Workshop production collaboration method and system

A workshop and production line technology, applied in the field of big data production applications, can solve the problems of information transmission lag, production line affecting production efficiency, etc., to achieve the effect of improving the service life of equipment, accurate monitoring of equipment operating status and operating environment, and reducing the probability of abnormality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

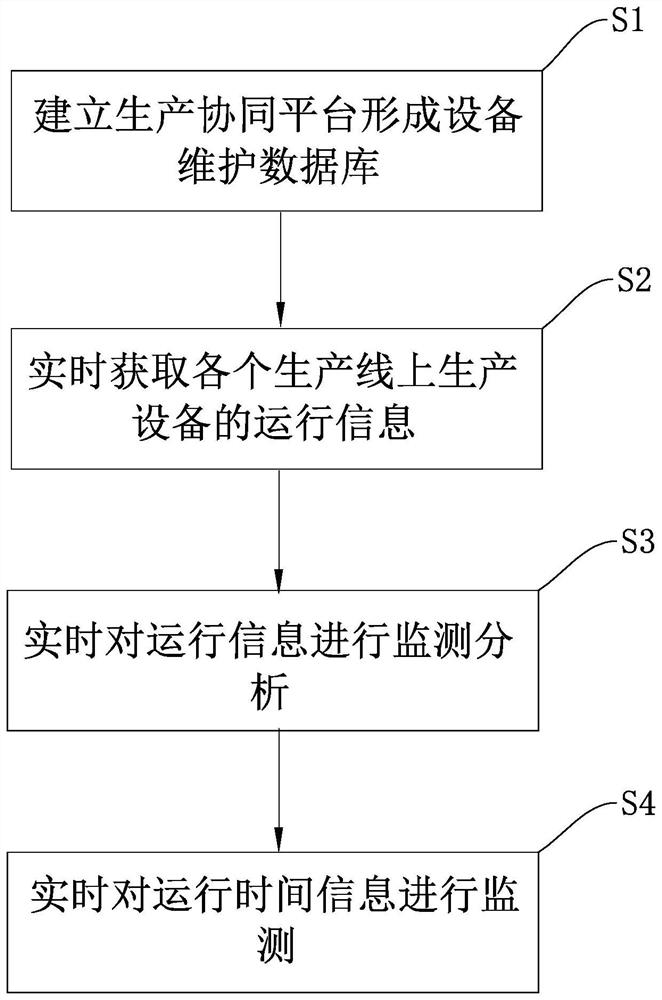

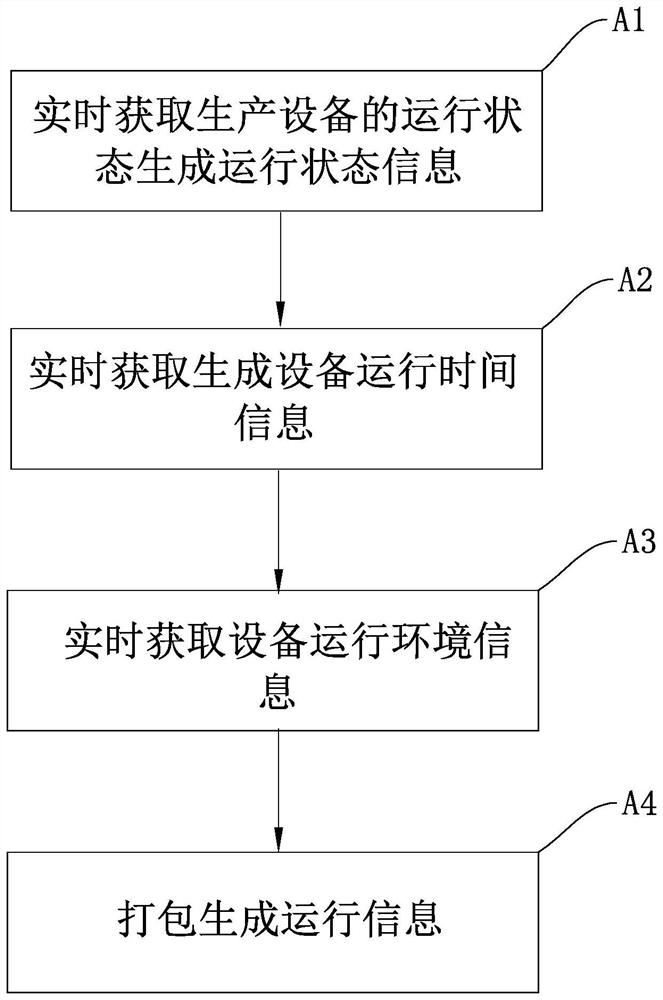

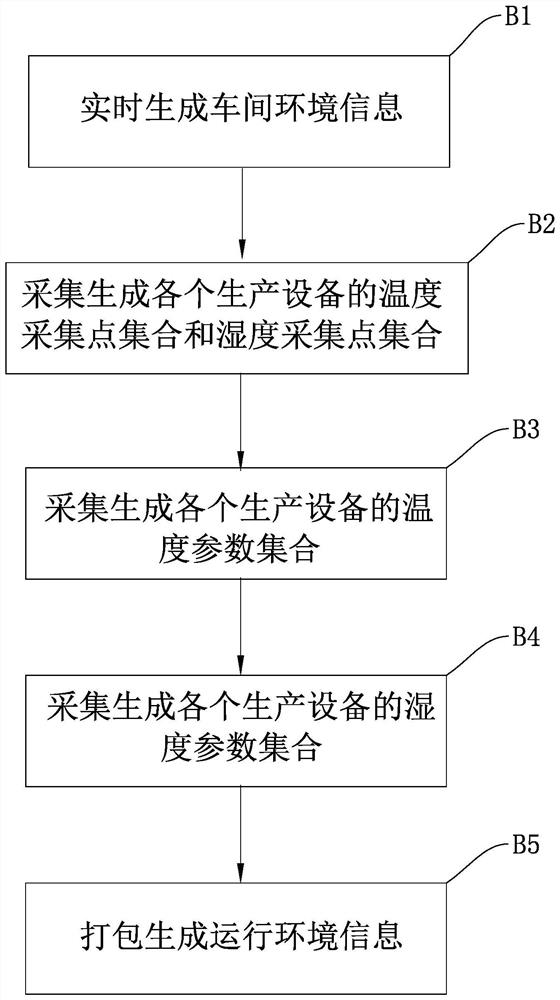

[0069] Attached to the following Figure 1-7 This application will be described in further detail.

[0070] The embodiment of the present application discloses a workshop production collaboration method. refer to figure 1 , a workshop production collaboration method, comprising the following steps:

[0071] S1. Establish a production collaboration platform to form an equipment maintenance database: establish a production collaboration platform, import order information to form an order database, and import equipment maintenance information to form an equipment maintenance database;

[0072] The equipment maintenance information includes equipment parameter information, equipment maintenance parameter information and equipment maintenance record information, and the equipment maintenance parameter information includes equipment maintenance cycle, equipment single operation duration threshold and equipment standard operating environment information;

[0073] S2. Obtain the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com