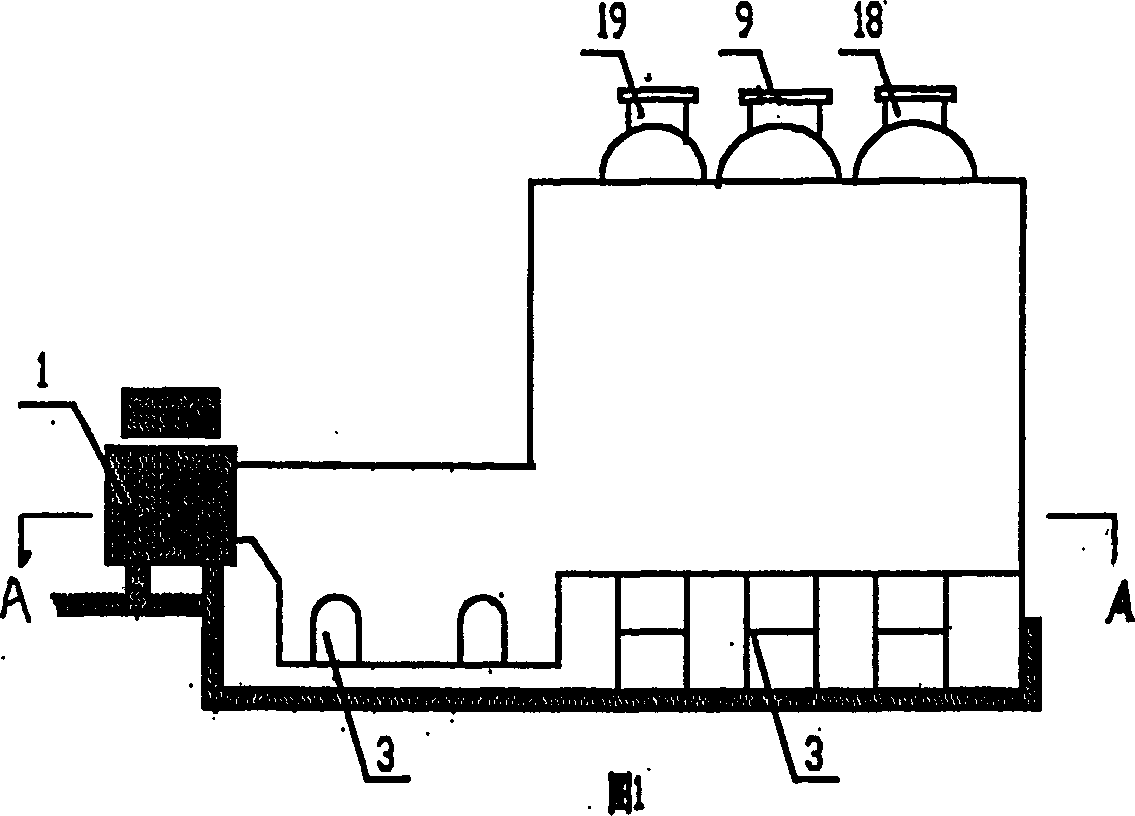

CS2 reactor furnace

A carbon disulfide and reaction furnace technology, which is applied in the field of carbon disulfide production equipment, can solve problems such as insufficient preheating of raw materials, unreasonable heating methods, and corrosion of the inner furnace body, so as to save fuel, improve production efficiency and economic benefits, and improve thermal efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

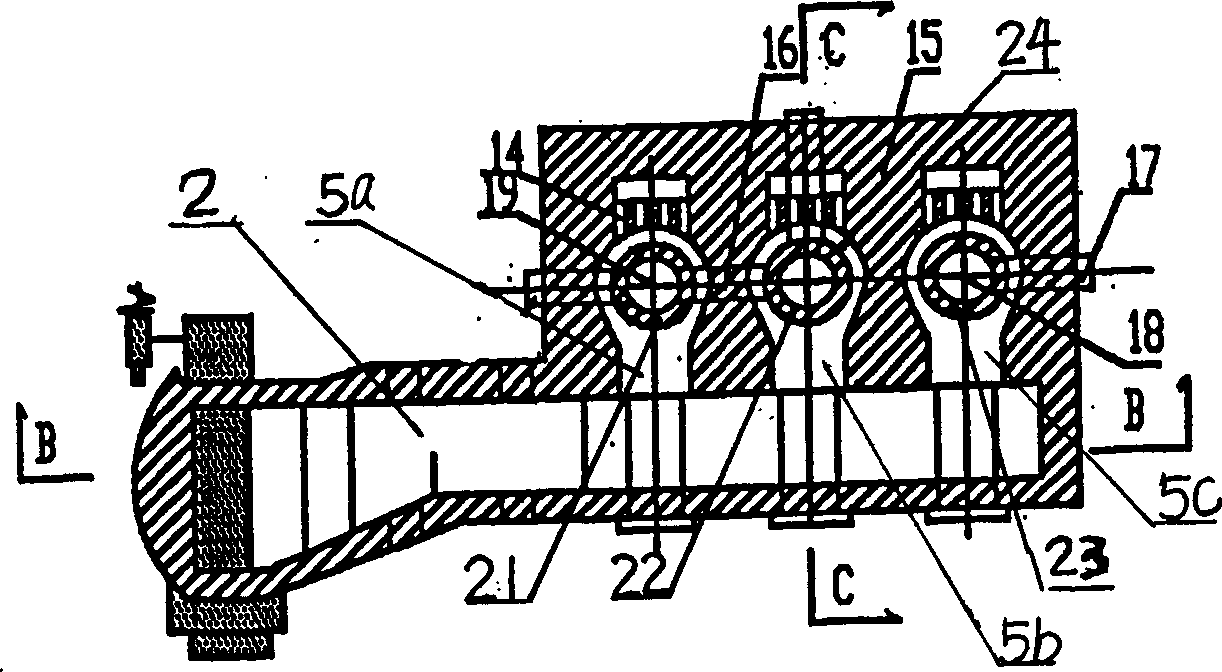

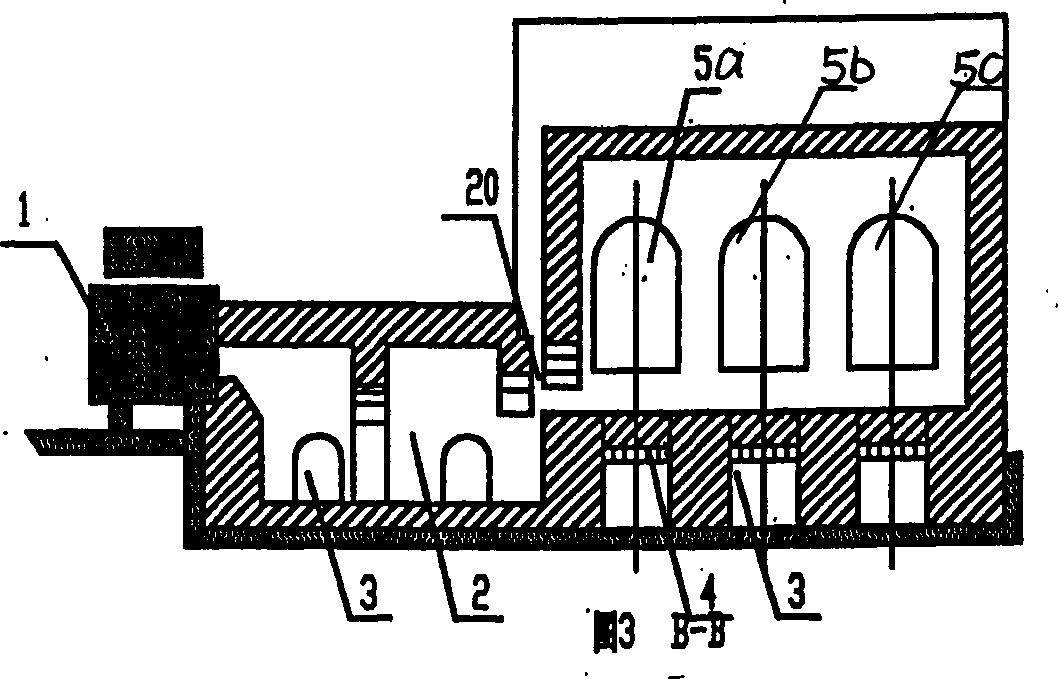

Embodiment 1

[0035] Embodiment 1 Get silicon bricks, the specification is 6 * 25 * 40 centimeters, build inner furnace body, sulfur gasification furnace, three furnace bodies of carbon material preheating furnace according to the above-mentioned method, diameter 0.8 meters, height 4 meters. The thickness of the thermal insulation outer wall is 0.5 meters, a two-ton gas-fired furnace, the diameter of the main fire channel is one meter, heating for 6-8 hours, when the temperature in the furnace reaches 700°C, take 840 kg of semi-coke and put it into the carbon material preheating furnace Preheat for about 2 hours, when the temperature of the carbon material reaches or approaches 700°C, take 3,000 kg of sulfur and add it to the sulfur gasifier in batches from the sulfur inlet, and at the same time take the preheated carbon material out of the carbon outlet and pass it through the inner Put the charcoal inlet on the upper part of the furnace body into the furnace to continue heating. At this ti...

Embodiment 2

[0036] Example 2 In the above reaction furnace, add 90.75Kg of coke powder, 3000Kg of sulfur in batches, react for 24 hours, and collect 3025Kg of carbon disulfide in total.

Embodiment 3

[0037] Example 3 The reaction furnace body is elliptical, with a major axis of 1 meter, a minor axis of 0.5 meters, and a height of 1.8 meters. The sulfur gasifier is a cylinder with a height of 1.8 meters and a radius of 0.5 meters. The above two furnace bodies are all made of high-alumina bricks. Built into shape. The carbon material preheating furnace is a circular cast iron furnace body with a radius of 0.6 meters and a height of 1.8 meters.

[0038] Embodiment 4 The body of the reaction furnace in the above example 3 is spherical. The diameter of the ball is 0.8 meters, and the bottom is a spherical shape fixed on the base of the furnace. There is a furnace cap on the upper part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com