Nb microalloyed structural steel with excellent bending performance and manufacturing method thereof

A technology of micro-alloying and manufacturing method, applied in metal rolling and other directions, can solve the problems of poor plasticity and toughness of steel plates, and deteriorate the processing performance of steel plates, and achieve low carbon equivalent, excellent bending process performance, and easy process control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

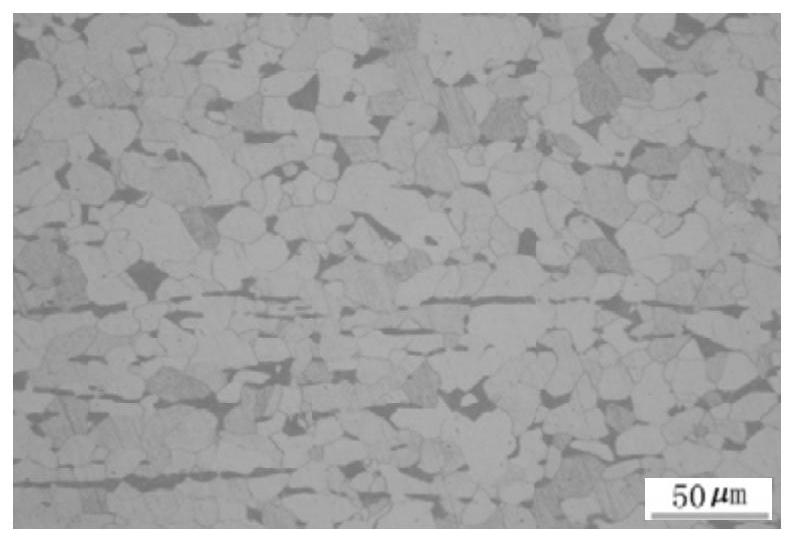

Embodiment 1

[0042] A kind of Nb micro-alloyed structural steel with excellent bending performance. Calculated by mass percentage, its melting composition is as follows: C: 0.15%; Si: 0.16%; Mn: 0.92%; Nb: 0.011%; Ti: 0.015%; Als : 0.025%; P: 0.015%; S: 0.005%; N: 0.0048%; the rest is Fe and unavoidable impurities.

[0043] Present embodiment relates to 10mm thickness low-alloy structural steel, the manufacturing method of this structural steel is as follows:

[0044] S1. Hot metal pretreatment: execute the deep desulfurization mode, and the molten iron S into the furnace is 0.005%. After spraying, remove slag for 4 minutes, add 100kg of slag-accumulating agent, stop for 3 minutes, and then remove slag for 5 minutes. The net slag removal time is 9 minutes. After removing slag, the bright surface reaches 100%;

[0045] S2. Smelting and continuous casting process: the final components of the converter smelting process include: C: 0.060%, S: 0.005%, P: 0.012%; the tapping temperature of the ...

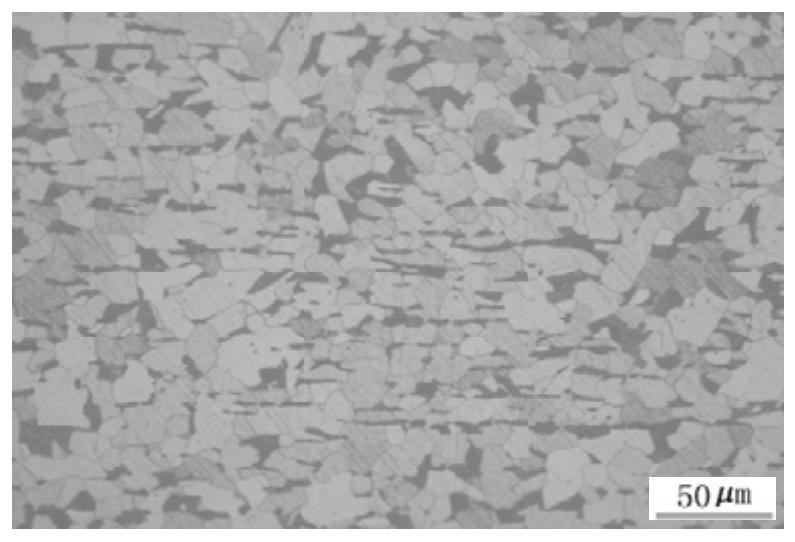

Embodiment 2

[0052] A kind of Nb micro-alloyed structural steel with excellent bending performance. Calculated by mass percentage, its melting composition is as follows: C: 0.17%; Si: 0.36%; Mn: 1.01%; Nb: 0.017%; Ti: 0.018%; Als : 0.030%; P: 0.017%; S: 0.004%; N: 0.0042%; the rest is Fe and unavoidable impurities.

[0053] Present embodiment relates to 30mm thickness low-alloy structural steel, the manufacture method of this structural steel is as follows:

[0054] S1. Hot metal pretreatment: adopt the deep desulfurization mode, the target S content is 0.004%; increase the amount of Mg injection to ensure the desulphurization effect; remove slag for 5 minutes after the injection is completed, add 120kg of slag aggregation agent, stop for 3 minutes and then remove 6 minutes, The net slag removal time is 11 minutes, and the bright side reaches 100% after slag removal;

[0055] S2. Smelting and continuous casting process: the final composition of the converter smelting process, C: 0.070%, S...

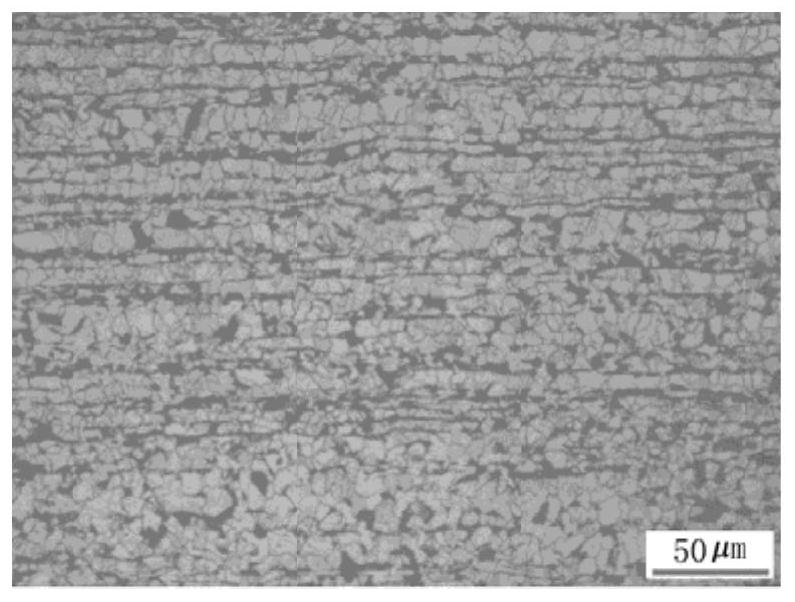

Embodiment 3

[0062] A kind of Nb micro-alloyed structural steel with excellent bending performance. Calculated by mass percentage, its melting composition is as follows: C: 0.18%; Si: 0.39%; Mn: 1.09%; Nb: 0.019%; Ti: 0.019%; Als : 0.038%; P: 0.015%; S: 0.002%; N: 0.0030%; the rest is Fe and unavoidable impurities.

[0063] Present embodiment relates to 40mm thickness low-alloy structural steel, the manufacture method of this structural steel is as follows:

[0064] S1. Hot metal pretreatment: adopt the deep desulfurization mode, the target S content is 0.004%; increase the amount of Mg injection to ensure the desulphurization effect; remove slag for 5 minutes after the injection is completed, add 110kg of slag aggregation agent, stop for 3 minutes and then remove 5 minutes, The net slag removal time is 10 minutes, and the bright surface reaches 100% after slag removal;

[0065] S2. Smelting and continuous casting process: the final composition of the converter smelting process, C: 0.070%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com