Combustion system of diesel engine

A technology of combustion system and diesel engine, which is applied in the direction of charging system, combustion engine, mechanical equipment, etc. It can solve the problems of air not being fully utilized, increasing the thickness of the piston top, increasing the mass of the piston, etc., so as to improve the air utilization rate , reduce heat transfer loss, increase the effect of turbulent kinetic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

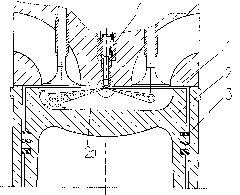

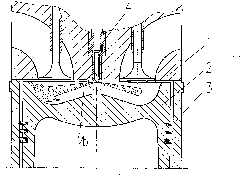

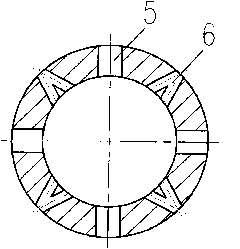

[0021] figure 1 A combustion system of a shallow basin combustor is shown. figure 2 A combustion system with a shallow ω-shaped combustor is shown. exist figure 1 , 2 Among them, the combustion system mainly includes a combustion chamber arranged on the top of the piston 2 with a diameter of less than 150mm, and the oil beam of the injector 4 located in the center of the cylinder head 1 is matched with the combustion chamber. The fuel injector 4 adopts one or more combinations of circular nozzle holes and combined nozzle holes with different apertures, and uses different types of nozzle holes on the fuel injector 4 to spray oil beams with different penetration distances and different diffusion angles. , Cooperate with shallow basin type combustion chamber 2a or shallow ω type combustion chamber 2b. The garden spray holes include straight spray holes 5 and tapered spray holes 7, and the combined spray holes include small combined spray holes 6 and large combined spray hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com