Patents

Literature

100results about How to "Reduce heat transfer loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

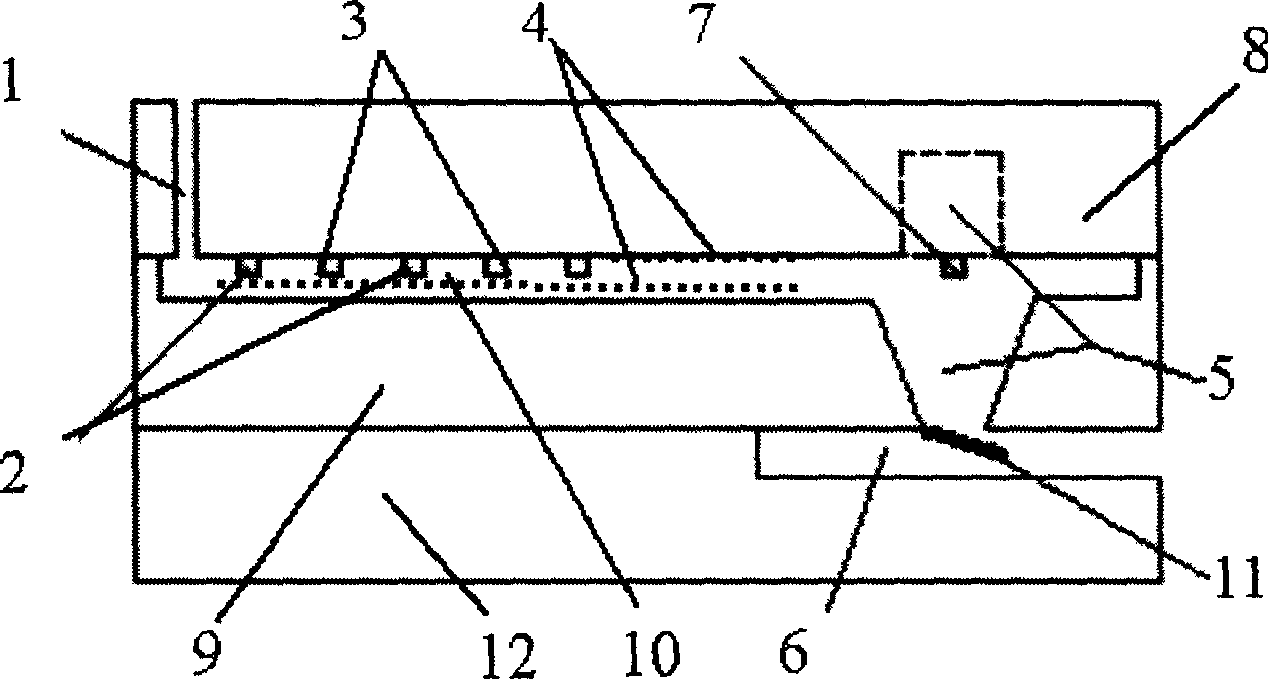

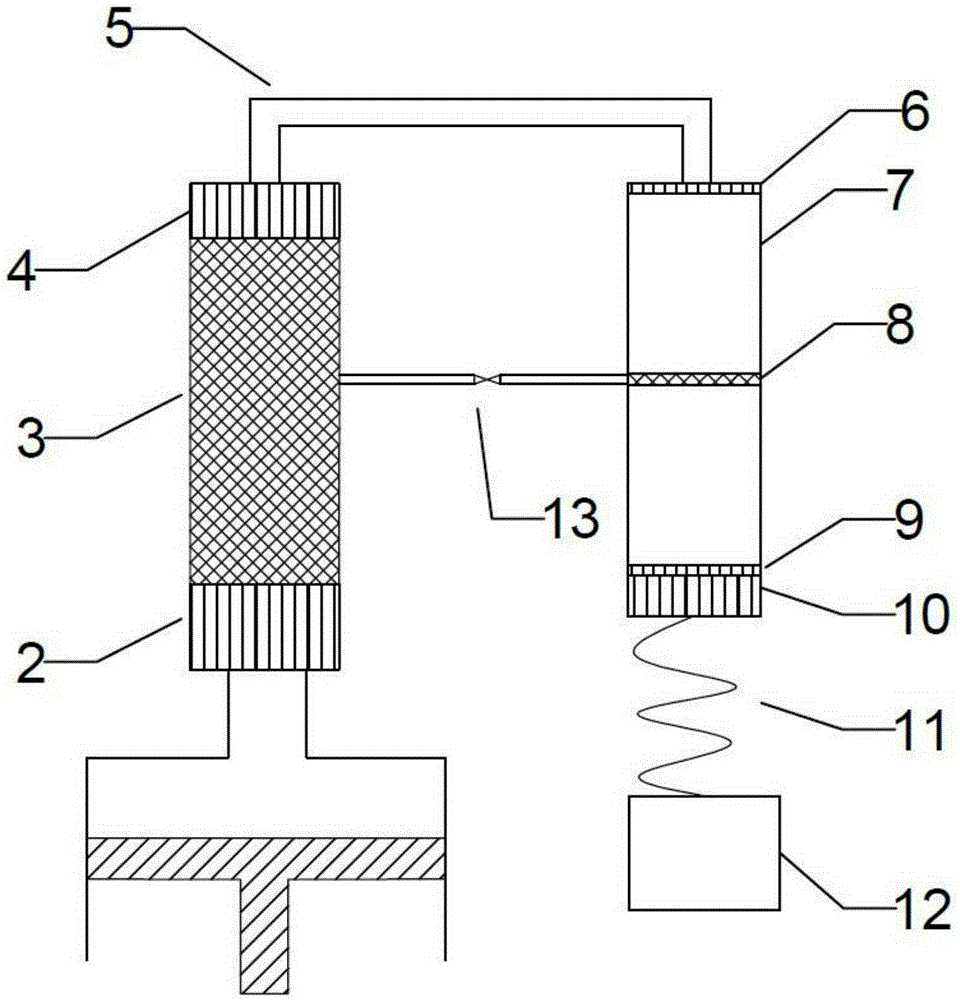

Mini reforming hydrogen-preparation reactor

InactiveCN101054160ARapid reforming hydrogen production reactionEven air distributionHydrogenHydrogenFuel cells

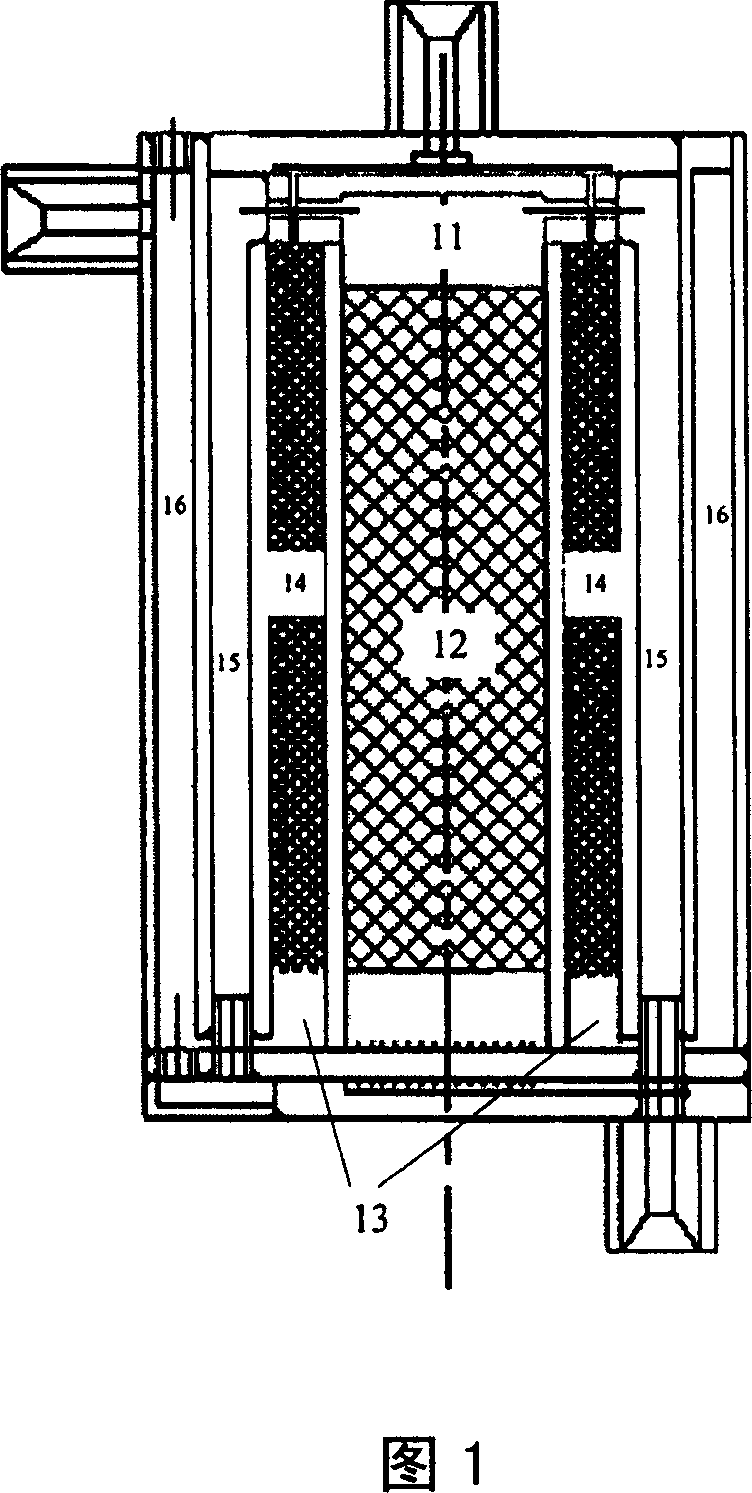

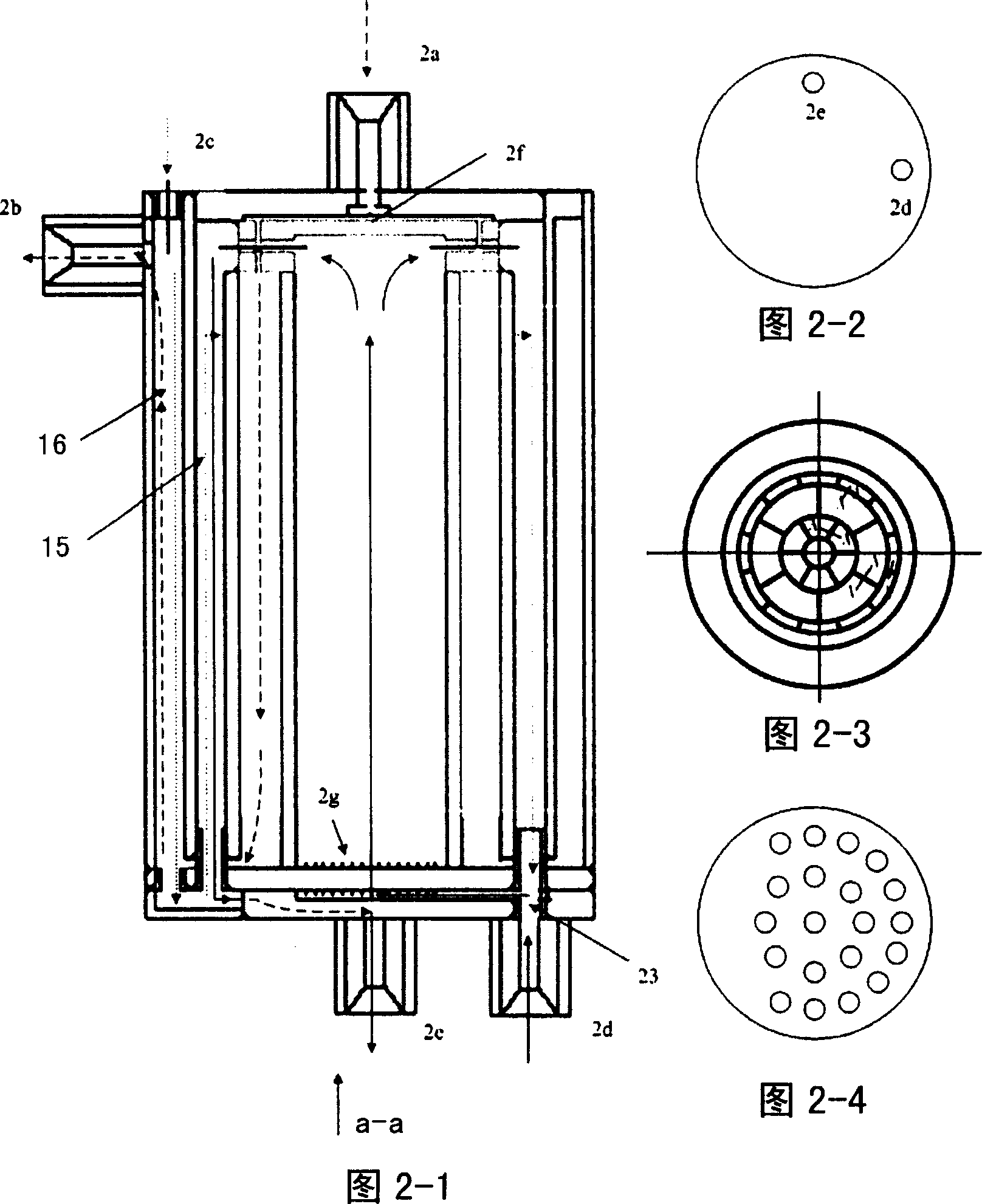

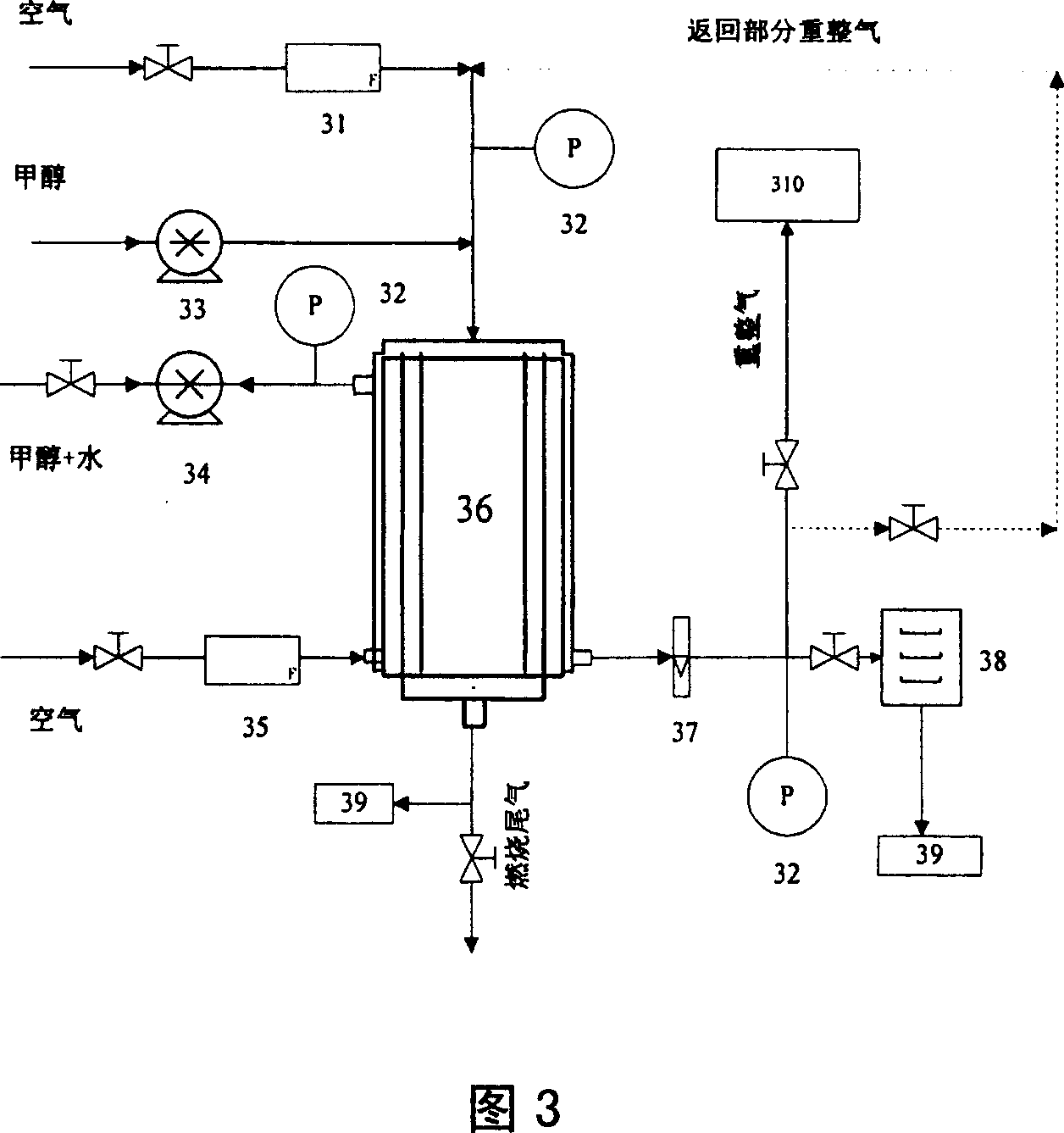

A minitype reactor for reforming hydrogen, which main part has telescopefeed structure, comprising a burning offgas heat exchange cavity, a reforming offgas heat exchange cavity, a burning cavity and a reforming cavity in sequence from outside; a fuel inlet is arranged communicating with the burning cavity; a reforming material inlet is arranged communicating with a built-in cavity of the burning offgas heat exchange cavity; reforming material liquid is preheated in the built-in cavity of the burning offgas heat exchange cavity then supplied into a built-in cavity of the reforming offgas heat exchange cavity; reforming material liquid flows in built-in cavities, burning offgas and reforming offgas exchange heat via tube wall of built-in cavities and flow oppose to reforming material liquid; a reforming air inlet is arranged, mixture gas of reforming air mixing with gas phase vaporized in the reforming offgas heat exchange cavity is supplied into the reforming cavity to process reforming hydrogen reaction. The catalytic burning reaction and reforming reaction of the invention has advantages of temperature easy to be control, stable running, easy operation; compact structure; the invention is suit for hydrogen source system of 10-500 W fuel cell minitype electrical source.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

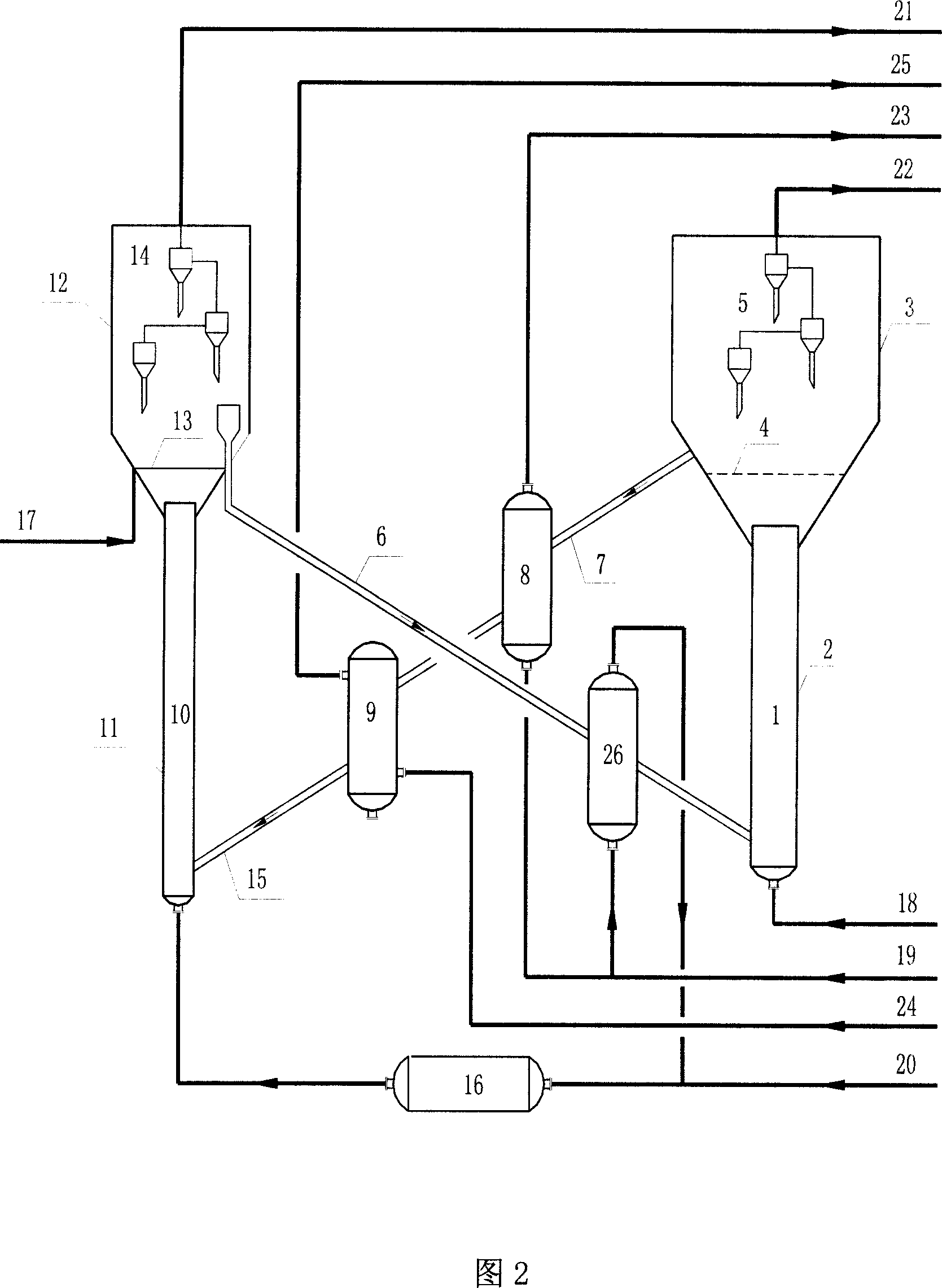

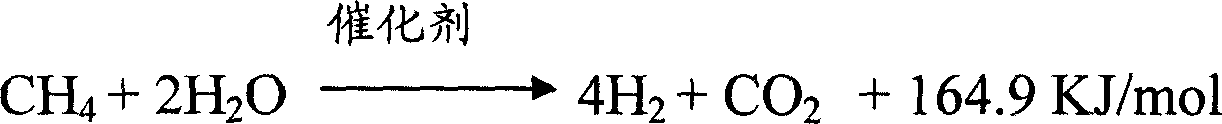

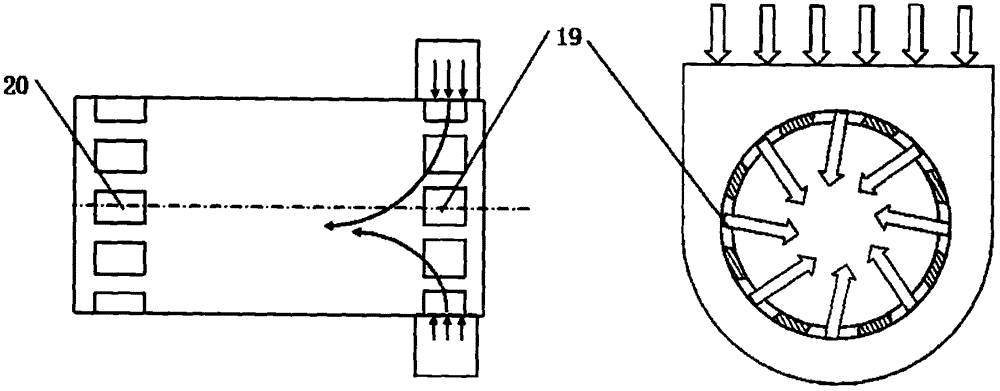

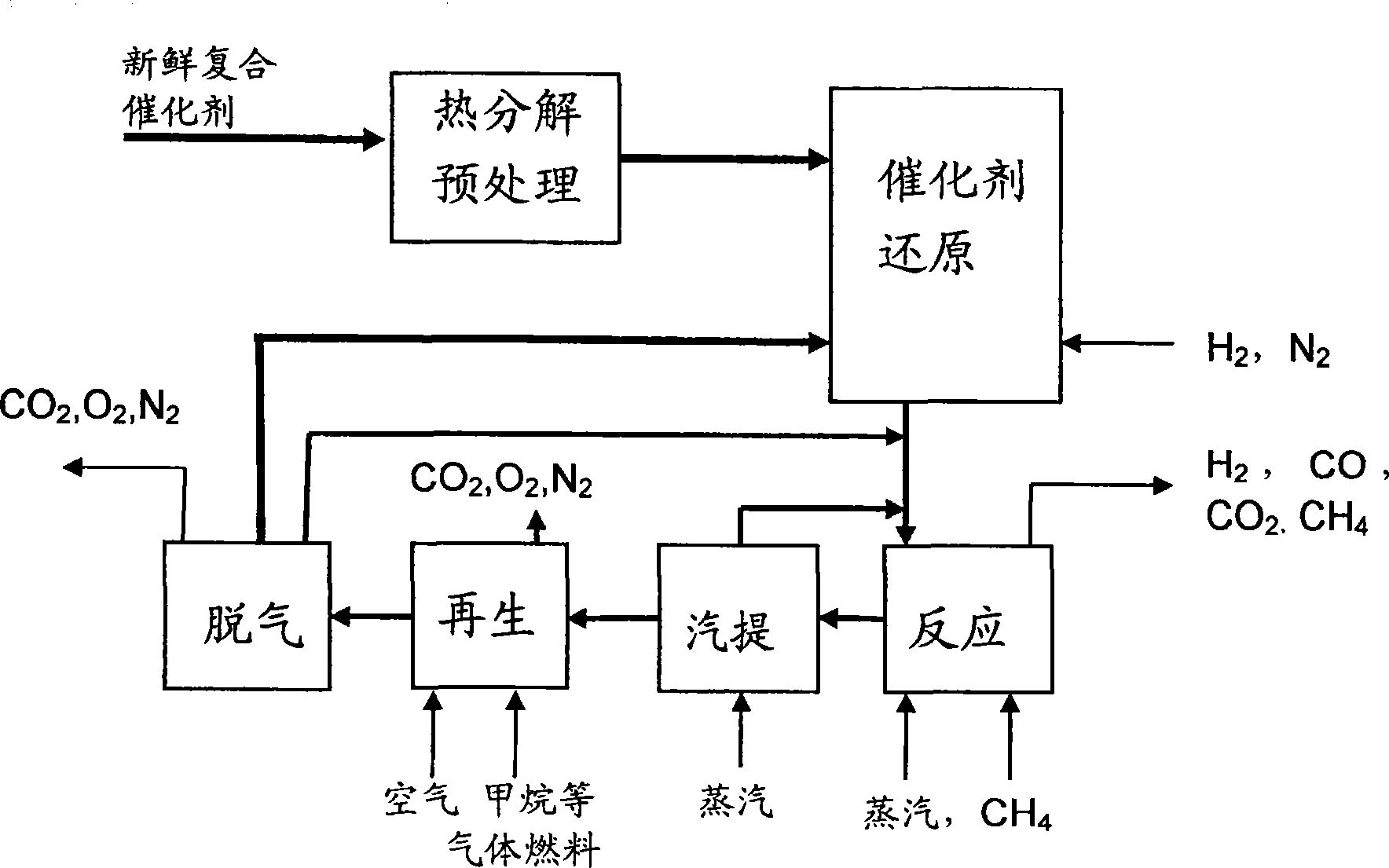

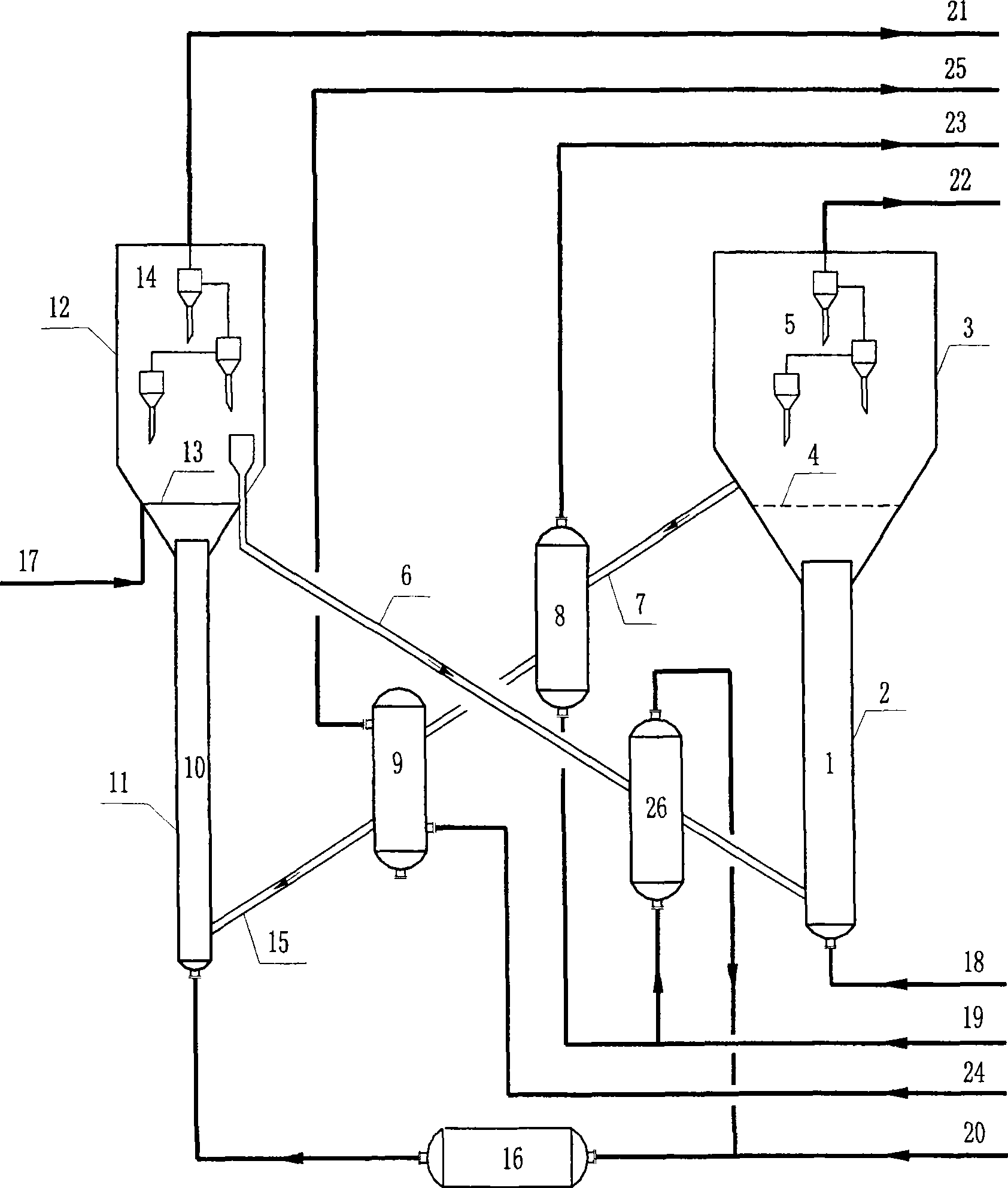

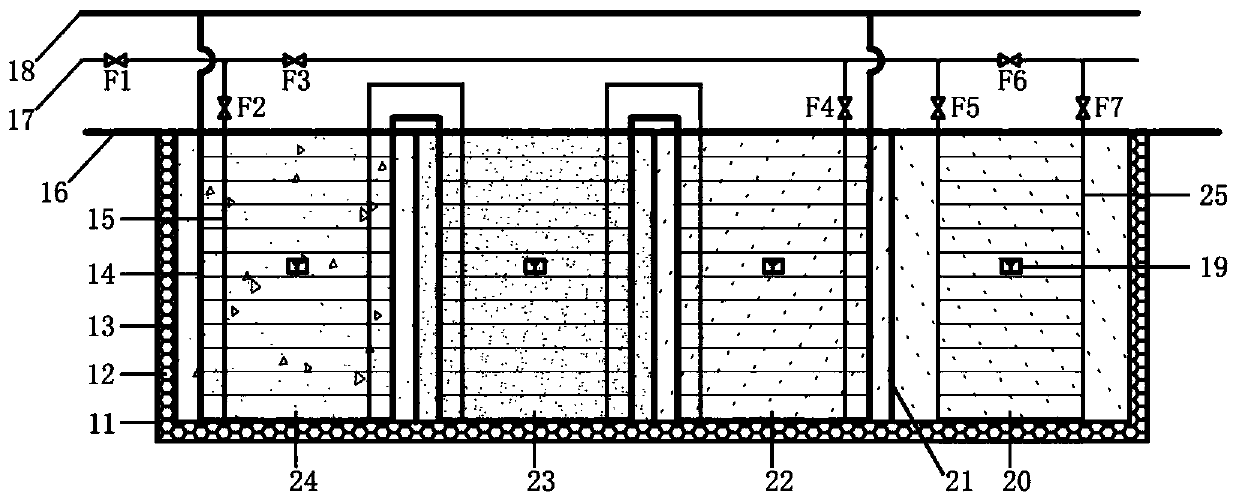

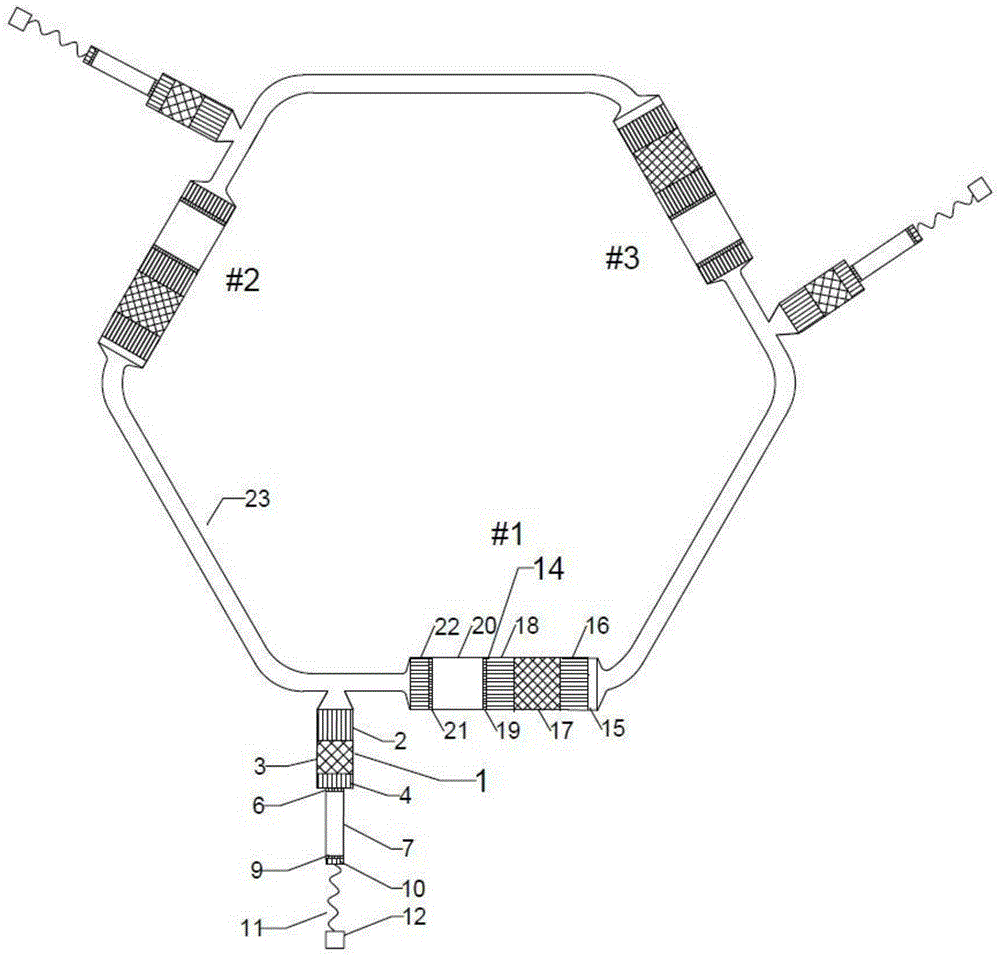

Adsorption forced methane steam reforming hydrogen manufacturing process and apparatus using circulating fluidized bed

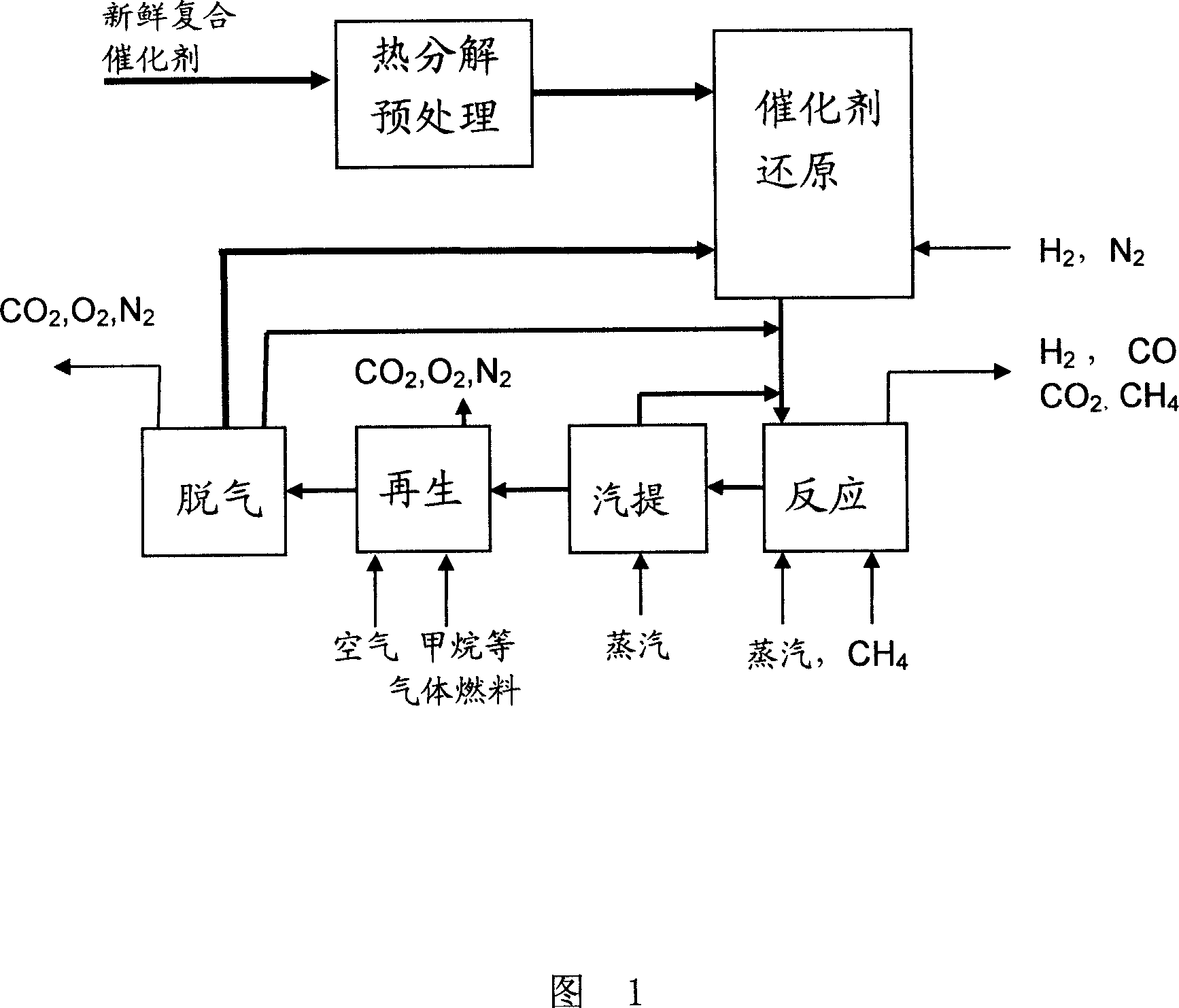

The invention discloses a hydrogen preparing process of strengthening methane steam reforming by cyclic fluidized bed adsorption, comprising: transporting 5-200 micron composite catalyst grains into a regenerator for pretreating; degasifying the pretreated composite catalyst and tranfering it to a fluidized bed reactor for reducing; charing methane and steam into the fluidized bed reactor in the water-carbon ratio of 2-10, and making the fluidized composite catalyst perform reforming hydrogen preparing reaction with methane and steam at the same time, and finally transferring the composite catalyst into regnerator to be regenerated and recycled, where the reacting time is 1s-5min, the reacting gas speed is 0.3-1.0m / s, and the ratio of composite catalyst to methane is 10 : 1-0.002 : 1 in g / ml. And it also discloses a device of implementing the above process. And the process can implement stable and continuous operation of fluidized bed reactor, and has advantages of high mass and heat transfer efficiencies.

Owner:CHINA PETROLEUM & CHEM CORP +1

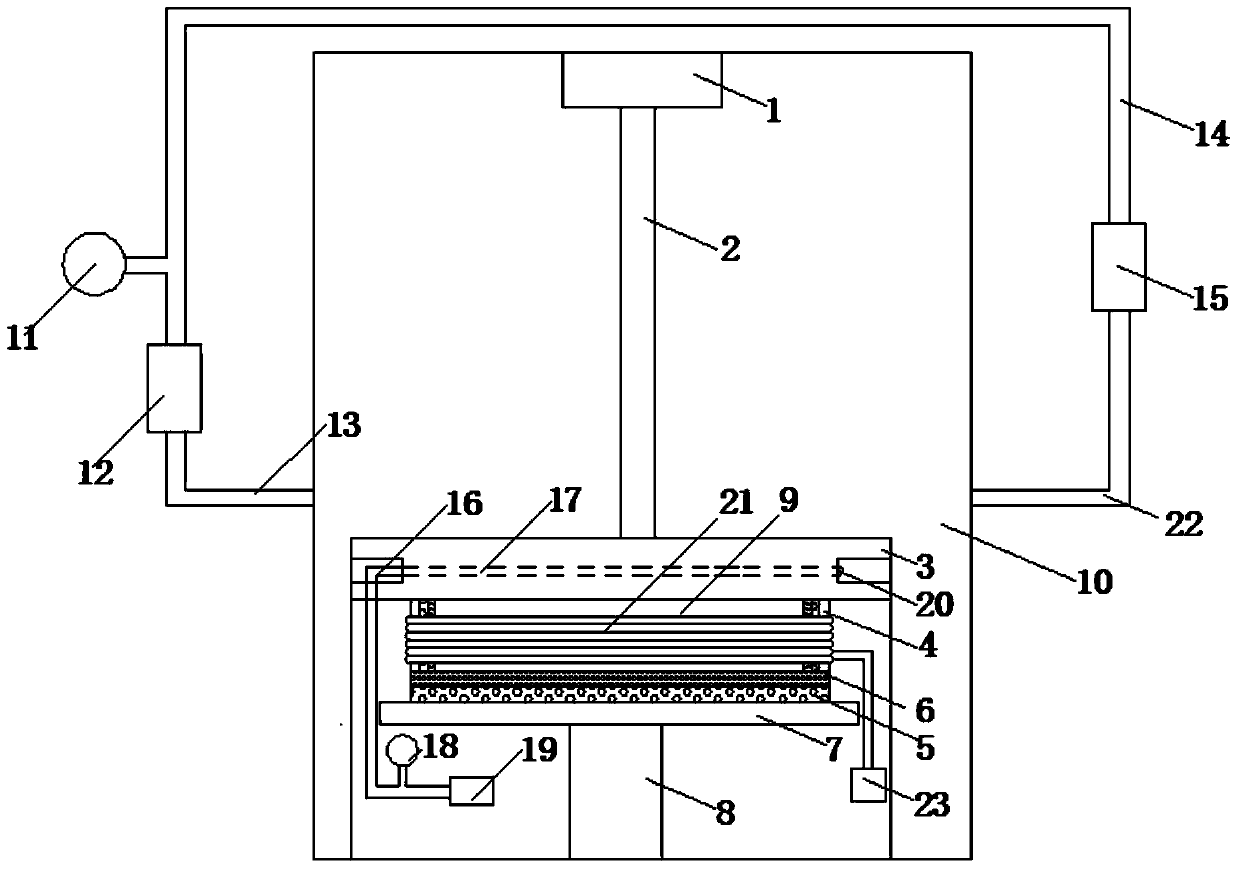

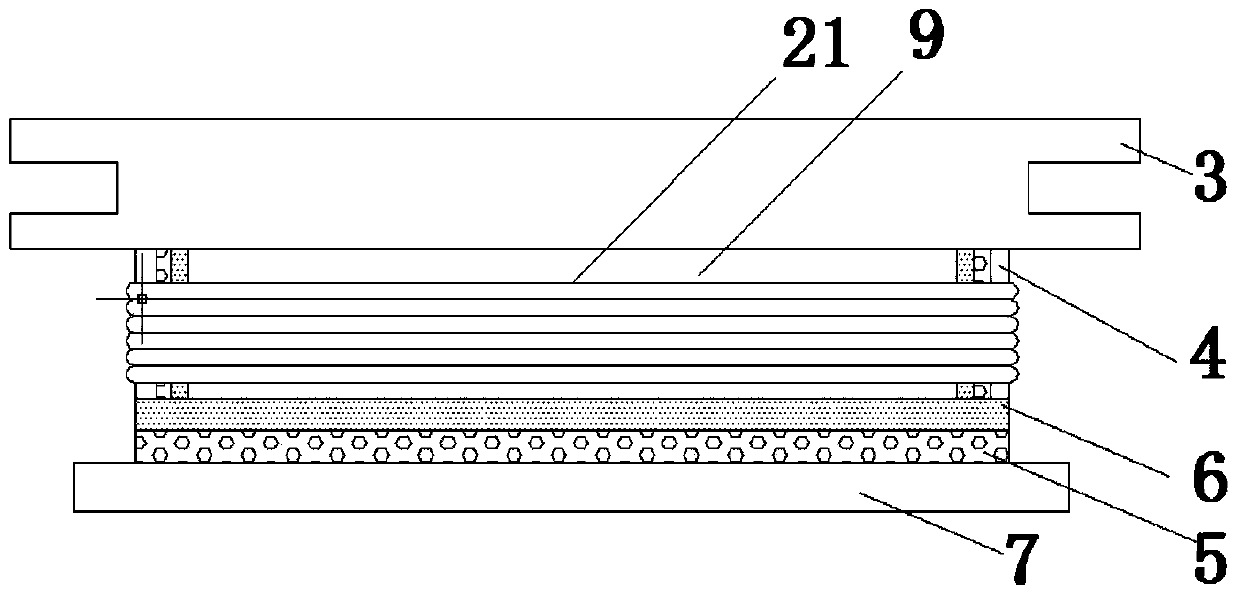

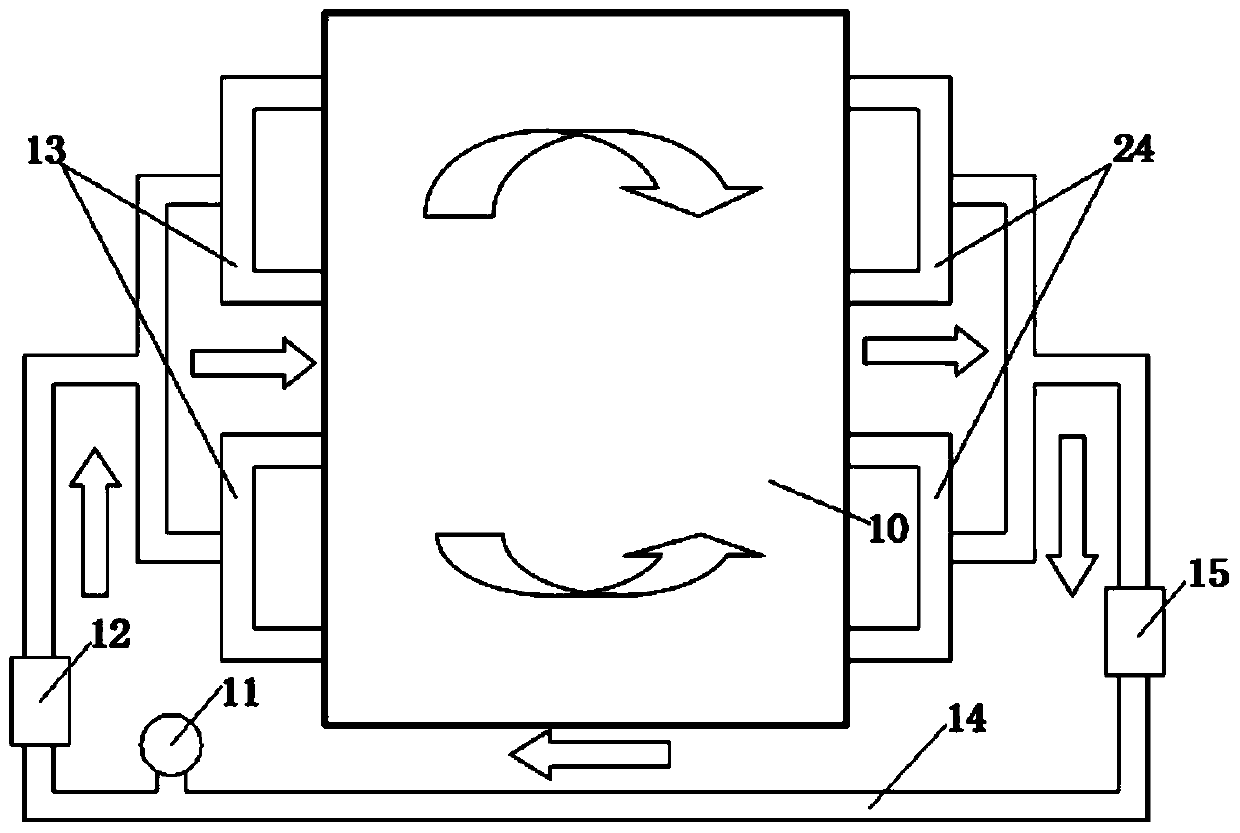

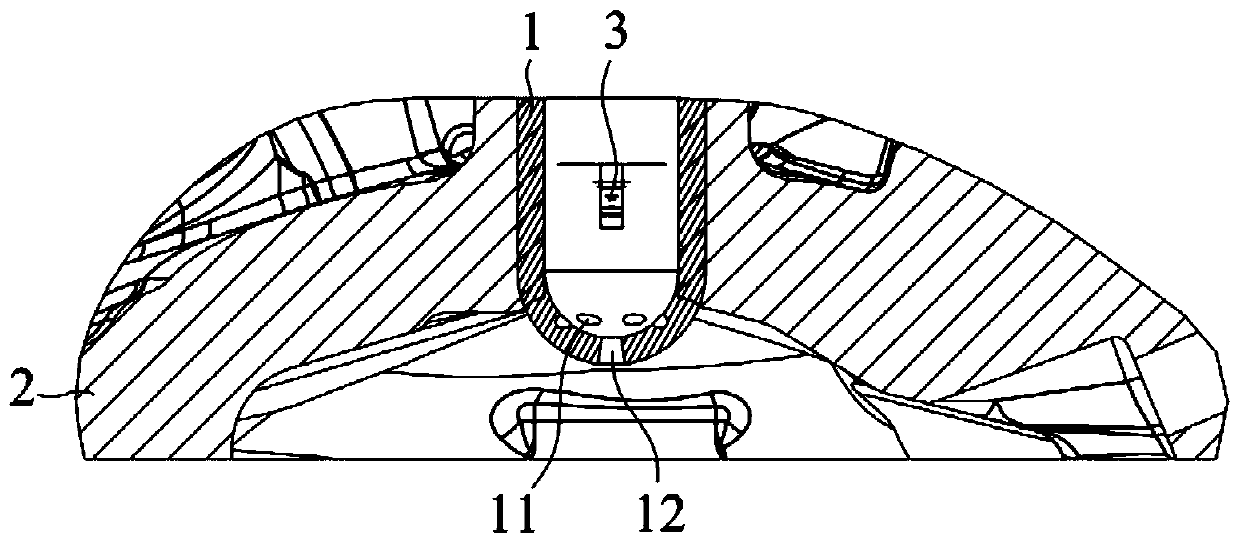

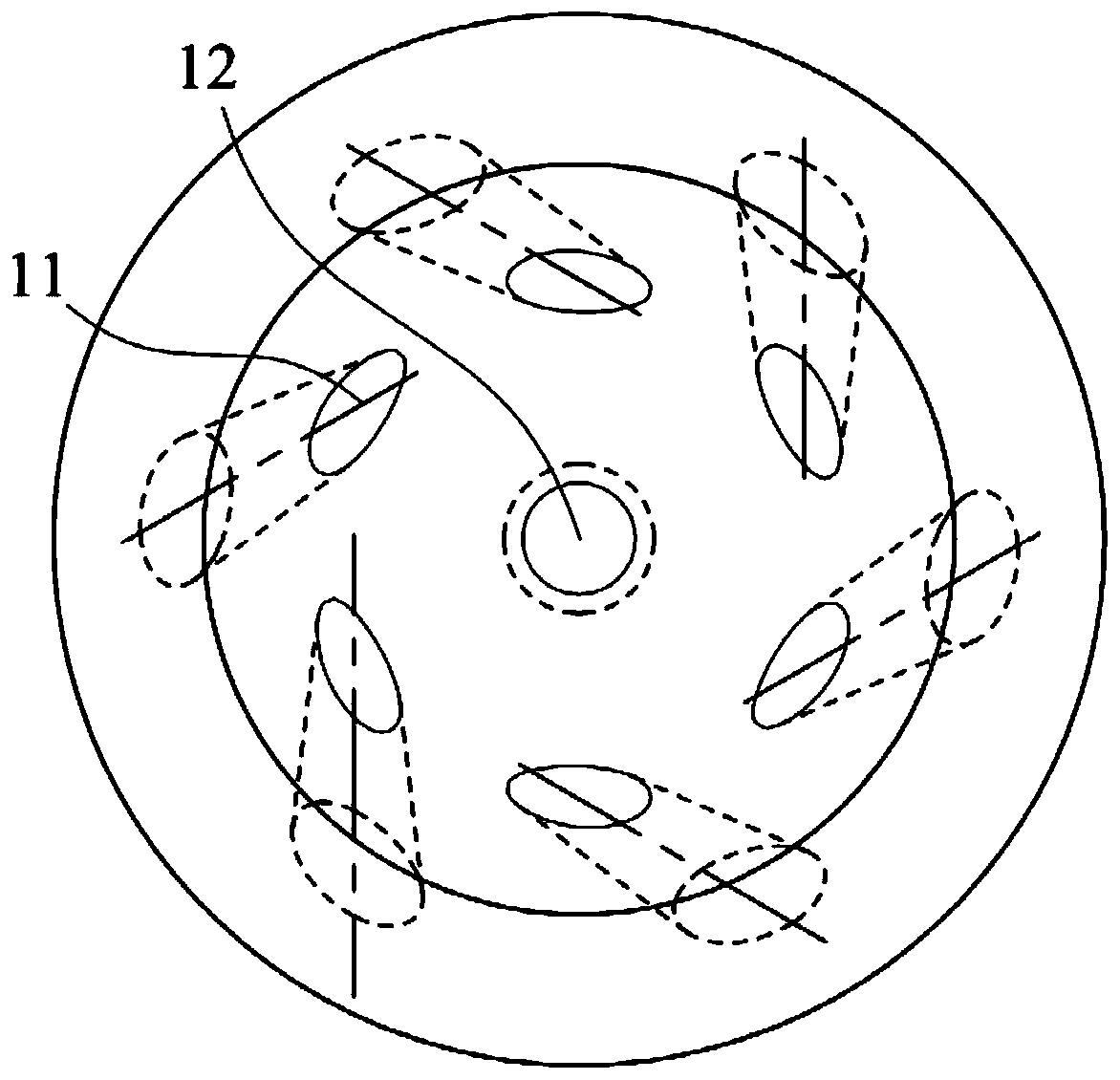

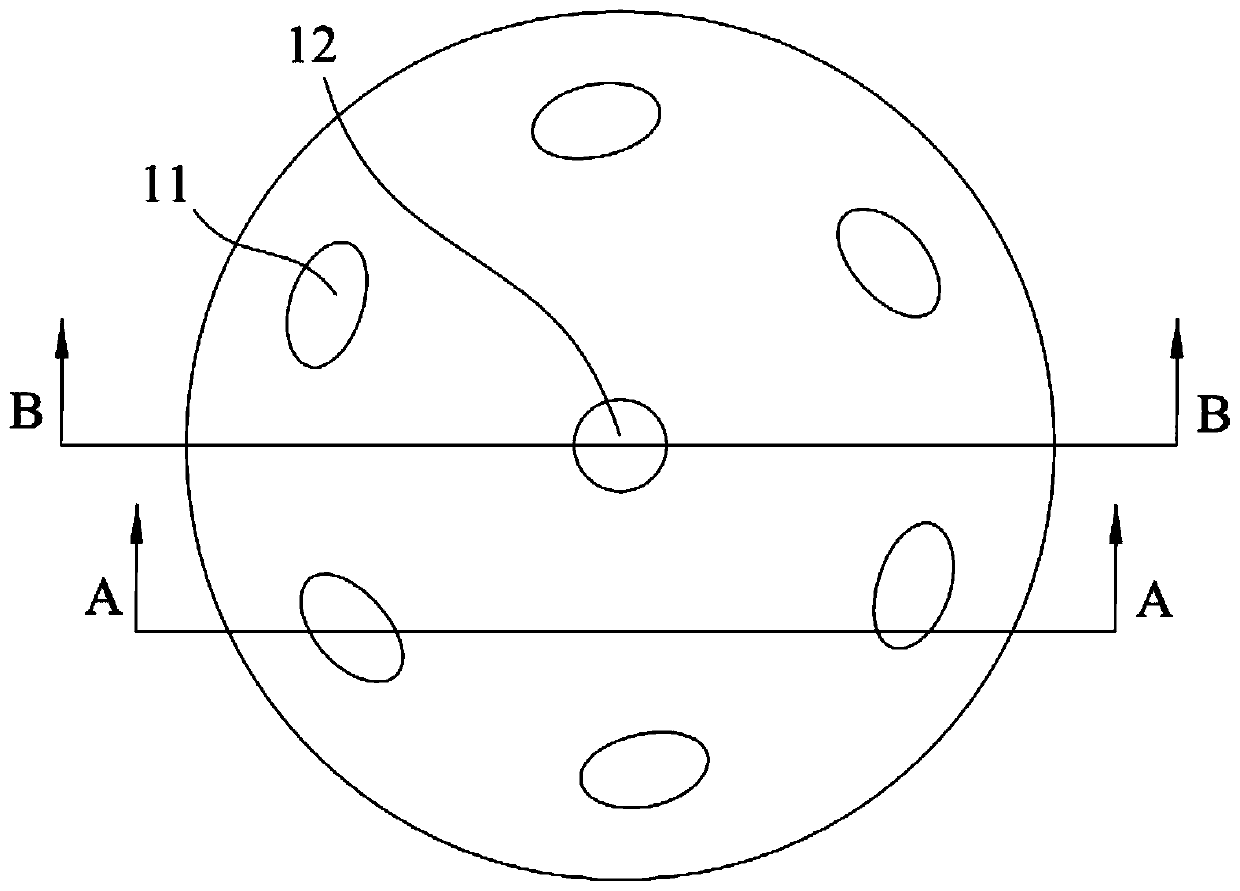

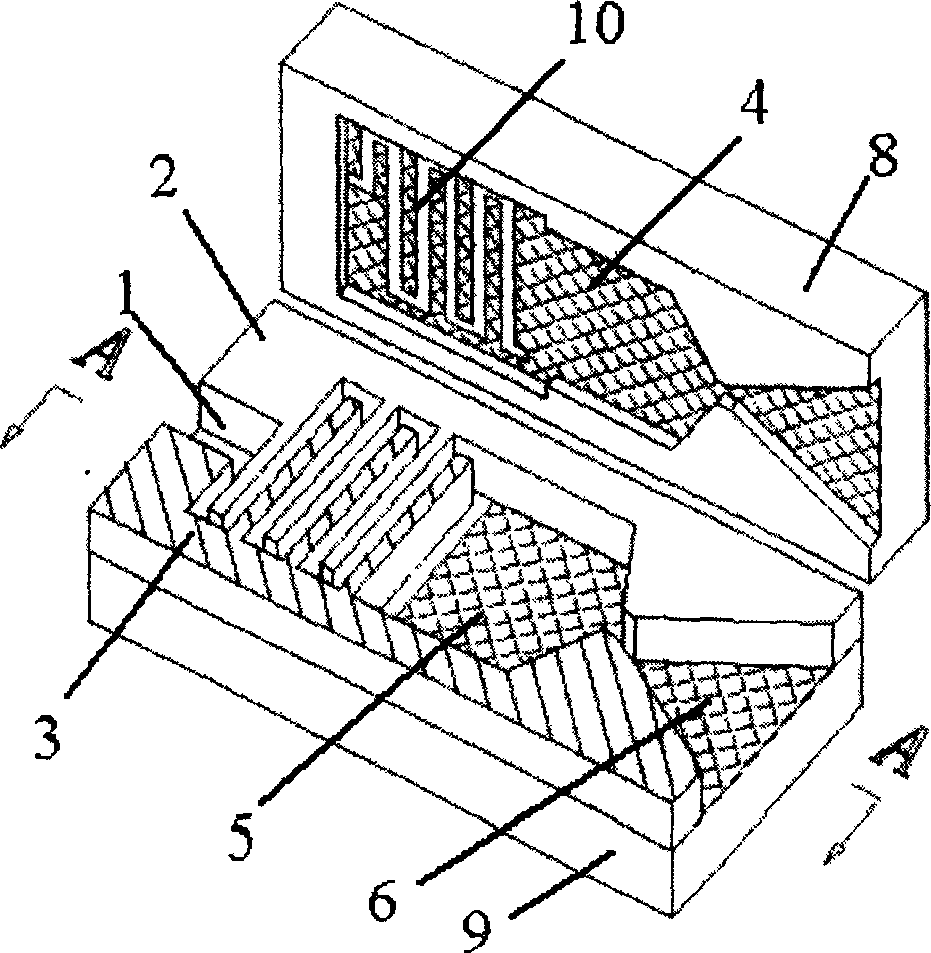

High-temperature powder bed system for laser additive manufacture

ActiveCN103990798AImprove energy utilizationShorten warm-up timeIncreasing energy efficiencyThermodynamicsInsulation layer

The invention discloses a high-temperature powder bed system for laser additive manufacture. The system comprises a working cavity, a laser device, a workbench, an electromagnetic heating layer, a heat insulation component and a laminar flow temperature uniforming component, the workbench is arranged in the working cavity, the electromagnetic heating layer is mainly composed of an electromagnetic induction plate and a coil, the electromagnetic heating layer is placed on the lower surface of the workbench and is attached to the workbench, and heat can be directly conducted to the workbench. A cooling flow way is arranged in the workbench, the bottom face and the side face of the electromagnetic heating layer are surrounded by the heat insulation component, and heat insulation and heat preservation of the electromagnetic heating layer can be achieved. The laminar flow temperature uniforming component is arranged outside the working cavity and used for achieving air flow circulation in the working cavity, and even temperature distribution of the workbench can be achieved. According to the part size, the work table board can be heated to be at the high temperature, heat preservation is performed, and temperature uniformization and the cooling functions after machining can be achieved. The aims of protecting the systems, and improving energy utilization rate and heating efficiency can be achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

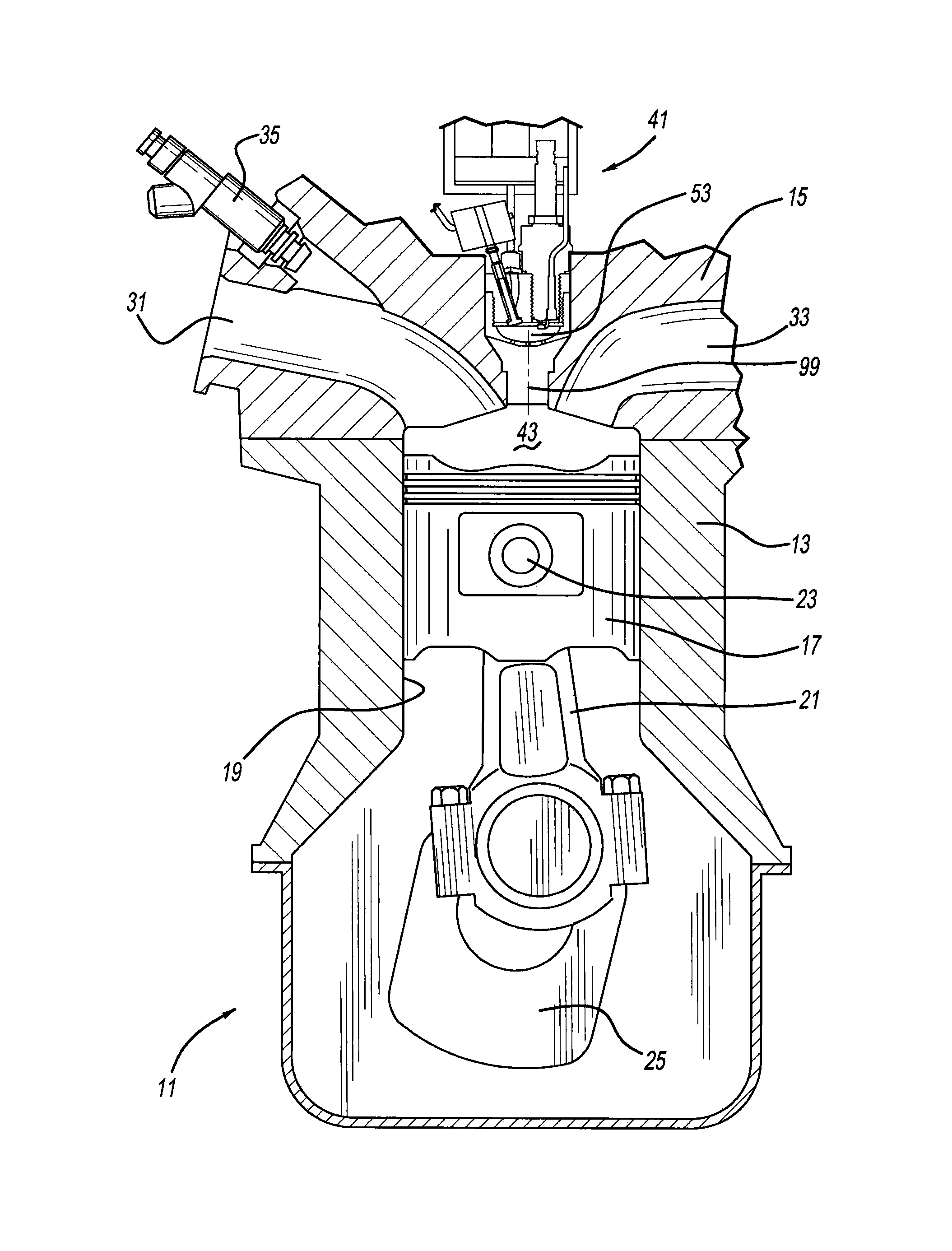

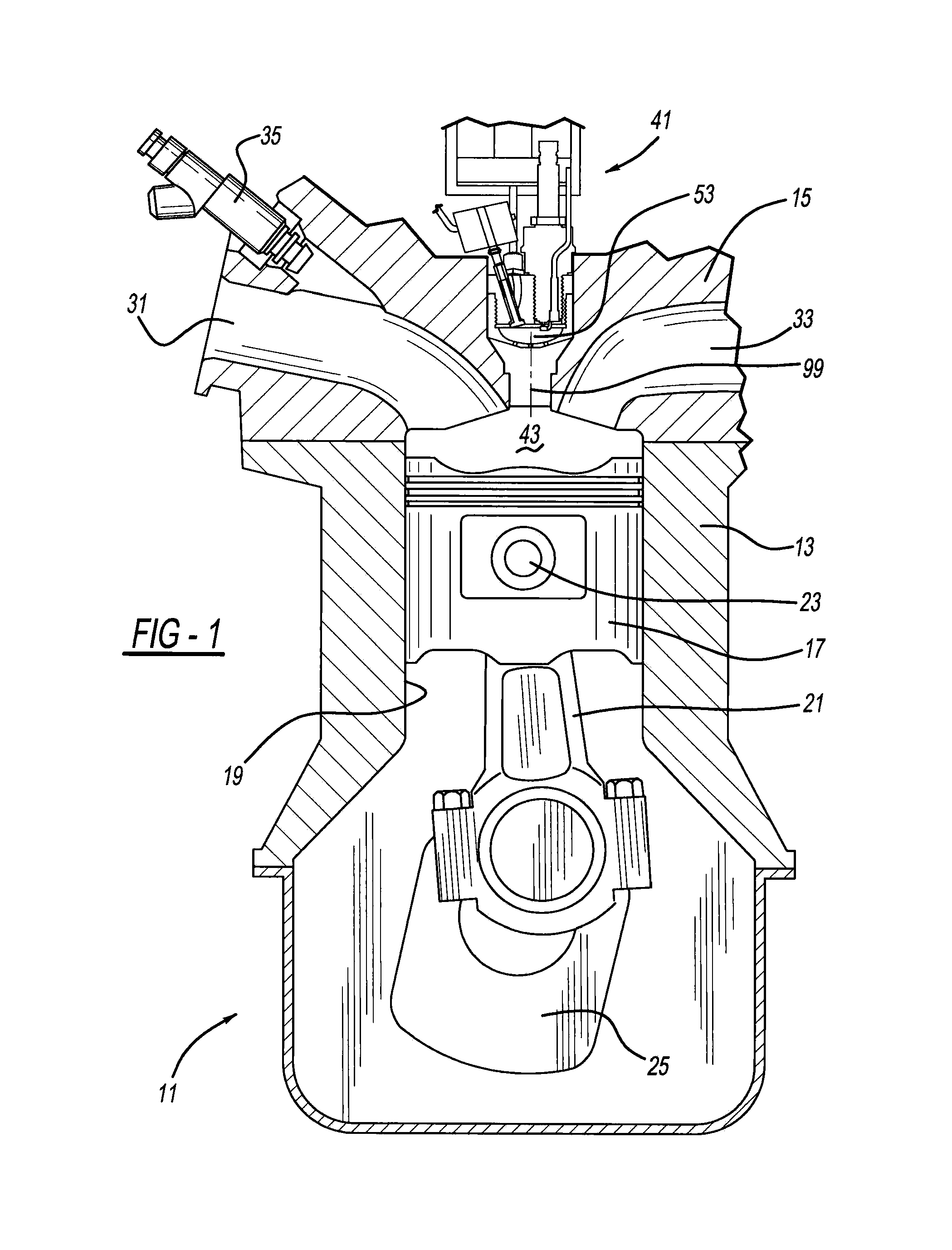

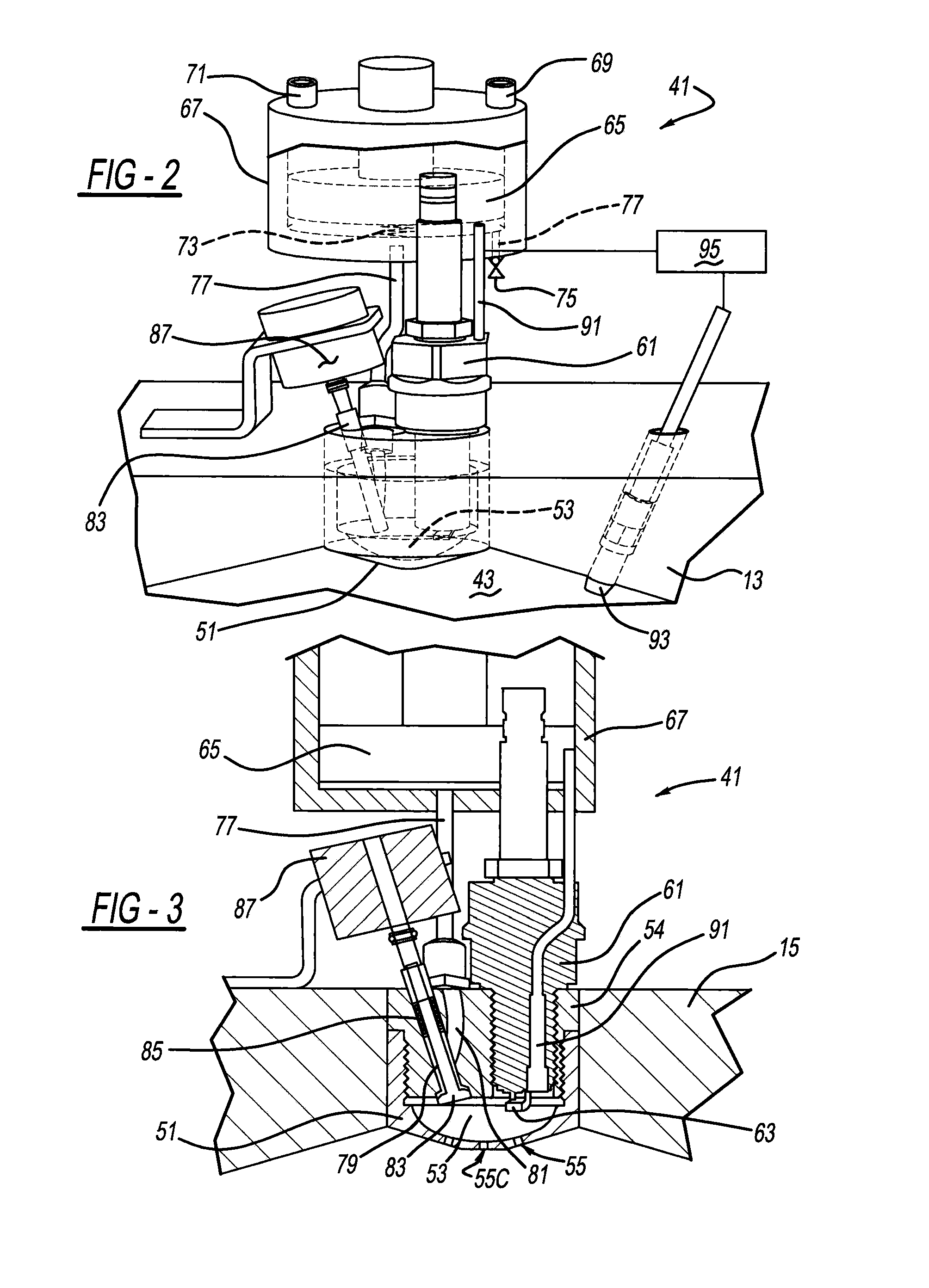

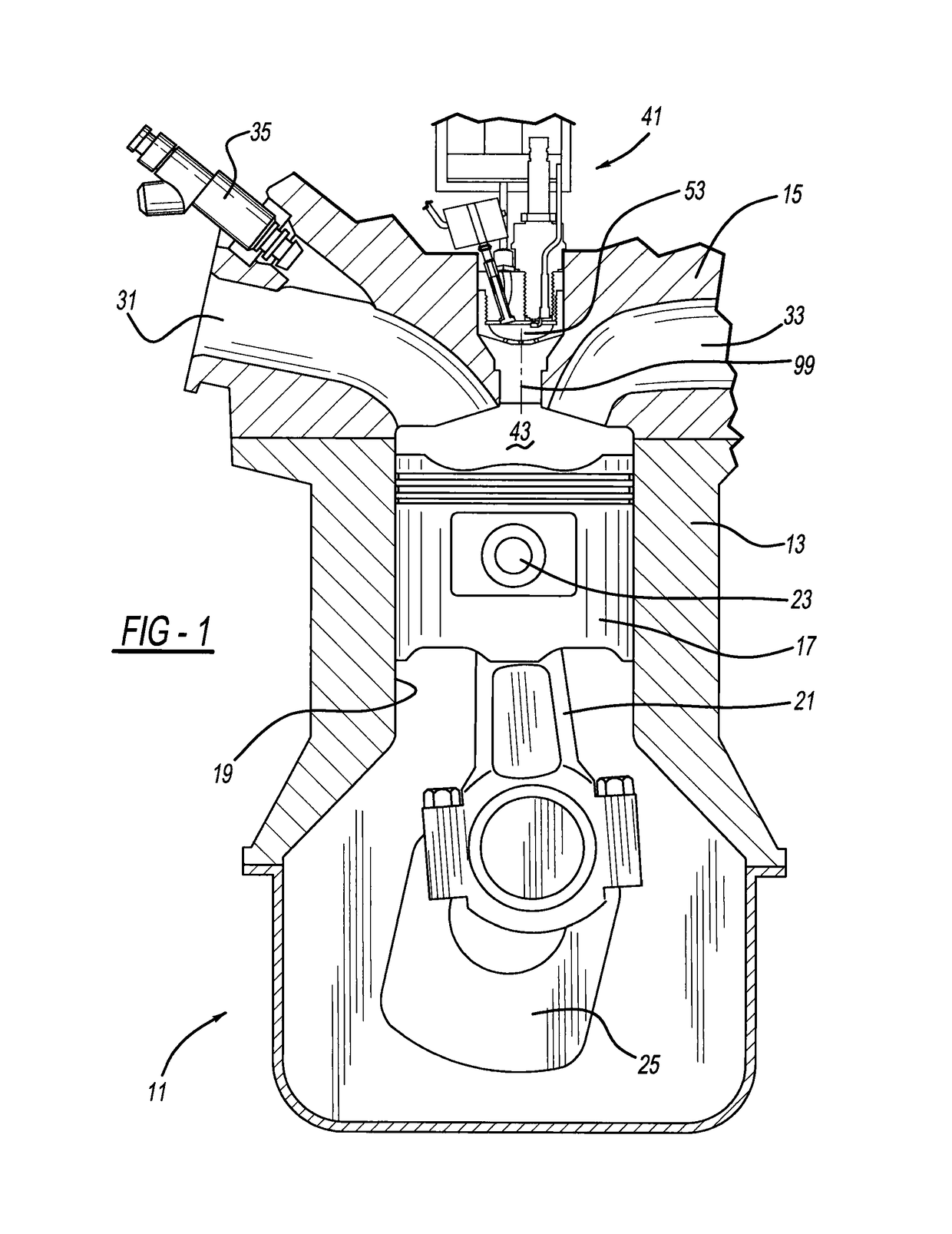

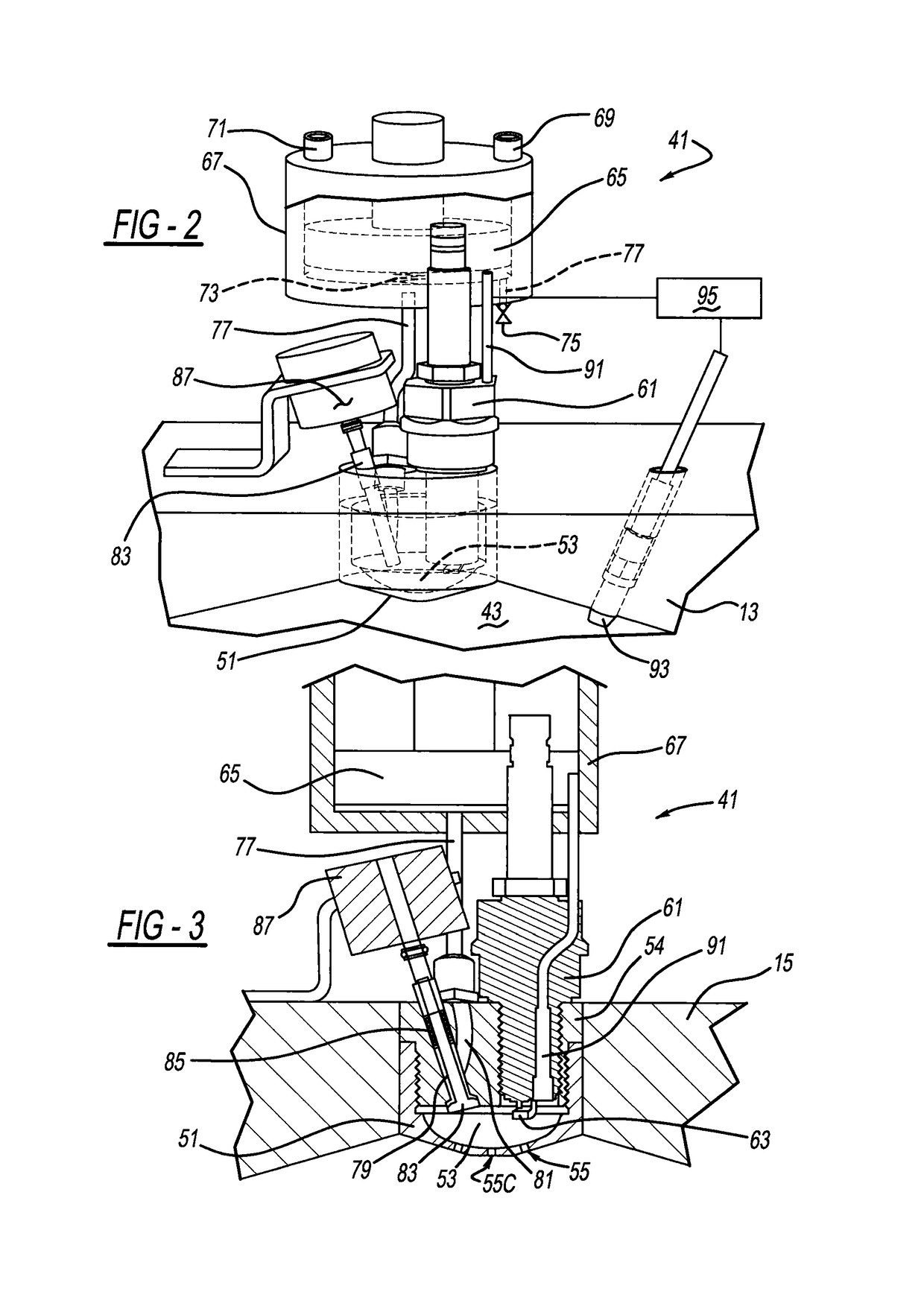

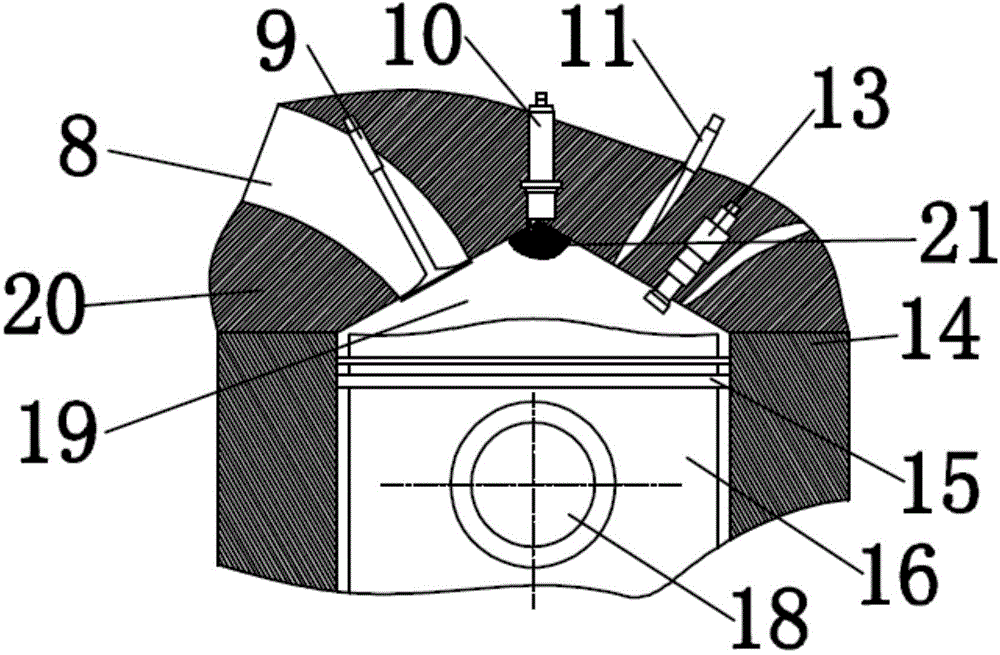

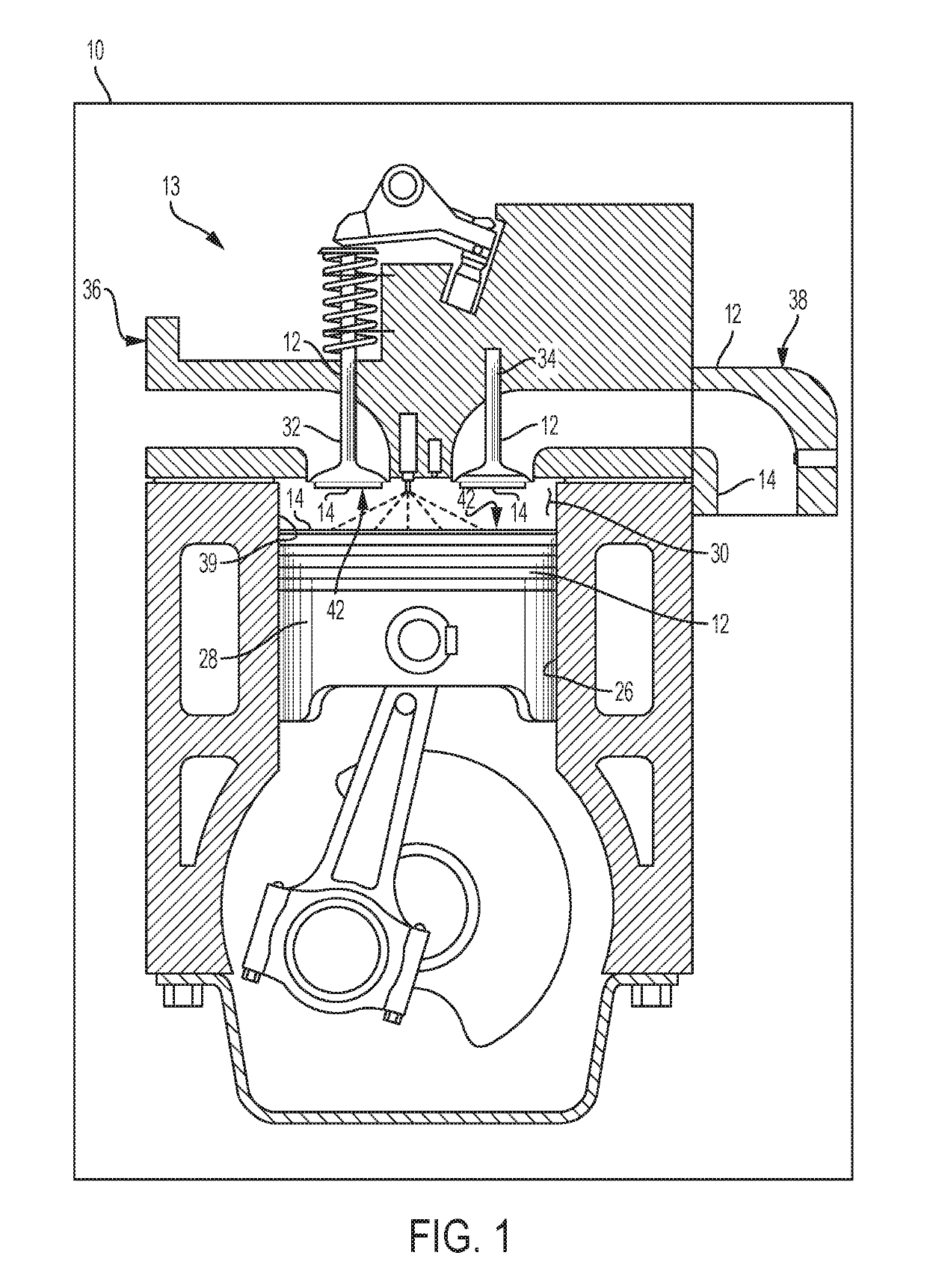

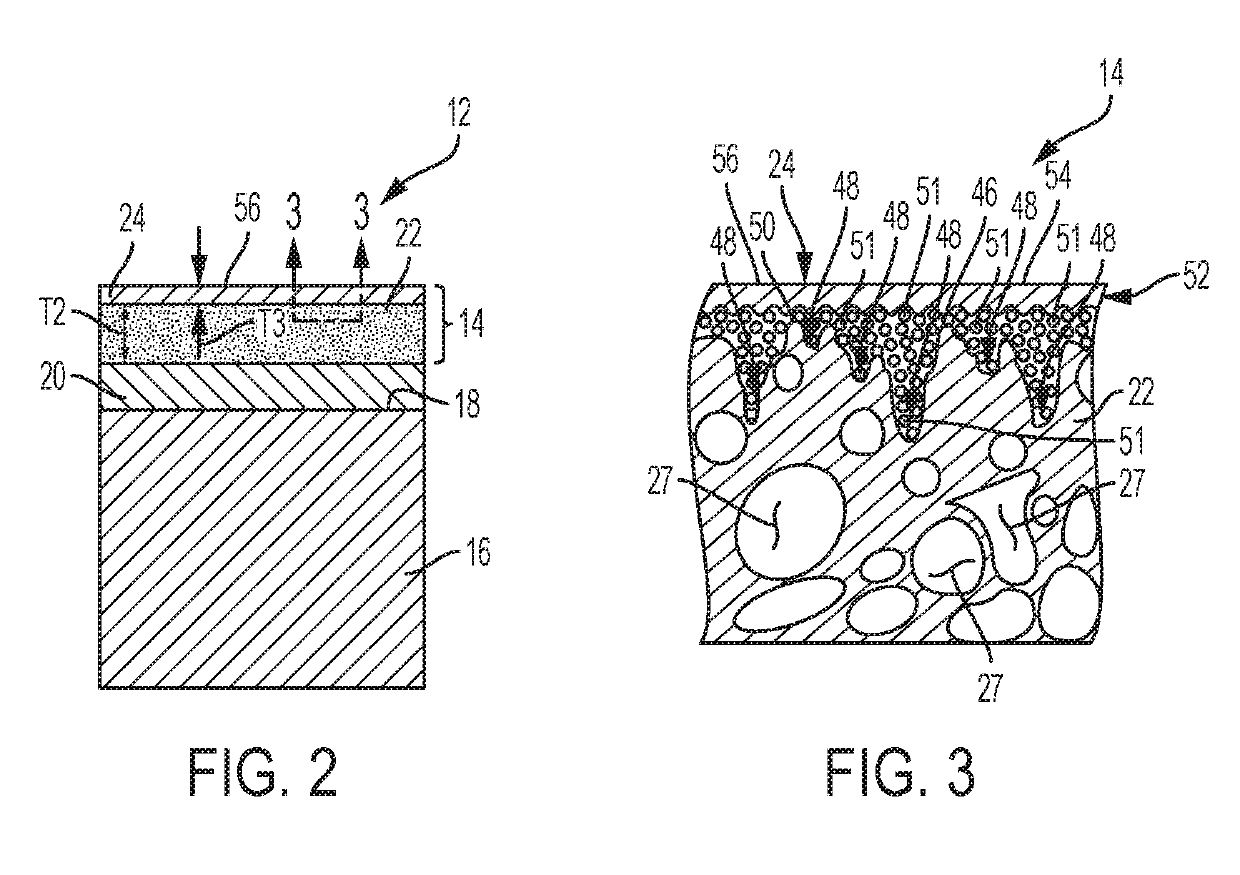

Internal combustion engine

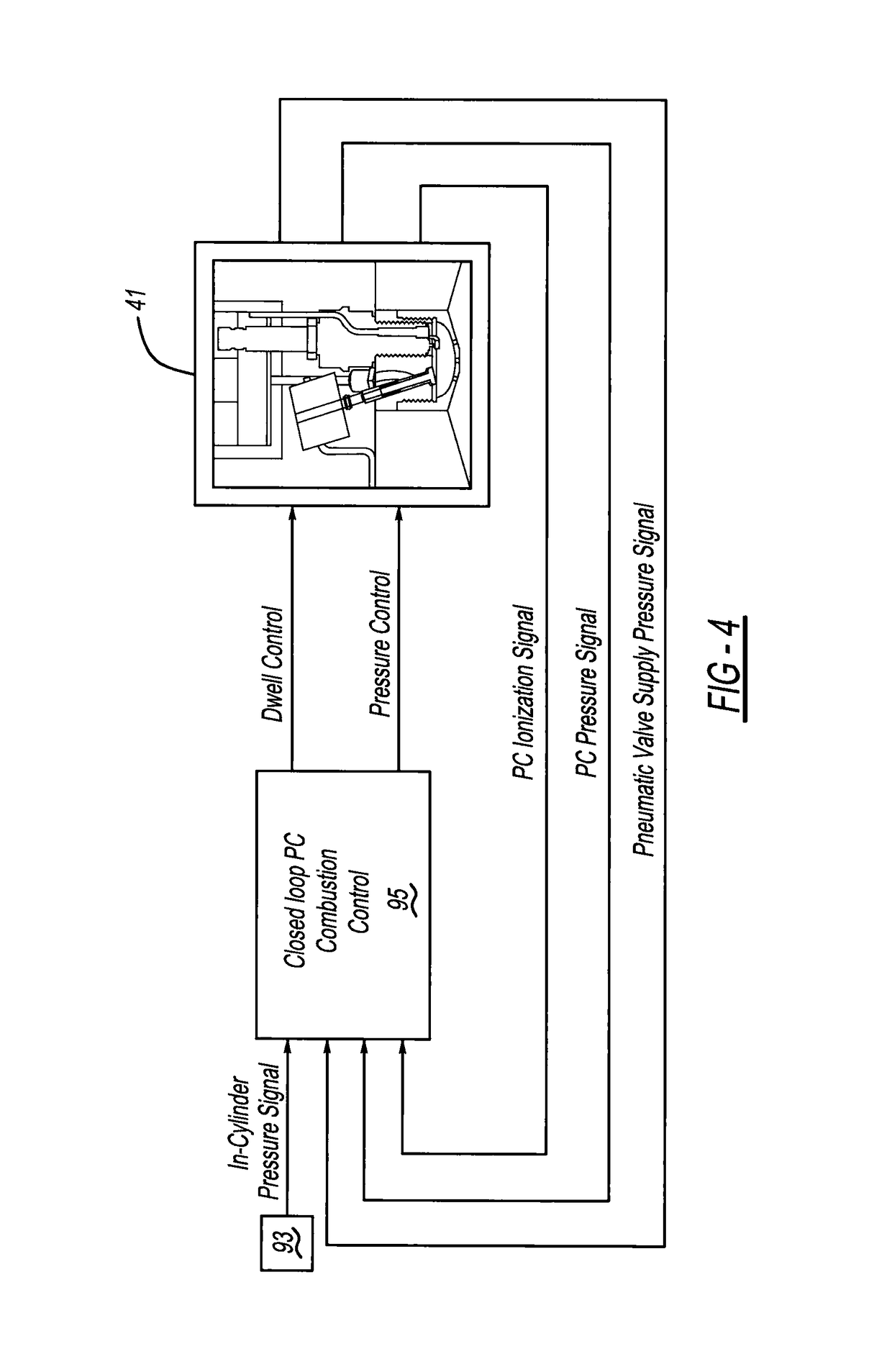

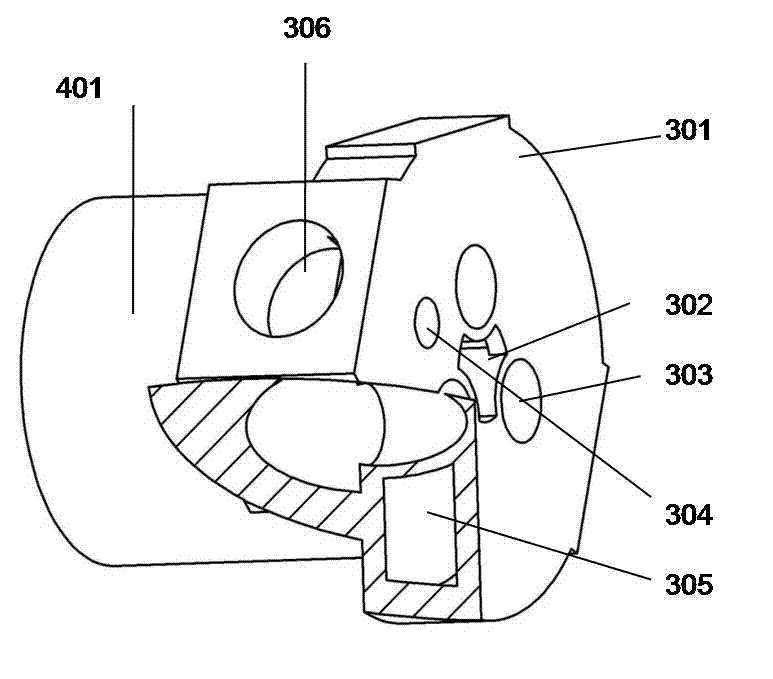

ActiveUS20160230645A1Lower overall cycle average pre-chamber wall temperatureReduce heat transfer lossInternal combustion piston enginesCylinder headsPistonInjector

An internal combustion engine includes a pre-chamber. In another aspect, pressure within a pre-chamber is equal to or greater than pressure within a main combustion chamber at least prior to ignition in the main combustion chamber. A further aspect provides a supplemental piston creating pressure and supplying a fuel-air mixture into a pre-chamber, and a spark or glow plug has an end located within the pre-chamber for ignition of the mixture therein. In yet another aspect, internal combustion engine control software automatically controls pressure within a turbulent jet ignition pre-chamber, controls a valve-actuator to admit a fuel-air charge into the pre-chamber, and causes an ignitor to initiate combustion in the pressurized pre-chamber. This also permits the rate of combustion to be controlled in the primary chamber regardless of the air-fuel ratio or the diluent fraction in the main chamber. Another aspect employs a pre-chamber purge pump with separate air and fuel injection. Moreover, an additional aspect separately supplies unmixed air and fuel into a turbulent jet ignition pre-chamber through a dual-mode, single injector unit.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

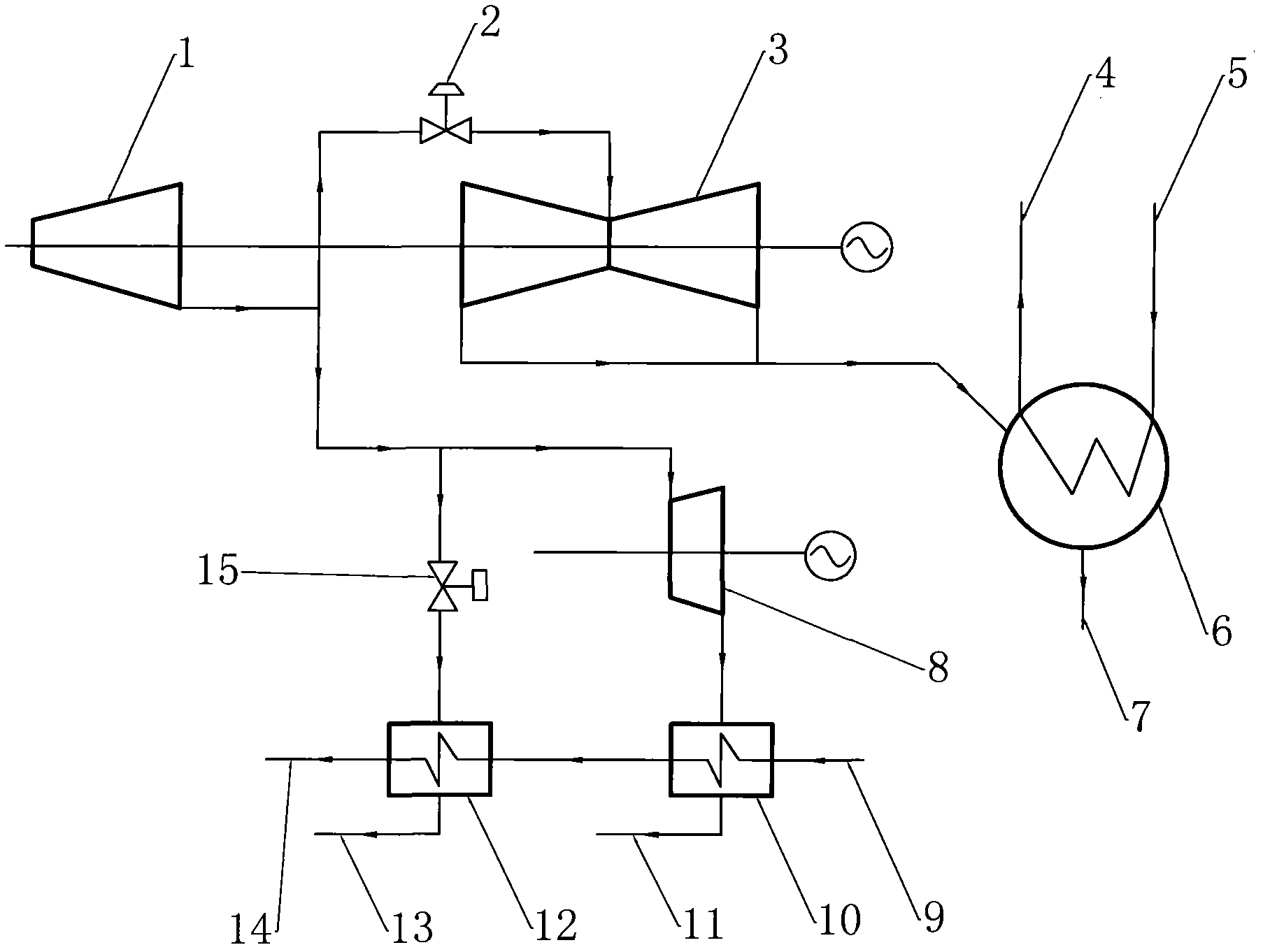

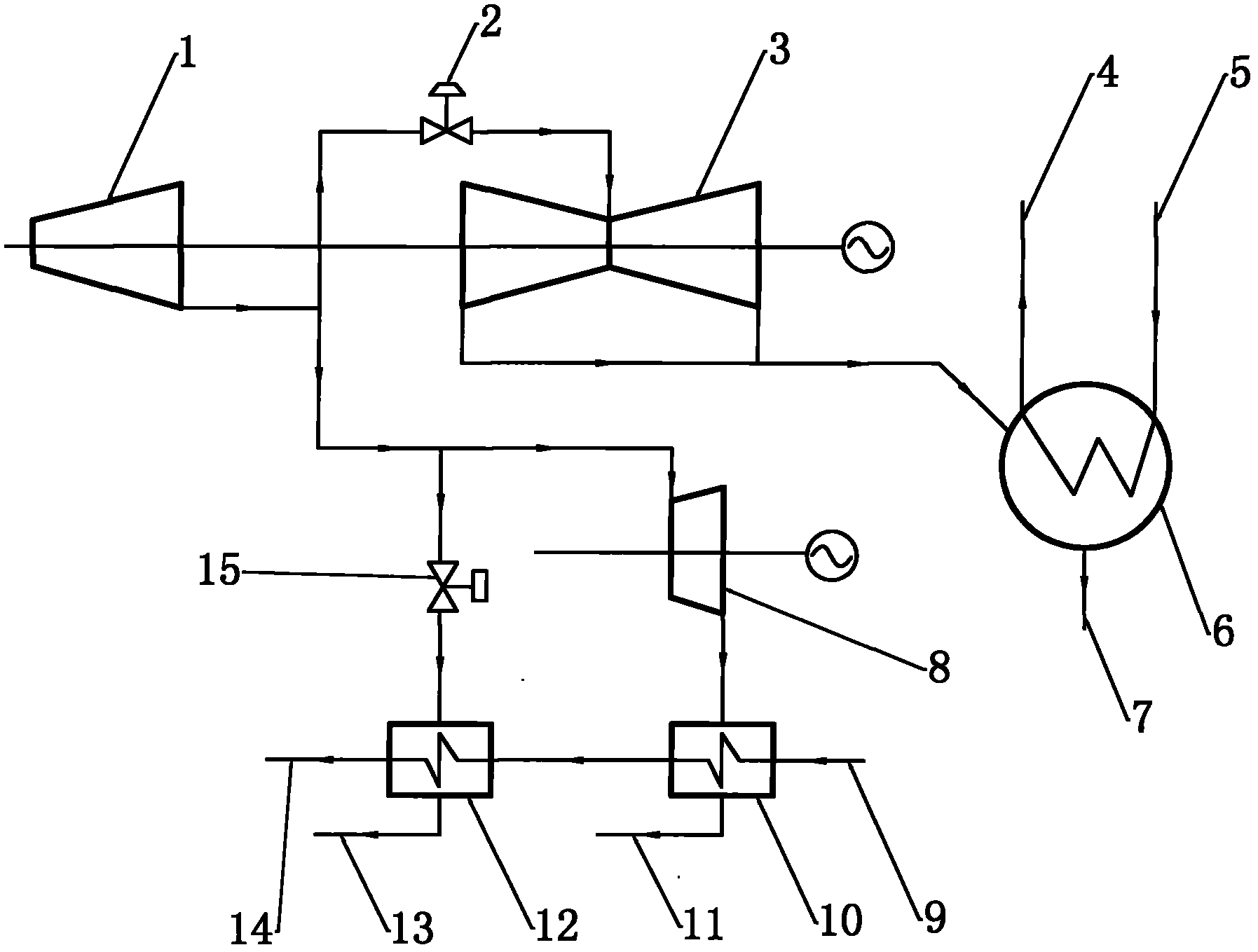

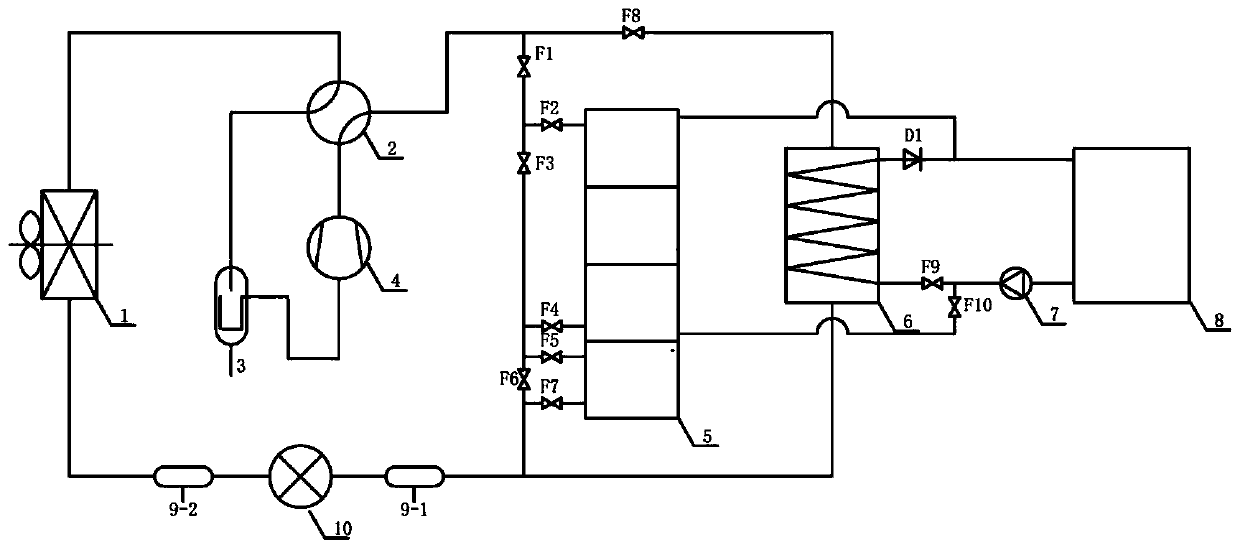

High-flow, low-parameter and high-backpressure expansion power energy-saving system

InactiveCN102011616AReduce heat transfer lossFew parametersHeat recovery systemsLighting and heating apparatusEngineeringStreamflow

The invention discloses an energy-saving device of a thermal power station, particularly discloses a high-flow, low-parameter and high-backpressure expansion power energy-saving system, comprising a turbine intermediate pressure cylinder and a heat supply backwater heater, which are connected by pipelines, the heat supply backwater heater is connected with a heat supply backwater main pipe and a heat supply backwater heater drain pipe, and the heat supply backwater heater drain pipe is connected with a turbine back-heat heating system, the high-flow, low-parameter and high-backpressure expansion power energy-saving system is characterized in that the pipeline between the turbine intermediate pressure cylinder and the heat supply backwater heater is provided with an expansion power machine. The high-flow, low-parameter and high-backpressure expansion power energy-saving system maximally reduces heat transfer loss between steam and heat supply hot water without influencing heat supply requirement, and converts part of energy in heat supply steam extraction process into high-quality power for output, so that energy is saved. The power output by the expansion power machine can drive generators or other power machines.

Owner:SHANDONG HONGAO POWER TECHNOLOGY CO LTD

Internal combustion engine

ActiveUS10161296B2Easy to packReduce wall temperatureInternal combustion piston enginesCylinder headsCombustion chamberValve actuator

An internal combustion engine includes a pre-chamber. In another aspect, pressure within a pre-chamber is equal to or greater than pressure within a main combustion chamber at least prior to ignition in the main combustion chamber. In yet another aspect, internal combustion engine control software automatically controls pressure within a turbulent jet ignition pre-chamber, controls a valve-actuator to admit a fuel-air charge into the pre-chamber, and causes an igniter to initiate combustion in the pressurized pre-chamber. This also permits the rate of combustion to be controlled in the primary chamber regardless of the air-fuel ratio or the diluent fraction in the main chamber. Another aspect employs a pre-chamber purge pump with separate air and fuel injection.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

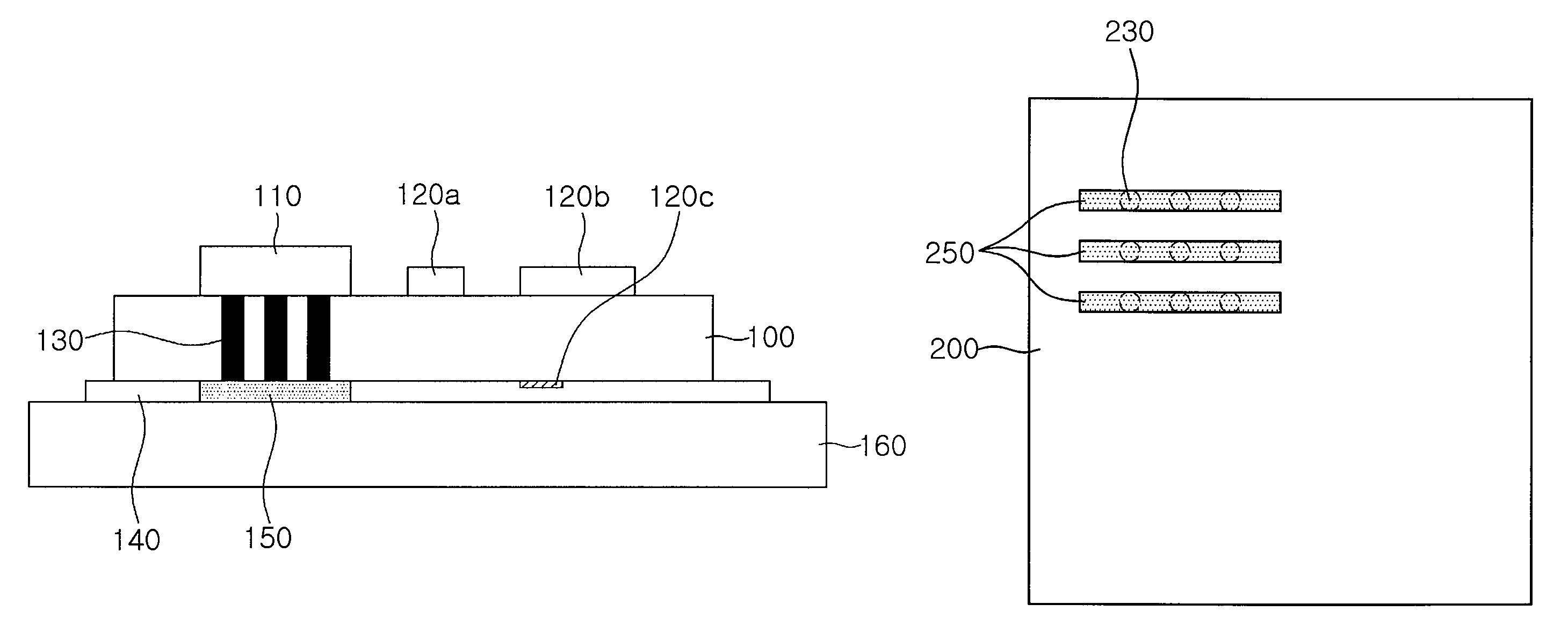

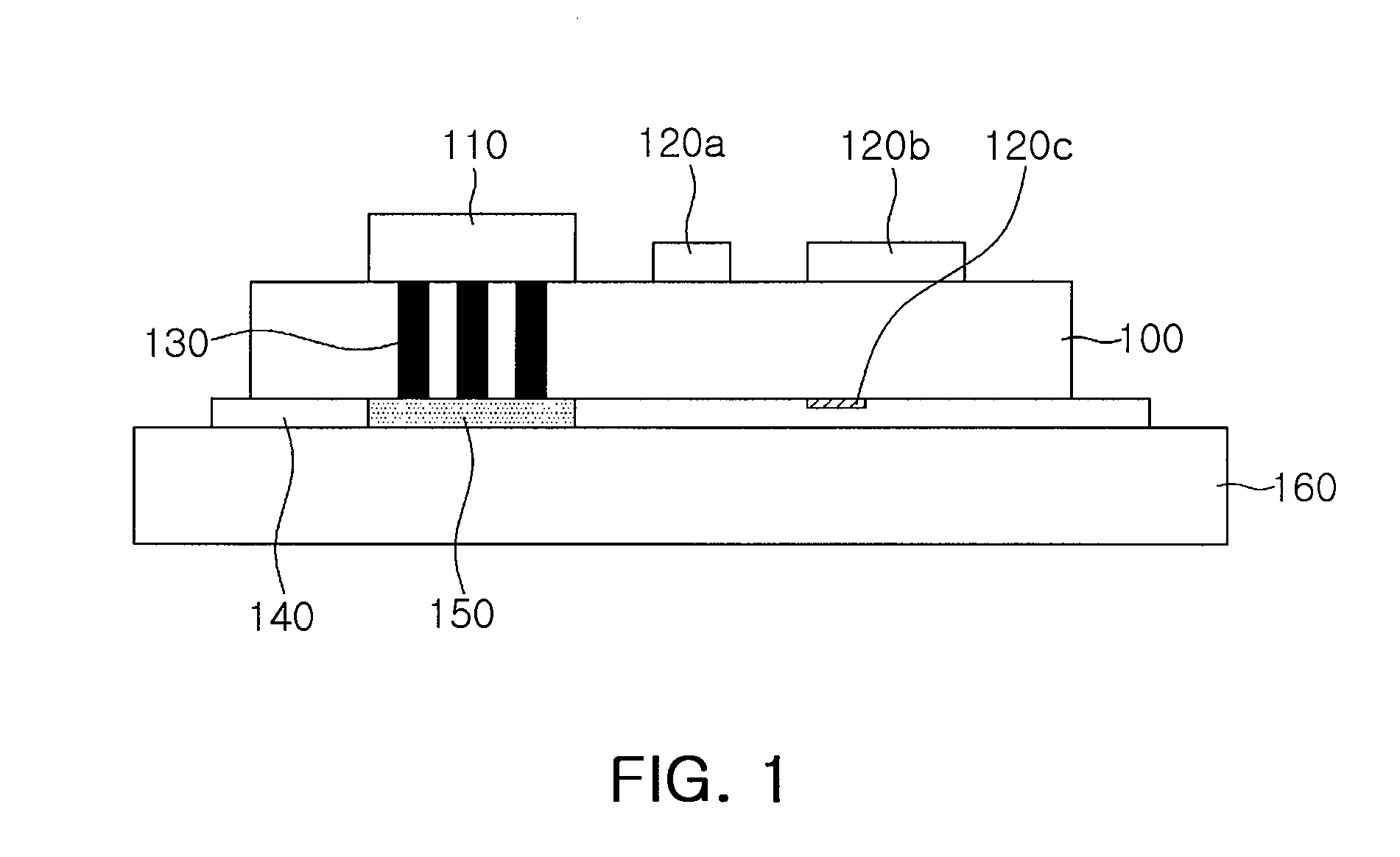

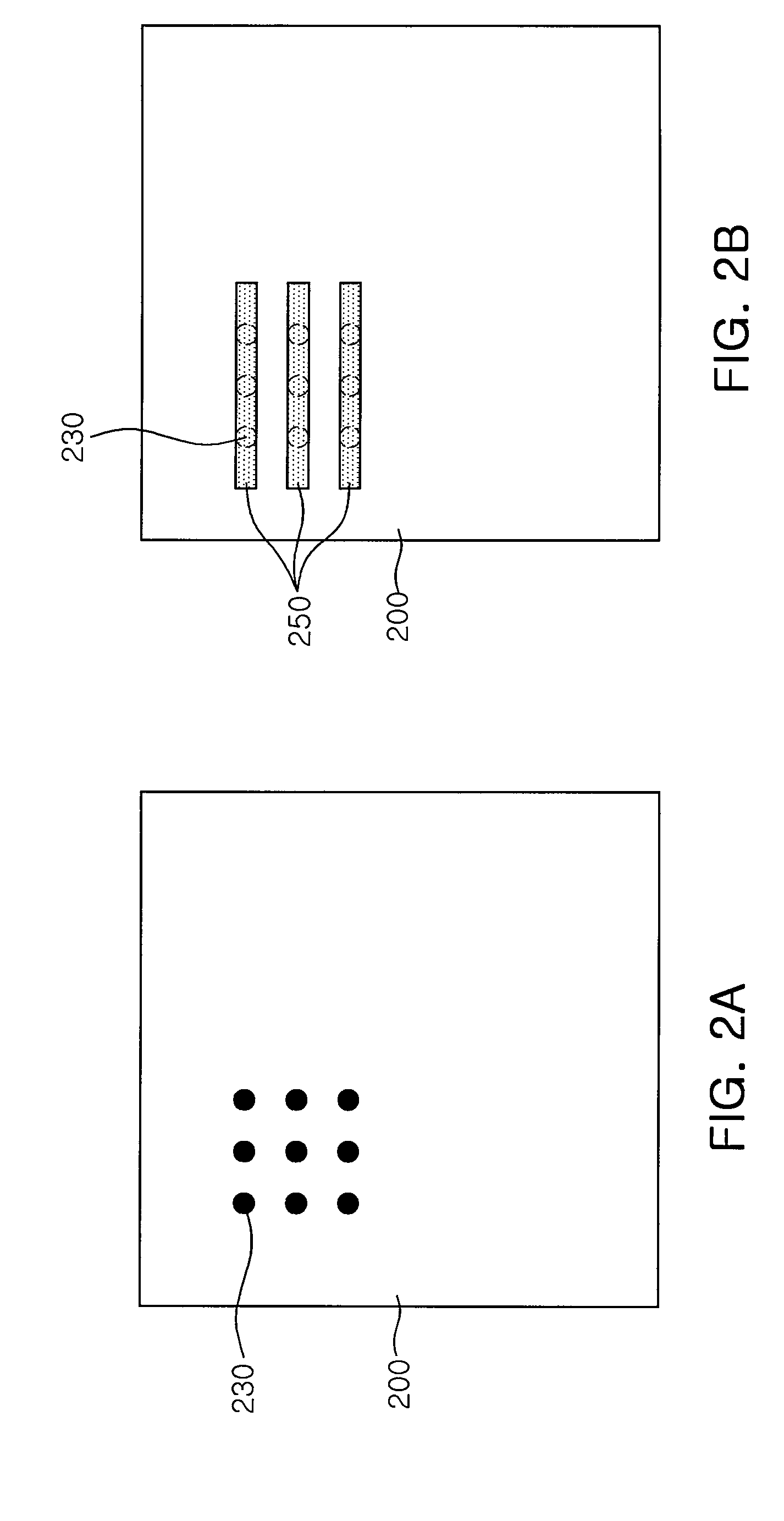

Electronic chip module

InactiveUS7872869B2Improve cooling efficiencyReduce heat transfer lossSemiconductor/solid-state device detailsPrinted circuit aspectsComputer moduleElectronic chip

Provided is an electron chip module having a heat sink that can increase heat dissipation efficiency. A bottom surface of a module circuit board and an upper surface of a heat sink are in direct contact with each other by using a metal wire, such that heat generated during the operation of a heat-generating device chip mounted onto the module circuit board can be effectively dissipated to the outside.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

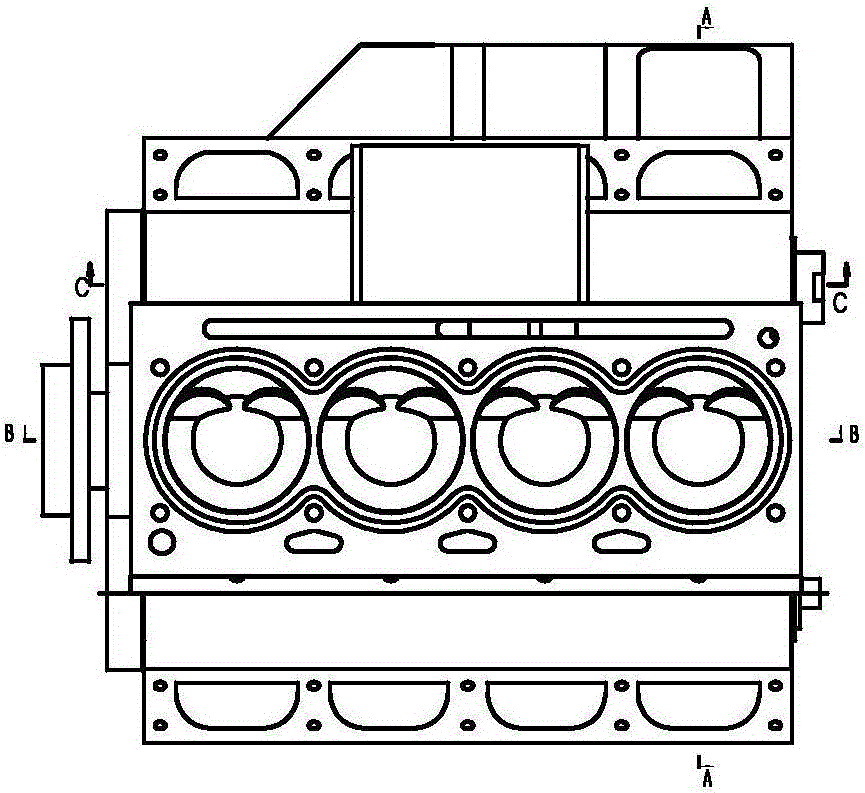

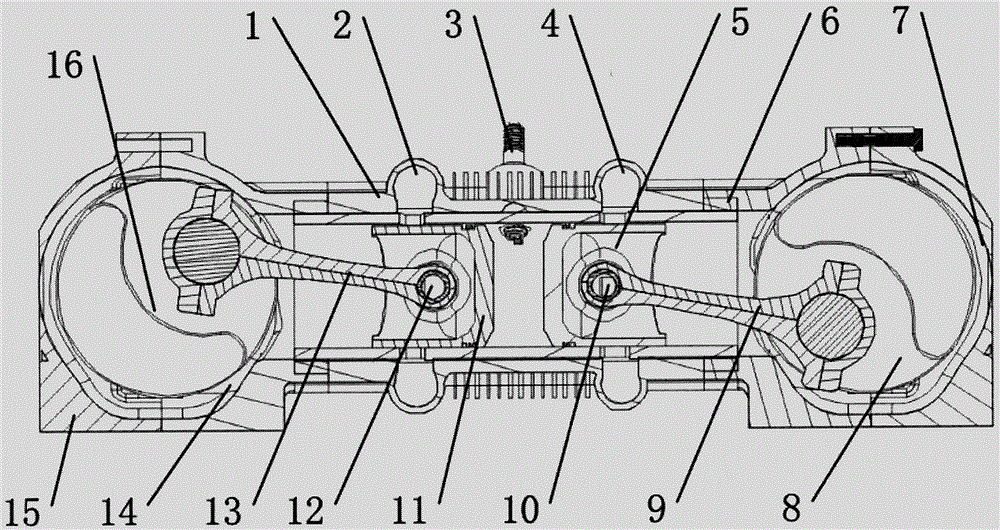

Double-crankshaft engine

ActiveCN105927380AReduce toughnessReduce manufacturing costCasingsConnecting rodsPiston GuideCylinder block

The invention discloses a double-crankshaft engine and belongs to the technical field of engines. The double-crankshaft engine comprises a piston and two crankshafts forming a double-crankshaft mechanism, and further comprises a cylinder block. The cylinder block comprises an air cylinder block part and a crankshaft supporting part. A piston guide rod is arranged at the lower end of the piston, the cylinder block is internally provided with a piston rod guide groove, the lower end of the piston is open and is provided with a piston end cover, and the piston end cover and the piston guide rod are detachably and fixedly connected; and the piston is a skirt-free piston with the piston guide end and the piston seal end separated, the piston seal end is a piston head, and the piston guide end is provided with the piston guide rod and the piston rod guide groove. The double-crankshaft engine is good in manufacturability, the piston is designed through isostress, strength is increased, abrasion-resisting design is adopted in a connecting part of a connecting rod and the piston, and the abrasion resisting performance and the reliability of the whole engine are improved.

Owner:XUZHOU XIAN BO ENGINE MACHINERY TECH CO LTD

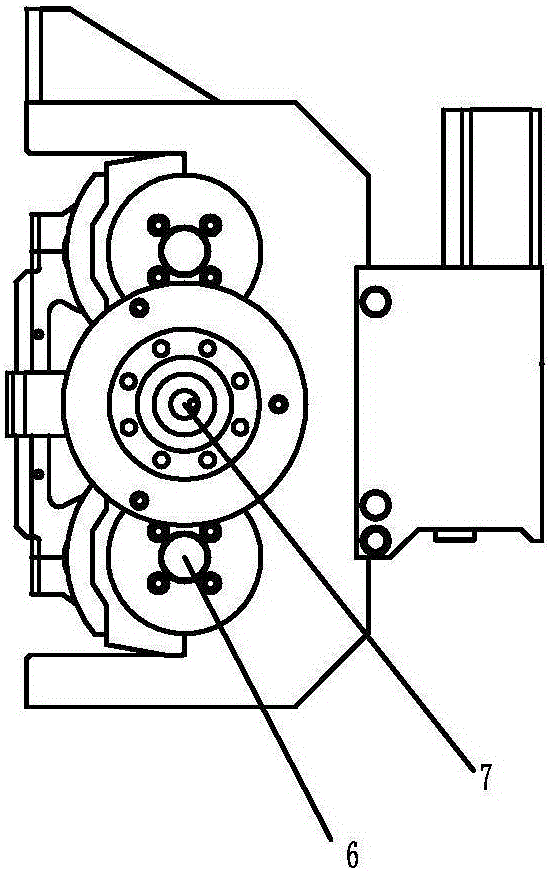

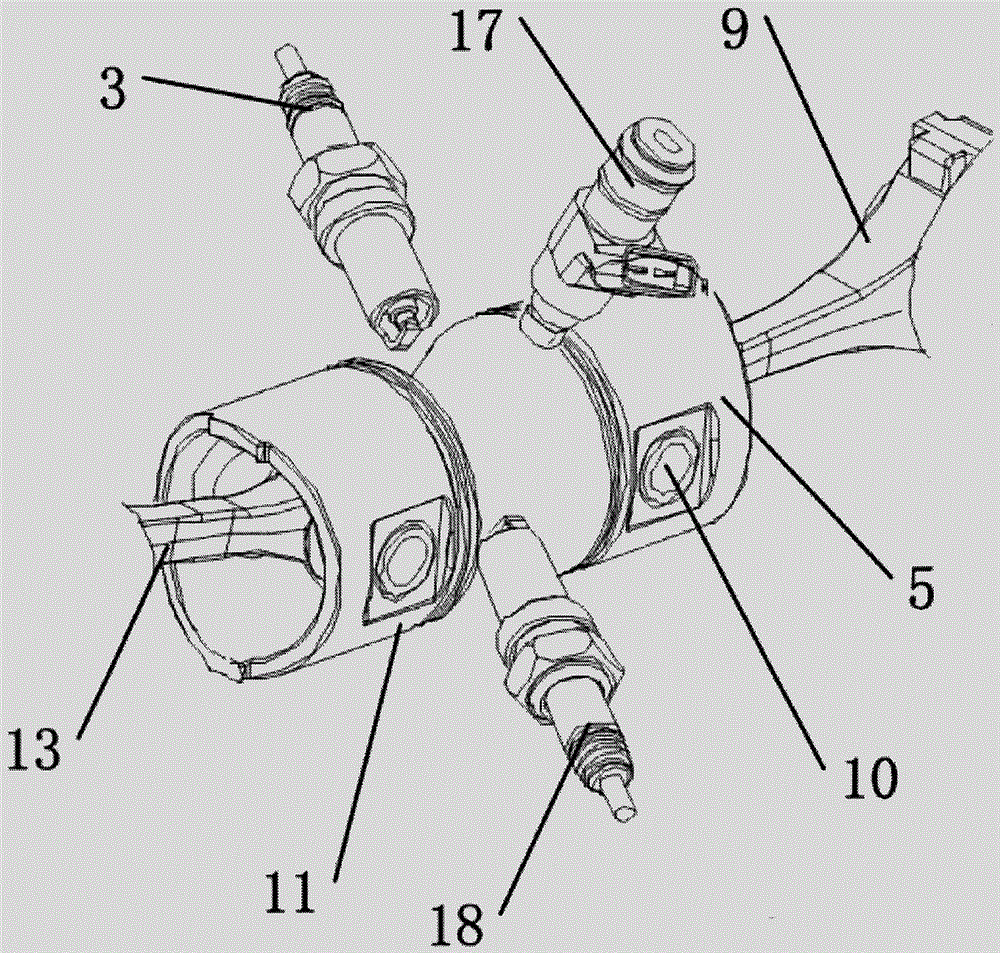

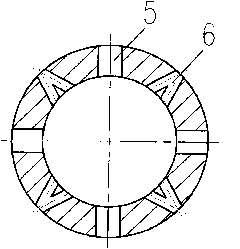

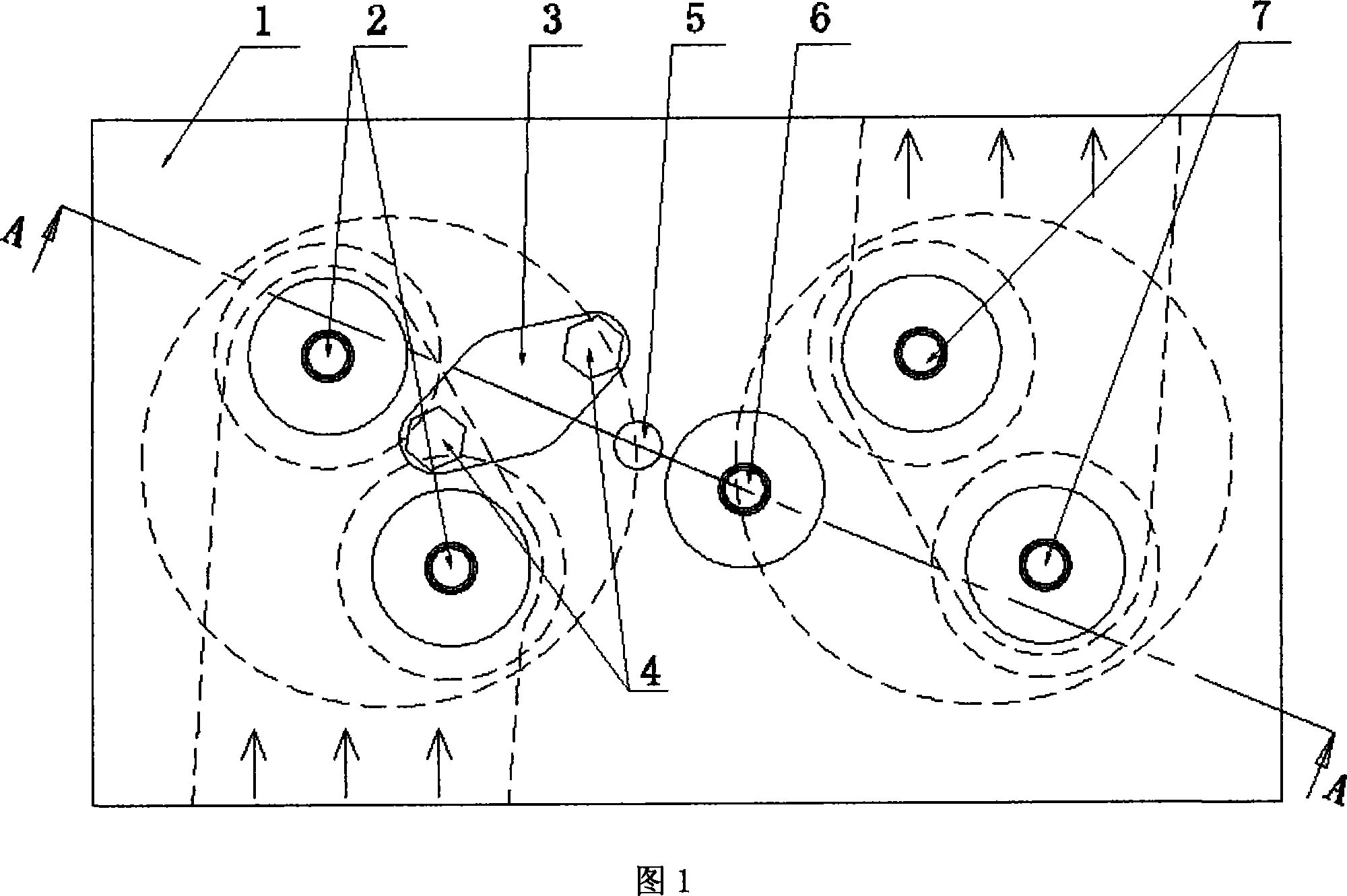

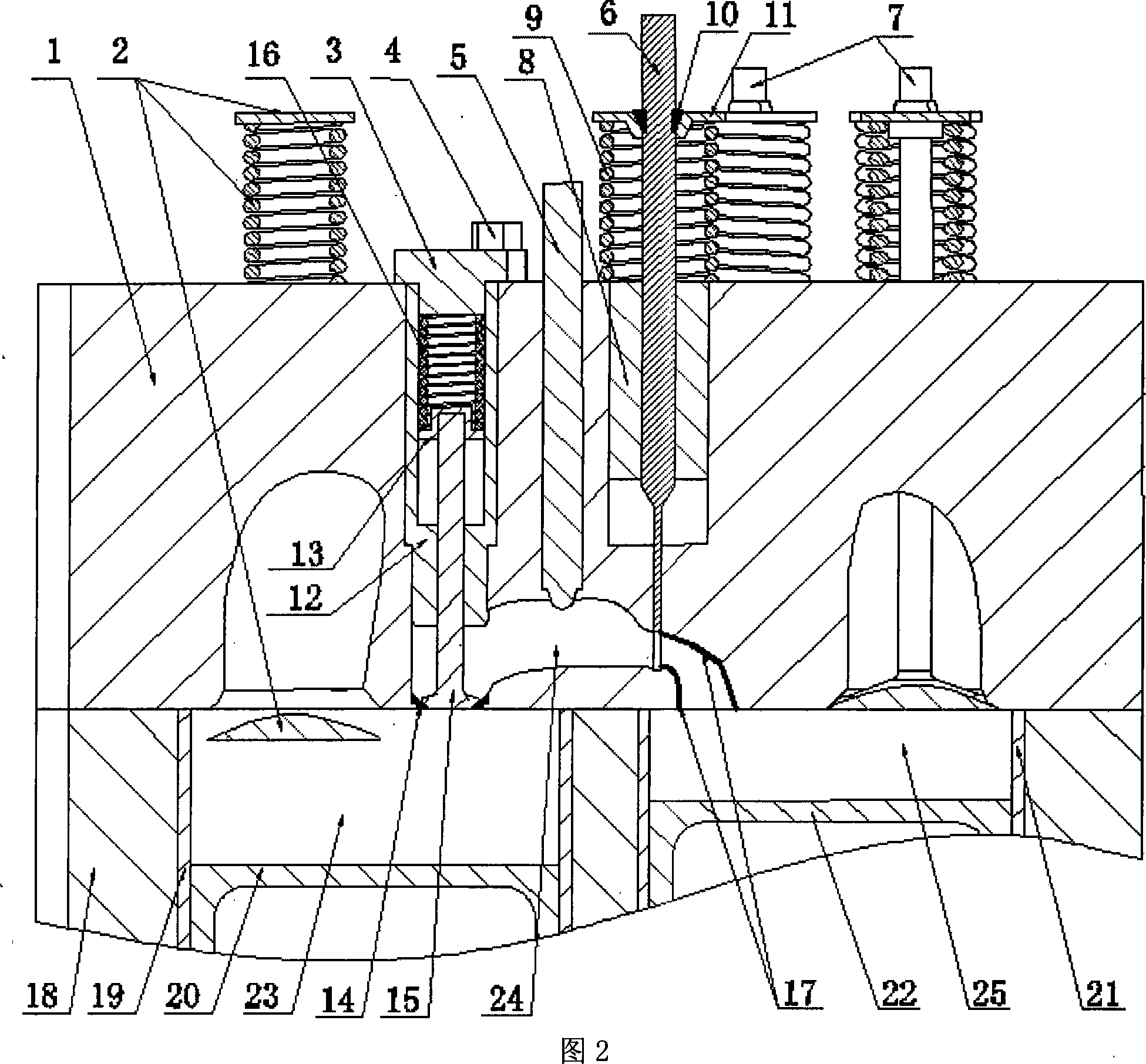

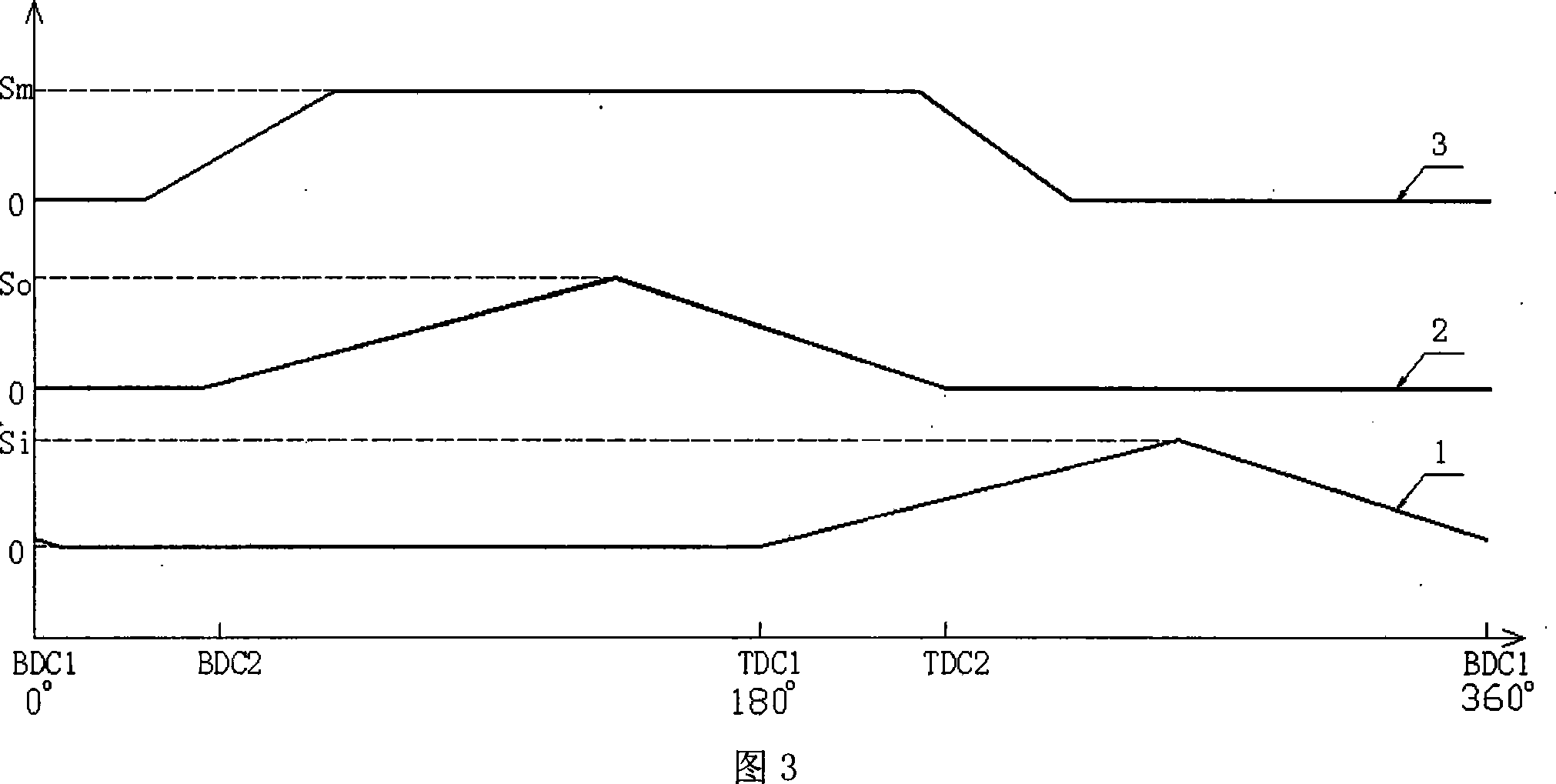

Opposite-piston, two-stroke and variable-compression-ratio type gasoline engine

InactiveCN105937440AShortened burn durationIncrease burn rateCombustion enginesWorking capacityInjector

The invention discloses an opposite-piston, two-stroke and variable-compression-ratio type gasoline engine, and relates to the field of internal combustion engines. The gasoline engine comprises a cylinder body, a gear synchronizing mechanism, a first spark plug, a second spark plug, a gasoline injector and a motor, wherein the cylinder body is connected with the gear synchronizing mechanism through a crankshaft; the first spark plug, the second spark plug and the gasoline injector are arranged on the outer circumferential wall of the cylinder body; the gear synchronizing mechanism provided with a gas feeding side gear and a gas exhausting side gear is connected to the motor; the gas feeding side gear is connected with a gas feeding side crankshaft; the gas exhausting side gear is connected with a gas exhausting side crankshaft; at least two intermediate gears are arranged between the gas feeding side gear and the gas exhausting side gear; the gas feeding side gear, the intermediate gears and the gas exhausting side gear which are engaged with each other are connected through connecting plates. According to the opposite-piston, two-stroke and variable-compression-ratio type gasoline engine, the movement phase difference of opposite pistons can be changed through the gear synchronizing mechanism, so that the cylinder working capacity can be changed when the opposite pistons are positioned at inner stopping points and outer stopping points, and as a result, the compression ratio of the gasoline engine in working can be varied.

Owner:ZHONGBEI UNIV

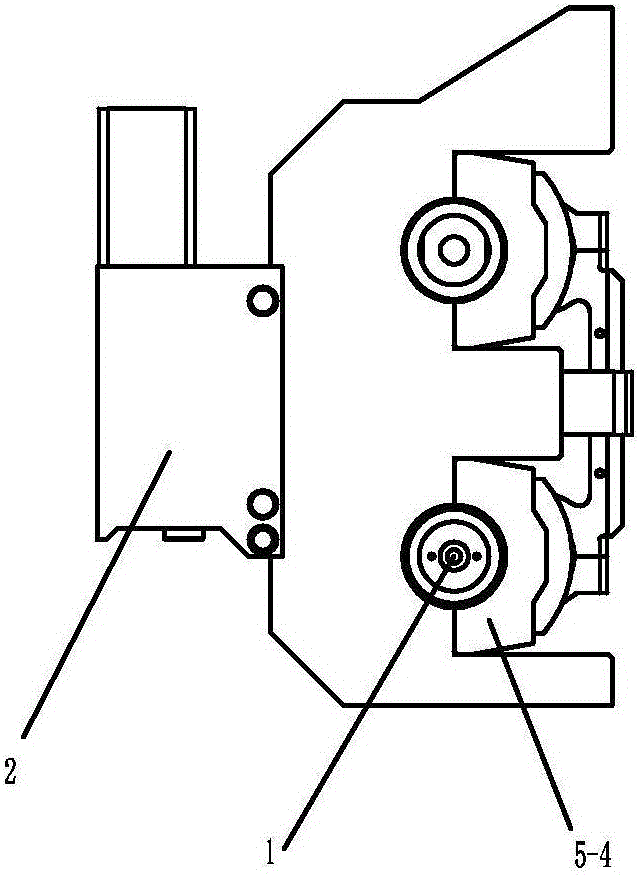

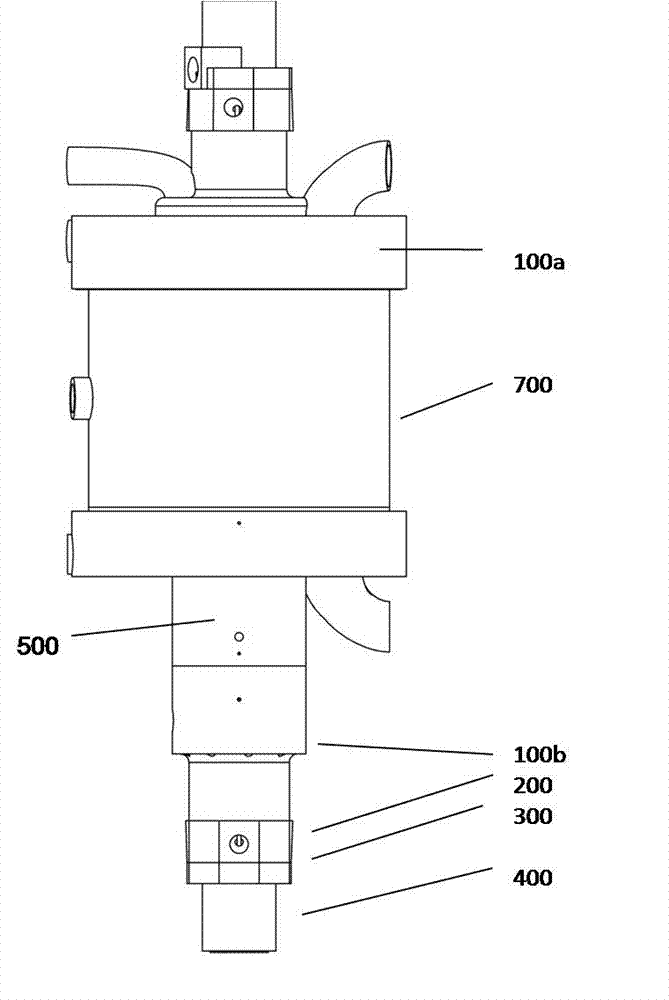

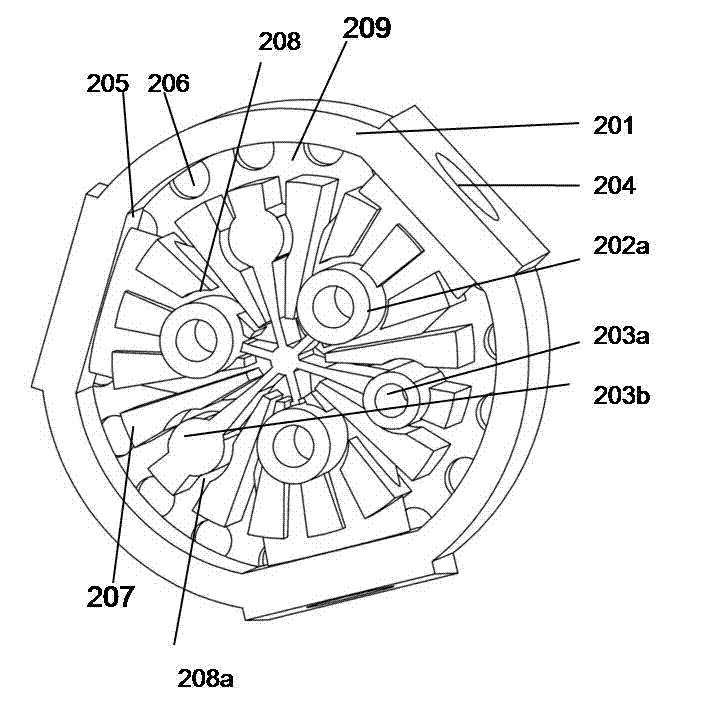

Piston intake two-stroke linear generating system

InactiveCN103016144AAchieve lubricationReduce pollutionMagnetic circuit rotating partsInternal combustion piston enginesExhaust valveDrive shaft

The invention discloses a piston intake two-stroke linear generating system, which is characterized in that the generating system is based on the linear generating scheme of double-cylinder opposite push-pull working, an auxiliary air cylinder and a piston fixed with a generating rotor shaft are added, the overall structure is as follows: a linear generator (700) is arranged in the middle part, a direct-connecting motor air cylinder component (100c), an air cylinder cover (200a) and an air valve driving section (400) are sequentially arranged on one side, and an auxiliary air cylinder component (500), a air cylinder component (100d) connecting the auxiliary air cylinder, an air cylinder cover (200a) and the air valve driving section (400) are sequentially arranged on the other side; two engine pistons (800a), a linear generator rotor (1000a) and an auxiliary piston component (900) are fixedly arranged together through a linear transmission shaft; an electromagnetic driving exhaust valve is arranged on the air cylinder top of the engine, an intake valve driven by inertia is arranged on a piston, the piston and the transmission shaft are of hollow cylinder shapes, vent holes are arranged on a linear motor dynamic inner cylinder and the transmission shaft, and air enters into the linear generator from two ends of the linear generator and enters the air cylinder through the hollow transmission shaft, the piston and an air valve; and gas (such as R134a) with a low heat ratio is used as working gas of the auxiliary air cylinder, and by adjusting the pressure of the auxiliary air cylinder, the working frequency of a system is adjusted.

Owner:TIANJIN CHANGING POWER TECH

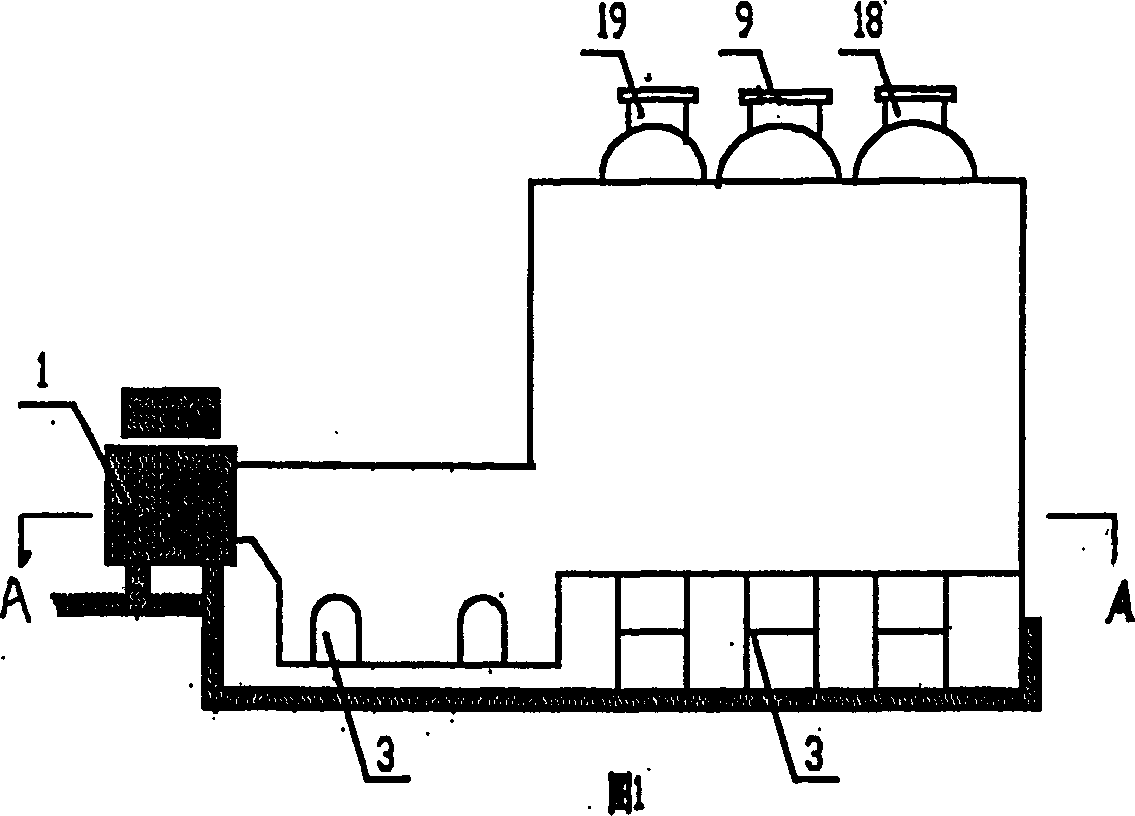

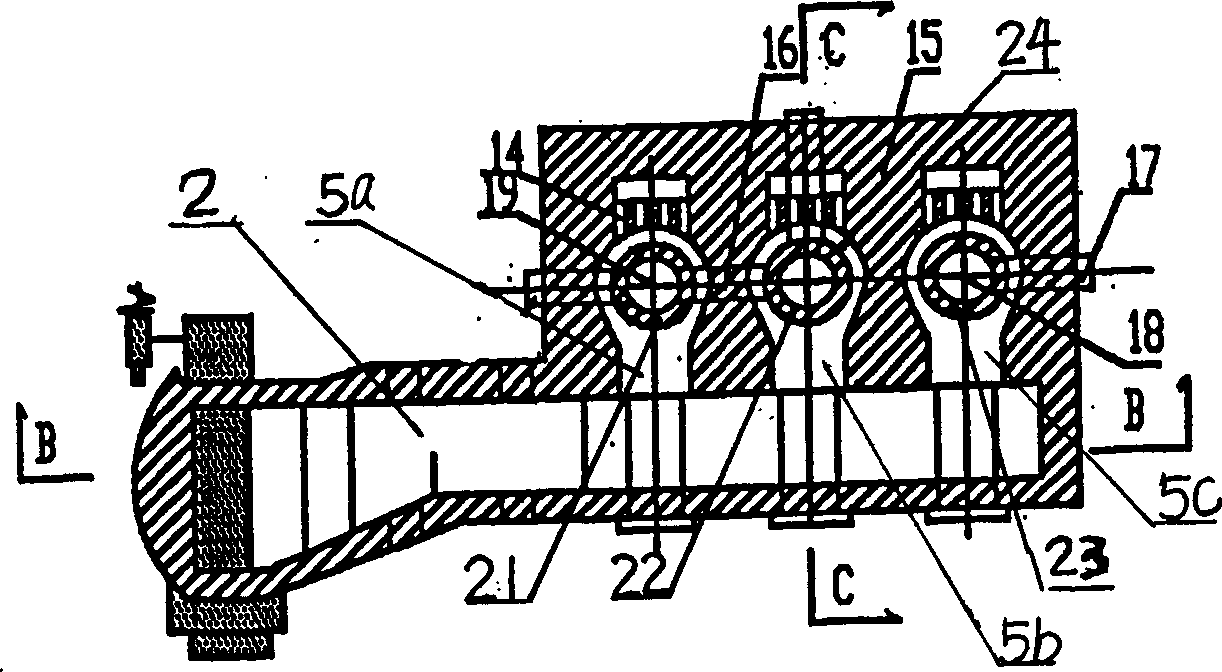

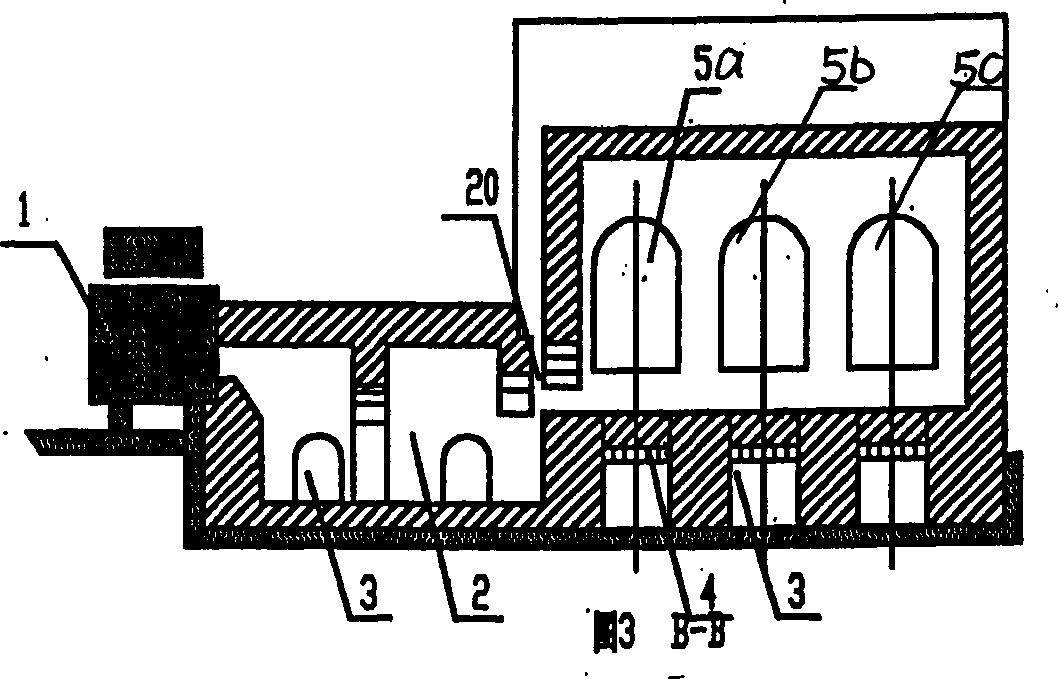

CS2 reactor furnace

The CS2 reactor furnace includes inner furnace body of refractory material, outer furnace body of refractory material, and heating chamber between the inner surface body and the outer furnace body. In the peripheral of the inner surface body, there are sulfur gasifying furnace and carbon material preheating furnace, and the sulfur gasifying, furnace is connected via sulfur vapor duct to the bottom of the inner furnace body. The CS2 reactor furnace of the present invention has no sulfurizing and oxidizing corrosion of inner furnace body and thus long service life. The material preheating speeds the reaction and raise the product yield. Heating the coal-burning gas furnace via the main fire channel communicated with the furnace body can save fuel and stabilize furnace temperature.

Owner:SHANGHAI BAIJIN CHEM GROUP

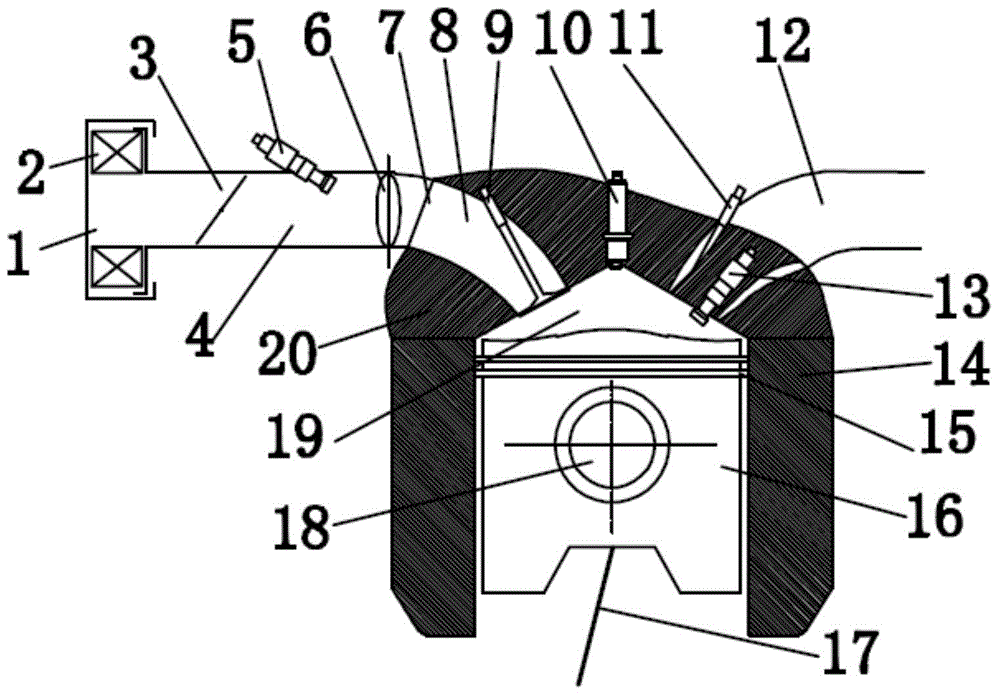

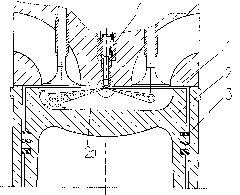

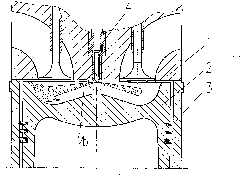

Pre-combustion chamber, internal combustion engine and automobile

InactiveCN111120077AShorten the penetration distanceAvoid contactInternal combustion piston enginesCombustion chamberInternal combustion engine

The invention relates to the technical field of automobiles, and discloses a pre-combustion chamber, an internal combustion engine and an automobile. A first injection hole is formed in the end, usedfor extending into a chamber of a main combustion chamber of the internal combustion engine, of the pre-combustion chamber, one end of the first injection hole communicates with a chamber of the pre-combustion chamber, and the other end of the first injection hole communicates with the chamber of the main combustion chamber. The hole diameter of the first injection hole gradually increases from one end communicating with the chamber of the pre-combustion chamber to one end communicating with the chamber of the main combustion chamber. The pre-combustion chamber has the advantages that when thehigh-temperature and high-pressure gas enters the chamber of the main combustion chamber of the internal combustion engine from the chamber of the pre-combustion chamber through the first injection hole, the penetration distance of the jet flame can be reduced, the situation that the jet flame is in contact with a piston or the cylinder wall of the main combustion chamber prematurely is avoided,and the heat transfer loss is reduced.

Owner:CHINA FIRST AUTOMOBILE

Adsorption reinforced methane steam reforming hydrogen production process and apparatus using circulating fluidized bed

ActiveCN100497160CHigh purityAchieve stabilityHydrogenChemical recyclingSteam reformingPtru catalyst

The invention discloses a hydrogen preparing process of strengthening methane steam reforming by cyclic fluidized bed adsorption, comprising: transporting 5-200 micron composite catalyst grains into a regenerator for pretreating; degasifying the pretreated composite catalyst and tranfering it to a fluidized bed reactor for reducing; charing methane and steam into the fluidized bed reactor in the water-carbon ratio of 2-10, and making the fluidized composite catalyst perform reforming hydrogen preparing reaction with methane and steam at the same time, and finally transferring the composite catalyst into regnerator to be regenerated and recycled, where the reacting time is 1s-5min, the reacting gas speed is 0.3-1.0m / s, and the ratio of composite catalyst to methane is 10 : 1-0.002 : 1 in g / ml. And it also discloses a device of implementing the above process. And the process can implement stable and continuous operation of fluidized bed reactor, and has advantages of high mass and heat transfer efficiencies.

Owner:CHINA PETROLEUM & CHEM CORP +1

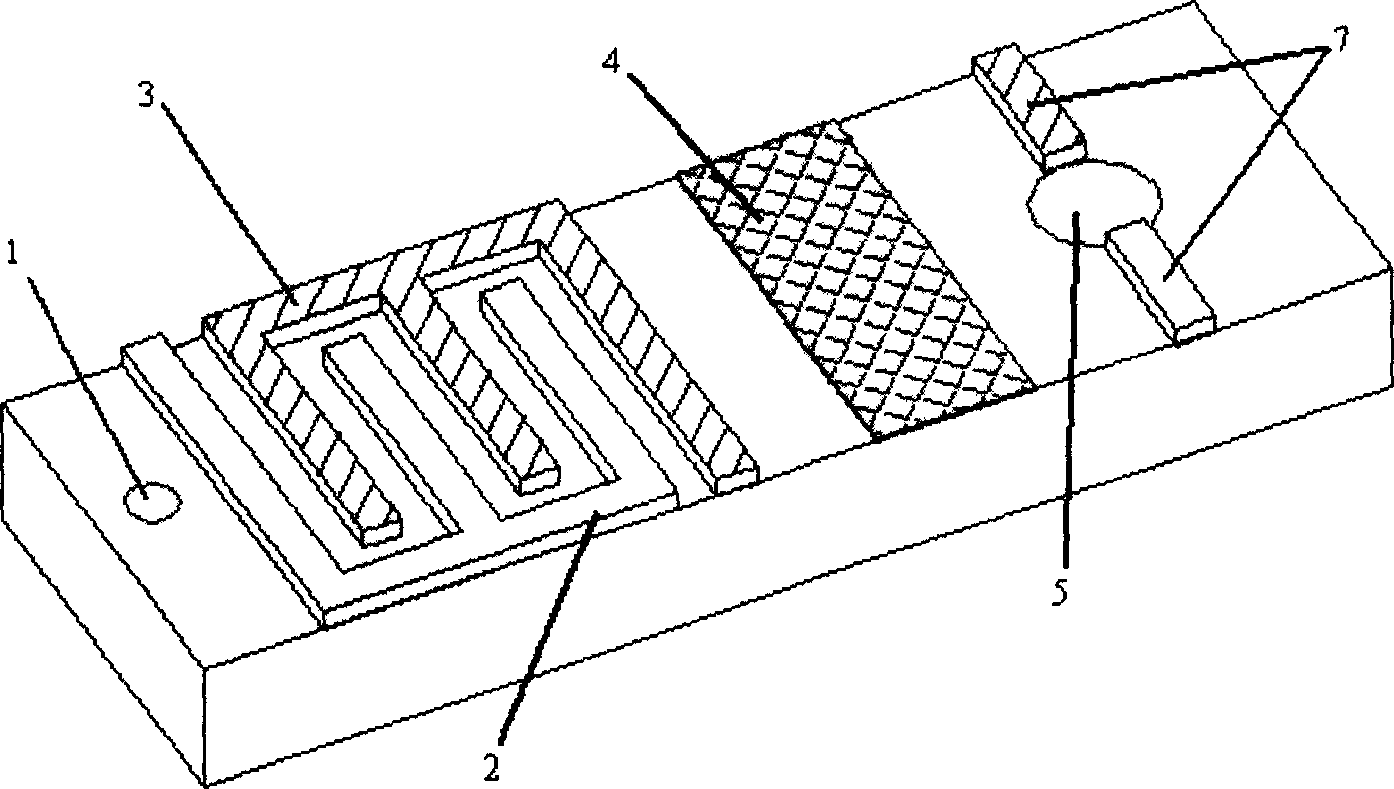

Minisize propeller with electrolyzing water function

InactiveCN1804386AImprove thermal efficiencyHigh specific impulse performanceElectrolysis componentsRocket engine plantsPropellerThermal efficiency

The invention relates to a micro-electrolysis water thruster which can utilize water or water solution, belonging to the micro-mechanical technique. It comprises: (1) a micro-electrolysis water thruster formed by three layered plates as a top plate, a bottom plate and spray plate with a one-way valve; (2) and a micro-electrolysis water thruster formed by layering top plate and bottom plate with high depth-width rate electrode or plane electrode without one-way valve. Wherein, the electrolysis reaction chamber is between the top and bottom plates which comprises an electrolysis anode and a electrolysis cathode; the burning chamber has a fire electrode; the hydrophobic film is plated on the inner surfaces of electrolysis reaction chamber and the burning chamber; and the one-way valve is between the burning chamber and the micro-spray pipe. The invention can generate hydrogen-oxygen mixed gas via the electrolyte of water to be fired to generate high-temperature high-pressure steam to be sprayed outside the spray pipe to form pushing power, which can improve the specific thrust property, thermal efficiency, responding speed and control accuracy, while its structure is compatible with MEMS to apply the micromation and integration.

Owner:TSINGHUA UNIV

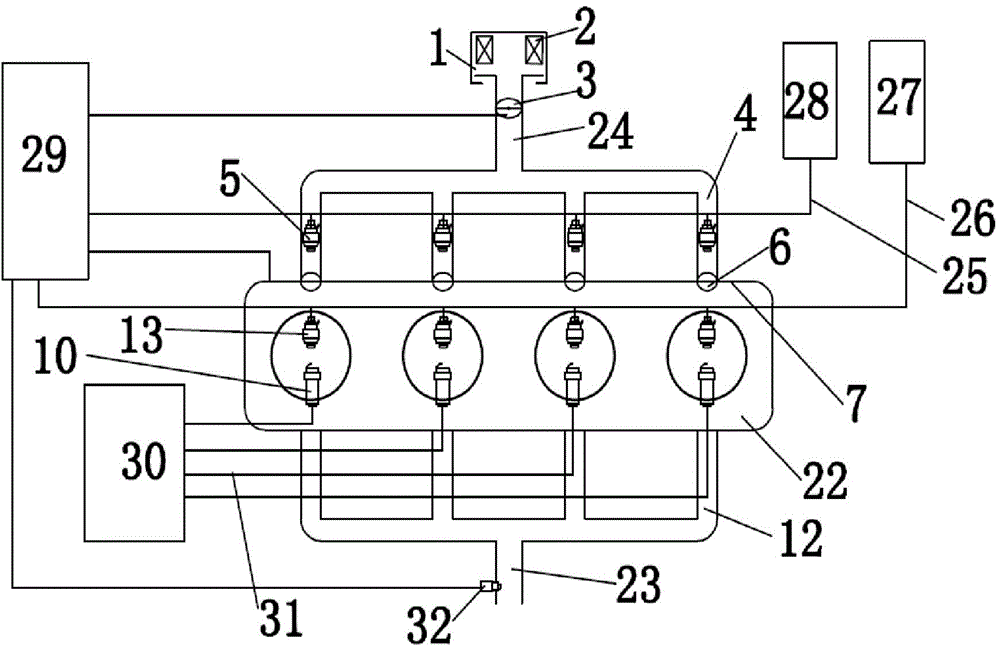

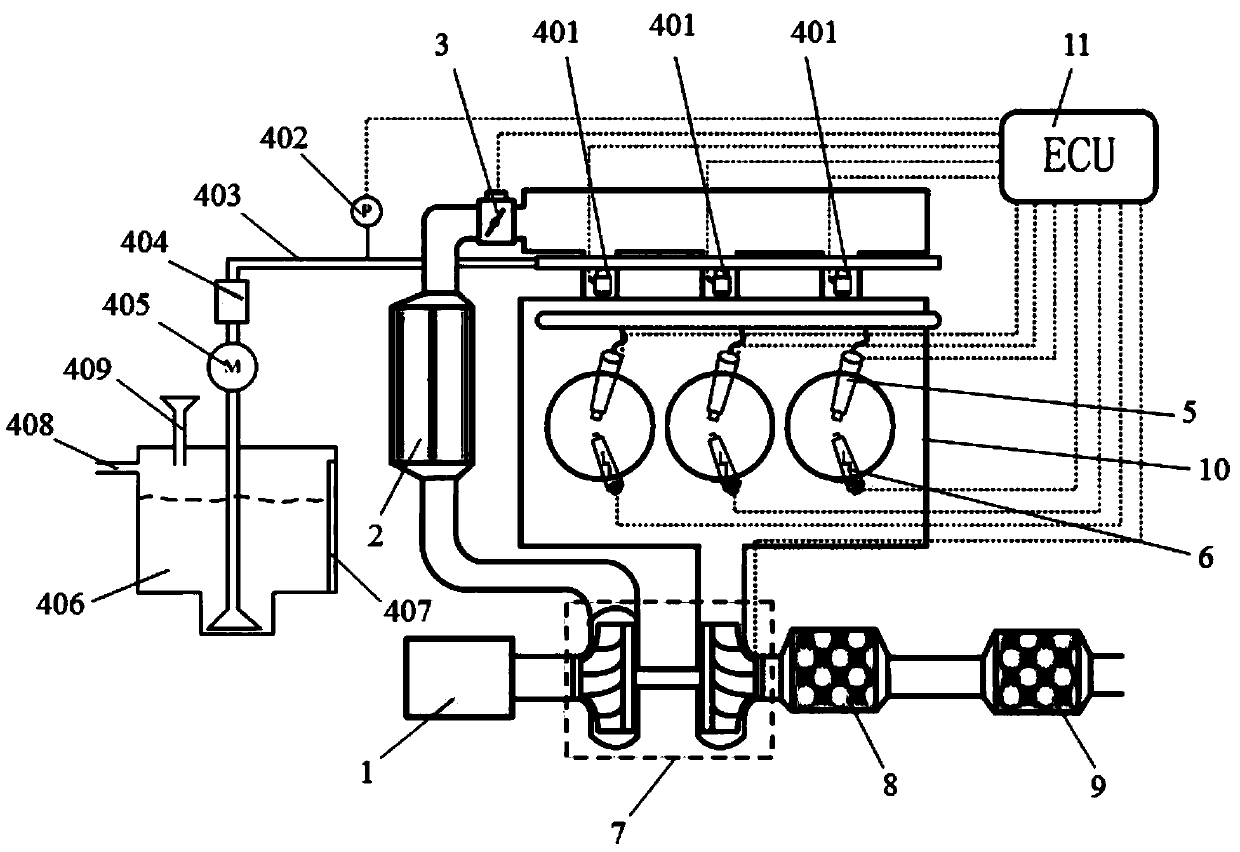

In-cylinder direct injection double-gas-fuel internal combustion engine capable of realizing ultra-lean combustion and control method

InactiveCN104948296ASatisfy lean burn requirementsChange the disadvantage of lack of powerElectrical controlInternal combustion piston enginesInlet channelCombustion

The invention relates to an in-cylinder direct injection double-gas-fuel internal combustion engine capable of realizing ultra-lean combustion and a control method, aims to solve the problems that combustion is unstable in an ultra-lean-combustion mode of a gas fuel spark ignition type internal combustion engine, the oil consumption is high and emission is heavy under the work conditions of cold start and small load and the like and develops a spark ignition type in-cylinder direct injection double-gas-fuel internal combustion engine capable of realizing ultra-lean combustion and a control method of the internal combustion engine. The internal combustion engine adopts an internal combustion engine technology combining in-cylinder direct injection and gas inlet channel injection based on double gas fuel, the internal combustion engine is provided with a gas flow control device which cooperates with a piston roof in a special shape, and accordingly, good mixed gas layering is realized. According to the special combustion characteristic of gas fuel, ultra-lean mixed gas in higher compression ratio can be adopted; gas flow movement of the mixed gas entering a cylinder is controlled, meanwhile, gas inflow is increased, ultra-lean combustion of the mixed gas in the cylinder is realized, the heat transfer loss is reduced, the heat efficiency is improved, and oil consumption and pollutants are reduced.

Owner:JILIN UNIV

Lean burn engine and automobile

ActiveCN111379634AEfficient and clean combustionLower combustion temperatureElectrical controlNon-fuel substance addition to fuelLean combustionWater pipe

The invention belongs to the technical field of engines, and relates to a lean burn engine and an automobile. The lean burn engine comprises a water spraying system and an electric control unit, wherein the water spraying system comprises air flue water sprayers, pressure sensors and a water supply device; the air flue water sprayers are connected with the water supply device through water pipes;the pressure sensors are used for detecting the pressure values of the water pipes and sending the pressure values to the electric control unit; the air flue water sprayers are arranged on air inlet channels of air cylinders of the engine and spray water to the air inlet channels; the electric control unit is in signal connection with the air flue water sprayers and the pressure sensors; and whenthe engine is in different work conditions, the pressure values of the water pipes change, the pressure sensors send corresponding signals to the electric control unit according to the different pressure values of the water pipes, and the electric control unit controls the air flue water sprayers to adjust the water spraying amount. According to the lean burn engine, the electric control unit controls the air flue water sprayers to adjust the water spraying amount according to different engine work conditions (loads), and efficient clean combustion of the engine is achieved.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Combustion system of diesel engine

InactiveCN101825045AReduce quality problemsReduce heat loadInternal combustion piston enginesFuel injection apparatusCombustion systemCombustion chamber

The invention relates to a combustion system of a diesel engine, which belongs to the field of injection and combustion of fuel of diesel engines. The combustion system mainly comprises a combustion chamber, wherein the combustion chamber is arranged at the top of a piston with the diameter smaller than 150mm; and a fuel beam of a fuel injector positioned in the center of a cylinder cover is matched with the combustion chamber. The fuel injector is formed by combining one or more circular injecting holes and combined injecting holes with different hole diameters and matched with a shallow basin type combustion chamber or a shallow omega type combustion chamber by utilizing oil beams with different penetration distances and different spreading angles. Because the combustion system is combined by adopting various injecting holes, the optimal matching between the fuel beams and the combustion chamber is easy for realization; the intense disturbance can be formed when the fuel in injecting sub-holes of the combined injecting holes are converged, the turbulence function is added, and the atomization is improved; and the combustion system which configures a combined injecting hole nozzle with large spray diffusance and a long penetration distance and a short penetration distance of the adjacent fuel beams on the combustion chamber greatly improves the air utilization ratio, promotes combustion, reduces discharge and heat transfer loss and improves economy.

Owner:DALIAN UNIV OF TECH

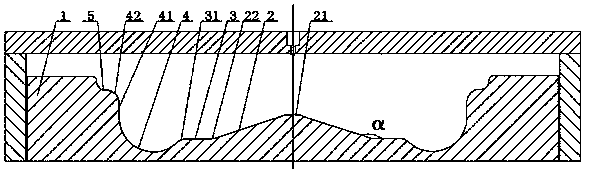

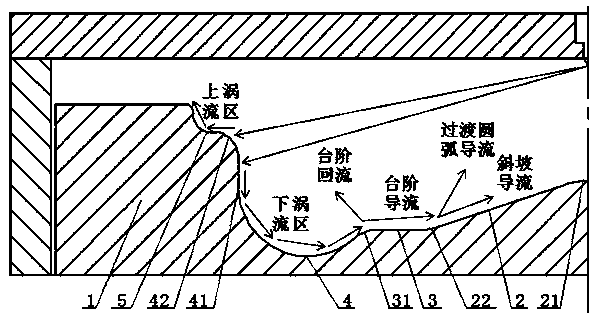

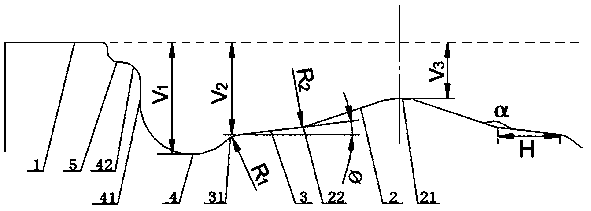

Low-heat-loss diesel engine combustor structure

InactiveCN109162804AImprove scalabilityReduce heat lossInternal combustion piston enginesPistonsCombustorCombustion chamber

A low-heat-loss diesel engine combustor structure comprises an air cylinder piston; a slope flow guiding conical surface and a lower vortex groove are coaxially formed in the top of the air cylinder piston; a flow guiding step surface is arranged between the lower vortex groove and the slope flow guiding conical surface; the included angle alpha between the flow guiding step surface and the slopeflow guiding conical surface is 120 degrees to 165 degrees; the included angle phi between the flow guiding step surface and the top surface of the air cylinder piston is 0 to 30 degrees; upper vortexgroove is formed in the portion, outside the lower vortex groove, of the top of the air cylinder piston; the projection width H of the flow guiding step surface on the top surface of the air cylinderpiston is 1 mm to 6 mm; the slope flow guiding conical surface is connected with the inner circumference of the flow guiding step surface through a first flow guiding arc; and the outer circumferenceof the flow guiding step surface is connected with the lower vortex groove through a second flow guiding arc. Through the design, fuel and flame can expand to the middle of a combustor, fuel is combusted fully, a high temperature region at the bottom of the piston moves to the middle of the combustor, and thus heat loads and heat transfer losses of the combustor are reduced.

Owner:DONGFENG COMML VEHICLE CO LTD

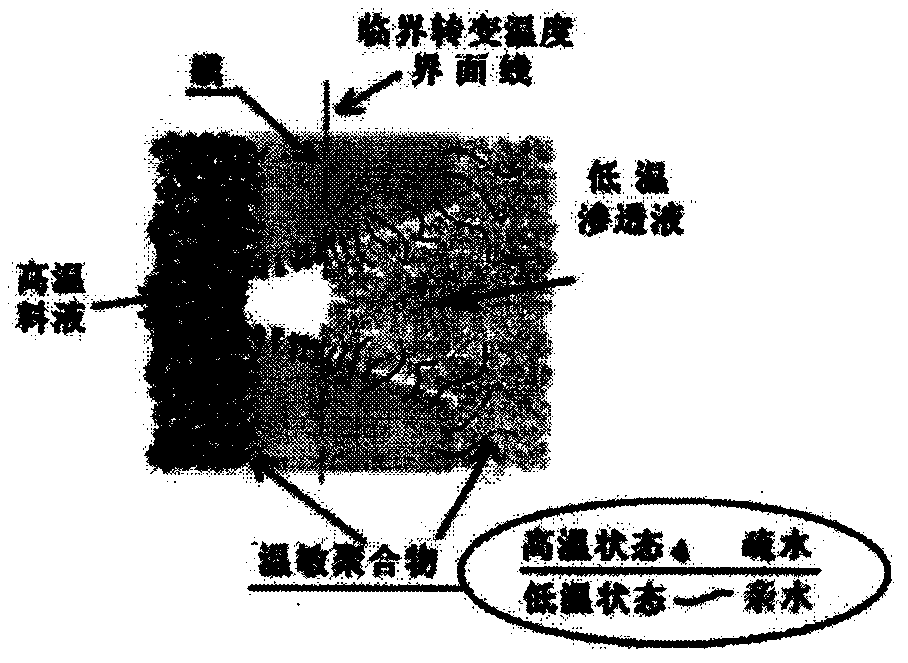

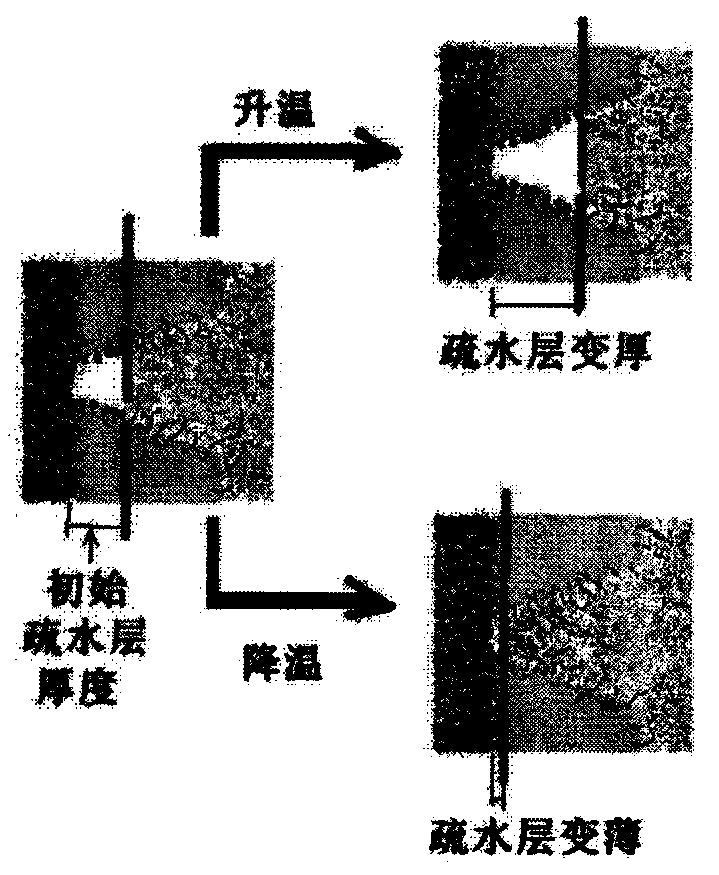

Preparation method for microporous membrane with structural self-regulating characteristics for membrane distillation

ActiveCN108654393AExcellent permeation fluxMass transfer driving force decreasedDistillationMembrane distillationLayer thickness

The invention discloses a preparation method for a microporous membrane with structural self-regulating characteristics for membrane distillation. The microporous membrane is prepared by mixing a temperature-sensitive high-molecular material having hydrophilic / hydrophobic transition characteristics with temperature change and a high-molecular membrane material and adopting a phase separation method, and the obtained microporous membrane has a double-layer membrane structure composed of a hydrophobic layer and a hydrophilic layer, wherein thicknesses of the hydrophobic layer and the hydrophiliclayer can be automatically regulated according to operating temperature in the membrane distillation process. The microporous membrane for the membrane distillation disclosed by the invention has anautomatically-adjustable hydrophobic layer thickness adapted to the operating temperature, greatly reduces mass transfer resistance and improves a permeation flux of the membrane, and at the same time, the corresponding thickened hydrophilic layer can significantly reduce temperature difference polarization and heat transfer loss of the whole membrane, and effectively solve a contradiction betweenmass transfer and heat transfer in the membrane distillation process; and the microporous membrane improves the membrane distillation process characteristics and thermal efficiency, and especially facilitates direct contact type membrane distillation concentration separation by fully utilizing waste heat of a lower-temperature material liquid, and has good application prospects.

Owner:NINGBO UNIV

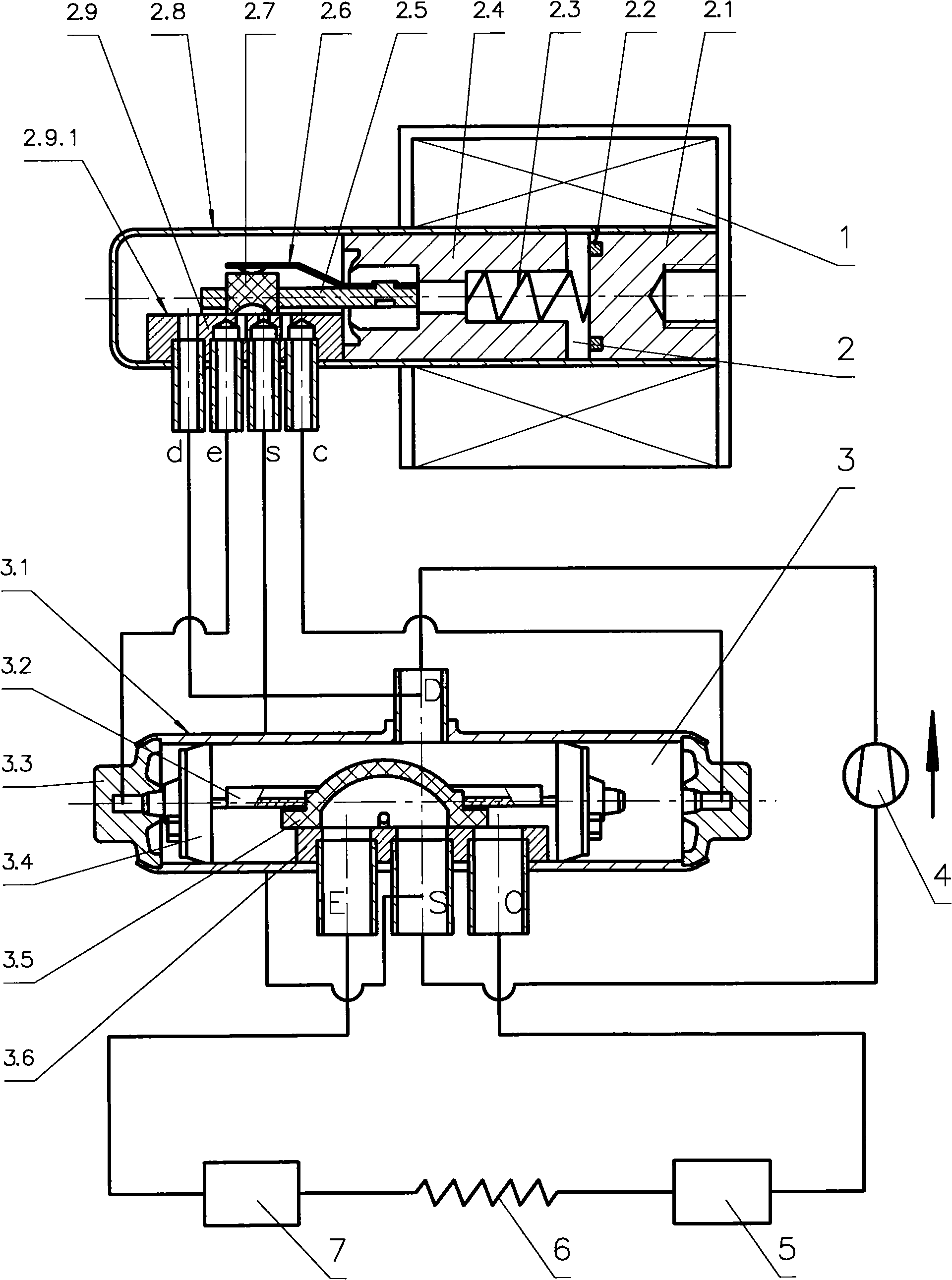

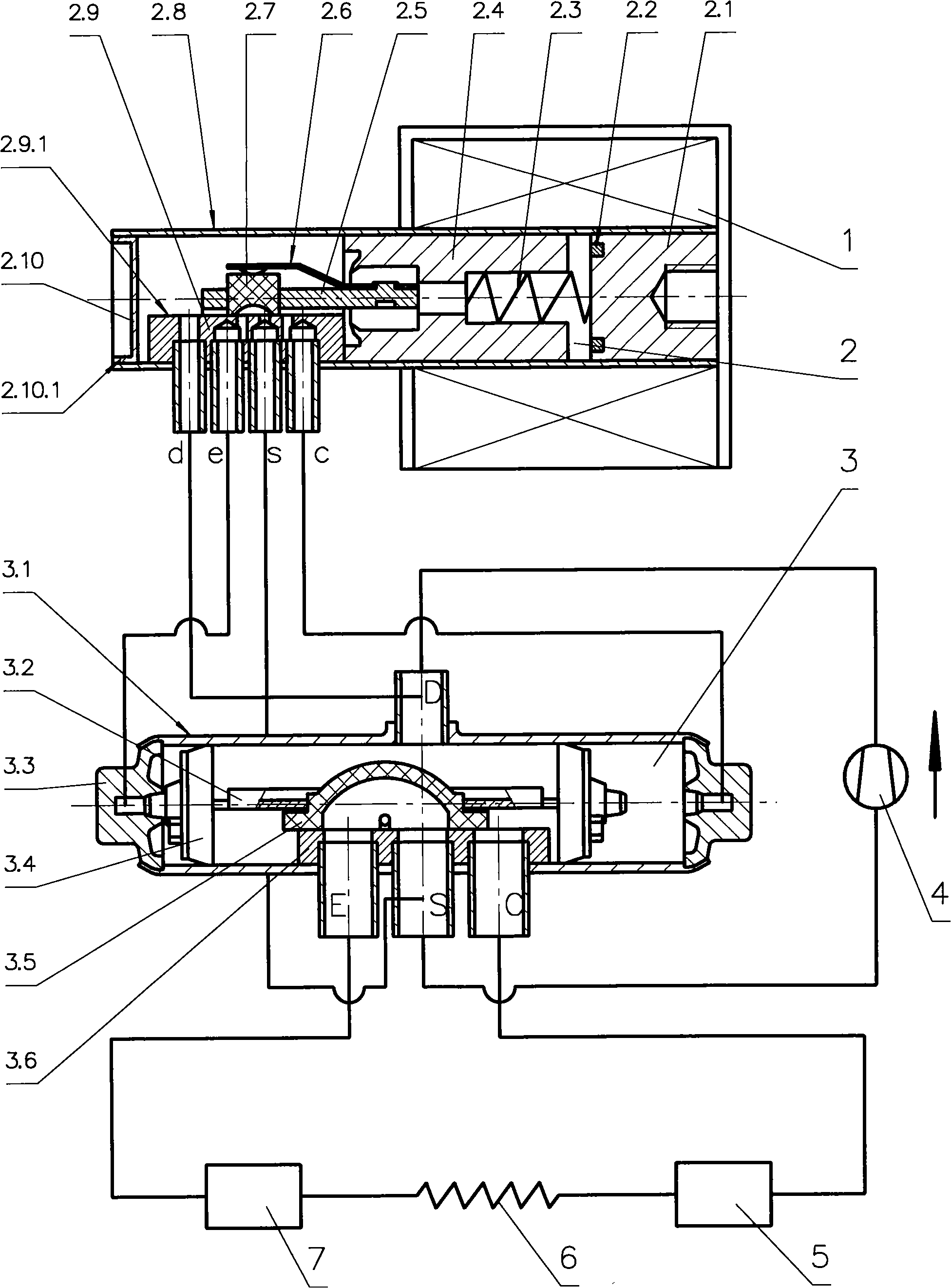

Electromagnetic valve

InactiveCN101338825AEase of precision machiningGuaranteed Surface PrecisionMultiple way valvesValve housingsStructural ProblemEngineering

The present invention relates to a novel electromagnetic valve with a pilot valve structure, which belongs to a system control element in a refrigeration-circulating system. The prior art has the defect that the structural problem causes the injury of the surface quality of a small valve seat, which reduces the qualified rate of products. The electromagnetic valve comprises a main valve, a pilot valve and an electromagnetic coil; wherein, the pilot valve is provided with a bushing; a small valve seat is welded in the cavity of the bushing; the end of the bushing, which is close to the electromagnetic coil, is hermetically welded with an end enclosure, and the other end of the bushing is blocked by an end cover. Since the end of the bushing, which is close to the small valve seat, is blocked by the end cover, both ends of the bushing are open, particularly, the end of the bushing, which is close to the small valve seat, is open, thereby, after being welded, the small valve seat can be precisely processed in order to avoid the injury of the surface quality of the small valve seat caused by welding, ensure the precision degree of the surface of the small valve seat and increase the qualified rate of products. Meanwhile, since the structure is simple, the qualified rate of mass production can be ensured.

Owner:ZHEJIANG SANHUA CLIMATE & APPLIANCE CONTROLS GRP CO LTD

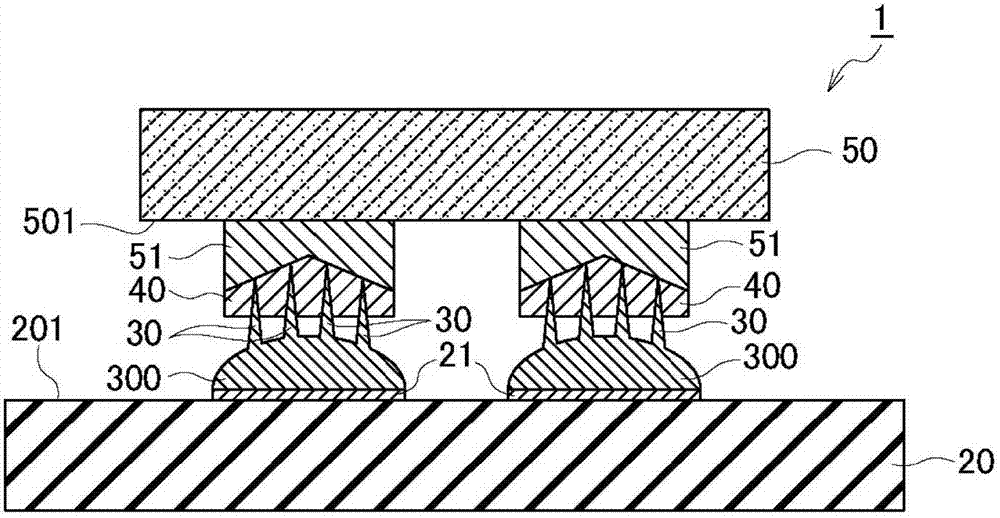

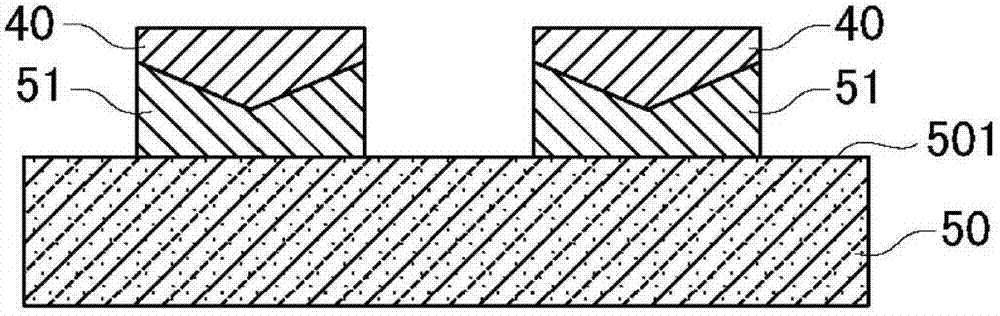

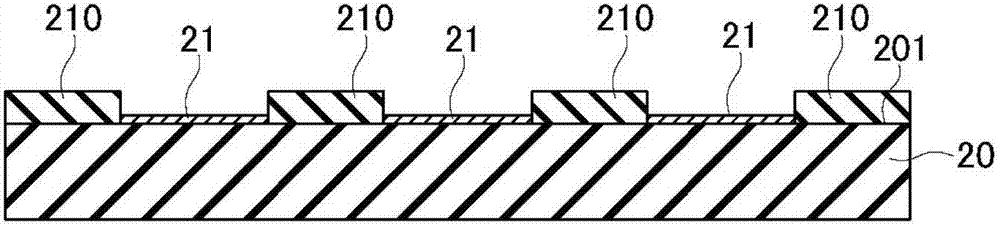

Semiconductor device and manufacturing method thereof

InactiveCN102820269AReduce heat transfer lossSemiconductor/solid-state device detailsSolid-state devicesEngineeringGraphite

The present invention provides a semiconductor device and a manufacturing method thereof. The semiconductor device can be installed with a flip-chip with a little heat loss between a chip and a printing substrate. The semiconductor device comprises: a printing substrate and a chip. The main surface of the printing substrate is configured with a substrate electrode pad with a plurality of spikes composed of graphite on the surface. The main surface of the chip opposite to the substrate electrode pad is provided with a chip electrode pad with conductive resin film contacted with the front ends of the spikes.

Owner:SANKEN ELECTRIC CO LTD

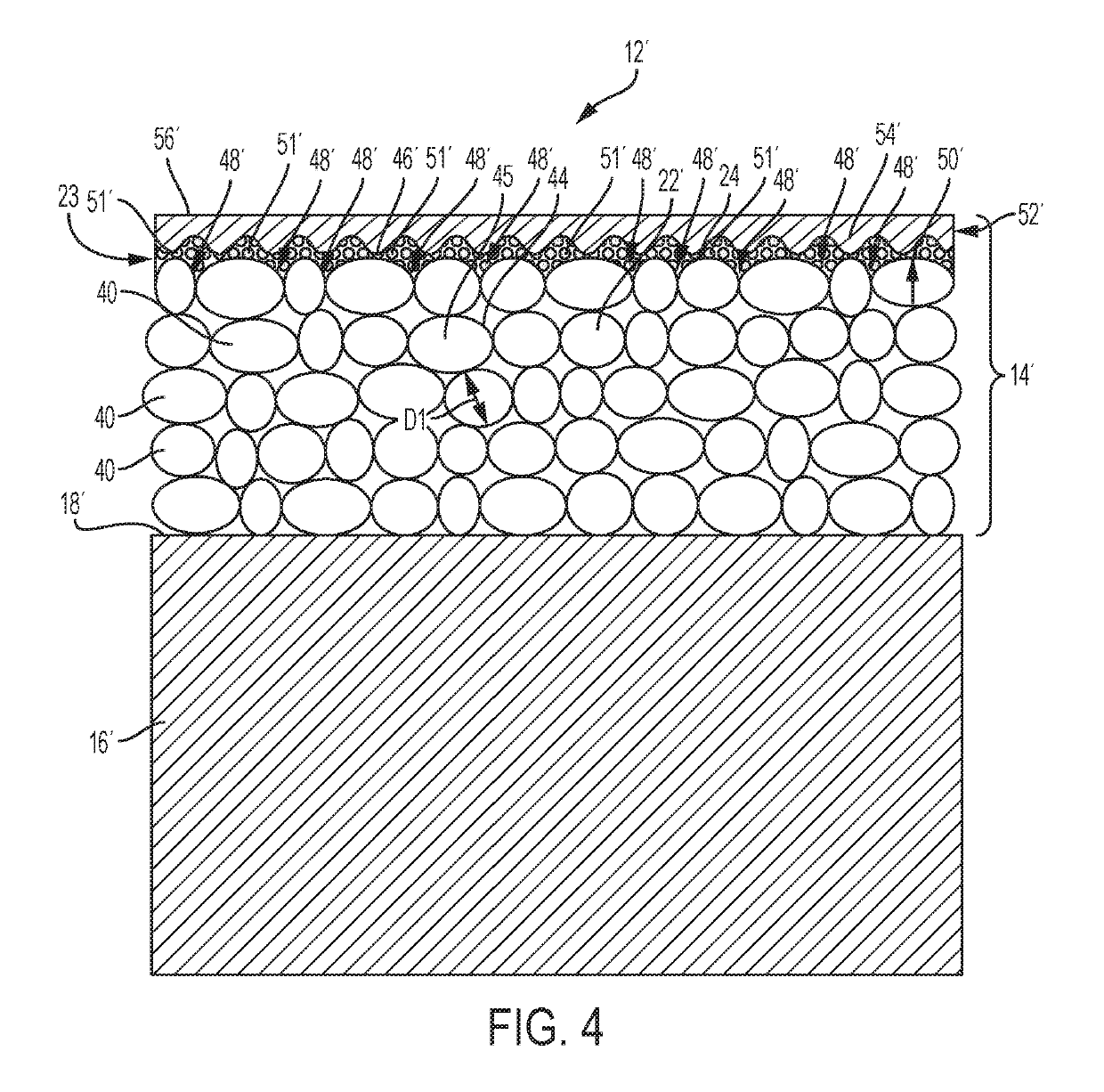

Gap-filling sealing layer of thermal barrier coating

InactiveUS20190194812A1Robust surface contactEffective combinationSuperimposed coating processMetal layered productsMetal particleThermal barrier coating

A multi-layer thermal barrier coating is provided that includes an insulating layer having an outer surface defining a plurality of crevices therein and a sealing layer bonded to the outer surface of the insulating layer. The sealing layer is substantially non-permeable and is configured to seal against the insulating layer. The sealing layer fills in at least a portion of the crevices. A method of forming a thermal barrier coating is also provided, which includes a step of providing a plurality of hollow round microstructures bonded together, each having a diameter in the range of 10 to 100 microns to create an insulating layer. The method further includes depositing a plurality of metal particles onto the insulating layer and heating the plurality of metal particles to form a substantially non-permeable sealing layer over the insulating layer.

Owner:GM GLOBAL TECH OPERATIONS LLC

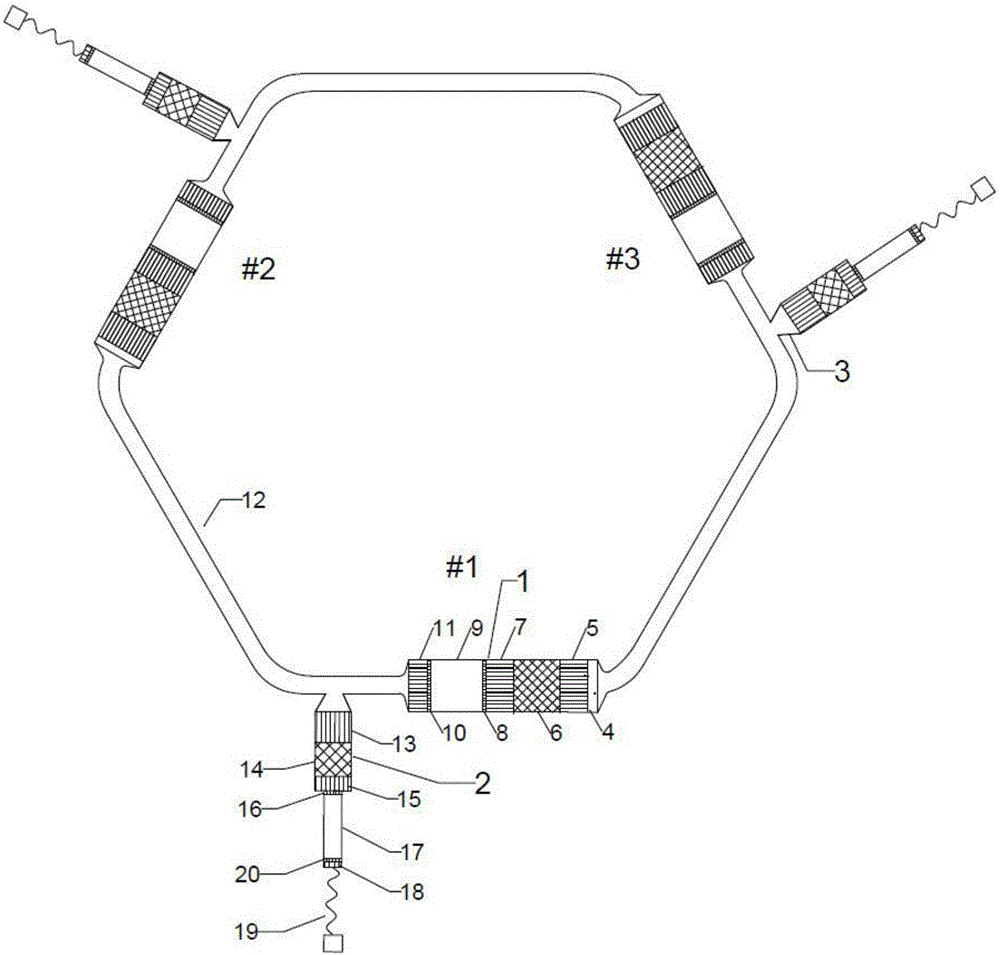

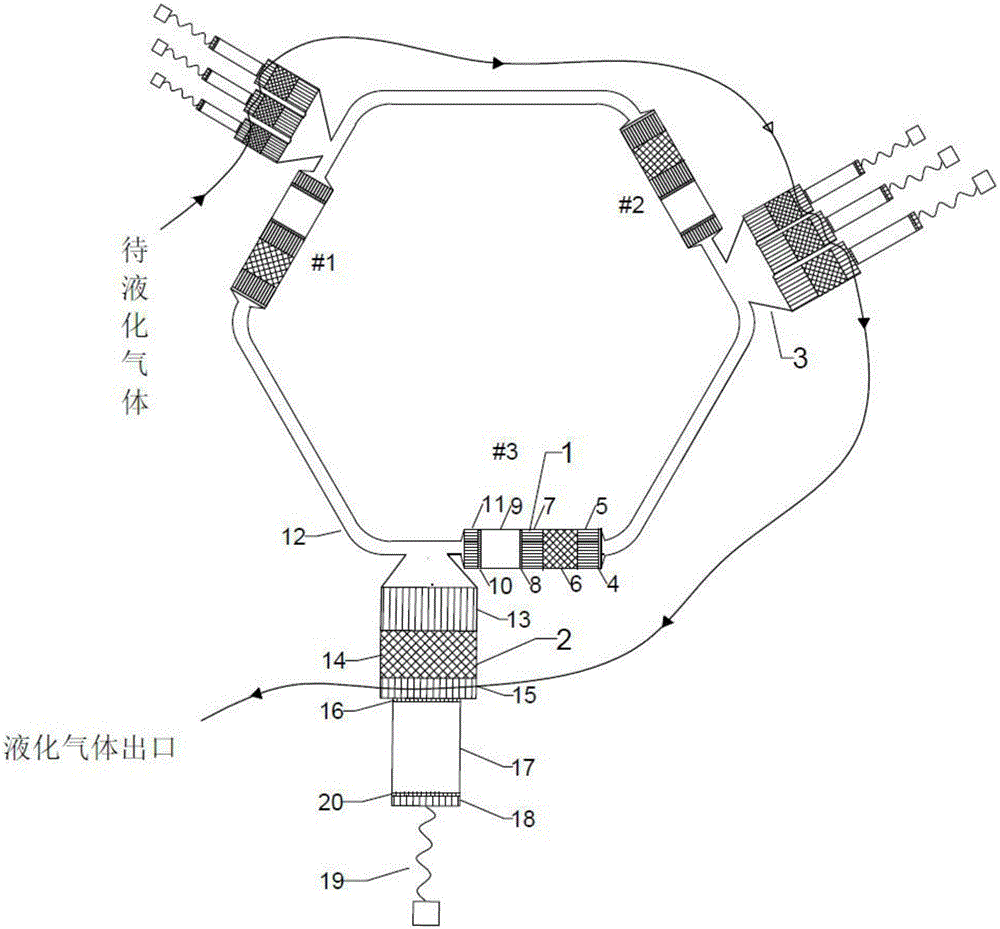

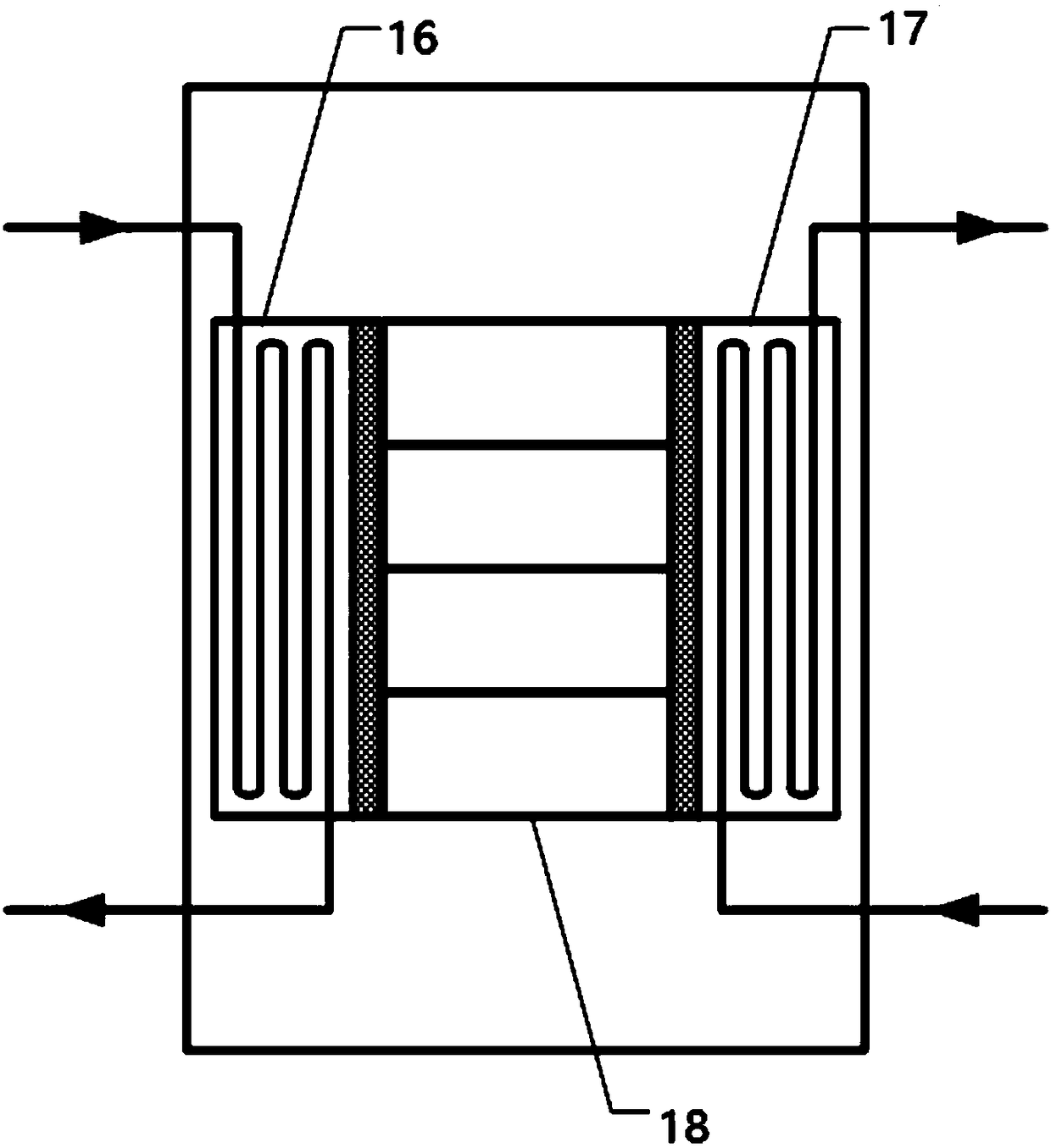

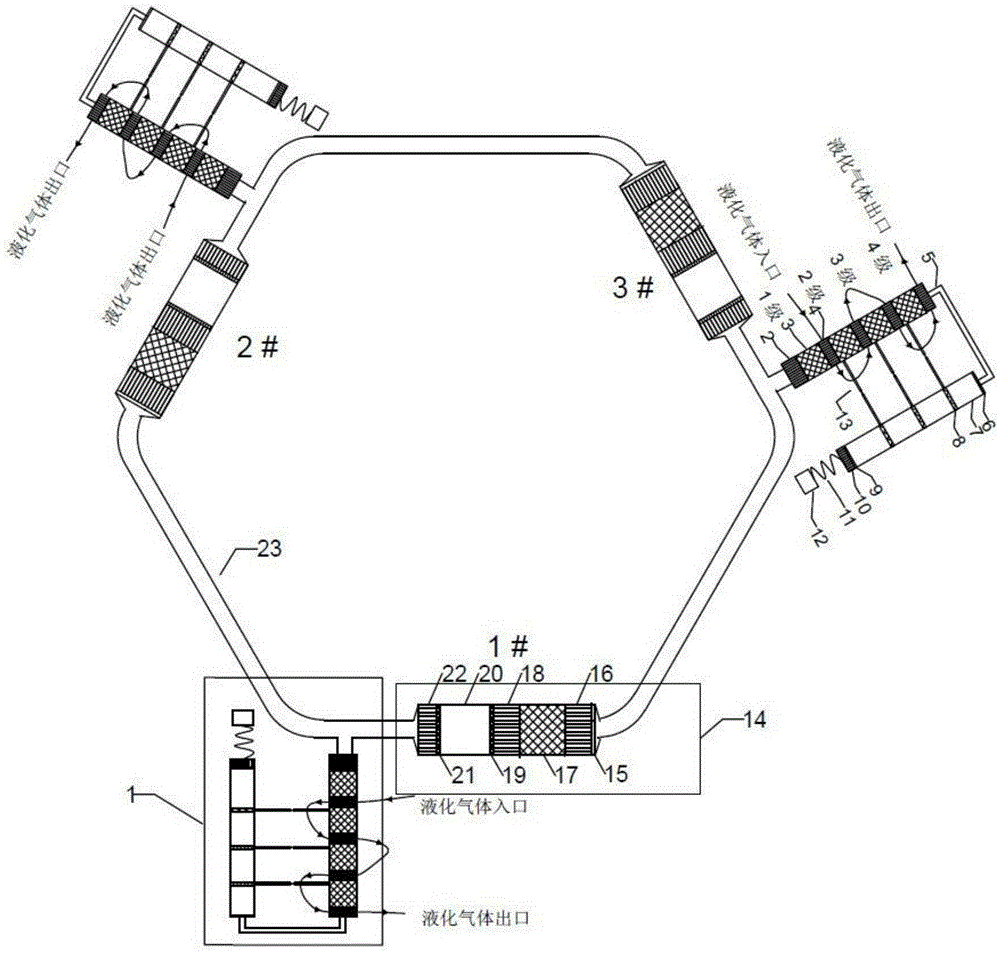

Gas multi-stage liquefying plant driven by acoustic resonance type thermo-acoustic engine

ActiveCN105066499AReduce the temperatureReduce heat transfer lossCompression machinesGas cycle refrigeration machinesLiquid statePulse tube refrigerator

The invention provides a gas multi-stage liquefying plant driven by an acoustic resonance type thermo-acoustic engine. The gas multi-stage liquefying plant is compedos of N stages of thermo-acoustic engine units of a loop structure and N stages of bypasses, wherein the loop structure is formed by connecting resonant tubes end to end; the N stages of bypasses are arranged in engine secondary water cooler outlets; the Nth-stage bypass is connected with a pulse tube refrigerator unit, and the rest bypasses are connected with at least three pulse tube refrigerator units; in the working process, engine heaters are heated, a system generates reciprocating oscillation pressure fluctuation and generates thermo-acoustic conversion in refrigerator heat regenerators, cold end heat is sent to refrigerator main coolers, and cold ends are kept at low temperatures; along with increase of the number of the stages of the bypasses, the temperatures of the cold ends are gradually reduced to the gas liquefaction temperature; gas sequentially flows through the cold ends of the first-stage bypass to the (N-1)th-stage bypass according to the cold end temperatures from high to low, sensible heat is released, and the temperatures are reduced to the liquefaction temperature; and the gas finally passes the cold end of the Nth-stage bypass to be transformed in a liquid state from a gas state. The temperature of the gas can be reduced in a gradient manner and heat transfer losses are reduced; and no mechanical moving part exists, the structure is compact, and the whole process of gas liquefaction can be achieved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Compressed action independent-chamber reciprocating type four-stroke engine

InactiveCN101054920AReduce lossIncrease inflation coefficientInternal combustion piston enginesValve drivesFour-stroke engineEngineering

Two adjacent combustion chambers of existing four-stroke engine, one is only used for inspiration to compress, another is only used for expansion apply work to exhaust, the cylinder cover for compressing is not provided with an exhaust fungus valve and an exhaust passage for exhausting waste gas of the existing engine, the cylinder cover for apply work is not provided with an air intake fungus valve and an air intake channel for snifting of the existing engine, a channel is on the cylinder cover to communicate two cylinders, and is provided with a one way air valve for draining compressed gas into the channel on cylinder end for compressing, and is provided with an air valve with certain time obstruct channel closing to the cylinder end for apply work, catalysts are coated on the channel wall of the cylinder end for apply work or a heat accumulator is provided in the channel. The engine adopts catalysis or heat accumulation ignition, the combustion is completely exhausted, the structure is more simple than that of the existing reciprocating type four-stroke engine, the weight is lost and the efficiency is improved to realize that the expansion volume is larger than the compression volume.

Owner:陈崟

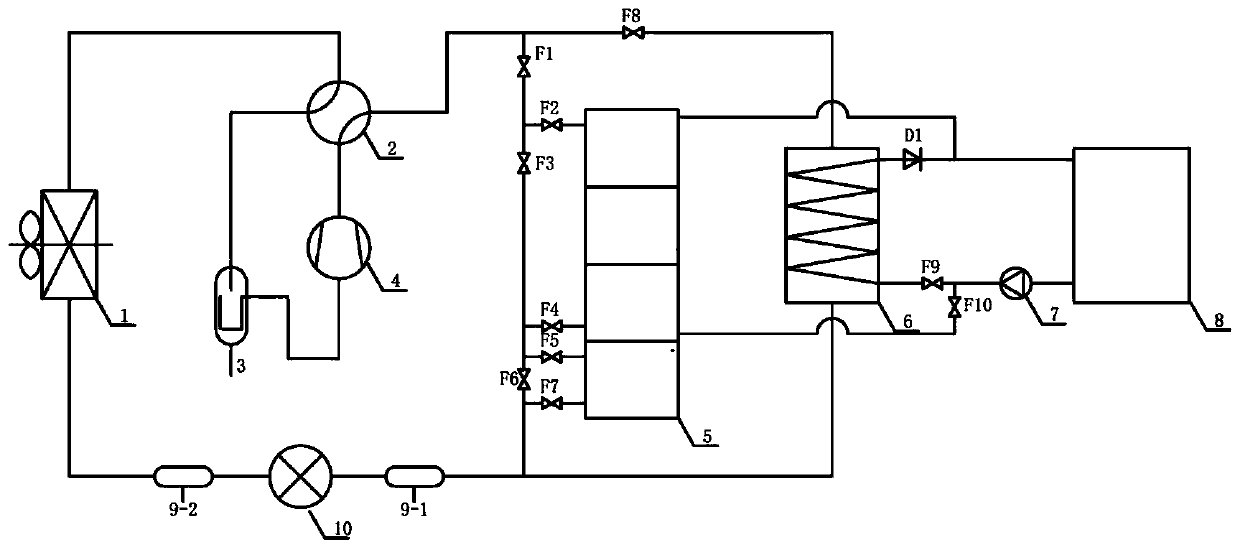

Air source heat pump heating system capable of cascade heat storage, heat supply and defrosting

PendingCN111140899AFlexible operationMaximize energy savingCentral heating with accumulated heatHeat storage plantsCirculator pumpEngineering

The invention discloses an air source heat pump heating system capable of cascade heat storage, heat supply and defrosting. The air source heat pump heating system involves a refrigerant circuit and aheating hot water circuit, wherein the refrigerant circuit involves an evaporator, a four-way reversing valve gas-liquid separator, a compressor, a cascade phase change heat storage device, a condenser, a filter and an expansion valve; and the heating hot water circuit comprises the cascade phase change heat storage device, the condenser, a hot water circulation pump, and a heating end device. According to the air source heat pump heating system, compared with the prior art, stored heat can be directly used for heating, the intermediate link is greatly reduced, and the energy utilization efficiency of the system is improved; the system can achieve six operational mode adjustments according to working conditions, and the economic benefits and the energy-saving benefits are maximized; and the cascade phase change heat storage device provided by the air source heat pump heating system can be divided into a middle-low-temperature heat storage unit for heating and a lower-temperature heatstorage unit for defrosting of a heat pump, so that the cascade utilization of the heat is realized.

Owner:TIANJIN UNIV

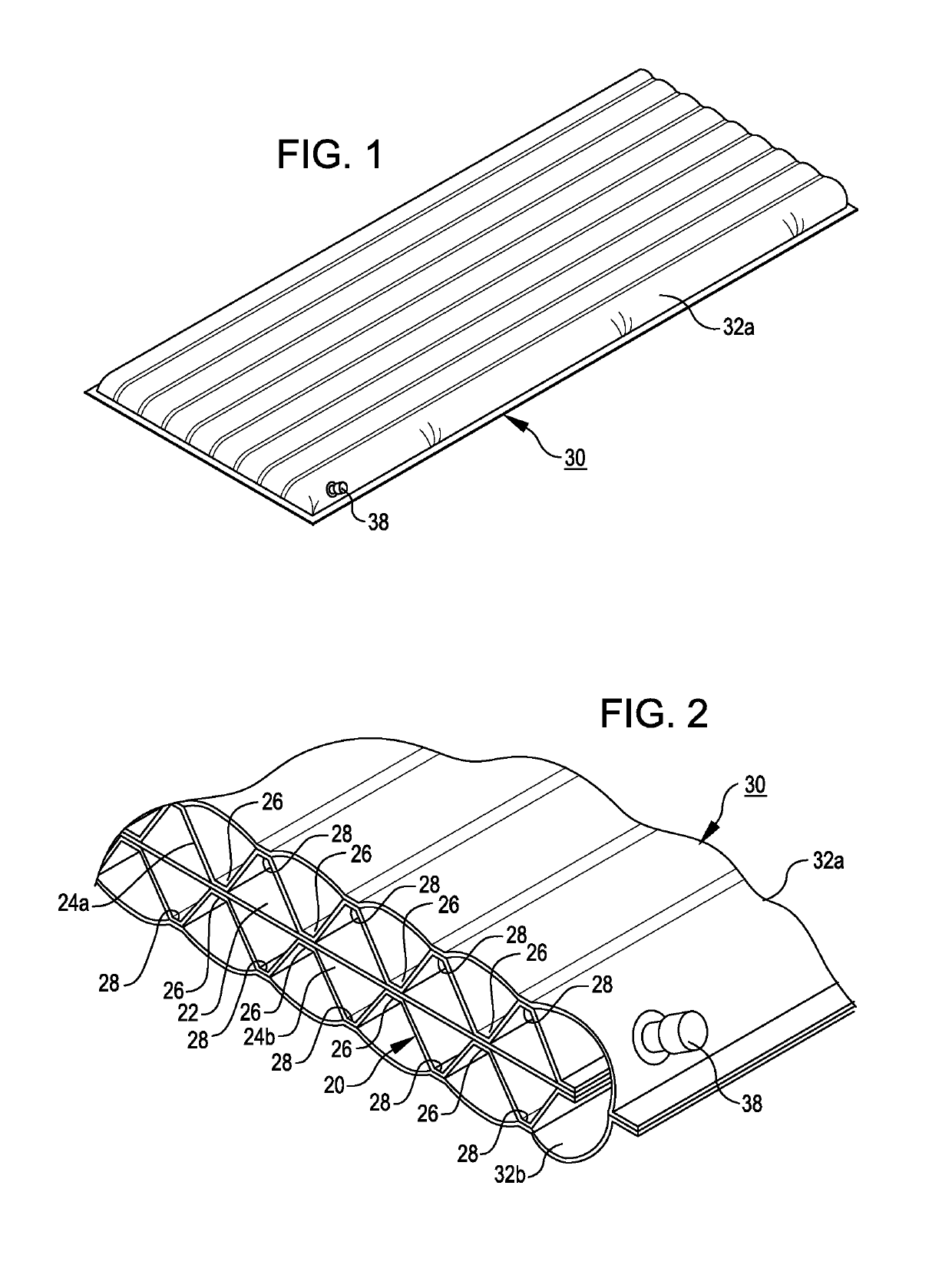

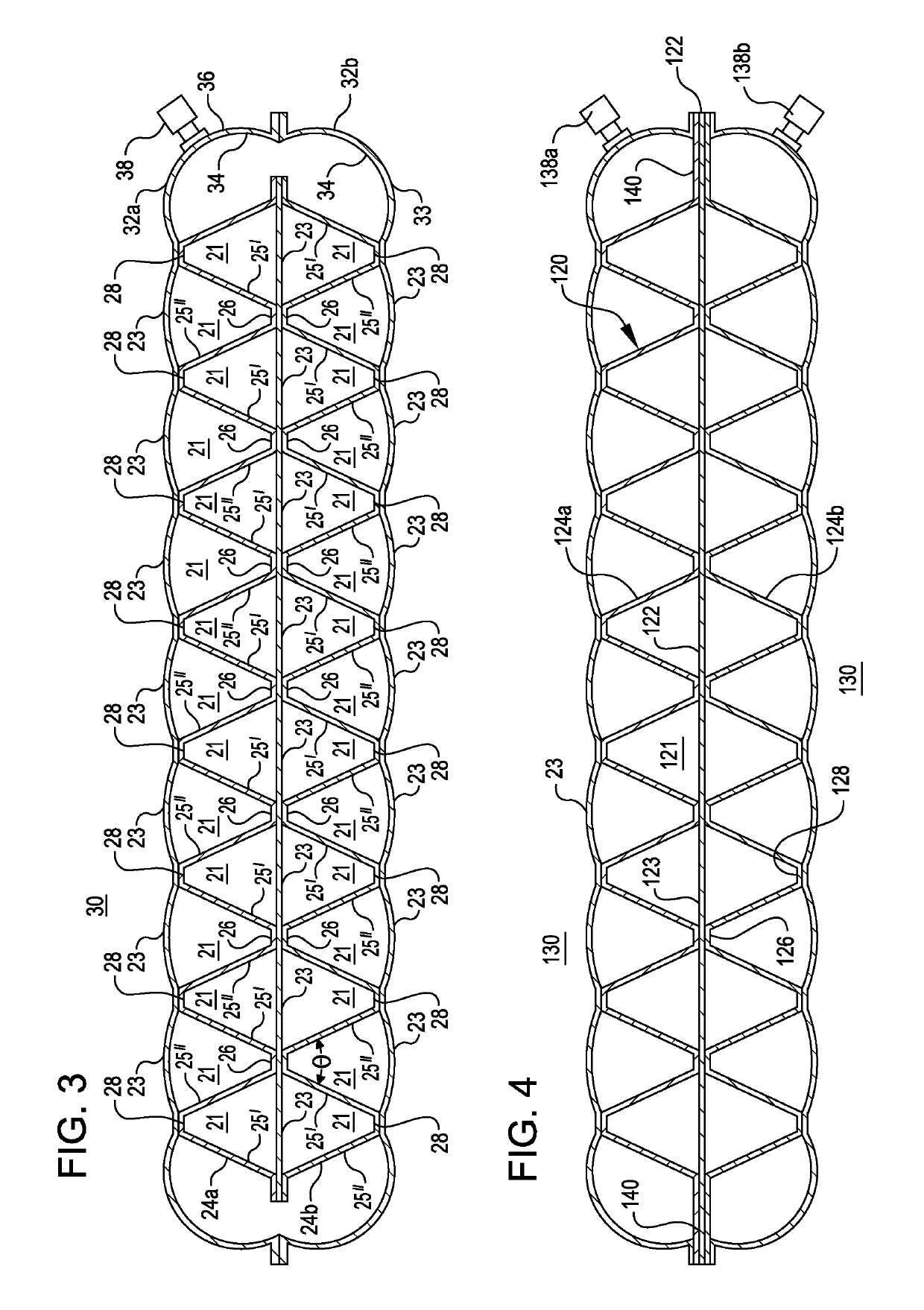

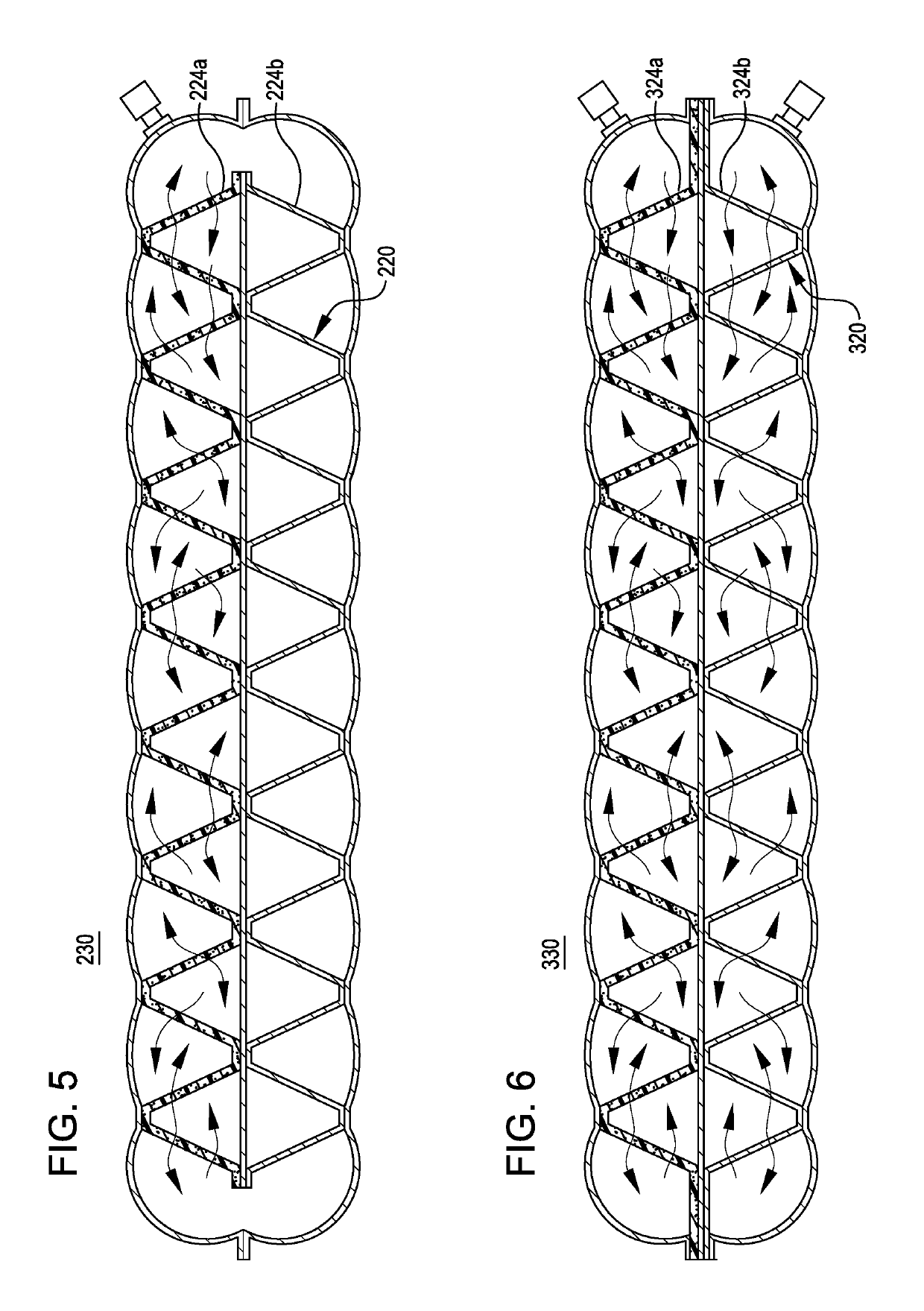

Cellular matrix with integrated radiant and/or convection barriers particularly for use with inflatable bodies

ActiveUS10384414B2Improve thermal efficiencyLong (or “high”PrismsTransportation and packagingCombined useEngineering

Cellular matrices generally having a plurality of generally identical cells (open-ended geometric prisms) arranged to form a repeating geometric form, and characterized by radiant and / or convection barriers at each cell to mitigate undesired thermal transmission in a plurality of directions there through. Barriers of various embodiments include non-film sheet material, such as non-woven (e.g., spun) or batting-type sheet material as well as a foam sheet material, which may be substituted for some or all of the film material otherwise comprising the matrix, and / or integration of a thermally reflective film or coating into the matrix and / or enveloping panels of an inflatable body to provide enhanced thermal radiation mitigation means. When used in conjunction with inflatable bodies, axes of the cells are oriented parallel to exteriorly exposed panels that define the chamber of the inflatable body in which the matrix is disposed, and in certain embodiments the panels defining the chamber also comprise portions of the matrix.

Owner:CASCADE DESIGNS INC

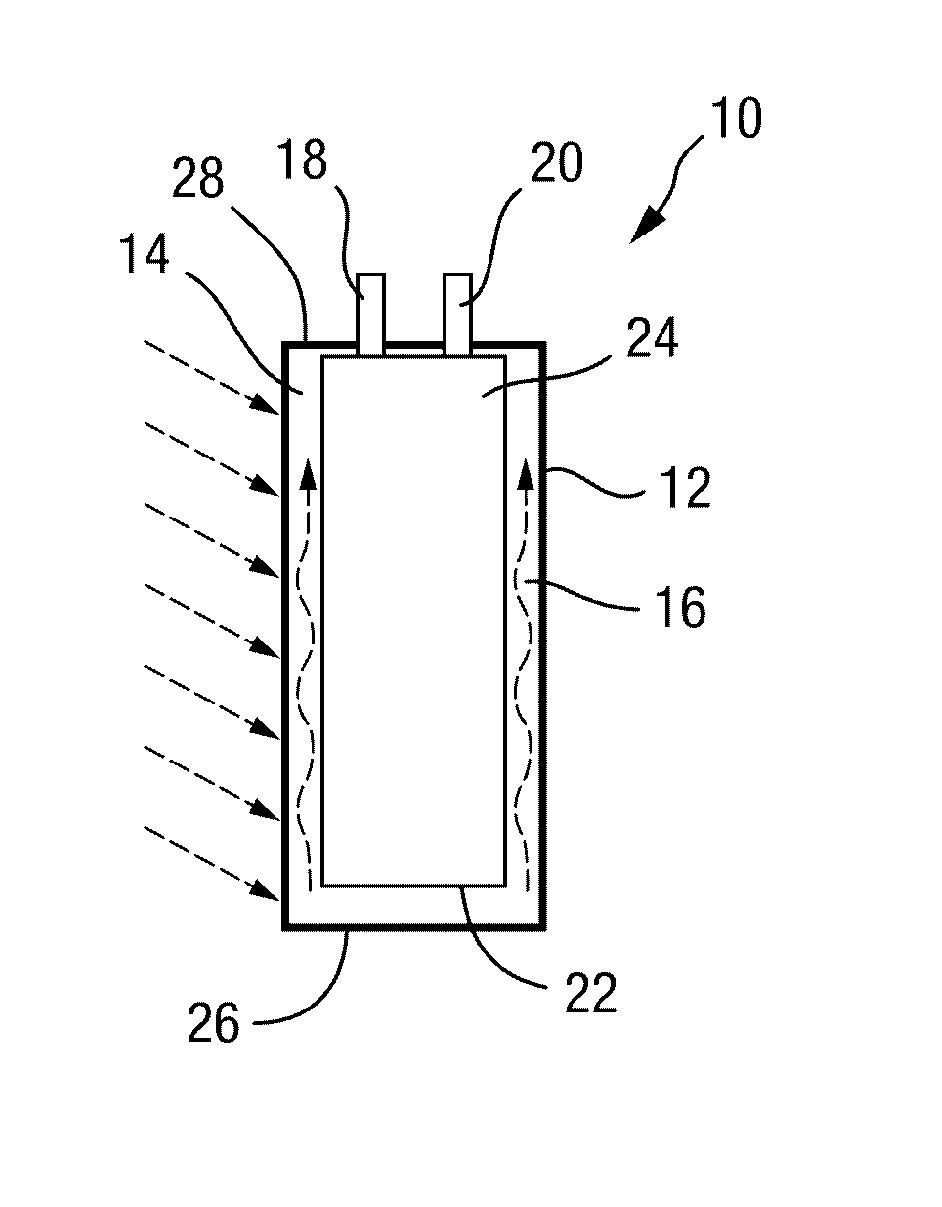

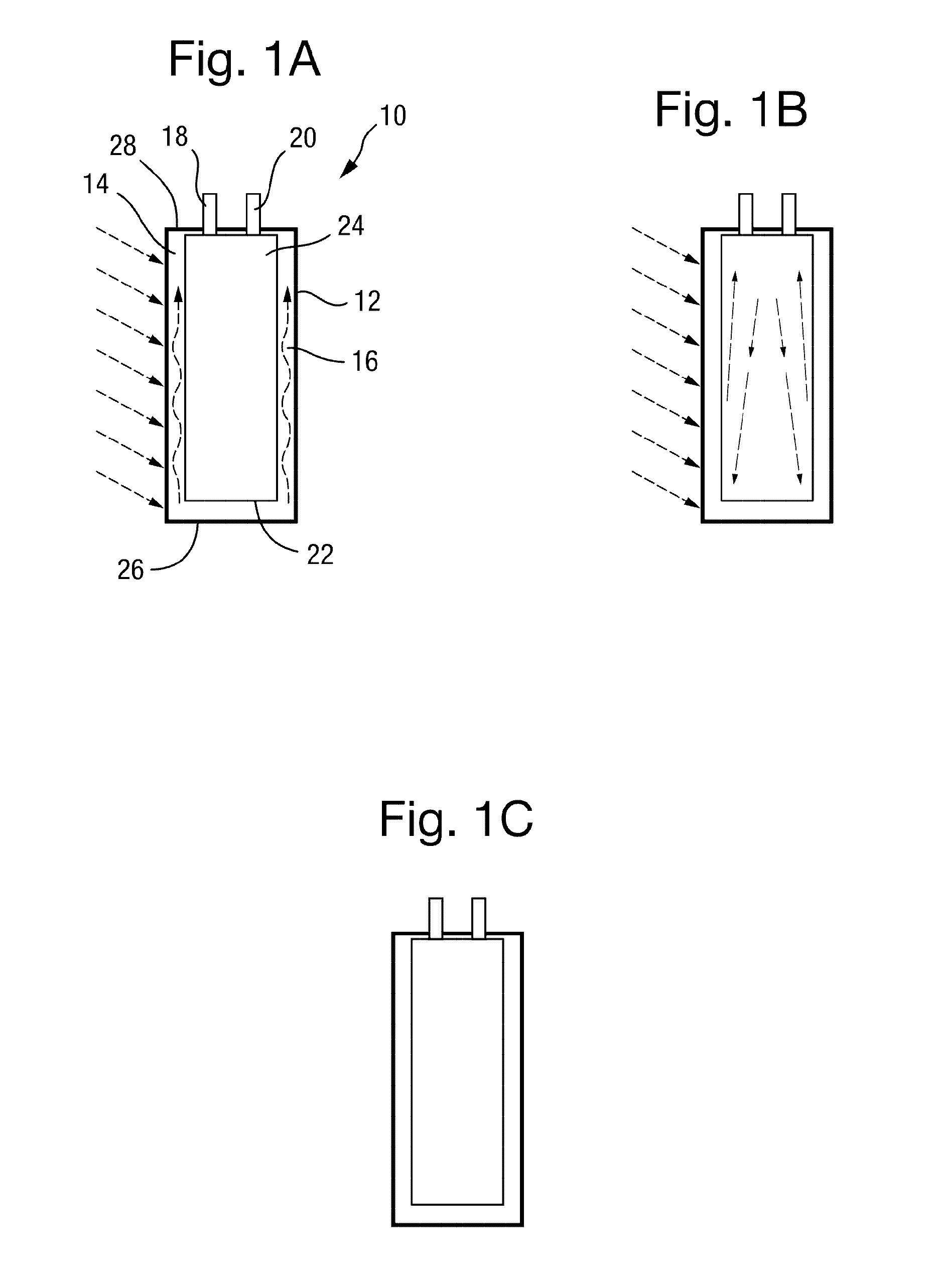

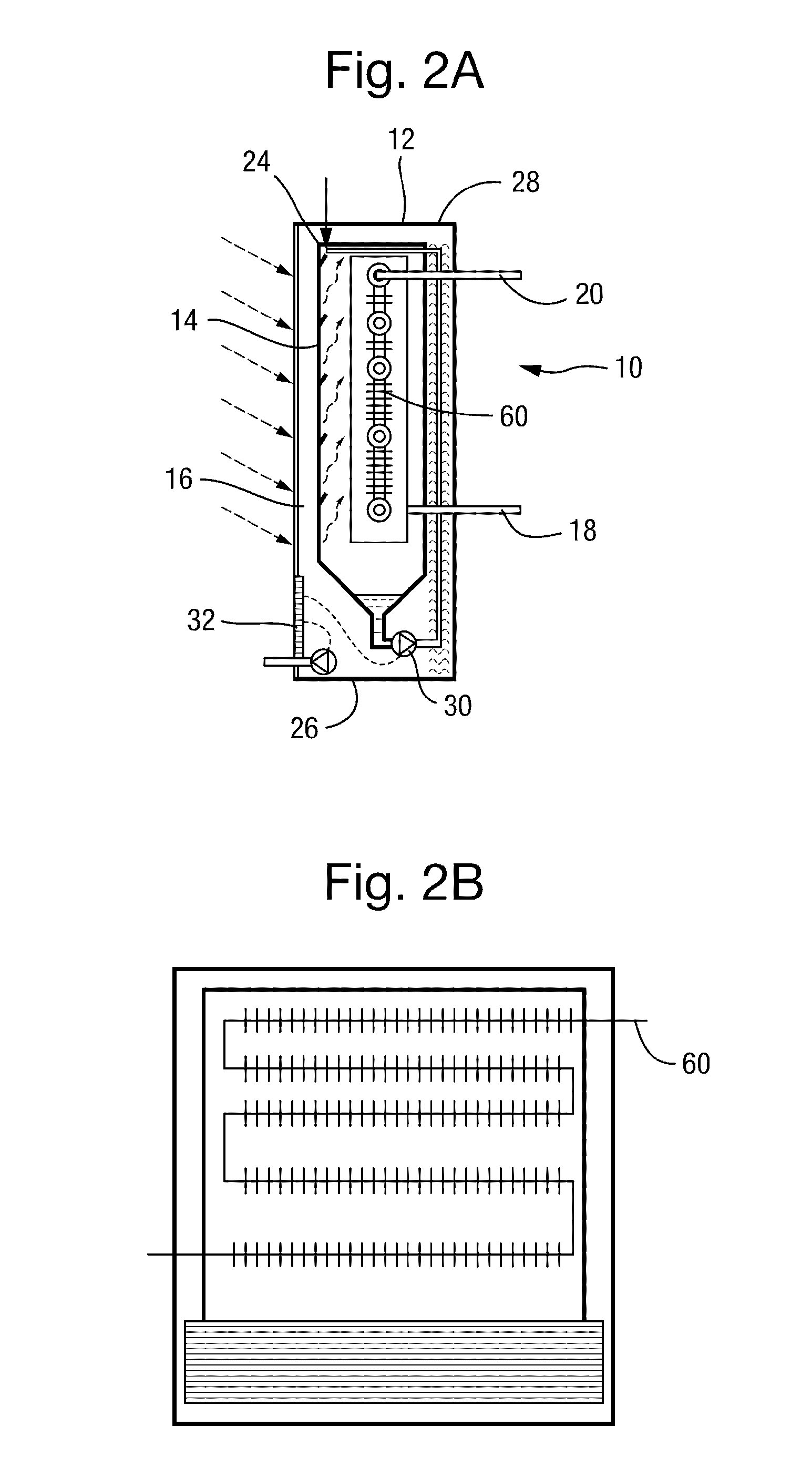

Solar Water Heater

InactiveUS20150204582A1Reduce heat transfer lossFast heat transferSolar heating energySolar heat devicesSolar waterEngineering

A solar water heating apparatus comprising inner and outer concentrically arranged vessels; a cavity defined between the vessels by an outer wall of the inner vessel and an inner wall of the outer vessel; a liquid-to-vapour phase change material provided in the cavity; an inlet for delivering unhealed water to the Inner vessel; and an outlet or withdrawing heated water from the inner vessel, and a pump which pumps the phase change material towards the inner wall of the outer vessel.

Owner:UNIVERSITY OF ULSTER

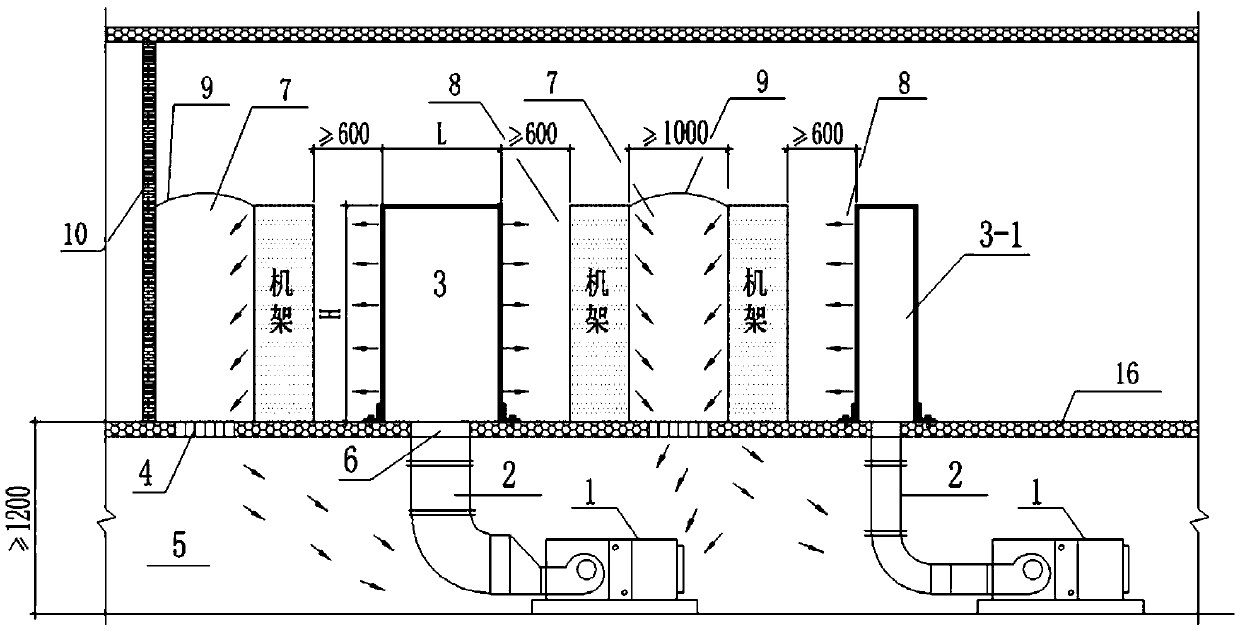

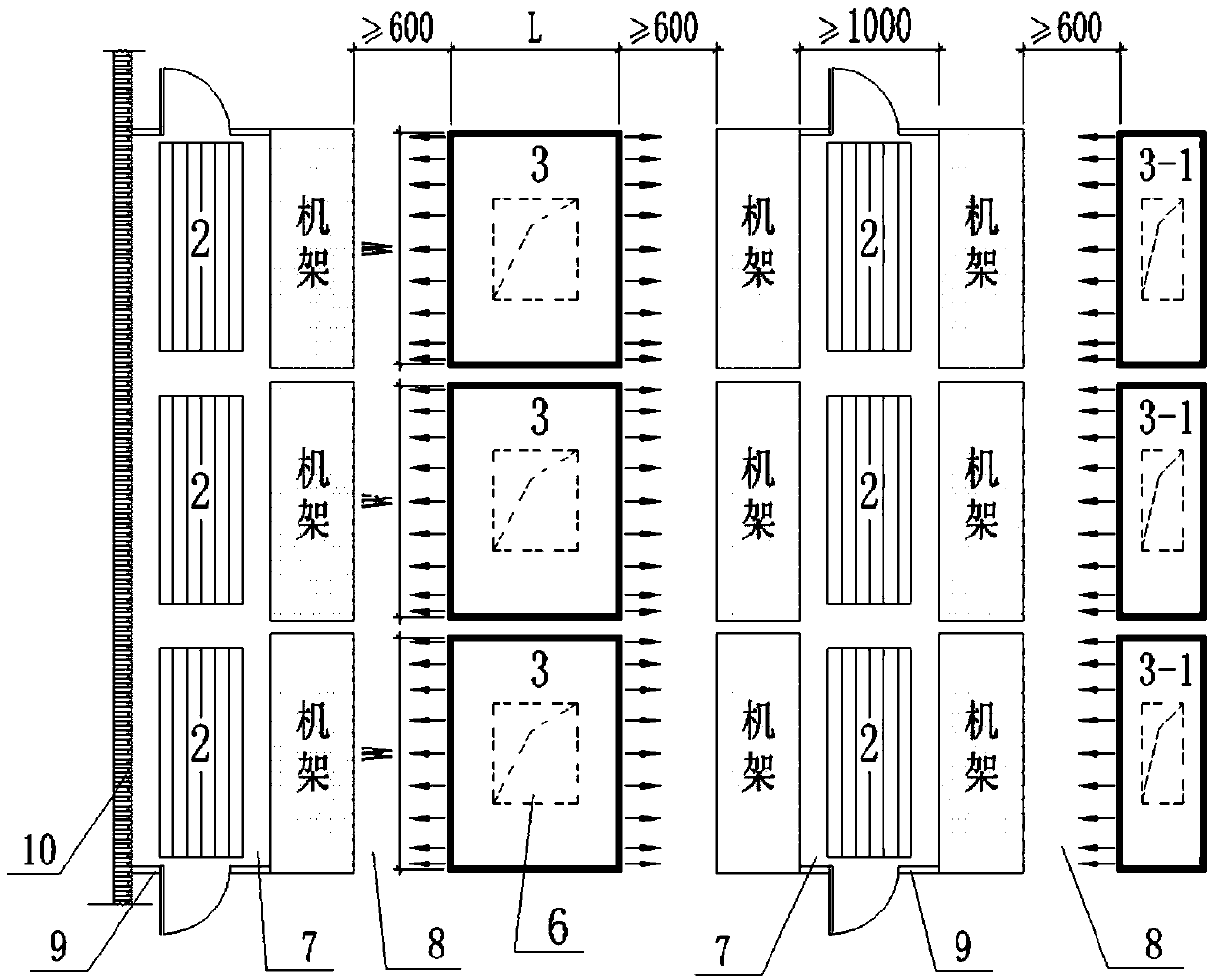

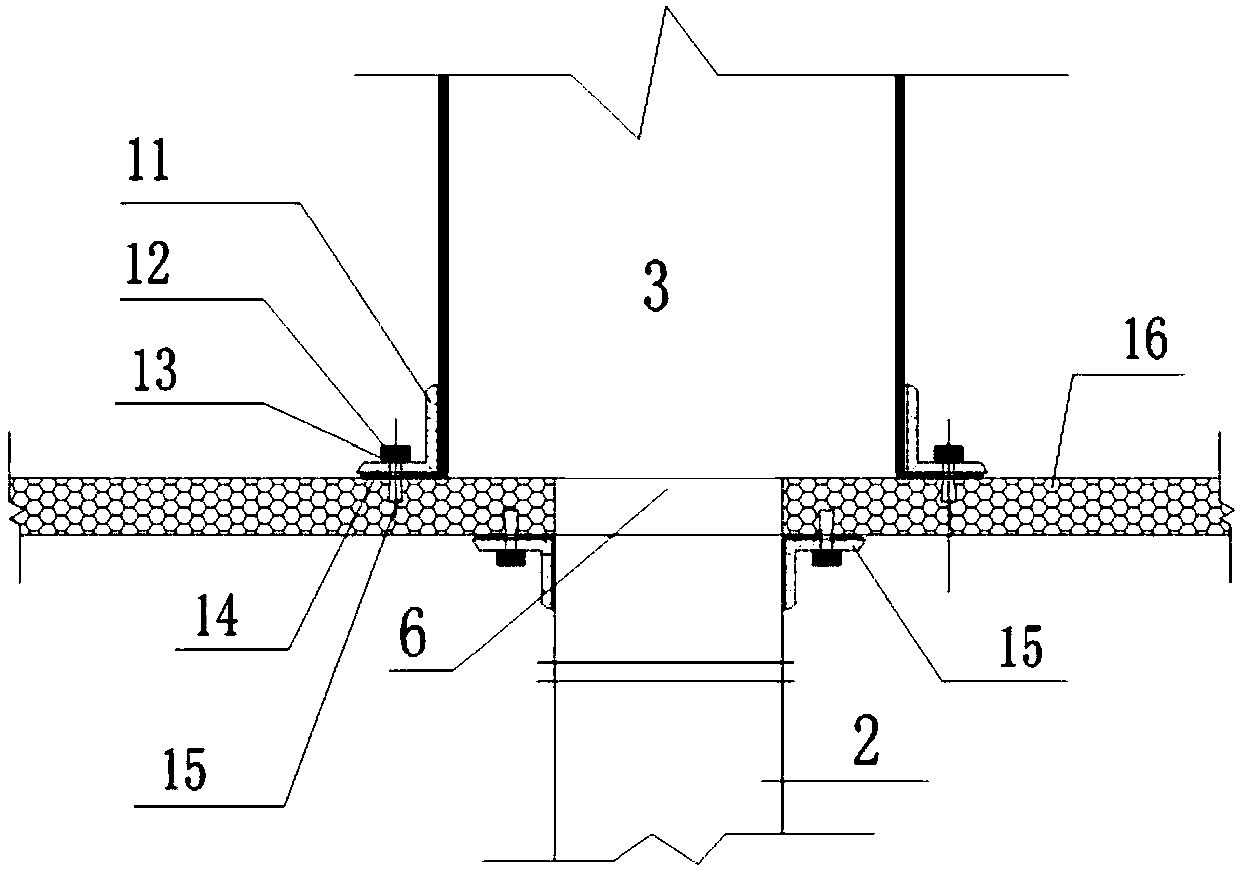

Novel special air conditioning system for data center computer room

InactiveCN109661158AImprove distributionSafe and stable operationCooling/ventilation/heating modificationsCold airData center

The invention relates to a novel special air conditioning system for a data center computer room. The novel special air conditioning system comprises an air treatment device, an air supply duct, a pore plate static-pressure air supply cabinet, a floor air return outlet and a floor air return static-pressure box. The floor air return static-pressure box is a computer room floor overhead layer. Theair treatment device is disposed in the computer room floor overhead layer or in an air conditioner room near the data center computer room. The pore plate static-pressure air supply cabinet is disposed in a cold passage. The floor air return outlet is disposed on the floor of a hot passage. The air is treated by the air treatment device and then is converted into cold air. The cold air passes through the air supply duct, enters the pore plate static-pressure air supply cabinet through an air supply hole at the bottom of the pore plate static-pressure air supply cabinet, and then enters an equipment cabinet for hot and cold exchange. The return air enters the floor air return static-pressure box from the air return outlet and is mixed with the outdoor fresh air in the air treatment device.The lower space of the overhead floor of the computer room is used as the air return static-pressure box to reduce a heat transfer loss. The pore plate static-pressure air supply cabinet and an IT cabinet achieve face-to-face air supply, so as to improve the distribution of the air supply airflow, and ensure the safe and stable operation of the computer room equipment.

Owner:GUANGZHOU UNIVERSITY

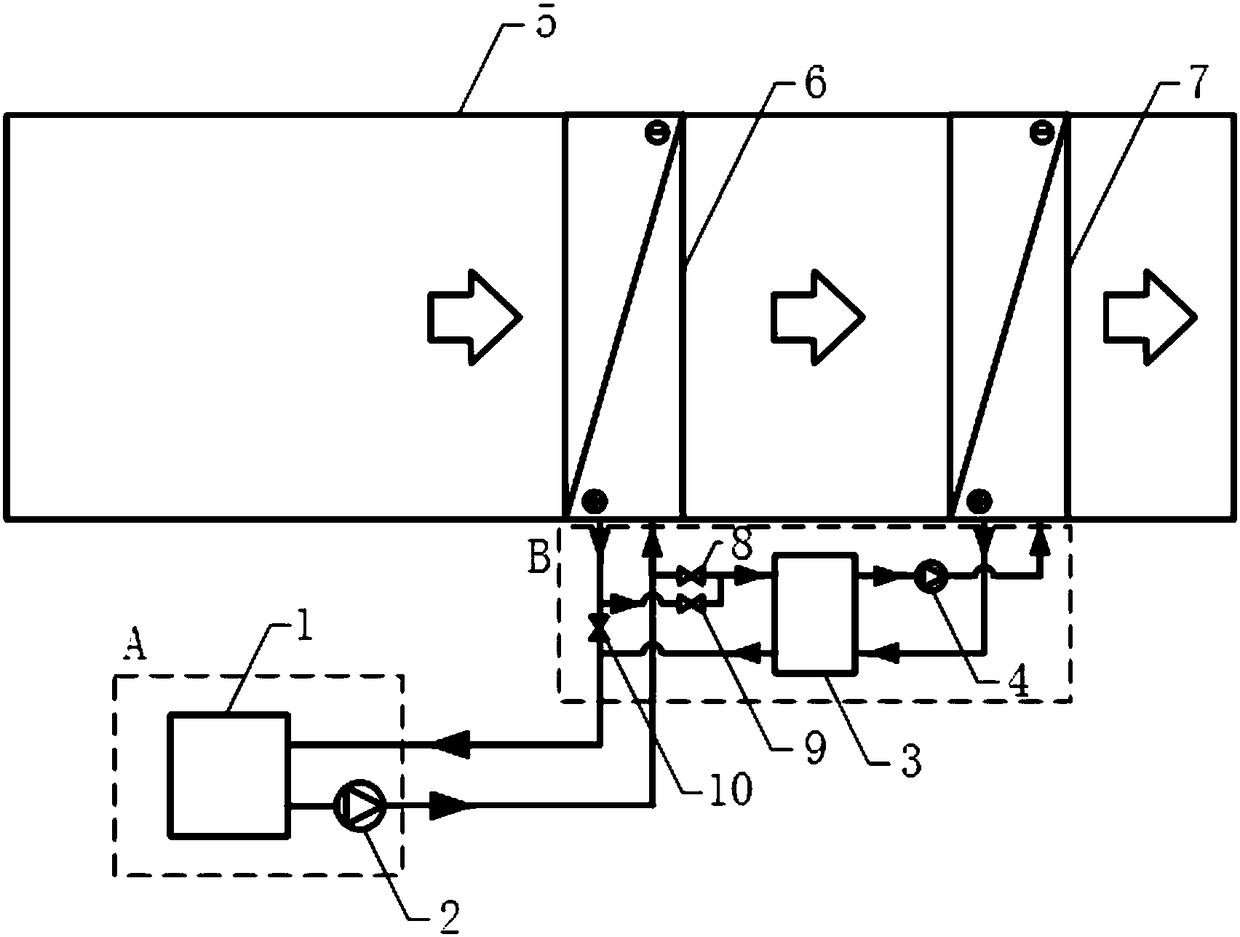

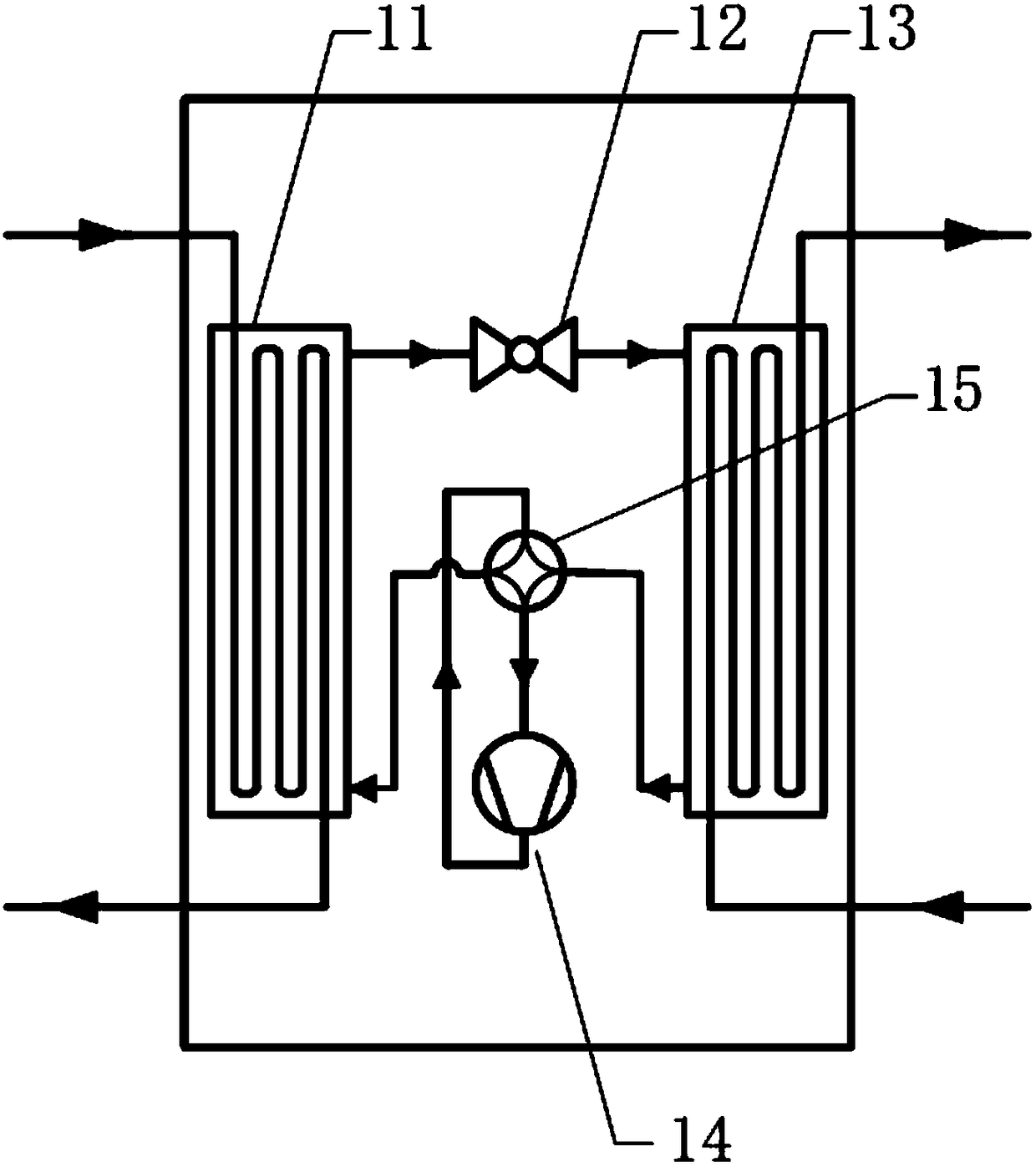

Air treatment equipment

PendingCN108332327ARealize the cooling and dehumidification functionImprove energy efficiencyMechanical apparatusLighting and heating apparatusAir treatmentEngineering

The invention provides air treatment equipment. The air treatment equipment comprises an air conditioning box, a heat exchange device, a cold / heat source unit, a water-water heat pump unit and a controller, wherein the heat exchange device comprises at least two groups of heat exchangers which are sequentially arranged in the air conditioning box, and when air flows in the air conditioning box, the air is subjected to heat exchange with the heat exchange device in a step-by-step mode; the cold / heat source unit is used for outputting cold / hot water outside; and the water-water heat pump unit comprises a water-water heat pump machine, a first pipeline assembly and a second pipeline assembly, wherein the first pipeline assembly communicates with the first end of the water heat pump machine and is connected with the water-water heat pump machine, the second end of the water heat pump machine communicates with the second pipeline assembly, and any two sets of heat exchangers in the heat exchange device communicate with water-water heat pump unit. According to the air treatment equipment the cold water temperature is greatly improved, the heat supply hot water temperature is reduced, and therefore the energy efficiency of the heat source unit is improved; a cold source or a heat source with a single temperature is adopted, so that the complexity degree of the cold source and the heat source and a pipe network is greatly reduced, and engineering implementation and operation control are facilitated; and the air is subjected to step-by-step heat exchange in the heat exchange device, so that the temperature change of the air is matched with the temperature change of cold water and hot water, and the heat transfer loss is reduced.

Owner:TSINGHUA UNIV

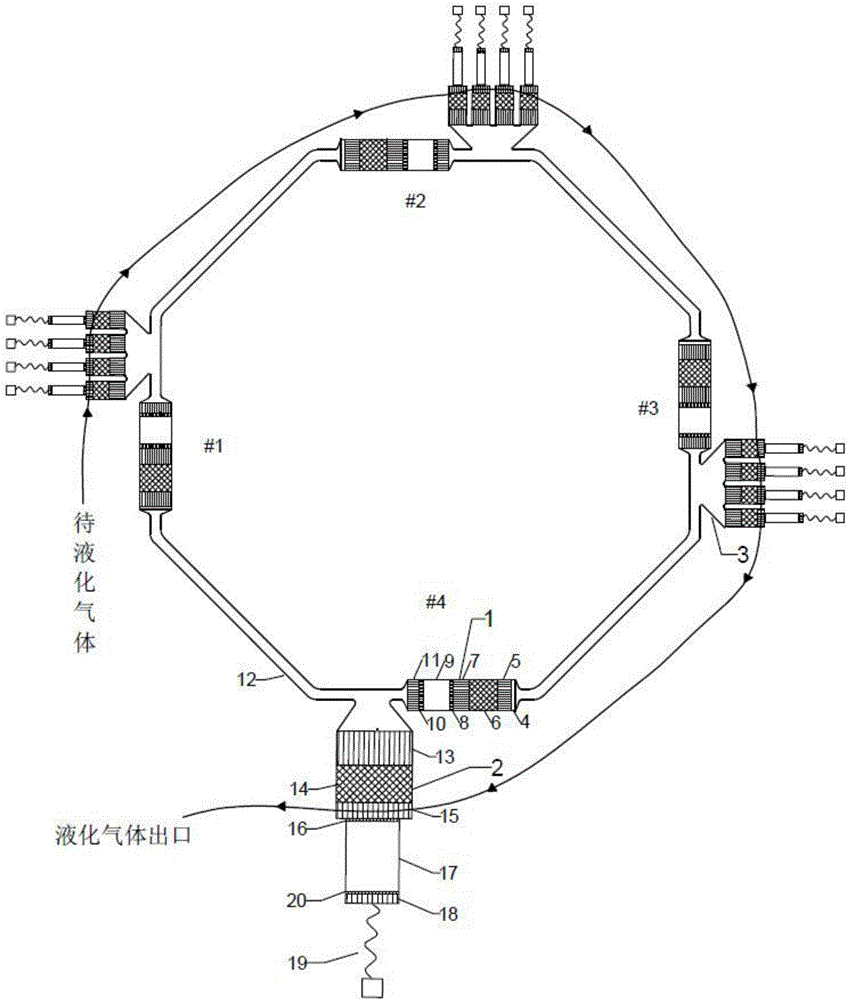

Multistage gas liquefaction plant driven by loop multistage thermoacoustic engine

ActiveCN105333694AConducive to liquefactionSimple structureSolidificationLiquefactionThermoacousticsPulse tube refrigerator

The invention discloses a multistage gas liquefaction plant driven by a loop multistage thermoacoustic engine. The multistage gas liquefaction plant comprises M thermoacoustic engine units and pulse tube refrigerating machine units, wherein the pulse tube refrigerating machine units are connected with the outlets of the thermoacoustic engine units in a by-pass manner; M is a positive integer ranging from 3 to 6; a refrigerating unit comprises a refrigerating machine regenerator and a low-temperature end heat exchanger; each pulse tube refrigerating machine unit comprises two or more refrigerating units; multiple by-pass pipelines are arranged between each refrigerating machine regenerator and a corresponding pulse tube, so that the refrigerating machine regenerator and the corresponding pulse tube are connected to form at least one by-pass airflow passage; acoustic power generated through self-excitation of the thermoacoustic engine has thermoacoustic conversion in the refrigerating machine regenerators; the multiple low-temperature end heat exchangers are maintained under different refrigerating temperatures; and the to-be-liquefied gas sequentially passes through all low-temperature end heat exchangers to be liquefied in a temperature stepped decrease manner. The multistage gas liquefaction plant has no moving part, and is compact in structure and high in power density; the loop structure enables the engine units to be in the traveling wave phase; the multipath bypass structure realizes gas expansion refrigeration to improve the efficiency of a pulse tube refrigerating machine; and in addition, the multistage refrigerating units reduce the gas temperature in a stepped manner to effectively reduce the irreversible heat transfer loss.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com