Patents

Literature

167 results about "Ferritic matrix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cold-rolled hot-galvanized dual-phase steel plate with flanging property and manufacturing method thereof

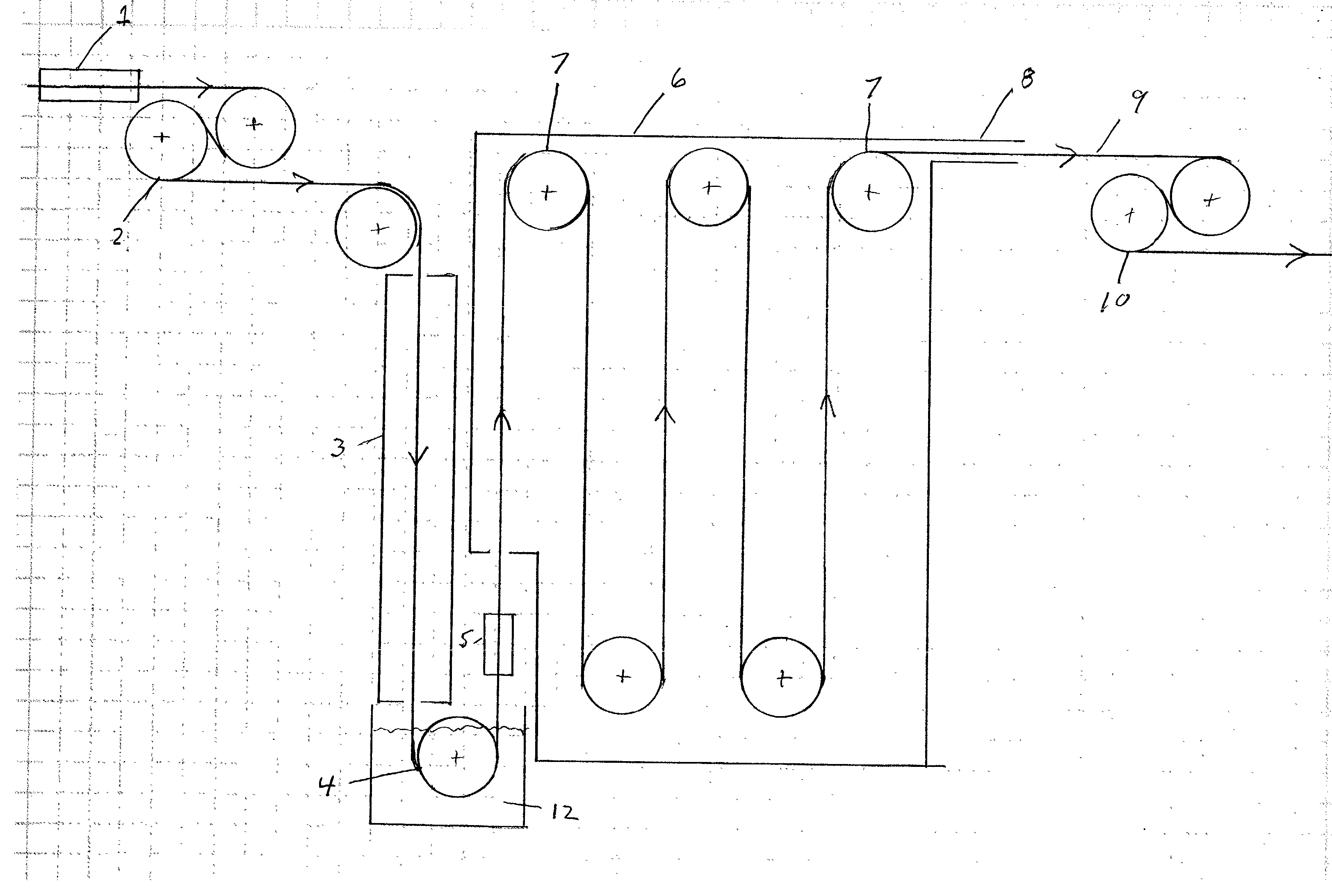

The invention relates to a cold-rolled hot-galvanized dual-phase steel plate with a flanging property and a manufacturing method thereof. The steel plate comprises the following chemical components by weight percent: 0.06% to 0.095% of C, 0.3% to 0.6% of Si, 1.4% to 1.8% of Mn, greater than 0% and less than or equal to 0.02% of P, greater than 0% and less than or equal to 0.01% of S, 0.02% to 0.05% of Al, 0.35% to 0.55% of Cr, 0.02% to 0.04% of Nb, greater than 0% and less than or equal to 0.005% of N and the balance of Fe. According to the steel plate provided by the invention, the austenite is dispersedly distributed in a ferrite matrix via the refining of austenite grains by adding the Nb element and controlling temperatures during hot rolling and finish rolling and a rolling temperature; the amount of the austenite after annealing is increased by limiting the content of C and carrying out high-temperature annealing in a continuous hot-galvanized annealing furnace, so that tissues in low-C martensite are obtained after quenching. Thus, the hardness of the martensite is decreased. As a result, a hardness difference between the martensite phase and the ferrite phase is reduced.

Owner:ANSC TKS GALVANIZING

Method and apparatus for bainite blades

InactiveUS20020100522A1Maximize propertyMaximize straightnessRotary intaglio printing pressFurnace typesPad printingFerritic matrix

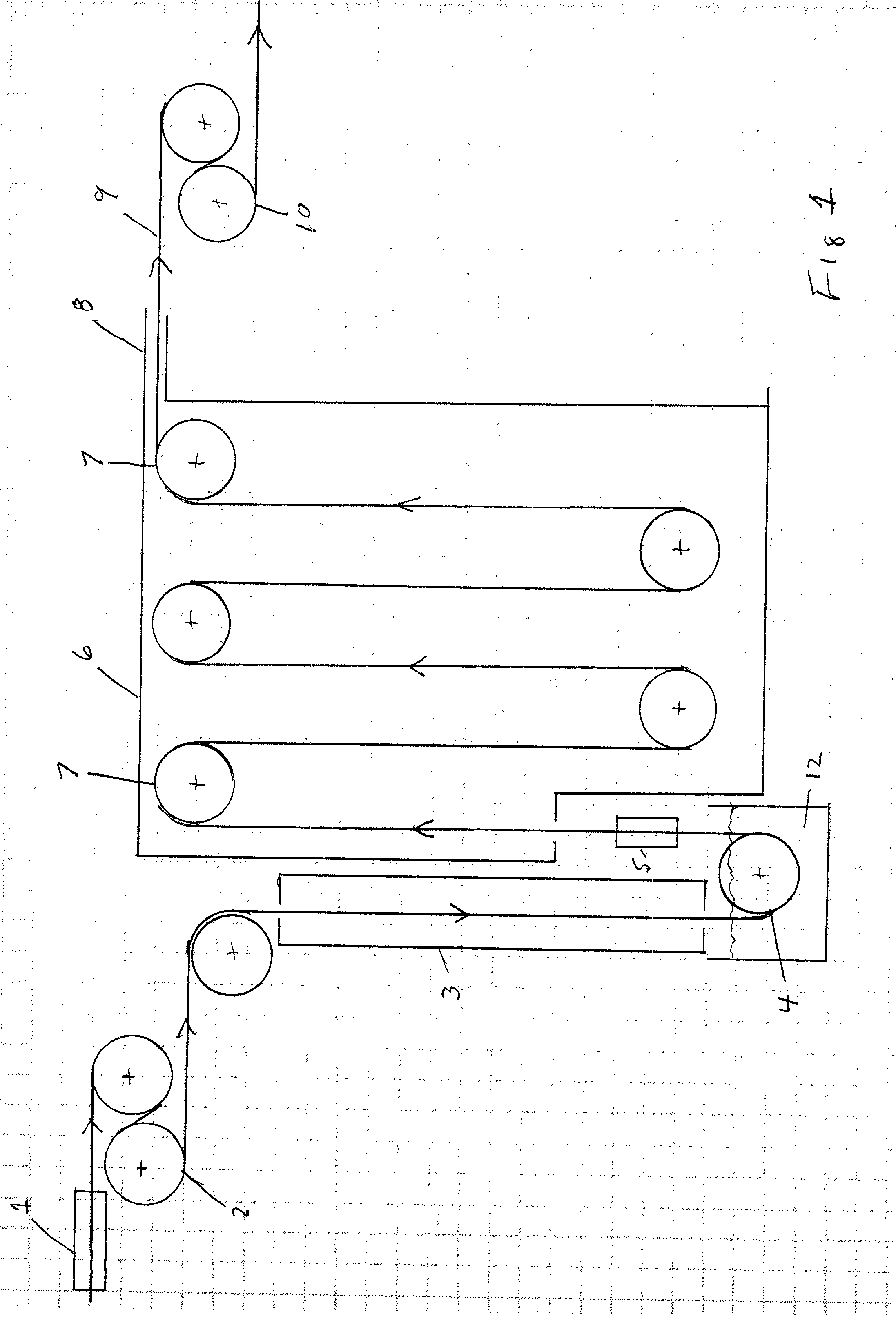

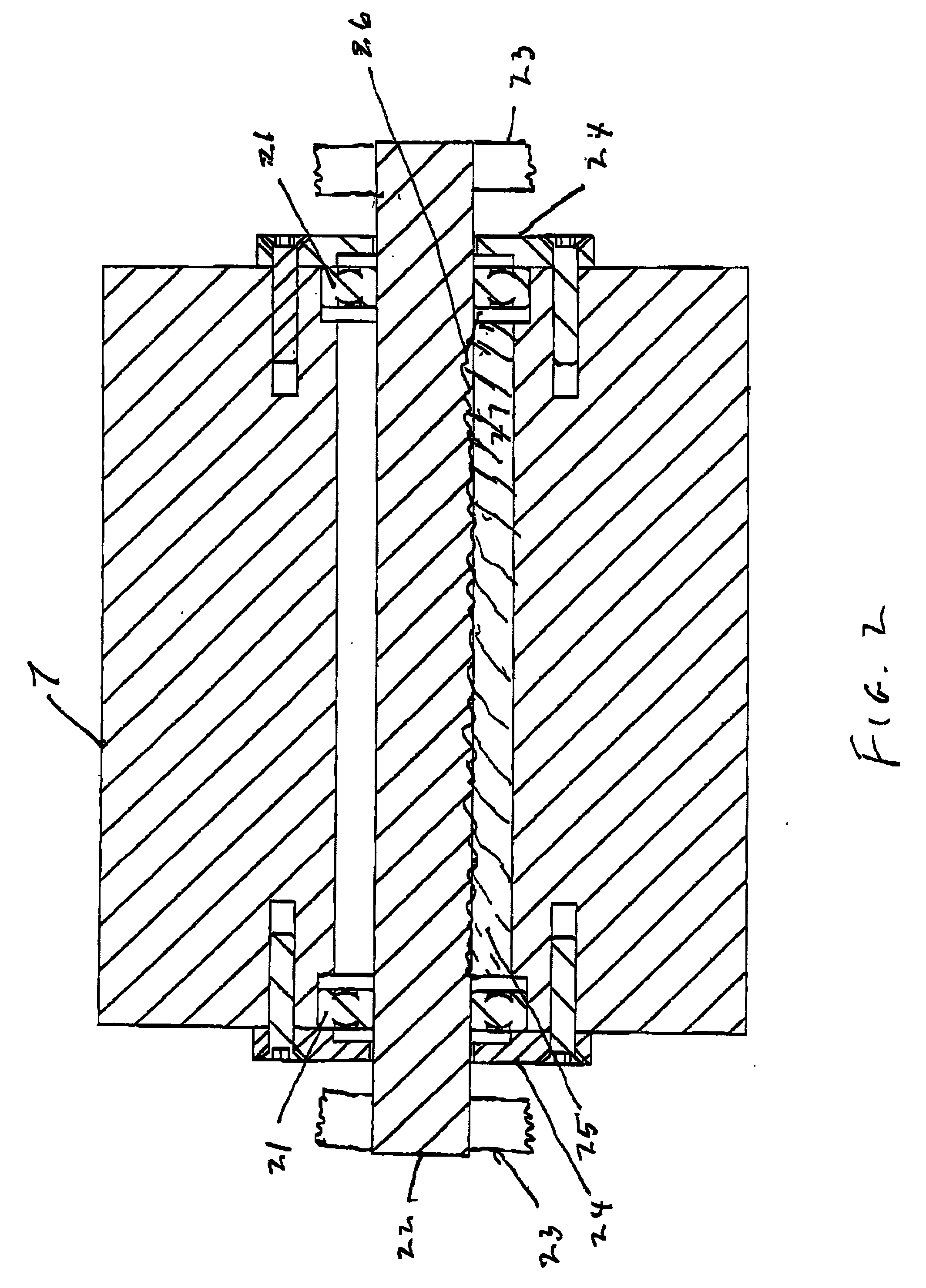

The present invention includes bainitic steel doctor blades, bainitic steel coating blades, bainitic steel creping blades and bainitic steel rule die knives used in gravure printing, flexographic printing, paper making, die cutting of materials including paper, plastic, foam, leather, etc. Other uses include printing processes such as pad printing and electrostatic printing. The invention also includes an improved method for producing bainitic steel strip. The present invention is accomplished by using bainitic steel components that exhibit superior straightness and wear properties and are bendable around small radii. The process of the present invention comprises the steps of annealing a carbon steel resulting in a microstructure of the steel having a dispersion of carbides in a ferritic matrix; cold rolling the annealed steel; cleaning the cold rolled steel to remove oil and dirt; bridle braking the cleaned steel to increase strip tension; austenitizing the steel; submersing the austenitized steel into a quenchant; removing excess quenchant; and isothermally transforming the austenitized steel into bainite. The present process of the invention also includes the use of turn rolls that are housed in an assembly containing salt and / or tin.

Owner:BENTON GRAPHICS

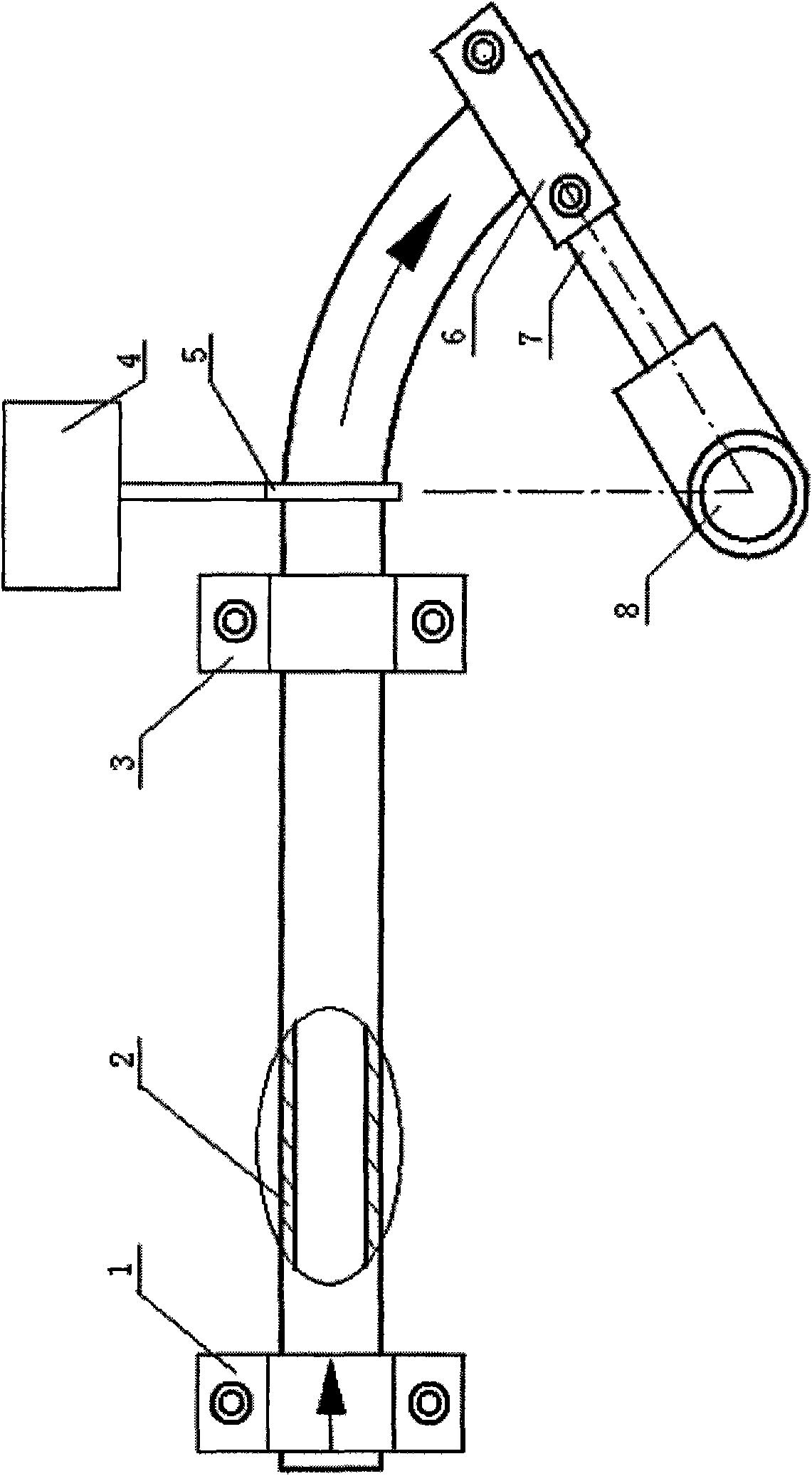

Continuous casting method of large-length hollow ductile cast iron sections and method for arcing hollow ductile cast iron sections after local continuous heating

InactiveCN101638748ASolve technical problems that are difficult to produceCorrosion resistancePhysical fieldVolumetric Mass Density

The invention relates to a continuous casting method of large-length hollow ductile cast iron sections and a method for arcing the hollow ductile cast iron sections after local continuous heating. Thesection comprises the following components by weight percent: 3.4-3.6% of C, 2.8-3.2% of Si, 0.40-0.60% of Mn, S less than or equal to 0.1%, P less than or equal to 0.1% and the balance Fe. Molten iron is subjected to shaping and continuous casting under multiple physical fields to become the hollow sections. The molten iron in heat preserving furnaces is separated from dross, sand and gas in twoways, thus completely solving the defects of dross inclusion, sand inclusion and pores; liquid column cores in a crystallizer carry out continual feeding on condensing tube shells, thus eliminating the possibility of shrinkage porosity inside the tube walls, obtaining highly dense cast structure of (ferritic matrix+spherical graphite) and eliminating crack initiation origins in thermoplastic deformation to be carried out later. The intense cooling speed in the crystallizer enables the volumes of eutectic cells to be only 1 / 15-1 / 25 of the volumes of traditional sand mould casts. The density ofthe graphite balls reaches around 500 / mm<2>. In plastic deformation, the micro slip orientation is increased and the ductility is enhanced, therefore, the hollow cast iron sections can be arced by medium frequency induction heating and bending.

Owner:SHAN XI TONGXIN LIANZHU PIPE IND

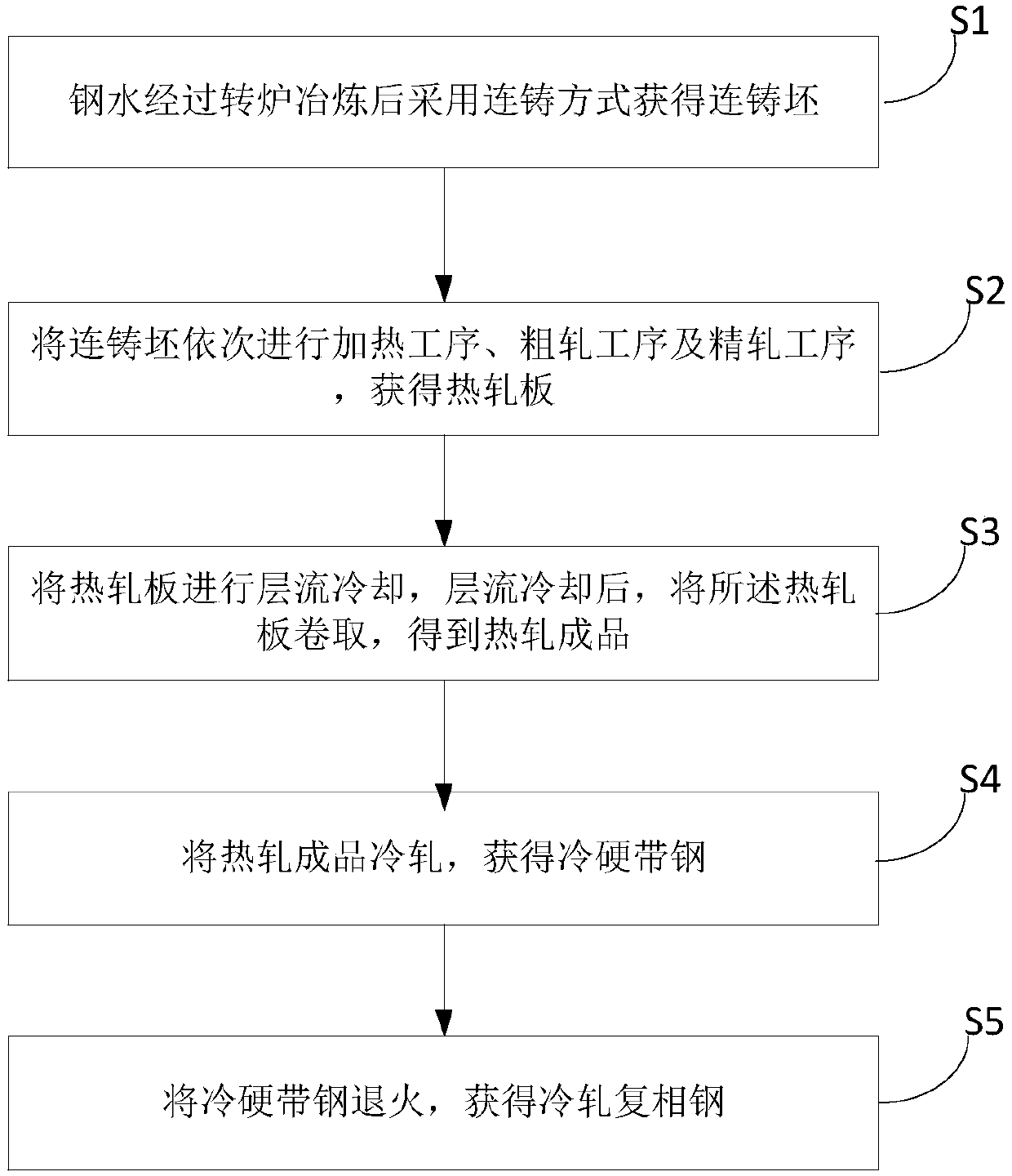

Tensile strength 1000 MPa-grade cold-rolled complex phase steel and preparation method thereof

The invention provides tensile strength 1000 MPa-grade cold-rolled complex phase steel and a preparation method thereof. The complex phase steel is composed of, by mass, 0.07-0.13% of C, 0.2-0.4% of Si, 1.8-2.5% of Mn, 0.2-0.6% of Cr, 0.1-0.4% of Mo, less than or equal to 0.02% of P, less than or equal to 0.015% of S, 0.02-0.06% of Nb, 0.02-0.06% of Ti and the balance iron and other inevitable impurity elements. The complex phase steel adopts low carbon equivalent design as composition design and has good welding performance, a small amount of microalloy elements of Nb and Ti and C elements are composited and added for forming nanometer precipitated phases, thus, grains are refined, meanwhile, the elements are dispersed and distributed in a complex phase steel ferritic matrix, sufficient precipitation strength is reached, therefore, the yield strength of a material is improved, the good bending and reaming properties are achieved, the tensile strength of the final cold-rolled complex phase steel is 1000 MPa or higher, the yield strength reaches 780 MPa or higher, the yield ratio is 0.8 or higher, the elongation after fracture is 8% or higher, the reaming ratio is 50% or higher, andthe application requirements in the field of automotive steel are met.

Owner:SHOUGANG CORPORATION

900MPa grade hot rolling non-tempering thin steel sheet and preparation method thereof

The invention relates to a 900MPa grade hot rolling non-tempering thin steel sheet and a preparation method thereof, belonging to the technical field of alloy steel. The steel sheet comprises the following chemical components in percentage by weight: 0.08-0.13wt% of C, less than or equal to 0.50wt% of Si, 1.0-2.0wt% of Mn, 0.08-0.20wt% of V, 0.08-0.15wt% of Ti, 0.15-0.40wt% of Mo, less than 0.015wt% of P, less than 0.005wt% of S, less than 0.005wt% of N, less than 0.002wt% of O and the balance of Fe and inevitable impurities. Through reasonable control of a V-Ti-Mo multielement microalloying and hot continuous rolling online TMCP (Thermal Mechanical Control Processing) process, a microstructure is obtained, wherein microalloy precipitated phases with grain size of about 5nm are dispersed and distributed on an ultra-fine grain ferrite matrix with grain size less than 5 mu m, so that the yield strength of the steel sheet can reach over 900MPa grade in a hot continuous rolling technical condition, thereby cancelling tempering thermal treatment after rolling. The steel sheet has the advantages that the production flow of the steel sheet is simplified, the energy consumption is reduced, the internal stress of the steel sheet is reduced, and the steel sheet has an important effect of improving the plate cut quality. The steel sheet can be widely applied to the field of mobile facilities such as automobiles, engineering machinery and containers.

Owner:CENT IRON & STEEL RES INST

Alloys for hardbanding weld overlays

Disclosed herein are iron-based alloys having a microstructure comprising a fine-grained ferritic matrix and having a 60+ Rockwell C surface, wherein the ferritic matrix comprises <10 μm carbide precipitates. Also disclosed are methods of welding comprising forming a crack free hardbanding weld overlay coating with such an iron-based alloy. Also disclosed are families of alloys capable of forming crack-free weld overlays after multiple welding passes.

Owner:SULZER METCO (US) INC

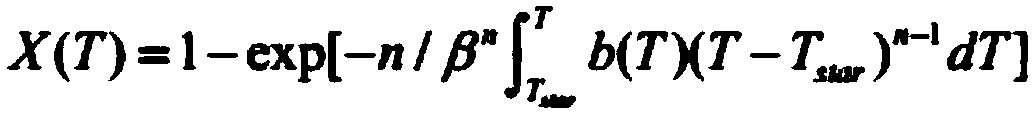

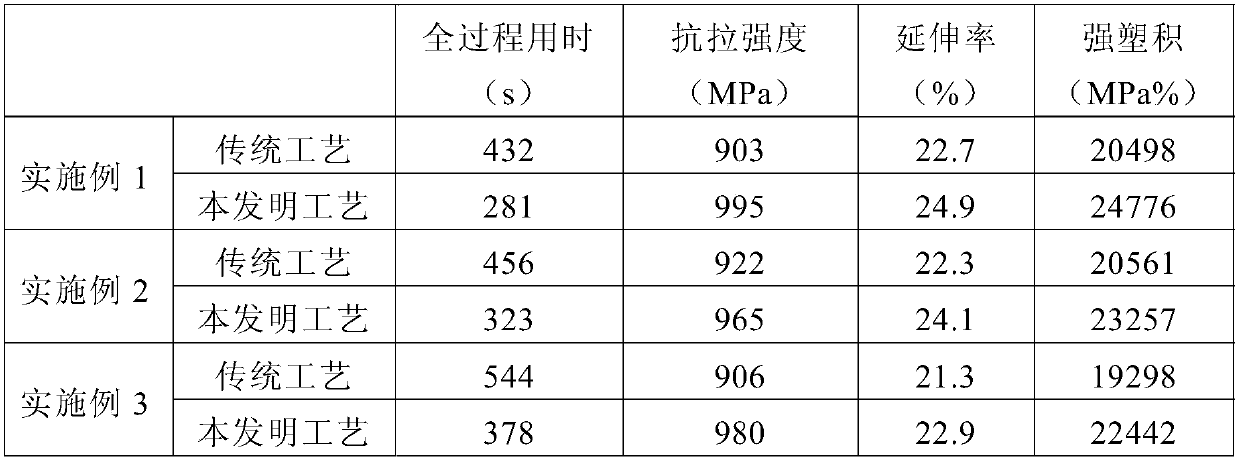

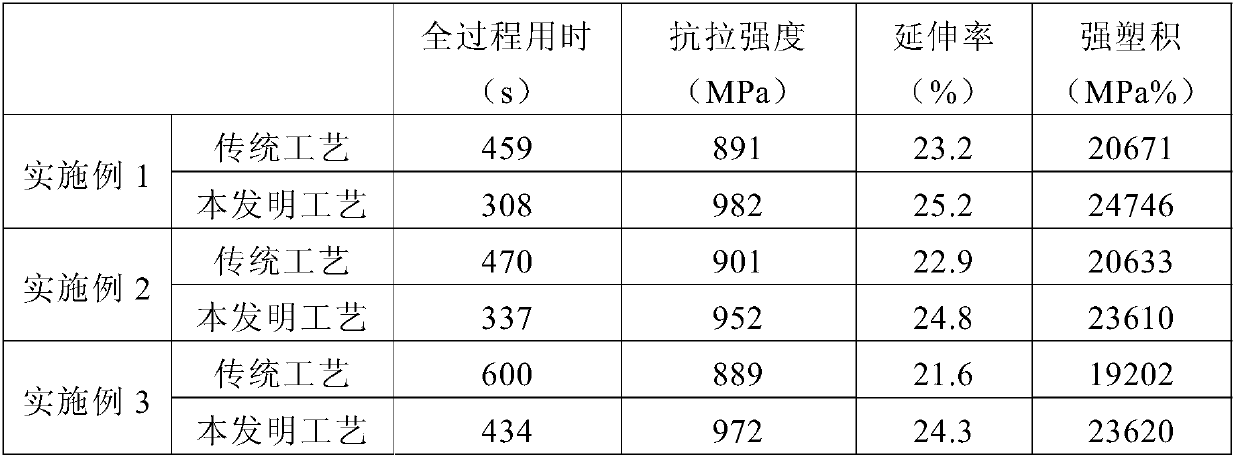

780 MPa-grade low-carbon low-alloy hot-dip galvanized TRIP steel and rapid heat treatment method thereof

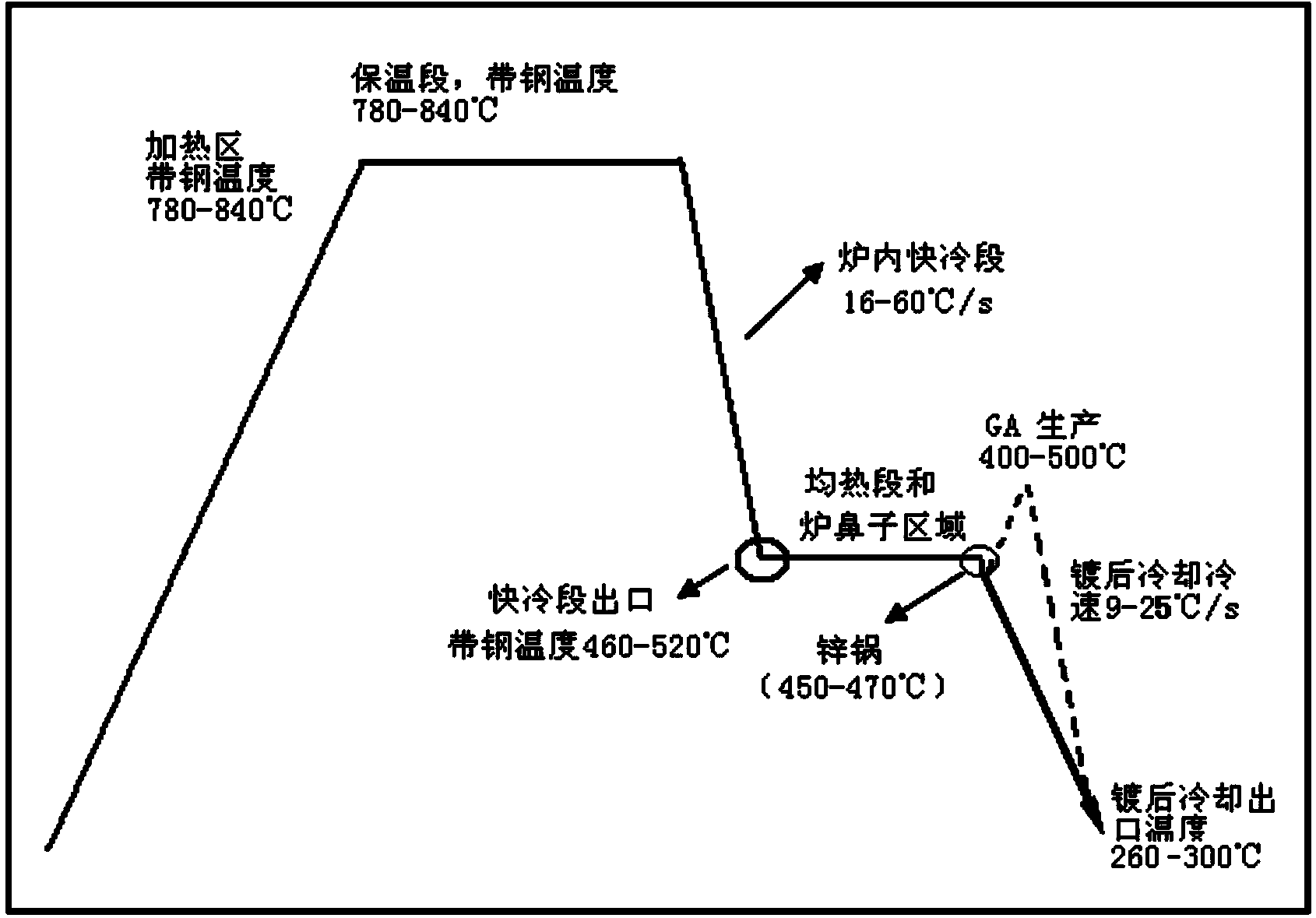

ActiveCN109943770AShorten the timeReduce energy consumptionHot-dipping/immersion processesFurnace typesAlloyMechanical property

The invention discloses a 780 MPa-grade low-carbon low-alloy hot-dip galvanized TRIP steel and a rapid heat treatment method thereof. The steel comprises the following chemical components of, in percentage by mass, 0.16-0.22% of C, 1.2-1.6% of Si, 1.6-2.2% of Mn, and the balance Fe and inevitable impurities. According to the 780 MPa-grade low-carbon low-alloy hot-dip galvanized TRIP steel and therapid heat treatment method thereof, the recrystallization and phase change processes in the heating process and the phase change process in cooling process are controlled, and finally a three-phase structure which is uniformly distributed on a ferrite matrix by bainite and austenite is obtained; the average grain size of the bainite and the austenite is 1-3 microns; the bainite is submicron granular; the austenite is in the shape of an island-shaped and are uniform-distributed isometric crystal; in the whole of the three-phase structure, the volume fraction of the bainite is 35% -75%, the volume fraction of the ferrite is 10%-60%, and the volume fraction of the austenite is 5%-15%; and through the rapid heat treatment, the mechanical property of the material is improved while the heat treatment efficiency is improved, and the material performance interval range is expanded.

Owner:BAOSHAN IRON & STEEL CO LTD

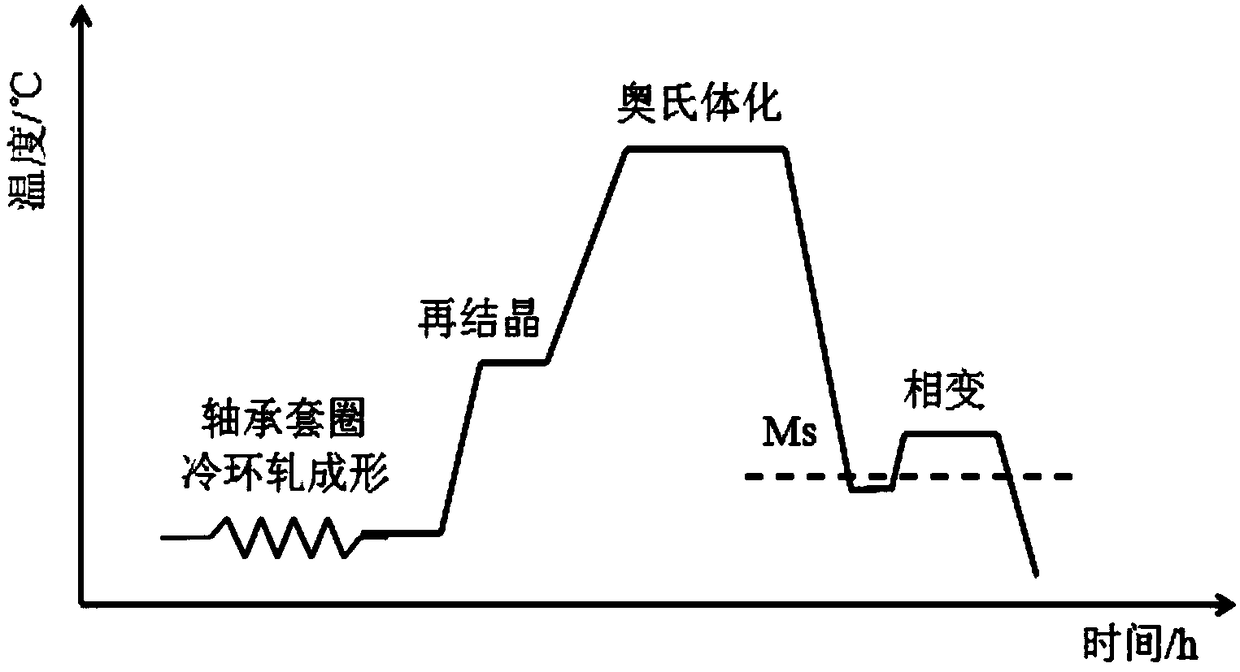

Manufacturing method capable of improving strength and toughness of cold-ring-rolled bearing ring and improving quenching deformation

InactiveCN108060291AImprove solubilityReduce heat treatment quenching deformationFurnace typesHeat treatment furnacesFerritic matrixCarbide

The invention discloses a manufacturing method capable of improving the strength and toughness of a cold-ring-rolled bearing ring and improving quenching deformation. The manufacturing method comprises the following steps: S1. cold-ring-rolling forming: carrying out rolling forming on a ring blank of the bearing ring through a cold-ring-rolling process; and S2. firstly, slowly heating the rolled-formed bearing ring to reach a certain temperature and carrying out recrystallization, and insulating heat for a period of time to eliminate the residual stress of cold-rolling; secondly, rapidly heating the bearing ring to reach a certain temperature and carrying out austenization; thirdly, carrying out pre-quenching treatment on the bearing ring and insulating heat, and forming lath martensites in partial low-carbon areas; fourthly, heating the bearing ring to reach a certain temperature and insulating heat, and carrying out bainite transformation; and finally, cooling the bearing ring to reach room temperature. According to the manufacturing method disclosed by the invention, the change of a ferrite matrix and spheroidized carbides is caused by virtue of cold-rolling plasticity, the pre-quenching process and the bainite phase-change heat treatment process are matched, and the microstructure of a material is controlled, so that the qualification rate of finished bearing rings is greatly increased, the strength and toughness of the material are greatly improved, and the fatigue life of the material is greatly prolonged.

Owner:WUHAN UNIV OF TECH

Manufacturing technology of hot work die steel forge piece

ActiveCN107686878AReduce contentOligodendrite segregationMetal-working apparatusSolution treatmentManufacturing technology

The invention relates to a manufacturing technology of a hot work die steel forge piece. The manufacturing technology comprises the steps including forging, high-temperature normalization, high-temperature tempering, ultrafine solution treatment, spheroidizing and sampling inspection. Through the procedures and related heat treatment, chemical components in the hot work die steel forge piece tendto be consistent, the structure inheritance is effectively cut off, and accordingly the purposes of refining grains and homogenizing structures are achieved. After spheroidizing, a spherical pearlitewith fine-particle-shaped carbide evenly distributed on a ferrite base body is obtained. An excellent organization structure is provided for final heat treatment.

Owner:山西同航特钢有限公司

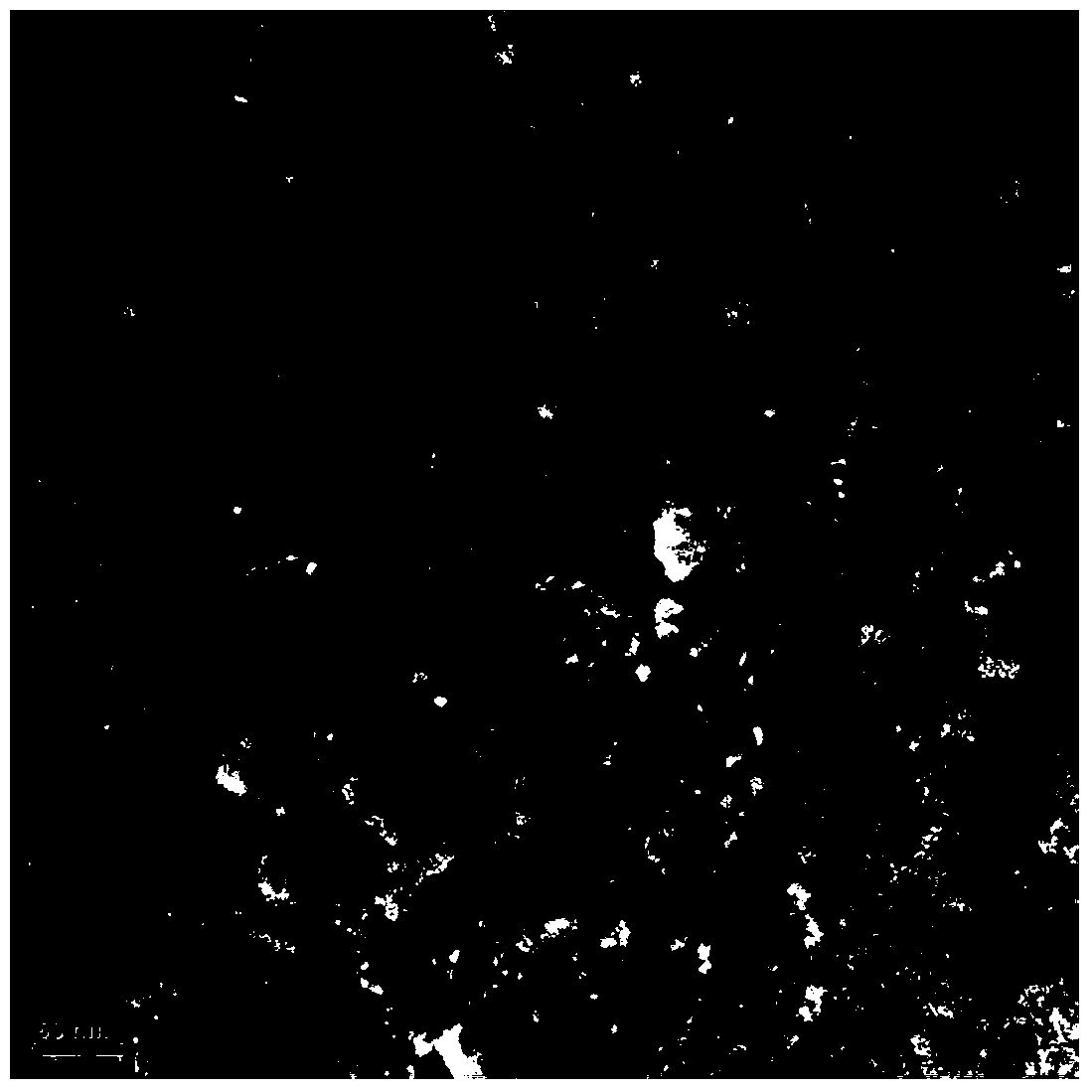

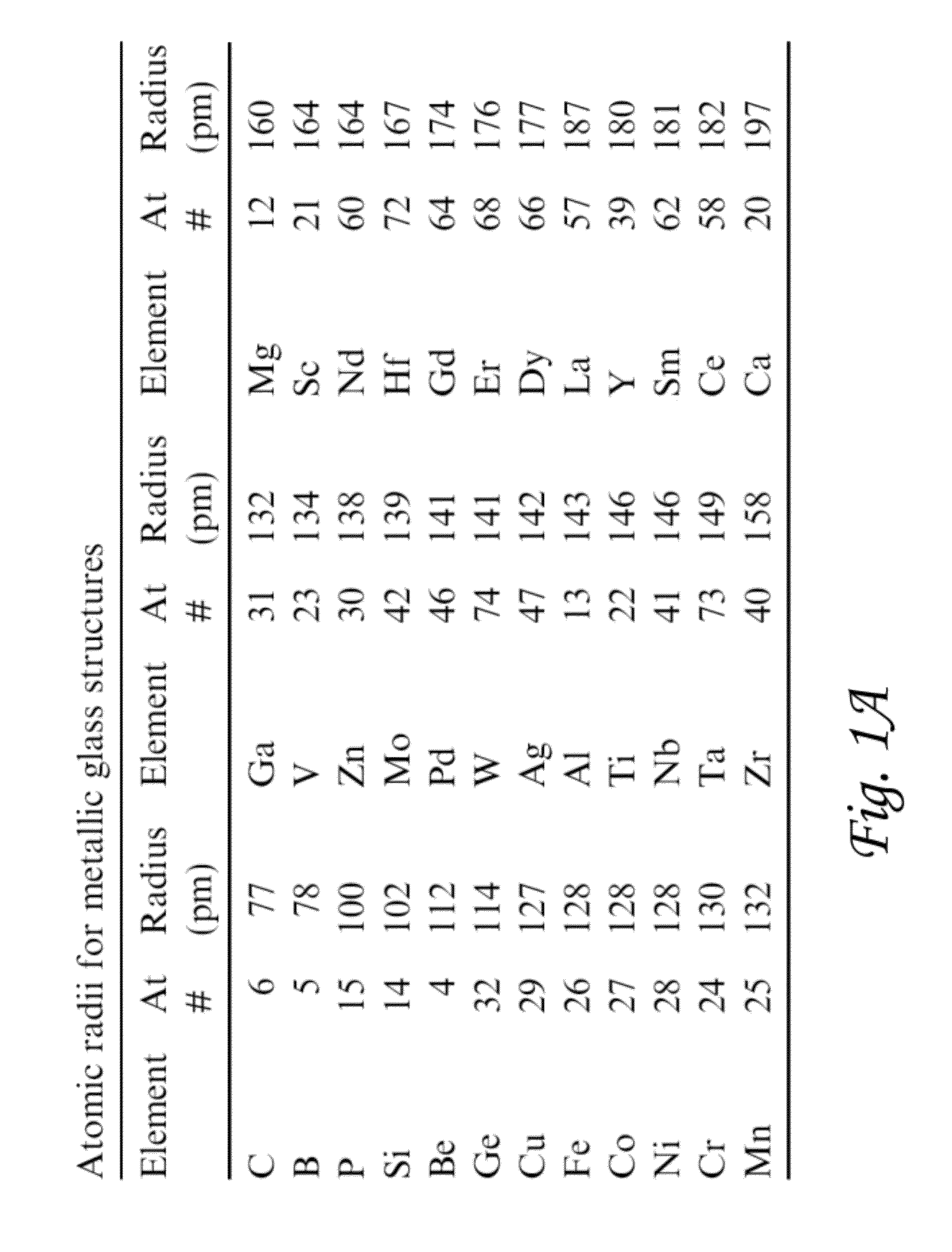

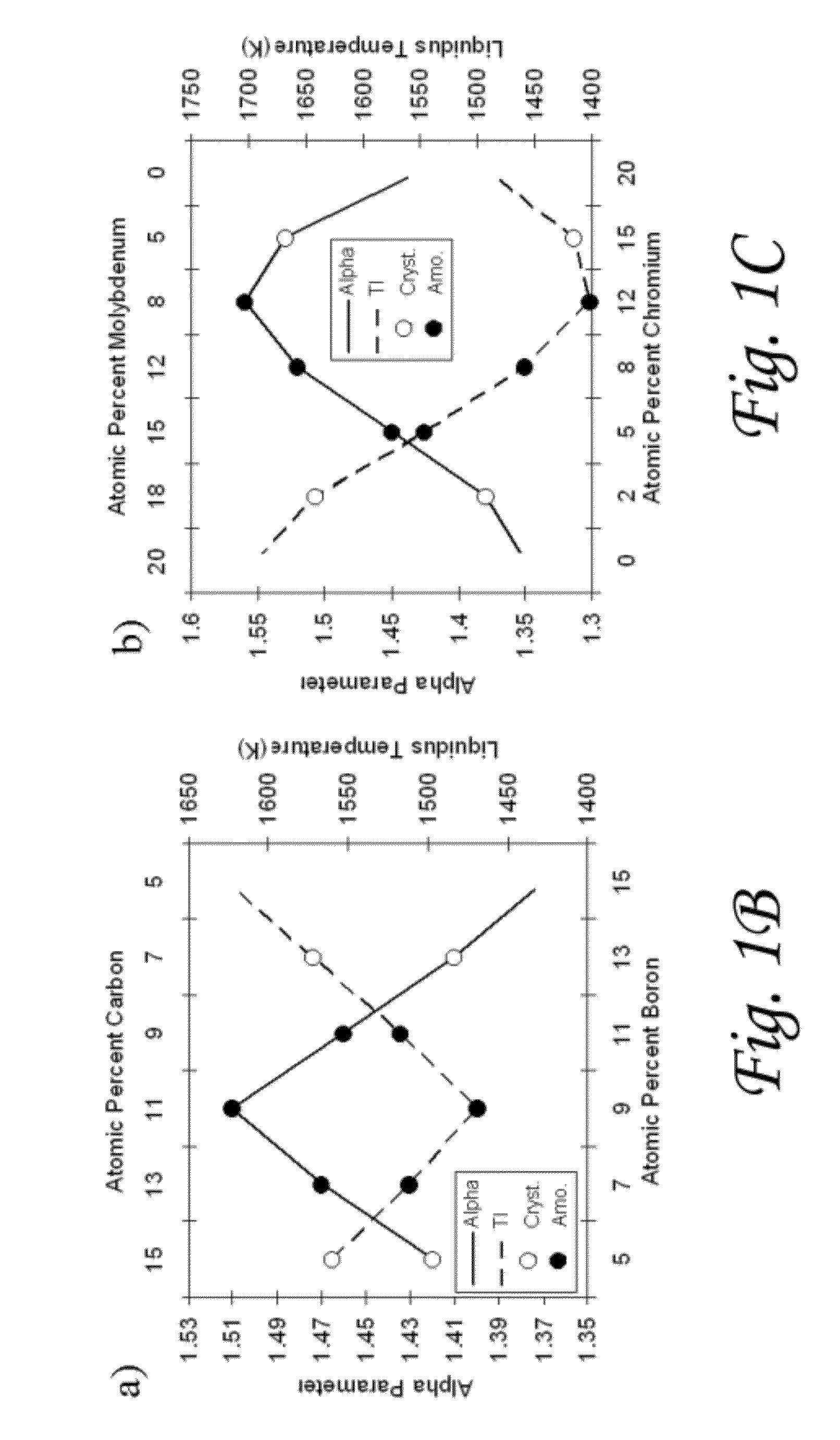

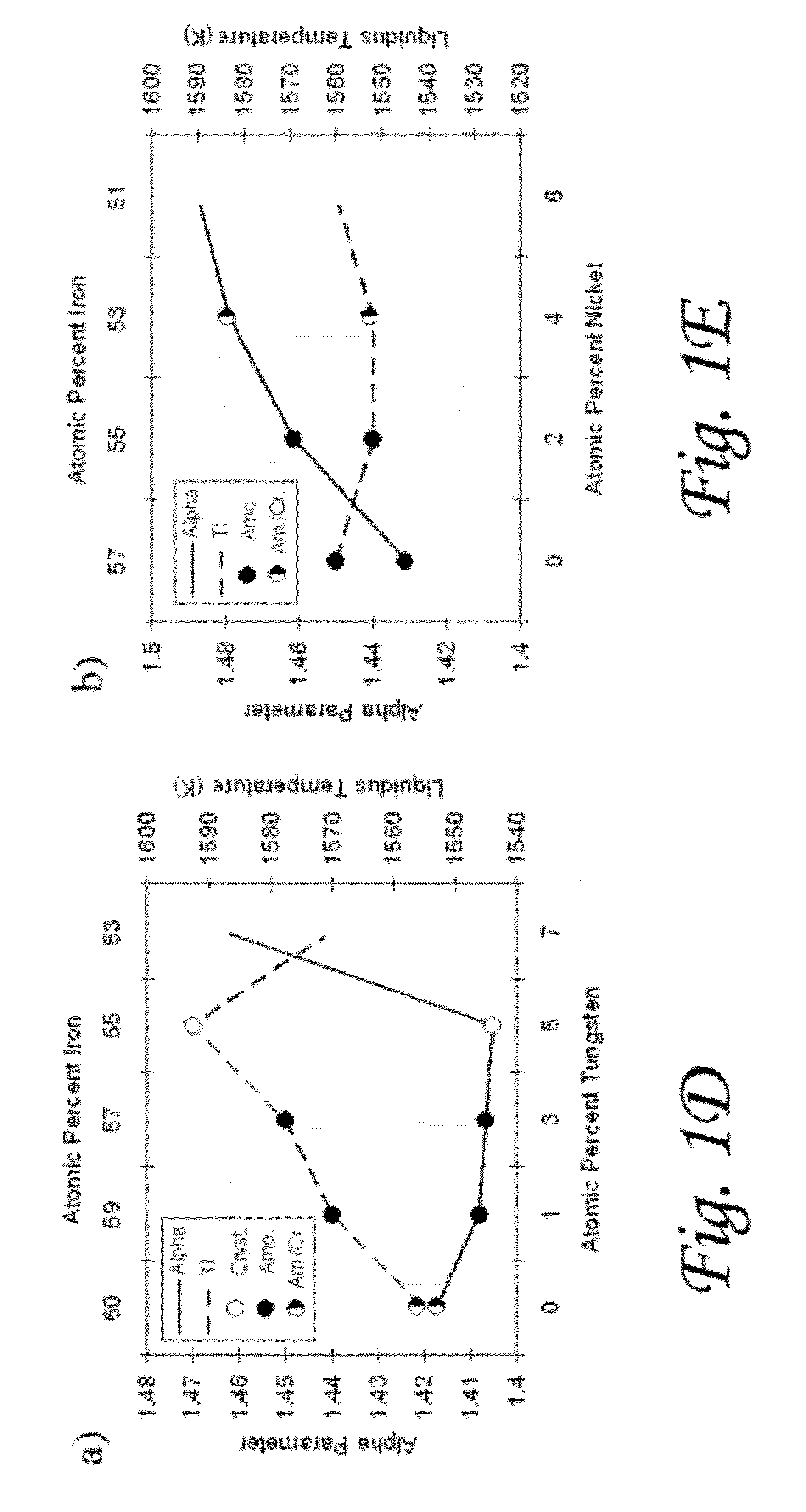

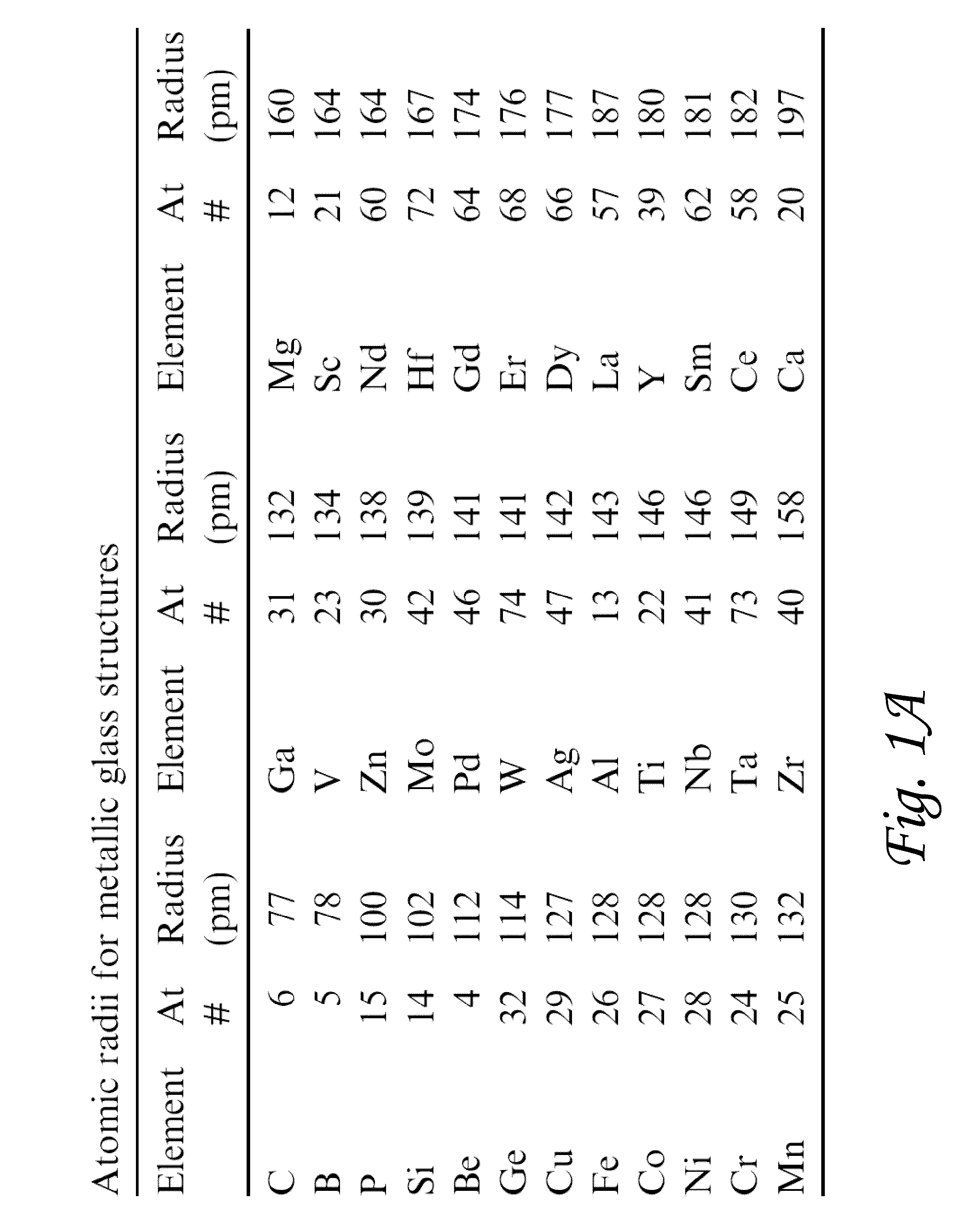

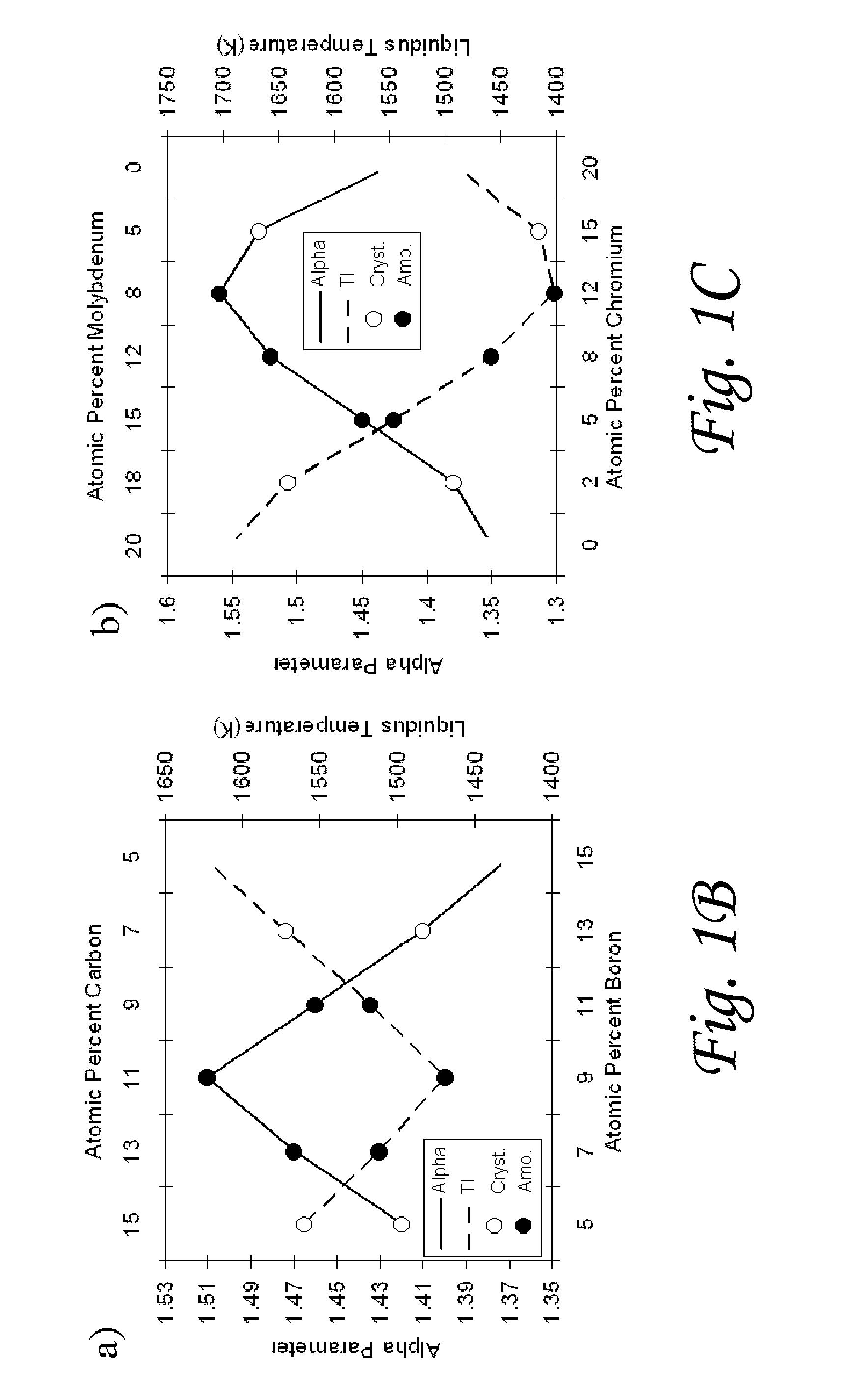

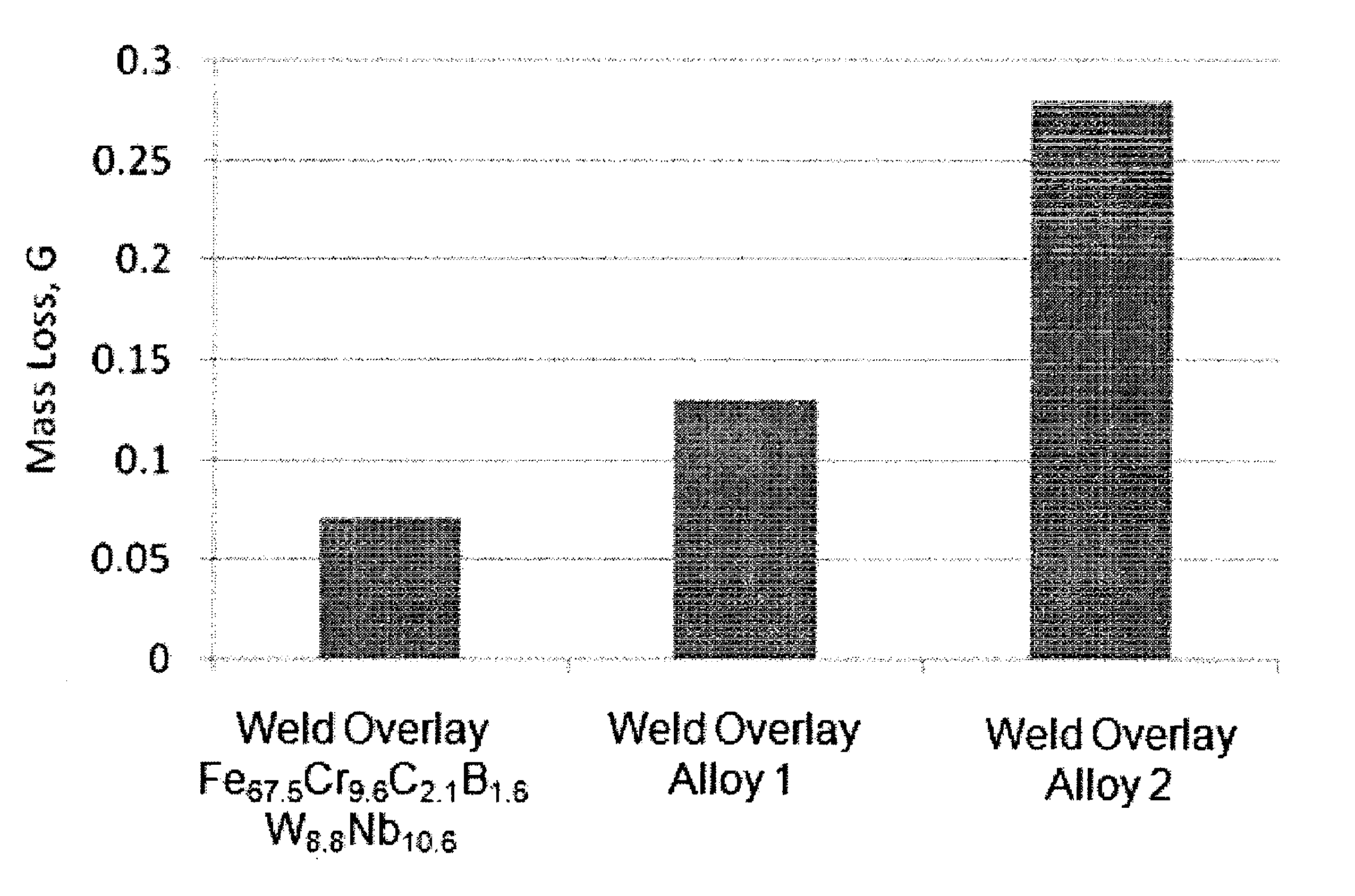

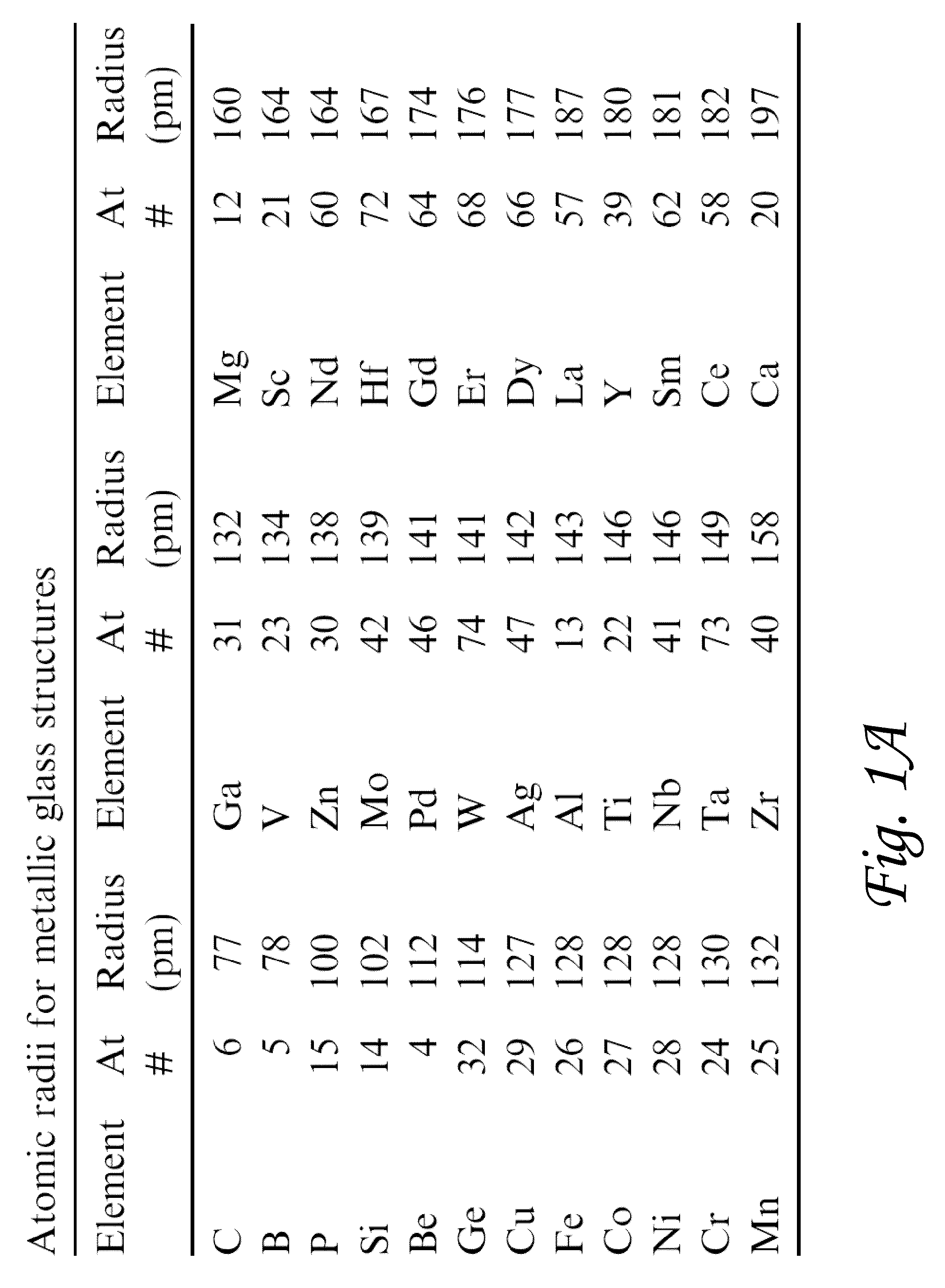

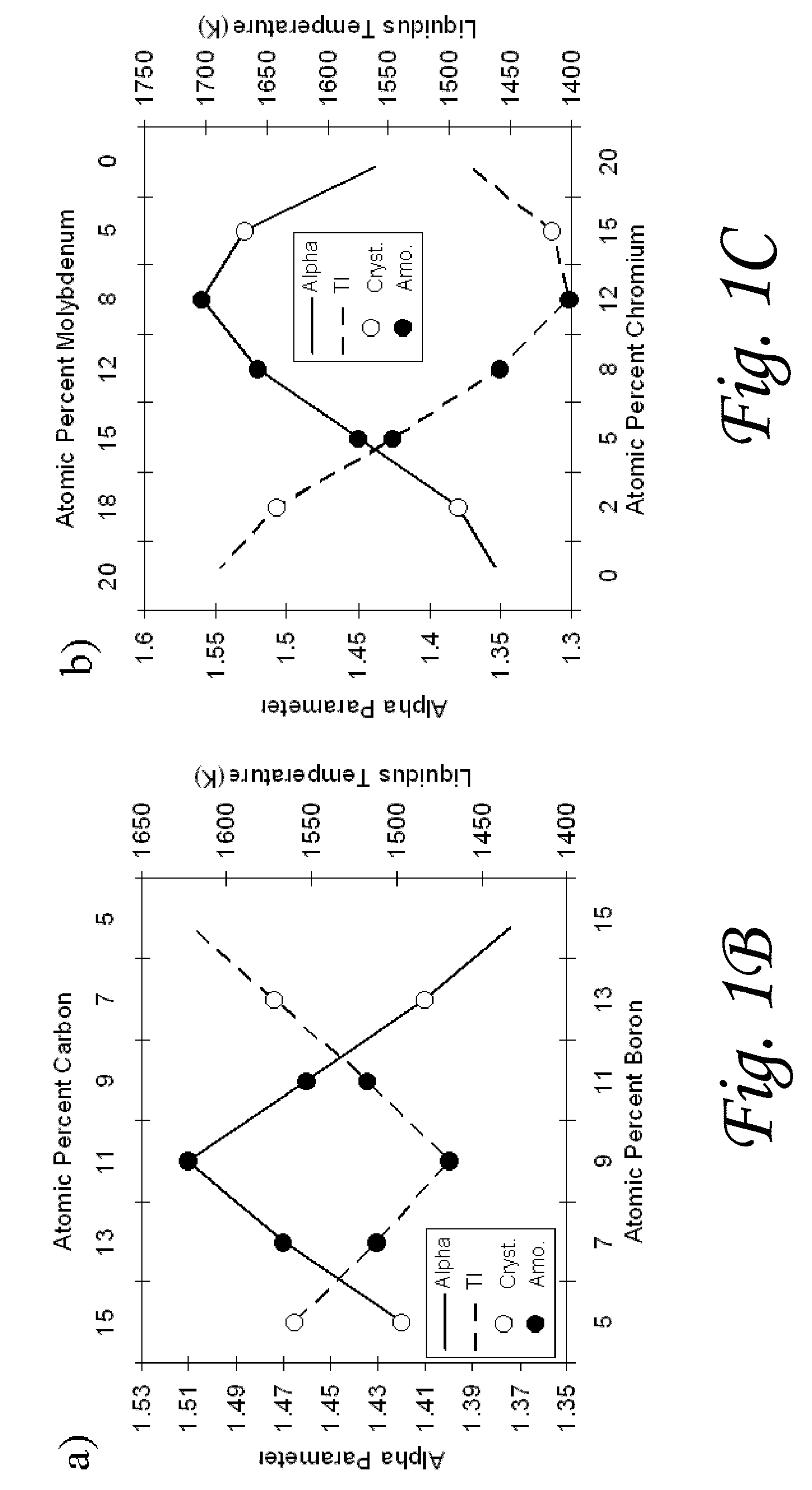

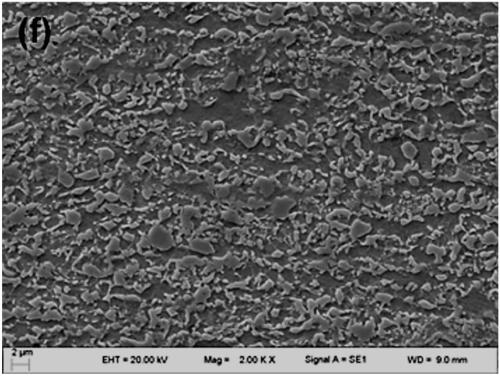

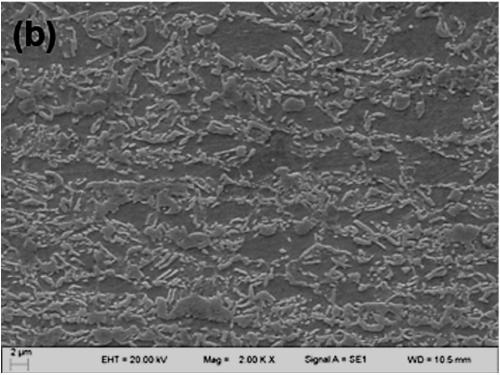

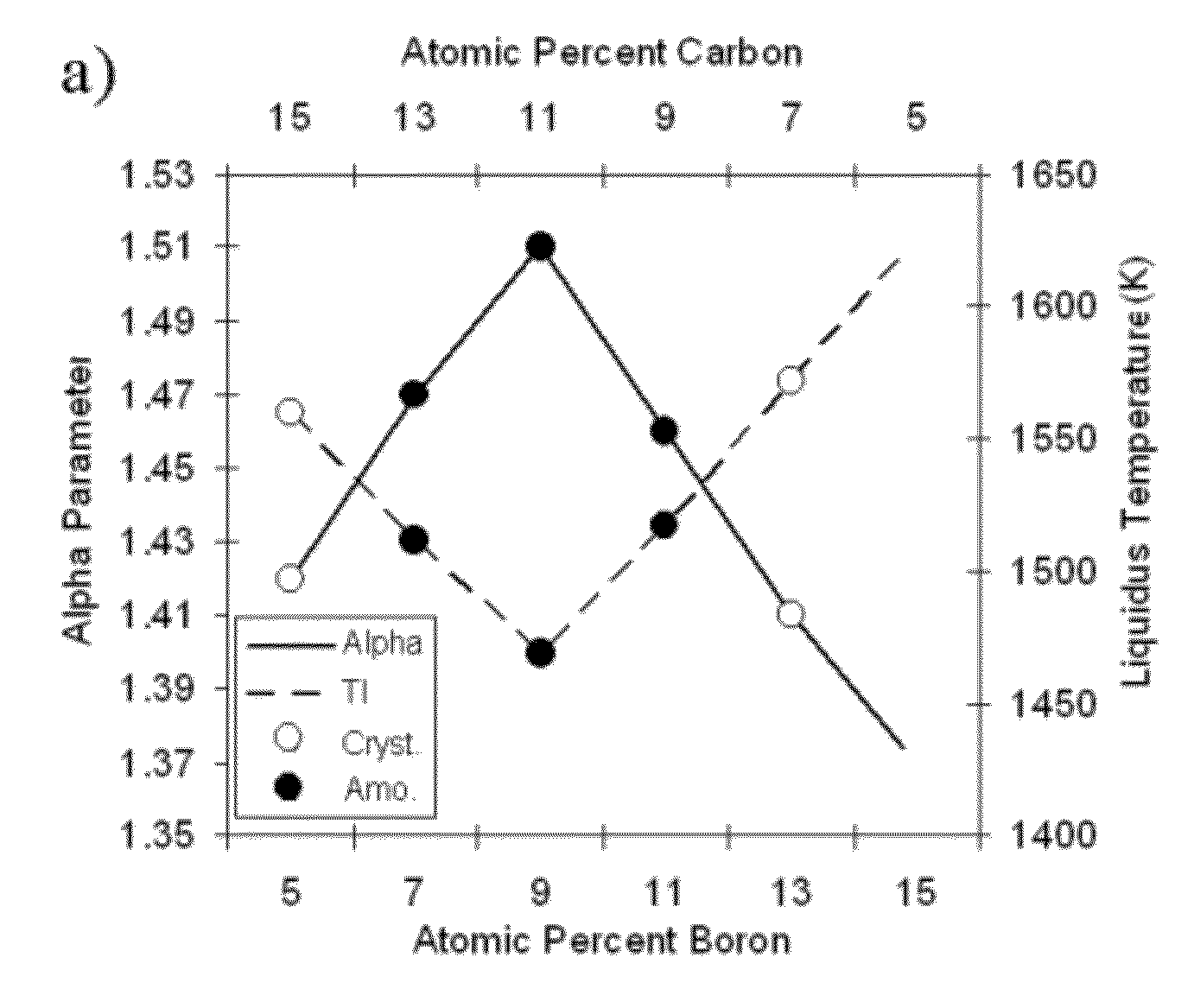

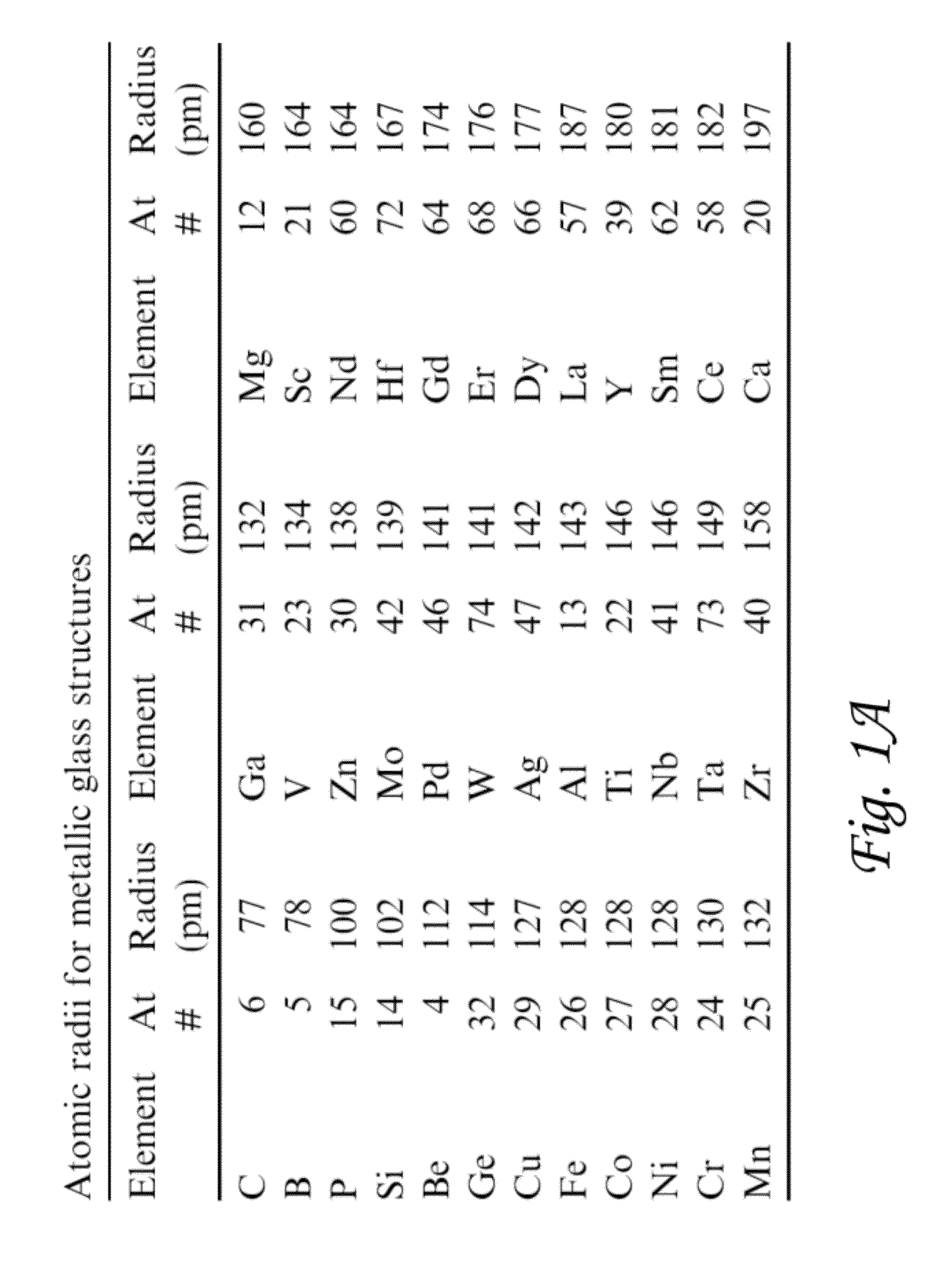

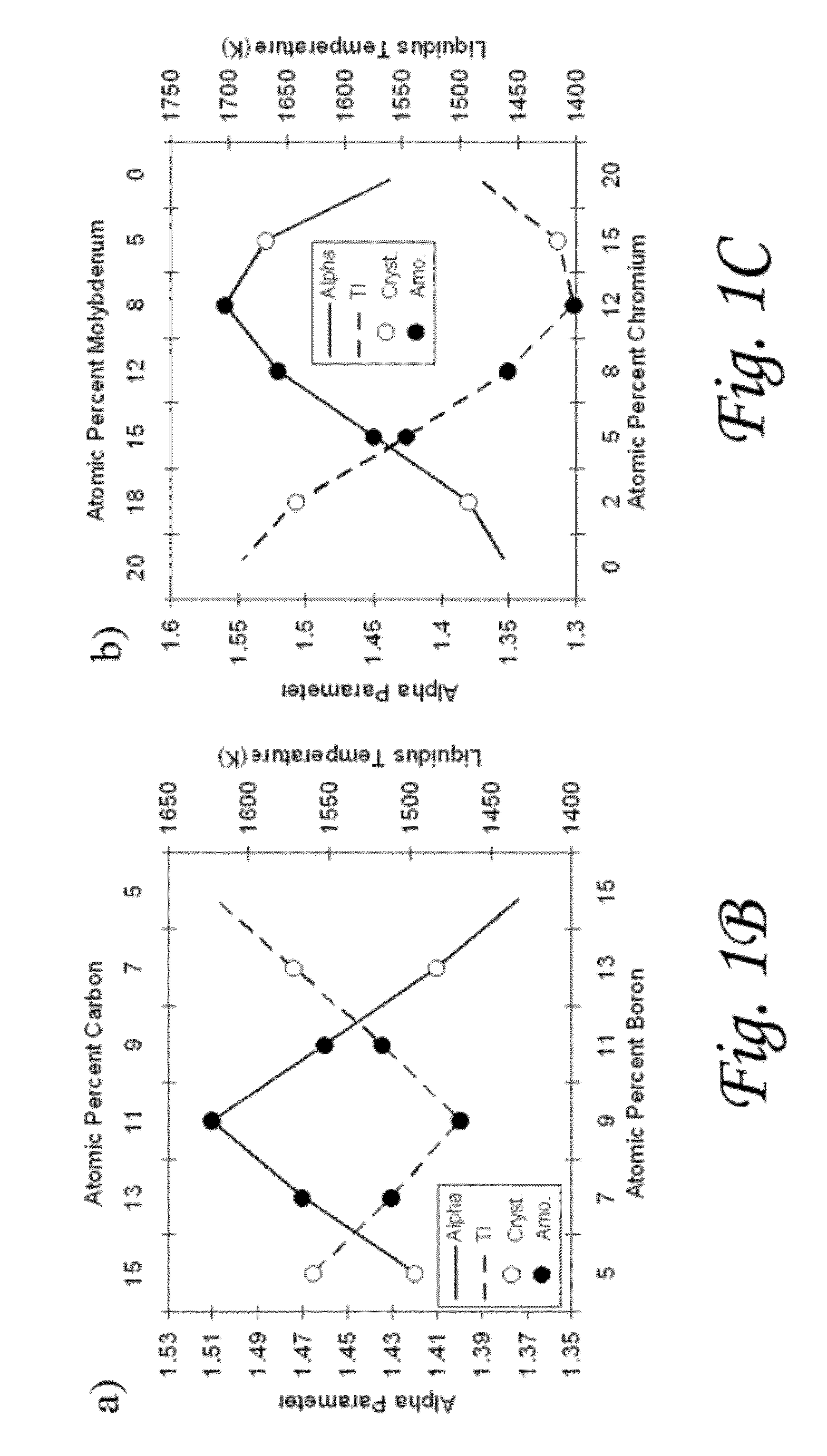

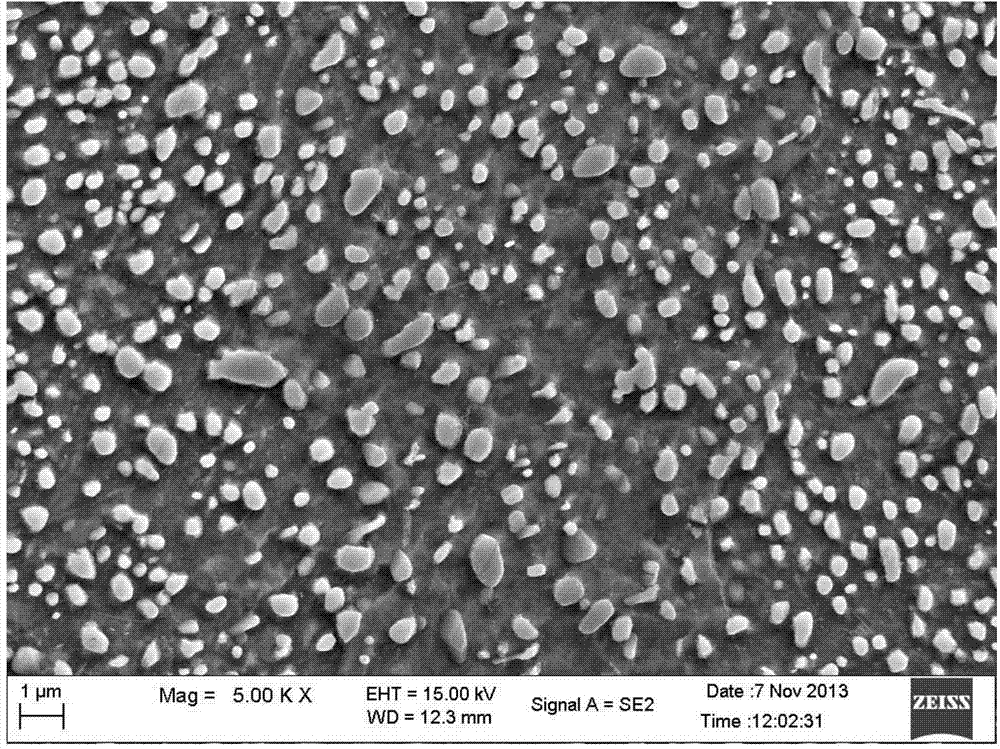

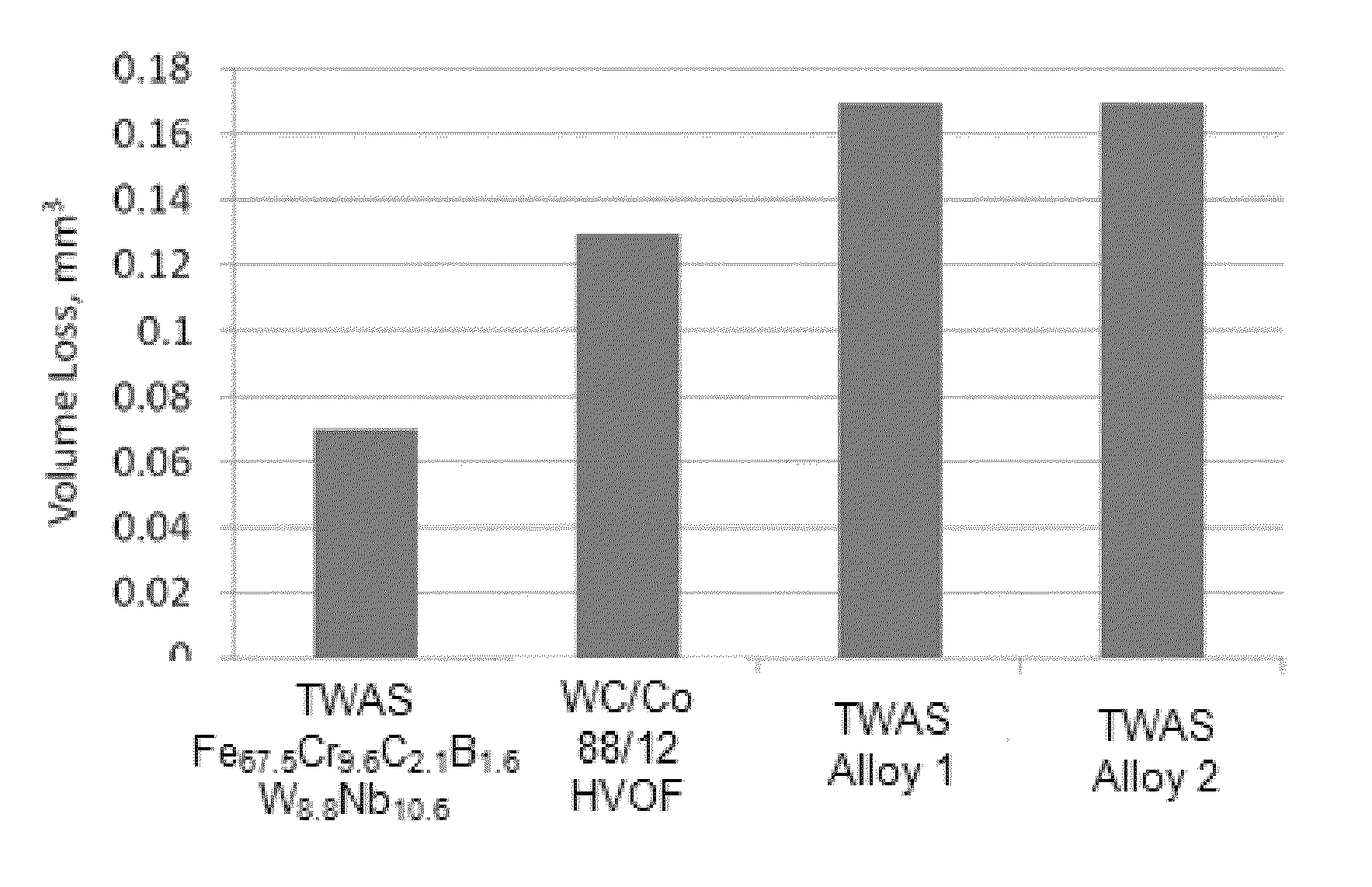

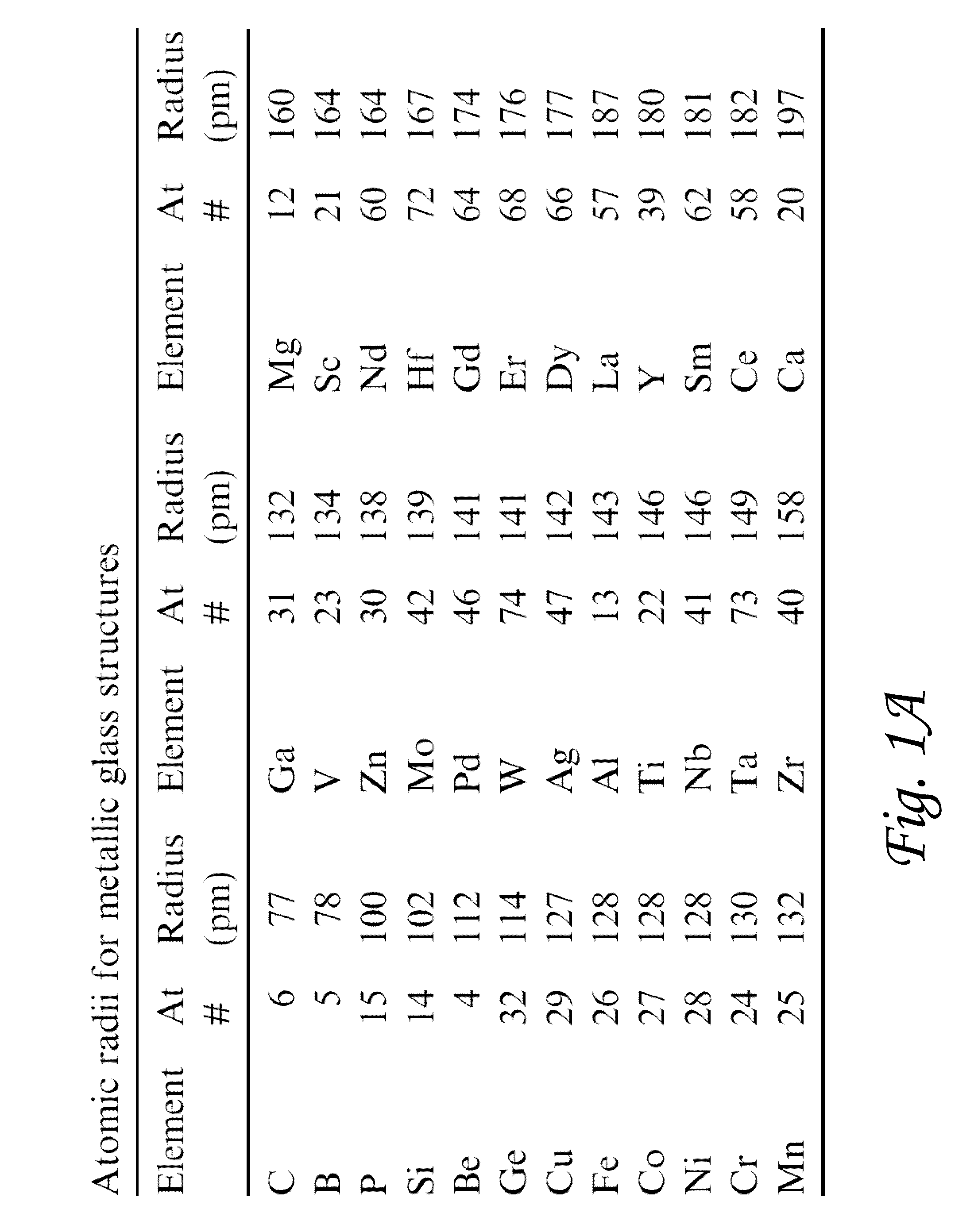

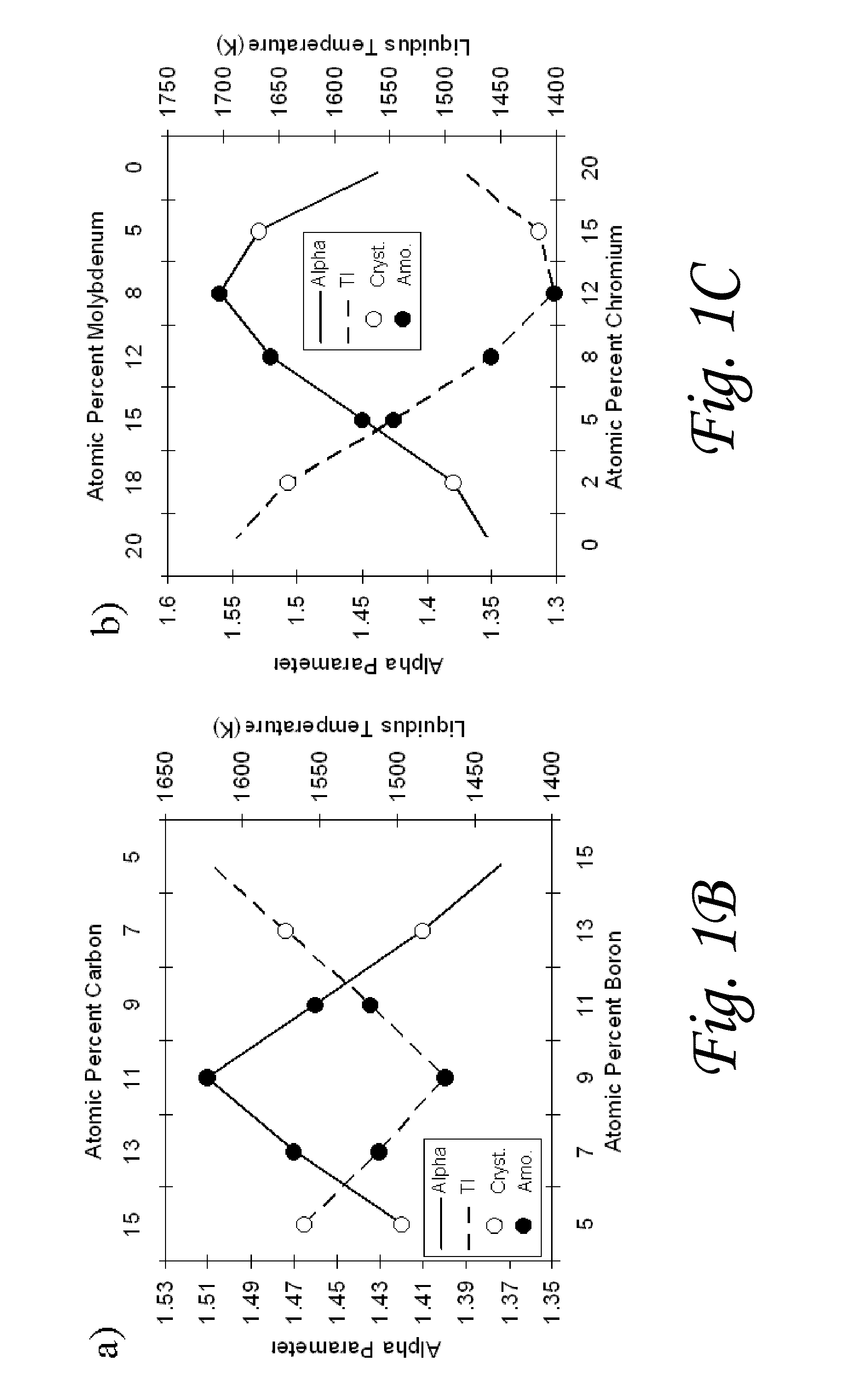

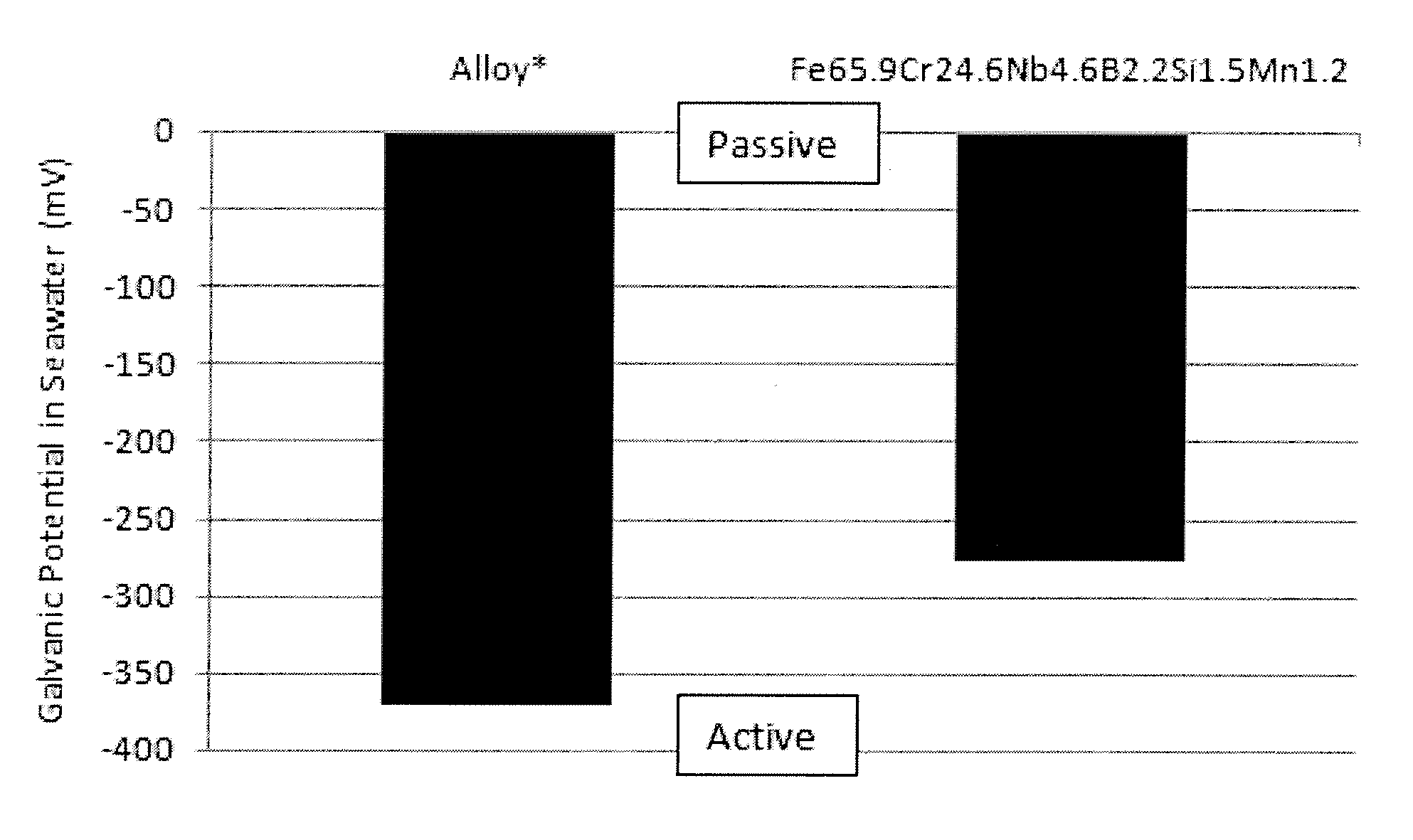

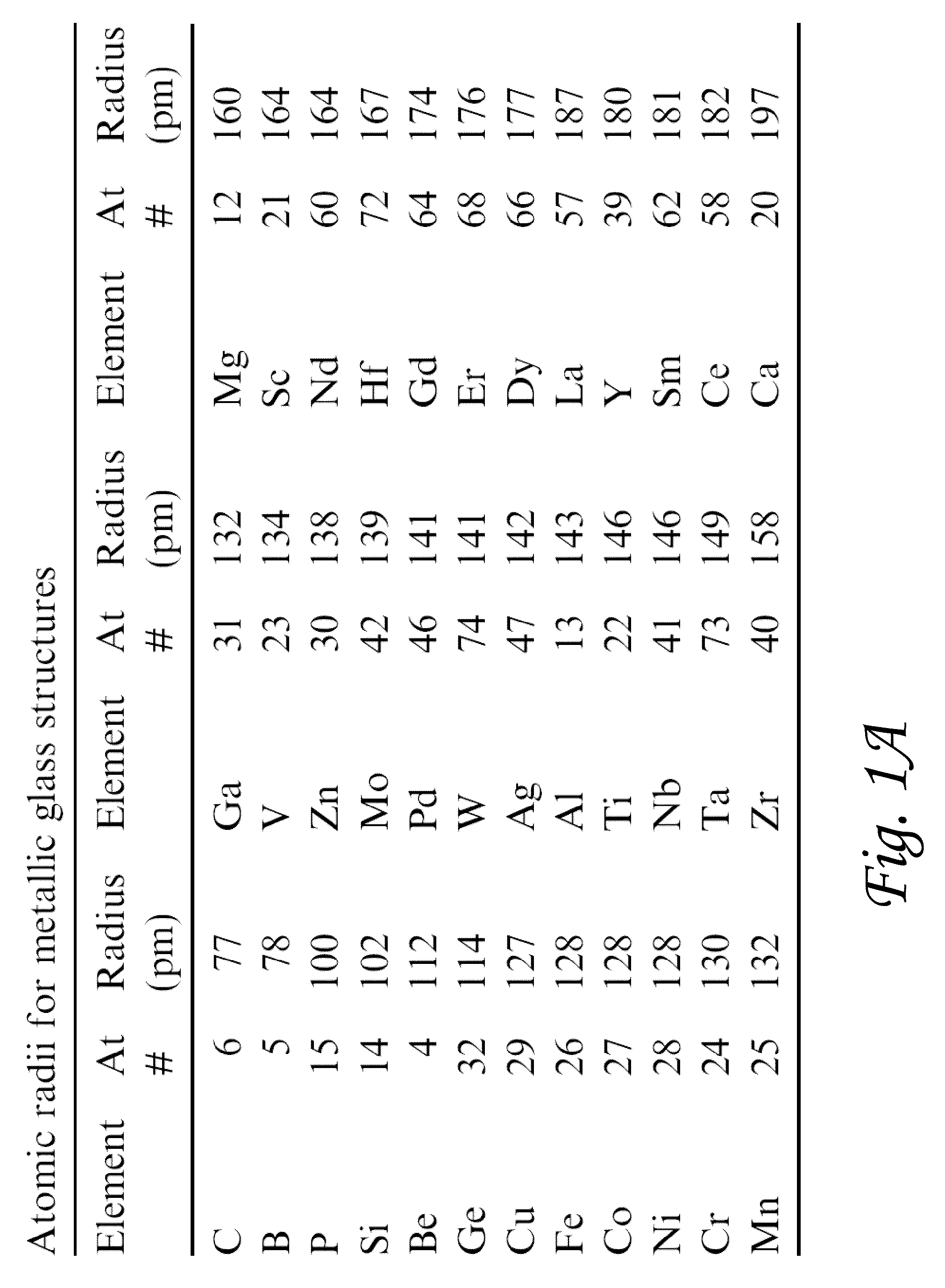

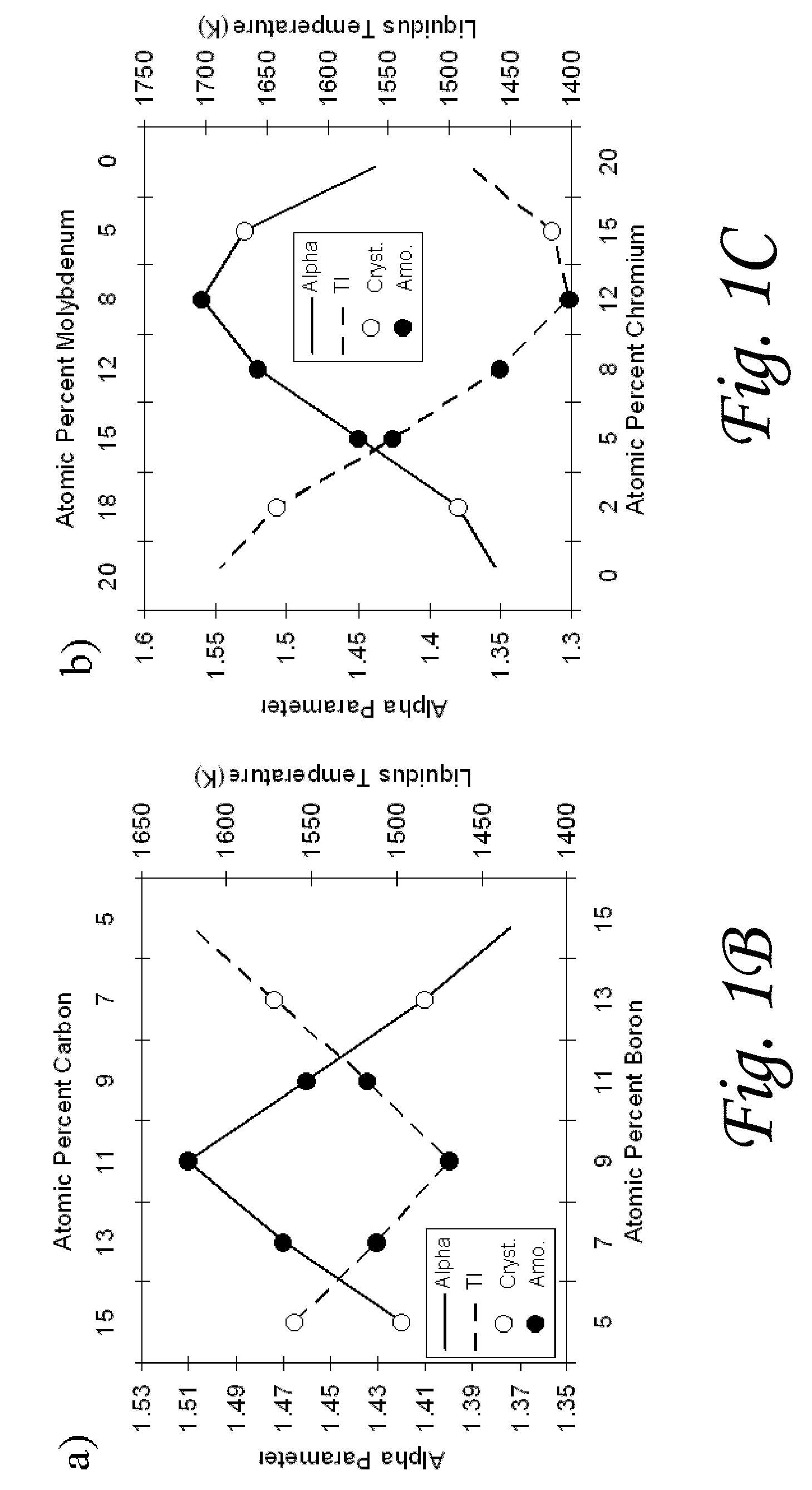

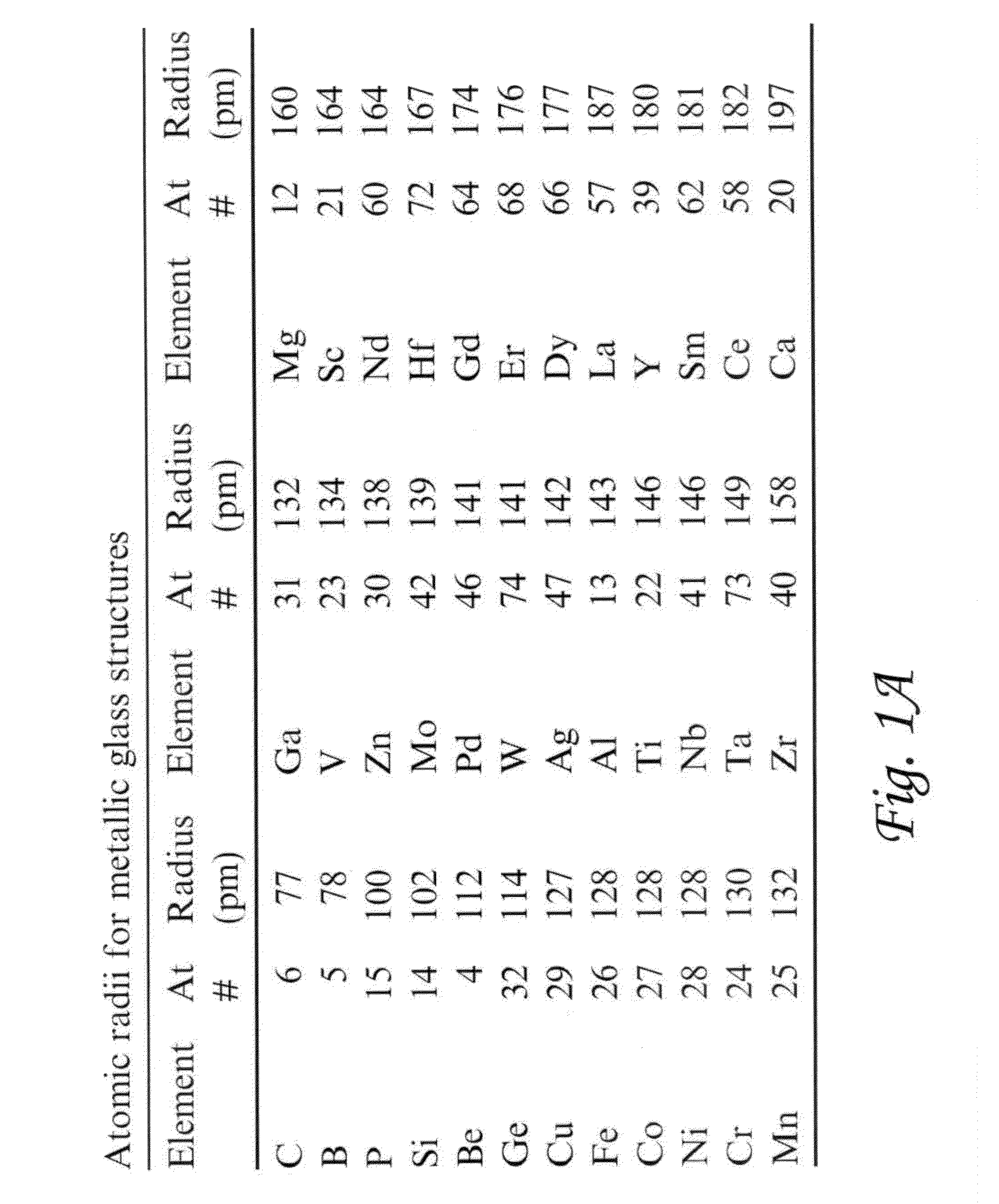

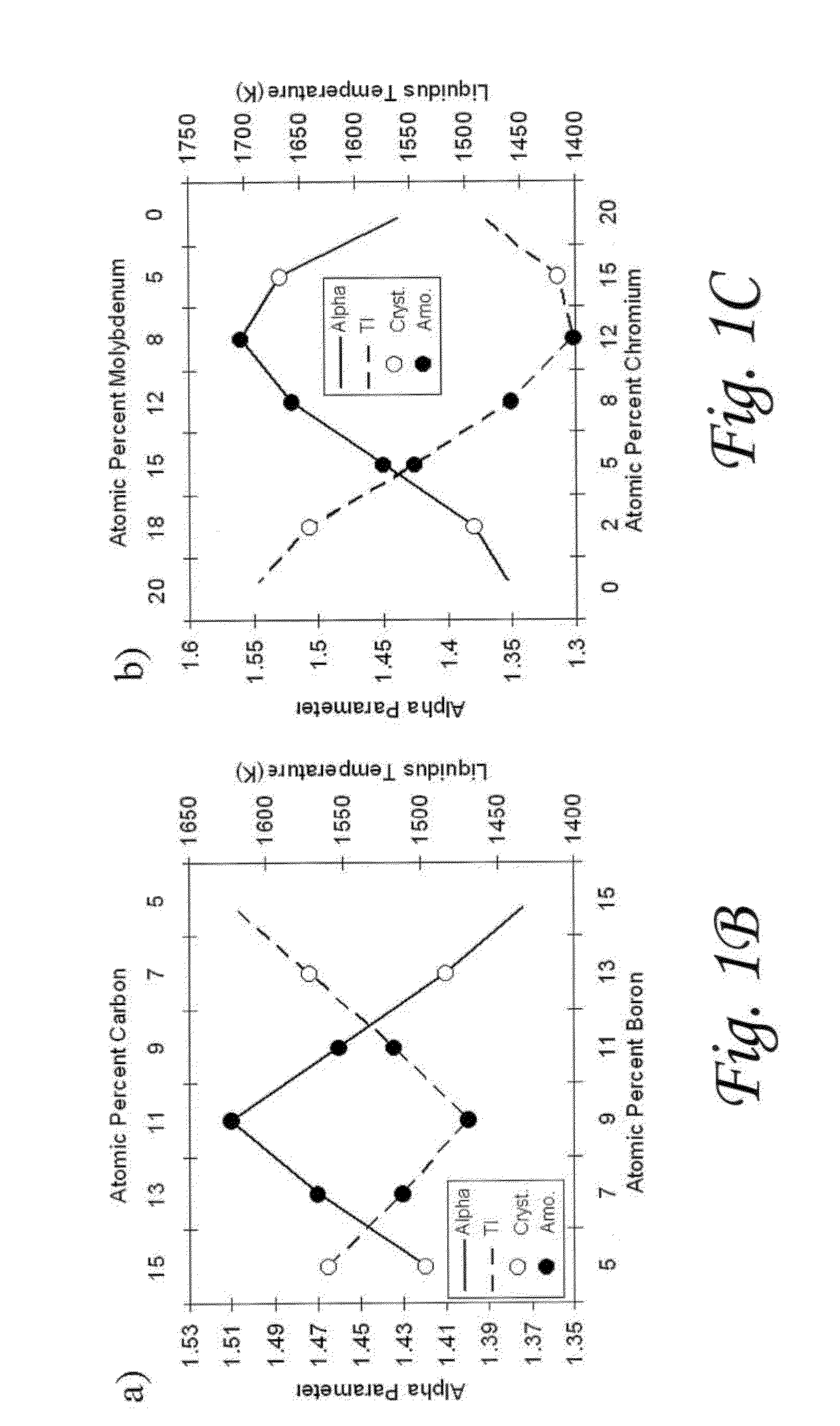

Compositions and methods for determining alloys for thermal spray, weld overlay, thermal spray post processing applications, and castings

Disclosed herein are iron-based alloys having a structure comprising fine-grained ferritic matrix and having a 60+ Rockwell C surface, wherein the ferrific matrix comprises <10 μm Nb and W carbide precipitates. Also disclosed are methods of welding comprising forming a crack free hardbanding weld overlay coating with such an iron-based alloy. Also disclosed are methods of designing an alloy capable of forming a crack free hardbanding weld overlay, the methods comprising the step determining an amorphous forming epicenter composition, determining a variant composition having a predetermined change in constituent elements from the amorphous forming epicenter composition, and forming and analyzing an alloy having the variant composition.

Owner:SCOPERTA INC

Compositions and methods for determining alloys for thermal spray, weld overlay, thermal spray post processing applications, and castings

Disclosed herein are iron-based alloys having a microstructure comprising a fine-grained ferritic matrix and having a 60+ Rockwell C surface, wherein the ferritic matrix comprises <10 μm Nb and W carbide precipitates. Also disclosed are methods of welding comprising forming a crack free hardbanding weld overlay coating with such an iron-based alloy. Also disclosed are methods of designing an alloy capable of forming a crack free hardbanding weld overlay, the methods comprising the steps of determining an amorphous forming epicenter composition, determining a variant composition having a predetermined change in constituent elements from the amorphous forming epicenter composition, and forming and analyzing an alloy having the variant composition.

Owner:SCOPERTA INC

780MPa-level low-carbon and low-alloy TRIP steel and rapid heat treatment method thereof

ActiveCN109943769AShort timeShorten the timeFurnace typesHeat treatment furnacesFerrite substrateAlloy

The invention provides 780MPa-level low-carbon and low-alloy TRIP steel and a rapid heat treatment method thereof. The steel comprises the following chemical components in percentage by mass: 0.16-0.22% of C, 1.2-1.6% of Si, 1.6-2.2% of Mn, and the balance Fe and other inevitable impurities. The method comprises the steps of rapidly heating, maintaining temperature within short time, and rapidly cooling. According to the steel and the method, the recrystallizing and phase changing processes in the heating and the phase change process in cooling are controlled, thus a three-phase structure thatbainite and austenite are uniformly distributed on a ferrite substrate can be obtained; the average crystal grain size of bainite and austenite is 1-3 microns; bainite is of a submicron particle form; austenite is of an island uniformly-distributed equiaxial crystal grain form; the whole three-phase structure comprises 35-75% by volume of bainite, 10-60% by volume of ferrite, and 5-15% by volumeof austenite; with the adoption of the rapid heat treatment, the mechanical performance of the material is improved while the heat treatment efficiency is improved; and the material performance area range is expanded.

Owner:BAOSHAN IRON & STEEL CO LTD

Alloys for hardbanding weld overlays

Disclosed herein are iron-based alloys having a microstructure comprising a fine-grained ferritic matrix and having a 60+ Rockwell C surface, wherein the ferritic matrix comprises <10 μm carbide precipitates. Also disclosed are methods of welding comprising forming a crack free hardbanding weld overlay coating with such an iron-based alloy. Also disclosed are families of alloys capable of forming crack-free weld overlays after multiple welding passes.

Owner:SULZER METCO (US) INC

GCr15 high carbon chromium bearing steel on-line rapid spheroidizing annealing technology

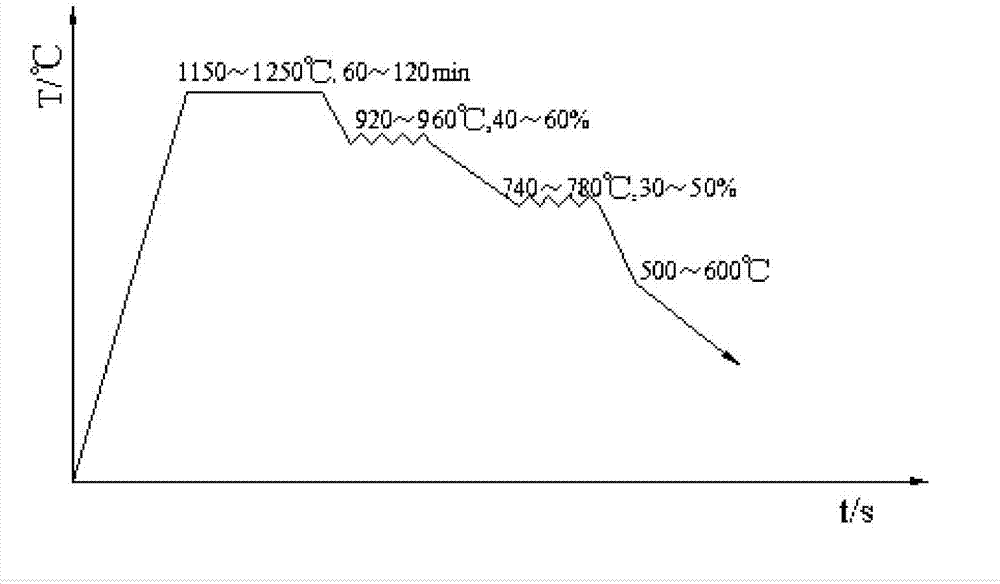

A GCr15 high carbon chromium bearing steel on-line rapid spheroidizing annealing technology belongs to the field of material engineering. The GCr15 high carbon chromium bearing steel comprises, by mass, 0.95-1.05% of C, 1.30-1.65% of Cr, 0.20-0.40% of Mn, 0.15-0.35% of Si, S<=0.015%, P<=0.02%, and the balance Fe. The technology comprises the following steps: heating to 1150-1250 DEG C along with the furnace temperature and keeping the temperature; rapidly cooling to 920-960 DEG C and applying stress to generate 40-60% of compression deformation; then rapidly cooling to 740-780 DEG C and generating 30-50% of compression deformation; then slowly cooling to 500-600 DEG C at a cooling speed of 0.3-0.5 DEG C / s; and finally rapidly cooling to room temperature. The technology is simple, after thermal deformation, the hot-rolled workpiece has the microstructure that fine uniform spherical carbides are dispersively distributed on ferrite matrix and is suitable for subsequent processing, and microstructure preparation work is provided for final quenching and tempering.

Owner:UNIV OF SCI & TECH BEIJING

Compositions and methods for determining alloys for thermal spray, weld overlay, thermal spray post processing applications, and castings

Disclosed herein are iron-based alloys having a structure comprising fine-grained ferritic matrix and having a 60+ Rockwell C surface, wherein the ferritic matrix comprises <10 μm Nb and W carbide precipitates. Also disclosed are methods of welding comprising forming a crack free hardbanding weld overlay coating with such an iron-based alloy. Also disclosed are methods of designing an alloy capable of forming a crack free hardbanding weld overlay, the methods comprising the step determining an amorphous forming epicenter composition, determining a variant composition having a predetermined change in constituent elements from the amorphous forming epicenter composition, and forming and analyzing an alloy having the variant composition.

Owner:SCOPERTA INC

Compositions and methods for determining alloys for thermal spray, weld overlay, thermal spray post processing applications, and castings

Disclosed herein are iron-based alloys having a microstructure comprising a fine-grained ferritic matrix and having a 60+ Rockwell C surface, wherein the ferritic matrix comprises <10 μm Nb and W carbide precipitates. Also disclosed are methods of welding comprising forming a crack free hardbanding weld overlay coating with such an iron-based alloy. Also disclosed are methods of designing an alloy capable of forming a crack free hardbanding weld overlay, the methods comprising the steps of determining an amorphous forming epicenter composition, determining a variant composition having a predetermined change in constituent elements from the amorphous forming epicenter composition, and forming and analyzing an alloy having the variant composition.

Owner:SCOPERTA INC

Oxidation-resistant alloying grey cast iron and preparation method thereof

The invention discloses an oxidation-resistant alloying grey cast iron and a preparation method of the oxidation-resistant alloying grey cast iron. The cast iron comprises the following components by mass percentage: 3.0-3.2% of C, 1.8-2.0% of Si, 0.50-0.70% of Mn, 0.10-0.50% of Cr, 0.20-0.30% of Ni, 0.03-0.50% of Mo, 0.5-3.0% of Al, 0.05-0.08% of Sr, 0.005-0.15% of Zn, and the balance of Fe and inevitable impurities. The preparation method comprises the steps of melting raw materials, culturing and processing, and pouring, wherein the tapping is carried out at 1450 to 1550 DEG C after melting; the molten iron is processed by being flushed in a ladle and cultured and processed along with the flow, and then slagged and casted. According to the oxidation-resistant alloying grey cast iron provided by the invention, the organization of the grey alloying cast iron material is structured by distributing 6-8 grades of D type graphite with little graphite of A type on a ferrite substrate, so that higher toughness, high heat conductivity and high-temperature oxidization resistance can be achieved, and good casting technical performance can be ensured as well; and the oxidation-resistant alloying grey cast iron can be applied to manufacturing a glass die and a light alloy metal type casting die which can bear the heat impacting of high-temperature formed liquid and cold-heat alternating stress for a long time.

Owner:SUZHOU DONGHAI GLASS MOLD

Hot rolling steel plate with characteristic of multiple grades in one steel, and manufacturing method thereof

The invention belongs to the technical field of metallurgy, and specifically relates to a hot rolling steel plate with a characteristic of multiple grades in one steel, and a manufacturing method thereof. The chemical components of the hot rolling steel plate comprise, by weight, 0.06-0.08% of C, 0.15-0.35% of Si, 1.20-1.50% of Mn, 0.01-0.02% of Nb, 0.01-0.02% of Ti, and the balance of Fe and impurities, wherein the tensile strength covers 520-715 MPa, the yield strength covers 385-498 MPa, the yield ratio covers 0.56-0.90, the elongation covers 23-36%, the work hardening index n value is 0.15-0.21, and the metallurgical structure is a ferrite matrix and martensite, a ferrite matrix and bainite, or a ferrite matrix and martensite and bainite. The preparation method comprises that: a hot-rolled steel plate sequentially passes through a laminar flow cooling section and an air cooling section, and then is cooled through an ultra-fast cooling section to achieve a temperature of 600-50 DEG C to coil, wherein the cooling rate at the ultra-fast cooling section is at least 80 DEG C / s. According to the present invention, the steel billet with the one component can be used for producing plural tissue types and proportions of steel plates with different strength grades, and rolling control and cooling control are adopted to achieve steel plate structure regulation so as to achieve the multiple grades in the one steel through the simple, inexpensive and low-cost component system.

Owner:NORTHEASTERN UNIV

Compositions and methods for determining alloys for thermal spray, weld overlay, thermal spray post processing applications, and castings

Disclosed herein are iron-based alloys having a microstructure comprising a fine-grained ferritic matrix and having a 60+ Rockwell C surface, wherein the ferritic matrix comprises <20 μm Nb and W carbide precipitates. Also disclosed are methods of welding comprising forming a crack free hardbanding weld overlay coating with such an iron-based alloy. Also disclosed are methods of designing an alloy capable of forming a crack free hardbanding weld overlay, the methods comprising the steps of determining an amorphous forming epicenter composition, determining a variant composition having a predetermined change in constituent elements from the amorphous forming epicenter composition, and forming and analyzing an alloy having the variant composition.

Owner:SCOPERTA INC

Ferrite-based tempering steel plate of which yield strength is 900MPa and production method

The invention discloses a ferrite-based tempering steel plate of which the yield strength is 900Mpa and a production method. The ferrite-based tempering steel plate not only is prepared from chemicalcomponents of C, Si, Mn, P, S, Ti, Mo, Nb, Alt, Ca and N, but also an appropriate amount of Cr is added, and the balance is Fe. Steel ladle+vacuum dual refining smelting and pouring are adopted, a continuous casting billet is subjected to hot charging and hot conveying, the charging temperature of the continuous casting billet in a heating furnace is greater than 400 DEG C, the heating temperaturein the heating furnace is 1230 to 1280 DEG C, the hot rolling finish rolling temperature is 820 to 900 DEG C, a quick-cooling rate which is greater than 25 DEGC / s is adopted for cooling after rolling, the rolling temperature is 560 to 640 DEG C, a steel coil is cut and flattened along a transverse cutting line, and the cut and flattened steel plate is subjected to tempering at (500 to 650 DEG C) / (15 to 50 minutes) in a wide flat steel heat treatment line. The production method of hot continuous rolling, steel coil flattening and opening and steel plate tempering is adopted, a microscopic structure of steel is used as a ferrite matrix, strengthening mechanism is based on precipitation strengthening and refined crystalline strengthening, and the ferrite-based tempering steel plate is low-carbon steel, has good welding and extending plasticity and forming performance, and is suitable for being used on engineering machinery vehicles or automobile vehicles.

Owner:湖南华菱涟源钢铁有限公司 +2

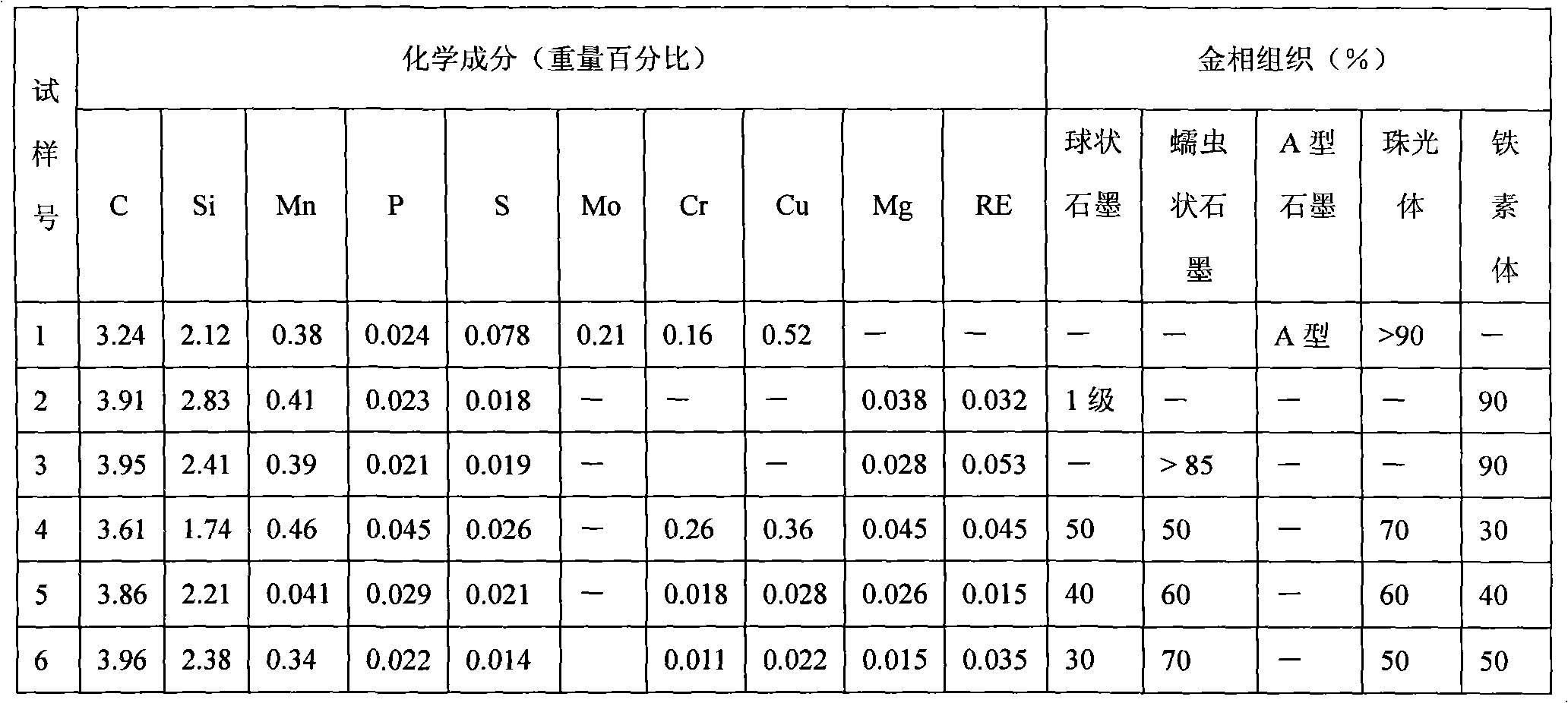

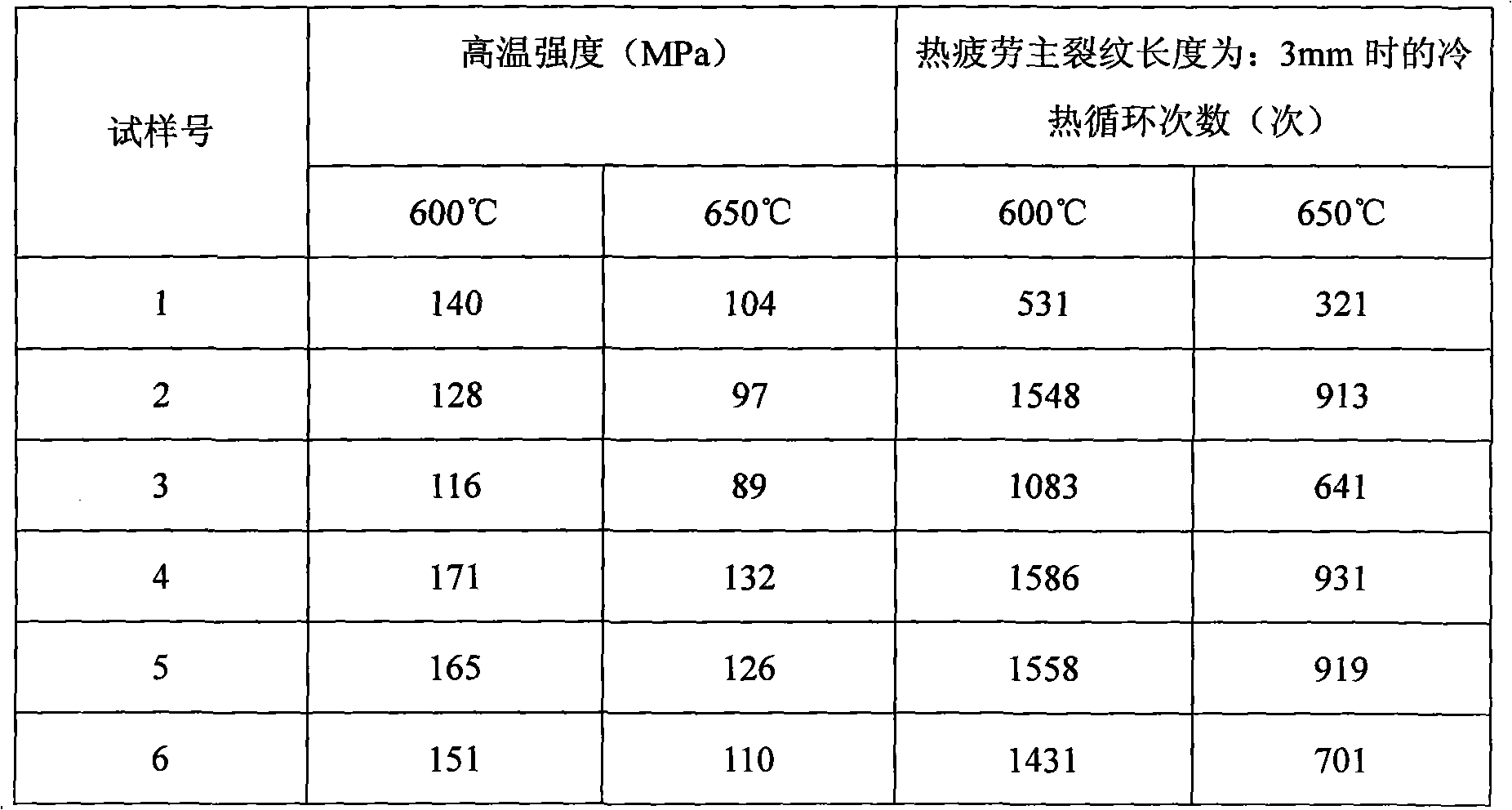

Cast iron for cast-iron brake drum

ActiveCN101967601AOvercome the contradiction of low thermal conductivityReduce toughnessBraking membersFerrite substrateChemical composition

The invention relates to an overweight heavy truck, in particular to cast iron for a cast-iron brake drum of the overweight heavy truck running on mountain roads or slopes and requiring frequent braking. Based on the chemical components of HT250, ferrite spheroidal graphite cast iron and ferrite vermicular iron, the chemical components of the cast iron are redesigned and comprise C, Si, Mn, P, S, Cr, Cu, Mg, RE and Fe; and the cast iron of which the spheroidal and vermicular graphite is distributed on a pearlite and ferrite diphase substrate simultaneously is obtained. The coexisting spheroidal and vermicular graphite replaces the A type graphite or single spheroidal graphite or single vermicular graphite in the traditional cast iron for the cast-iron brake drum; and the pearlite and ferrite diphase substrate replaces the single pearlite or ferrite substrate in the traditional cast iron for the cast-iron brake drum. The high-temperature strength of the brake drum is enhanced, the thermal fatigue resistance of the brake drum is improved and the service life of the brake drum is prolonged.

Owner:JILIN UNIV

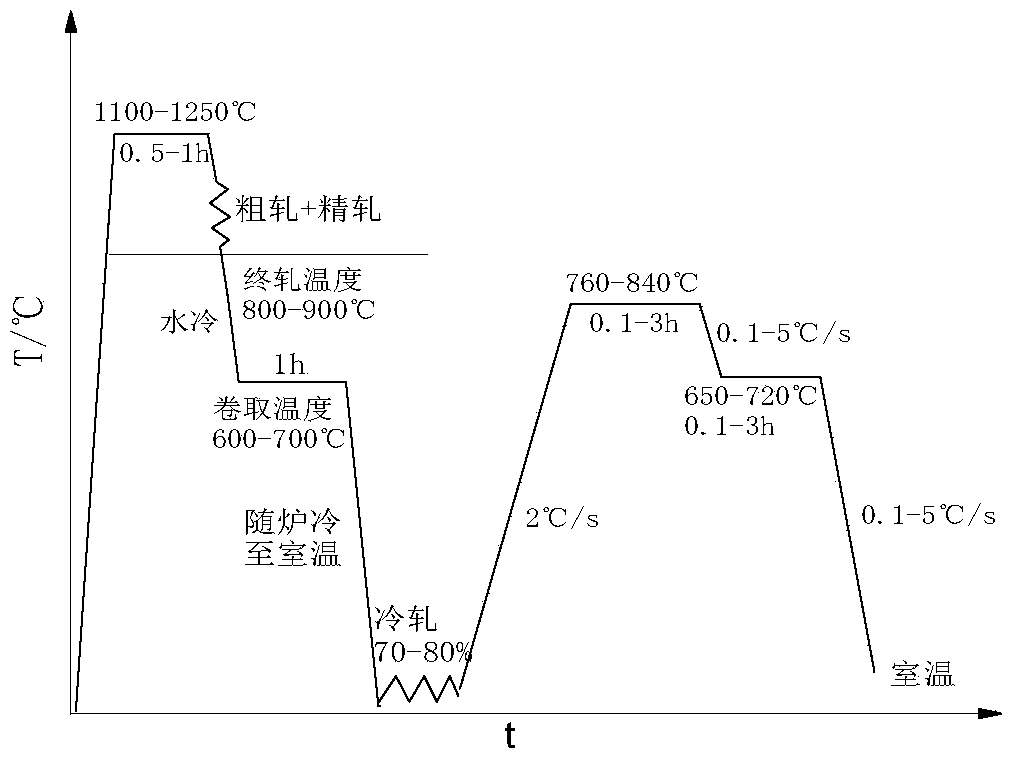

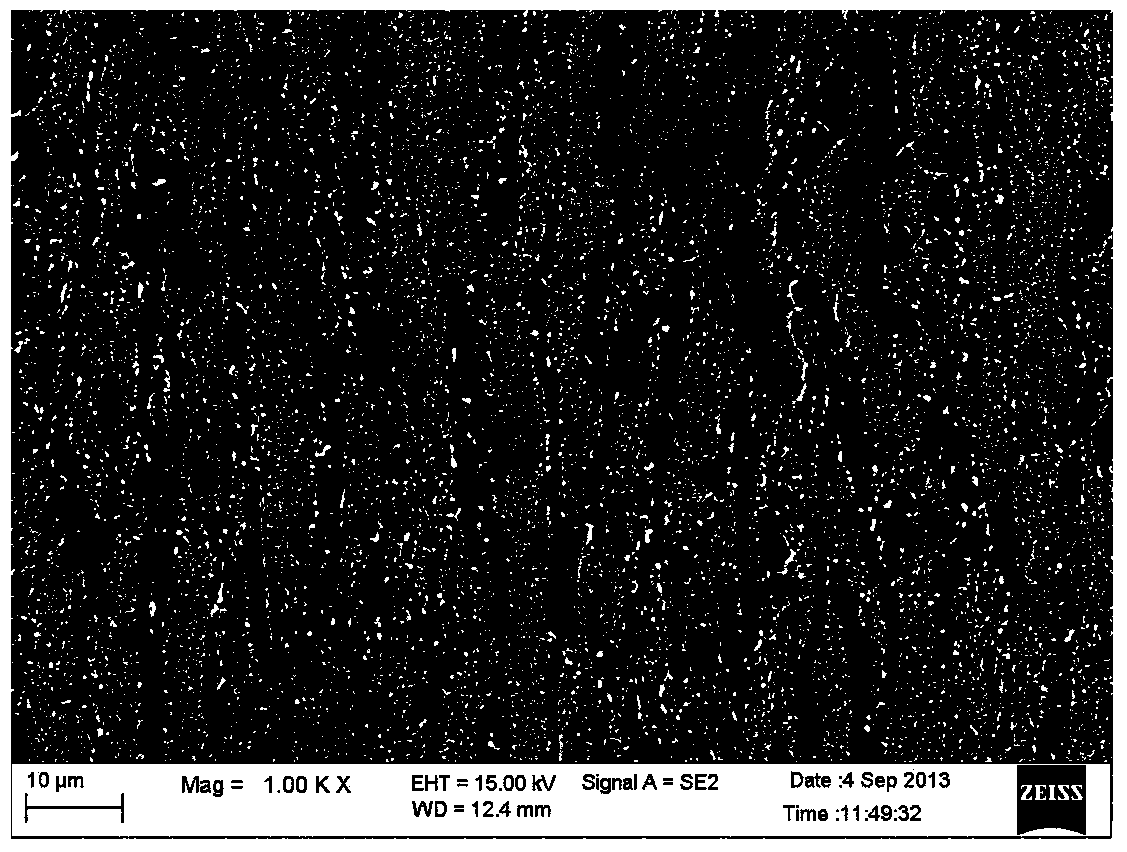

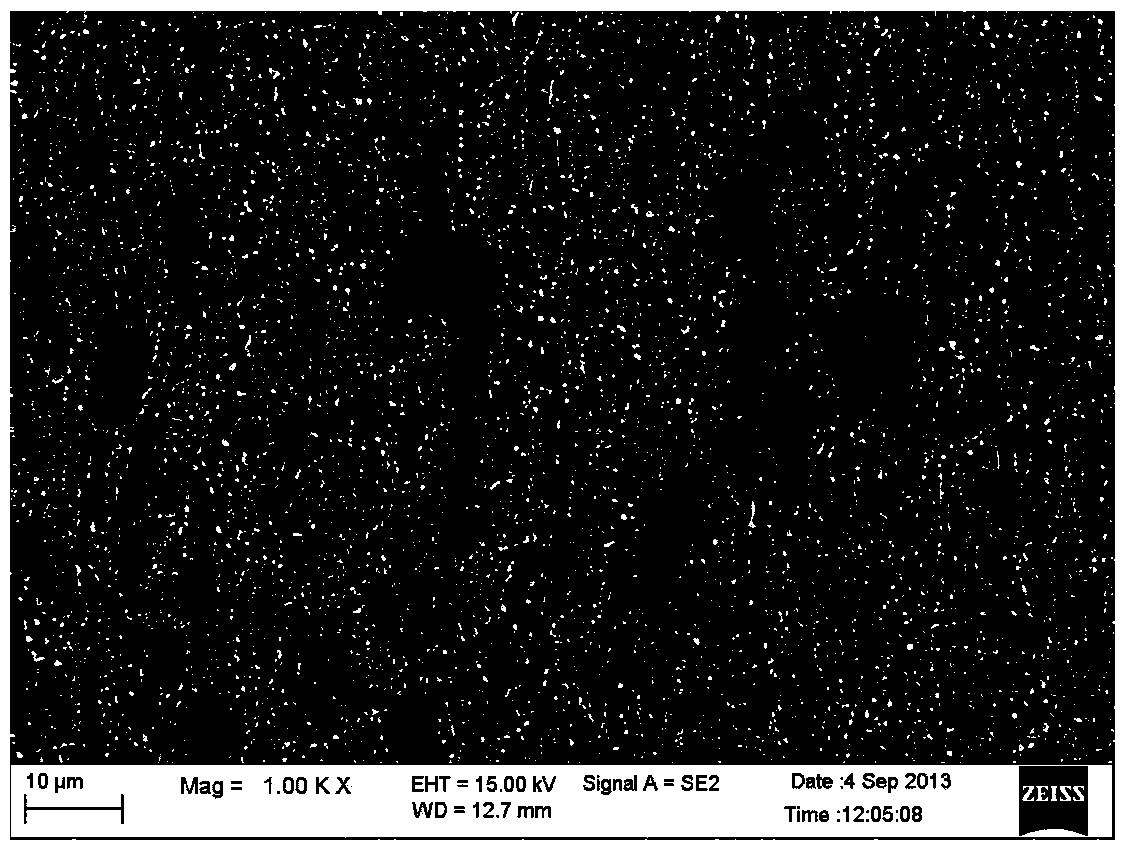

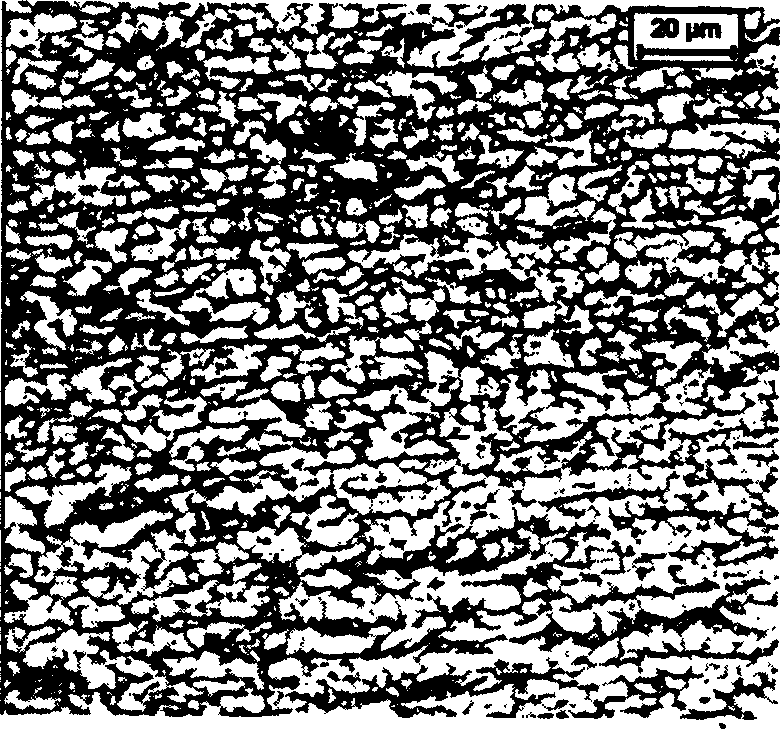

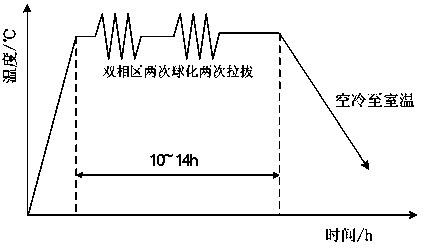

Annealing method of ultrahigh-strength hot-forming steel

The invention discloses an annealing method of ultrahigh-strength hot-forming steel, belonging to the technical field of heat treatment on high-strength automobile steel. After hot rolling and cold rolling, the ultrahigh-strength hot-forming steel is subjected to annealing treatment to obtain a steel plate substrate before hot forming. The hot rolling process comprises the steps of heating a hot-rolled plate blank to 1,100-1,250 DEG C, and preserving heat for 0.5-1 hour, wherein the final rolling temperature is 800-900 DEG C, the coiling temperature is 600-700 DEG C, and the cold rolling reduction rate is 70-80%. The annealing process comprises the steps of slowly heating the cold-rolled steel plate to a two-phase region (alpha+gamma), namely a temperature above A1; preserving heat for 0.1-5 hours; cooling to a temperature below A1 at a cooling speed of 0.1-10 DEG C per second; preserving heat for 0.1-5 hours; finally, cooling to room temperature at a cooling speed of 0.1-10 DEG C per second. According to the ultrahigh-strength hot-forming steel prepared by the method disclosed by the invention, granular carbides are dispersed on a ferrite matrix of the microscopic structure of the steel plate before hot forming, the carbides are uniformly distributed, the reversion and re-crystallization of the ferrite are sufficient, and the sufficiency and uniformity of austenitizing in a hot forming heating stage are facilitated; compared with a traditional cover annealing process, the annealing time is short, and the production efficiency is high.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of low carbon 42MPa grade composite fortified ultrafine crystal grain band steel

A 420 MPa-class low-carbon band steel with superfine crystal grains contains C (0.1-0.14 wt.%), Si (0.18-0.40), Mn (0.85-1.10), P (0-0.01), S (0-0.01) and Fe (rest). Its preparing process includes such steps as smelting, conticasting, coarse rolling, fine rolling, cooling, and winding. Its advantages are multi-phase structure including ferrite, bainite and pearlite, high yield strength (420-450 MPa), high tension strength (530-550 MKPa) and low cost. It can replace high-strength low-alloy steel.

Owner:NORTHEASTERN UNIV

V-N microalloyed high-toughness large-specification steel angle and production method thereof

ActiveCN103911549AOptimizing the formulation of chemical ingredientsExcellent performance indexTemperature control deviceFerrite substrateProduction line

The invention relates to a V-N microalloyed high-toughness large-specification steel angle and a production method thereof. The V-N microalloyed high-toughness large-specification steel angle is composed of the following chemical components in percentage by weight: 0.14-0.20% of C, 0.20-0.50% of Si, 1.30-1.55% of Mn, less than or equal to 0.020% of P, less than or equal to 0.010% of S, 0.009-0.016% of N, 0.06-0.10% of V, 0.015-0.030% of Als and the balance of Fe. According to the formula of the chemical components and in a large-scale profile steel production line, the crystalline grains are thinned by controlling the parameters of continuous casting and rolling processes, and a cementite in a pearlite is distributed in a form of granules or in a short-rod form by use of a rapid controlled cooling process, and fine vanadium carbonitride or vanadium oxide particles are scattered and distributed on a ferrite substrate, and therefore, the purpose of improving the strength and the low-temperature toughness of the large-specification steel angle is reached; the mechanical property indexes of the V-N microalloyed high-toughness large-specification steel angle meet the standard requirements of Q460E.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

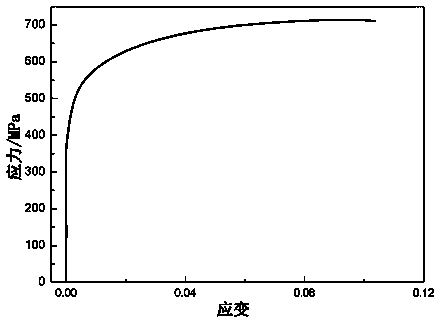

Preparation technology for nodular cast iron with TRIP (transformation-induced plasticity) effect

The invention relates to a preparation technology for nodular cast iron with a TRIP (transformation-induced plasticity) effect. The preparation technology can be used for producing a nodular cast iron part, of which the strength of extension is greater than 700MPa, the elongation is 8%, and the product of strength and elongation is greater than 6000MPa%. The cast tissue is a complex phase tissue of ferrite base, bainite, retained austenite, a bit of martensite and graphite, soft ferrite base endows the whole cast with good ductility, hard bainite, distributed in the ferrite base in a complex intertwining manner, serves as a skeleton so as to improve the strength of the cast, a bit of martensite is the hardest phase in the tissue and plays a role in improving the strength of the cast, furthermore, a bit of retained austenite not only improves the ductility of the cast, but also can produce a TRIP effect at room temperature. Therefore, the nodular cast iron with the TRIP effect has better comprehensive property than common isothermal quenching nodular cast iron, improves both the ductility and strength of the cast, and has higher product of strength and elongation.

Owner:UNIV OF SCI & TECH BEIJING

Heatproof alloy vermicular cast iron and method for preparing same

The invention discloses heatproof alloy vermicular cast iron and a method for preparing the same. The vermicular cast iron comprises, by weight, 2.6% to 3.1% of C, 3.4% to 4.5% of Si, 0,20% to 0.40% of Mn, 0.20% to 0.30% of Ni, 0.40% to 0.60% of Mo, 0.5% to 0.8% of Al, 0.05% to 0.08% of Sr, 0.02% to 0.04% of Ca, 0.04% to 0.06% of Mg, 0.03% to 0.05% of Er and the balance being Fe and unavoidable impurities. Smelting and vermiculizing treatment, inoculation and pouring are performed on the materials, wherein the tapping temperature after smelting is in a range between 1450 DEG C to 1550 DEG C, slagging-off pouring is performed to molten iron after in-ladle flushing and along-flow inoculation. Material tissues of the alloy vermicular cast iron are that vermicular graphite with a vermiculizing rate of 5 to 60 is distributed on a ferrite matrix, not only high toughness, heat conductance and high temperature oxidation resistance proprieties are provided, but also good casting process performances are provided, and the cast iron can be used for manufacturing glass molds and light alloy metal casting moulds which bear high temperature forming liquid thermal shock and cold and hot alternate alternating stress for a long time.

Owner:SUZHOU DONGHAI GLASS MOLD

High-strength weather-resistant steels and production method thereof

The invention provides high-strength weather-resistant steels. The high-strength weather-resistant steels comprise the following chemical compositions of, in percentage by weight, 0.06%-0.07% of C, 0.23%-0.26% of Si, 1.40%-1.50% of Mn, less than or equal to 0.009% of P, less than or equal to 0.007% of S, less than or equal to 0.015% of Als, 0.0%-0.19% of Ni, 0.0%-0.51% of Cr, 0.31%-0.33% of Cu, 0.110%-0.12% of Ti, 0.030%-0.036% of Nb, 0.0%-0.09% of Sb, less than or equal to 0.055% of N, and the balance Fe and inevitable impurities. According to the high-strength weather-resistant steels, the balance of high strength, high plasticity and high toughness is achieved, meanwhile, near-all-ferrite matrix tissue is obtained, extra volume of the grain boundary is greatly reduced, relatively high coiling temperature is adopted, dislocation density is greatly reduced, and high weather resistance is achieved.

Owner:湖南华菱涟源钢铁有限公司 +2

Continuous annealing low-alloy and high-strength steel plate and production method thereof

A continuously annealed low-alloy high-strength steel plate and its production method, the mass percentage of its components is: C 0.06~0.10%, Si≤0.50%, Mn 0.6~1.2%, P≤0.025%, S≤0.025%, N≤50ppm, Als 200~500ppm, Nb 0.030-0.060%, the rest is iron and inevitable impurities. This high-strength steel plate adopts a low-carbon design, and the material strength is enhanced through Si and Mn solid solution strengthening. Through separate Nb micro-alloying, the material strength is improved while still maintaining good shape; this high-strength steel plate does not use Ti elements for processing. Microalloying is beneficial to the stability of finished product performance; this high-strength steel plate has good strength, plasticity and formability. This method adds an appropriate amount of Si element and purifies the ferrite matrix, so that the steel obtained has good shaping. At the same time, combined with the relevant continuous retreat process parameters, the material has continuous yield characteristics, ensuring that the user can The surface quality of the product.

Owner:TANGSHAN IRON & STEEL GROUP

Manufacturing method for automobile transmission gear

The invention discloses a manufacturing method for an automobile transmission gear, and relates to the field of manufacturing of automobile parts. The method comprises the following steps: (1) blank forging, (2) spheroidizing annealing, (3) turning machining, (4) hobbing, (5) gear shaving, (6) carburization, (7) quenching and tempering and (8) grinding machining. According to the method, spheroidizing annealing treatment is adopted, so that the cutting performance of the gear is improved, a structure with spheroidized or granular carbide uniformly distributed on a ferrite substrate is obtained for preparation for subsequent heat treatment; a gas carburization method is adopted, and volatile kerosene is used as a carburizer, so that carburization effects are effectively improved, the thickness of a carburized layer is increased, the surface of the gear is hard and wear-proof, and high toughness of the core of the gear is maintained; quenching and tempering heat treatment is adopted after carburization, so that the carburization effects are further consolidated, and the mechanical performance of the gear is improved.

Owner:JIANGXI UNIV OF TECH

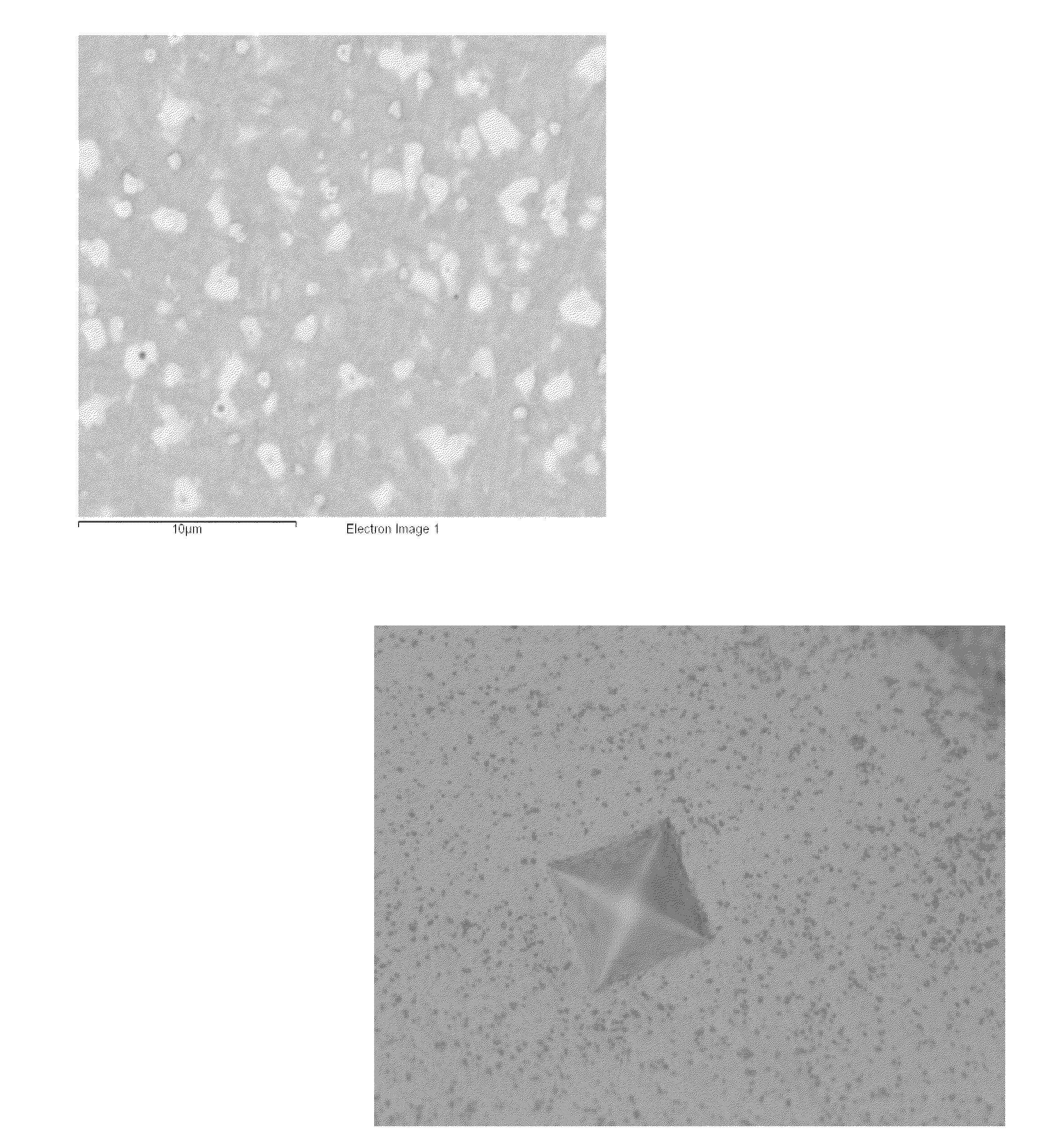

Spheroidizing annealing method for Cr and Mo steel with sheet type microstructure

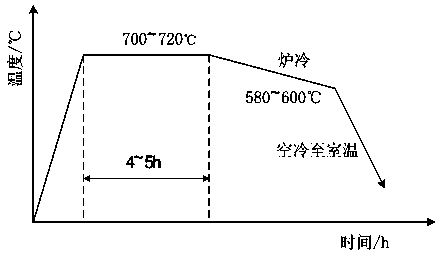

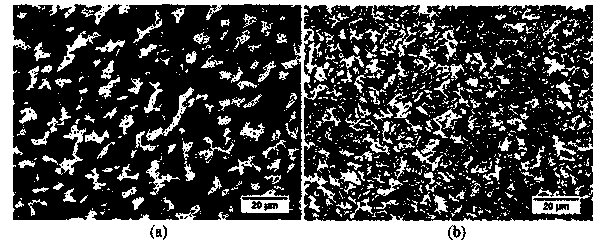

The invention belongs to the technical field of metallurgy, and in particular relates to a spheroidizing annealing method for Cr and Mo steel with a sheet type microstructure. The spheroidizing annealing method comprises the steps of putting a Cr and Mo steel rolled product sample into a heating furnace, heating to 700-720 DEG C, preserving the temperature for 4-5 hours, then performing furnace cooling to 580-600 DEG C, taking out the Cr and Mo steel rolled product from the furnace, and cooling to room temperature, wherein the microhardness of the Cr and Mo steel rolled product subjected to spheroidizing annealing is 162.20-175.35HV, and the microstructure of the Cr and Mo steel rolled product consists of granular carbides dispersed on a ferritic matrix; the granular carbides have spheroidized structures in the level 5-6. According to the method, sub-medium temperature is preserved for certain time, and then the furnace cooling time is controlled, so that spheroidizing-annealed steel with high performance is obtained. The high preserved temperature is lower than the preserved temperature of the original technology, and the heat preservation time is shortened by almost three times, so that the energy consumption is obviously reduced, and the spheroidizing annealing efficiency is improved; the hardness of the steel subjected to the spheroidizing annealing technology is obviously reduced, the structure of a spheroidal pearlite is dispersive and fine, and the spheroidizing rate is high; the Cr and Mo steel subjected to spheroidizing annealing is high in cold heading performance and has a good application prospect.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com