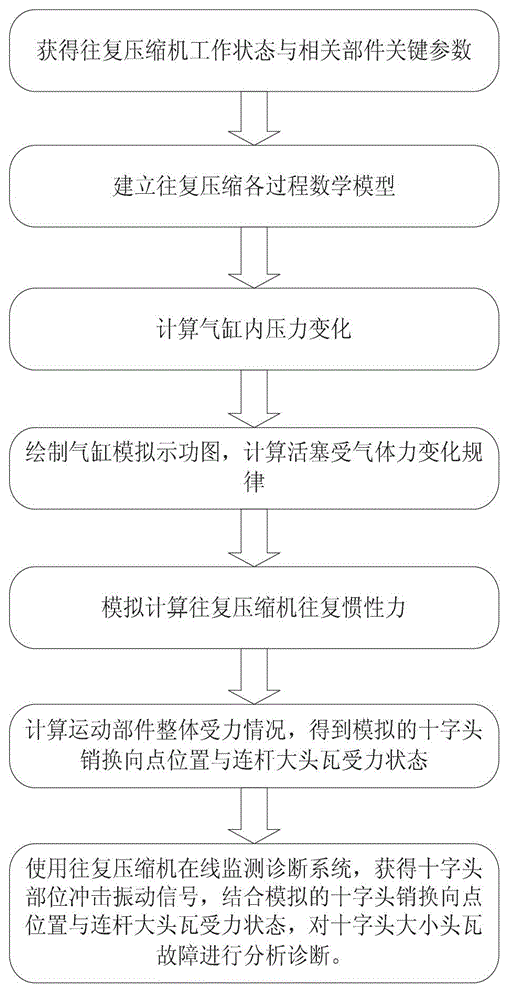

Large and small head tile fault diagnosis method of reciprocated compressor connecting rod based on simulated indicator diagram

A technology of fault diagnosis and connecting rod large end, applied in mechanical equipment, machine/engine, liquid variable capacity machinery, etc., can solve problems such as the inability to draw out dynamic pressure signals, and the inability to effectively diagnose the small end of the connecting rod.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

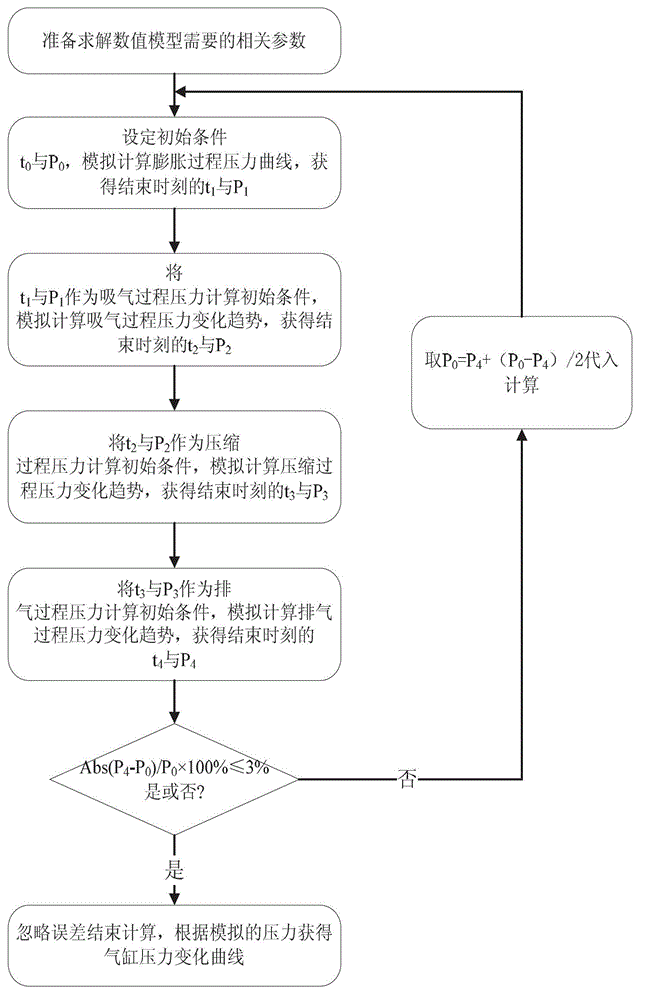

Method used

Image

Examples

Embodiment Construction

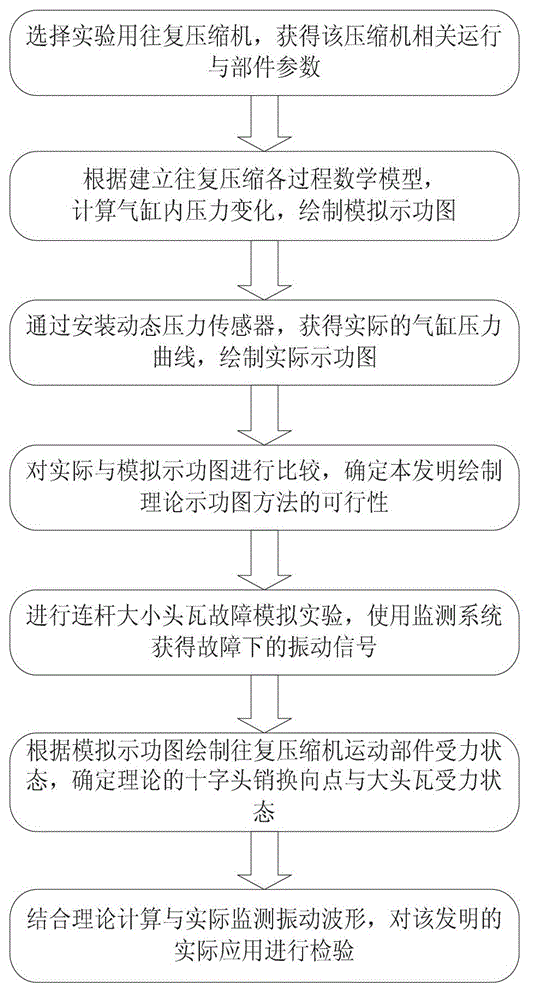

[0051]The present invention selects a reciprocating compressor for the experiment to carry out the example implementation, and the reciprocating compressor model is DW12 / 2, double-acting type, and specific implementation method and result are as follows:

[0052] 1. Obtain the suction and discharge pressure of the reciprocating compressor, the spring stiffness of the suction valve, the pre-compression of the spring, the displacement of the valve plate, the spring stiffness of the exhaust valve, the pre-compression of the spring, the displacement of the valve plate, the pressure area of the valve plate, and the reciprocating compression Engine cylinder clearance volume, piston area, cross-sectional area of piston rod, crankshaft radius parameters;

[0053] The suction and discharge pressures of the reciprocating compressor are used as the working state data of the compressor, which can be obtained through the DCS system of the compressor, denoted as P 吸 ,P 排 .

[0054] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com