Pumping unit jig frequency, balance real-time capacity adjusting method and device thereof

An intelligent adjustment and pumping unit technology, applied in the field of digital construction and management of oilfields, can solve the problems of high labor, material and financial costs, low work efficiency, long analysis and processing cycles, etc., to solve the lag of parameter adjustment and improve production. Efficiency and the effect of improving the level of digital management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

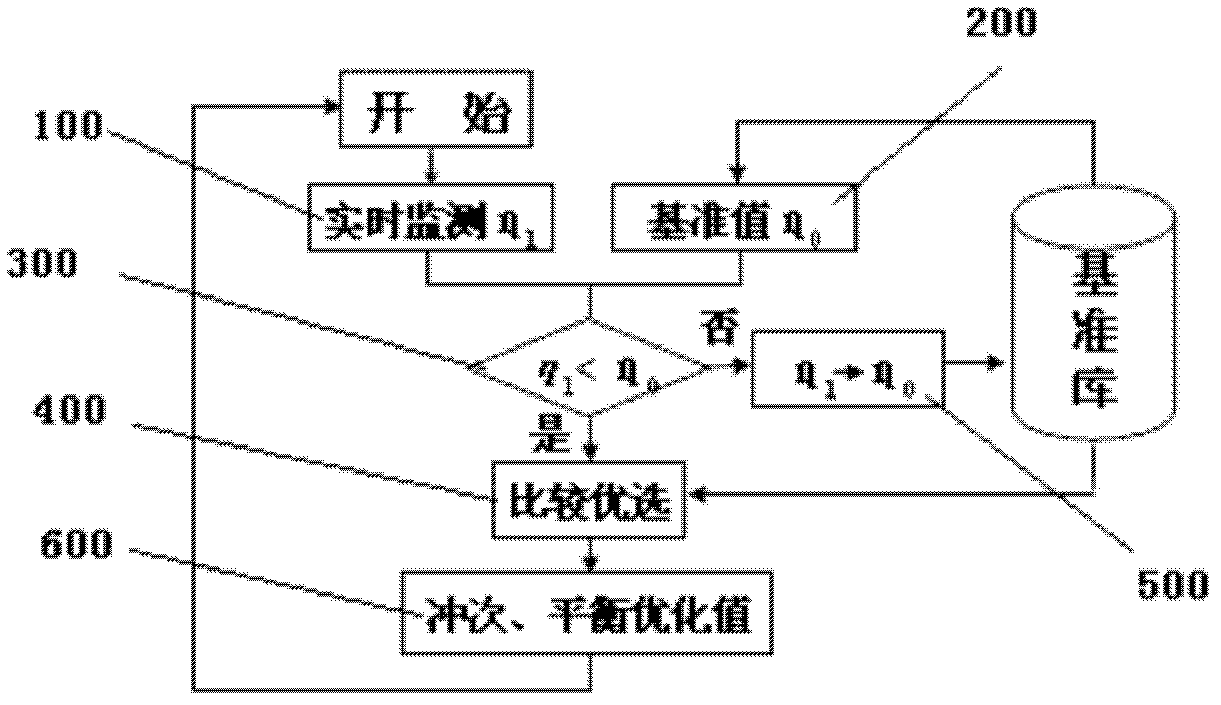

[0076] Such as figure 1 As shown, the embodiment of the present invention provides a real-time intelligent adjustment method for stroke times and balance of a pumping unit, the method comprising:

[0077] Step 100, establish a dynamic analysis system for oil well conditions, and obtain the actual system efficiency η in real time 1 ;

[0078] Step 200, establish a benchmark database, and set the given system efficiency η under different parameters according to experience 0 ;

[0079] Step 300, adjust according to the goal of optimal system efficiency, and compare the actual system efficiency η 1 Is it less than a given system efficiency η 0 , if yes, execute step 400, if no, execute step 500;

[0080] Step 400, by comparing the actual system efficiency η 1 and a given system efficiency η 0 , the parameter value under the larger of the two is preferred, and step 600 is executed;

[0081] Step 500, if the actual system efficiency η 1 Better than a given system efficiency...

Embodiment 2

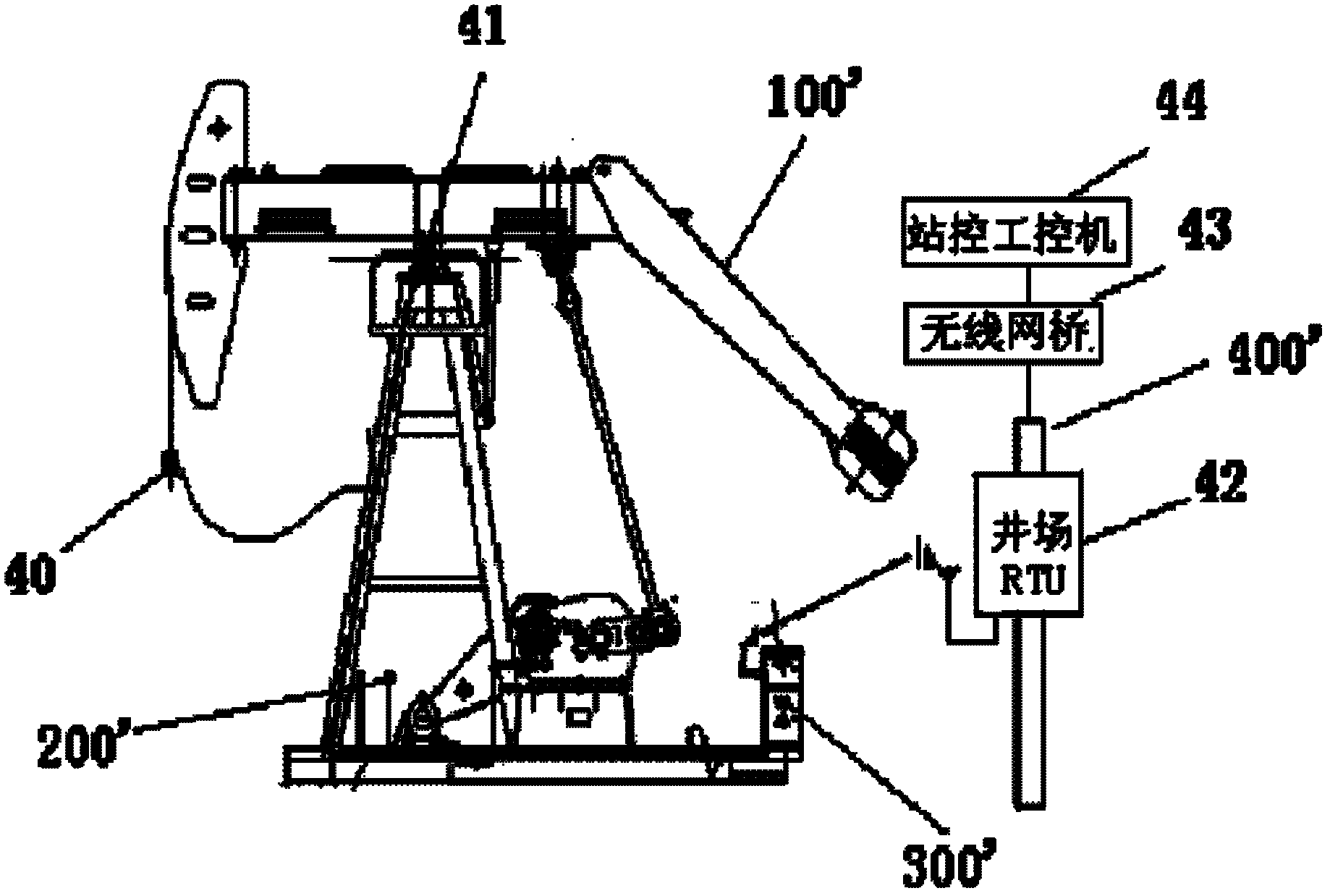

[0130] Such as image 3 As shown, the embodiment of the present invention also provides a device applied to the method of real-time intelligent adjustment of stroke times and balance of the pumping unit. 'and the digital pumping unit integrated control device 300' and the lead screw balancing device 100', wherein the work diagram method oil well metering device 400', the electric parameter data real-time acquisition device 200' and the digital pumping unit integrated control device 300' are all is prior art;

[0131]The gong diagram method oil well metering device 400' is installed on the pumping unit, and the gong diagram method oil well metering device 400' is used to monitor the working conditions of the pumping unit around the clock, collecting a dynamometer diagram every ten minutes , and carry out calculation and analysis to obtain the real-time fluid volume and working condition diagnosis results of the oil well;

[0132] Specifically, the oil well metering device 400...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com