A hollow submicron sphere, its preparation method and application

A submicron, hollow technology, applied in the field of organic-inorganic hybrid hollow submicron spheres and their preparation, can solve the problems of wide particle size distribution of hollow microspheres, a large number of organic solvents, complex system components, etc. Simple process and simple system composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

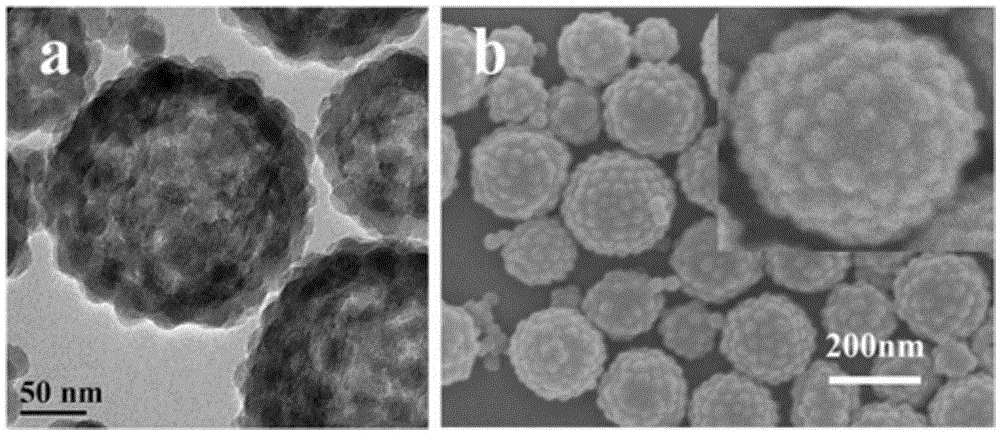

[0051] The raw materials are 3-methacryloyloxypropyltrimethoxysilane (TPM), silica colloid particles (LudoxTM40) with a particle size of 30 nm, isoamyl acetate (PEA), and the initiator is potassium persulfate. Add 0.5mL of TPM, 0.65mL of silica colloidal particle dispersion, and 1mL of PEA into 40mL of water, stir at 15°C for 16 hours, pass nitrogen gas and exhaust oxygen for 30 minutes, then raise the temperature to 70°C, add 10mg of potassium persulfate to initiate polymerization, and the polymerization reaction lasts for 12 Hour. The resulting emulsion was centrifuged, washed three times with ethanol, dispersed in water, and freeze-dried to obtain a white powdery solid.

[0052] The above-mentioned powder was dispersed in ethanol to make a transmission electron microscope sample and a scanning electron microscope sample, and the particle morphology was observed. like figure 1 As shown, the particles have an obvious hollow structure, and there are nanoparticles embedded in...

Embodiment 2

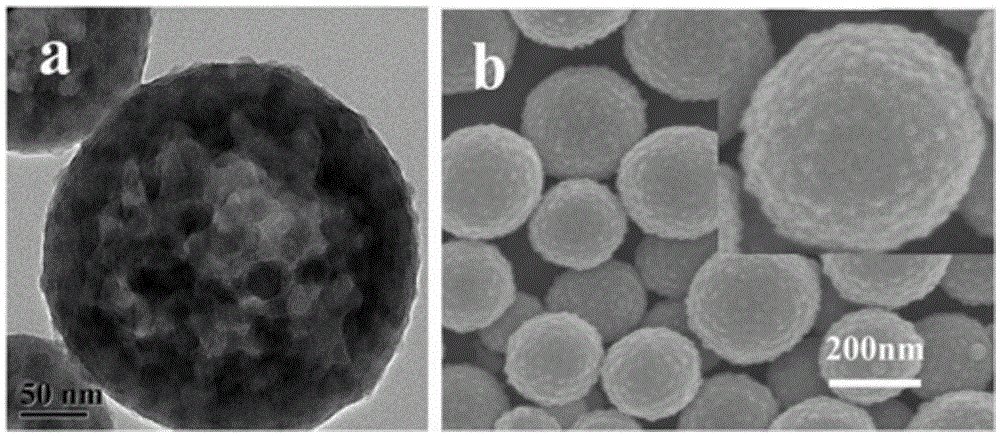

[0054] The raw materials are 3-methacryloyloxypropyltrimethoxysilane (TPM), colloidal silica particles (LudoxHS40) with a particle size of 12 nanometers, isoamyl acetate (PEA), and the initiator is potassium persulfate. Add 1mL of TPM, 0.28mL of silica colloidal particle dispersion, and 2mL of PEA into 40mL of water, stir at 20°C for 24 hours, pass nitrogen gas and exhaust oxygen for 30 minutes, then raise the temperature to 65°C, add 10mg of potassium persulfate to initiate polymerization, and the polymerization reaction lasts for 12 hours . The resulting emulsion was centrifuged, washed three times with ethanol, dispersed in water, and freeze-dried to obtain a white powdery solid.

[0055] The above-mentioned powder was dispersed in ethanol to make a transmission electron microscope sample and a scanning electron microscope sample, and the particle morphology was observed. like figure 2 As shown, the particles have an obvious hollow structure, and there are nanoparticles ...

Embodiment 3

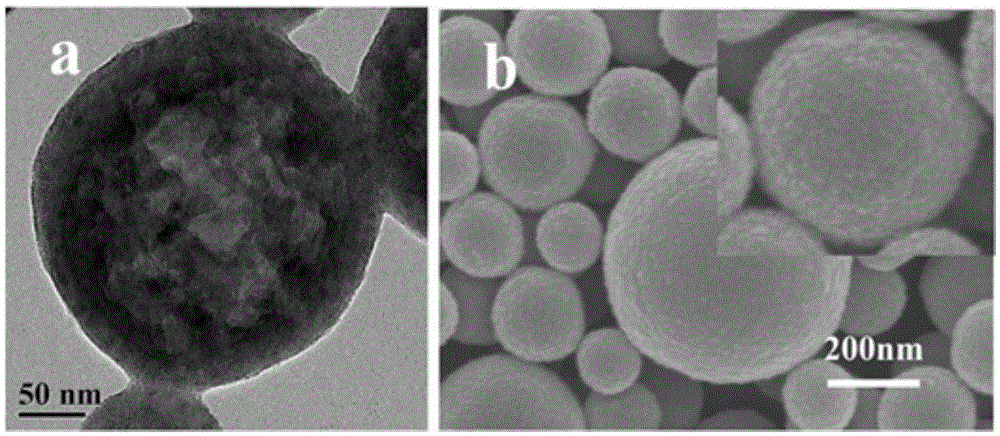

[0057] The raw materials are 3-methacryloyloxypropyltrimethoxysilane (TPM), silica colloidal particles (LudoxHS40) with a particle size of 7 nm, isoamyl acetate (PEA), and the initiator is potassium persulfate. Add 1mL of TPM, 0.225mL of silica colloidal particle dispersion, 2mL of PEA into 40mL of water, stir at 20°C for 24 hours, pass nitrogen gas and exhaust oxygen for 30 minutes, then raise the temperature to 65°C, add 10mg of potassium persulfate to initiate polymerization, and the polymerization reaction lasts for 12 hours . The resulting emulsion was centrifuged, washed three times with ethanol, dispersed in water, and freeze-dried to obtain a white powdery solid.

[0058] The above-mentioned powder was dispersed in ethanol to make a transmission electron microscope sample and a scanning electron microscope sample, and the particle morphology was observed. like image 3 As shown, the particles have an obvious hollow structure, and there are nanoparticles embedded in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com