Intelligent identification method for operation condition of sucker rod type oil pumping unit

A technology for intelligent identification and operating conditions, which is applied to earthwork drilling, mining fluids, boreholes/well components, etc., and can solve problems such as a large amount of manpower and material resources, and accuracy errors in identification of working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

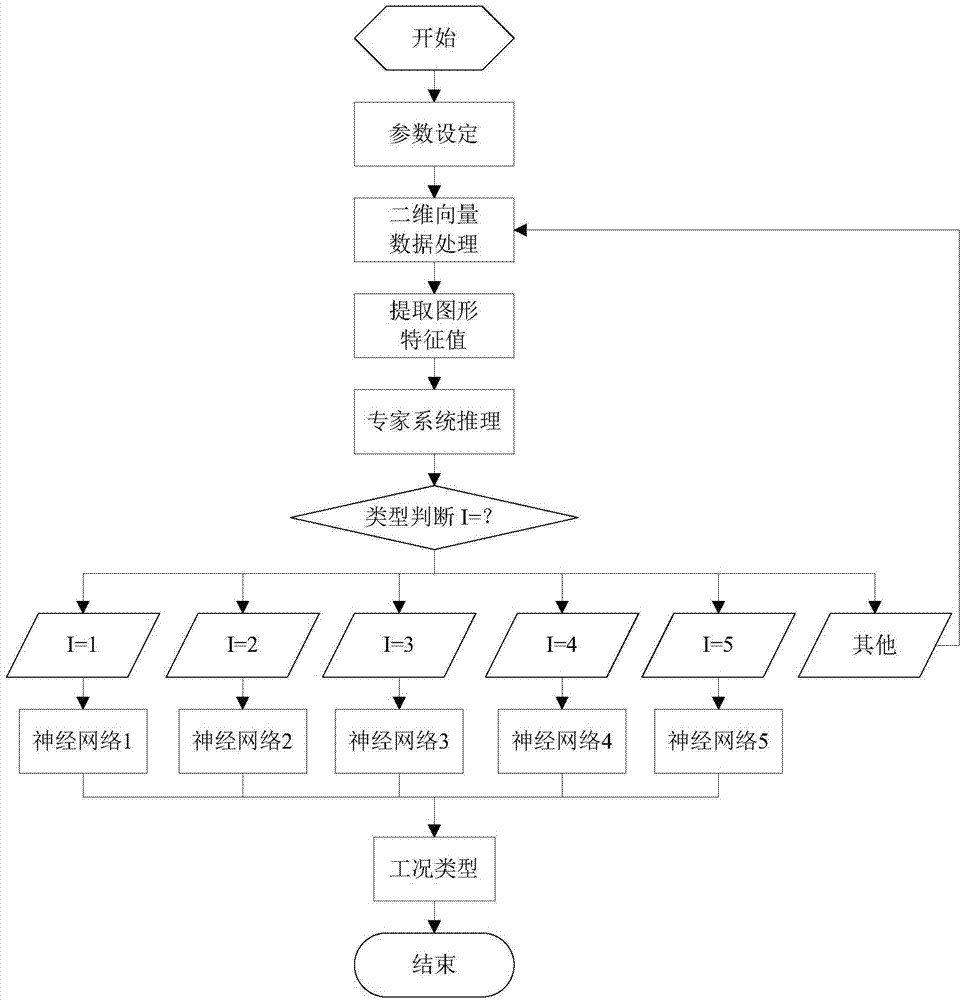

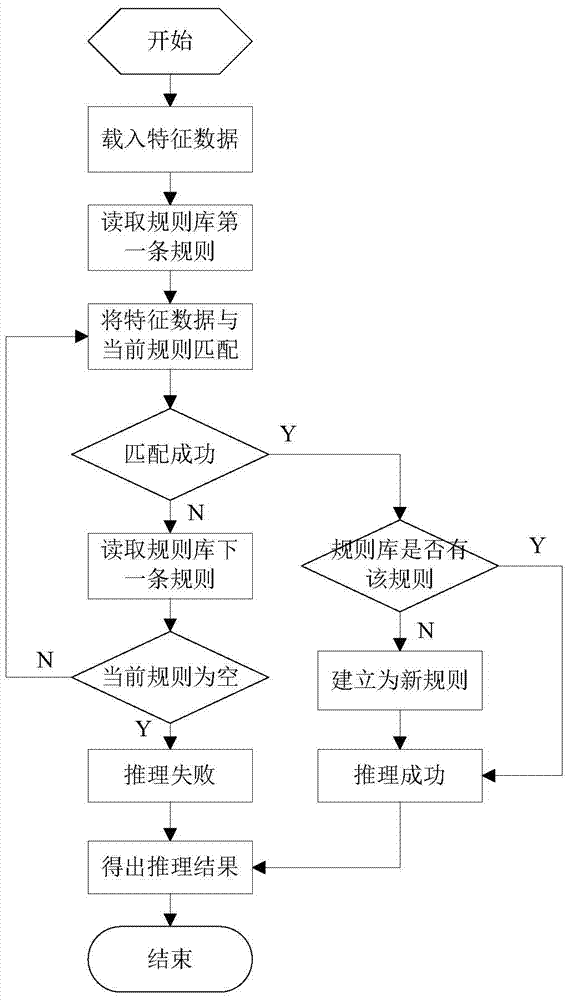

[0042] Such as figure 1 The intelligent identification method of the operating condition of the rod pumping unit includes the following steps:

[0043] Step 1: Collect the above-hole dynamometer diagram and convert it into an underground dynamometer diagram. The specific steps are as follows:

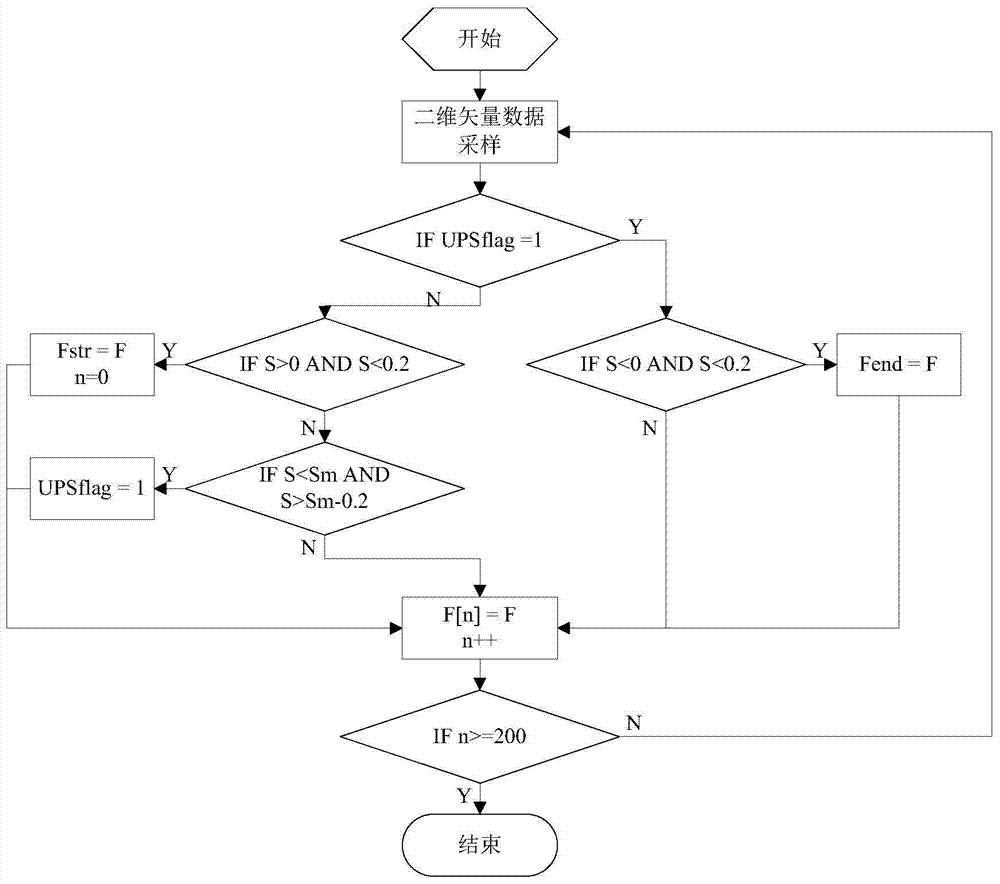

[0044] Step 1.1, in order to ensure the integrity of the input signal data information and fully characterize the working condition characteristics of the automatic control system of the rod pumping unit, that is, the collected input signal fully represents the change trend of the dynamometer curve, and the dynamometer curve The resolution is relatively delicate, the shape of the dynamometer diagram in the four areas is clear, and the information of the original signal is restored by means of discrete sampling points; the sampling frequency of the ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com