Hot rolling steel plate with characteristic of multiple grades in one steel, and manufacturing method thereof

A hot-rolled steel plate and steel plate technology, applied in the field of hot-rolled steel plate and its manufacturing, can solve the problems of various component systems and complex processes, and achieve the effects of reducing production costs, low cost, and expanding the variety of hot-rolled products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of the above-mentioned one-steel multi-stage hot-rolled steel plate is:

[0032] According to the chemical composition: 0.08%C, 0.15%Si, 1.50%Mn, 0.02%Nb, 0.01%Ti, the balance is Fe to smelt molten steel and cast it into billets;

[0033] Heat the billet to 1200°C, keep it warm for 2 hours, and then carry out hot rolling. The hot rolling adopts a two-stage rolling process of austenite recrystallization zone + austenite non-recrystallization zone, the starting rolling temperature is 1150°C, and the final rolling temperature is 810°C. ℃ to obtain a hot-rolled steel plate with a thickness of 4.0mm;

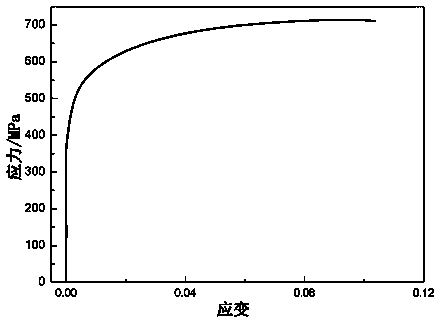

[0034]The hot-rolled steel plate is sequentially cooled to 720°C in the laminar flow cooling section, air-cooled in the air-cooling section for 5s, and then cooled to 250°C in the ultra-rapid cooling section, and then coiled. The cooling rate of the ultra-rapid cooling is at least 80°C / s. Ferrite-martensite-bainite composite steel with tensile strength...

Embodiment 2

[0037] The preparation method of the above-mentioned one-steel multi-stage hot-rolled steel plate is:

[0038] According to the chemical composition: 0.08%C, 0.15%Si, 1.50%Mn, 0.02%Nb, 0.01%Ti, the balance is Fe to smelt molten steel and cast it into billets;

[0039] Heat the billet to 1180°C, keep it warm for 2 hours, and then carry out hot rolling. The hot rolling adopts a two-stage rolling process of austenite recrystallization zone + austenite non-recrystallization zone, the starting rolling temperature is 1100°C, and the final rolling temperature is 820 ℃ to obtain a hot-rolled steel plate with a thickness of 5.0 mm;

[0040] The hot-rolled steel plate is sequentially cooled to 700°C in the laminar flow cooling section, air-cooled in the air-cooling section for 4s, and then cooled to 150°C in the ultra-rapid cooling section, and then coiled. The cooling rate of the ultra-rapid cooling is at least 80°C / s, and the obtained Ferrite-martensite-bainite composite steel with ...

Embodiment 3

[0043] The preparation method of above-mentioned one-steel multi-stage low-cost hot-rolled steel plate is:

[0044] According to the chemical composition: 0.08%C, 0.15%Si, 1.50%Mn, 0.02%Nb, 0.01%Ti, the balance is Fe to smelt molten steel and cast it into billets;

[0045] Heat the billet to 1220°C, keep it warm for 2 hours, and then carry out hot rolling. The hot rolling adopts a two-stage rolling process of austenite recrystallization zone + austenite non-recrystallization zone, the starting rolling temperature is 1050°C, and the final rolling temperature is 840 ℃ to obtain a hot-rolled steel plate with a thickness of 6.0mm;

[0046] The hot-rolled steel plate is sequentially cooled to 685°C in the laminar flow cooling section, air-cooled in the air-cooling section for 3s, and then cooled to 50°C in the ultra-rapid cooling section, and then coiled. The cooling rate of the ultra-rapid cooling is at least 80°C / s, and the obtained The ferrite-martensite-bainite composite stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com