Drawing device, capable of detection, of riveting machine

A drawing device, riveting machine technology, applied in the direction of riveting connection, connection, connection and connection completed by deformation, etc., can solve the problem of single function and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

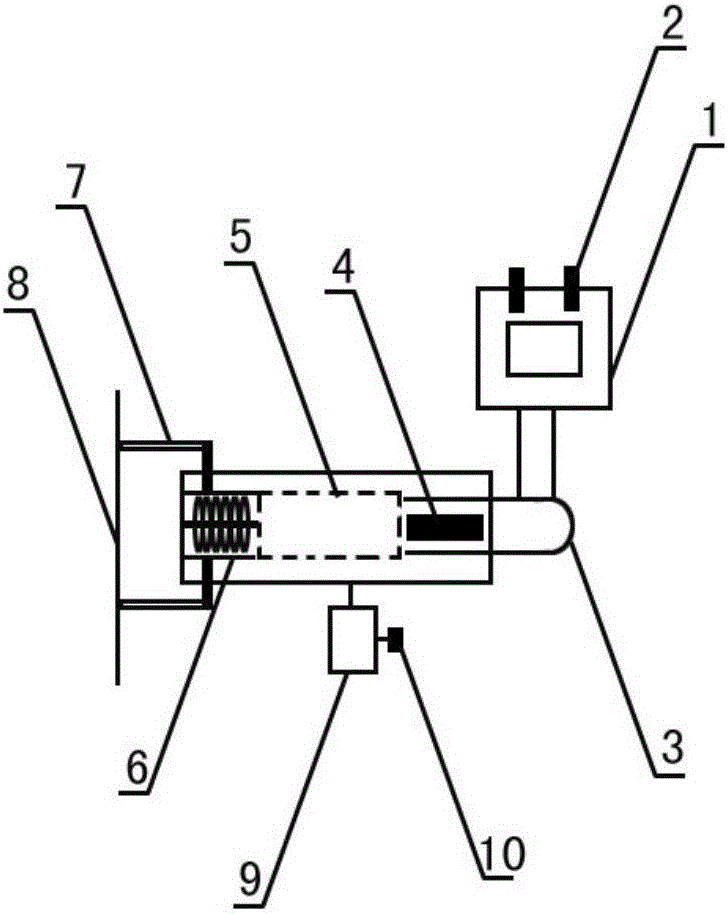

[0012] Embodiment: as shown in the accompanying drawing. A riveting machine with a detection function of the pulling device, including a frame body (1), the frame body (1) is a push-pull model as a whole, and the front end is provided with a connecting base block (2), which is connected to the line position positioning part through a twisting shaft (3) Including the card end device (4), the concave line body card slot (5), the stretching device (6), the movable rod (7) is connected with the hand pushing device (8), and the frame body (1) is installed on the riveted The side of the workbench is parallel to it. After the terminal is riveted, the wiring harness is fixed in the tank body to stretch the hand pushing device (8) for detection, and the corresponding data is transmitted to the display device (9).

[0013] The pulling device of the riveting machine with a detection function is provided with a prompting device (10), which sends a corresponding prompting message when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com