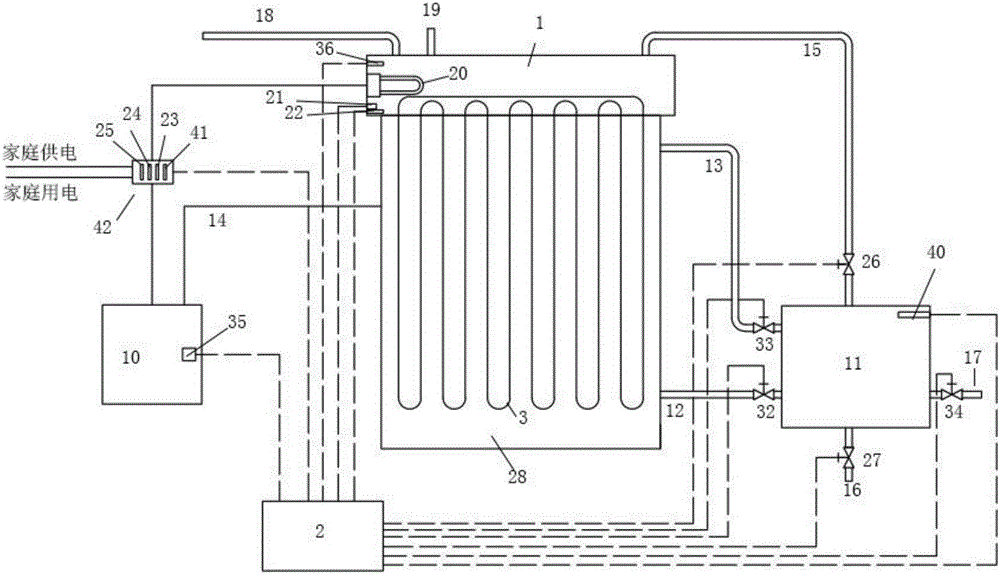

All-weather photo-thermal photovoltaic integrated automatic control heat pipe water heater

ActiveCN106766237ANo guarantee rate zeroHigh initial investmentSolar heating energySolar heat collector controllersAutomatic controlEvaporation

The invention provides an all-weather photo-thermal photovoltaic integrated automatic control heat pipe water heater. The water heater comprises a solar water tank, a support, heat pipes, a thermoelectric generation module, a storage battery, a cold water circulation system and a controller which are mutually connected. The all-weather photo-thermal photovoltaic integrated automatic control heat pipe water heater has the effect that the problem of energy waste caused by hot water boiling and evaporation in an existing hot water tank is effectively solved through the water heater. Heat exchange between a water storing tank and the cold end for cooling the thermoelectric generation module is conducted through a cold water inlet pipe and a cold water outlet pipe, so that the temperature in the water storing tank can be increased by 10-20 DEG C, correspondingly, water supplied to the solar water tank from the water storing tank is preheated once, and heat is fully utilized. The all-weather photo-thermal photovoltaic integrated automatic control heat pipe water heater can not only provide hot water for a user, but also fully utilize the temperature difference between cold water and the hot water to generate electricity, thereby saving energy and being environmentally friendly, safe and efficient.

Owner:TIANJIN CHENGJIAN UNIV +1

Reverse-flow type pulse detonation combustor

ActiveCN105972638AShorten the axial distanceExtended use timeContinuous combustion chamberCombustion chamberFuel gas

The invention provides a reverse-flow type pulse detonation combustor. The reverse-flow type pulse detonation combustor comprises a diffusion case, an outer combustor case, an inner combustor case, a combustor head case, a vortex guide unit, an oil nozzle, an electric spark, a fuel gas shaping chamber, a J-type reverse-flow detonation tube and a Shchelkin threaded strengthening device. An axial main air intake hole and a radial auxiliary air intake hole are formed in the air intake mixing section of the head portion of the J-type reverse-flow detonation tube, and the air intake mixing section is connected with the outer combustor case through an ignition base. The bent air exhaust section on the tail of the J-type reverse-flow detonation tube is fixed in a mounting hole in the inner combustor case and connected with the fuel gas shaping chamber. The vortex guide unit is installed behind the fuel gas shaping chamber. The axial distance of the detonation combustor can be decreased through the bent air exhaust section, the influence of detonation feedback is reduced through the volume between an inner sleeve and an outer sleeve of the combustor, air is preheated through the bent exhaust section so that combustible materials are mixed more sufficiently, and detonation combustion is made to be organized more easily.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Tail edge cooling structure of turbine rotor blade and engine with tail edge cooling structure

InactiveCN106593544AReduce wall temperatureLarge coverage areaBlade accessoriesMachines/enginesCold airTurbine blade

The invention discloses a tail edge cooling structure of a turbine rotor blade and an engine with the tail edge cooling structure, and relates to the technical field of engines. According to the tail edge cooling structure of the turbine rotor blade, the tail edge of the blade is provided with a plurality of mutually independent expansion type cooling split gaps in the height direction of the blade; and the opening widths of the expansion type cooling split gaps in the height direction of the blade are gradually expanded along a direction from an inner cavity of the blade to the outer surface of the blade. The rotor blade on the engine comprises the tail edge cooling structure of the turbine rotor blade. The tail edge cooling structure has the advantages that as the multiple mutually independent expansion type cooling split gaps are formed in the tail edge of the blade in the height direction of the blade, on one hand, the expansion type split gaps enlarge the covering area of cold air, and on the other hand, gradual expansion replaces sudden expansion, thus reducing the intensity of a vortex at a cold air outlet and attenuating the degree of cold air separation due to extrusion of the vortex; and therefore, coverage of the cold air can be enhanced, the cooling effect is improved, and the wall surface temperature of the tail edge of the blade is reduced.

Owner:AECC SHENYANG ENGINE RES INST

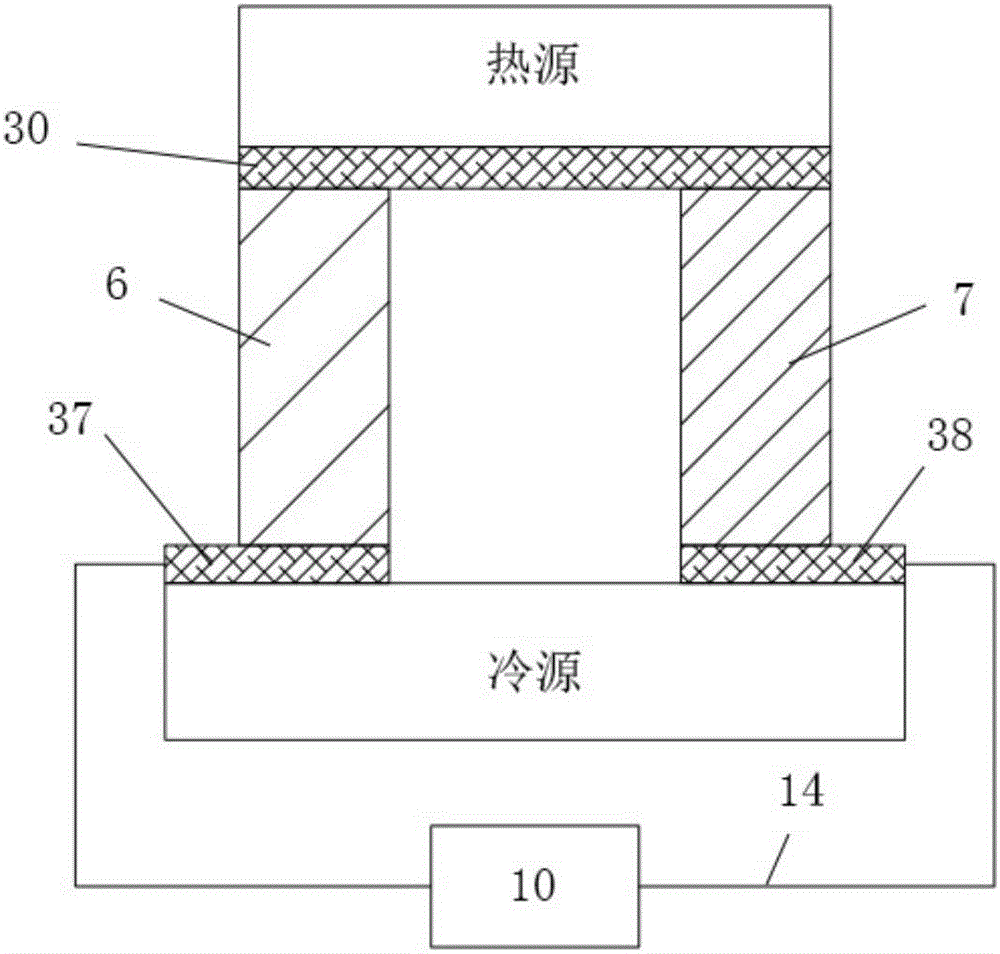

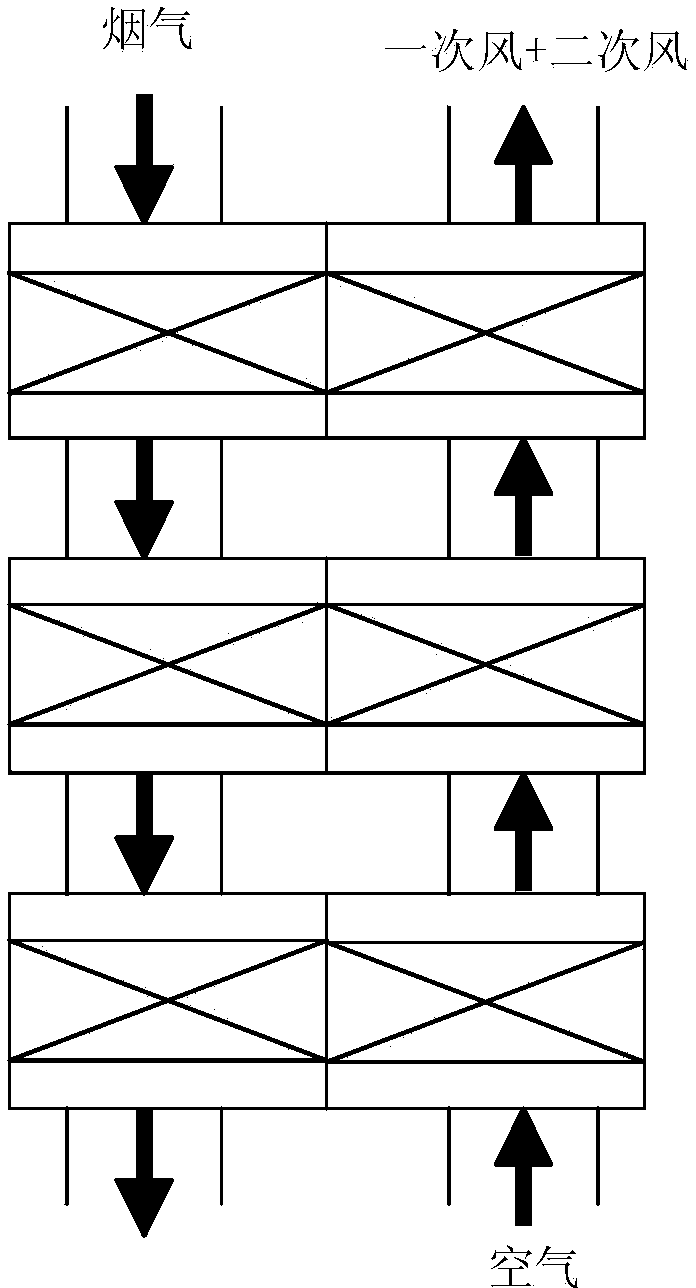

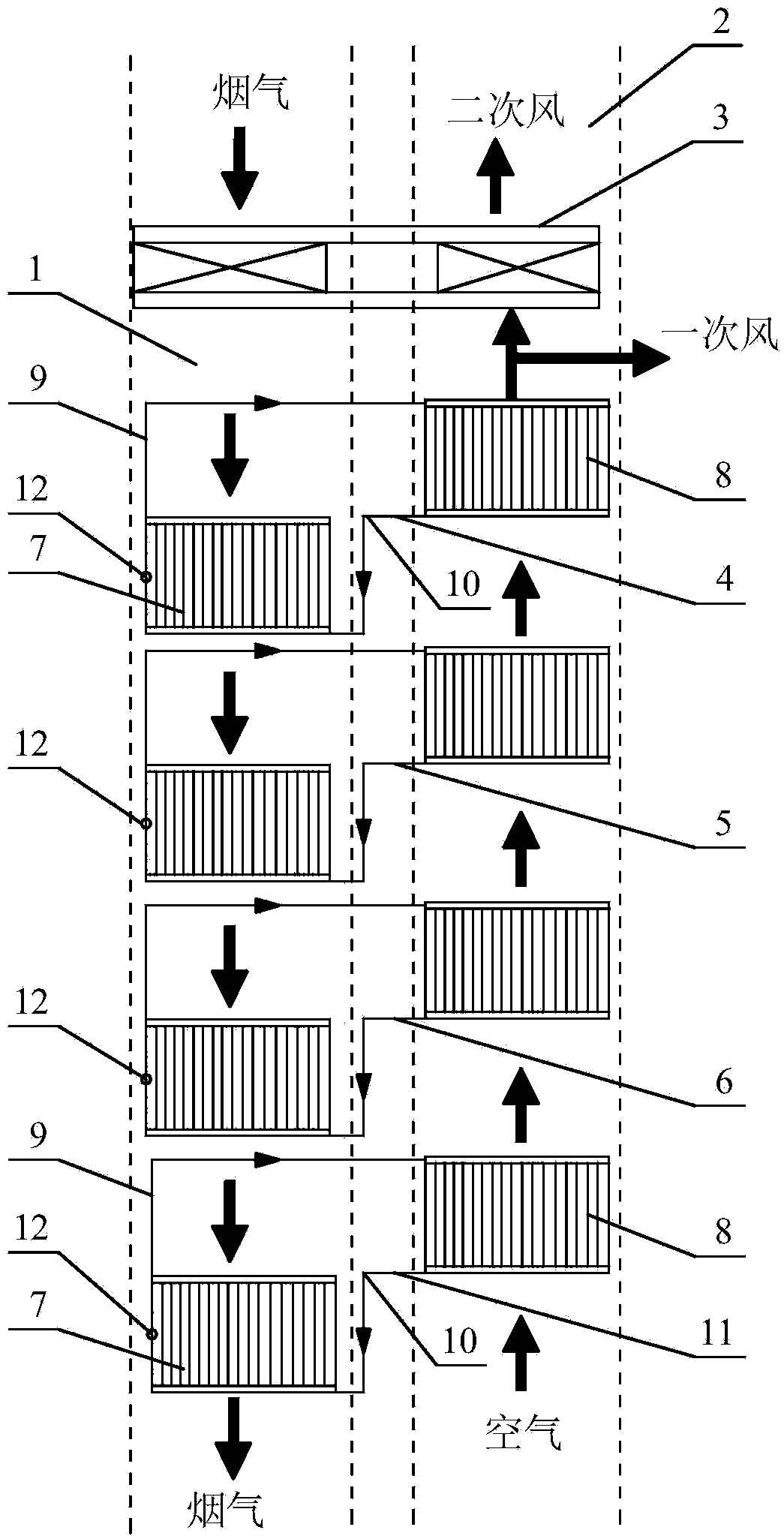

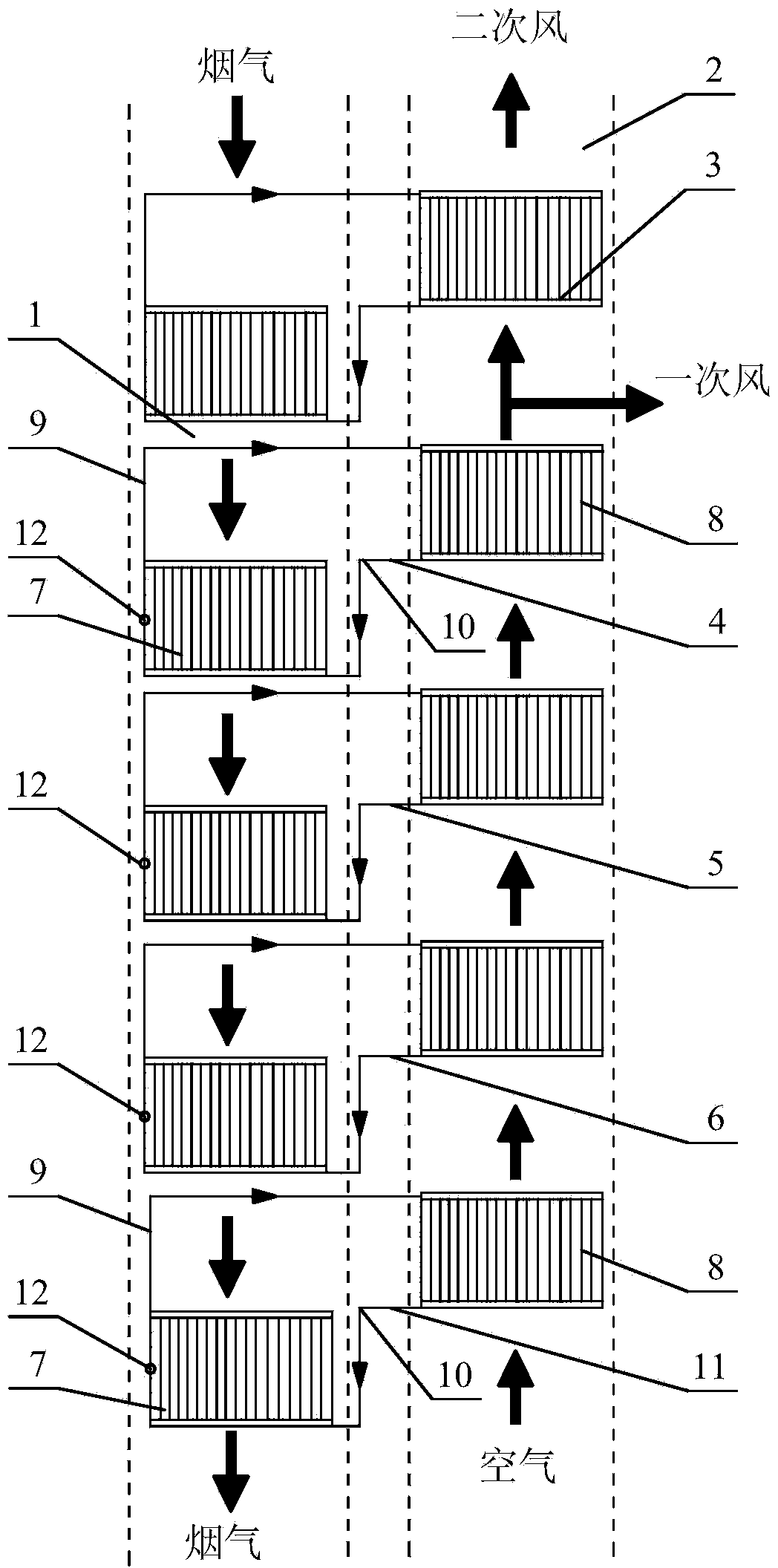

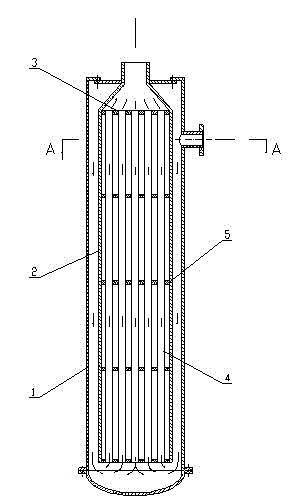

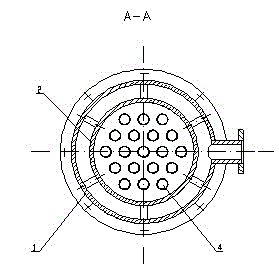

Combined air preheater suitable for SCR (Selective Catalytic Reduction) post-denitration, and anti-corrosion and anti-blocking method

InactiveCN103982906AEliminate the phenomenon of heating surfaceAvoid corrosionEmission preventionCorrosion preventionFreezing Point TemperatureAir preheater

The invention provides a combined air preheater suitable for SCR (Selective Catalytic Reduction) post-denitration, which comprises a flue and an air duct which are arranged downstream a denitration device, and also comprises a secondary air section, a primary air section, an ammonium bisulfate condensation resistant section and an ammonium bisulfate curing section which are sequentially arranged along the flue gas flowing direction, wherein the primary air section, the ammonium bisulfate condensation resistant section and the ammonium bisulfate curing section are phase change heat exchangers, and the phase change heat exchanger comprises a heat absorbing section positioned in the flue, a heat releasing section positioned in the air duct, and a riser and a downcomer which are used for connecting the heat absorbing section and the heat releasing section; the heat releasing section is higher than the heat absorbing section, and a circulating medium is arranged in the phase change heat exchanger; the wall surface temperature of the ammonium bisulfate condensation resistant section is higher than the dew-point temperature of ammonium bisulfate, and the wall surface temperature of the ammonium bisulfate curing section is lower than the freezing point temperature of ammonium bisulfate. The combined air preheater puts an end to the phenomenon that liquid ammonium bisulfate blocks the heating surface of the air preheater due to dust, and also effectively prevents the liquid ammonium bisulfate from corroding the air preheater.

Owner:HOTANT THERMAL TECH JIANGSU

Spiral electric heating device for high-temperature high-pressure gas

ActiveCN104132455AImprove structural strengthImprove heat transfer effectAir heatersSilver plateLow emissivity

The invention discloses a spiral electric heating device for high-temperature high-pressure gas, and relates to an electric heating gas device. A heating core is arranged in an inner barrel, and in other words, a resistance electric heater electric heating tube is arranged in the inner barrel. A heat-proof heat insulation material is laid on the outer wall of the inner barrel, and a protective layer is laid on the exterior of the heat insulation material. A spiral guide plate is welded to the inner wall of an outer barrel, a ceramic screw rod is installed in the resistance electric heater electric heating tube, a spiral guide plate is welded to the inner wall of the outer barrel, the spiral guide plate is provided with one head or two heads or multiple heads, the ceramic screw rod is provided with one head or two heads or multiple heads, a metal core bar is arranged in the center of the ceramic screw rod, and the ceramic screw rod is formed by being sleeved with one or more ceramic parts in series. The protective layer outside the heat insulation material is made of a low-emissivity material such as a thin copper plate and a galvanized sheet or made of chromium plated with a layer of low-emissivity material or silver plated with a layer of low-emissivity material or made of other metal materials with low emissivity or nonmetal materials with low emissivity. According to the spiral electric heating device, energy is saved, and the spiral electric heating device is durable, and especially suitable for occasions with heated gas high in pressure and large in temperature rise.

Owner:CYBROG SHENYANG ENERGY & INTELLIGENCE EQUIPCO

Movable mixed-burning steam generating device

ActiveCN103900070AImprove combustion efficiencyImprove cooling effectSteam generation plantsSteam boilersCombustion chamberMonitoring system

The invention discloses a movable mixed-burning steam generating device which comprises a cylindrical barrel, a cover plate, a flame barrel combustion chamber, a water film cooling system, a gas atomization device and a monitoring system. The cylindrical barrel serves as a shell of the device, the cover plate is arranged at the air inlet end of the barrel, and the flame barrel combustion chamber, the water film cooling system, the gas atomization device and the monitoring system for high-temperature multi-purpose gas operation are respectively sequentially coaxially arranged on inner front portion of the barrel, the inner middle of the barrel, the inner rear portion of the barrel and on the barrel along the flow direction of gas. A fuel connecting pipe and high-pressure air connecting pipes are arranged on the cover plate. The flame barrel combustion chamber is arranged in the barrel in a dangling manner, an inner swirler and an outer swirler are arranged inside an inlet section of the head of a flame barrel, the inner swirler is disposed in the outer swirler, a premixing chamber used for premixing of fuel and air is arranged in the rear of the inner swirler, and the premixing chamber is of a structure which is restrained first and then expanded; a nozzle connected with the fuel connecting pipe is disposed in the inner swirler. The movable mixed-burning steam generating device has the advantages of high reliability, long service life, energy efficiency, reasonable and movable structure and the like.

Owner:CHENGDU ENGINE GROUP

Oil supply and cooling integrated air suction type pulse detonation engine structure

InactiveCN111256168AExpand the scope of workImprove job stabilityContinuous combustion chamberIntermittent jet plantsCombustion chamberCooling effect

The invention provides an oil supply and cooling integrated air suction type pulse detonation engine structure. The oil supply and cooling integrated air suction type pulse detonation engine structureis characterized in that a fuel oil channel is formed in the wall face of the DDT section of the front middle section of a combustion chamber, high temperature of the DDT section of the pulse detonation combustion chamber is fully utilized, fuel oil is preheated and pre-evaporated to a certain extent, and subsequent atomization and combustion process are facilitated; the fuel oil absorbs heat, sothat the wall surface temperature of the front middle section, namely the DDT section, of the combustion chamber is greatly reduced, and compared with traditional air cooling, cooling effects are remarkably improved due to the fact that fuel oil specific heat is far larger than that of air; cooling inlet air, cooling liquid and external auxiliary equipment are omitted, so that sufficient air participates in combustion in the combustion chamber, a working range of an engine is widened, and the thrust-weight ratio is increased; a large number of oil spraying holes are formed in the wall face ofthe front middle section of the engine and the wall face of an engine inlet, a large-area and full-space oil supply mode enables oil and gas in the engine combustion chamber to be evenly distributedand combusted sufficiently, and accordingly the working stability of the pulse detonation engine can be improved; and fuel oil sprayed out of the oil spraying holes in the wall face of the front middle section and incoming flow form a certain angle, and the DDT distance is shortened to a certain extent through disturbance effects, and therefore the axial length of the engine is reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Double cam axial engine with over-expansion, variable compression, constant volume combustion, rotary valves and water injection for regenerative cooling

InactiveUS9194287B1Decrease compression and compression workIncrease the compression ratioInternal combustion piston enginesEngine operationsDetonationEngineering

An axial engine includes a cam assembly housing moveable away from a cylinder head to reduce a compression ratio during conditions giving rise to detonation and movable towards the cylinder head to raise the compression ratio when operation allows the higher compression ratio. Piston rod ends ride in counter rotating slots balancing lateral forces on the piston rods. Piston dwell at Top Dead Center (TDC) provides for constant volume combustion and extended piston travel during the power stroke allows for over-expansion. Rotary valves improve volumetric efficiency and water injection supports increased compression ratio leading to improved thermodynamic efficiency.

Owner:MNC ENG

Combined cooling type rectification support plate flame stabilizer

PendingCN107191968AAvoid ablationGuaranteed to workContinuous combustion chamberShock coolingEngineering

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com