Electromagnetic valve

A solenoid valve and a new type of technology, applied in the field of solenoid valves, can solve the problems of surface quality damage, low pass rate, and high process scrapping rate, and achieve the effects of simple structure, improved product pass rate, and guaranteed pass rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

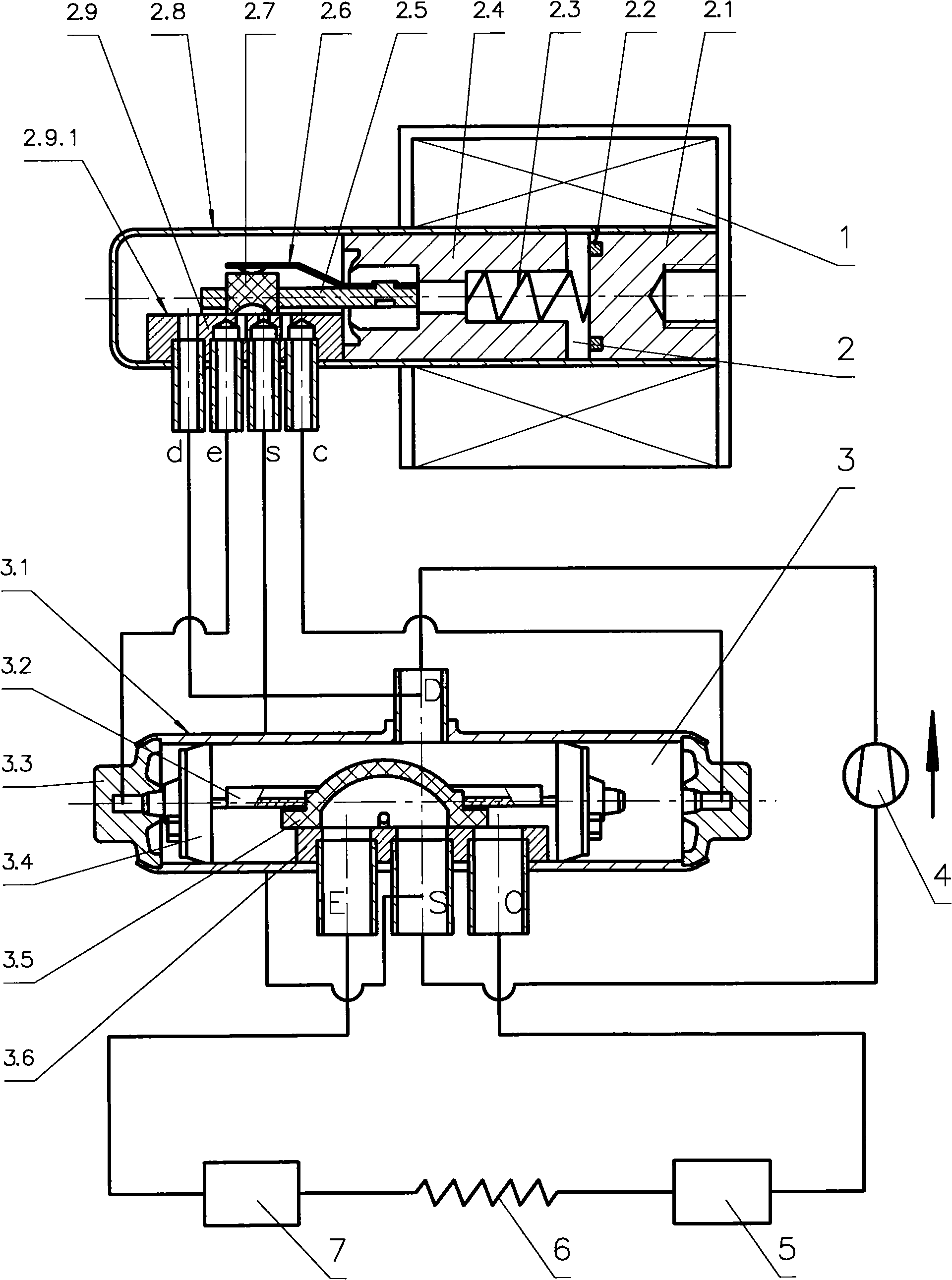

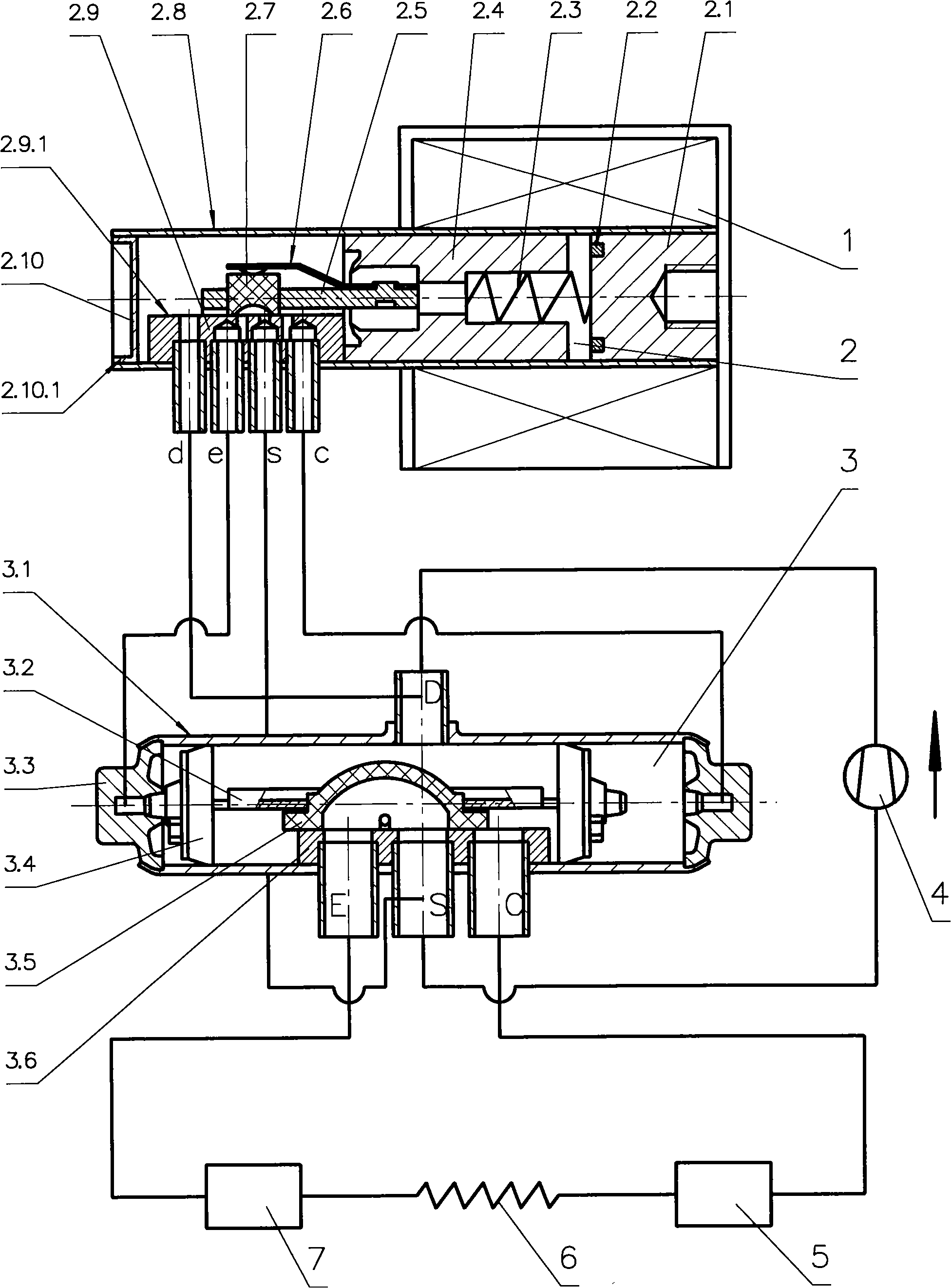

[0035] Such as figure 2 As shown, the solenoid valve with figure 1 Compared with the structure shown, it is also composed of the main valve 3, the pilot valve 2 and the electromagnetic coil 1. Except for the differences mentioned below, the other structures and working principles of the detailed structure are not substantially different from those of the prior art, and will not be repeated here. .

[0036] figure 2 Solenoid valve shown with figure 1 The structures shown differ in the structure of their pilot valves:

[0037] The end of the sleeve 2.8 of the pilot valve adjacent to the small valve seat (the left end in the figure) is blocked by an end cover 2.10. Usually, the end cover 2.10 is sealed on the sleeve 2.8 adjacent to the small valve seat 2.9 in the form of welding. One end; in order to facilitate welding and ensure a good sealing effect, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com