Frequency conversion control method and device for oil-well pump combining indicator diagram with working fluid level

A frequency conversion control and dynamometer technology, which is used in pump control, liquid variable capacity machinery, machines/engines, etc., can solve the problems of unsatisfactory energy saving effect and single input of frequency conversion control, achieve significant energy saving effect and overcome measurement errors. and misadjustment, the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

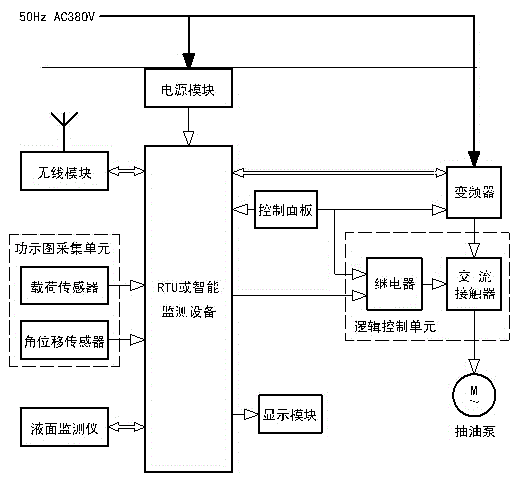

[0020] The schematic diagram of the device structure in this example is as follows figure 1 As shown, it is composed of indicator diagram acquisition unit, liquid level monitor, RTU or intelligent monitoring equipment, frequency converter, control panel, logic control unit, display module, wireless module and power module and other parts.

[0021] The dynamometer acquisition unit is composed of a load sensor and an angular displacement sensor. The load sensor is installed at the donkey head rope hanger to convert the pressure value into an analog value. The angular displacement sensor is installed at the beam bracket of the oil well pump to capture the angle of the beam during the up and down movement of the donkey's head, and convert the angle value into an analog value. The liquid level monitor is installed on the casing of the oil well pump, and is fired by inflating or deflating the gas cylinder to capture the downhole knot wave and liquid level wave, and obtain the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com