Patents

Literature

349 results about "Indicator diagram" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

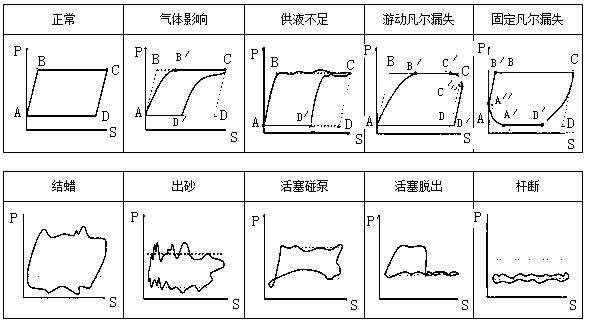

INDICATOR DIAGRAM An indicator diagram is a graph between pressure and volume ; the former being taken on vertical axis and the latter on the horizontal axis. This is obtained by an instrument known as indicator.

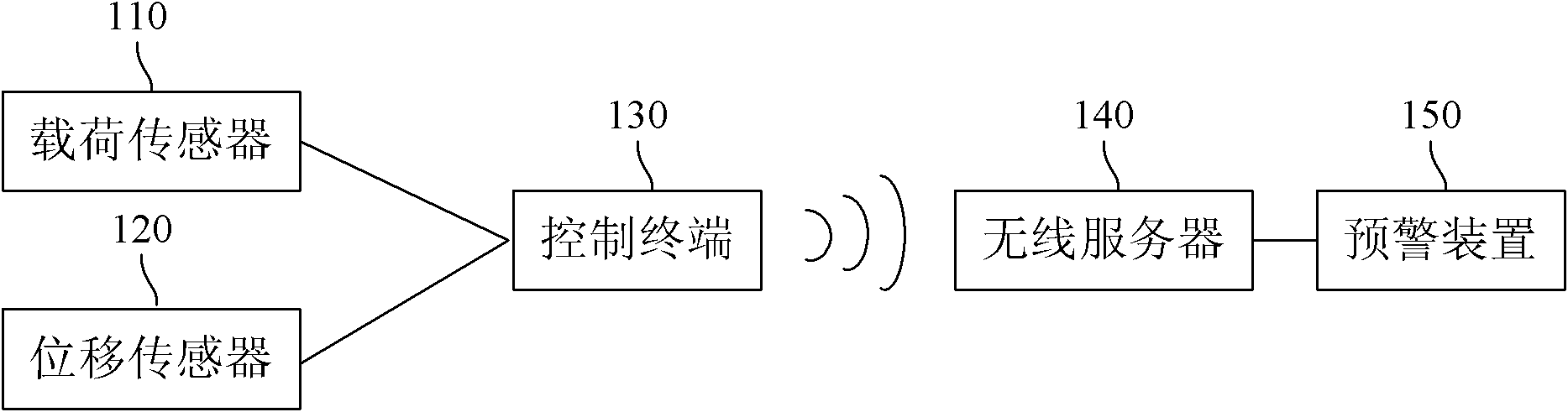

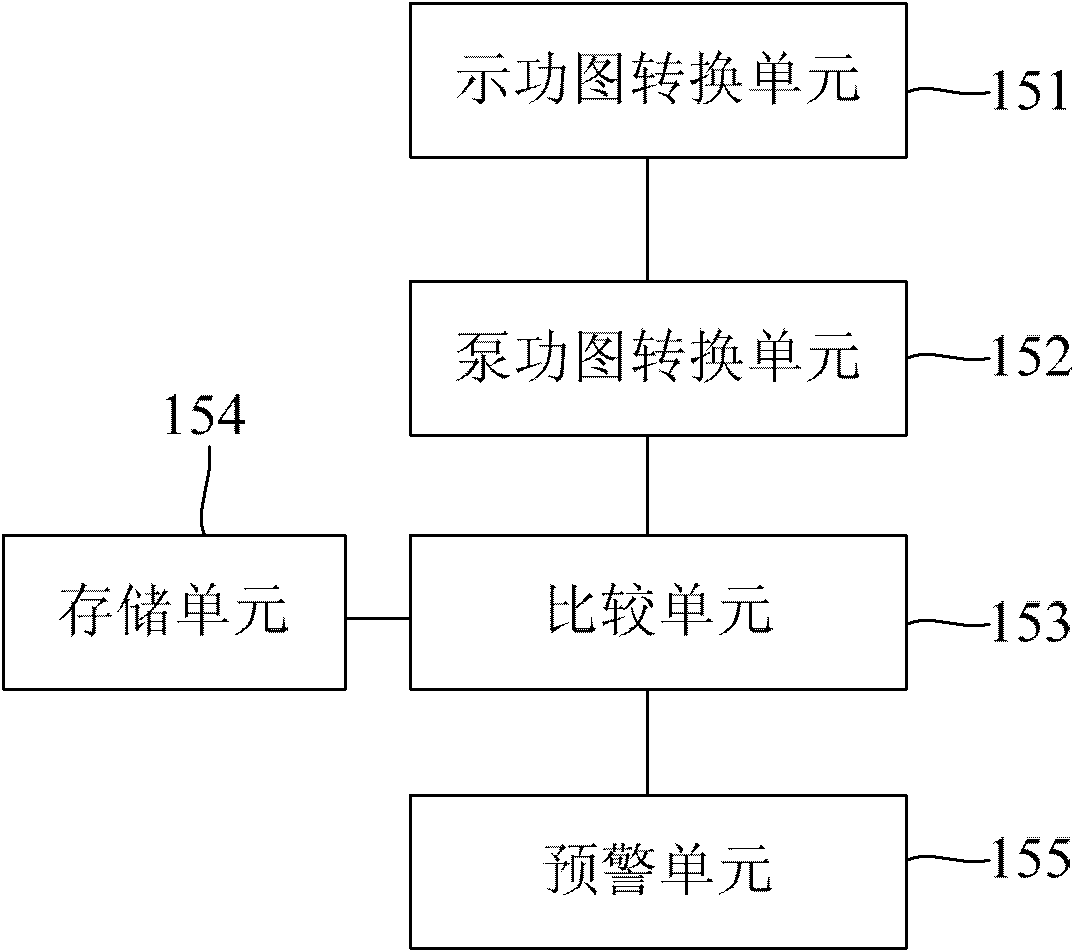

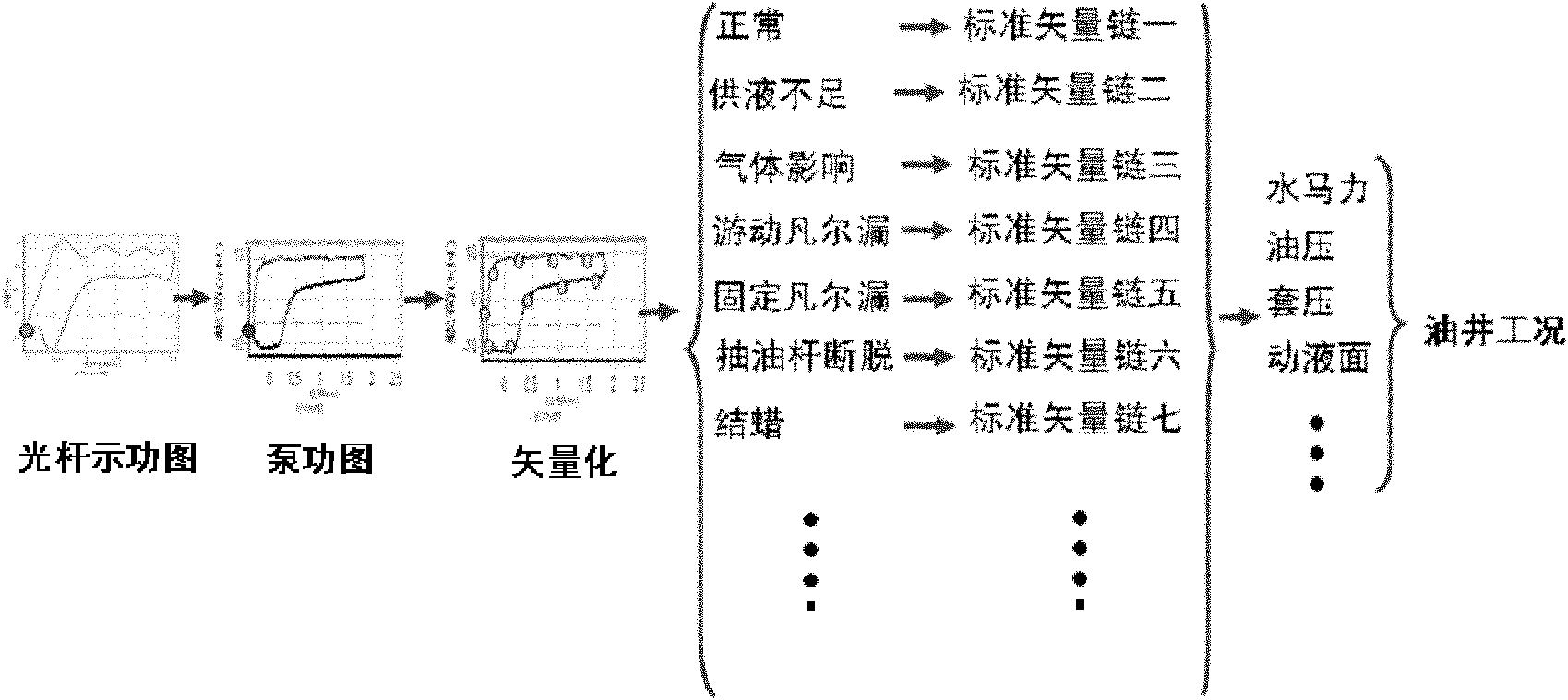

Real-time fault early warning method and system of oil well

InactiveCN102094626AImplement fault diagnosisRealize early warningSurveyConstructionsPower diagramIndicator diagram

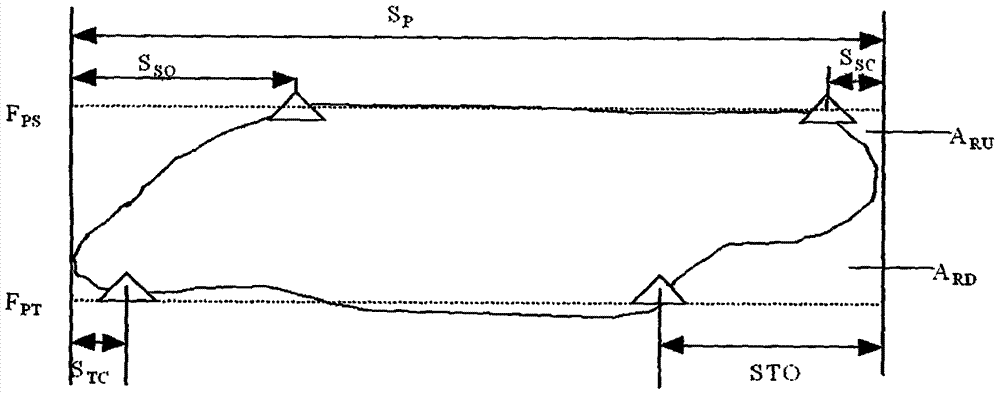

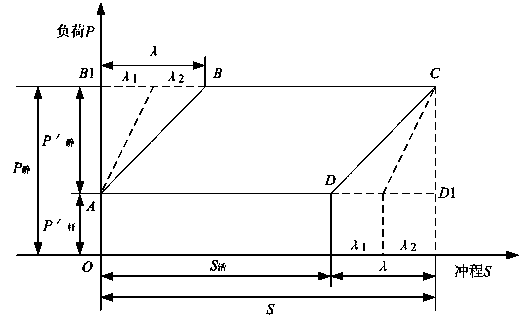

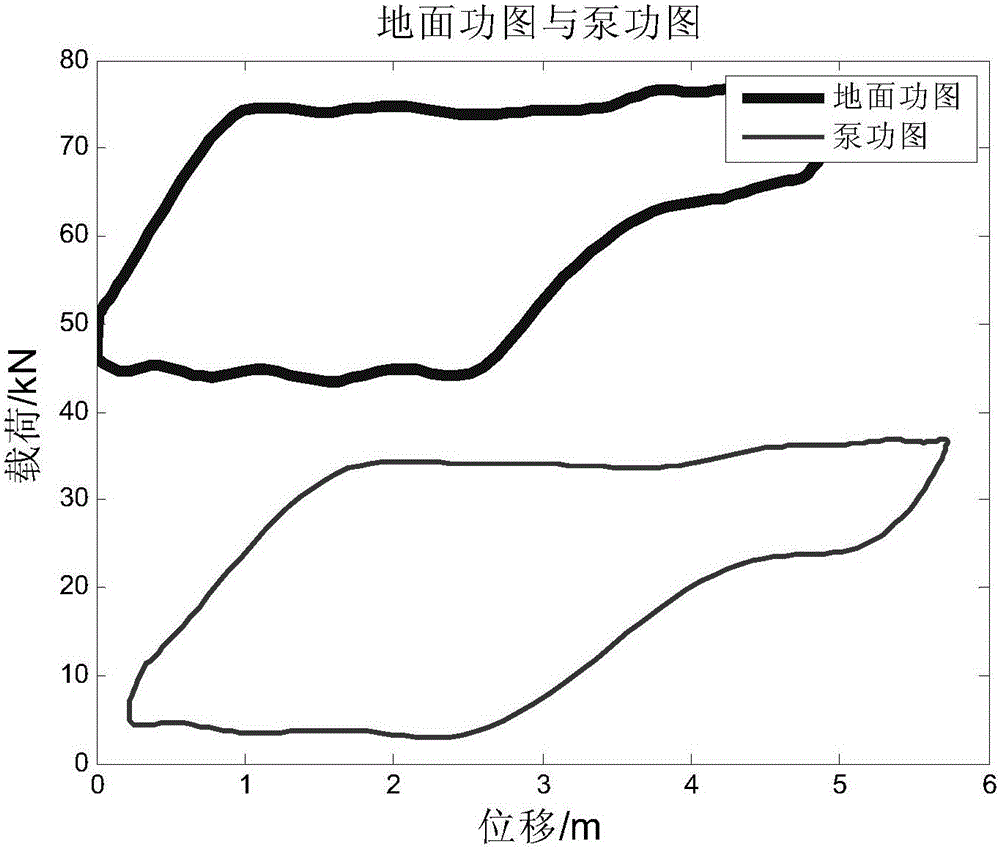

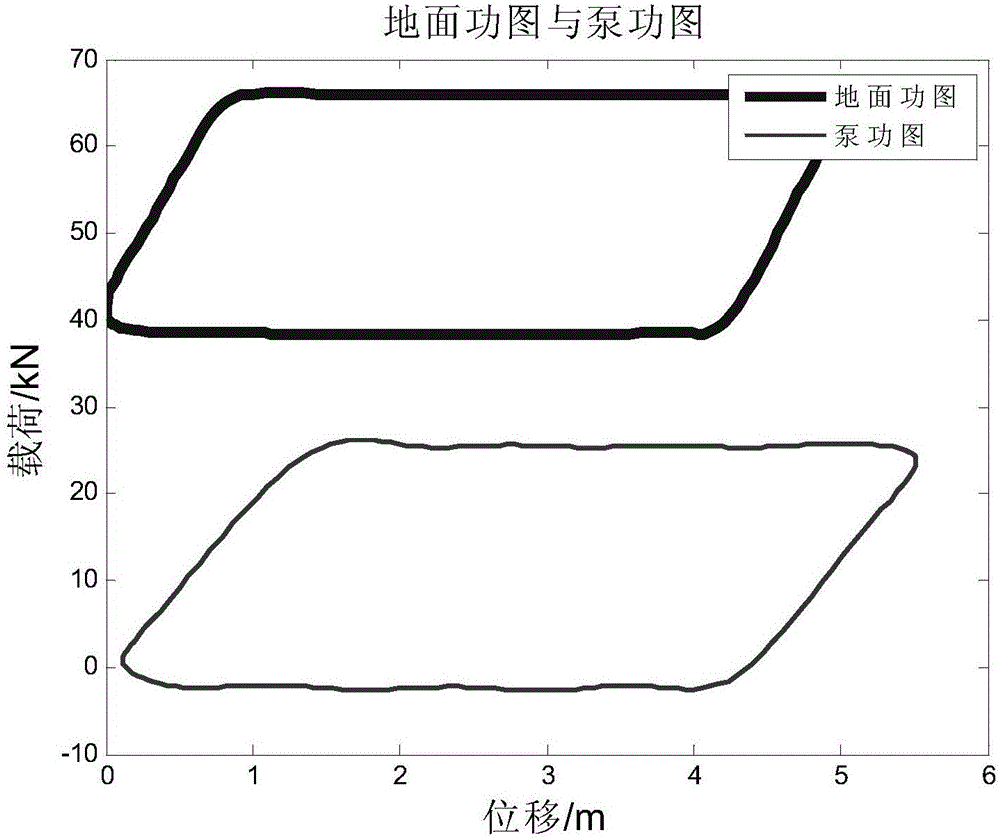

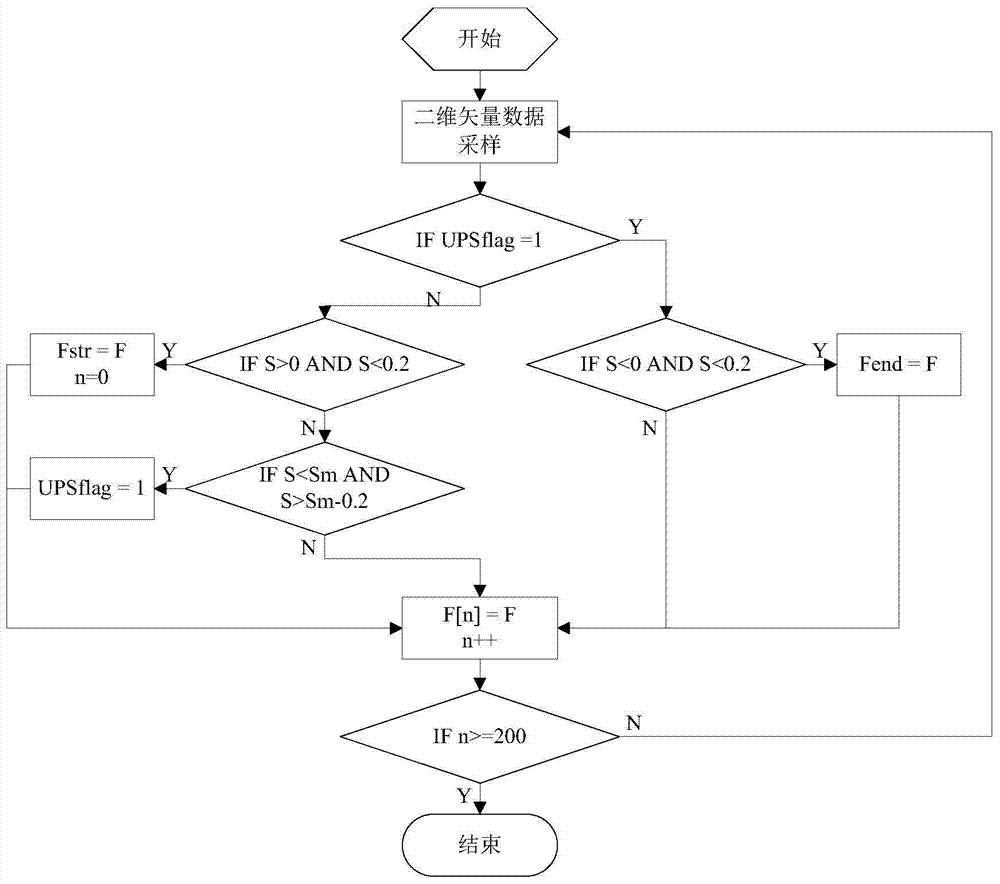

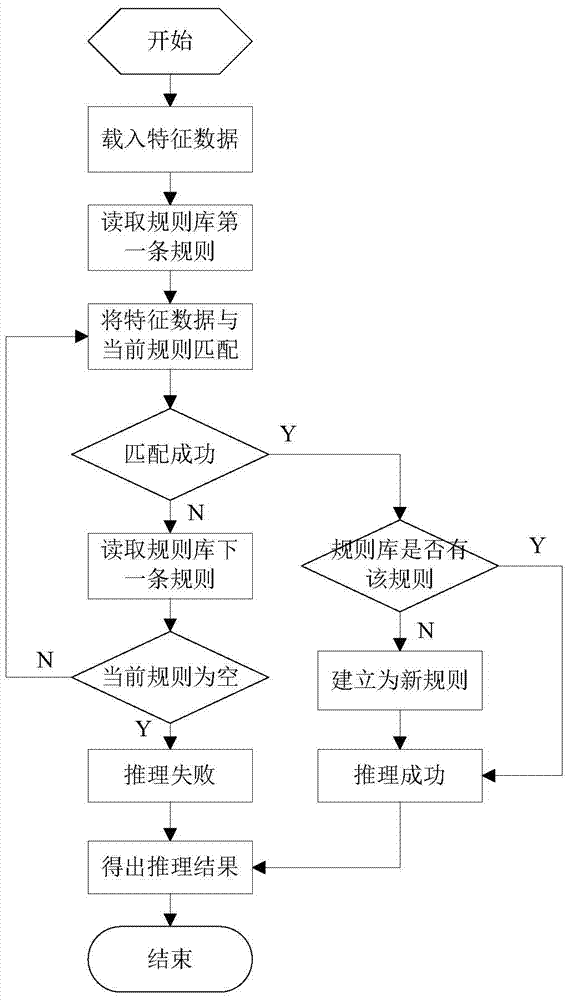

The embodiment of the invention provides a real-time fault early warning method and system for an oil well. The method comprises the following steps of: obtaining a load and a displacement of an oil pumping rod; obtaining a polish rod indicator diagram according to variation rules of the load and the displacement of the oil pumping rod and time, and transforming the polish rod indicator diagram into a pump power diagram; pre-processing data points of the pump power diagram by adopting a polygonous approximation method, and filtering the data points which have little influence on the geometrical characteristics of the pump power diagram; carrying out normalized operation on the pump power diagram after being processed by the polygonous approximation method, establishing a vector chain of the pump power diagram, and comparing the vector chain with the vector chain in a standard fault vector chain warehouse; obtaining a judgment result on a working condition of the oil well according to a comparison result; and carrying out fault early warning according to the judgment result. In the embodiment of the invention, a fault condition is determined by the steps of obtaining the load and the displacement of the oil pumping rod, accordingly obtaining the polish rod indicator diagram and the pump power diagram and comparing the vectorized pump power diagram with a standard power diagram, thereby automatic fault diagnosis and early warning can be realized. Moreover, the accuracy of a fault diagnosis result is high.

Owner:PETROCHINA CO LTD

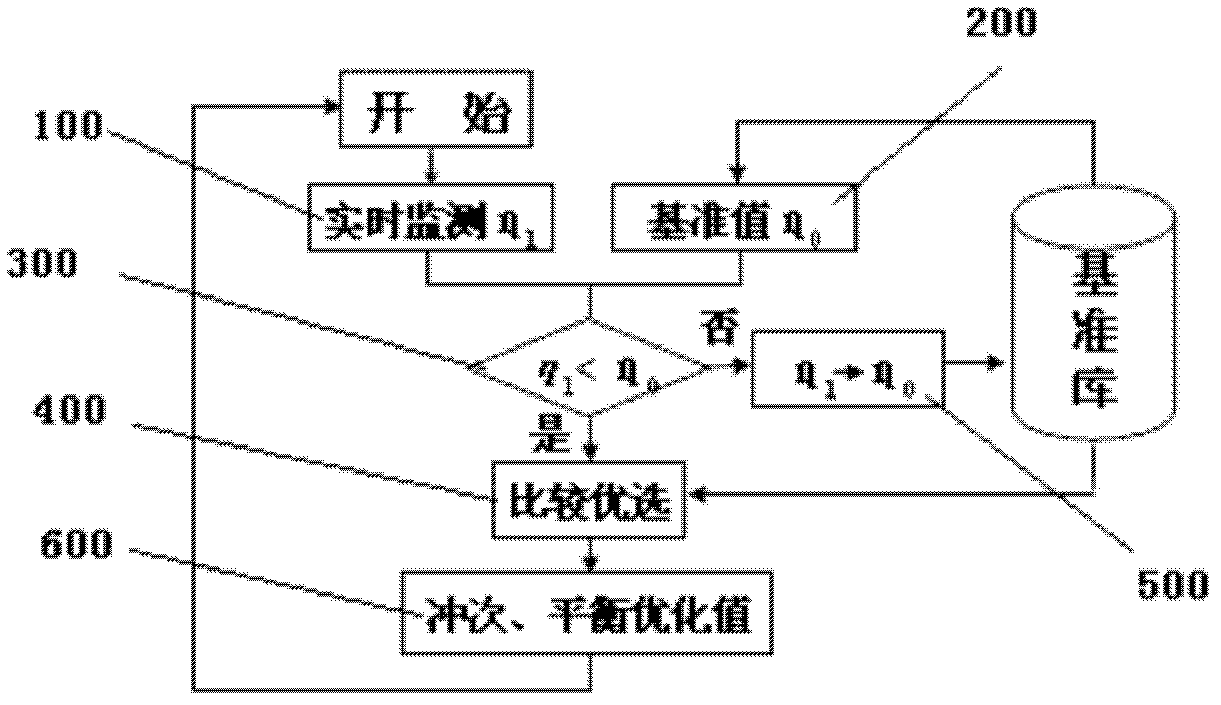

Pumping unit jig frequency, balance real-time capacity adjusting method and device thereof

ActiveCN103161430AAchieve refined managementIncrease productivityFluid removalReal-time dataPower flow

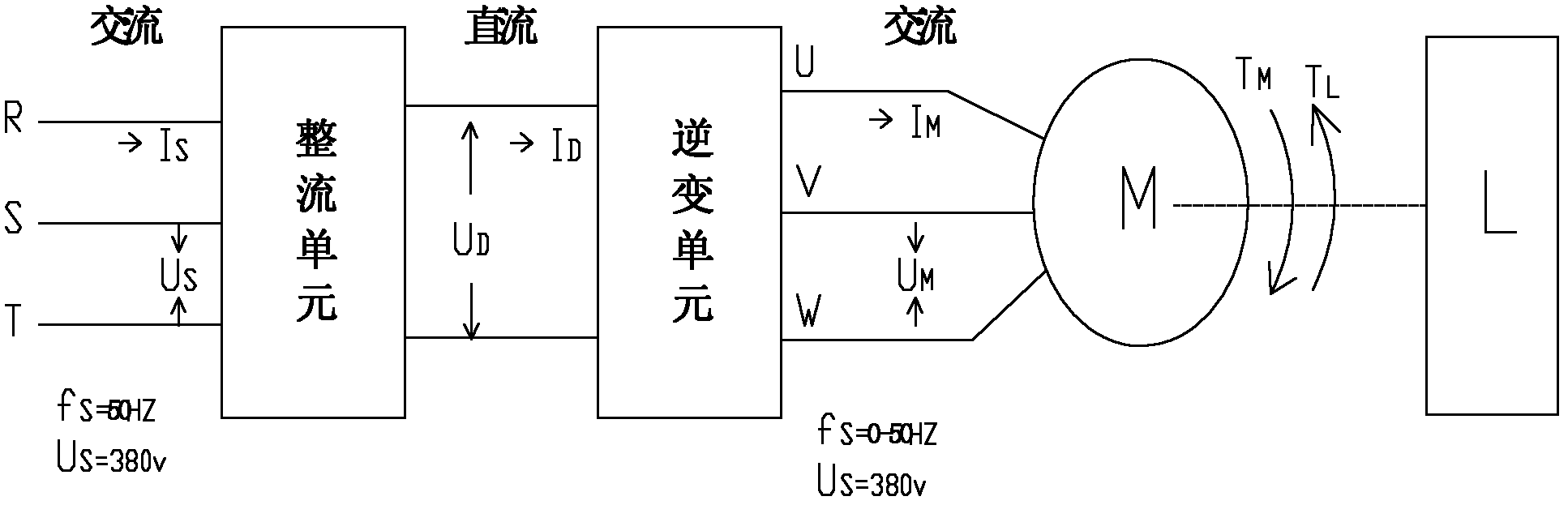

The invention discloses a pumping unit jig frequency, balance real-time capacity adjusting method and a device of the pumping unit jig frequency, balance real-time capacity adjusting method, and belongs to the field of oilfield digital construction and management. A traditional parameter adjustment method is changed, the problems of parameter adjustment hysteretic quality, high staff labor intensity and incapable expression of oilfield potential to the largest extent are solved, and oilfield production efficiency and oilfield digital management level are improved. Due to the fact that pumping unit working conditions are analyzed in real time and a parameter is intelligently adjusted according to measured real-time data, a pumping unit can operate under a reasonable working system, the oilfield potential is expressed to the largest extent, and delicacy management of an oilfield is achieved. Due to the fact that indicator diagram data and electric parameter data are collected in real time and rotating speed of a motor is controlled through a digital pumping unit integrated control device according to system efficiency optimized jig frequency, and stepless jig frequency is adjusted. Balance degree is calculated through current and power obtained in real time, balance of the pumping unit is adjusted through a screw balance adjustment device, and therefore the balance of the pumping unit is adjusted, the pumping unit keeps operating under an optimized production parameter, and the oilfield potential is expressed to the largest extent.

Owner:PETROCHINA CO LTD

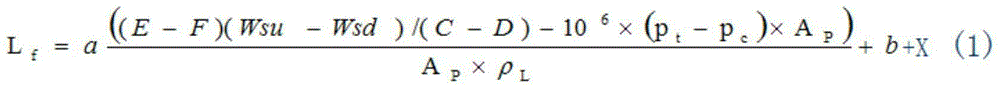

Method and system for improving oil pumping well indicator diagram oil gauging precision

ActiveCN107288617AHigh precisionAccurately grasp the dynamic changes of productionSurveyConstructionsIndicator diagramOil well

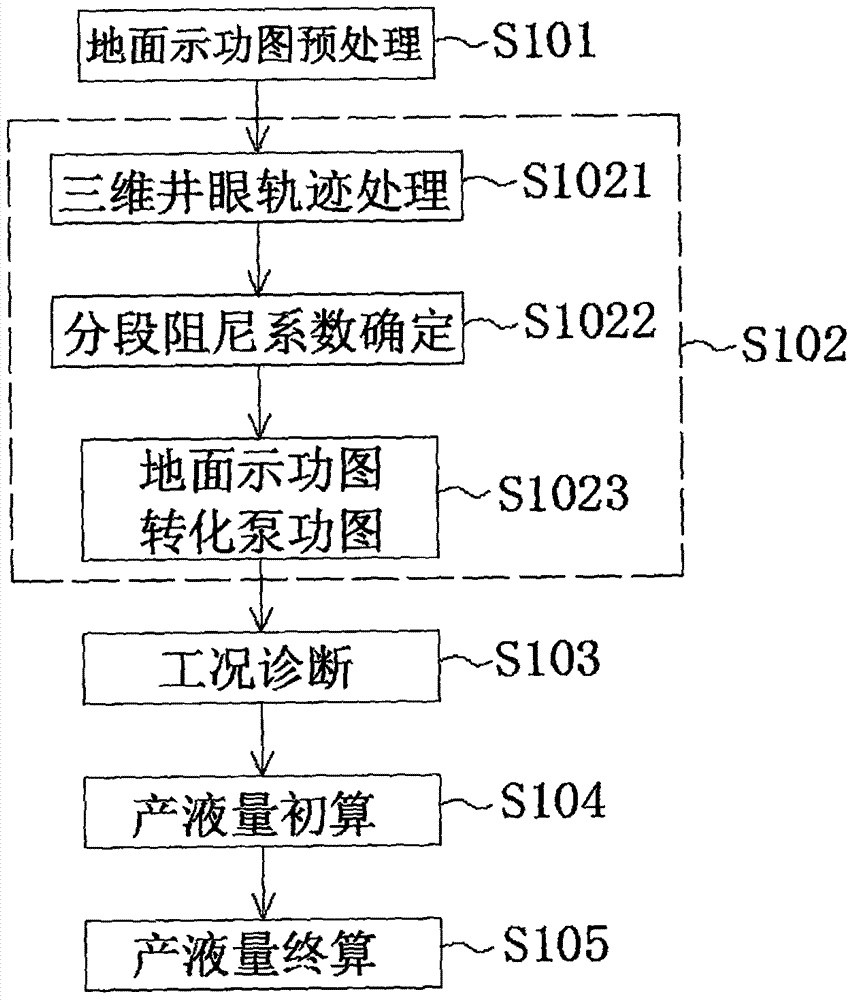

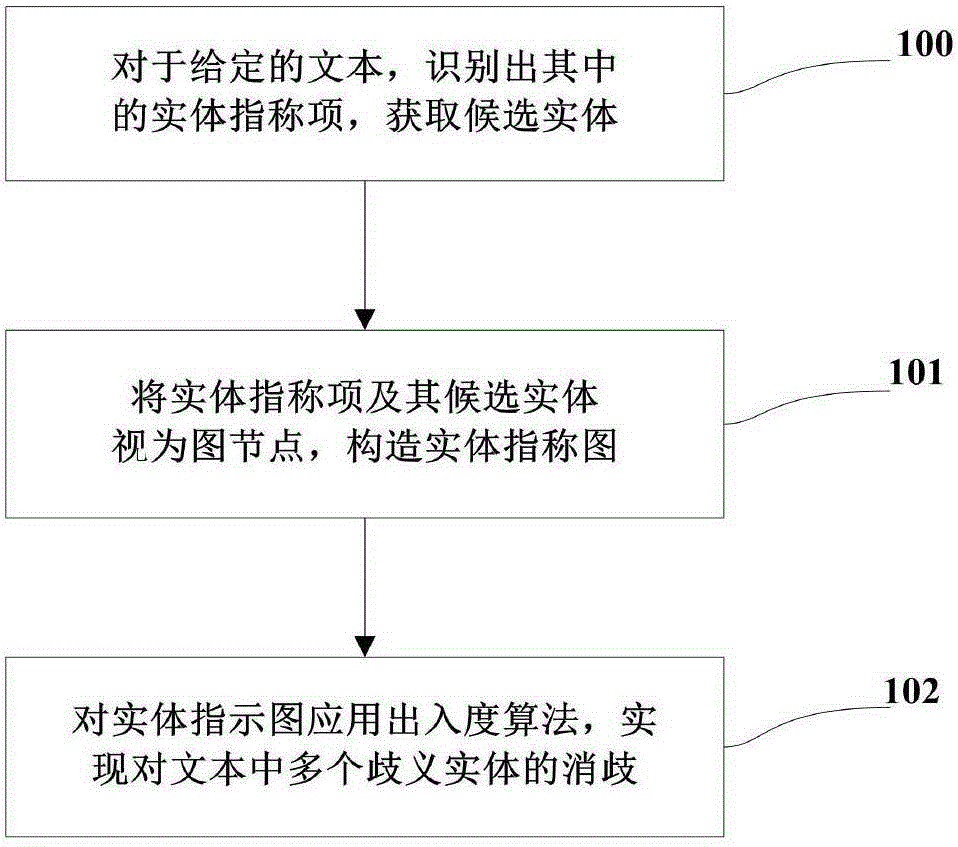

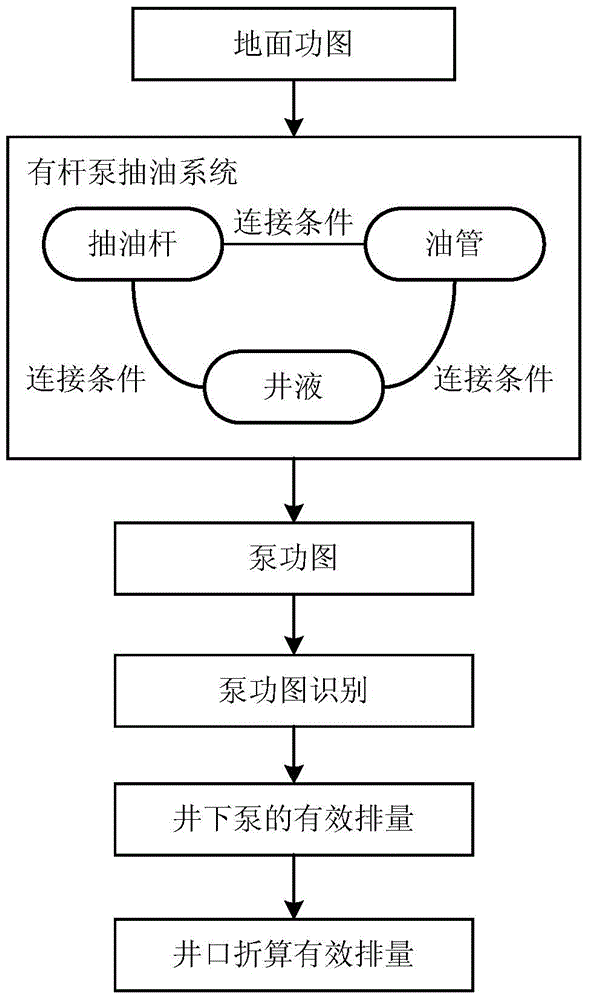

The invention relates to the technical field of pumping units, in particular to a method for improving oil pumping well indicator diagram oil gauging precision. The method comprises the following steps of 101, ground indicator diagram pretreatment, 102, ground indicator diagram transformation, 103, working condition diagnosis, 104, liquid production capacity preliminary calculation, and 105, liquid production capacity final calculation. The invention further comprises a system for improving the oil pumping well indicator diagram oil gauging precision, the system comprises an indicator diagram treatment module, a working condition diagnosis and classification module, a liquid production capacity calculation module and a liquid production capacity correction module which are connected in sequence. By means of the method and the system, analysis diagnosis optimization is conducted on indicator diagram data of an oil pumping well which are collected and transmitted to a real-time database, the precision of liquid production capacity measurement of the oil pumping well can be improved greatly, production dynamic change of the oil well is commanded accurately, and production management level of the oil well is improved effectively.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

System and method for controlling interval pumping of oil well

ActiveCN102122161ARealize remote intelligent self-dynamic interval controlRealize energy saving and consumption reductionEnergy industryFluid removalStem lengthReal time analysis

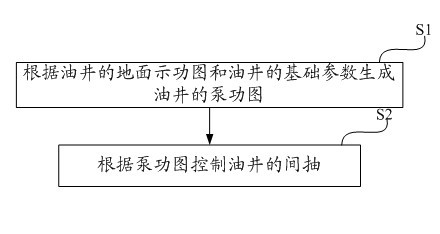

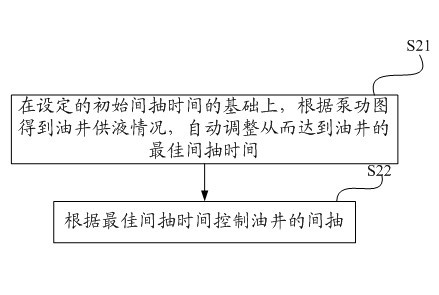

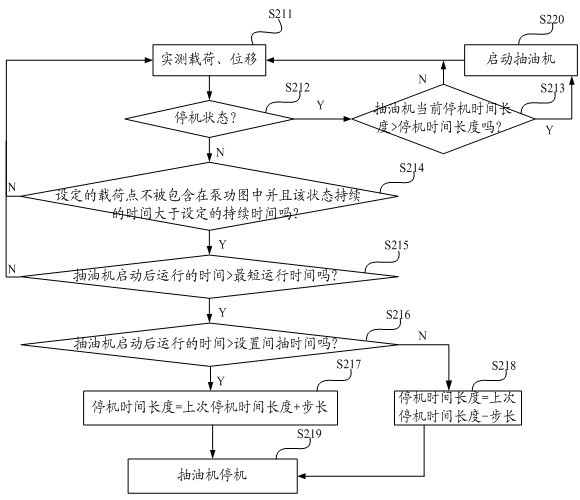

The invention discloses a method for controlling interval pumping of an oil well, which comprises the following steps of: generating a pump dynamograph of the oil well according to a ground indicator diagram of the oil well and basic parameters of the oil well, wherein the basic parameters include a water content parameter of the oil well, a gas oil ratio, a viscosity, a stem diameter, a stem length, a pump diameter, a pump depth and the like; and controlling the interval pumping of the oil well according to the pump dynamograph. The invention further discloses a system for controlling the interval pumping of the oil well, which comprises an acquiring module, a ground indicator diagram generation module, a pump dynamograph generation module and an interval pumping control module. With thesystem and the method for controlling the interval pumping of the oil well, the optimal interval extraction starting point and interval extraction time can be analyzed in real time in combination with the oil production law of the oil well, remote intelligent self dynamic interval pumping control of the oil well is implemented, and consequently energy for the oil well is saved, consumption of theoil well is reduced and loss of operating apparatuses is also reduced.

Owner:PETROCHINA CO LTD

Chinese integrated entity linking method based on graph model

InactiveCN105183770AImprove accuracyImprove efficiencySpecial data processing applicationsEntity linkingNODAL

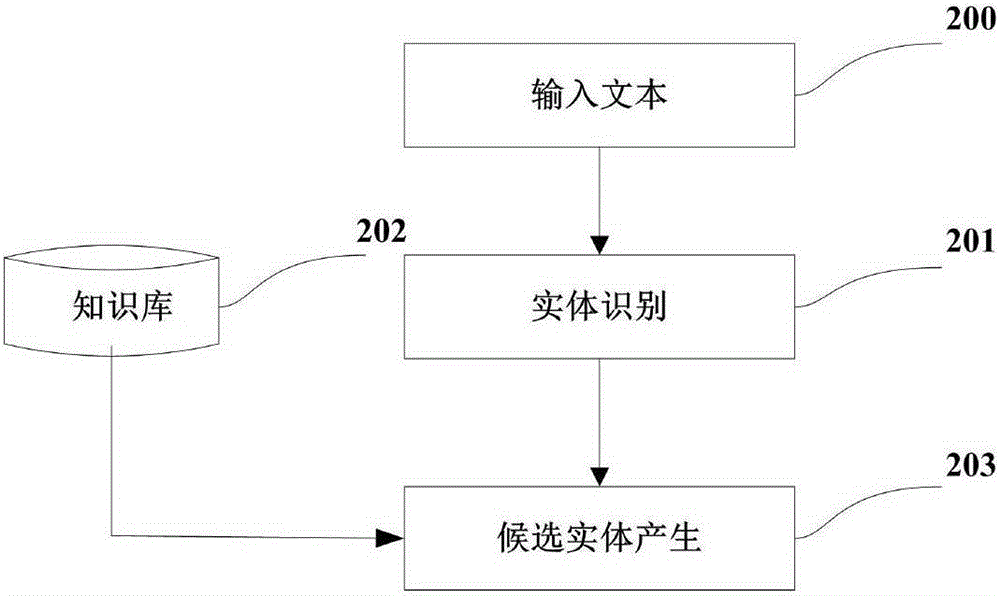

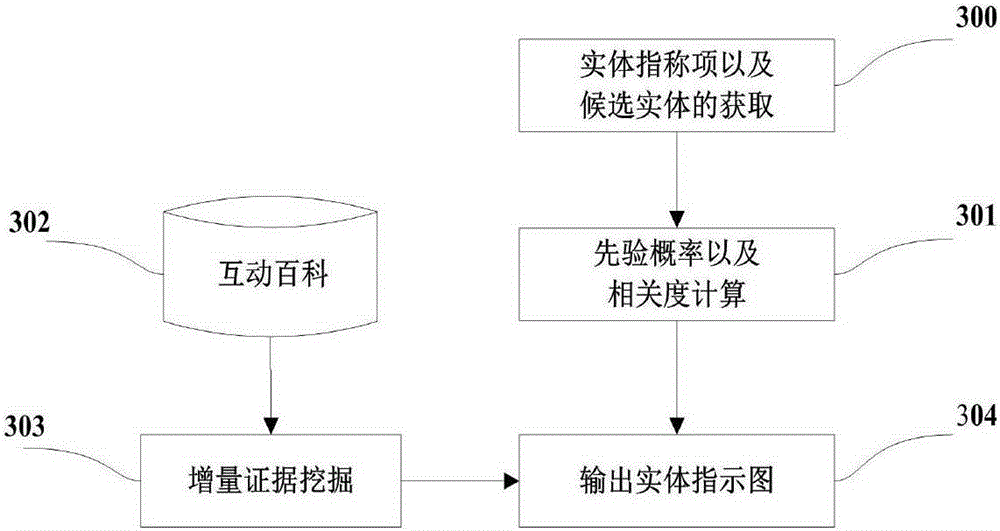

The present invention discloses a Chinese integrated entity linking method based on a graph model. An ambiguous entity in a text can be mapped into a specific entity in a real world, in order to provide aid for knowledge base expansion, information extraction and search engines. The method mainly comprises three parts of generating a candidate entity, constructing an entity indicator diagram, and disambiguating an integrated entity. For a given text, an entity referent item therein is recognized to obtain the candidate entity. The entity referent item and the candidate entity thereof are regarded as graph nodes to construct an entity referent graph. An in-degree and out-degree algorithm is applied to the entity indicator diagram for implementing disambiguation of multiple ambiguous entities in the text. The present invention does not depend on the knowledge base completely in the establishment of the entity indicator diagram, and also can implement incremental evidence mining to find evidence on an encyclopedia webpage. Dependence path analysis is employed to find the possibly related entity referent item. When the dependence path sizes of two entity referent items are within a set range, the two entity referent items are regarded as the possibly related entity referent items. Further, whether their candidate entities have relations in the real world is determined, so that the efficiency of disambiguation is greatly improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

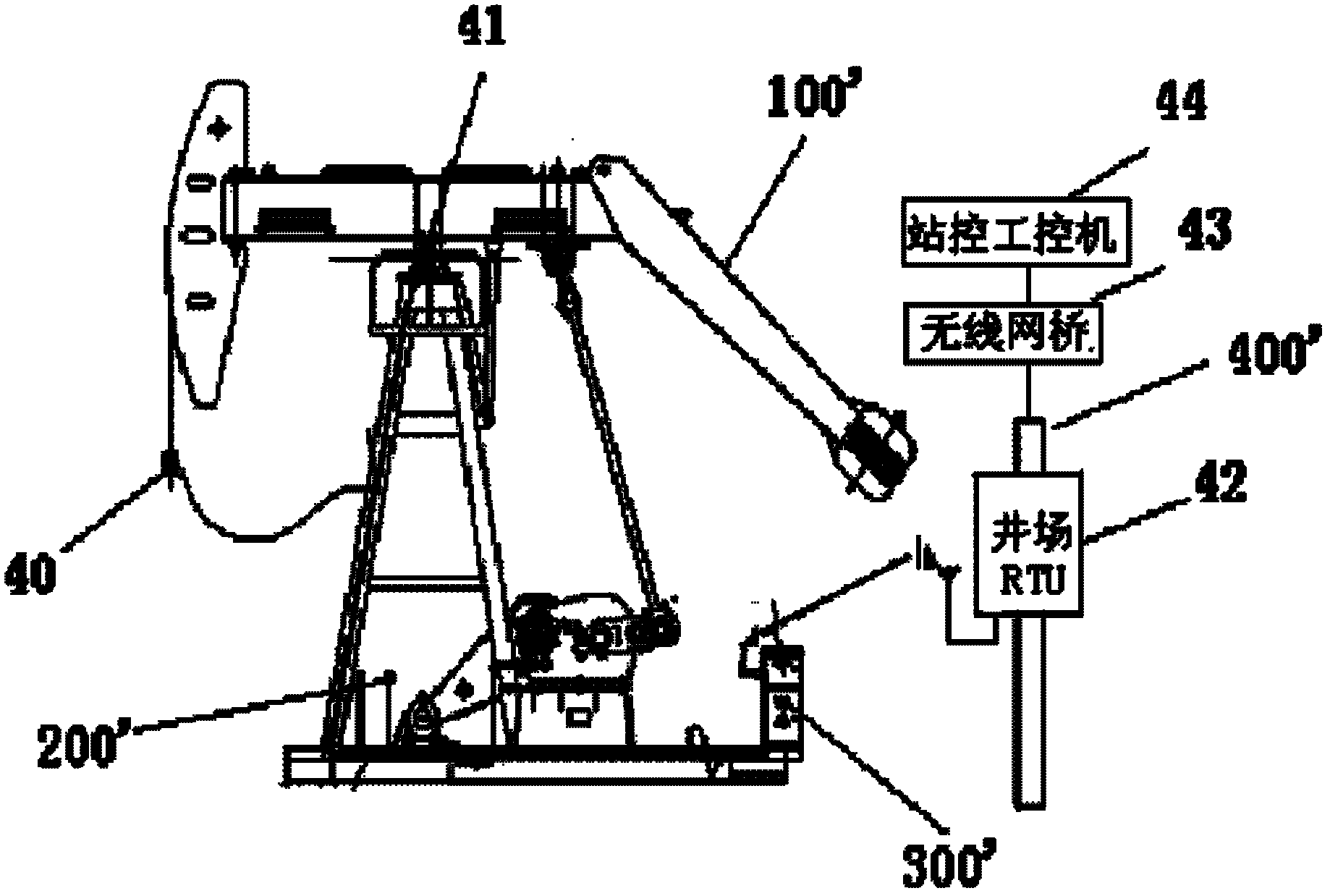

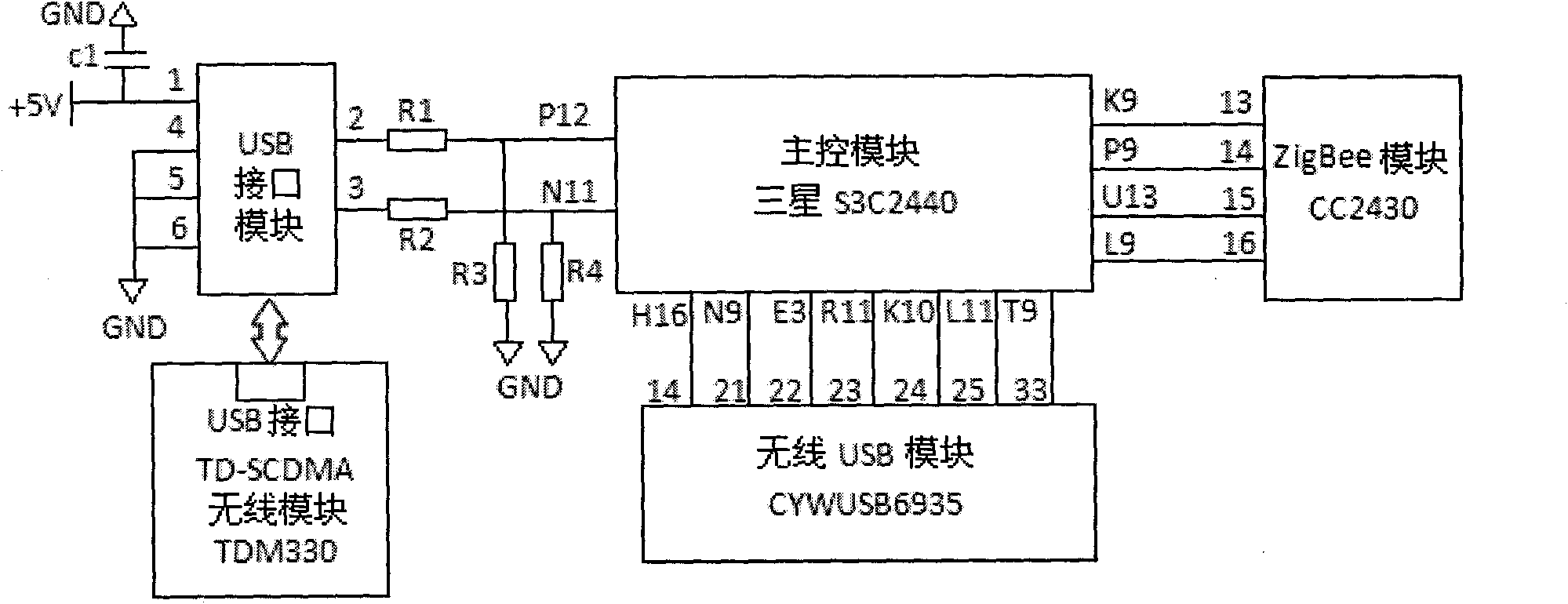

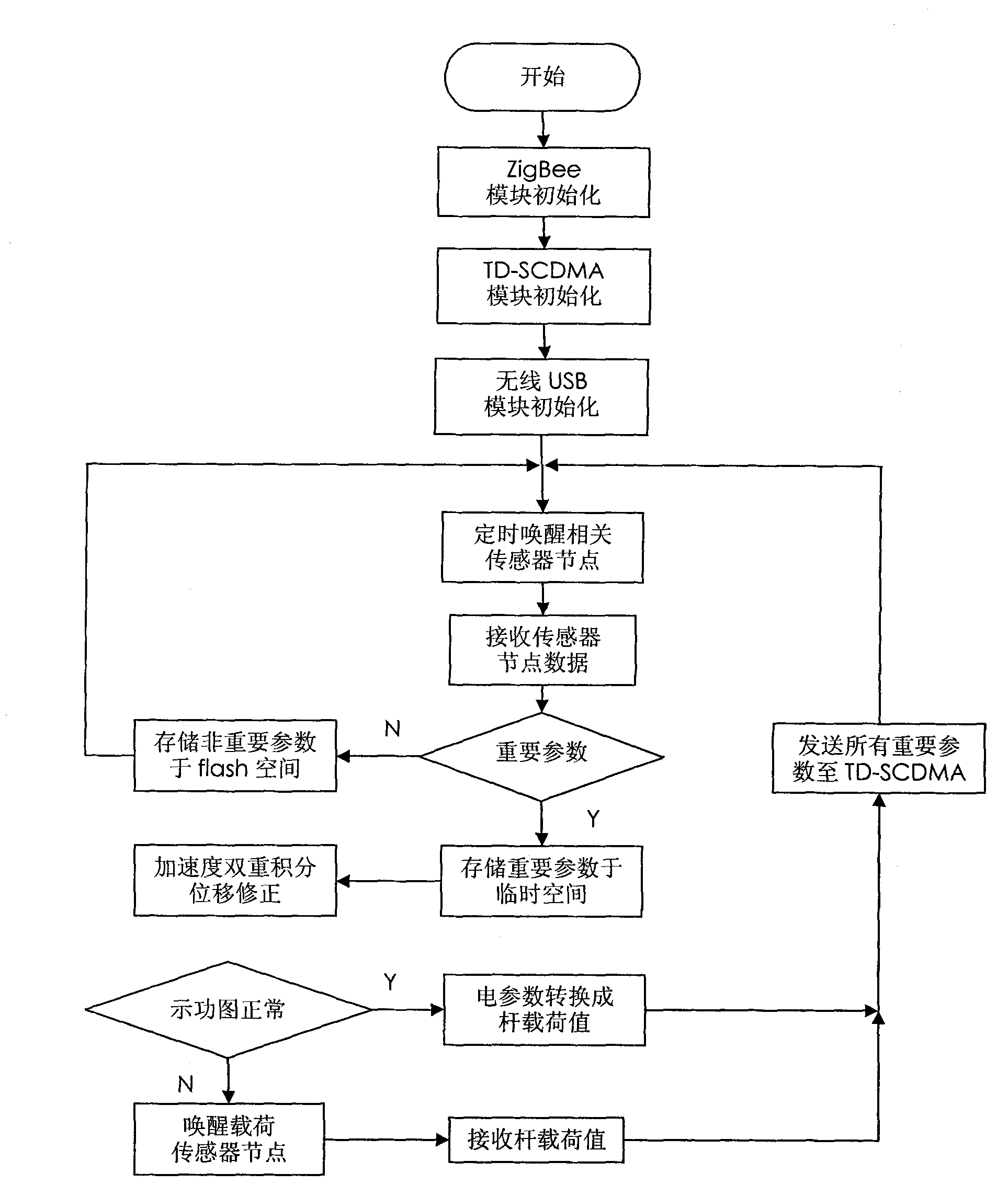

Beam pumping unit remote monitoring method and system based on wireless sensor network and TD-SCDMA (Time Division-Synchronization Code Division Multiple Access)

InactiveCN101819432AImprove reliabilitySave electricityEnergy efficient ICTNetwork topologiesWireless mesh networkIndicator diagram

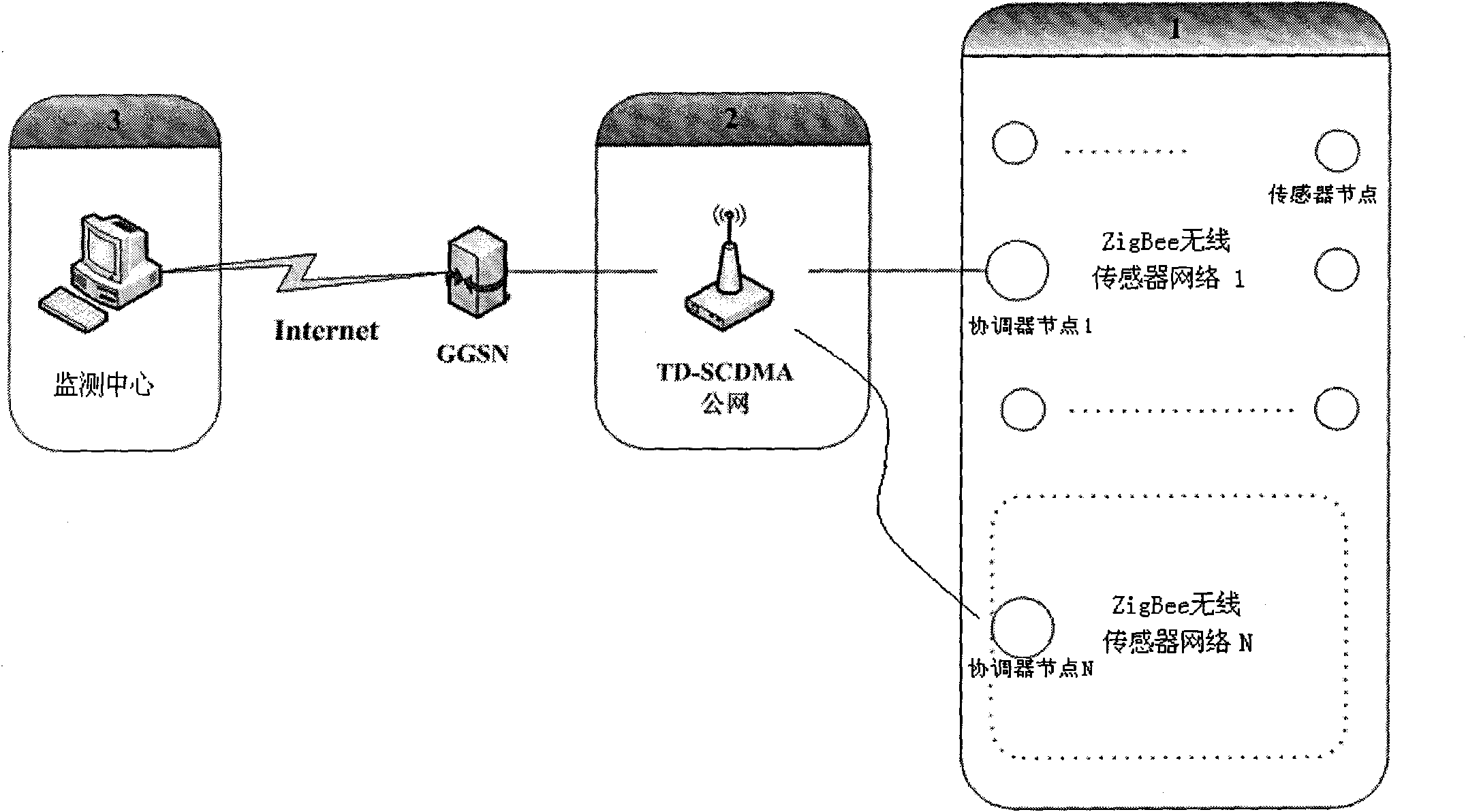

The invention discloses beam pumping unit remote monitoring method and system based on a wireless sensor network and a TD-SCDMA (Time Division-Synchronization Code Division Multiple Access). The system comprises three parts of a wireless sensor network of a local scope, a TD-SCDMA public network and a beam pumping unit remote monitoring center. The wireless sensor network comprises a plurality of sensor nodes and a unique coordinator node which is also used as a ZifBee / TD-SCDMA gateway; important beam pumping unit working condition parameters are uploaded to the beam pumping unit remote monitoring center through the TD-SCDMA gateway on line in real time; general working condition parameters are temporarily stored on the coordinator node, acquired by an inspector with wireless USB acquirer in hand in fixed time and off-line aggregated to the beam pumping unit remote monitoring center; and a beam pumping unit indicator diagram (rod load and displacement relationship diagram) is obtained by adopting a cooperative work mode of indirect and direct measurement, which improves the reliability of the monitoring system. The ZigBee wireless sensor network replaces traditional complicated sensor node wiring communication, which improves the reliability of a field detection system; and moreover, the sensor node adopts an intermittent working mode with timing awakening, which saves the electric energy.

Owner:ZHEJIANG UNIV

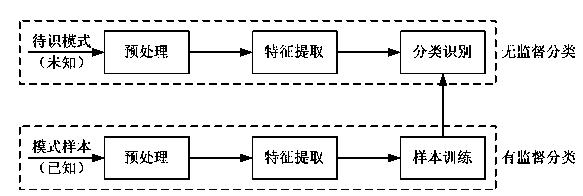

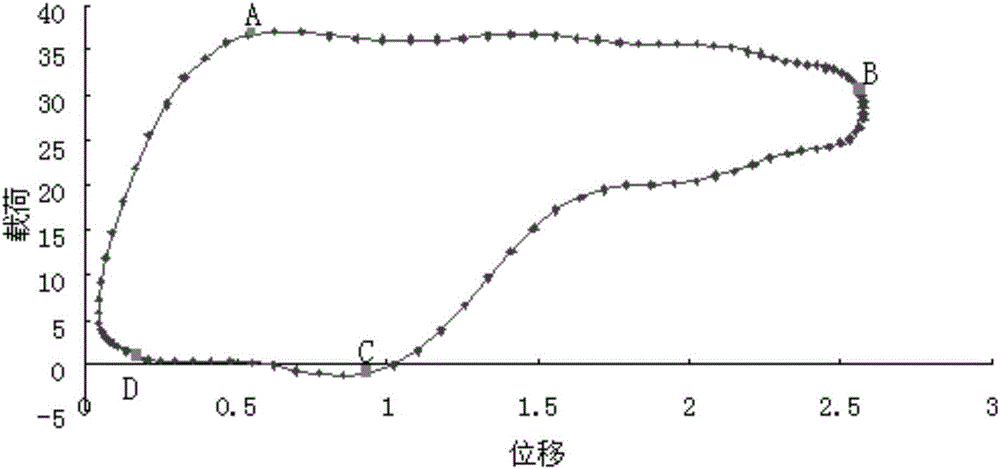

Pumping unit indicator diagram identification method based on ART2

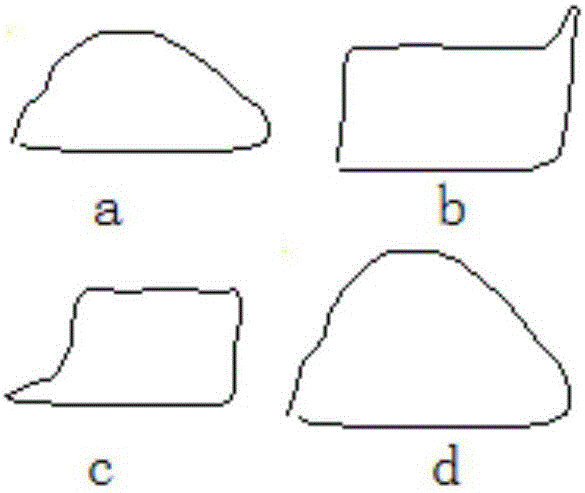

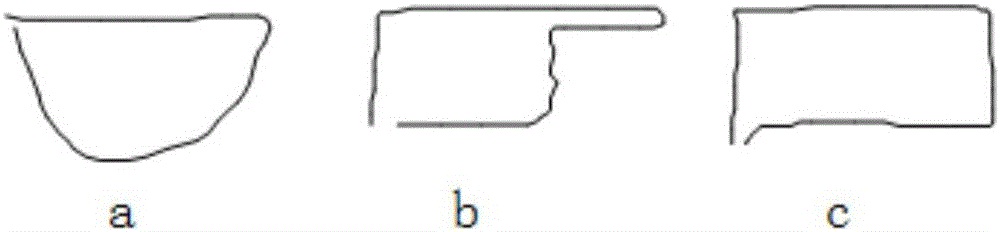

InactiveCN104110251AEfficient identificationAccurate identificationConstructionsCharacter and pattern recognitionTime changesIndicator diagram

The invention discloses a pumping unit indicator diagram identification method based on an ART2. By collecting load and suspension center displacement signals of a pumping unit, a closed curve formed along with time changes in a pumping period is drawn with polished rod displacement signals serving as an x-coordinate and loading signals serving as a y-coordinate, and a pumping unit indicator diagram sample is obtained. If the category of the pumping unit indicator diagram sample is known, the pumping unit indicator diagram sample is identified through a mode with a supervision module. If the sample category of the pumping unit indicator diagram sample is unknown in advance, the pumping unit indicator diagram sample is identified through a mode without the supervision module. The pumping unit indicator diagram sample is identified through an ART2 neural network, according to an identification result, fault diagnosis and underground work condition judgment are performed on the pumping unit, and a judgment result is displayed. The pumping unit indicator diagram identification method based on the ART2 has the advantages of performing fault diagnosis and underground work condition judgment on the pumping unit, identifying the indicator diagram stably, efficiently and accurately, and the like.

Owner:ANHUI DORJE ELECTRIC

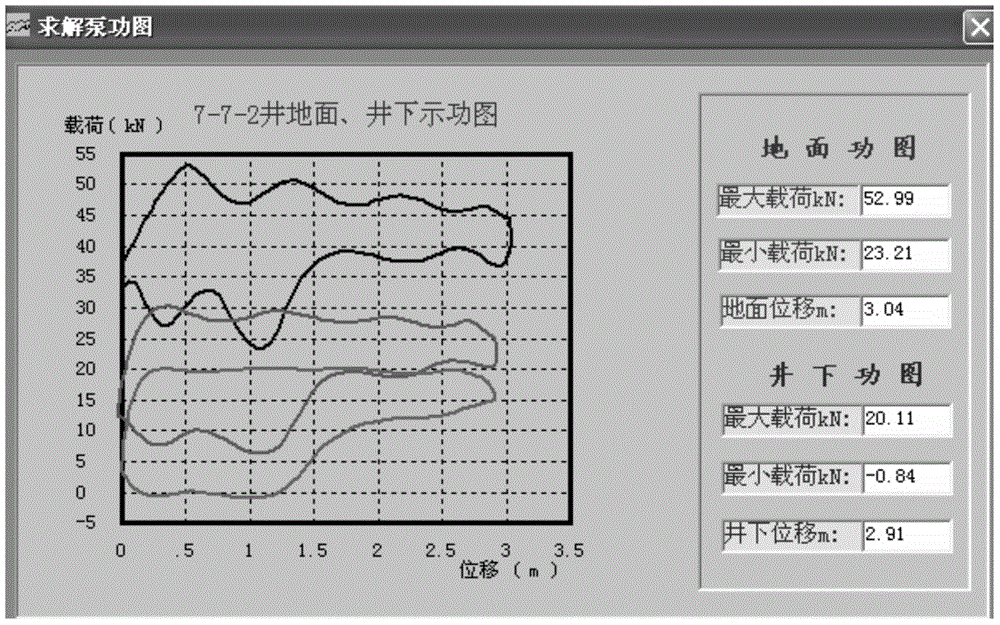

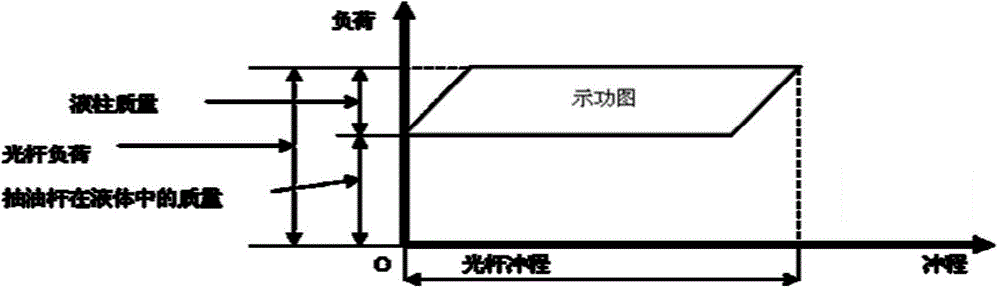

Method for online calculation of working fluid level of oil well by using pumping unit pump indicator diagram

The invention discloses a method for online calculation of a working fluid level of an oil well by using a pumping unit pump indicator diagram. The method for online calculation of the working fluid level of the oil well by using the pumping unit pump indicator diagram is characterized by comprising the following steps: a ground indicator diagram is obtained; a computer is used for mathematically processing to eliminate such influences as deformation of a pumping rod column, viscous resistance of the rod column, vibration and inertia to obtain an underground pump indicator diagram simple in shape and capable of truly reflecting pump working conditions; an underground pump indicator diagram model is built to calculate a fu's series solution and a viscous resistance coefficient v of the underground pump indicator diagram; and then, a curvature model is built according to the relationship between the obtained underground pump indicator diagram and a valve opening / closing point and the viscous resistance coefficient v to determine the valve opening / closing point.

Owner:SINOPEC SHENGLI OILFIELD

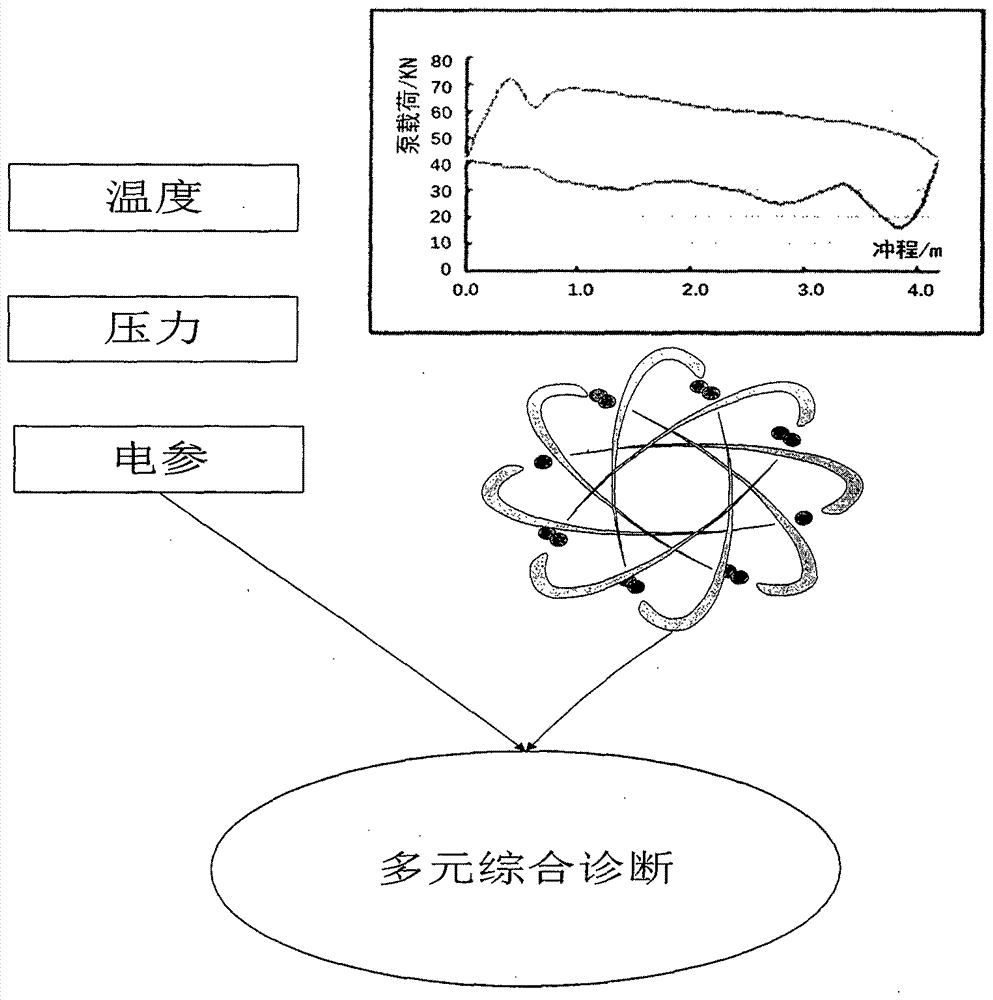

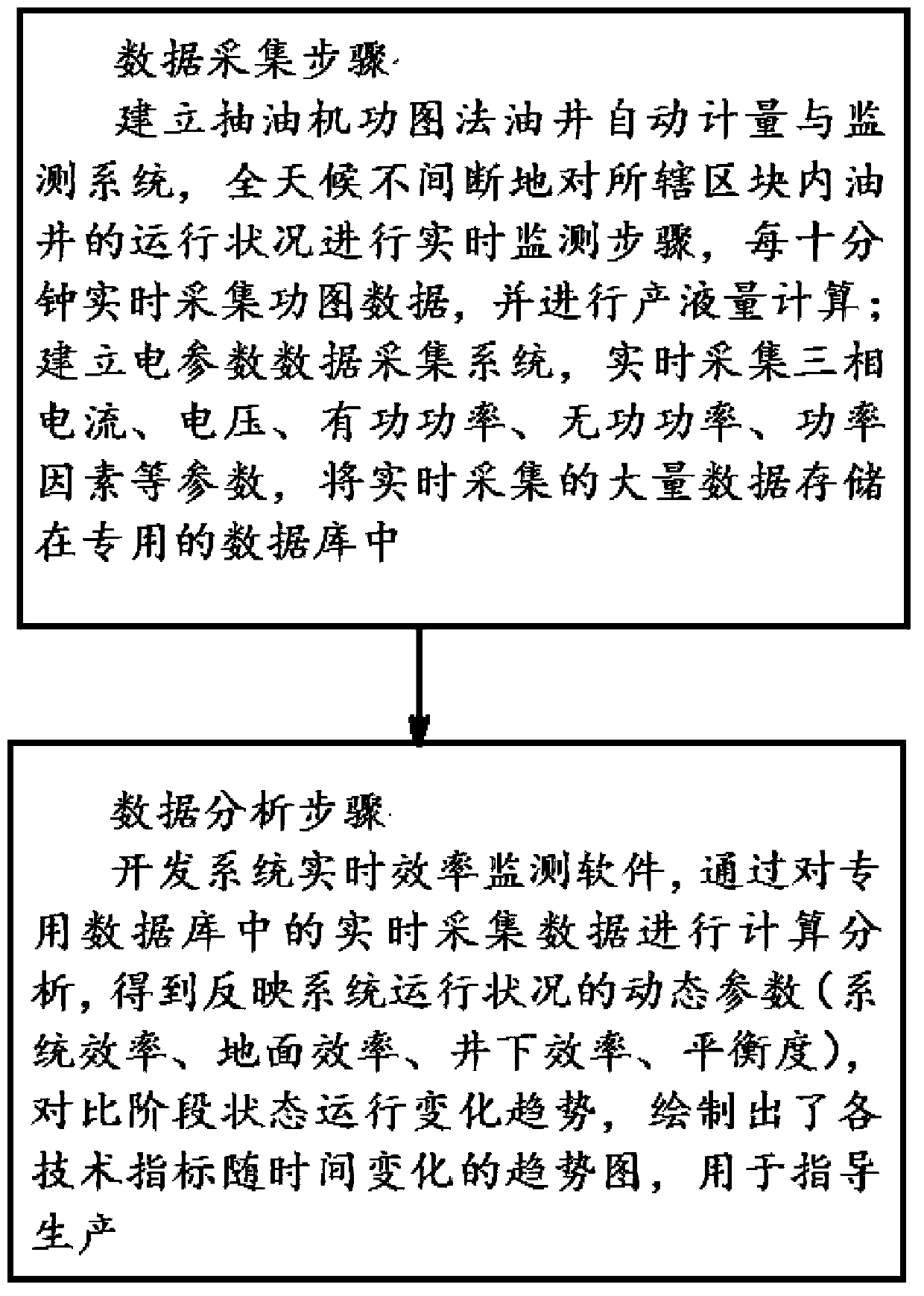

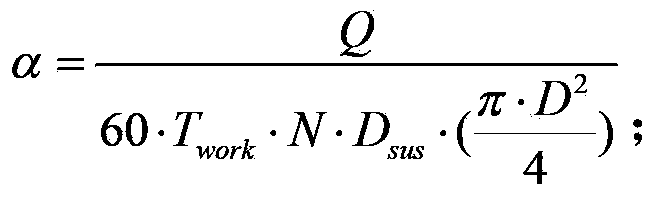

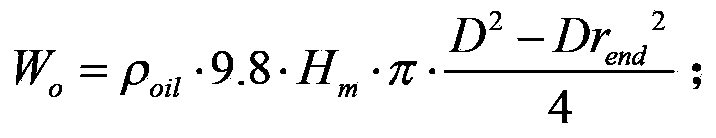

Method for monitoring efficiency of rod oil pumping system in real time

InactiveCN104213904AImprove efficiencyReduce energy consumptionConstructionsPower factorData acquisition

The invention relates to a method for monitoring the efficiency of a rod oil pumping system in real time and belongs to the technical field of computer oil field digitalization construction. The method comprises the steps of data collection and the step of data analysis. The step of data collection comprises the following steps that an oil pumping machine indicator diagram method oil well automatic metering and monitoring system is established, the operation states of oil wells in a supervision section are monitored in real time in all weather without interruption, indicator diagram data are collected every ten minutes, and the liquid production capacity is calculated; an electrical parameter data collecting system is established, the parameters such as three-phase current, voltage, active power, reactive power and power factors are collected in real time, and the mass data collected in real time are stored in a special database. The step of data analysis comprises the following steps that system real-time efficiency monitoring software is developed, dynamic parameters reflecting the operation states of the system are obtained by calculating and analyzing the real-time collected data in the special database, and a tendency chart of changes of all technical indexes along time is drawn by comparing stage state operation changing tendencies and is used for guiding production.

Owner:PETROCHINA CO LTD

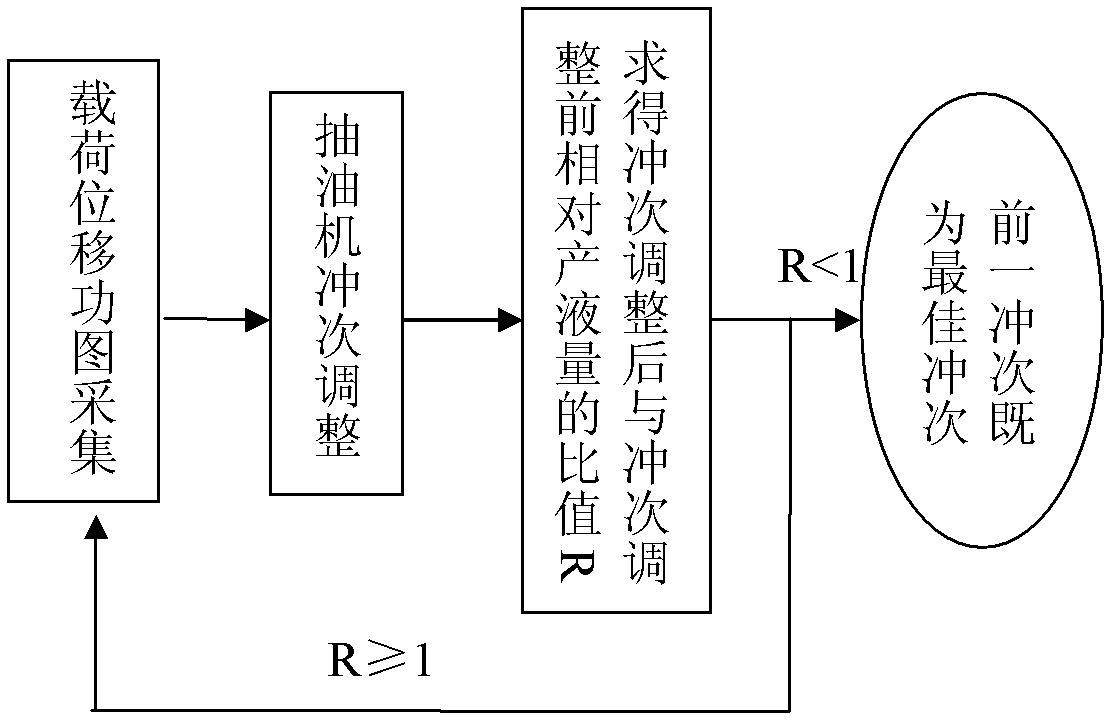

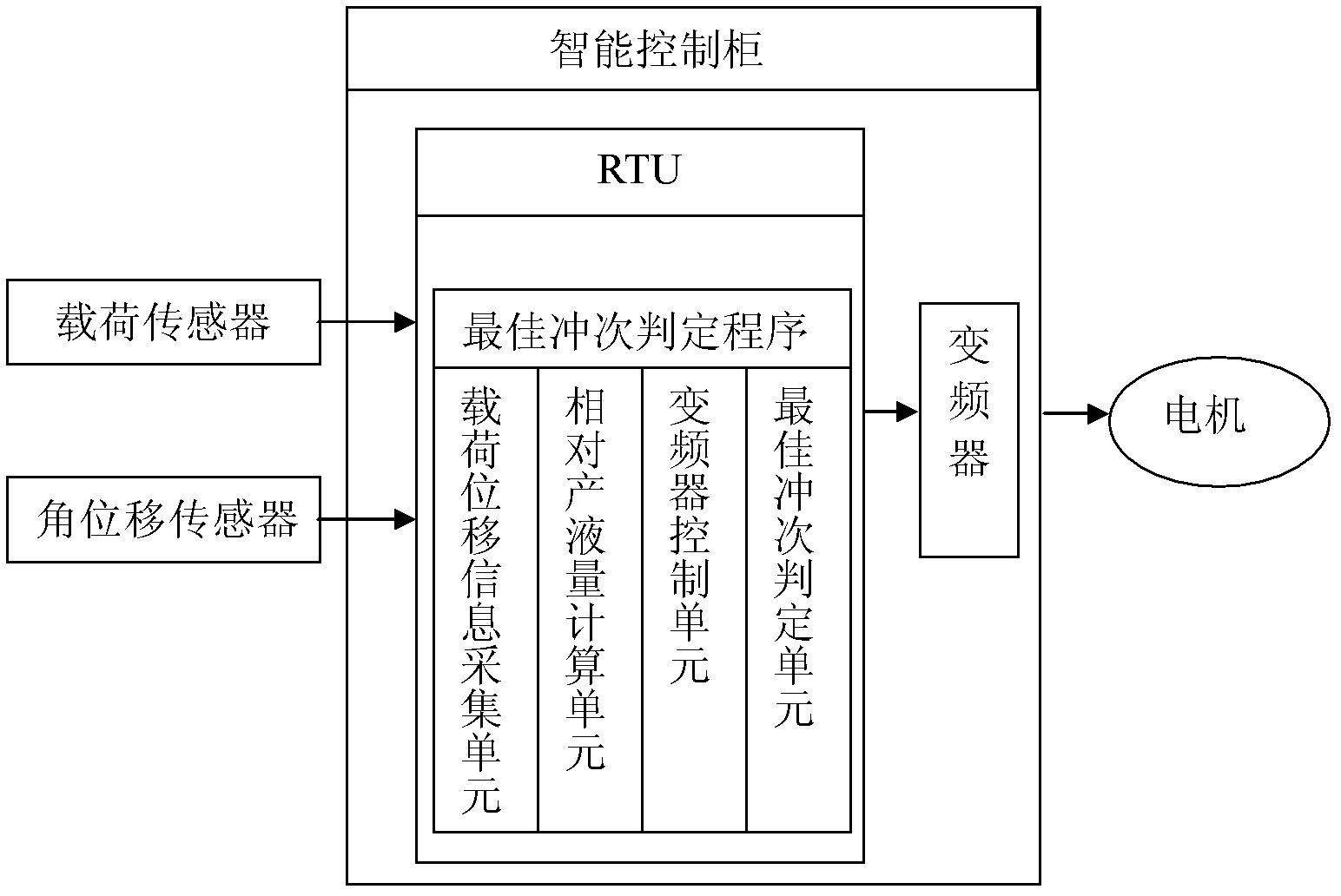

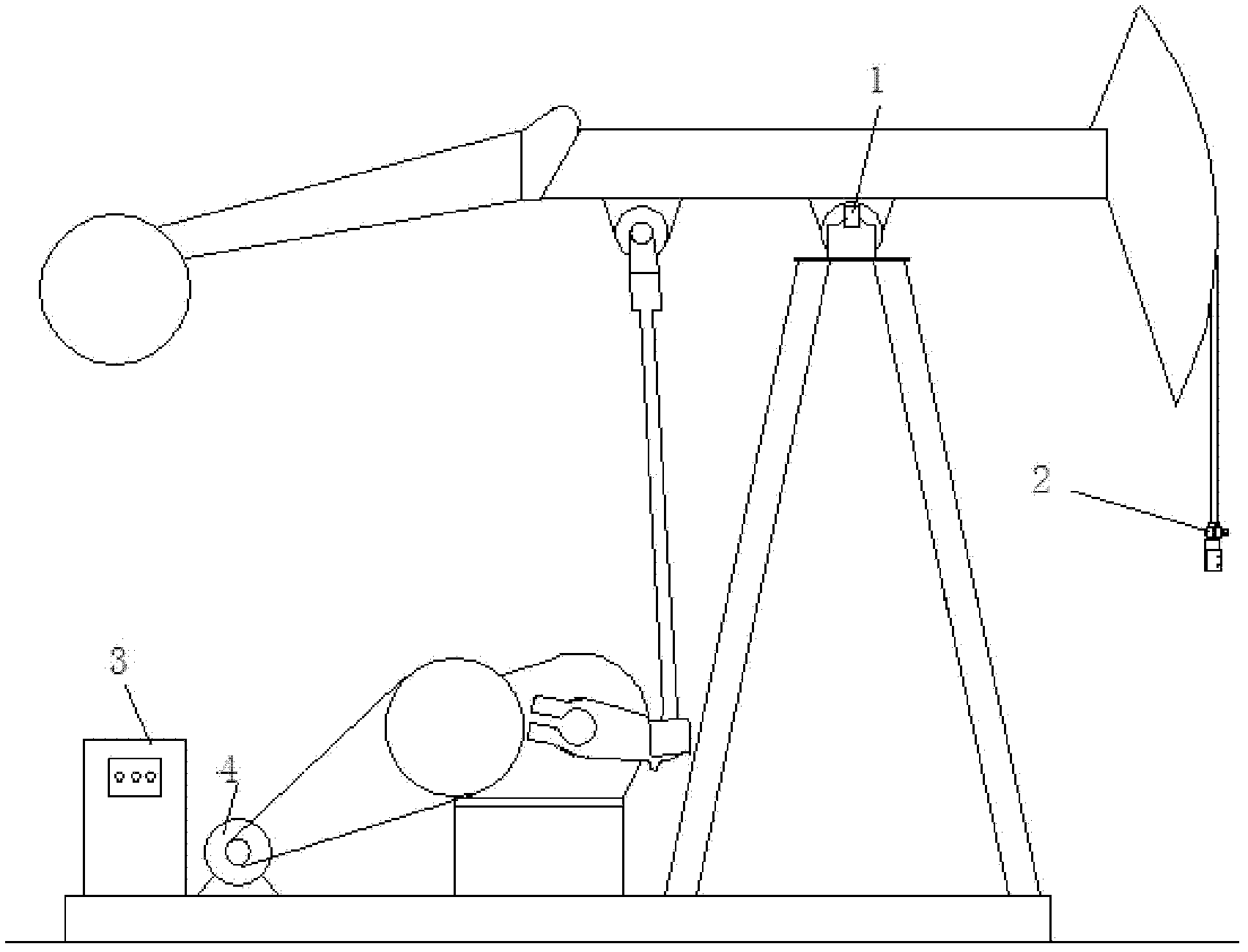

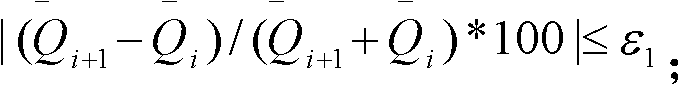

Method and device for judging optimal times of stroke of pumping unit

The invention discloses a method and a device for judging optimal the time of stroke of a pumping unit. The method comprises the following steps of: obtaining a current load displacement indicator diagram according to data of load and displacement sensors; changing the time of stroke, re-collecting the load displacement data to obtain the changed load displacement indicator diagram after the changing of the time of stroke; calculating relative liquid yield according to the ground indicator diagram before and after the changing of the time of stroke, judging the variation situation of the ratio of; and continuously running the programs until the minimal time of stroke is obtained under the maximal daily liquid yield, i.e., the optimal time of stroke is obtained. The device mainly comprises the load sensor, the angular displacement sensor, an RTU (remote terminal unit), a frequency changer, and on the like. Due to the fact that the optimal time of stroke judging program adopts the relative variation value of the daily liquid yield instead of the absolute value of the daily liquid yield, so the program is low in computing amount and small in occupied internal memory, and is capable of directly running on the RTU, further, the pumping unit can finish the data collection, computation and control independently by self without depending on the computation and the control of a host computer, and the system is ensured to run more reliably.

Owner:PETROCHINA CO LTD

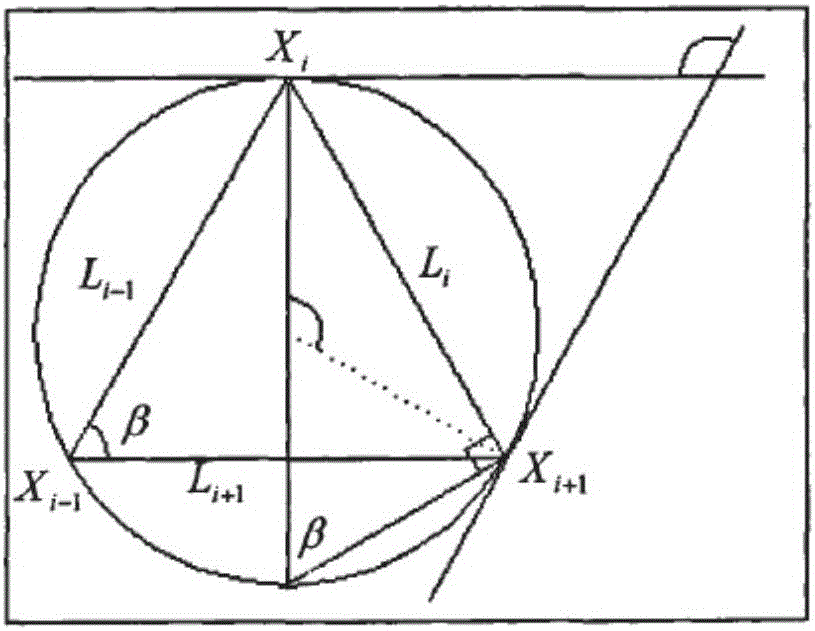

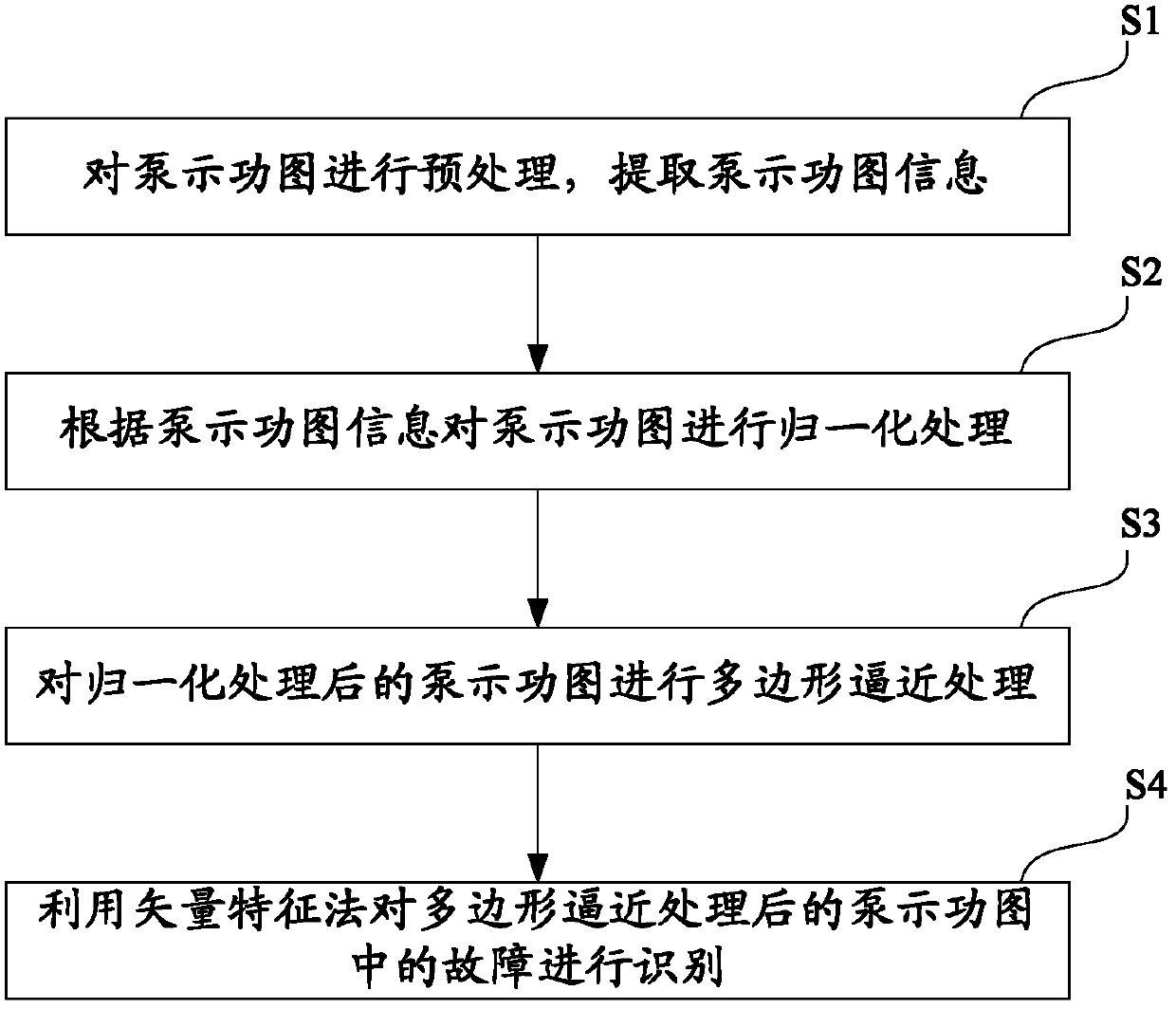

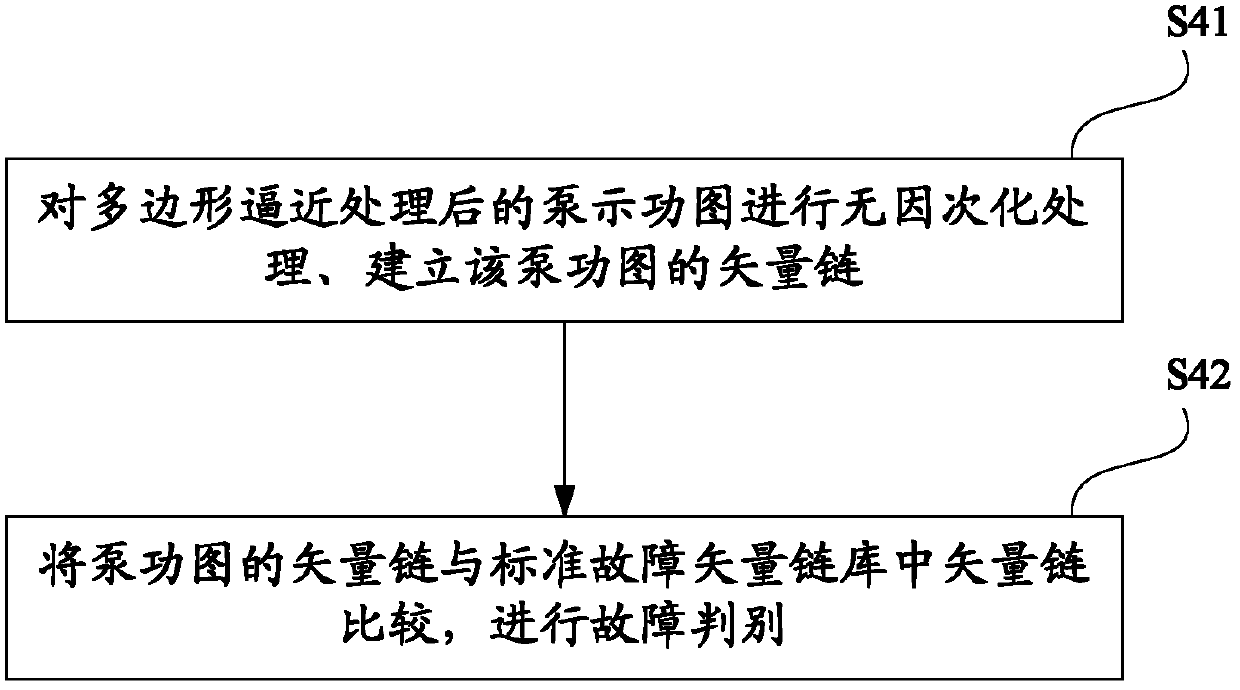

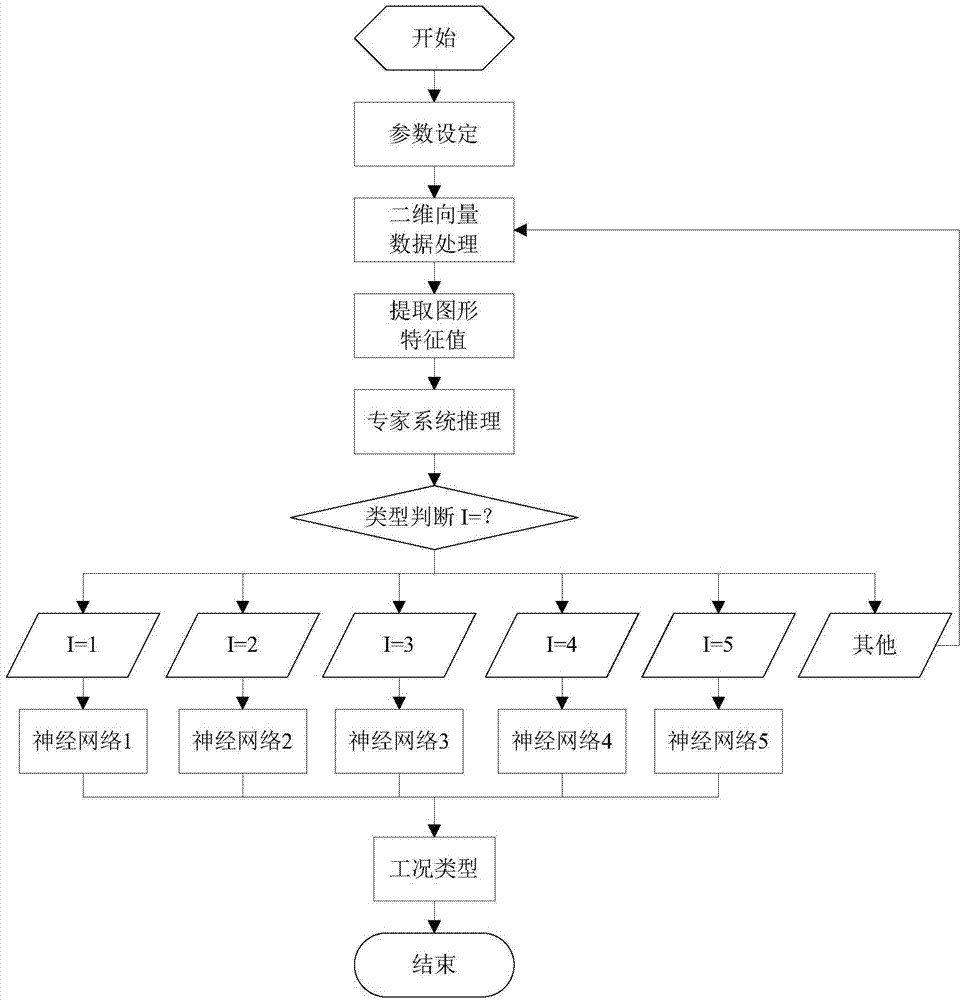

Method and system for recognizing and judging pump indicator diagram

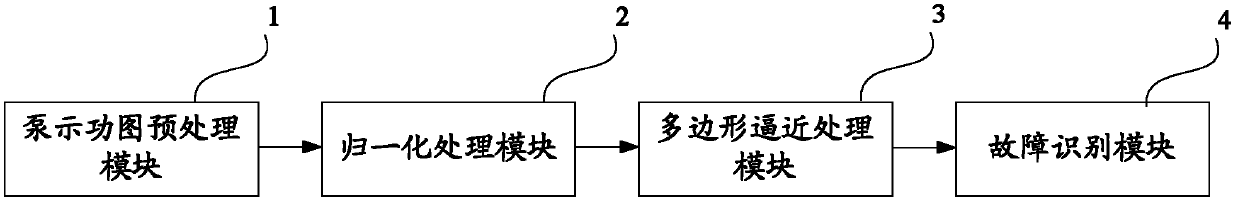

ActiveCN102184414AImprove recognition accuracyAccurate identificationPump testingCharacter and pattern recognitionAlgorithmEngineering

The invention discloses a method and system for recognizing and judging a pump indicator diagram. The method comprises the following steps of: pre-processing the pump indicator diagram, and extracting pump indicator diagram information; normalizing the pump indicator diagram according to the pump indicator diagram information; performing polygonal approximation processing on the normalized pump indicator diagram; and recognizing a fault in the pump indicator diagram, which is subjected to the polygonal approximation processing, by using a vector characteristic method. The system comprises a pump indicator diagram pre-processing module, a normalization processing module, a polygonal approximation processing module and a fault recognizing module. By the method and system for recognizing andjudging the pump indicator diagram, provided by the invention, the pump indicator diagram recognition accuracy rate of a deep well can be improved, and the working condition of an oil well is accurately judged.

Owner:PETROCHINA CO LTD

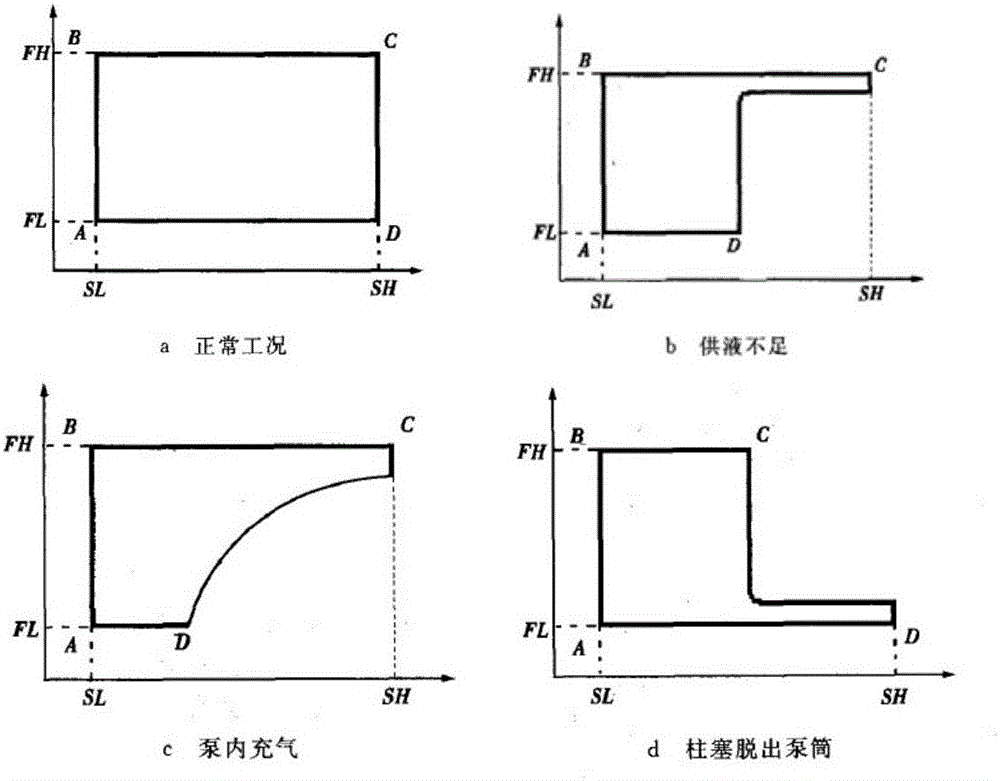

Method and device for diagnosing working conditions of underground oil well pump

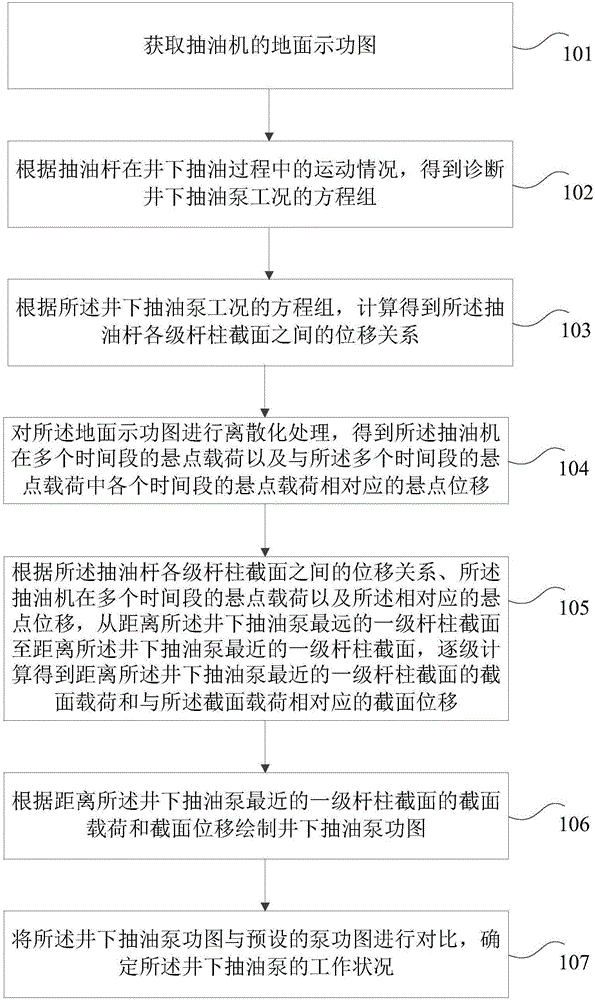

ActiveCN106089184AImprove diagnostic accuracyGuaranteed accuracyConstructionsInformaticsIndicator diagramPumpjack

The invention provides a method and device for diagnosing the working conditions of an underground oil well pump. The method comprises the following steps: obtaining an equation set for diagnosing the working conditions of an oil well pump according to the movement conditions of a sucker rod, and calculating the displacement relationship between the cross section of the sucker rod on each level; discretizing a ground indicator diagram to obtain the polished rod load of a pumping unit in multiple time periods as well as the polished rod displacement corresponding to the polished rod load of each time period; stepwise calculating the cross section load of the bolt-support cross section on the level closest to the oil well pump as well as the cross section displacement corresponding to the cross section load from the bolt-support cross section on the level farthest from the oil well pump to the bolt-support cross section closest to the oil well pump, and drawing the indicator diagram of the oil well pump; and comparing the indicator diagram of the oil well pump with a preset pump indicator diagram to determine the working conditions of the underground oil well pump. In the embodiment of the invention, by adopting the method, the diagnosis precision of the working conditions of the underground oil well pump is effectively improved, and the accuracy of the diagnosis result of the working conditions of the underground oil well pump is guaranteed.

Owner:PETROCHINA CO LTD

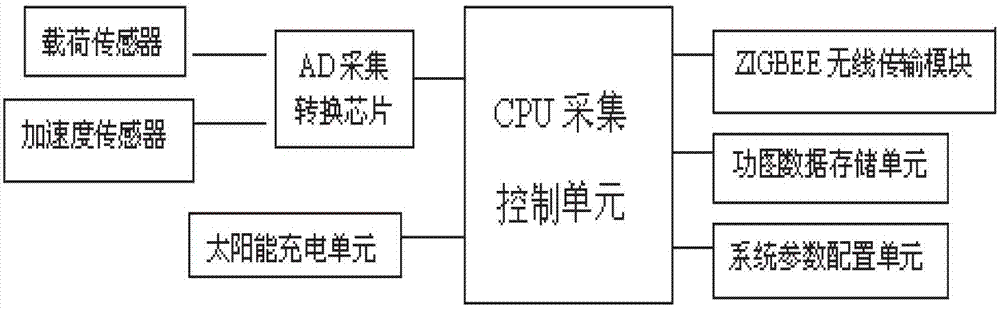

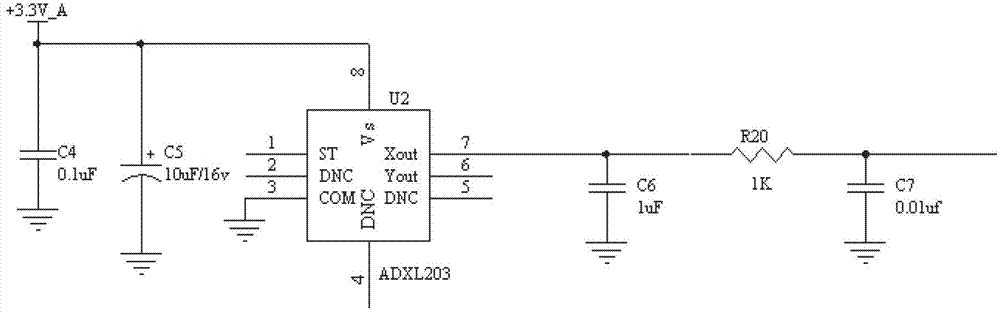

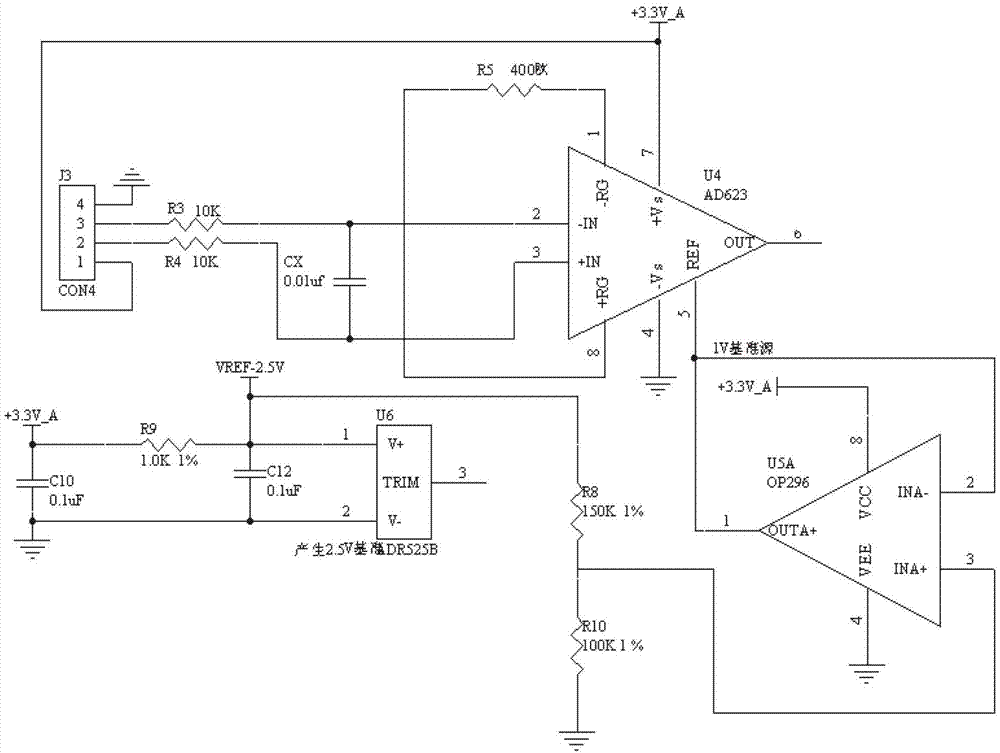

Wireless low-power-consumption oil well indicator based on Zigbee network

InactiveCN102966346AImprove reliabilityGood repeatabilitySurveyConstructionsAutomatic controlEngineering

The invention provides a wireless low-power-consumption oil well indicator based on a Zigbee network. The wireless low-power-consumption oil well indicator based on the Zigbee network comprises an acceleration and load synchronous sampling unit, a Zigbee wireless transmission unit, an indicator diagram data storage unit, a solar charging unit, a CPU (central processing unit) acquisition control unit, a system parameter configuration unit and a power supply management unit, wherein the acceleration and load synchronous sampling unit consists of a load sensor, an acceleration sensor and an AD (analog to digital) acquisition and conversion chip. The indicator provided by the invention has the advantages that the field measurement repeatability is good, the reliability is high, the working efficiency is improved, the condition of an oil well can be known in real time, and the remote automatic testing and the remote automatic control of a well site are realized.

Owner:西安冠林智能科技有限公司

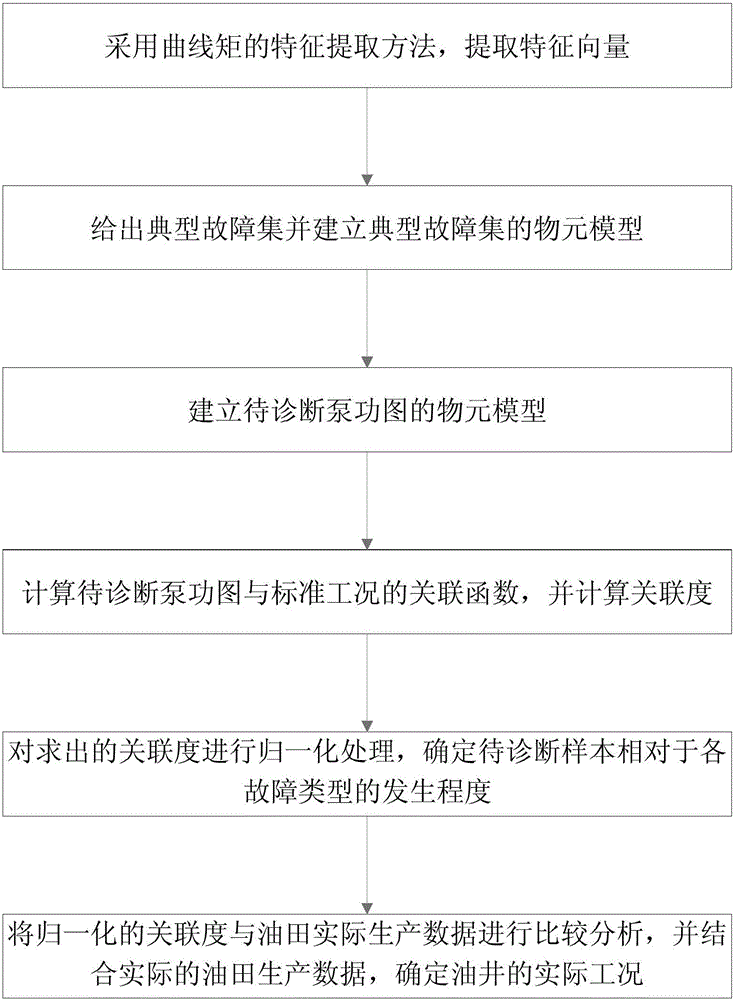

Method for pumping well fault diagnosis based on pump indicator diagram

ActiveCN106321072AGood varietyImprove practicalityConstructionsSpecial data processing applicationsEngineeringIndicator diagram

The invention relates to a method for pumping well fault diagnosis based on a pump indicator diagram. The method comprises the steps that ground indicator diagrams are collected and converted into the pump indicator diagram; and the fault diagnosis is conducted to the obtained pump indicator diagram. The method provided by the invention is designed based on deep understanding of working principles of rod pumping system, and is highly comprehensive and practical; the method can be effectively applicable to different well situations; and the ground indicator diagrams collected by a WIA-PA wireless indicator can be used efficiently and accurately for the fault diagnosis of the rod pumping system.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

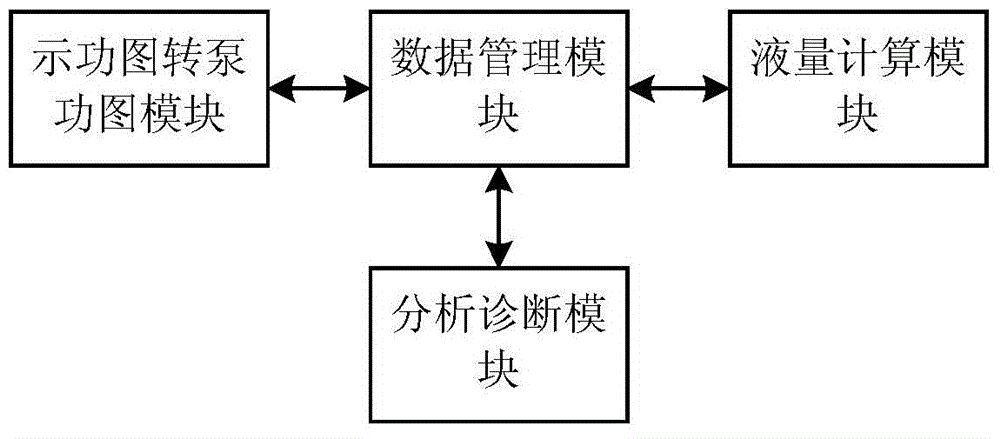

Pumping unit indicator diagram liquid production capacity measurement technology

The invention discloses a pumping unit indicator diagram liquid production capacity measurement technology. The technology comprises an analysis and diagnosis module, an indicator diagram-to-pump diagram module, a liquid measure calculation module and a data management module, wherein the analysis and diagnosis module is used for calculating each level of rod indicator diagram and pump diagram of a ground indicator diagram by using a diagnostic model; the indicator diagram-to-pump diagram module is used for converting the ground indicator diagram into the pump diagram by using a wave equation; the liquid measure calculation module is used for performing liquid measure calculation based on the ground indicator diagram and production data obtained by the analysis and diagnosis module and each level of rod indicator diagram and pump diagram of the ground indicator diagram calculated by the analysis and diagnosis module; the data management module is used for controlling the liquid measure calculation module to perform liquid measure calculation based on the processing results of the analysis and diagnosis module and the indicator diagram-to-pump diagram module. According to the pumping unit indicator diagram liquid production capacity measurement technology, the defects such as high cost, large operation difficulty and low measurement accuracy in the prior art can be overcome to realize the advantages of low cost, small operation difficulty and high measurement accuracy.

Owner:BEIJING BOZHONGJIAHE PETRO TECH

Intelligent identification method for operation condition of sucker rod type oil pumping unit

InactiveCN104295286AAccurate running statusGuaranteed uptimeConstructionsFluid removalIndicator diagramMaterial resources

The invention discloses an intelligent identification method for the operation condition of a sucker rod type oil pumping unit. The intelligent identification method comprises the steps that firstly, on-well indicator diagrams are collected and converted into underground indicator diagrams; qualitative analysis and quantitative calculation are conducted on the underground indicator diagrams, so that the feature values of the indicator diagrams of various working conditions are obtained; finally, the working state of the sucker rod type oil pumping unit is analyzed through the feature values of the indicator diagrams of various working conditions. By the adoption of the intelligent identification method for the operation condition of the sucker rod type oil pumping unit, the operation state of a current system can be accurately and rapidly judged when the operation condition of the sucker rod type oil pumping unit is identified in real time, the actual operation condition is provided, implementation is easy, operation is stable, the purpose that the working condition of the sucker rod type oil pumping unit is automatically identified, and the operation state of the system is adjusted in real time can be achieved easily , the overall efficiency is improved, and manpower and material resources are saved greatly.

Owner:XIAN UNIV OF TECH

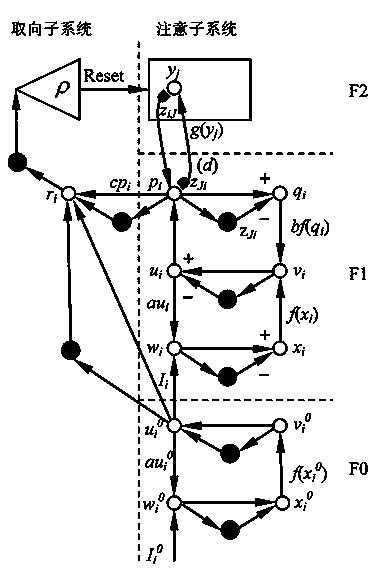

Indicator diagram recognition method based on regularized attention convolutional neural network

ActiveCN110163302ACharacter and pattern recognitionNeural architecturesIndicator diagramAutodidacticism

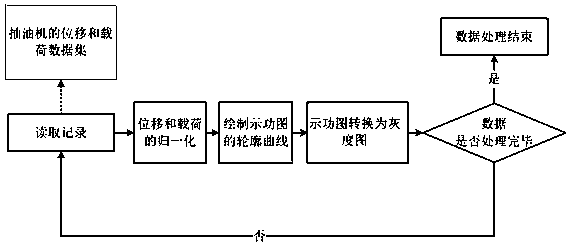

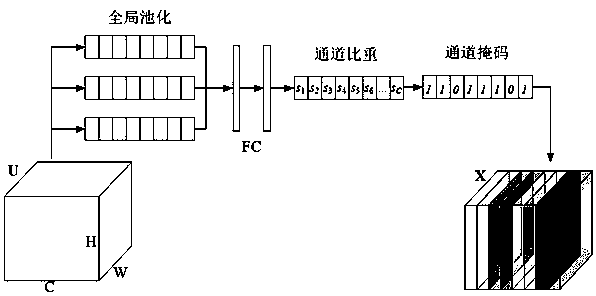

The invention relates to an indicator diagram identification method based on a regularized attention convolutional neural network, which comprises the following steps of: 1, establishing a data preprocessing module, and carrying out dimension and grey-scale map processing on a working condition sample set of an oil pumping unit; 2, establishing a regularized attention convolution module, and reinforcing, inhibiting and inactivating the autonomously learned convolution features; 3, embedding the regularized attention convolution module into the convolutional neural network to form a regularizedattention convolutional neural network; 4, establishing an indicator diagram recognition module, and inputting the gray level image of the indicator diagram into the regularized attention convolutional neural network for recognition; 5, establishing an attention loss function, and training a regularized attention convolutional neural network model; 6, inputting the oil pumping unit working condition data collected in real time into the indicator diagram recognition model, and repeating the steps 2-4; 7, taking the indicator diagram identification method based on the RA-CNN as a core, and constructing an intelligent diagnosis system of the working condition of the oil pumping unit. The identification precision of the indicator diagram can be effectively improved.

Owner:NORTHEAST GASOLINEEUM UNIV

Oil pumping unit indicator diagram diagnosis system and diagnosis method

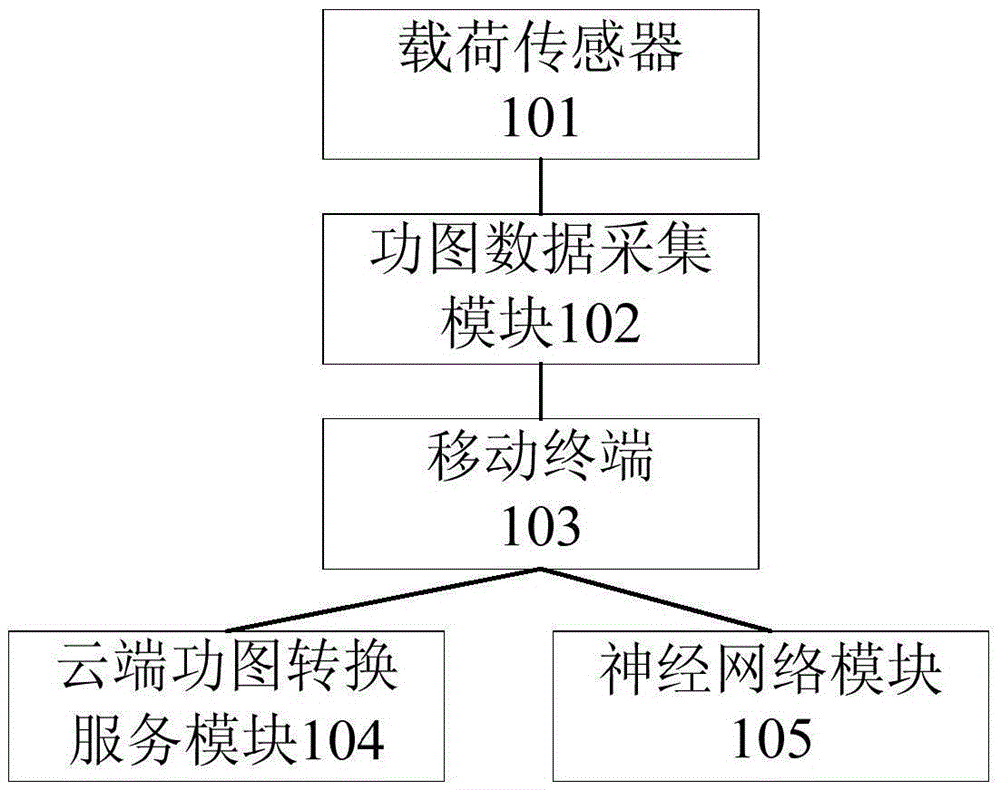

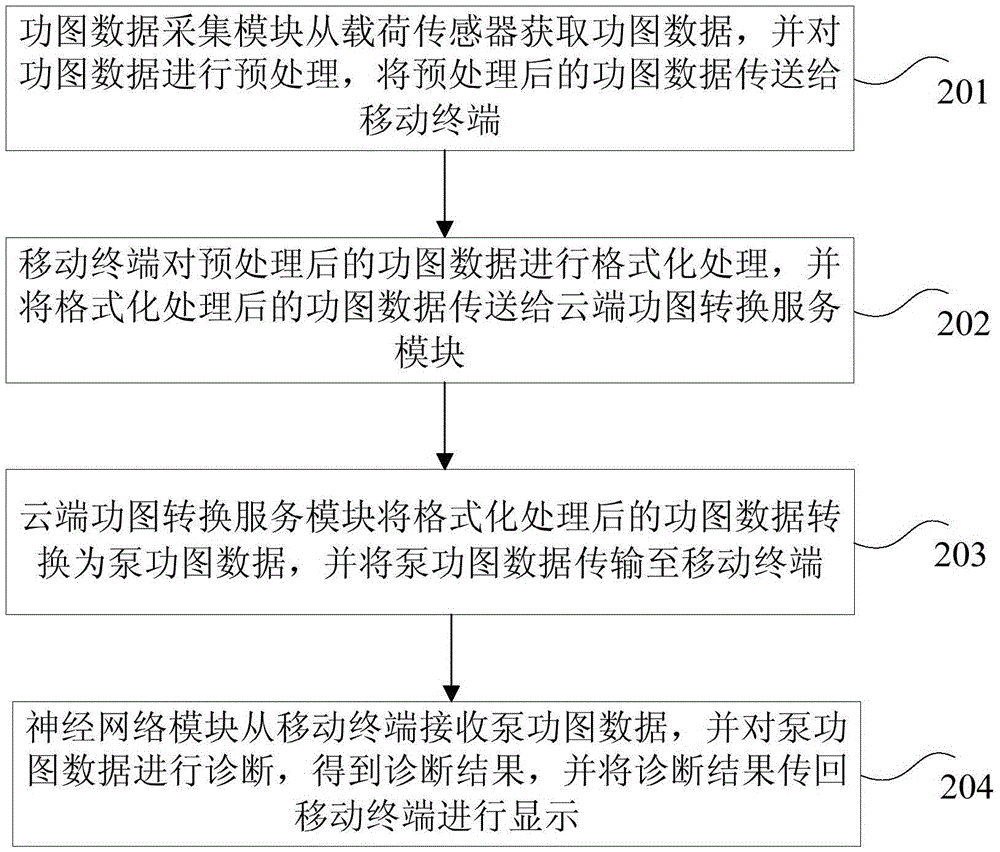

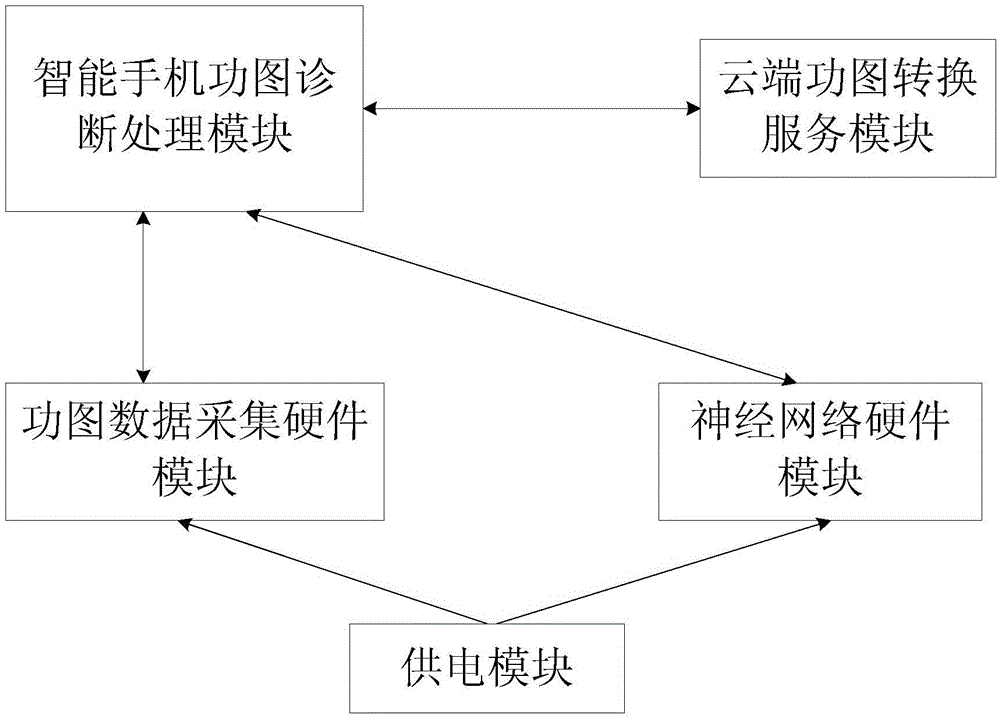

The invention provides an oil pumping unit indicator diagram diagnosis system and a diagnosis method. The diagnosis system comprises: a load sensor for collecting indicator diagram data; an indicator diagram data collecting module for acquiring indicator diagram data from the load sensor and pre-processing the indicator diagram data, and transmitting pre-processed indicator diagram data to a mobile terminal; a mobile terminal for formatting the pre-processed indicator diagram data; a cloud terminal indicator conversion service module for converting the formatted indicator diagram data into a pump indicator diagram data and transmitting the pump indicator diagram data to the mobile terminal; and a nerve network module for receiving the pump indicator diagram data from the mobile terminal, performing diagnosis on the pump indicator diagram data, obtaining a diagnosis result, transmitting the diagnosis result to the mobile terminal for display. The diagnosis system and the diagnosis method of the invention address the problem of low efficiency of prior art technology in performing diagnosis on oil-pumped well failure, and achieve the purpose of performing diagnosis on the oil-pumped well failure in a simple and efficient manner.

Owner:PETROCHINA CO LTD

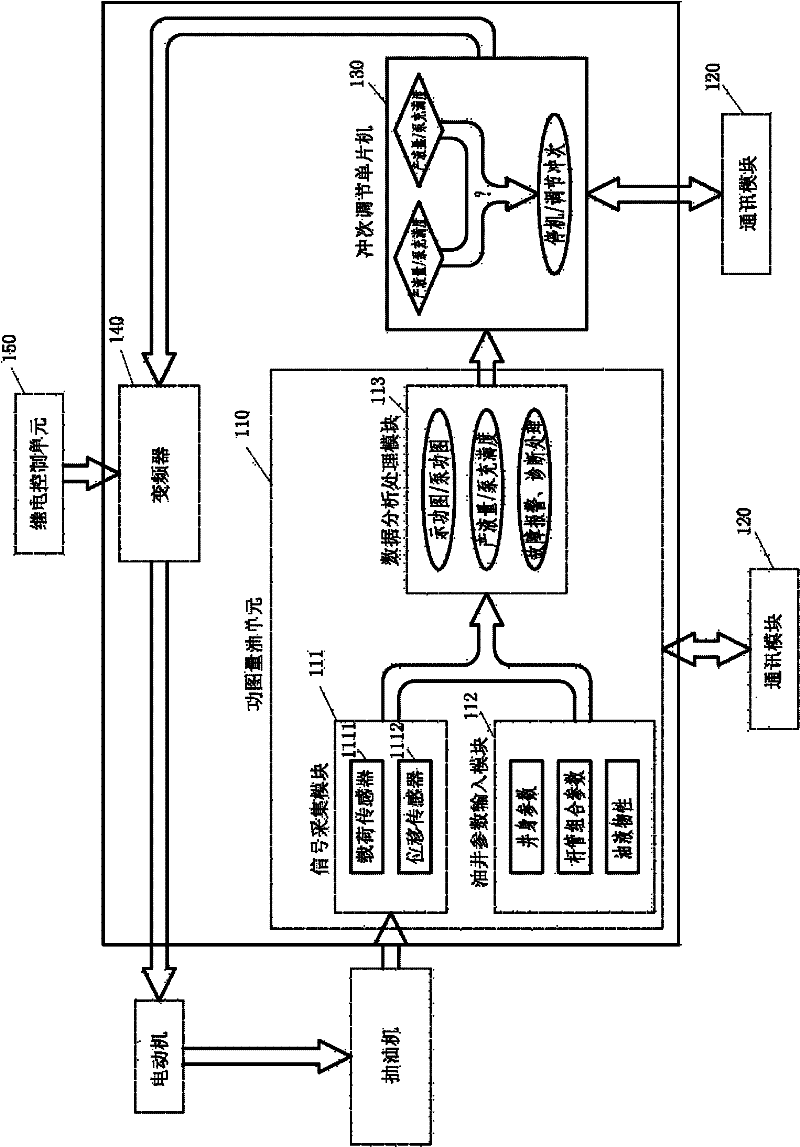

Stroke frequency regulating device of oil pumping machine

ActiveCN102213084AReal-time monitoring of working conditionsLow failure rateAC motor controlFluid removalMicrocontrollerMicrocomputer

The invention provides a stroke frequency regulating device of an oil pumping machine. The stroke frequency regulating device comprises an indicator diagram oil gauging unit, a stroke frequency regulating single-chip microcomputer and a frequency converter, wherein the indicator diagram oil gauging unit is used for acquiring oil well data and processing the oil well data according to oil well parameters to obtain the pump efficiency and the liquid yield of an oil well; the stroke frequency regulating single-chip microcomputer is connected with the indicator diagram oil gauging unit and is used for judging to obtain the minimal working stroke frequency data of the oil pumping machine according to the pump efficiency and the liquid yield of the oil well; and the frequency converter is connected with the stroke frequency regulating single-chip microcomputer and is used for regulating the working frequency of an electric motor of the oil pumping machine according to the minimal working stroke frequency data. According to the invention, the working stroke frequency can be precisely regulated according to the liquid yield per day of a specific oil well; in addition, the stroke frequency regulation of the oil pumping machine is completely digitalized, and can be controlled remotely without manual operation on site; the stroke frequency regulating device provided by the invention has the features of response instantaneity and high stroke frequency regulating precision and can monitor the working condition of the oil pumping machine in real time, so that the fault rate of a mechanical mining system is reduced.

Owner:PETROCHINA CO LTD

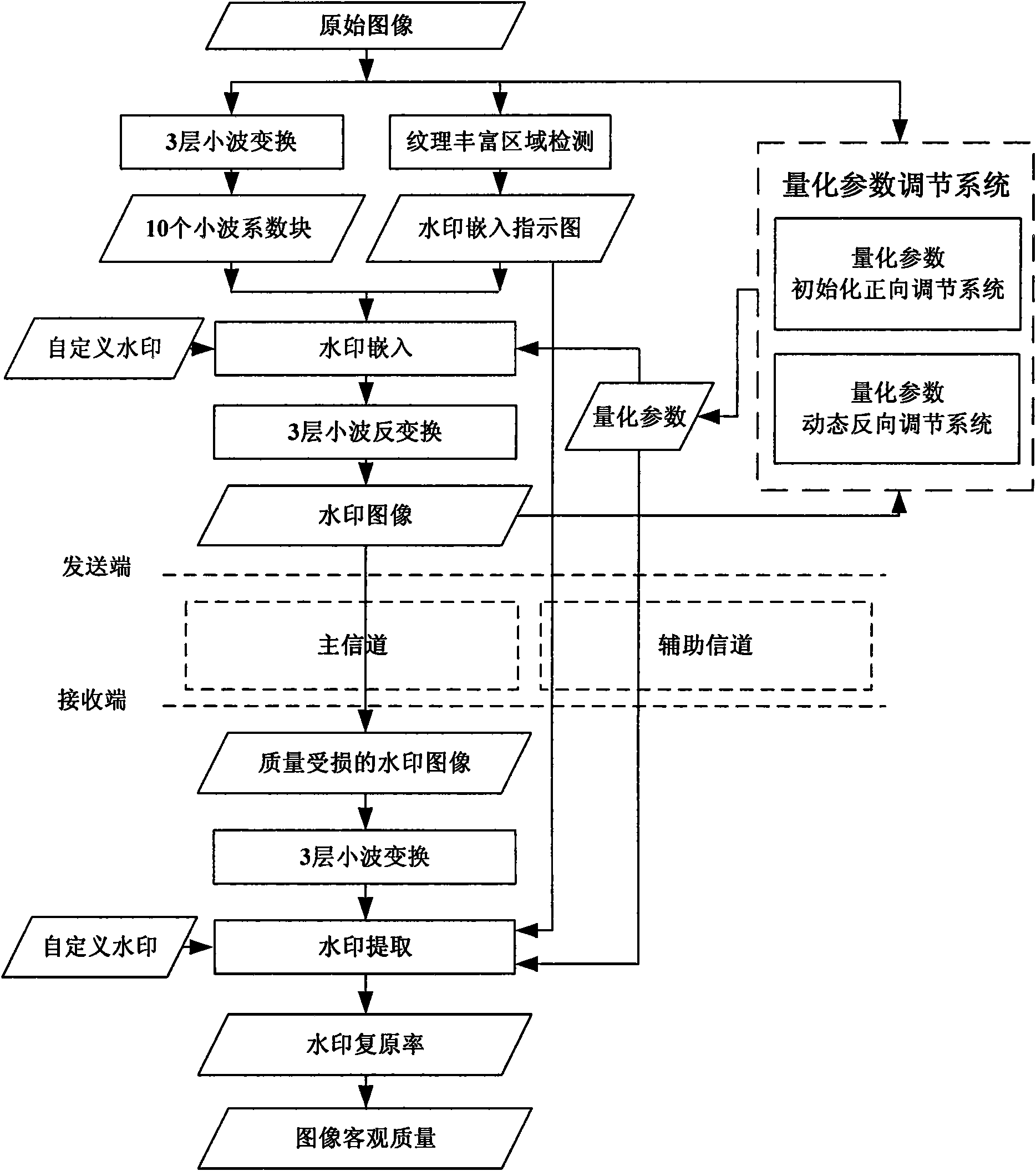

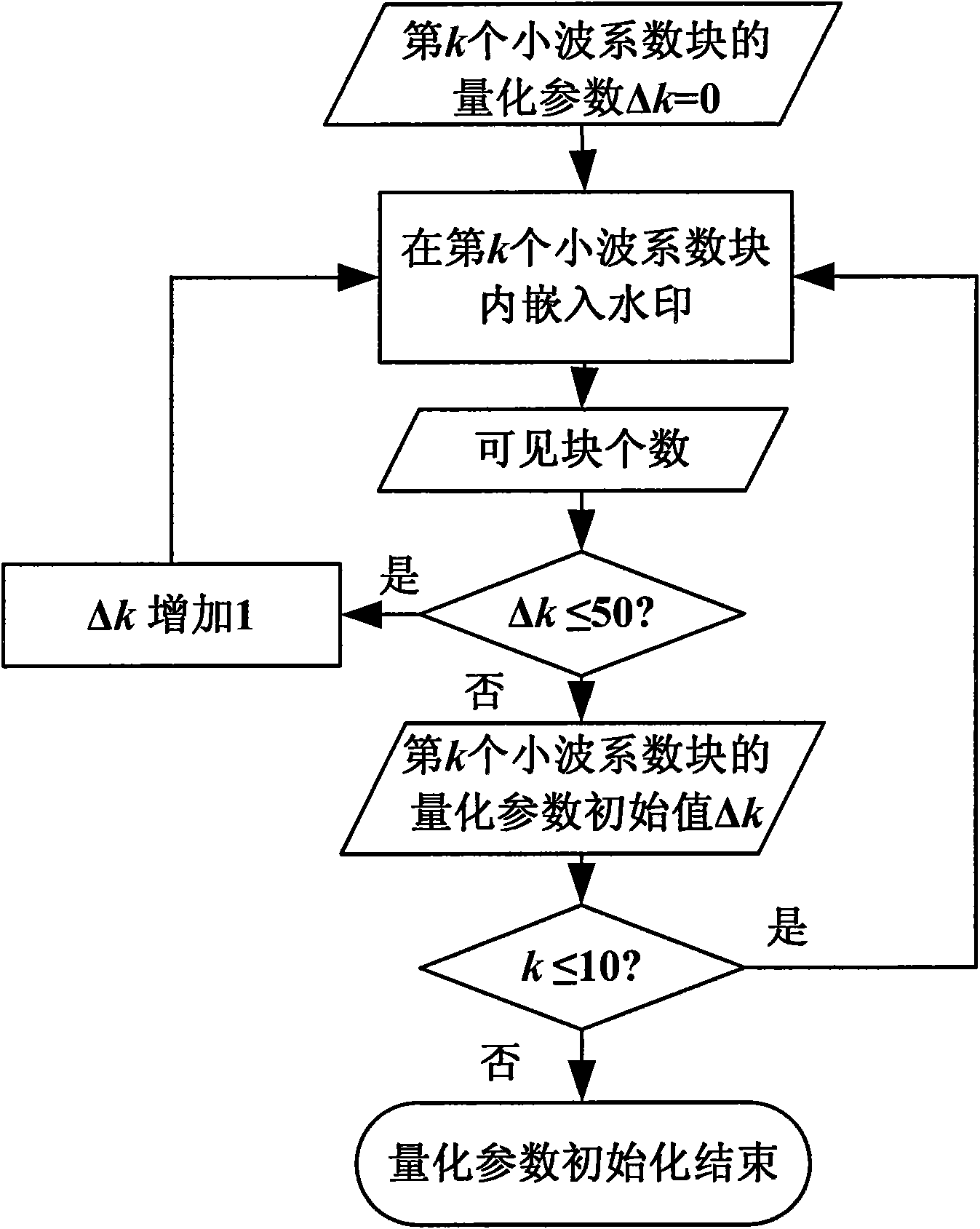

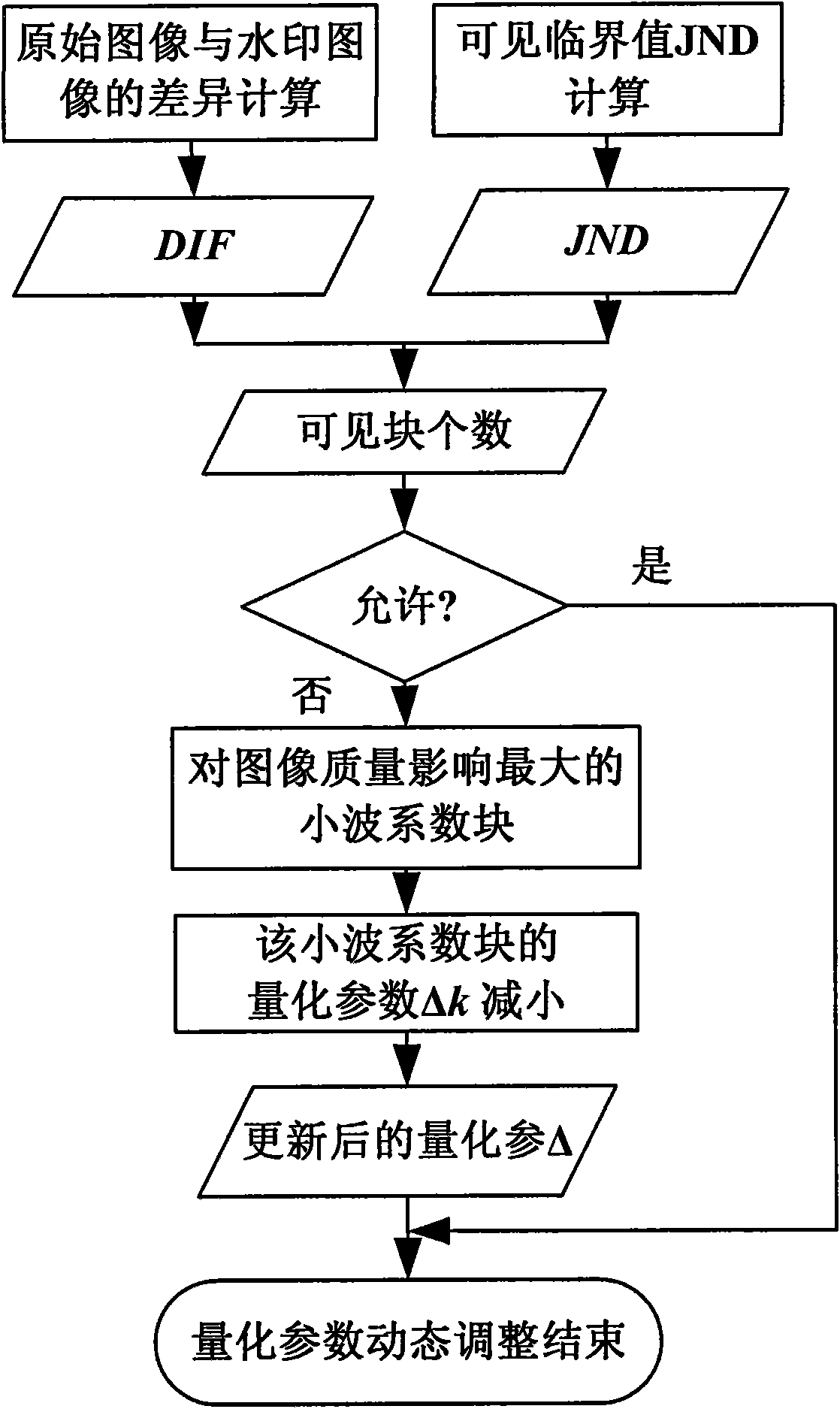

Method for evaluating objective quality of partial reference type image

ActiveCN101605272AMonitor transmission qualityTelevision systemsImage data processing detailsObjective qualityReference type

The invention discloses a method for evaluating objective quality of a partial reference type image. The method comprises the following steps of: 1) at the image sending end, analyzing the texture complexity of the original image to obtain a watermark embedding indicator diagram; 2) at the image sending end, using a quantization parameter initialization adjusting system and a quantization parameter dynamic reverse adjusting system to determine a quantization parameter; 3) at the image sending end and the image receiving end, performing the wavelet transform of the original image to obtain wavelet self sub-band images, and according to the watermark embedding indicator diagram and the quantization parameter, embedding and extracting digital watermarks in all wavelet sub-band images; and 4) at the image receiving end, weighting the recovery rates of the watermarks extracted in the wavelet sub-band images, and obtaining the evaluation of the objective quality of the image. Under the condition of insufficient original images at the image receiving end, by the method, the objective quality of the images can be correctly reflected by using the digital watermarks hidden in the images, so that the method has a wide application prospect.

Owner:ZHEJIANG UNIV

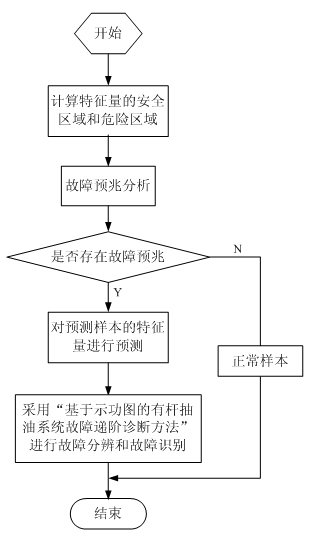

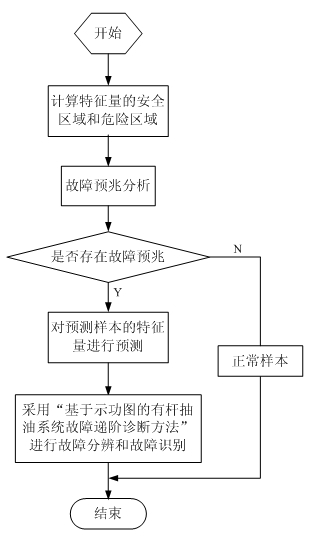

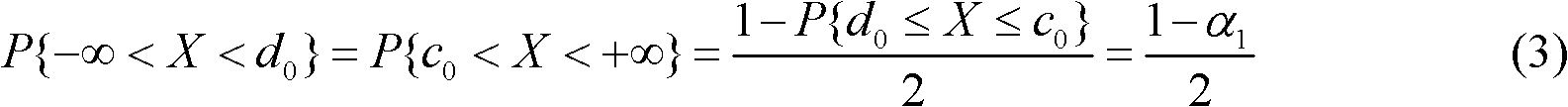

Failure prediction method of rod pumping system based on indicator diagram

InactiveCN102043900AHigh precisionImproving the Efficiency of Failure PredictionSpecial data processing applicationsMoving averageMechanical models

The invention discloses a failure prediction method of a rod pumping system based on an indicator diagram. The failure prediction method is as follows: taking normal (or steady state) sample ground indicator diagram as an entry point; on the basis of failure foretoken analysis, adopting an autoregressive moving average (ARMA) time sequence model to carry out prediction on the characteristic quantity of a predicated sample; and finally, adopting 'a failure hierarchical method of the rod pumping system based on the indicator diagram' to carry out failure diagnosis and failure recognition. By utilizing the failure prediction method, a mechanical model of the rod pumping system does not need to be established and solved, and the problem of a training set does not exist; and simultaneously, byadopting the failure foretoken analysis, a large amount of time is saved, the efficiency of failure predication is improved, and the predication accuracy is effectively improved due to adoption of the failure foretoken analysis and the ARMA time sequence model together.

Owner:HOHAI UNIV +1

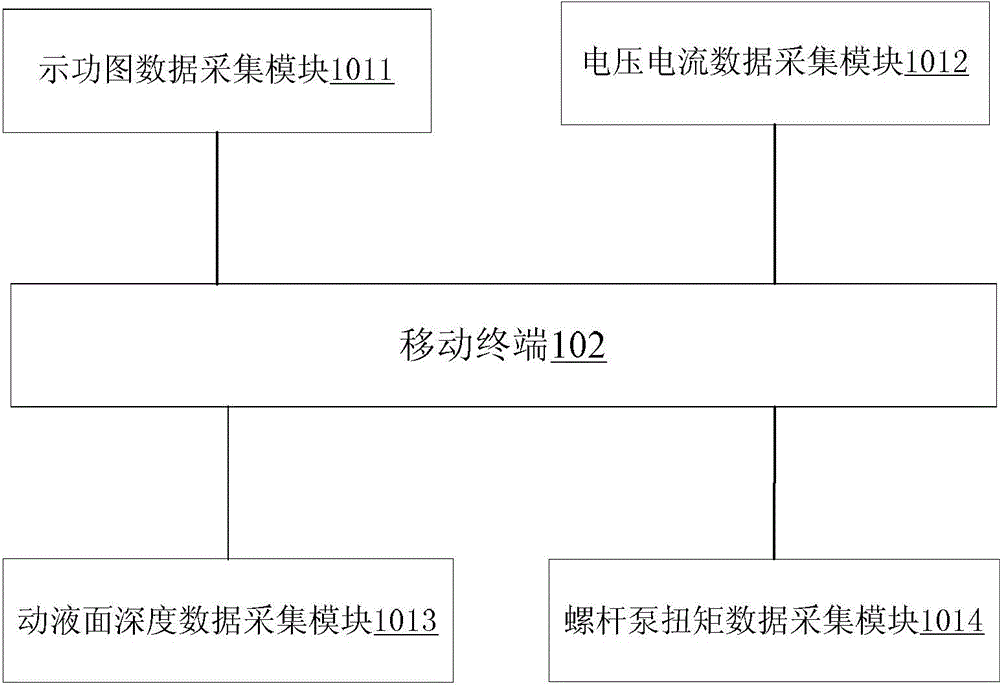

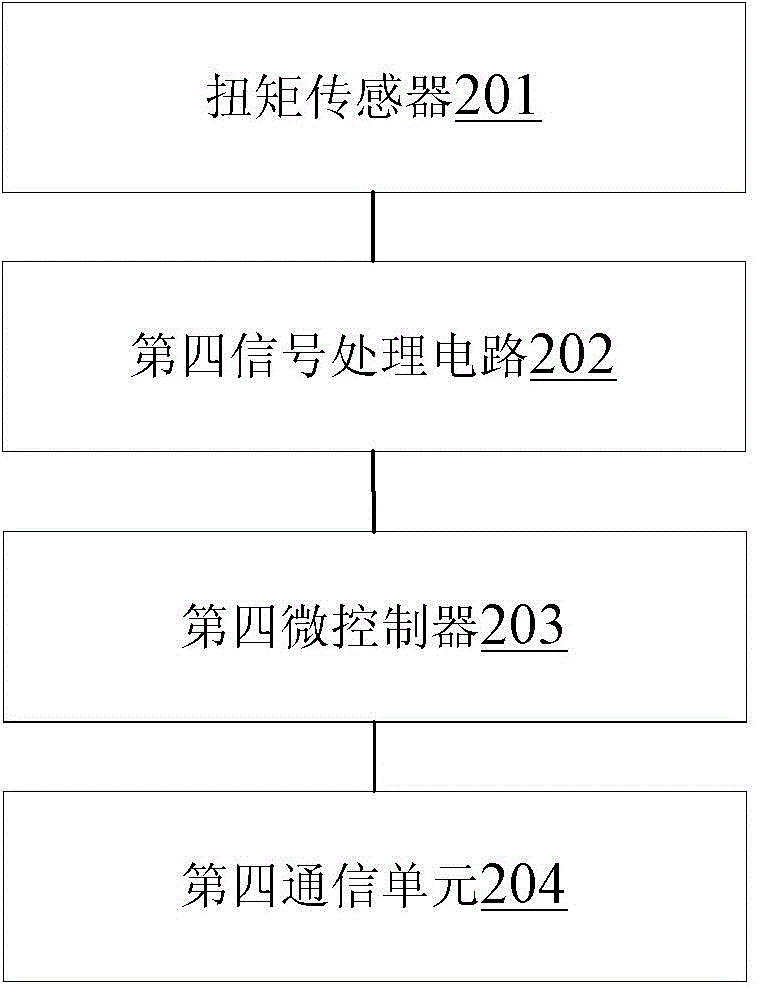

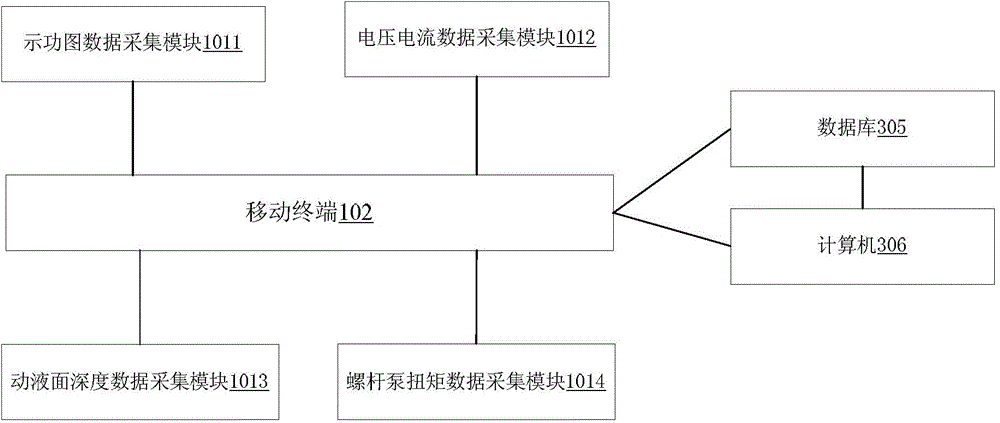

Oil well test and analysis system

The embodiment of the invention provides an oil well test and analysis system. The system comprises a data collection device, a voltage current data collection module, a working fluid level depth data collection module, a screw rod pump torsion data collection module and a mobile terminal; the data collection device is used for collecting multiple types of oil well parameters and transmitting the oil well parameters to the mobile terminal; the data collection device comprises an indicator diagram data collection module for collecting and analyzing the oil parameters needed by an indicator diagram of an oil well; the voltage current data collection module collects the voltage current data of the oil well; the working fluid level depth data collection module collects and analyzes the oil well parameters needed by the depth of a working fluid level of the oil well; the screw rod pump torsion data collection module collects the torsion data of a screw rod pump in the oil well; the mobile terminal receives and analyzes the oil well parameters transmitted from the data collection device for generating an image corresponding to each type of oil well parameter. The oil well test and analysis system disclosed by the embodiment realizes the test functions on diversified parameters, the accuracy of an analysis and diagnosis result of the oil well test parameters is favorably ensured, and meanwhile, the mobile terminal can finish the field analysis on the collected data and the optimal time for equipment regulation is prevented from being missed.

Owner:PETROCHINA CO LTD

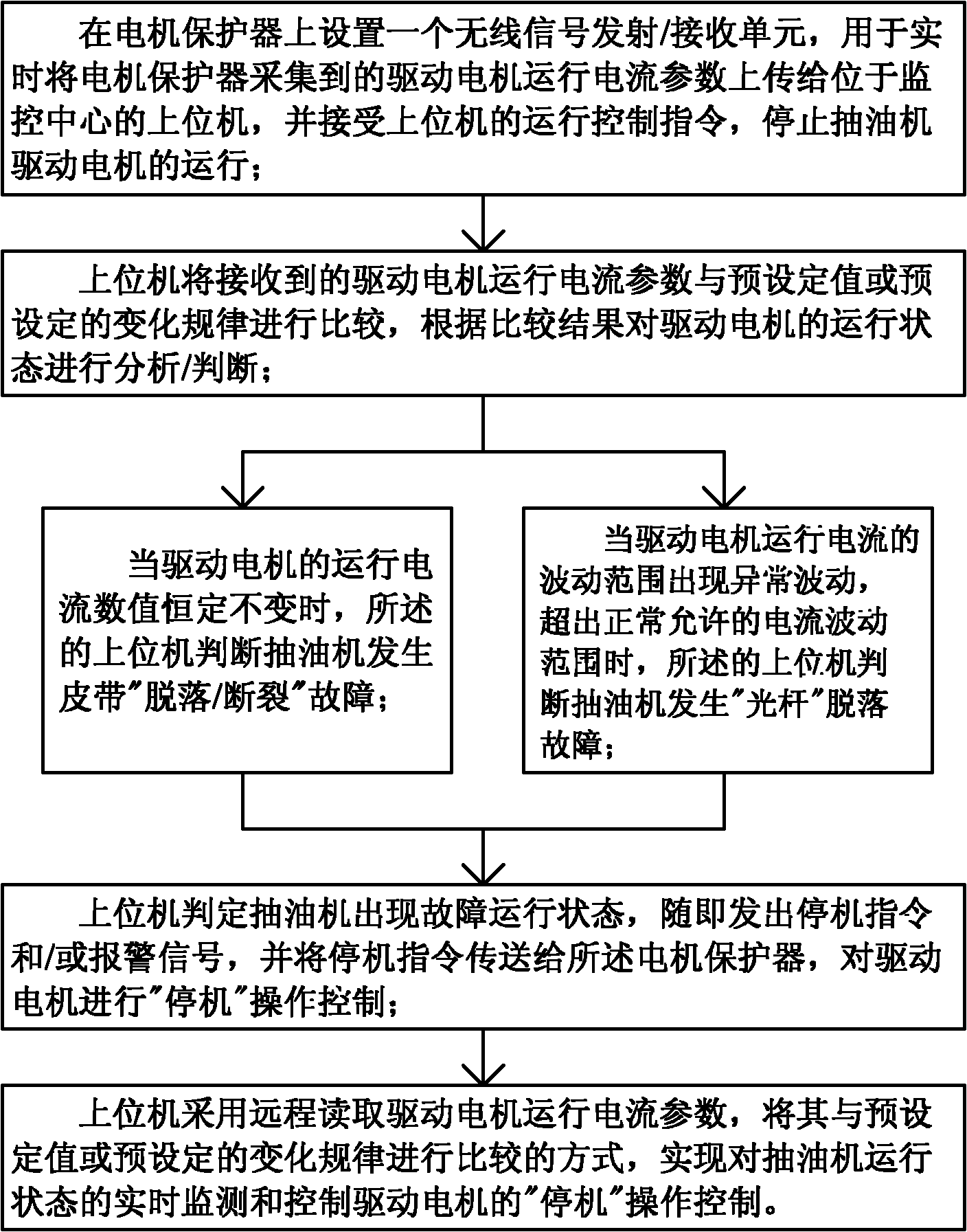

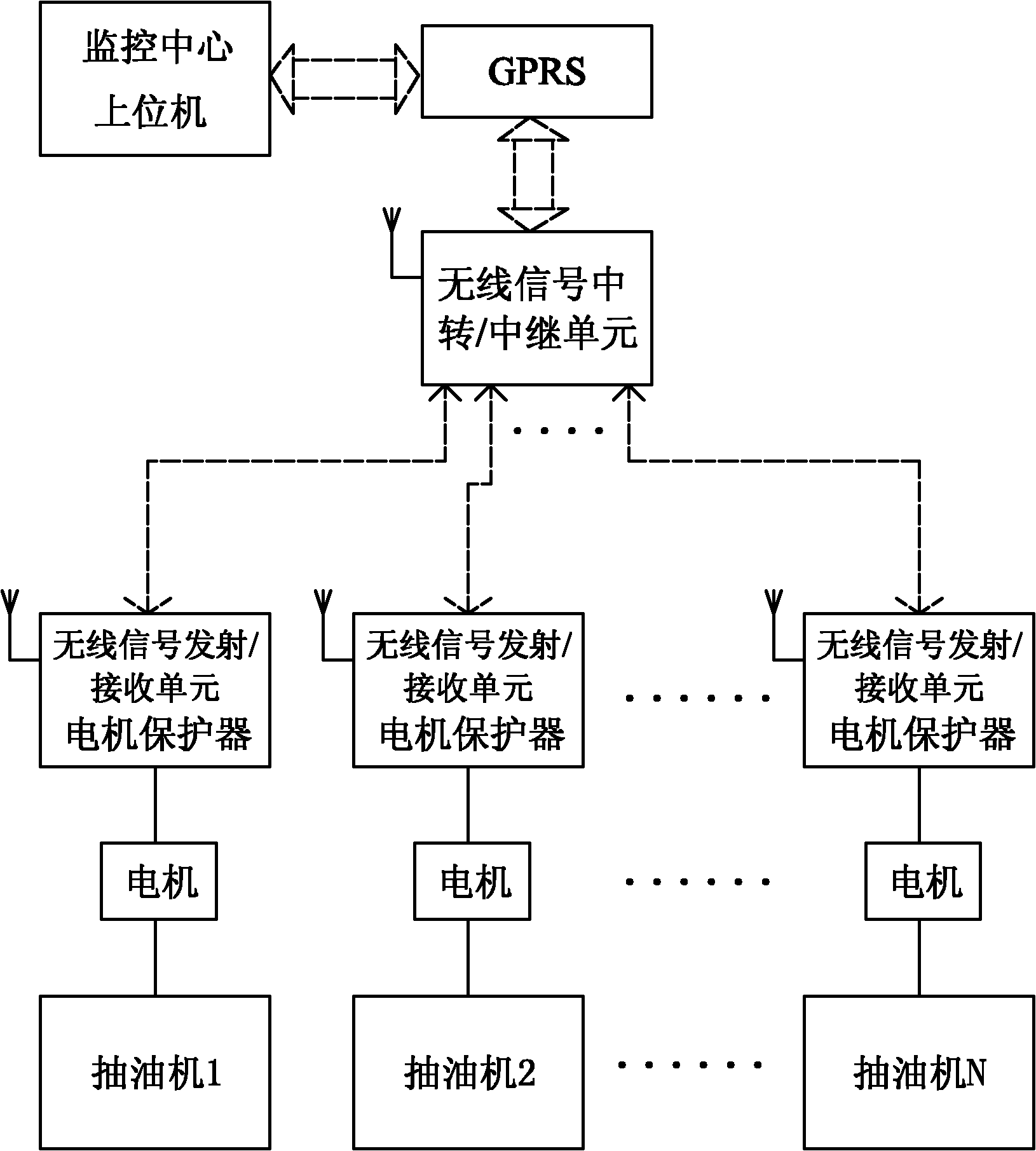

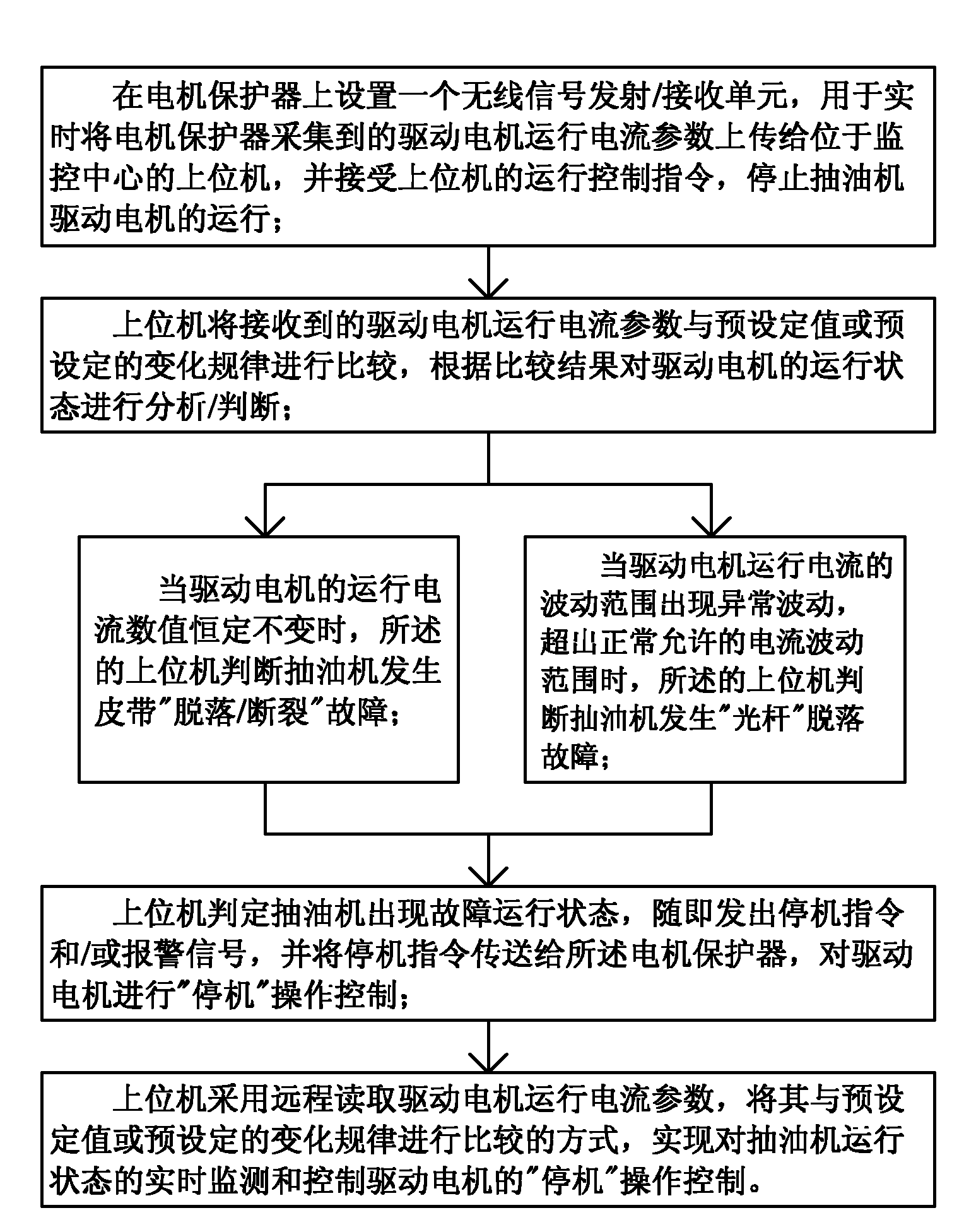

System for monitoring running of oil extractor in oil field

InactiveCN101819436AFor monitoring purposesDoes not affect operationFluid removalTotal factory controlState variationOil field

The invention discloses a system for monitoring the running of an oil extractor in an oil field. A motor protector is arranged at a driving motor of the oil extractor, and a host computer is arranged in a centralized monitoring center, wherein wireless signal transmitting / receiving units are arranged on the motor protector; and the host computer compares received state changing rules of running current parameters of the driving motor, remotely reads the running current parameters of the driving motor to perform comparison, and judges various faults. Preset values and preset changing rules of the running current parameters of the driving motor can be obtained from curves in an oil well indicator diagram or from load analyses in a four-stroke process of the oil extractor. A 'one-to-many' wireless signal transmission network structure is adopted between a wireless signal retransmitting / relaying unit and each wireless signal transmitting / receiving unit; and wireless signals of a plurality of the wireless signal transmitting / receiving units are uploaded to the host computer. A GPRS wireless communication network is adopted between the wireless signal retransmitting / relaying unit and the host computer to perform data transmission so as to transmit the wireless signals to the host computer.

Owner:山东卓尔电气有限公司

Indicator diagram-based oil pumping machine regulating and controlling method

InactiveCN104570991AAdvantages of regulation methodOptimize operating parametersEnergy industryFluid removalFrequency conversionClosed loop

The invention relates to an indicator diagram-based oil pumping machine regulating and controlling method. The method comprises the following steps: acquiring production parameters of an oil pumping machine well in real time; drawing an indicator diagram of an oil producing well by combining the parameters of the pump hanging, the pump diameter, the stroke, the stroke frequency and the liquid production capacity of an oil well, and calculating the saturation degree of the indicator diagram; performing analysis processing on the data of the indicator diagram and drawing a static load line; solving dynamic fluid level data of the oil well by utilizing dynamic fluid level calculating software; determining the reasonable submergence depth of the oil well according to the dynamic fluid level data of the oil well; performing analysis and calculation on the real-time production parameters of the oil well through a computer to obtain reasonable operating parameters of an oil pumping machine; remotely and intelligently regulating output frequency by utilizing a frequency conversion technology; changing the operating rotating speed of a motor of the oil pumping machine, so that the real-time closed-loop regulation of the working conditions of the oil well is realized. The regulating and controlling method disclosed by the invention is mainly used for optimizing the operating parameters of the oil pumping machine; the operating parameters of the oil pumping machine are regulated in real time; the automatic closed-loop control is realized.

Owner:PETROCHINA CO LTD

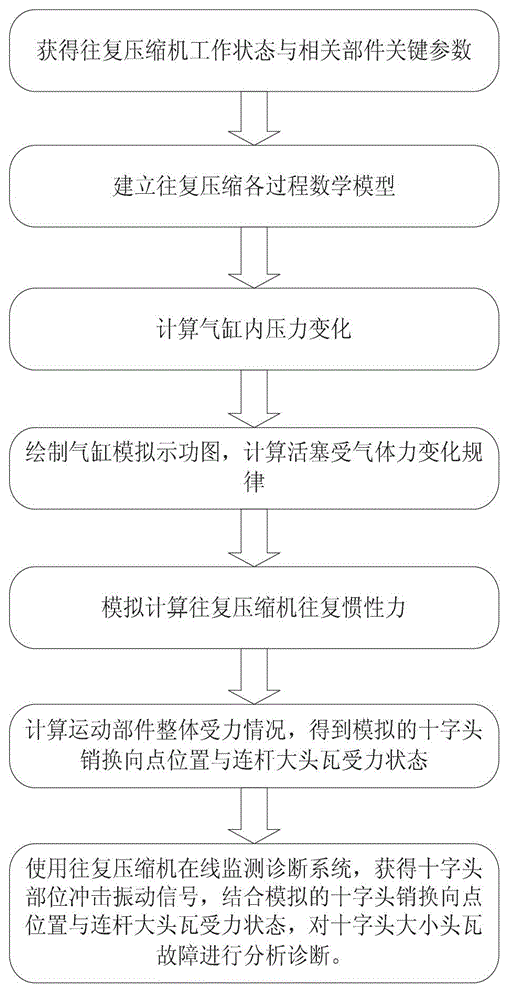

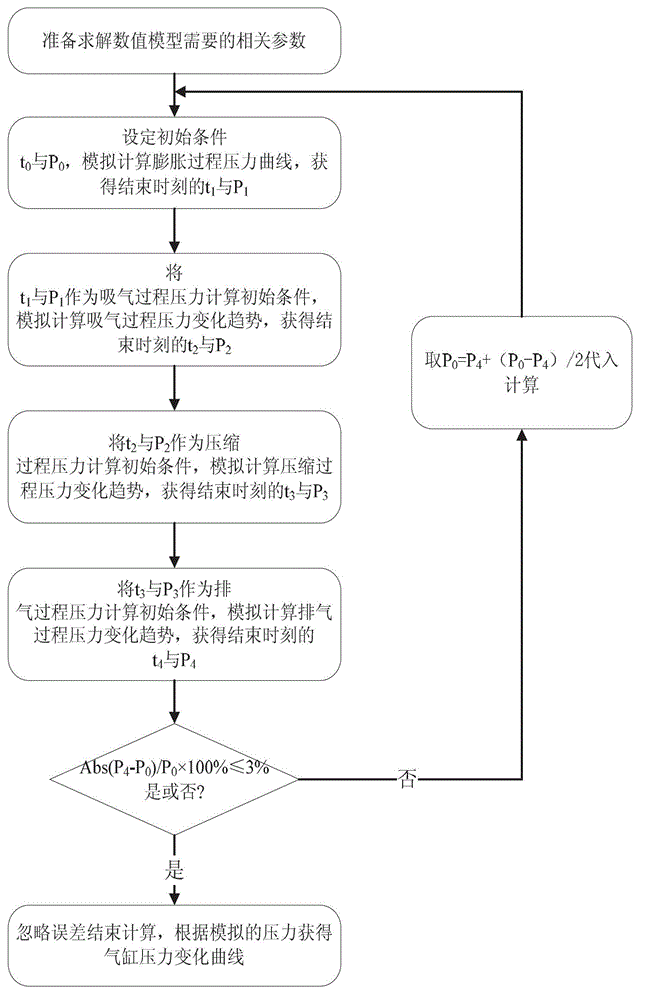

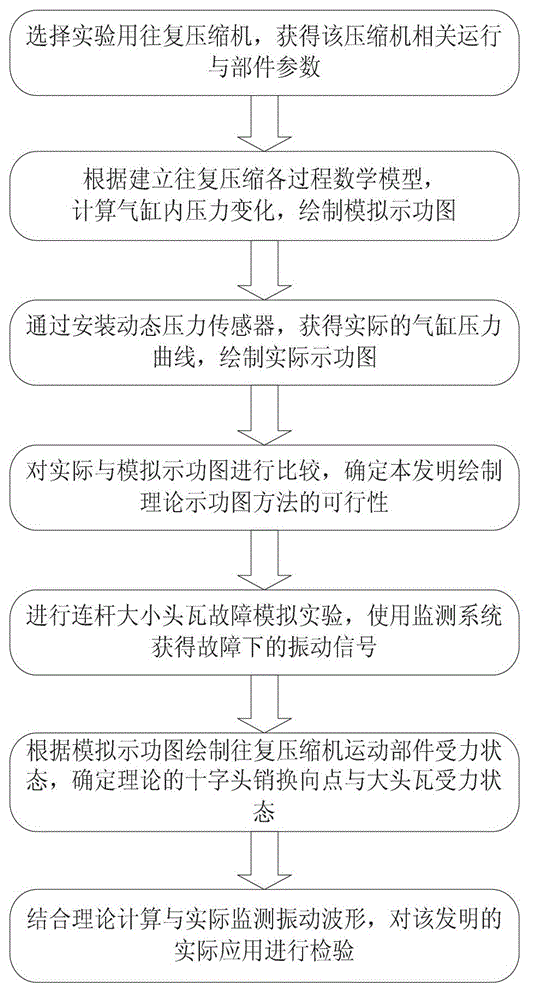

Large and small head tile fault diagnosis method of reciprocated compressor connecting rod based on simulated indicator diagram

ActiveCN102913431AReduce the economic cost of fault monitoringAvoid security risksPump testingPositive-displacement liquid enginesEngineeringIndicator diagram

The invention relates to fault diagnosis of a reciprocated compressor and provides a large and small head tile fault diagnosis method of a reciprocated compressor connecting rod based on a simulated indicator diagram. The method comprises the following steps of: based on a numerical simulation method, carrying out numerical simulation to obtain an air cylinder pressure change rule of a reciprocated compressor under an actual work state; drawing the simulated indicator diagram; and calculating gas pressure on a piston. Reciprocated inertia force of a set is calculated according the rotating speed of the set and the mass of a reciprocated movement part; and a whole stressing condition of the movement part is calculated by combining the gas pressure on the piston, so as to obtain a cross head pin theoretical steering point and a stressing state of a connecting rod large head tile. The reciprocated compressor is used for an online monitoring diagnosis system to obtain an impact vibration signal of a cross head part; and the fault of a connecting rod small head tile is analyzed and diagnosed by combining the theoretical cross head pin steering point and the theoretical stressing state of the connecting rod large head tile. The method does not need to mount a dynamic pressure sensor, namely large and small head tile faults can be diagnosed; and the cost is reduced and the risk of instructing a power hole or mounting the dynamic pressure sensor is avoided.

Owner:BEIJING UNIV OF CHEM TECH

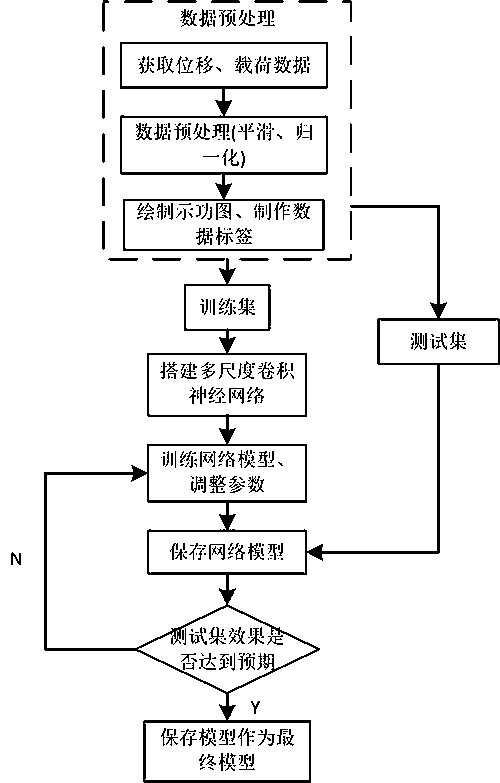

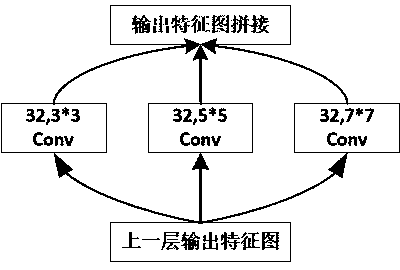

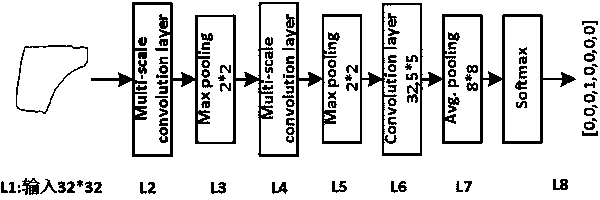

Oil pumping unit fault diagnosis method based on multiscale convolutional neural network

InactiveCN110132626AComprehensive dataImprove the accuracy of fault diagnosisStructural/machines measurementNeural architecturesDiagnosis methodsIndicator diagram

The invention discloses an oil pumping unit fault diagnosis method based on a multiscale convolutional neural network. The conventional fault diagnosis method has problems of dependence on artificialselection of features, complicated calculation and poor accuracy rate, and the existing deep neural networks applied to the oil pumping unit fault diagnosis are all completed in a single path, size ofa filter is set singly at each layer, and flexibility of parameters is limited. A multiscale convolutional block is taken as a core structure, and the oil pumping unit fault diagnosis method based ona multiscale convolutional neural network is improved. The method avoids influence of complicated feature engineering and uncertainty of feature selection on fault identification accuracy rate in theconventional fault diagnosis method, meanwhile, the method can extract global and local features with more abundant and effect indicator diagrams, and can improve fault diagnosis accuracy rate.

Owner:SOUTHWEST PETROLEUM UNIV

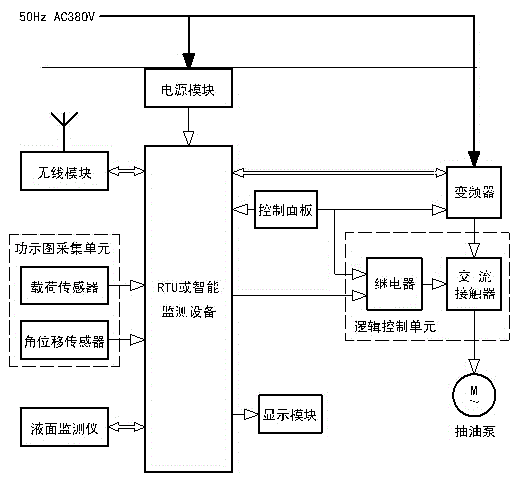

Frequency conversion control method and device for oil-well pump combining indicator diagram with working fluid level

ActiveCN105464953AOvercoming Measurement ErrorsOvercoming adjustmentPump controlPositive-displacement liquid enginesControl systemTransverter

The invention discloses a frequency conversion control method and device for an oil-well pump combining an indicator diagram with a working fluid level. Data of an indicator diagram acquisition unit and data of a liquid level monitor are input into a remote terminal unit (RTU) or intelligent monitoring equipment simultaneously, the authenticity of pump efficiency data of the current system is judged according to the pump fullness calculated in accordance with the indicator diagram by the RTU or the intelligent monitoring equipment and the oil-well pump submergence obtained through the liquid level monitor in a combination mode, the authentic pump efficiency data are effectively input for frequency conversion adjustment, and thus the frequency output result of a frequency converter is determined so that a measurement error caused by a single detection parameter can be overcome, and the best energy saving effect of the oil-well pump system is ensured. According to the frequency conversion control method and device for the oil-well pump combining the indicator diagram with the working fluid level, the indicator diagram and the working fluid level are combined to serve as the input basis of frequency conversion control, so that the measurement error and error adjustment caused by the single detection parameter are effectively overcome; the structure is simple, and frequency conversion adjusting functions in different modes of manual adjustment, automatic adjustment, remote adjustment and the like can be achieved; the frequency conversion control method and device are suitable for the frequency conversion energy-saving control system of a beam oil-well pump.

Owner:贵州航天凯山石油仪器有限公司

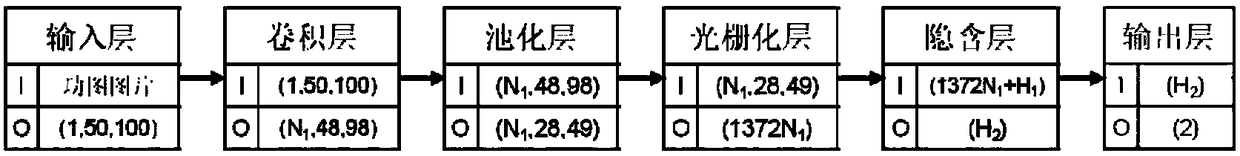

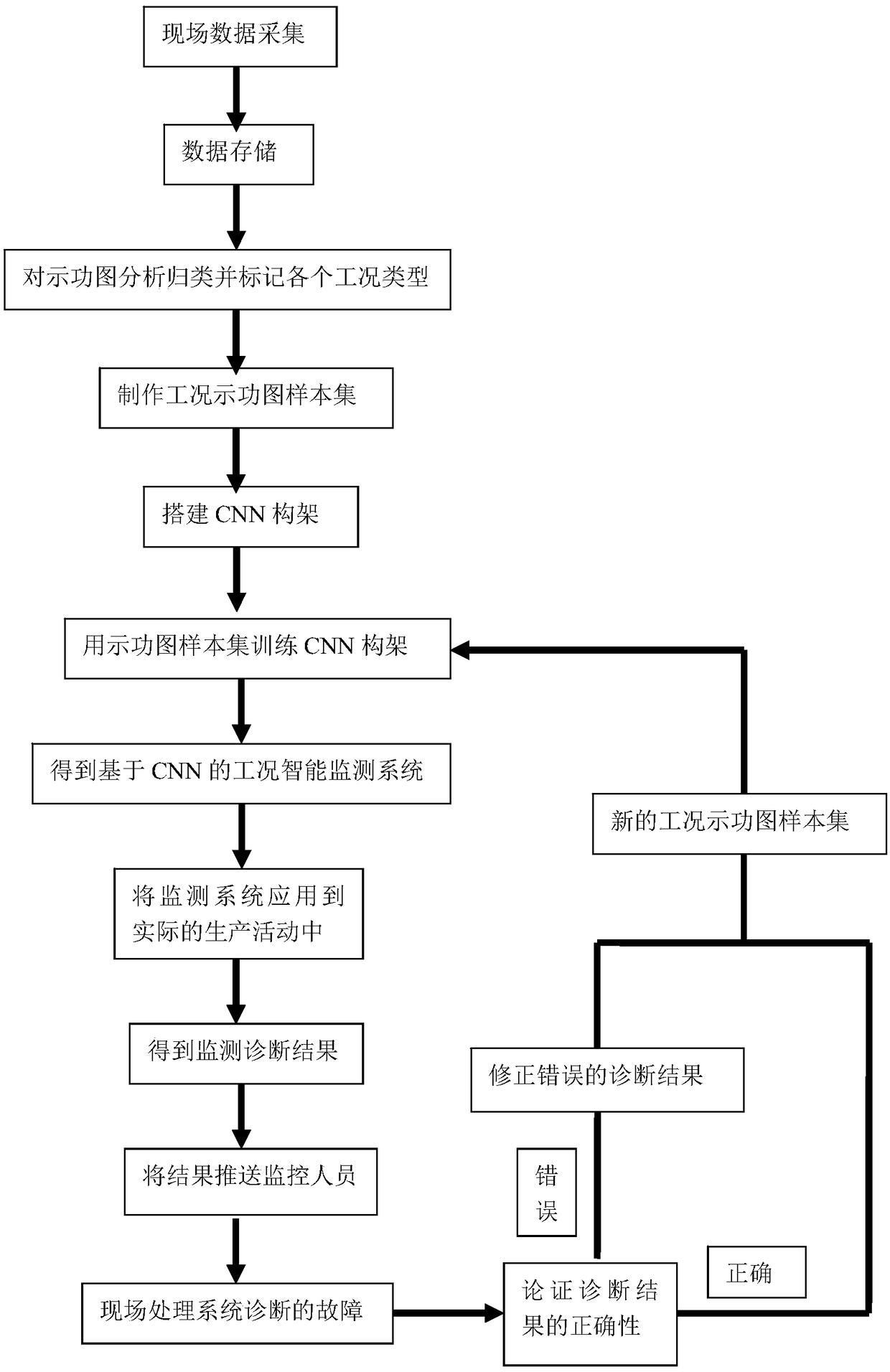

Intelligent monitoring method for working conditions of sucker rod pump based on reinforcement learning of convolutional neural network (CNN)

InactiveCN108122075AReduce mistakesPromote growthResourcesNeural architecturesFeature extractionMonitoring system

The invention relates to an intelligent monitoring method for working conditions of a sucker rod pump based on reinforcement learning of a convolutional neural network (CNN). A monitoring system mainly comprises three parts: construction of the CNN for monitoring the working conditions of the sucker rod pump, actual application of the CNN for monitoring the working conditions of the sucker rod pump as well as learning and update of the CNN for monitoring the working conditions of the sucker rod pump. According to the monitoring method disclosed by the invention, by using the CNN, loss of a great deal of useful information in the numeralization process of an indicator diagram obtained by feature extraction is avoided; the CNN can directly identify inputted indicator diagram pictures so as to reduce errors; meanwhile, on the basis of reinforcement learning, the growth opportunity of a CNN intelligent monitoring system can be effectively improved; accuracy of the working conditions is improved in the repeated working condition diagnosis and reinforcement learning process; possible errors of comparison of a small amount of sample data with a large amount of actual production data is avoided, and the effects that the more the CNN is used, the more intelligent the CNN is, and the more the CNN is used, the easier the CNN is are realized.

Owner:胜利油田鲁明油气勘探开发有限公司 +1

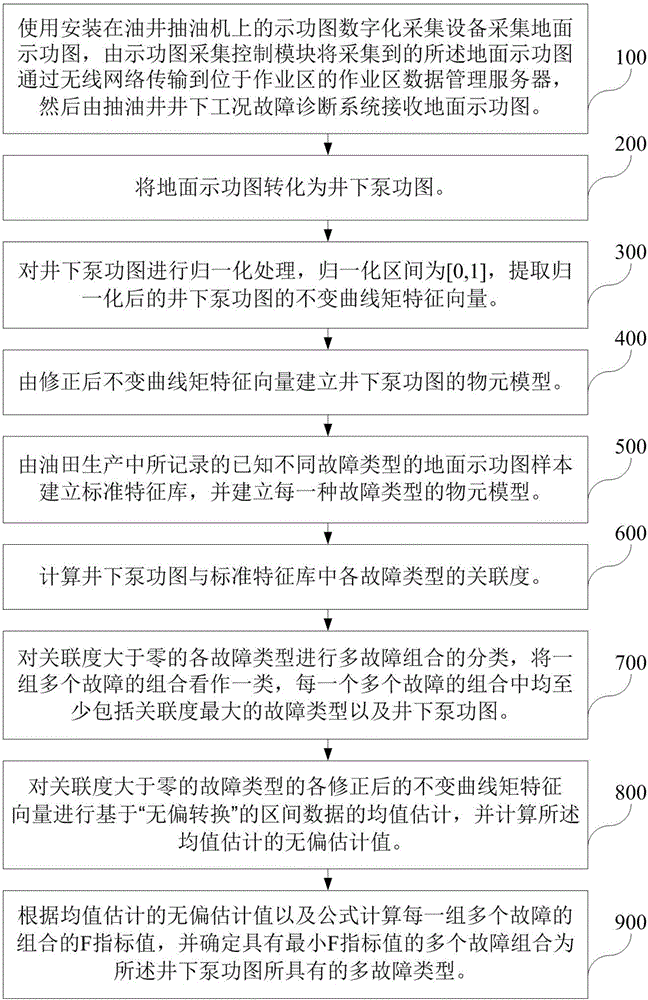

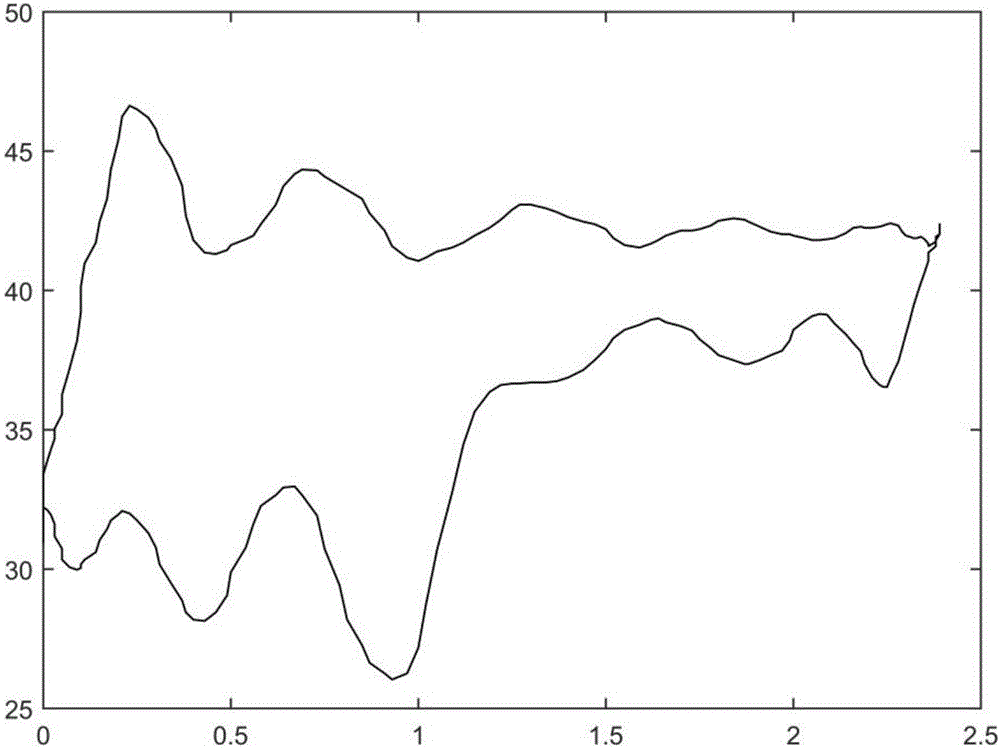

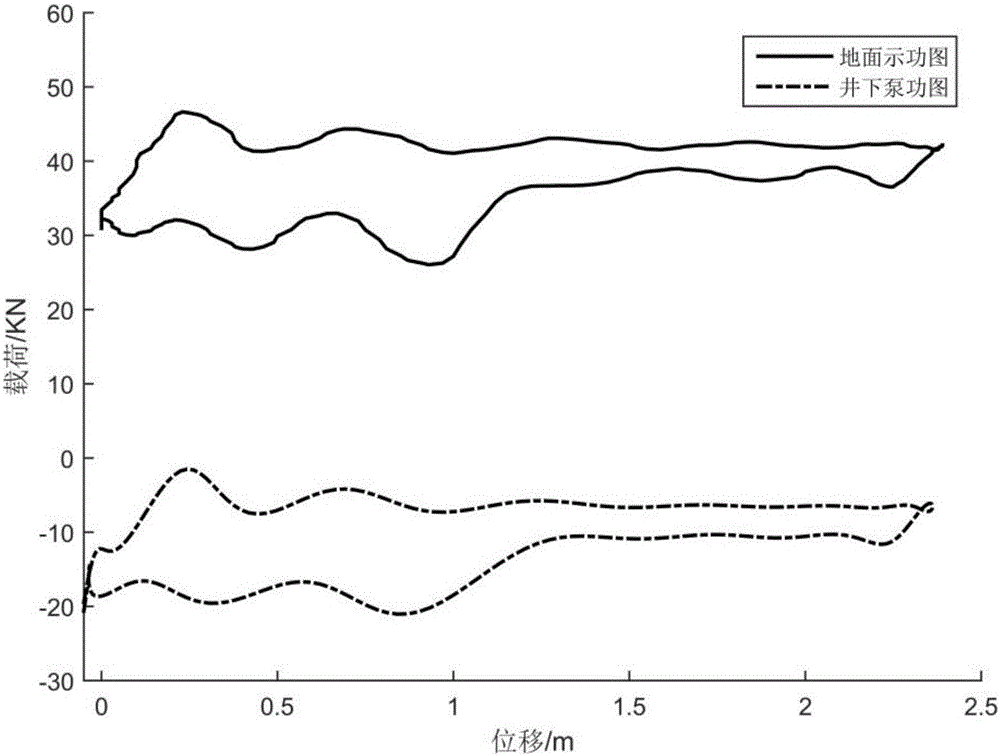

Multi-fault diagnosing method for oil well with sucker rod pump based on indicator diagram

InactiveCN106121622AIncrease credibilityReduce computational complexityConstructionsInformaticsFeature vectorIndicator diagram

The invention discloses a multi-fault diagnosing method for an oil well with a sucker rod pump based on an indicator diagram and relates to the technical field of oil production. The multi-fault diagnose method comprises the following steps of transforming a collected ground surface indicator diagram into a down hole pump indicator diagram; setting up a standard feature library of every fault type according to existing indicator diagram data in oilfield production; adopting interval data to express an eigenvalue of every invariant curve moment eigenvector; then calculating the relevancy between a collected sample and every fault type in the standard feature library; judging the possible fault types of the collected sample, and thus improving the credibility of fault diagnosing; at last, conducting multi-fault combination on the possible fault types of the collected sample; and deciding the possible multi-fault type by calculating an F index value of each combination. The multi-fault diagnosing method is simple in principle, small in calculating complexity, easy to achieve, and high in accuracy degree of diagnosing.

Owner:BOHAI UNIV

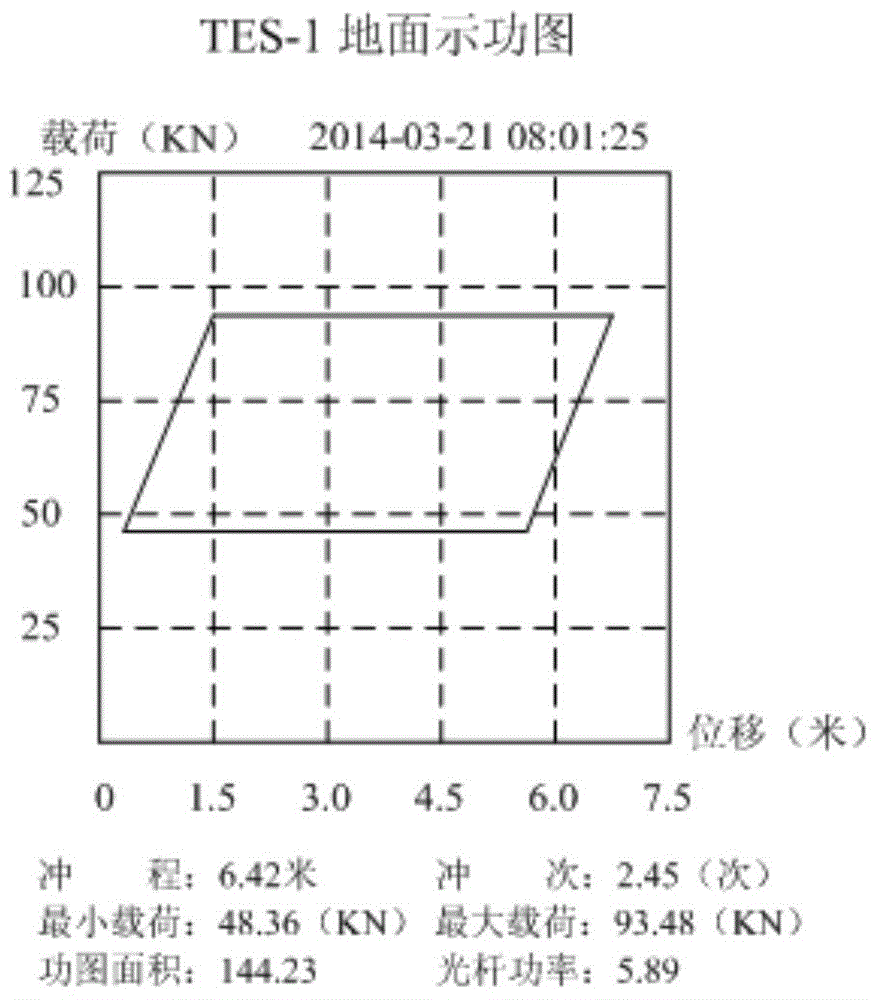

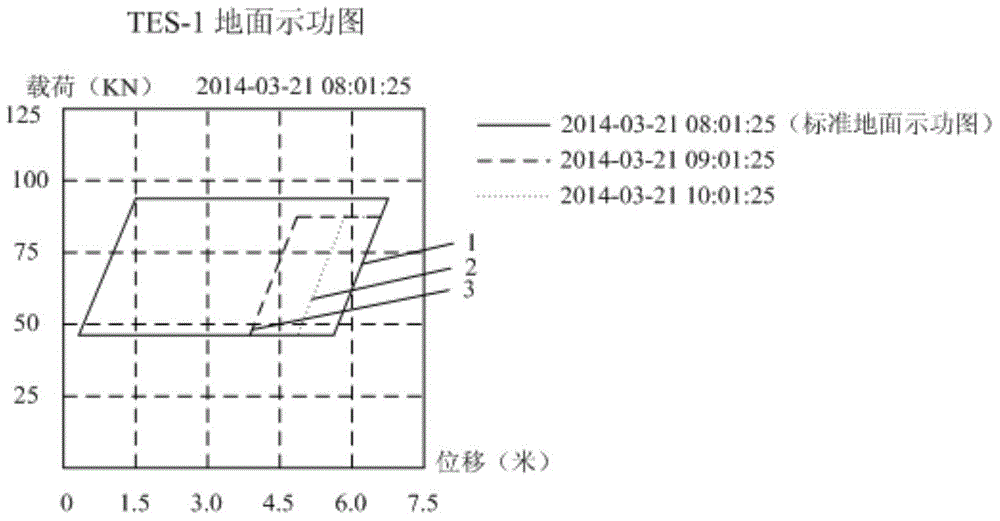

Oil well indicator diagram data analysis method

InactiveCN104564020AShorten the time to discover work abnormalitiesPrevent well fallSurveyConstructionsIndicator diagramOil well

The invention provides an oil well indicator diagram data analysis method. The method comprises the following steps : setting an indicator diagram of an oil well at a certain collection time point under a daily steady operation state as a standard indicator diagram, comparing indicator diagrams of the oil well at other collection time points with the set standard indicator diagram, and searching oil well operating parameter change conditions. According to the oil well indicator diagram data analysis method, the indicator diagram at different collection time points are put in a same coordinate system, and different modes, such as colors and line types are adopted for labeling, and comparison is performed in time so as to discover changes generated by the indicator diagram, so that the working condition change conditions of the oil well are mastered; the labor strength of manpower is reduced; the oil well operation abnormity discovery time is shortened; the on-site problem copping response speed is improved; the oil well is prevented from more severe accidents such as well collapse and well lying and the oil well management level is improved.

Owner:SHANDONG TIANGONG PETROLEUM EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com