Patents

Literature

34results about How to "Simple system composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

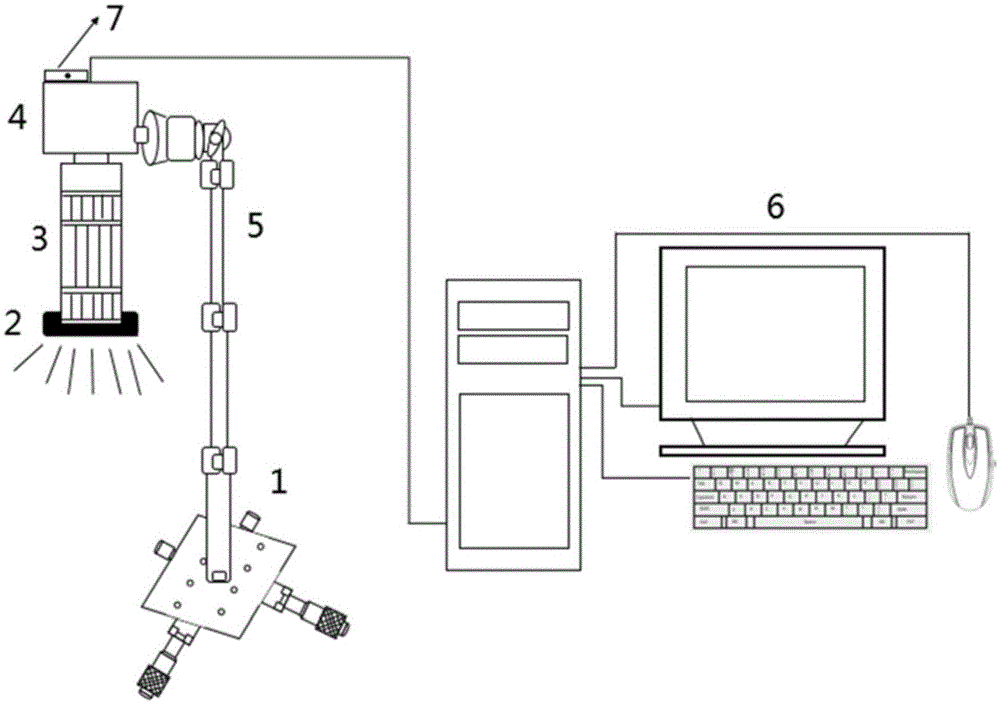

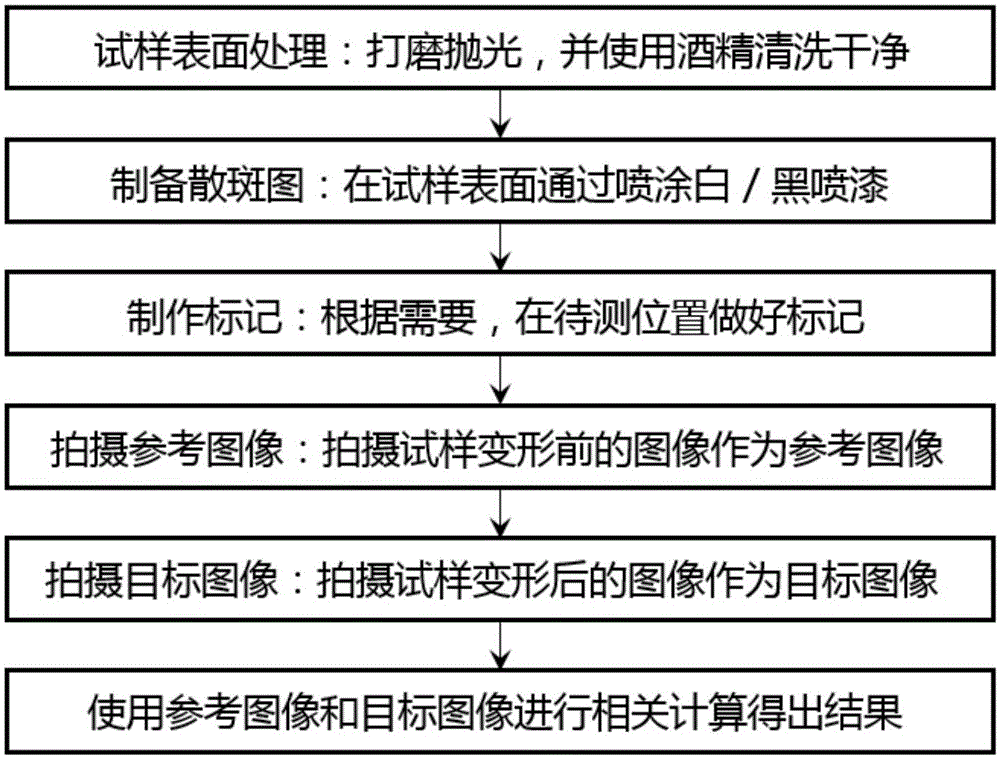

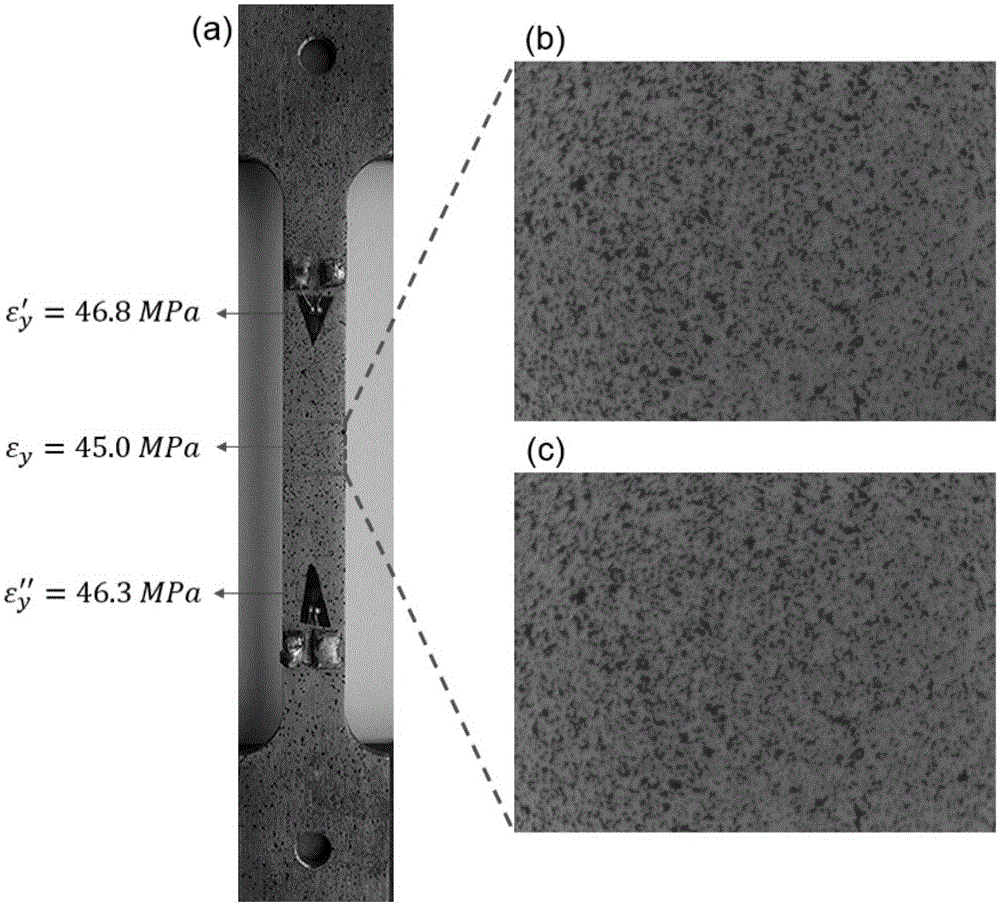

Stress test system based on digital image correlation method and application thereof

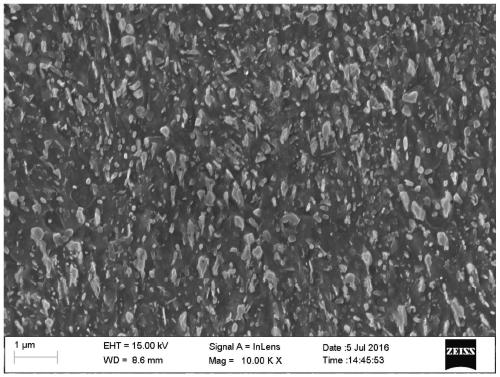

InactiveCN105044104ASimple system compositionGood effectMaterial analysis by optical meansDigital cameraImaging lens

The invention relates to a stress test system based on a digital image correlation method and application thereof. The stress test system mainly comprises a digital camera, an imaging lens, a monochrome LED lighting source, a displacement platform, a camera support rod, a levelling instrument and a computer used for collection and analysis of a digital image, and the test process mainly comprises six steps. The test system has the characteristics of simple constitution, stable lighting source, easily adjustable height and direction of the digital camera, and the like. The specklegrams before and after drilling can be subjected to digital image correlation calculation, so that the test result can be obtained. The stress test system has the advantages of simplicity in operation, low test cost, high precision and the like. In the test process, a strain gage is not used, and the limitation that the strain gage is used for measuring the residual stress can be avoided. The system provided by the invention can be used for large / small scale test and overall / local test.

Owner:SHANGHAI JIAO TONG UNIV

Electrochemistry processing method for generating oxide film on surface of aluminium or aluminium alloy material

InactiveCN101392397ASimple system compositionReduce pollutionAnodisationComposite electrolyteCarboxylic acid

The invention relates to an electrochemical treatment method for forming oxide film on the surface of aluminum or aluminums alloy material, pertaining to the surface protection and finishing field of aluminum or aluminum alloys. The aluminum or aluminum alloy is placed in a compound electrolyte solution, with oxidation by alternating current, and then a film with the thickness of 10-30Mum, hardness 200-450HV and excellent finishing performance can be produced. The compound electrolyte solution is composed of aromatic dicarboxylic acid and derivatives of aromatic dicarboxylic acid, aliphatic carboxylic acid and ammonium salt or organic amine compounds. The work pieces to be oxidized are hung at the two ends of AC electrode while being oxidized; therefore, the efficiency of electro-oxidation in alternating current is one time higher than the efficiency of electro-oxidation in direct current and simultaneously the rectifying installation is saved. The electrochemical treatment method solves the problems such as thinness (less than 10Mum), yellowing and low hardness of the oxide film produced by sulfuric acid alternating current.

Owner:HUNAN UNIV

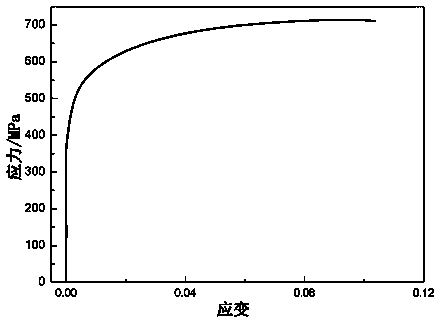

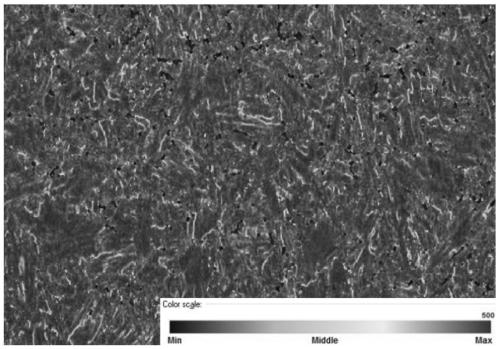

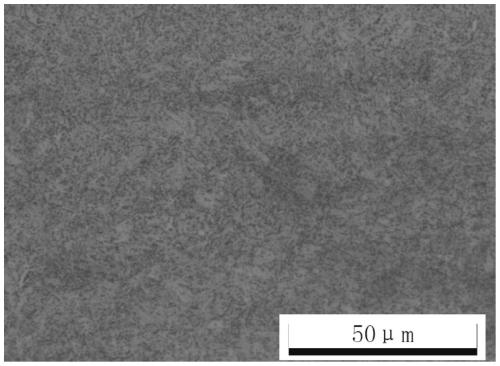

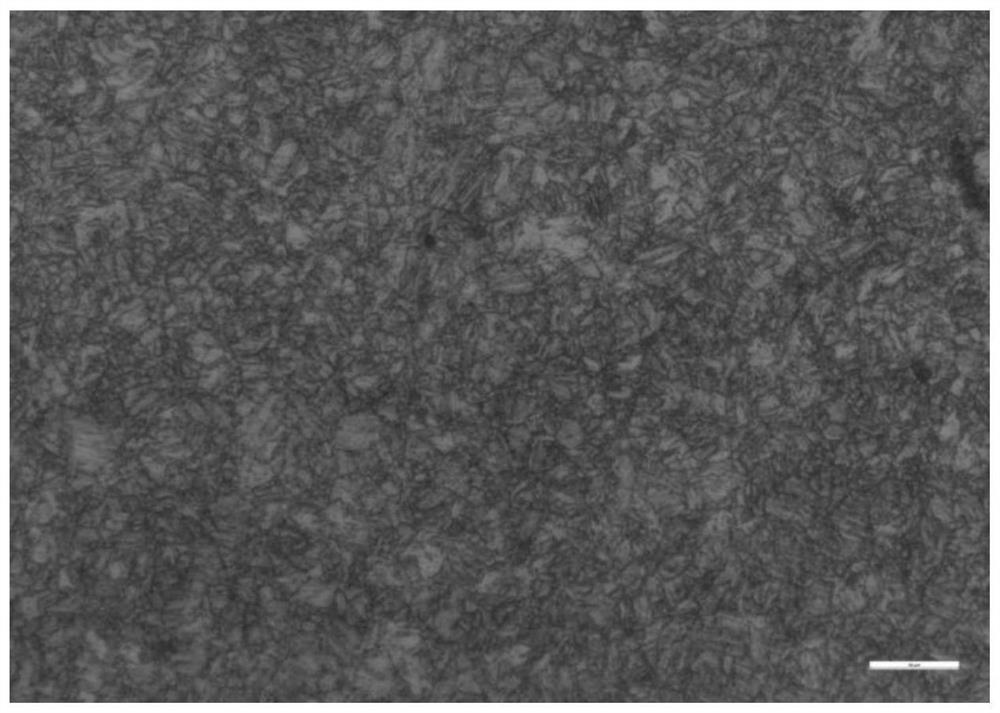

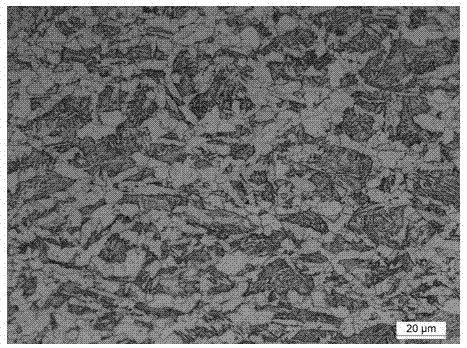

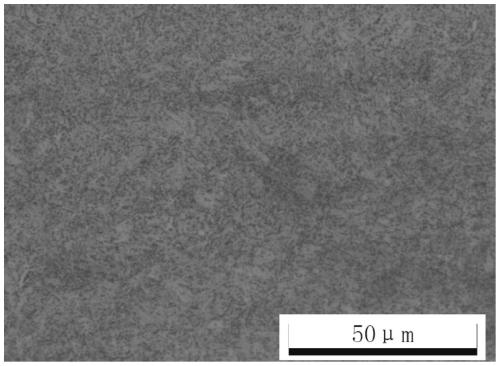

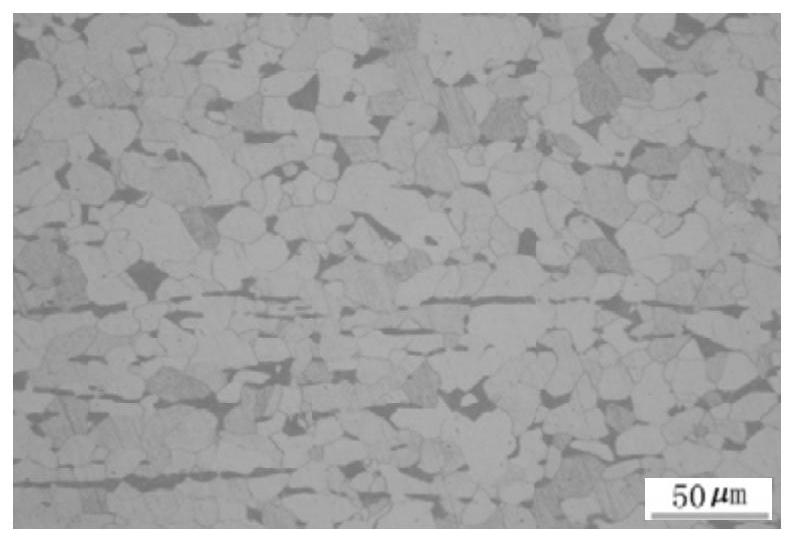

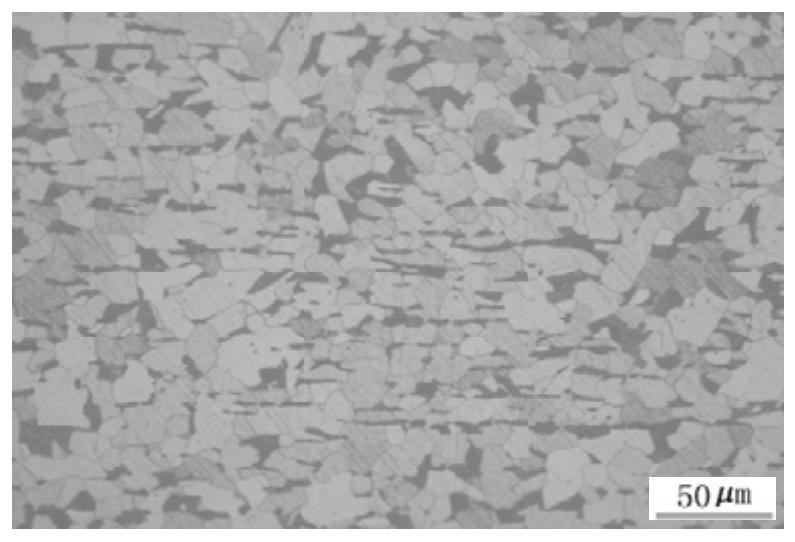

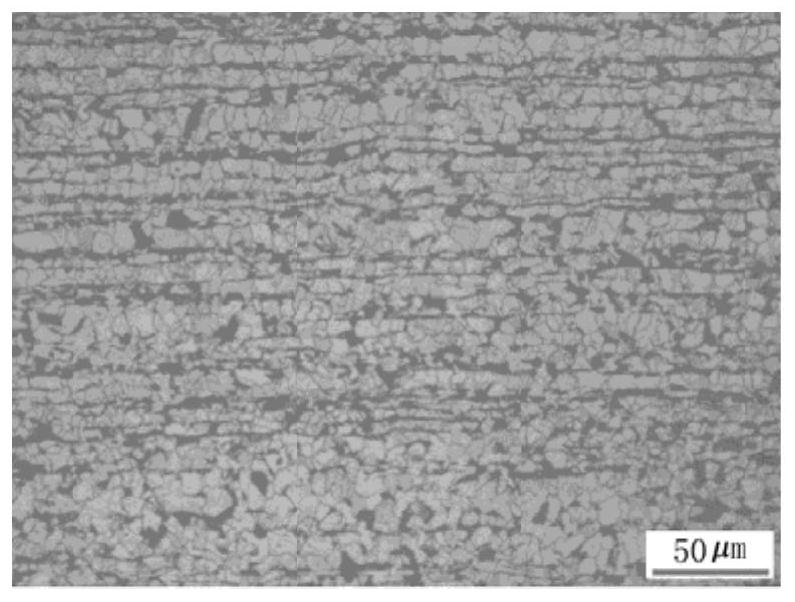

Hot rolling steel plate with characteristic of multiple grades in one steel, and manufacturing method thereof

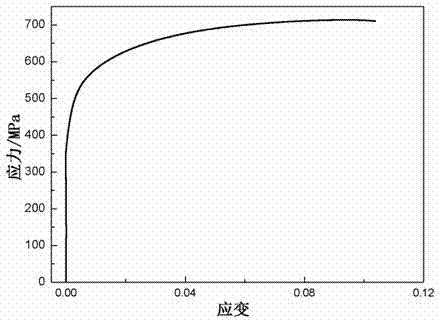

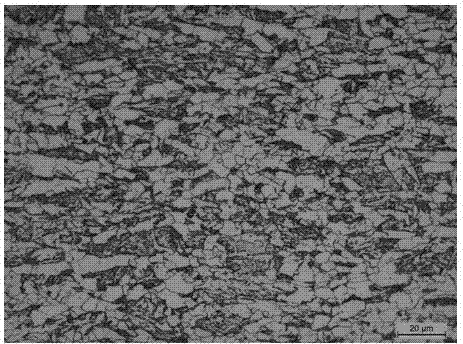

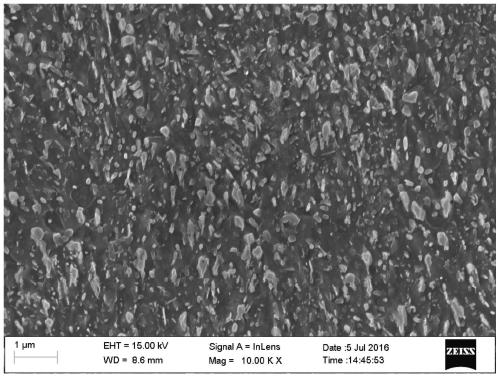

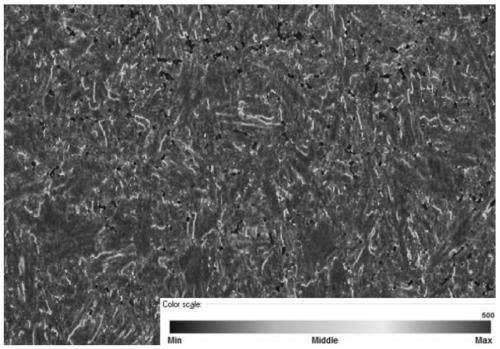

The invention belongs to the technical field of metallurgy, and specifically relates to a hot rolling steel plate with a characteristic of multiple grades in one steel, and a manufacturing method thereof. The chemical components of the hot rolling steel plate comprise, by weight, 0.06-0.08% of C, 0.15-0.35% of Si, 1.20-1.50% of Mn, 0.01-0.02% of Nb, 0.01-0.02% of Ti, and the balance of Fe and impurities, wherein the tensile strength covers 520-715 MPa, the yield strength covers 385-498 MPa, the yield ratio covers 0.56-0.90, the elongation covers 23-36%, the work hardening index n value is 0.15-0.21, and the metallurgical structure is a ferrite matrix and martensite, a ferrite matrix and bainite, or a ferrite matrix and martensite and bainite. The preparation method comprises that: a hot-rolled steel plate sequentially passes through a laminar flow cooling section and an air cooling section, and then is cooled through an ultra-fast cooling section to achieve a temperature of 600-50 DEG C to coil, wherein the cooling rate at the ultra-fast cooling section is at least 80 DEG C / s. According to the present invention, the steel billet with the one component can be used for producing plural tissue types and proportions of steel plates with different strength grades, and rolling control and cooling control are adopted to achieve steel plate structure regulation so as to achieve the multiple grades in the one steel through the simple, inexpensive and low-cost component system.

Owner:NORTHEASTERN UNIV

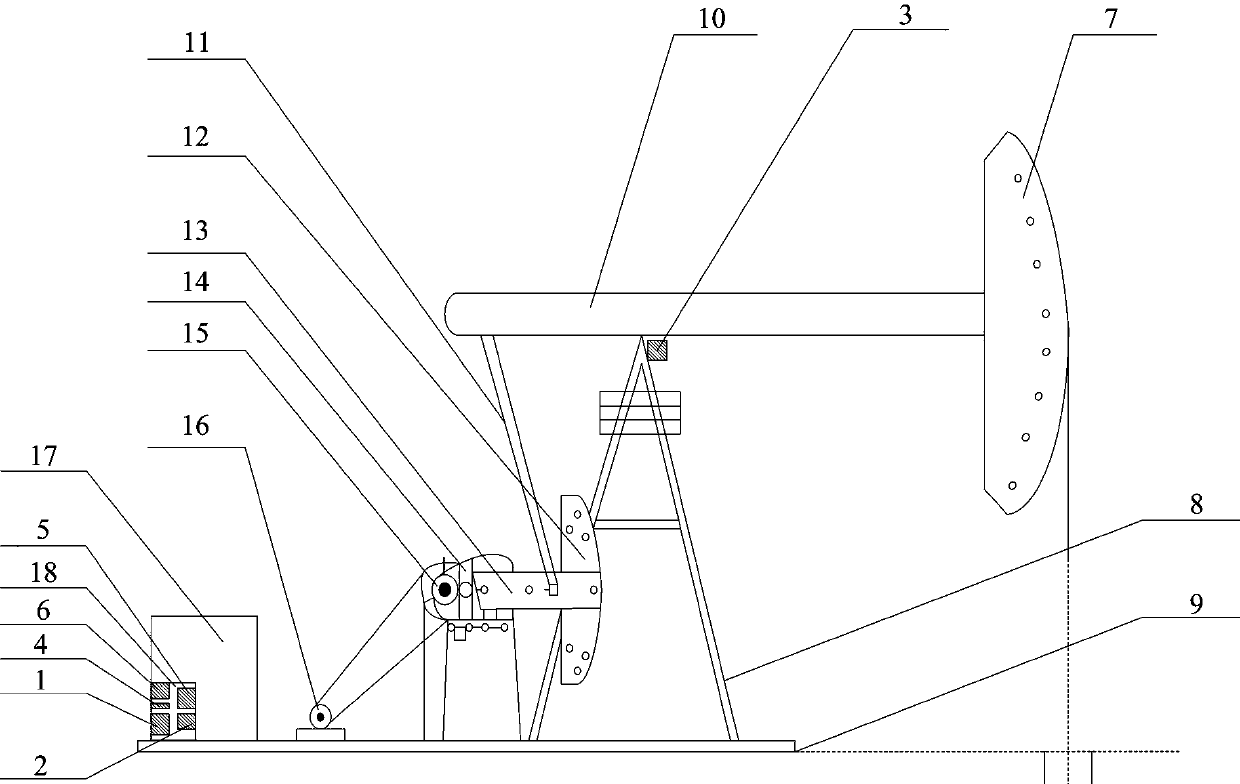

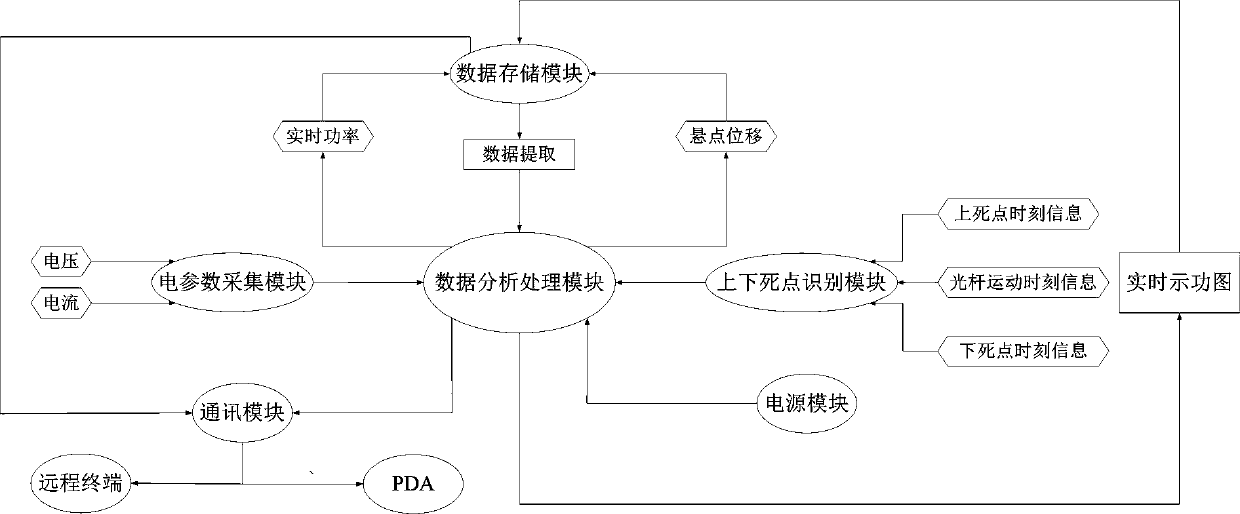

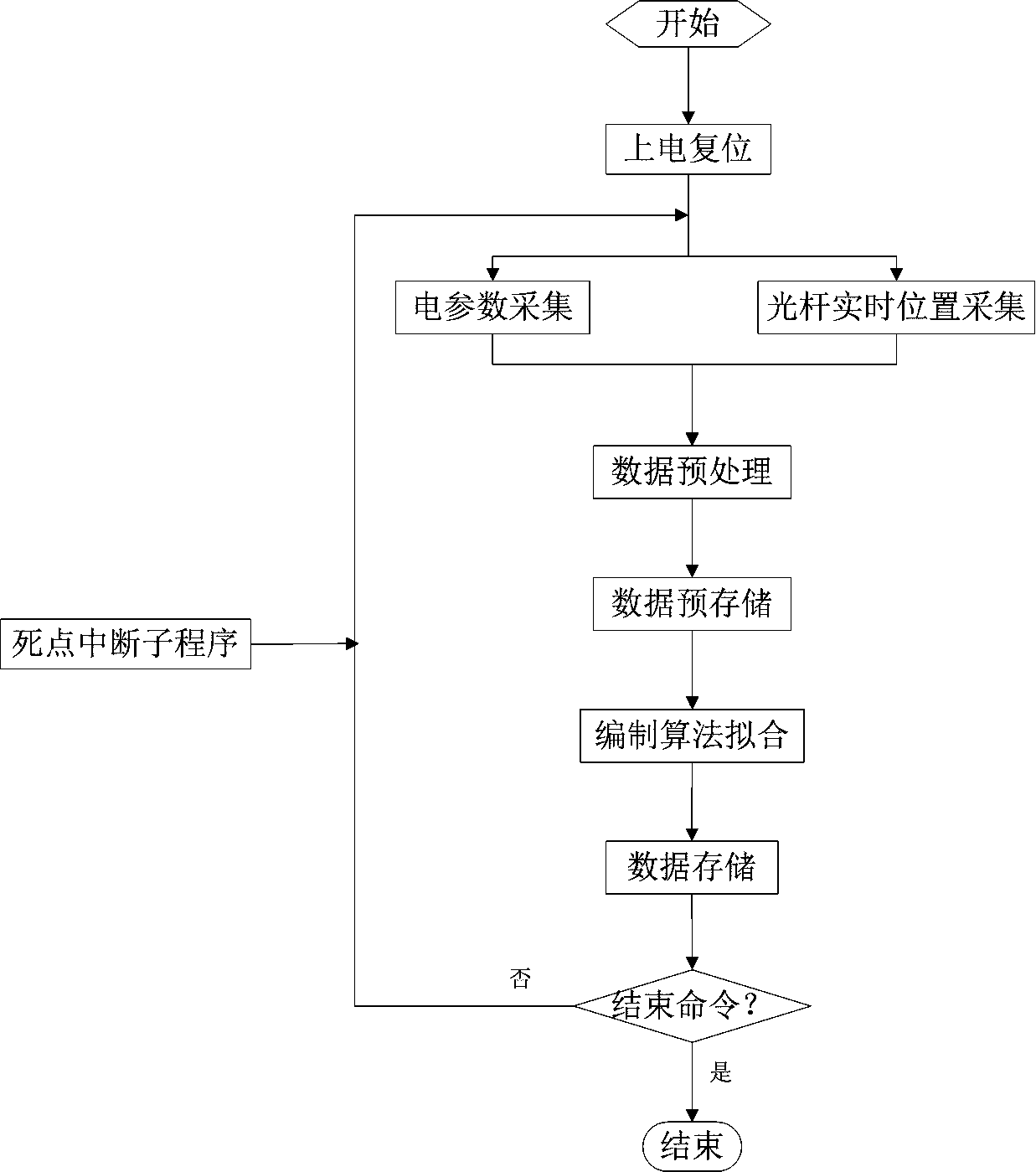

Device and method for measuring indicator diagram by electric parameters

The invention relates to a device and method for measuring an indicator diagram by electric parameters. The device comprises a data analysis and processing module, a data storage module, an oil pumping unit upper and lower dead point recognition module, an electric parameter acquisition module, a communication module and a power supply module. Motor three-phase voltage and current parameters of an oil pumping unit are collected so that real-time power is obtained, real-time suspension point displacement is calculated or measured by combination of the upper and lower dead point recognition module, the relation between the power and the suspension point displacement is obtained, and finally the relation between the suspension point displacement of each moment in a complete stroke and suspension point load is obtained according to the relations of the torque and the power as well as the torque and the suspension point load, that is the indicator diagram is obtained. According to the device and method for measuring the indicator diagram by the electric parameters, the defect existing when a sensor measures the indicator diagram traditionally is effectively solved, and the indicator diagram is measured while the electric parameters are monitored. The structure is simple, the size is small, the device can be directly mounted in an oil well distribution box, the maintenance is convenient, and real-time data exchange and historical data reading of the device with a remote monitoring system of an oil filed can be realized.

Owner:HARBIN UNIV OF SCI & TECH +1

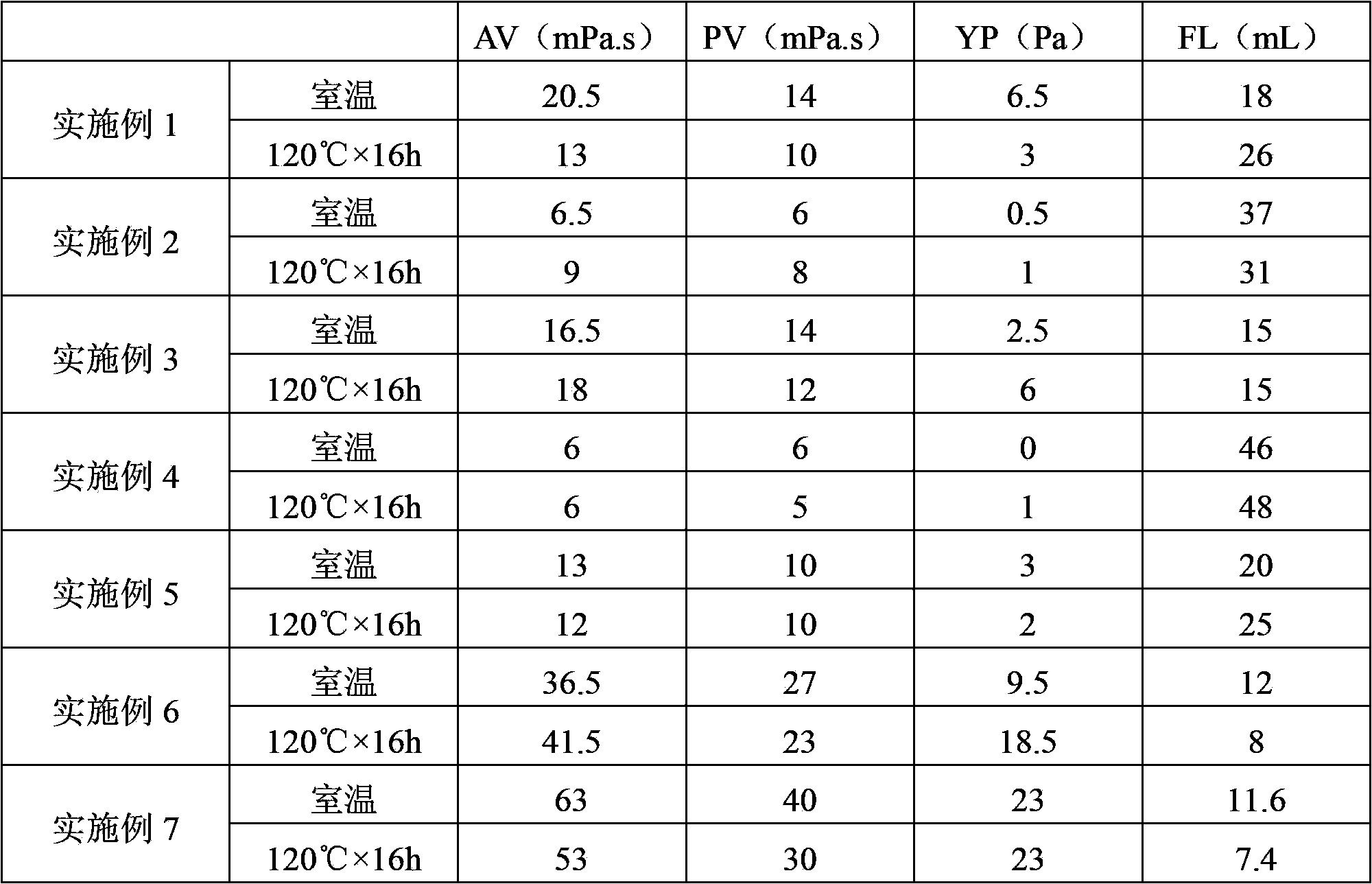

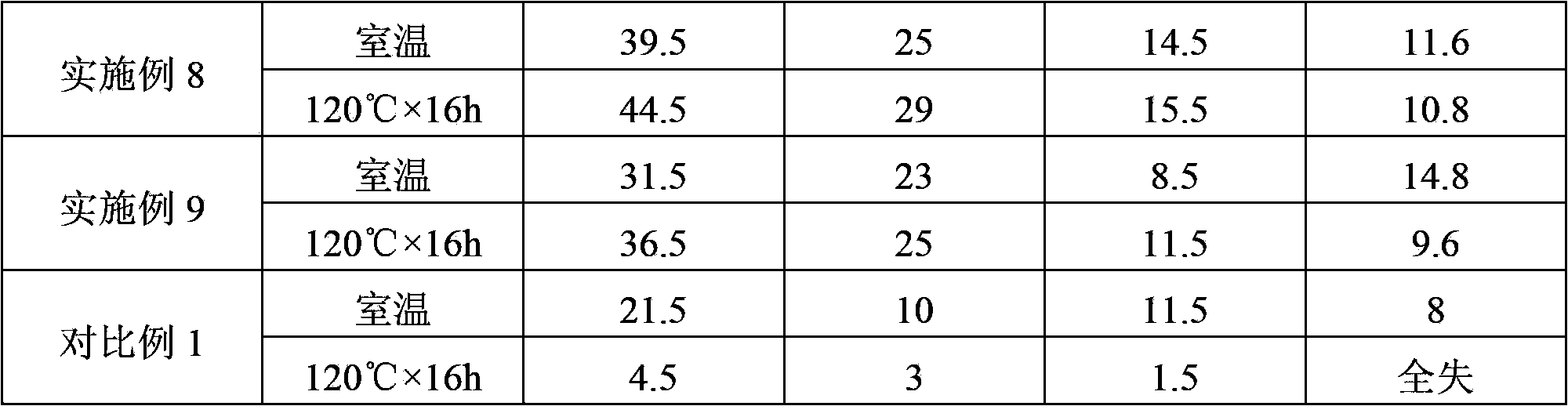

Solid-free drilling fluid

InactiveCN103509536ASimple system compositionSimple processing capacityDrilling compositionSalt resistanceFiltration

The invention provides solid-free drilling fluid. The solid-free drilling fluid comprises water and polymer swelling particles, and preferably, the solid-free drilling fluid also comprises alkali and / or salt. The solid-free drilling fluid provided by the invention can be formed by matching polymer swelling particles with different types, different swelling multiples and different particle sizes according to stratum requirements. The solid-free drilling fluid has the advantages of stable performance, high temperature resistance, high salt resistance, high rheological property, high lubricity and high filtration reducing property, and has simpler slurry matching and maintenance processes compared with conventional solid-free drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

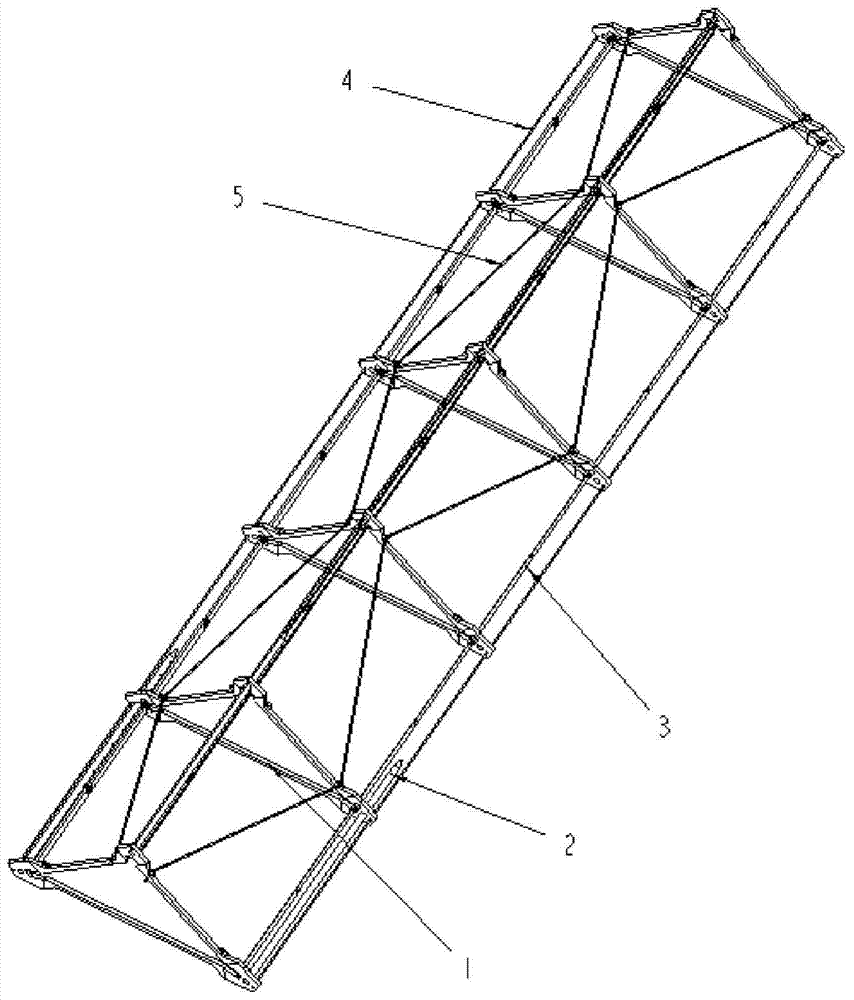

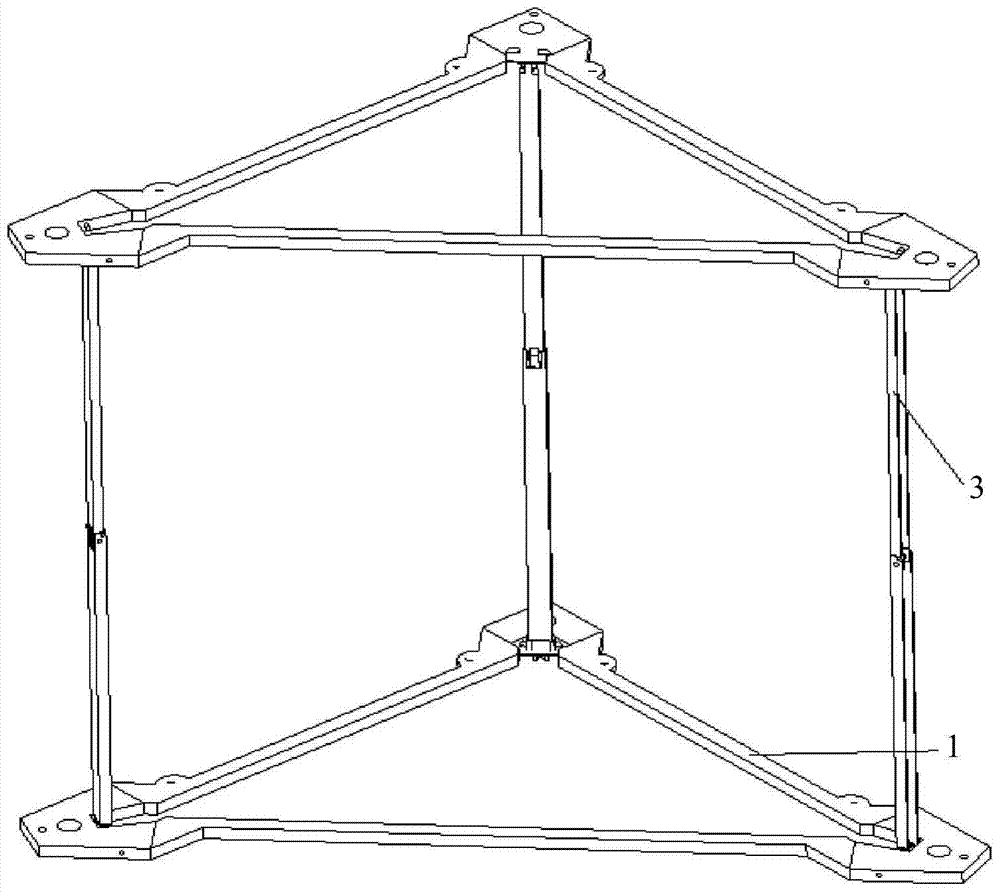

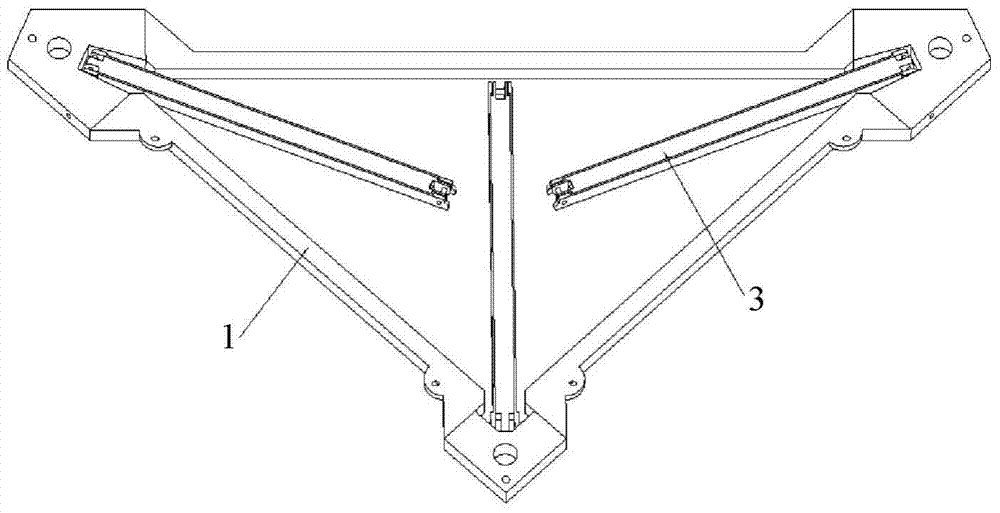

Triangular cable pole hinge type foldable truss

ActiveCN104294913ASimple system compositionReliable folding actionBuilding constructionsRigid frameSystem configuration

The invention provides a triangular cable pole hinge type foldable truss which comprises a guide rod, a folding cable, a tension cable, a plurality of truss units and a plurality of hinge rods. The truss units are triangular rigid frames. All the triangular rigid frames are sequentially connected with the guide rod from top to bottom. The triangular rigid frame at the bottommost portion is fixedly connected with the guide rod. The other triangular rigid frames arranged upwards along the guide rod are movably connected with the guide rod. The triangular rigid frames are connected through hinge rods. The folding cable sequentially penetrates through the two ends of all the triangular rigid frames from top to bottom and is fixedly connected with the triangular rigid frames at the top and at the bottom. The tension cable is sequentially penetrates through the two ends of the triangular rigid frames from top to bottom in a zigzag shape and is fixedly connected with the triangular rigid frames at the top and at the bottom. The triangular cable pole hinge type foldable truss is simple in system configuration, high in shrinking percentage and capable of stretching out and drawing out repeatedly, spacecraft space maneuvering or ontrack maintenance is facilitated, the ontrack folding requirement of a future large-scale soft solar cell array and the like can be met, and the application prospects are wide.

Owner:SHANGHAI SATELLITE ENG INST

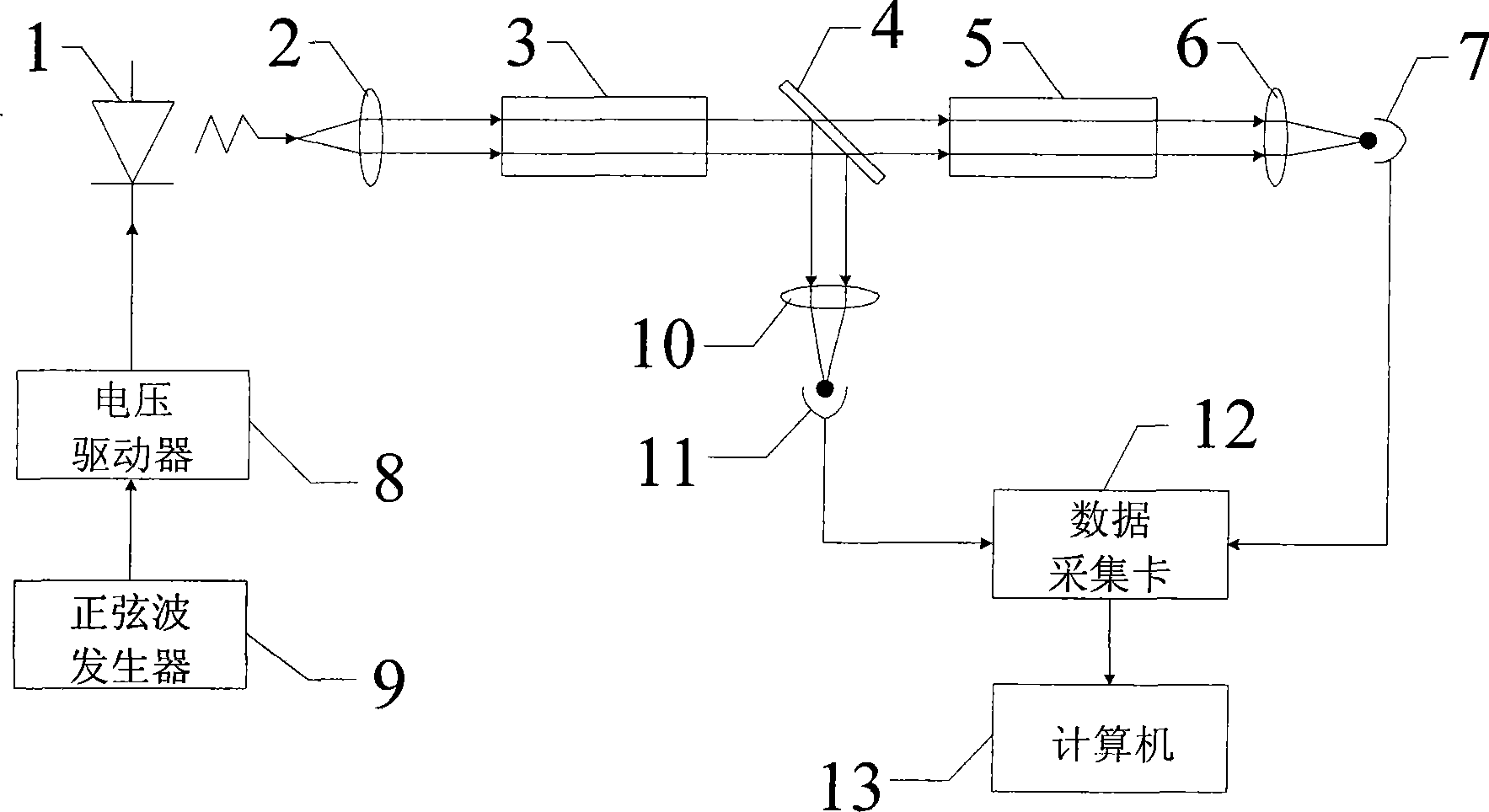

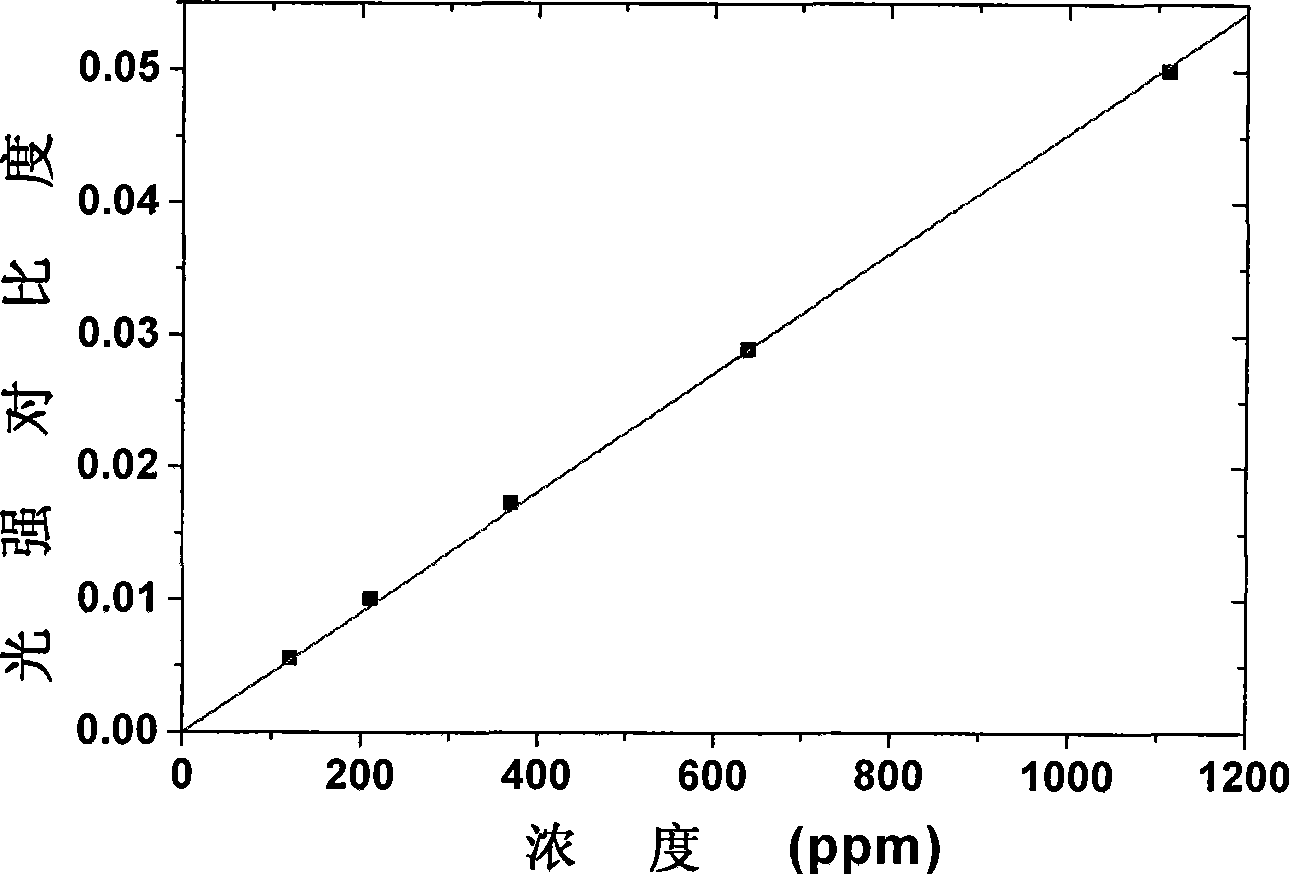

Sulphur dioxide gas concentration detection apparatus based on associated spectrum technology

InactiveCN101498665AEliminate distractionsSimple system compositionTransmissivity measurementsPhysicsSulfur dioxide

The invention relates to a device for detecting the sulfur dioxide gas concentration based on the correlation spectrum technology, belonging to the gas concentration detecting field and aiming at solving the problems that the prior device for detecting the sulfur dioxide gas concentration is prone to light intensity variation interference or has complex structure and high cost. In the device for detecting the sulfur dioxide gas concentration, the output end of a sine-wave generator is connected with the input end of a voltage driver, and the output end of the voltage driver is connected with the voltage input end of a light emitting diode; the light output by the light emitting diode is split into reflected light and transmitted light by a light splitter after being transmitted by a collimating lens and then passing through a sample cell and the light splitter, wherein the reflected light is focused on a second detector, and the transmitted light is focused on a first detector by a first convex lens after passing through the sample cell; the medium in the sample cell is sulfur dioxide gas to be measured, and the medium in a reference cell is sulfur dioxide gas of saturation concentration. The invention is applicable to various occasions needing measuring the sulfur dioxide gas concentration.

Owner:HARBIN INST OF TECH

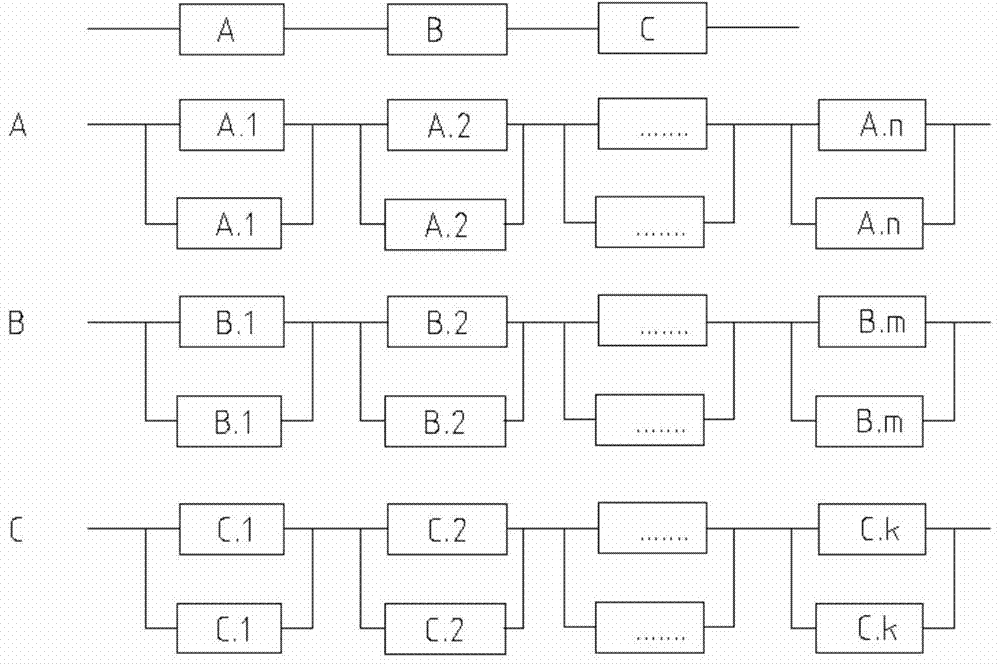

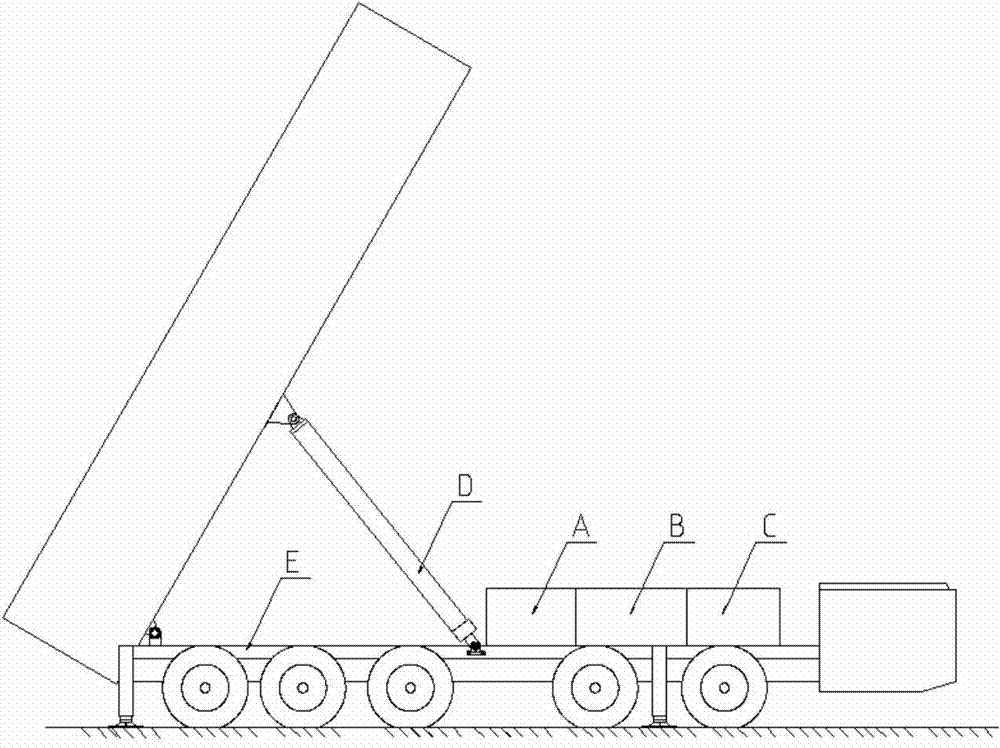

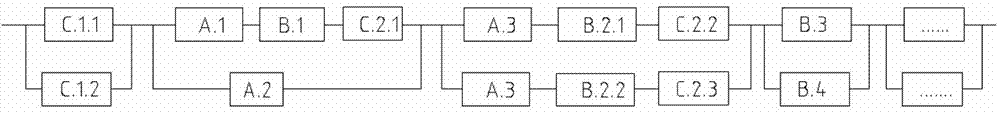

Full-redundant erection system and design method thereof

ActiveCN104763707ASimple system compositionThe number of stand-alone products is reducedFluid-pressure actuator testingFluid-pressure actuator componentsSystem failureDesign methods

The invention provides a full-redundant erection system, and aims at achieving full redundancy of the system function under the condition that the single-machine products are decreased, simplifying the system, improving the system reliability and reducing the requirement on the single-machine product reliability. The full-redundant erection system comprises a hydraulic system, a control system, a power supply and distribution system, a performing mechanism and an erection bearing structure which are interconnected according to a cross redundancy structure. With the adoption of the full-redundant erection system, the system reliability is improved, and the requirement on the single-machine reliability is reduced; the system composition is simplified; the quantity of single-machine products is decreased; the used space for the structure is small; the reliability is high; the requirement on the single-machine reliability is reduced; the integrity is high; any fault in the system can be quickly recognized or located according to a reliability map of the system.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

Corrosion resistant and squeezing highly resistant oil casing pipe and preparation method thereof

The invention discloses a corrosion resistant and squeezing highly resistant oil casing pipe and a preparation method thereof. The oil casing pipe comprises, by weight percentage, 0.22%<=C<=0.30%, 0.15%<=Si<=0.35%, 0.40%<=Mn<=0.60%, S<=0.003%, P<=0.01%, 0.02%<=Al<=0.04%, 0.75%<=Cr<=1.20%, 0.25%<=Mo<=0.55%, Ca<=0.0025%, N<=0.08% and the balanced Fe and unavoidable impurities. The oil casing has theadvantages that the squeezing resistant strength of the prepared oil casing pipe is 30% or above higher than the squeezing resistant strength required by API 5C3 standards, the hydrogen sulfide corrosion resistance performance is conformed to demands in API 5CT (45 edition) PSL3, and the oil casing pipe can be extensively applied to the exploitation of oil and gas wells of acid medium deep wells, ultra-deep wells and the like with complicated geological conditions

Owner:DALIPAL PIPE

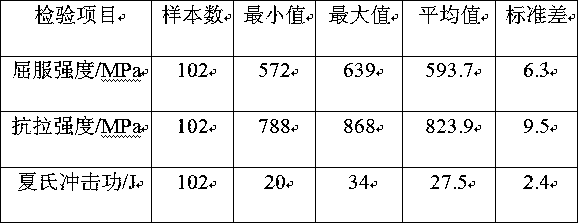

Manual electric arc welding welding rod used for ultralow-temperature high manganese steel

InactiveCN112894197ALow priceReduce manufacturing costWelding/cutting media/materialsSoldering mediaAlloyUltimate tensile strength

The invention relates to a manual electric arc welding welding rod used for ultralow-temperature high manganese steel. According to the technical scheme, the manual electric arc welding welding rod is composed of a welding rod core and a coating; the welding rod core comprises the following chemical components of 0.75-0.95 wt% of C; 26-30 wt% of Mn; 4.5-6.5 wt% of Ni; 1.5-3.5 wt% of Cr; 3.5-5.5 wt% of Al; P less than or equal to 0.002 wt%; S less than or equal to 0.002 wt%; and the balance Fe and inevitable impurities, the coating comprises the following chemical components of 40-45 wt% of fluorite; 15-20 wt% of marble; 4-10 wt% of rutile; 3-6 wt% of zircon sand; 1-2 wt% of sodium carbonate; and the balance Fe powder; and a preparation method of the manual electric arc welding welding rod comprises the following steps of blending according to the chemical components of the coating, mixing, adding a binder, uniformly stirring, and pressing and coating on the surface of the welding rod core to prepare the manual electric arc welding welding rod used for the ultralow-temperature high manganese steel. The manual electric arc welding welding rod used for the ultralow-temperature high manganese steel is low in cost and simple in alloy system; and formed weld metal has the characteristics of ultralow temperature and high toughness, and the strength is matched with the strength of the ultralow-temperature high manganese steel.

Owner:浙江鸿途焊接科技有限公司 +2

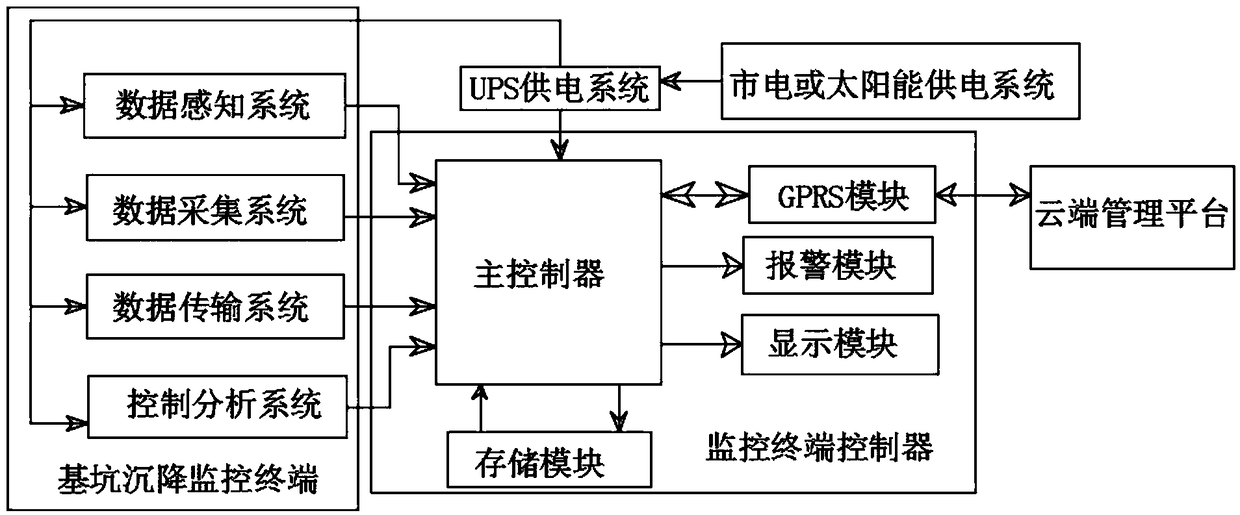

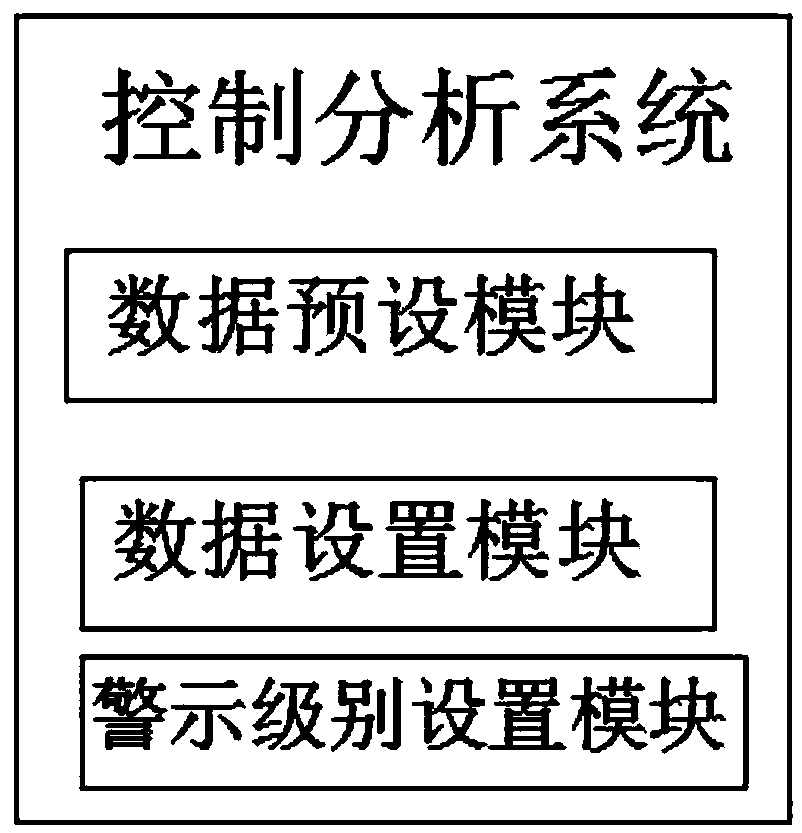

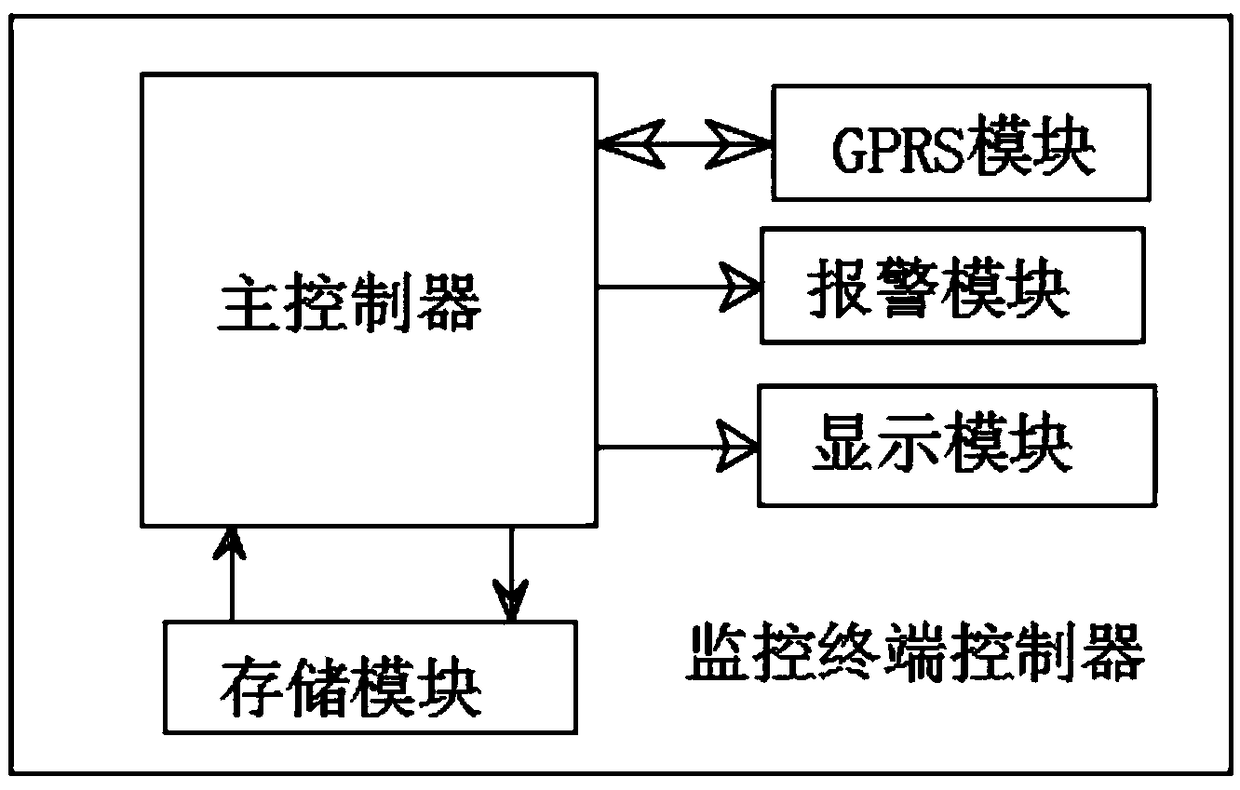

Real-time monitoring system for foundation pit

InactiveCN109183859ASimple system compositionClear structureFoundation testingIn situ soil foundationMonitoring dataData transmission systems

The invention discloses a real-time monitoring system for a foundation pit. The real-time monitoring system for the foundation pit comprises a foundation pit settling monitoring terminal, a monitoringterminal controller, a cloud management platform and a power source module. The foundation pit settling monitoring terminal is in communication connection with the monitoring terminal controller through a wired or wireless network. The monitoring terminal controller is in communication connection with the cloud management platform through a general packet radio service (GPRS) module. The foundation pit settling monitoring terminal comprises a data perceiving system, a data collecting system, a data transmitting system and a control analyzing system. By means of the real-time monitoring systemfor the foundation pit, real-time collection, transmission, calculation and analysis of important operational data of the foundation pit can be achieved; various monitoring data are displayed visually; and historical changing process and the current state of the data are monitored. The real-time monitoring system is characterized by being simple in systematic composition, clear in structure, stable in operation, convenient to maintain, energy-saving and environmentally-friendly and high in automation degree. The system is suitable to be applied and popularized.

Owner:河南蓝特电子科技有限公司

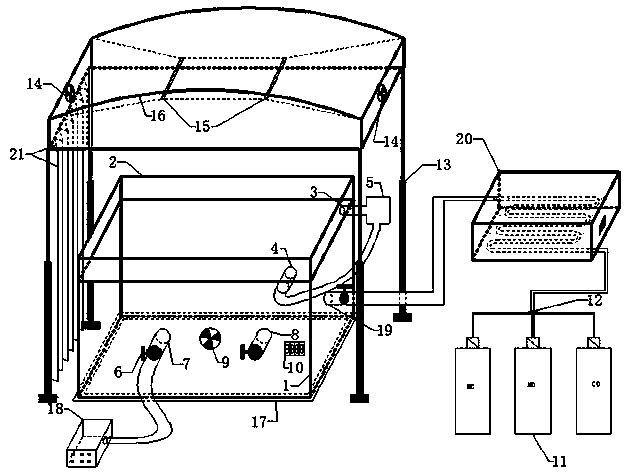

Indoor and outdoor detection device for photocatalytic degradation of exhaust gas of road surface

InactiveCN109142352AIntuitive test dataIntuitively judge the degradation efficiencyDispersed particle separationMaterial analysis by optical meansGas analysisUltraviolet

The invention relates to an indoor and outdoor detection device for photocatalytic degradation of exhaust gas of a road surface. The detection device comprises an automobile exhaust gas supply device,a reaction box body, a light source and an energy system thereof and a gas analysis device. The exhaust gas supply device is composed an HC pure gas storage tank, a CO pure gas storage tank and an NOX pure gas storage tank, and the reaction box body is made of high-transmission polymethyl methacrylate, sealed with a thin layer of the road surface through a cushion block and a sealant and internally provided with a micro fan which is fixed by a sucker. A fence structure is designed on a top plate, a water pump is adopted for circulated water supply through a water inlet and a water outlet. A light source device comprises two ultraviolet high-pressure mercury lamps, a reflector and two fans and is placed on a lifting bracket. The gas analysis device is designed on the basis of chemiluminescence. The detection device can adapt to indoor and outdoor photocatalytic detection of the exhaust gas of the road surface, a special material is adopted for sealing the box body and the road surface,on-site detection does not damage the performance of the road surface, a Marshall rutting plate can be placed in the reaction box body during an indoor test, and the test range is wide. The detectiondevice can control various reaction conditions of a catalytic degradation reaction and has high practicability.

Owner:TONGJI UNIV

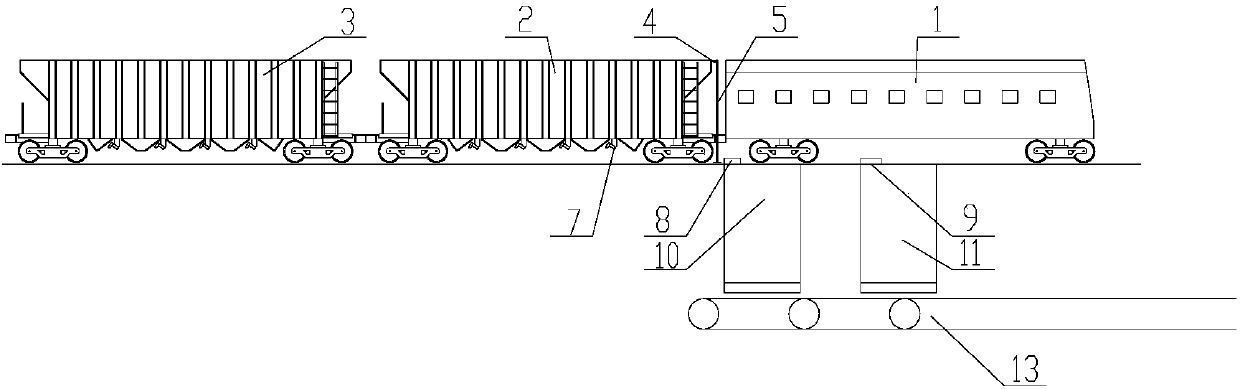

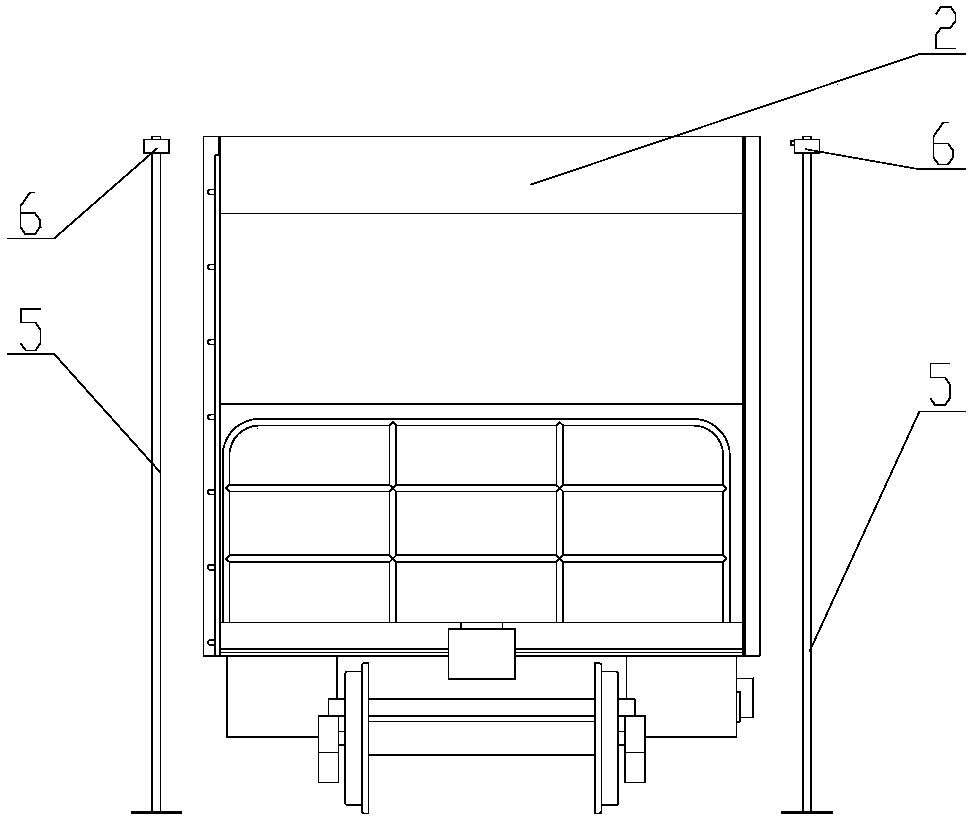

Automatic coal unloading system and method of hopper car based on photoelectric correlated sensor technology

PendingCN107585170AEfficient unloading of coalSimple system compositionHopper carsProgramme control in sequence/logic controllersCoalEngineering

The invention discloses an automatic coal unloading system of a hopper car based on a photoelectric correlated sensor technology. The automatic coal unloading system of the hopper car based on the photoelectric correlated sensor technology comprises a photoelectric correlated sensor unit, an execution unit and a control terminal (13), wherein the photoelectric correlated sensor unit comprises supports (5); an optoelectronic switch illuminator (4) is arranged at the top end of one support (5); an optoelectronic switch photoelectric receiver (6) is arranged at the top end of the other support (5); and the execution unit comprises a bottom door opening and closing mechanism (7), a first door opening and meeting device (8) and a second door opening and meeting device (9). The invention furtherdiscloses an automatic coal unloading method of the hopper car based on the photoelectric correlated sensor technology. According to the automatic coal unloading method of the hopper car provided bythe invention, the photoelectric correlated sensor technology is adopted, and the illuminator and the photoelectric receiver arranged at appropriate positions of two sides of a walking track of the bottom-opened hopper car form a correlated separating type optoelectronic switch, so that the bottom door opening and closing mechanism of the bottom-opened hopper car is opened, and coals can be automatically and efficiently unloaded.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

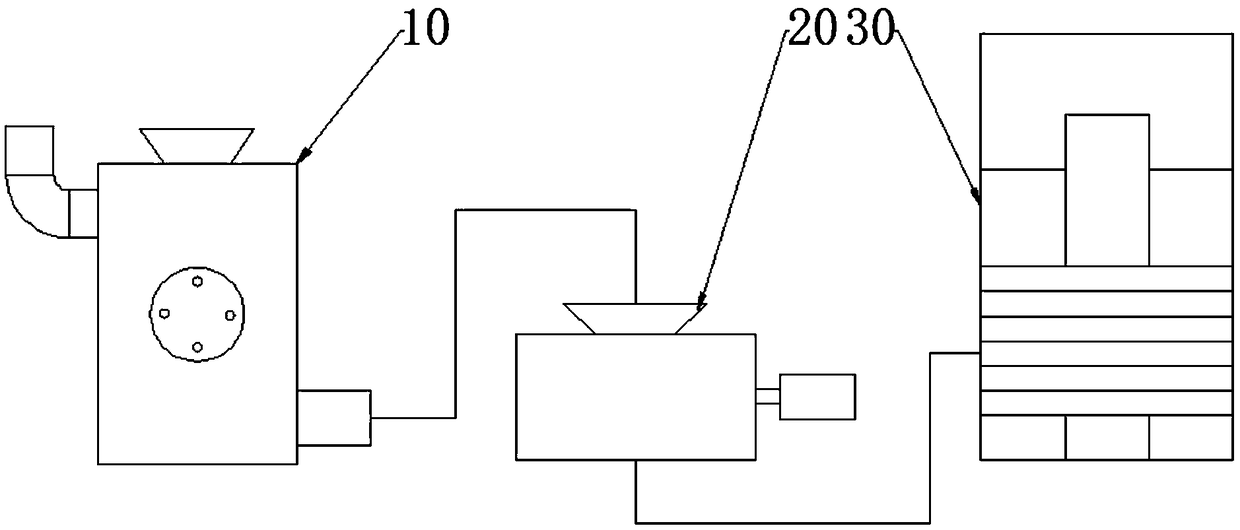

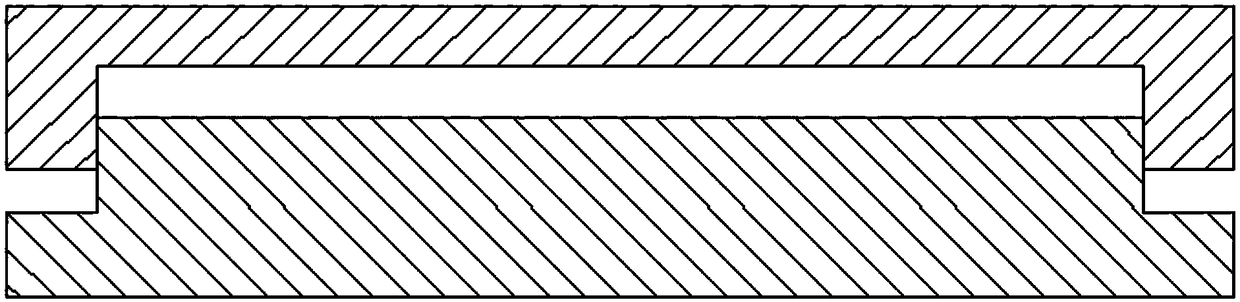

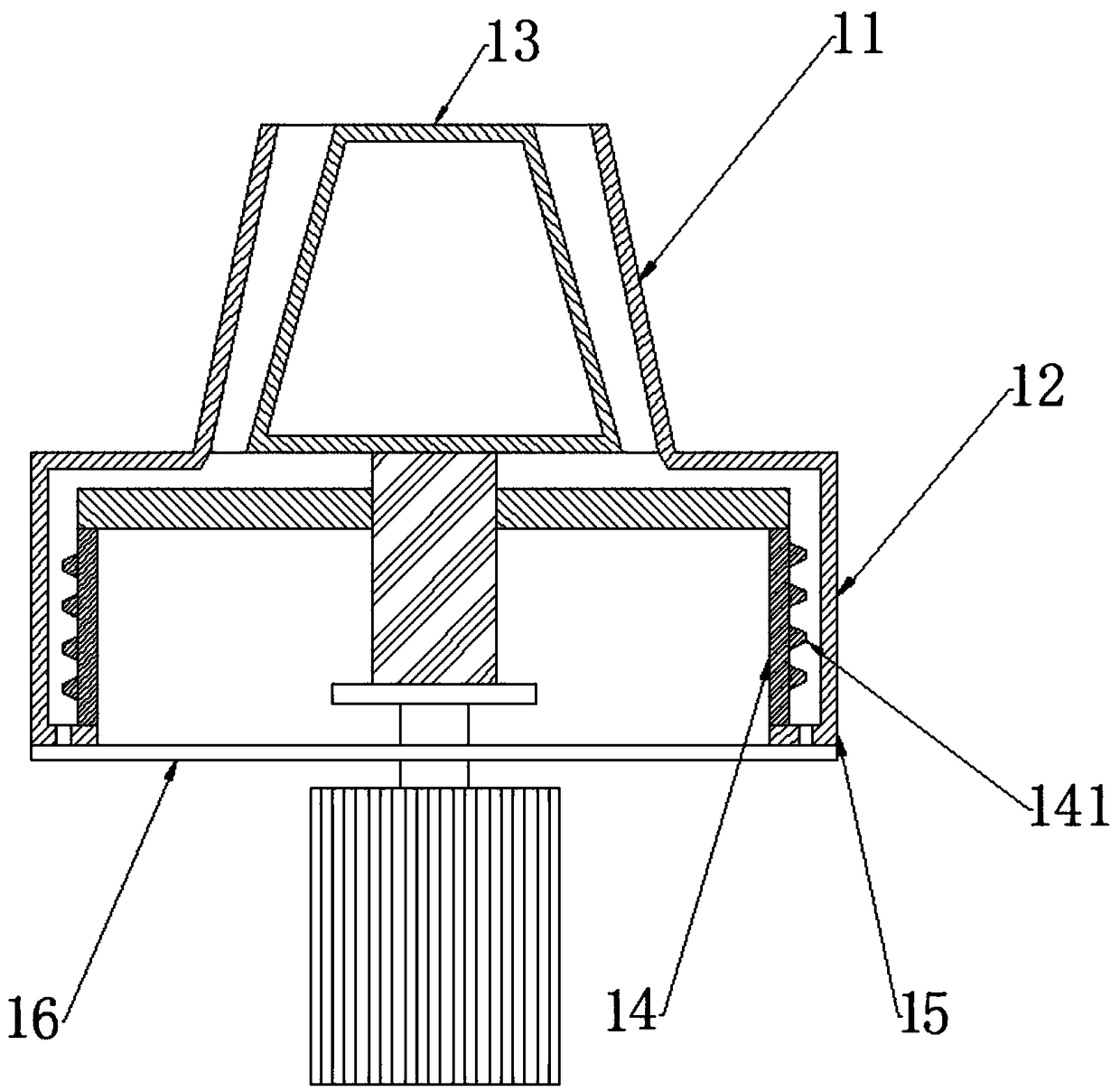

Partially fusible composite scrap recycling system

PendingCN109203298ASimple system compositionReduce upfront investmentPlastic recyclingScrapMaterials science

Disclosed is a partially fusible composite scrap recycling system. The partially fusible composite scrap recycling system comprises a crushing device, a melting device, a granulating device, a glue mixing device and a forming device. The crushing device is used for crushing materials into particles or powder; the melting device receives the crushed particles or powder and heats materials to form plastic bodies; the granulating device is used for producing the plastic bodies into secondary particles; the glue mixing device is used for mixing the secondary particles with glue to form coagulationbodies; and the forming device comprises a mold and a pressurizing device, wherein the mold is used for forming the coagulated bodies, and the pressurizing device is used for pressurizing the mold. By means of the partially fusible composite scrap recycling system, waste containing organic fusible substances can be efficiently recycled with low investment and cost.

Owner:LIAOYANG YIMENG CARPET MFG

N80 steel grade oil casing and preparation method thereof

The invention relates to the technical field of oil casings and particularly discloses an N80 steel grade oil casing and a preparation method thereof. The N80 steel grade oil casing comprises the following elemental compositions of, by weight, 0.26-0.30% of C, 0.15-0.35% of Si, 1.35-1.45% of Mn, 0.06-0.08% of V, 0.10-0.30% of Cr, 0.02-0.04% of Al, less than or equal to 0.002% of S, less than or equal to 0.01% of P, less than or equal to 0.01% of N, less than or equal to 0.005% of Ti, less than or equal to 0.08% of Ni, less than or equal to 0.08% of Cu, less than or equal to 0.01% of Mo, less than or equal to 0.01% of Nb and the balance Fe and inevitable impurity elements, wherein Mn / C is greater than or equal to 4. According to the N80 steel grade oil casing provided by the invention, an alloy composition system is simple, and the N80 steel grade oil casing has high strength and high toughness by reasonably controlling the elements of C, Mn, Cr and V.

Owner:DALIPAL PIPE

Electrochemistry processing method for generating oxide film on surface of aluminium or aluminium alloy material

InactiveCN101392397BSimple system compositionReduce pollutionAnodisationComposite electrolyteCarboxylic acid

The invention relates to an electrochemical treatment method for forming oxide film on the surface of aluminum or aluminums alloy material, pertaining to the surface protection and finishing field of aluminum or aluminum alloys. The aluminum or aluminum alloy is placed in a compound electrolyte solution, with oxidation by alternating current, and then a film with the thickness of 10-30Mum, hardness 200-450HV and excellent finishing performance can be produced. The compound electrolyte solution is composed of aromatic dicarboxylic acid and derivatives of aromatic dicarboxylic acid, aliphatic carboxylic acid and ammonium salt or organic amine compounds. The work pieces to be oxidized are hung at the two ends of AC electrode while being oxidized; therefore, the efficiency of electro-oxidation in alternating current is one time higher than the efficiency of electro-oxidation in direct current and simultaneously the rectifying installation is saved. The electrochemical treatment method solves the problems such as thinness (less than 10Mum), yellowing and low hardness of the oxide film produced by sulfuric acid alternating current.

Owner:HUNAN UNIV

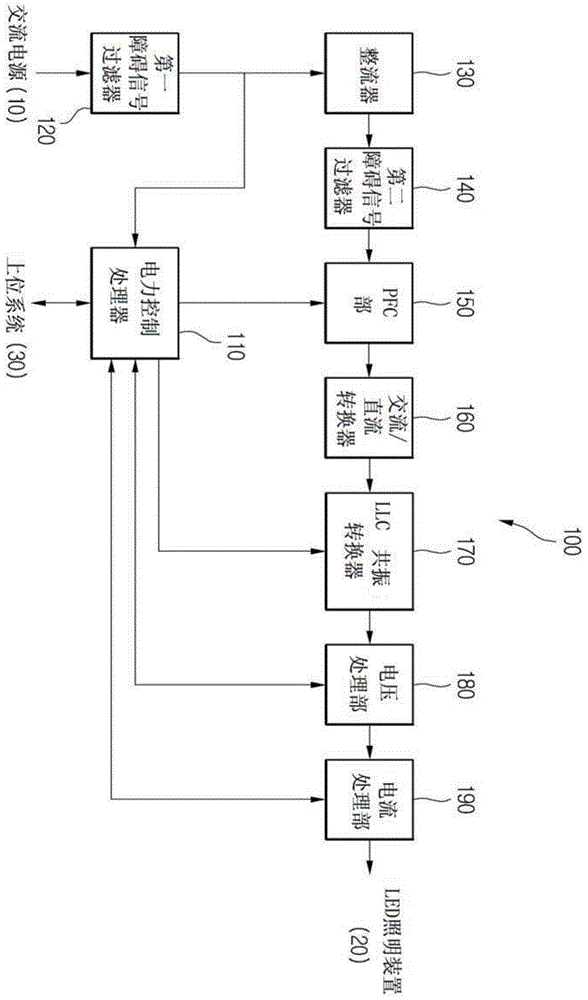

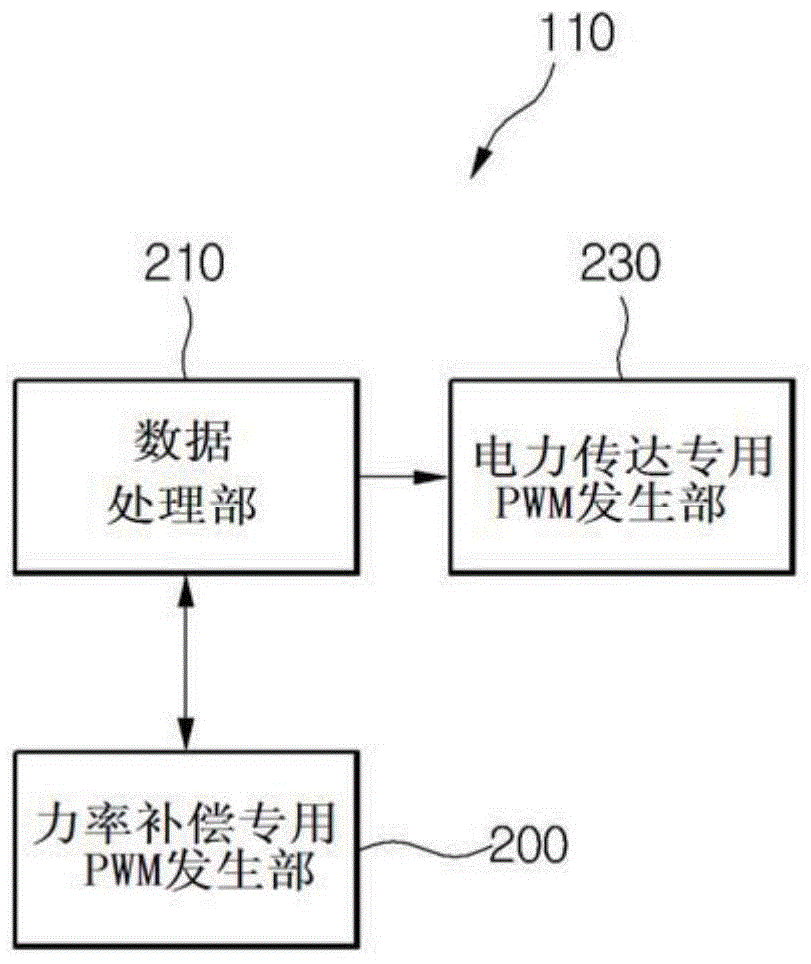

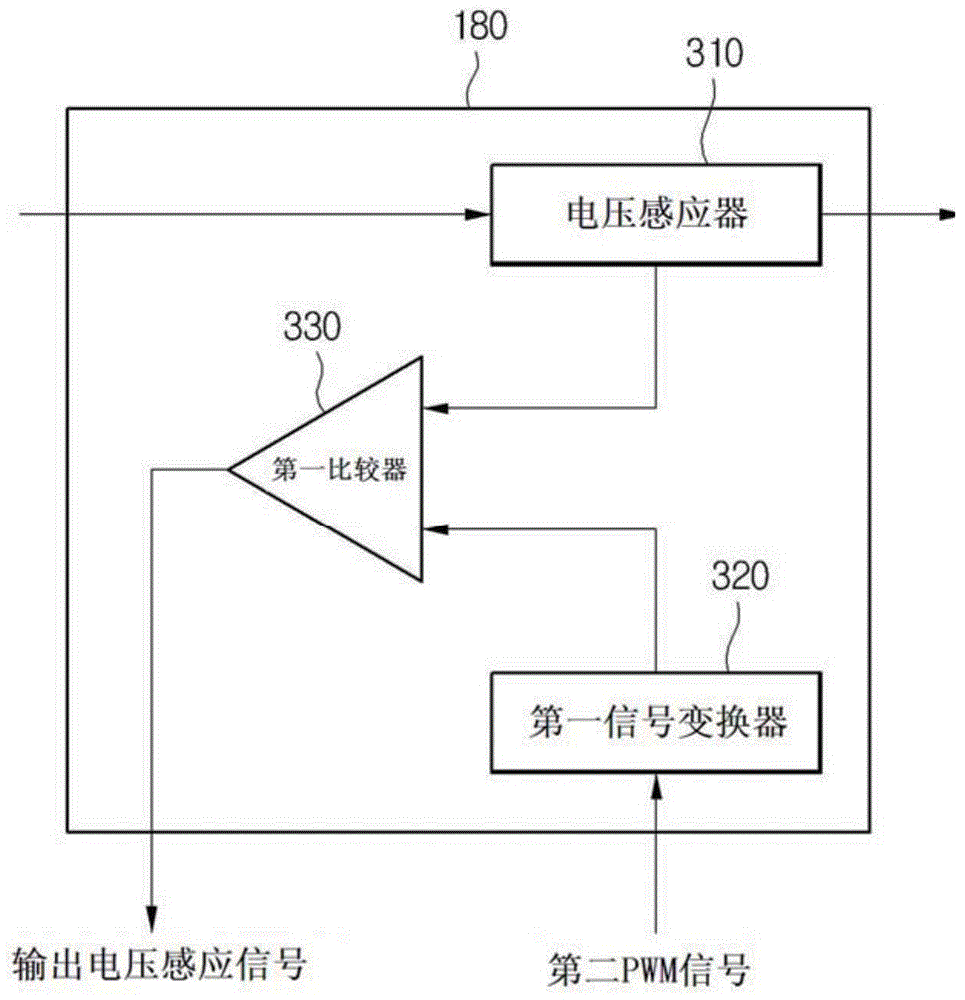

LED illumination power supplying device and control method thereof

InactiveCN104981044ASimple system compositionElectric light circuit arrangementPower controlStructure modification

The invention provides an LED power supplying device with a wide voltage input range and a wide load control range. The LED power supplying device comprises a power control processor, a PFC portion, a DC / AC converter, an LCC resonance converter, a voltage processing portion, and a current processing portion. By means of the power control processor capable of integrally controlling the LED power supplying device, power control can be effectively executed and the system composition of the LED power supplying device is simplified. Further, even though not being subjected to structure modification, the LED power supplying device may provides power for various LED modules and provide a wide voltage input range and a wide load control range. In addition, the invention may fix a voltage and current control manner and provides a power supplying device unequipped with an electrolytic capacitor.

Owner:金男奎

High-strength seamless line pipe and manufacturing method thereof

The invention relates to the technical field of seamless line pipe manufacturing, and particularly discloses a high-strength seamless line pipe and a manufacturing method thereof. The seamless line pipe is composed of the following components in percentage by weight: more than or equal to 0.06 percent and less than or equal to 0.1 percent of C, more than or equal to 0.15 percent and less than or equal to 0.35 percent of Si, more than or equal to 1.55 percent and less than or equal to 1.75 percent of Mn, more than or equal to 0.35 percent and less than or equal to 0.55 percent of Cr, more than or equal to 0.15 percent and less than or equal to 0.25 percent of Mo, more than or equal to 0.01 percent and less than or equal to 0.03 percent of Ti, more than or equal to 0.001 percent and less than or equal to 0.002 percent of Mg, less than or equal to 0.01 percent of S, less than or equal to 0.01 percent of P and the balance of Fe and inevitable impurities, wherein the carbon equivalent CEPcm is less than or equal to 0.25 percent. The seamless line pipe provided by the invention is simple in component system, low in manufacturing cost and excellent in strength, toughness and corrosion resistance, can be widely applied to oil and gas transportation in ultra-deep water sea areas, and has a wide market prospect.

Owner:DALIPAL PIPE

System for culturing regenerated haploid plant from winter jujube anther and culture method thereof

InactiveCN106962198AConvenient researchSimple system compositionPlant tissue cultureHorticulture methodsGenetic theoryPlantlet

The invention relates to the technical field of agriculture, in particular to a system for culturing a regenerated haploid plant from winter jujube anther and a culture method thereof. The system comprises an anther culture medium, a primary callus culture medium and a secondary callus culture medium, wherein the anther culture medium consists of 1 / 2 of MS, 0.8-1.2mol / L of 2, 4-D, 18-22g / L of maltose and 3.2-3.7g / L of agar; the primary callus culture medium consists of MS, 0.8-1.2mg / L of TDZ, 18-22g / L of maltose and 3.2-3.7g / L of agar; the secondary callus culture medium consists of MS, 1.8-2.2mg / L of triacontanol, 18-22g / L of maltose and 3.2-3.7g / L of agar. The system is simple in composition and facilitates culture; through haploid breeding, jujube trees can also adopt seed propagation to substitute asexual propagation, and a pure material can be provided for genetic research on a jujube variety with a highly heterozygous genotype, so that the breeding period is shortened and the research on the genetic theory of the jujube trees is promoted.

Owner:SHIJIAZHUANG POMOLOGY INST OF HEBEI ACADEMY OF AGRI & FORESTRY SCI

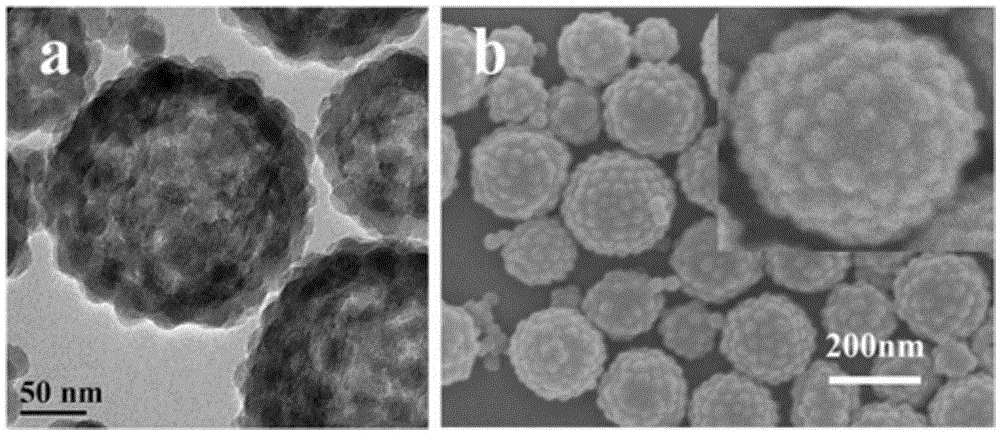

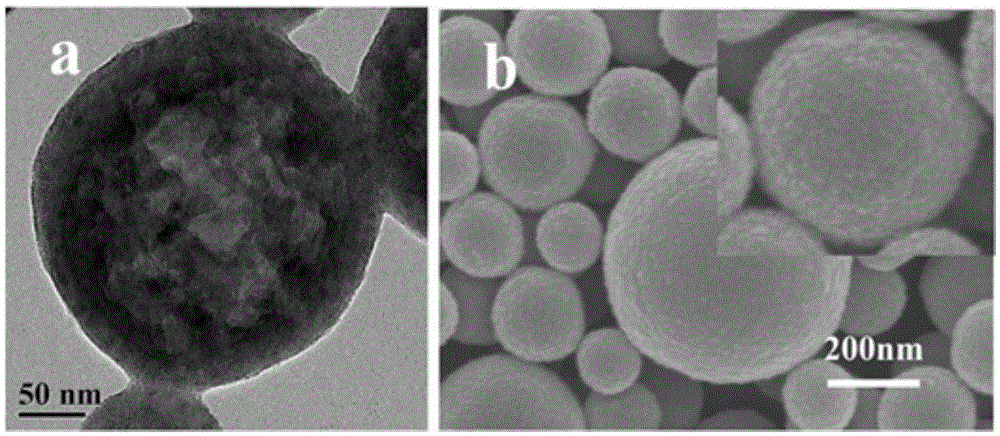

A hollow submicron sphere, its preparation method and application

ActiveCN103962074BUniform particle size distributionGood repeatabilityMicroballoon preparationMicrocapsule preparationNanoreactorMicrosphere

The invention discloses a hollow sub-microsphere as well as a preparation method and an application thereof. A shell of the sub-microsphere adopts an organic and inorganic composite structure, so that the thermodynamic stability and the structural stability are high; meanwhile, the hollow sub-microsphere has internally-hydrophobic and externally-hydrophilic characteristics, can be applied to fields of oil-water separation, hydrophobic drug delivery, catalyst protection, nano-reactors and the like and is a material with the broad application prospect. The preparation method is simple in process and good in repeatability, and removal conditions of templates are mild; and water is used as a dispersion medium, so that environmental pollution is little.

Owner:INST OF CHEM CHINESE ACAD OF SCI

A high-strength heat-resistant oil casing material and its preparation method

ActiveCN112143972BImprove high temperature strengthSimple system compositionFurnace typesProcess efficiency improvementThermodynamicsHeat resistance

The invention discloses a high-strength heat-resistant oil casing material and a preparation method thereof. The composition weight percentage of the oil casing material is: 0.25%≤C≤0.30%, 0.15%≤Si≤0.35%, 0.9%≤Mn ≤1.1%, 0.9%≤Cr≤1.1%, 0.04%≤V≤0.08%, 0.01%≤Ti≤0.03%, Al≤0.01%, the balance is Fe and unavoidable impurities; the oil casing provided by the invention 0.01% to 0.03% of Zr element can also be added to the material, which can further improve the heat resistance of the oil casing material. The oil and casing material of the invention has a simple composition system, low manufacturing cost, excellent high-temperature mechanical properties and anti-collapse performance, can be widely used in heavy oil thermal recovery well drilling, and has broad market prospects.

Owner:DALIPAL PIPE

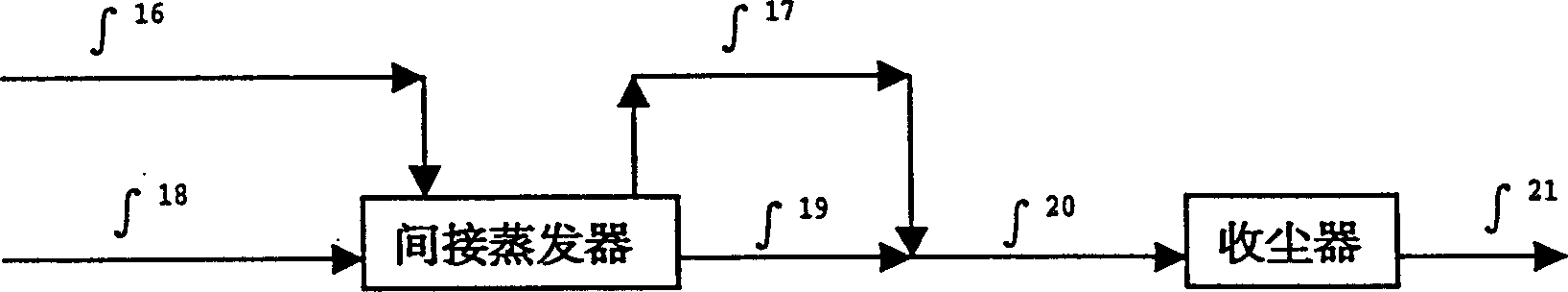

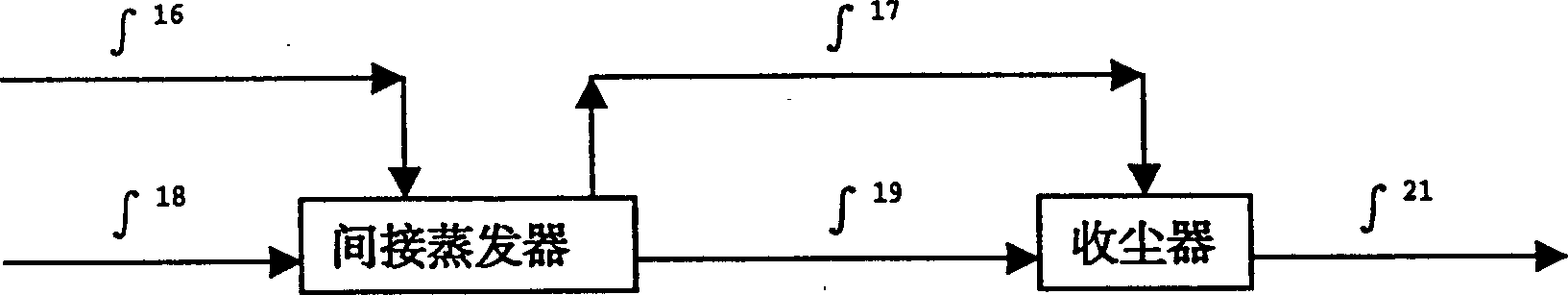

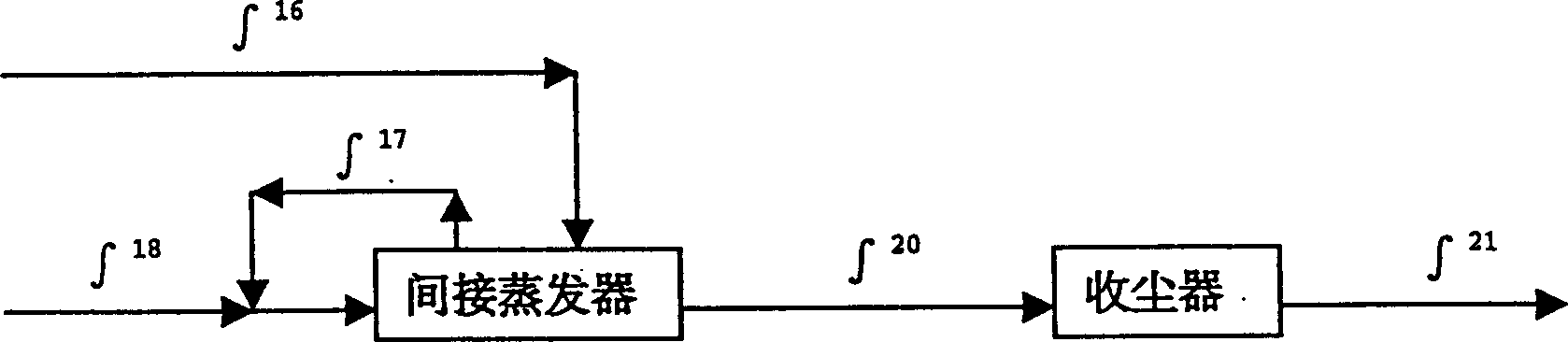

Fume cleaning regulating method and apparatus by indirect evaporating liquid utilizing the residual heat of fume

InactiveCN1263549CEnergy savingSimple system compositionElectrostatic separationDispersed particle separationProcess engineeringElectricity

A method of cleansing smokes by indirectly evaporating liquid through remaining heat of smoke and its device. The device comprises heat source, evaporating container, heat conductive member. Taking advantage of the remaining heat of smoke, liquid is evaporated by the heat conductive member. When the liquid is heated and evaporated, it greatly absorbs energy from warm smoke containing dust by the heat conductive member, the temperature of the smoke drops to an objective value. Steam from the liquid is mixed with smoke by a steam pipeline before a dust-collecting machine. In the manner, the smoke is cool, increase humidity, purified, which improve the purifying effect of the dust-collecting machine.

Owner:陶国龙

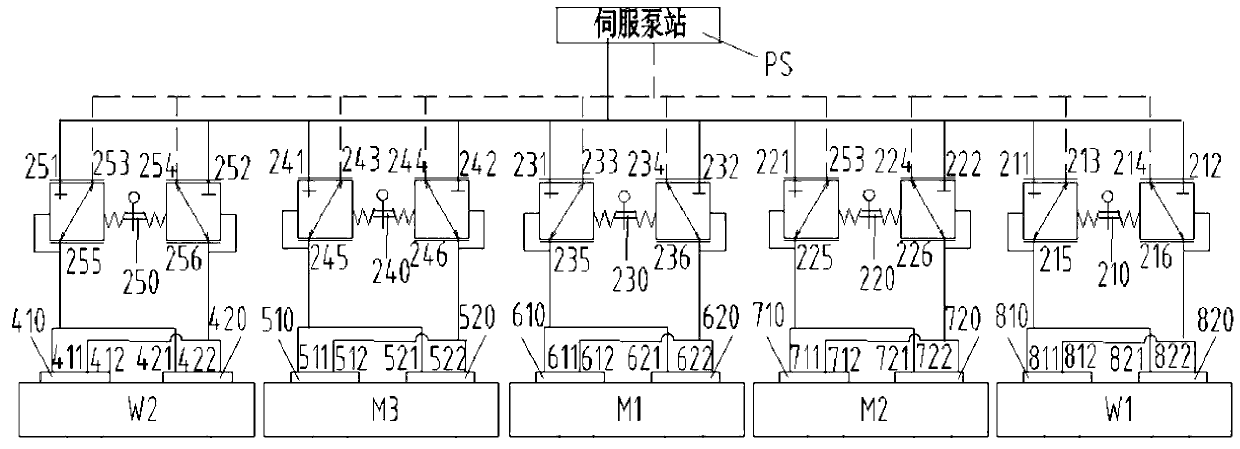

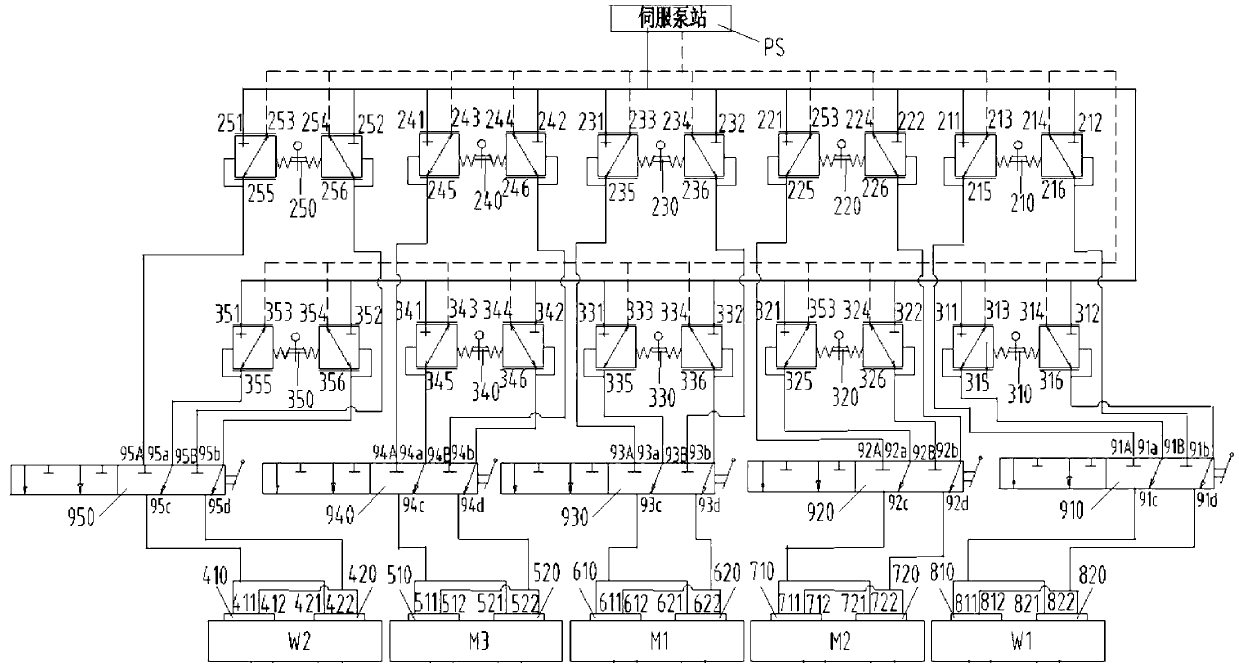

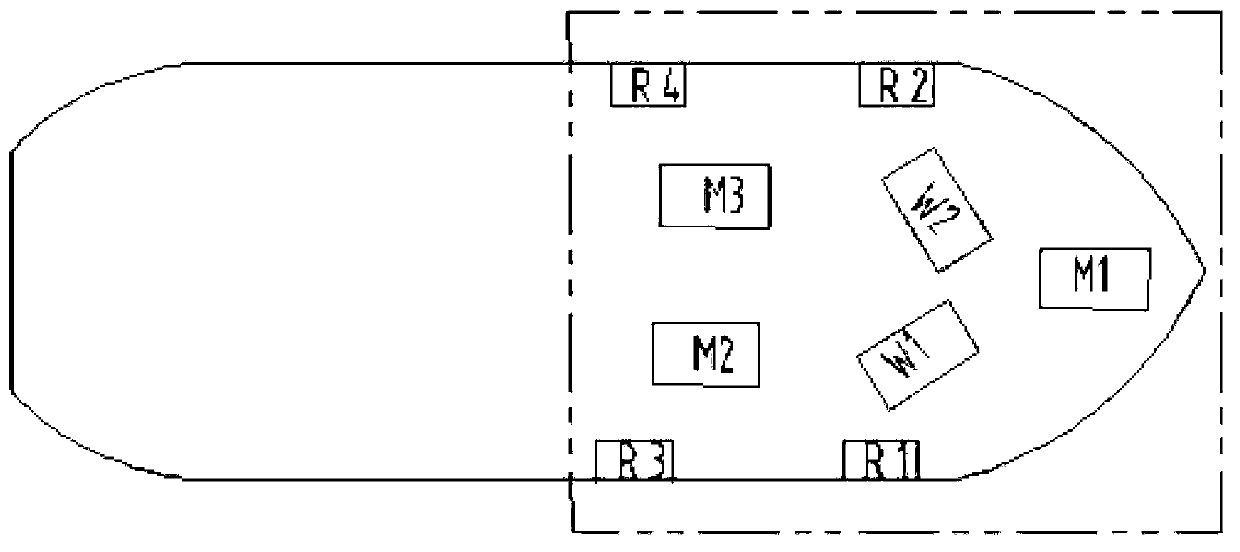

Work control system of anchor and mooring machines

ActiveCN103342307ASimple system compositionLow costWinding mechanismsMarine engineeringControl system

The invention discloses a work control system of anchor and mooring machines, and belongs to the technical field of the anchor and mooring machines of a transportation ship. The work control system of the anchor and mooring machines comprises a servo pump station and a plurality of first direction switching valves, wherein the first direction switching valves correspond to all the anchor and mooring machines one to one, a first oil port and a second oil port of each first direction switching valve are connected with an oil outlet of the servo pump station, a third oil port and a fourth oil port of each first direction switching valve are connected with an oil return port of the servo pump station, a fifth oil port of each first direction switching valve is connected with a first oil port of a first controller and a first oil port of a second controller of a motor of the corresponding anchor and mooring machine, and a sixth oil port of each first direction switching valve is connected with a second oil port of the first controller and a second oil port of the second controller of the motor of the corresponding anchor and mooring machine. The work control system of the anchor and mooring machines only needs the first direction switching valves to control the anchor and mooring machines to work, is simple in structure, and is low in cost. In addition, the work control system of the anchor and mooring machines does not involve an electric part, and only involves the mechanical motions of the first direction switching valves, thereby being high in reliability.

Owner:WUHAN MARINE MACHINERY PLANT

MIG/MAG welding wire for -196°C working temperature

ActiveCN106938375BLow content priceReduce manufacturing costWelding/cutting media/materialsSoldering mediaWorking temperatureImpurity

The invention relates to a melting electrode gas shielded welding wire suitable for the working temperature of -196°C. The technical solution is: the chemical composition of the metal gas shielded welding wire is: C is 0.30~0.55wt%, Mn is 24~26wt%, Ni is 6.4~8.2wt%, W is 2.5~4.0wt%, P≤0.002wt%, S≤0.001wt%, the balance is Fe and unavoidable impurities. The invention has low preparation cost and simple alloy composition system; the formed weld metal has the characteristics of ultra-low temperature and high toughness, its strength matches that of ultra-low temperature high manganese steel, and the welded joint has high strength and excellent mechanical properties of ultra-low temperature toughness, which can meet the requirements of Specifications for strength and cryogenic toughness of devices to be welded at ‑196°C.

Owner:WUHAN UNIV OF SCI & TECH

Hot rolling steel plate with characteristic of multiple grades in one steel, and manufacturing method thereof

Owner:NORTHEASTERN UNIV LIAONING

High-strength heat-resistant oil casing material and preparation method thereof

ActiveCN112143972AImprove high temperature strengthSimple system compositionFurnace typesProcess efficiency improvementHeat resistanceComponents of crude oil

The invention discloses a high-strength heat-resistant oil casing material and a preparation method thereof. The oil casing material comprises the following components of, in percentage by weight, greater than or equal to 0.25% and less than or equal to 0.30% of C, greater than or equal to 0.15% and less than or equal to 0.35% of Si, greater than or equal to 0.9% and less than or equal to 1.1% ofMn, greater than or equal to 0.9% and less than or equal to 1.1% of Cr, greater than or equal to 0.04% and less than or equal to 0.08% of V, greater than or equal to 0.01% and less than or equal to 0.03% of Ti, greater than or equal to 0.01% of Al and the balance Fe and inevitable impurities. The preparation method comprises the following steps that 0.01%-0.03% of Zr element can also be added intothe oil casing material provided by the invention, so that the heat resistance of the oil casing material can be further improved. The oil casing material disclosed by the invention is simple in component system, low in manufacturing cost and excellent in high-temperature mechanical property and collapse resistance, can be widely applied to drilling and production of heavy oil thermal productionwells, and has a wide market prospect.

Owner:DALIPAL PIPE

A kind of corrosion-resistant high anti-extrusion petroleum casing and preparation method thereof

ActiveCN109913757BImprove performanceSimple system compositionPhysical chemistryComponents of crude oil

The invention discloses a corrosion resistant and squeezing highly resistant oil casing pipe and a preparation method thereof. The oil casing pipe comprises, by weight percentage, 0.22%<=C<=0.30%, 0.15%<=Si<=0.35%, 0.40%<=Mn<=0.60%, S<=0.003%, P<=0.01%, 0.02%<=Al<=0.04%, 0.75%<=Cr<=1.20%, 0.25%<=Mo<=0.55%, Ca<=0.0025%, N<=0.08% and the balanced Fe and unavoidable impurities. The oil casing has theadvantages that the squeezing resistant strength of the prepared oil casing pipe is 30% or above higher than the squeezing resistant strength required by API 5C3 standards, the hydrogen sulfide corrosion resistance performance is conformed to demands in API 5CT (45 edition) PSL3, and the oil casing pipe can be extensively applied to the exploitation of oil and gas wells of acid medium deep wells, ultra-deep wells and the like with complicated geological conditions

Owner:DALIPAL PIPE

Nb microalloyed structural steel with excellent bending performance and manufacturing method thereof

InactiveCN113913692AHigh strengthMeet the processing technology requirementsMetal rolling arrangementsMetallic materialsAlloy

The invention belongs to the technical field of metal materials, and particularly relates to Nb microalloyed structural steel with excellent bending performance and a manufacturing method thereof. The Nb microalloyed structural steel comprises the following smelting components of 0.15-0.18% of C, 0.15-0.40% of Si, 0.90-1.10% of Mn, 0.010-0.020% of Nb, 0.010-0.020% of Ti, 0.015-0.040% of Als, less than or equal to 0.018% of P, less than or equal to 0.005% of S and less than or equal to 0.0050% of N. According to the Nb microalloyed structural steel with the excellent bending performance and the manufacturing method thereof, the component design of medium C-low Mn-micro Nb is adopted, a two-stage controlled rolling and controlled cooling process is adopted, and a stacking slow cooling measure after rolling is adopted, so that the low-alloy structural steel with the thickness being less than or equal to 40mm, the yield strength being greater than or equal to 360MPa, the tensile strength being greater than or equal to 500MPa, the longitudinal impact energy at -40 DEG C being greater than or equal to 100J and the excellent bending process performance is produced.

Owner:天津市新天钢钢铁集团有限公司

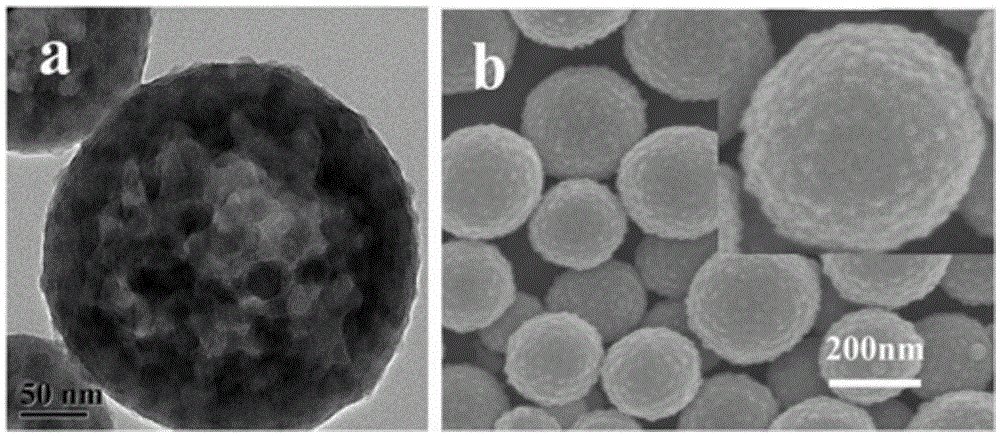

A kind of submicron composite ball and its preparation method and its application as silicone rubber porcelain filler

ActiveCN106317964BEasy to wetGood dispersionPigment treatment with organosilicon compoundsPolymer scienceDecomposition

The invention discloses a submicron composite sphere and a preparation method thereof, and an application of the submicron composite sphere as a silicone rubber ceramic-forming filling material. The filling material is of an inorganic nanosheet-polymer composite structure, and comprises a hydrophobic silicon-containing polymer part and a hydrophilic inorganic nanosheet part; and the inorganic nanosheet coats the surface of the polymer part to form an armor structure. The preparation method for the filling material has the advantages of simple process, good product repeatability, good process controllability and facilitation to large-scale production. The composite sphere is used as the ceramic-forming filling material of silicone rubber, and on the basis of guaranteeing high strength and original shape of a ceramic product, the filling material has low ceramization temperature and can match with the decomposition temperature of silicone rubber; the ceramic product has good self-support properties; excellent dispersibility and compatibility in a silicone rubber matrix can be achieved without the need of further modification; and the silicone rubber containing the filling material facilitates to molding processing.

Owner:INST OF CHEM CHINESE ACAD OF SCI

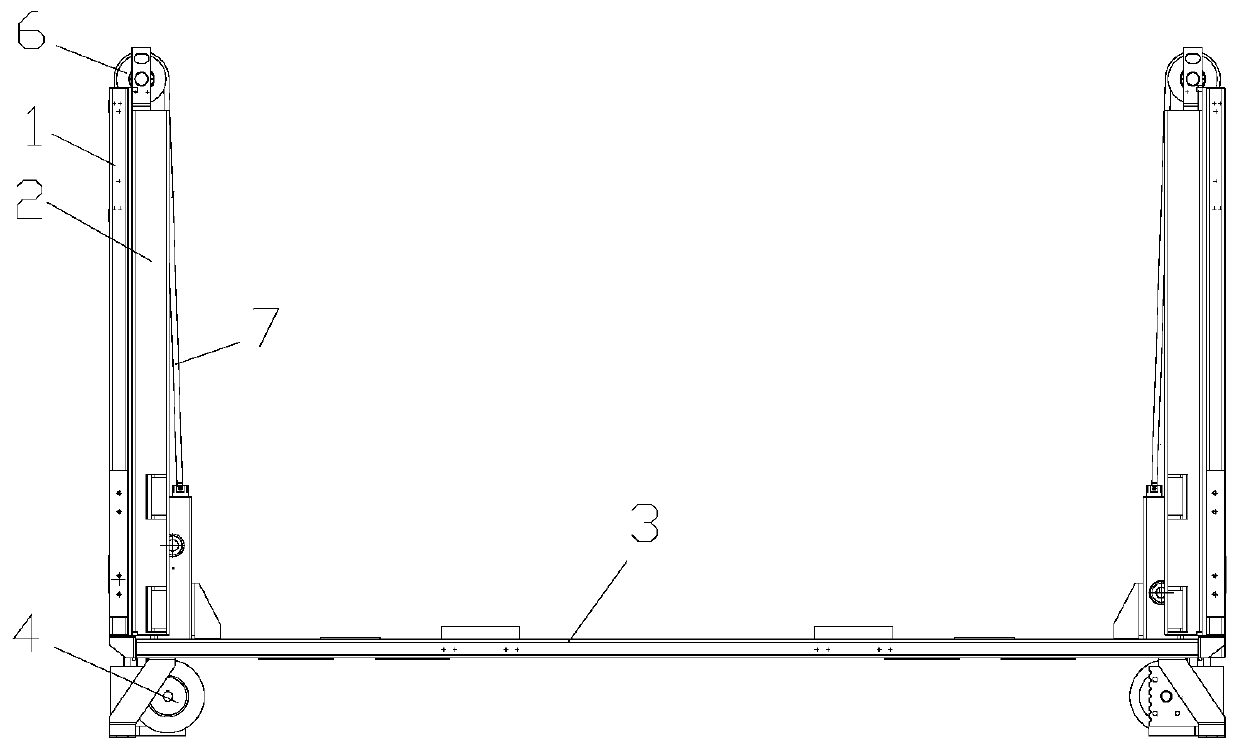

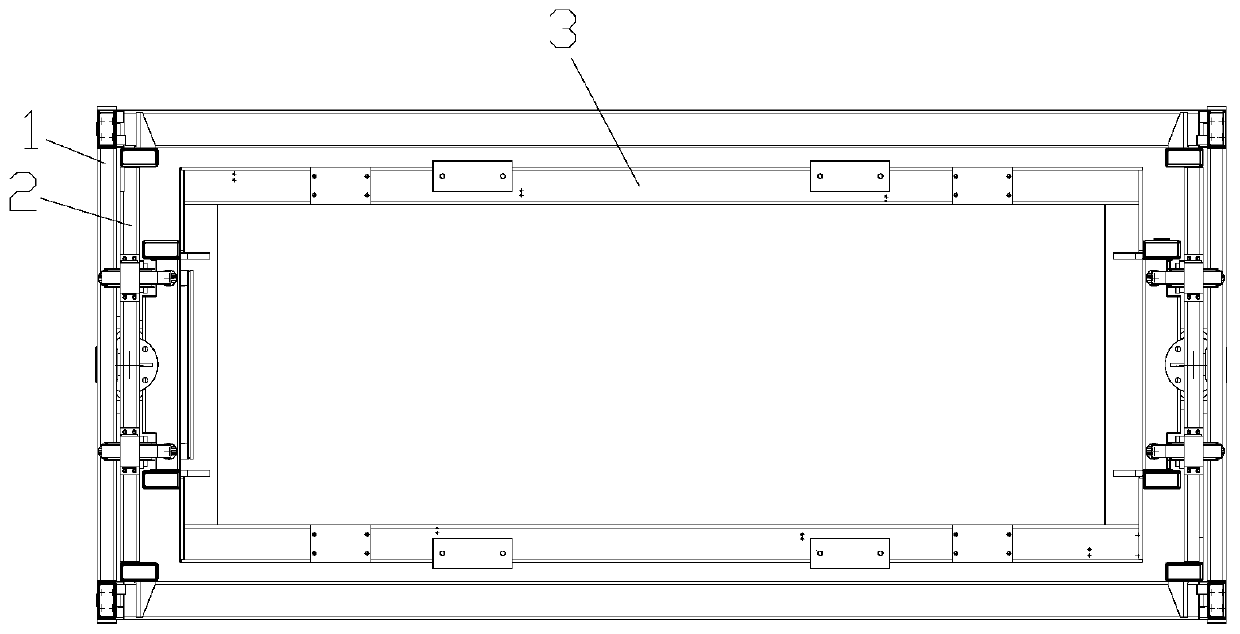

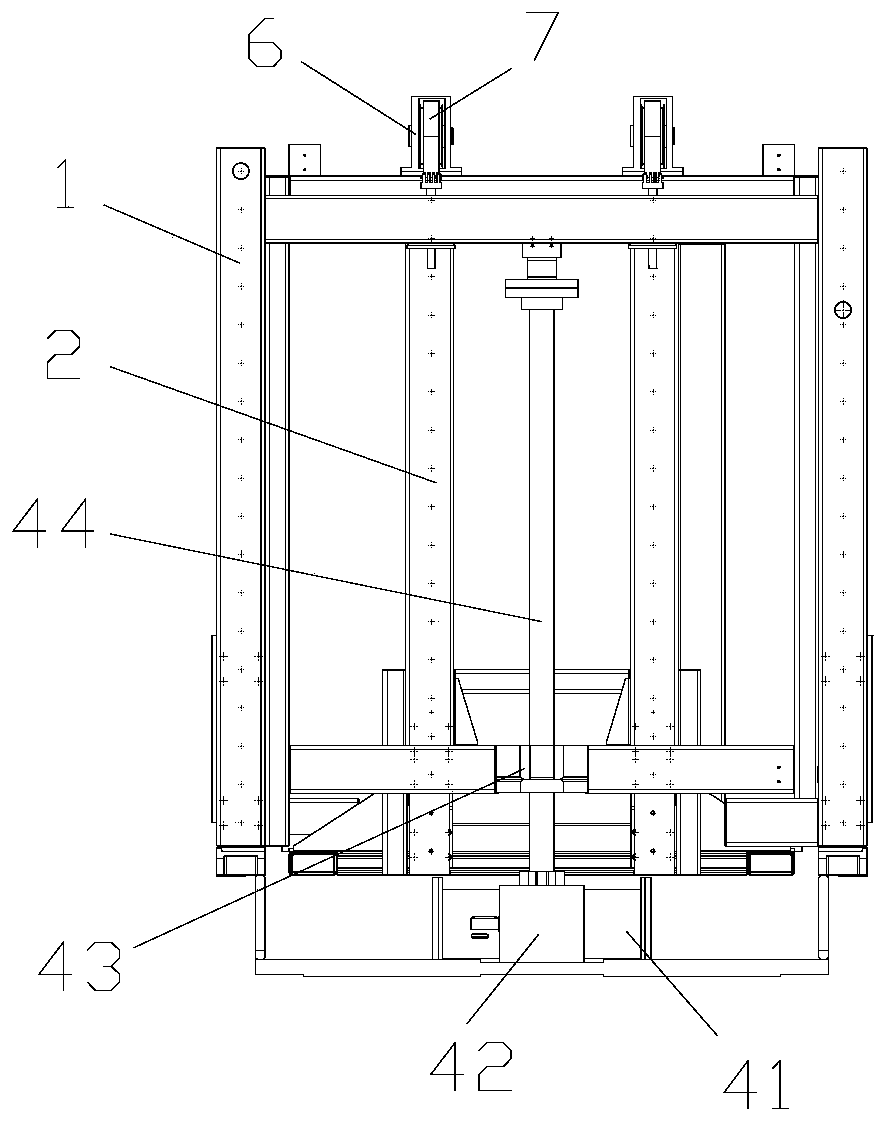

Vehicle-mounted automatic lifting platform for intelligent transferring, storing and conveying system

InactiveCN111483738AReduce the number of supporting equipmentSimple system compositionStorage devicesIn vehicleEngineering

The invention belongs to the technical field of intelligent transferring, storing and conveying systems, and particularly relates to a vehicle-mounted automatic lifting platform for an intelligent transferring, storing and conveying system. The vehicle-mounted automatic lifting platform comprises a main body frame, a moving frame, an objective table, a lifting driving device and a traction device,wherein the moving frame is slidably connected with the main body frame in the vertical direction, the two ends of the objective table are slidably connected with the moving frame in the vertical direction, and the traction device is arranged above the moving frame and connected with the main body frame and the objective table; and the lifting driving device is arranged on the main body frame andconnected with the moving frame, the lifting driving device drives the moving frame to lift, and the moving frame enables the objective table to move up and down relative to the moving frame throughthe traction device. According to the vehicle-mounted automatic lifting platform, the functions of intelligent transferring, storing and conveying are achieved, meanwhile, the number of matched intelligent transferring, storing and conveying system equipment is reduced, system composition is simplified, system reliability is improved, using and maintaining difficulty is lowered, and system construction cost is reduced.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com