Opposite-piston, two-stroke and variable-compression-ratio type gasoline engine

An opposed piston, two-stroke technology, applied in mechanical equipment, combustion engines, machines/engines, etc., can solve the problems of increased mechanical load and thermal load, difficulty in variable compression ratio, and reduced power output, so as to improve combustion rate, shortening the duration of combustion, and reducing the effects of knocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

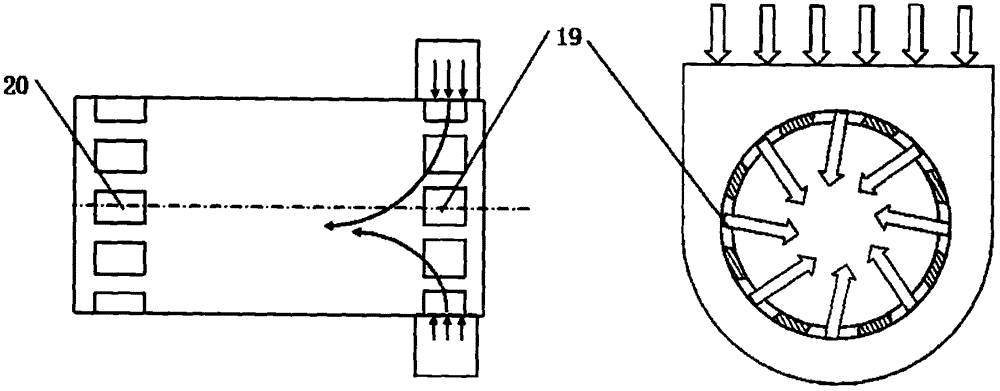

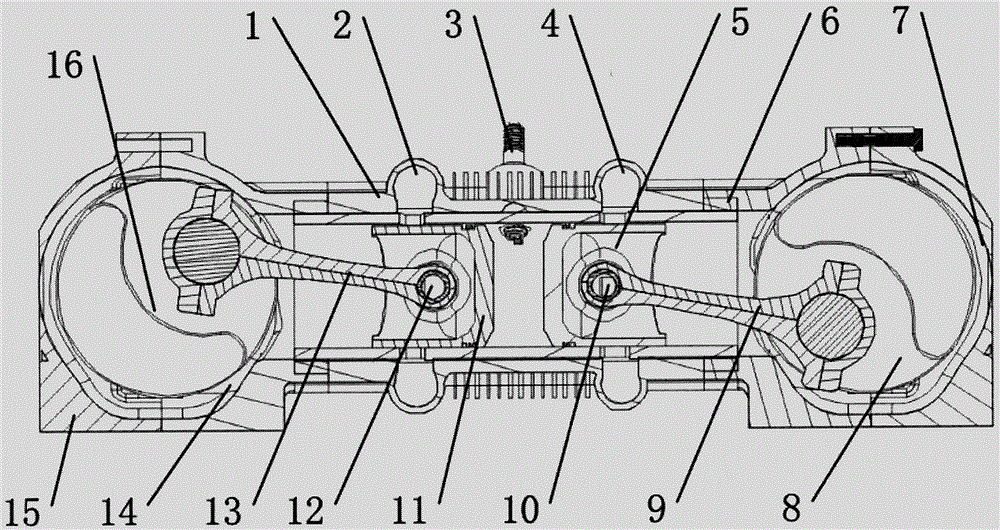

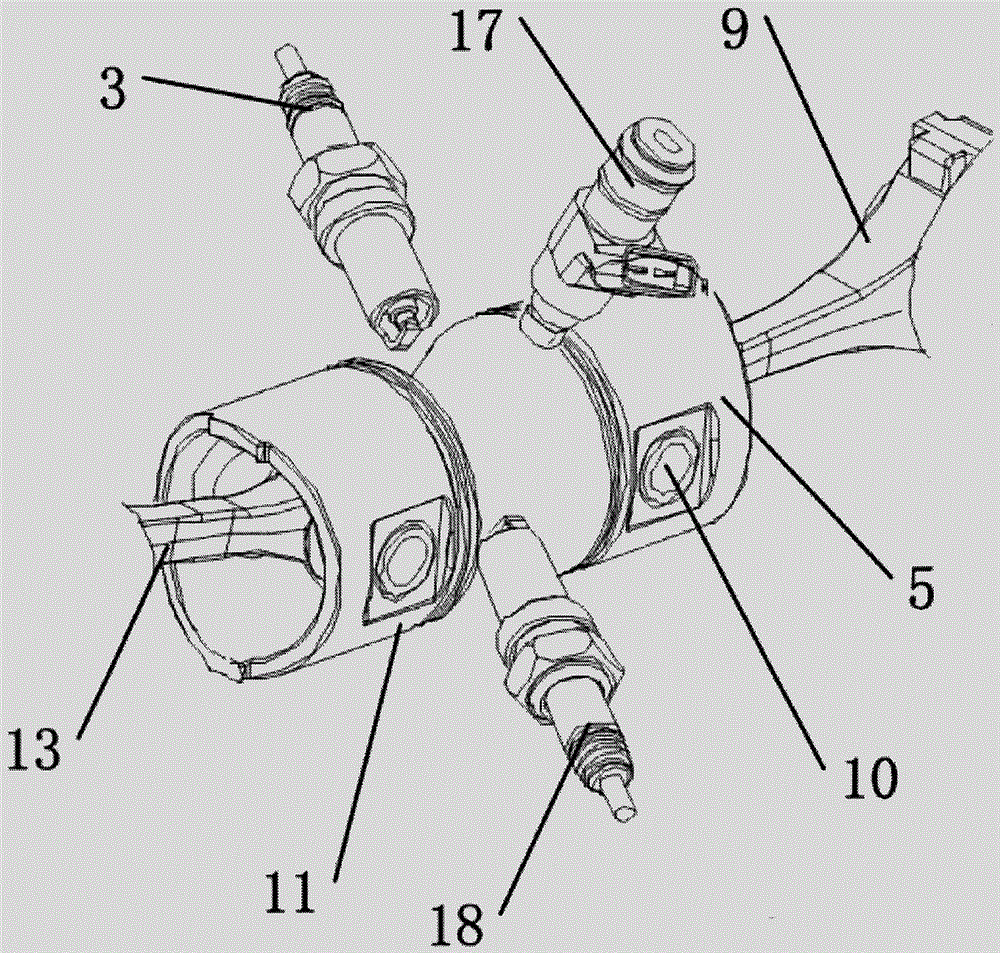

[0041] Such as Figure 1-Figure 2 As shown, an example of an opposed-piston two-stroke variable compression ratio gasoline engine provided by the present invention is shown. The gasoline engine mainly includes: cylinder block 1, gear synchronization mechanism, first spark plug 3, second spark plug 18, injection The oil tank 17 and the stepper motor, the cylinder block 1 and the gear synchronous mechanism are connected through the crankshaft, the crankshaft includes the intake side crankshaft 16 and the exhaust side crankshaft 8, and the first spark plug 3, the second spark plug 18 and the fuel injector 17 are arranged On the outer peripheral wall of the center line of the cylinder block 1, the first spark plug 3 and the second spark plug 18 are symmetrically distributed on the outer peripheral wall of the cylinder block 1 by 180°, and the fuel injector 17 is arranged on the first spark plug 3 and the second spark plug 18 , and the angle between the injector 17 and the first sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com