Beam pumping unit remote monitoring method and system based on wireless sensor network and TD-SCDMA (Time Division-Synchronization Code Division Multiple Access)

A technology of TD-SCDMA and wireless sensor network, which is applied in the field of remote monitoring of pumping units, can solve the problems of cumulative error, short vulnerable life, low precision, etc., increase data bandwidth and transmission rate, eliminate cumulative error, The effect of reducing communication costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

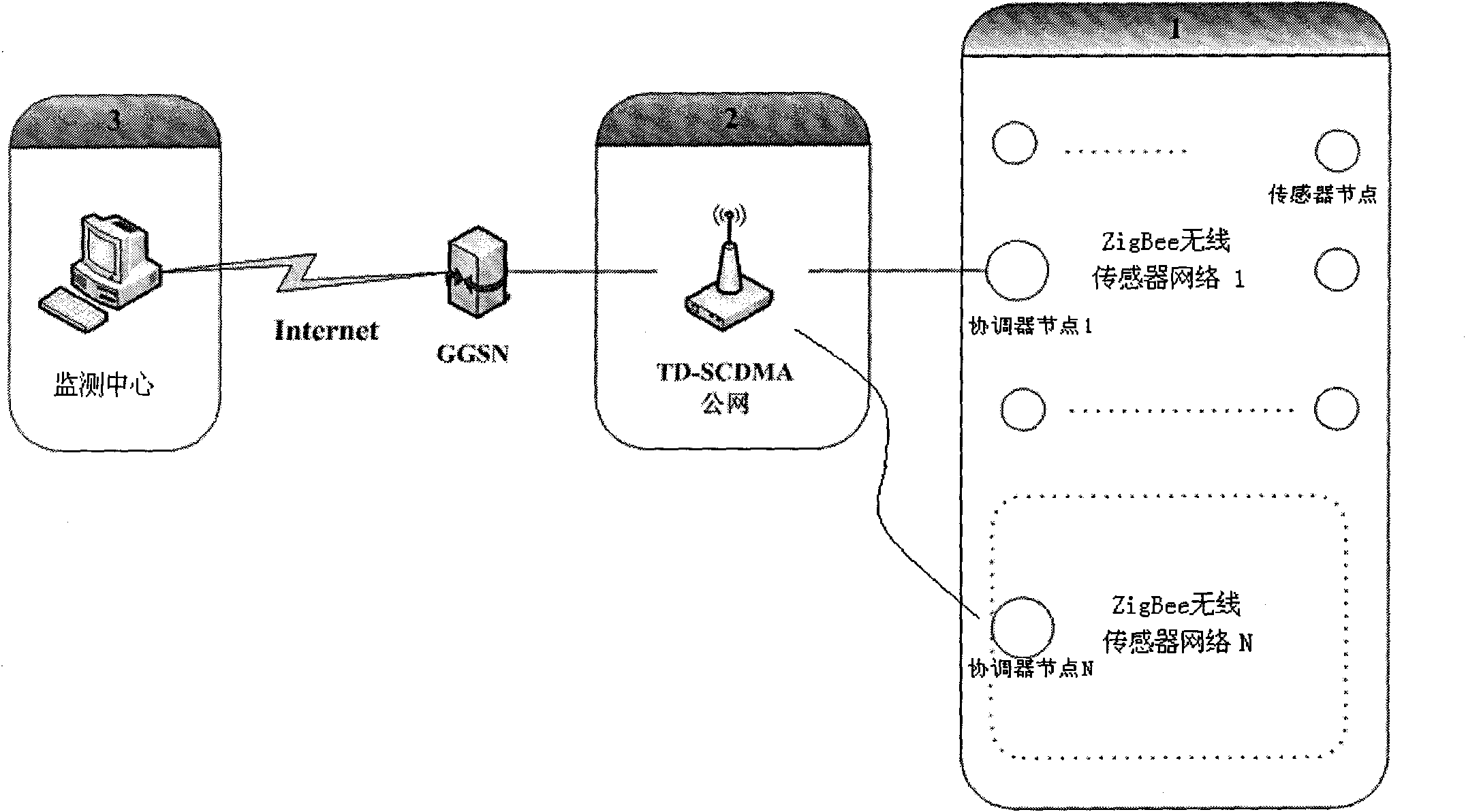

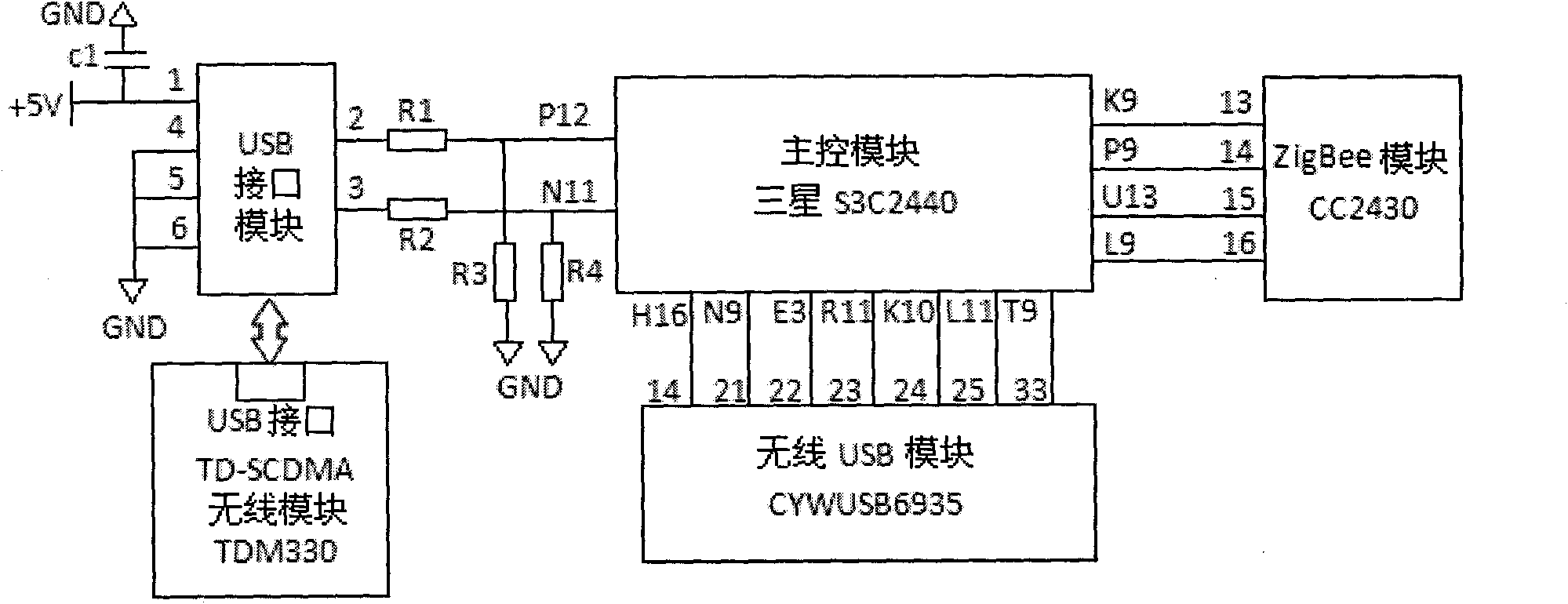

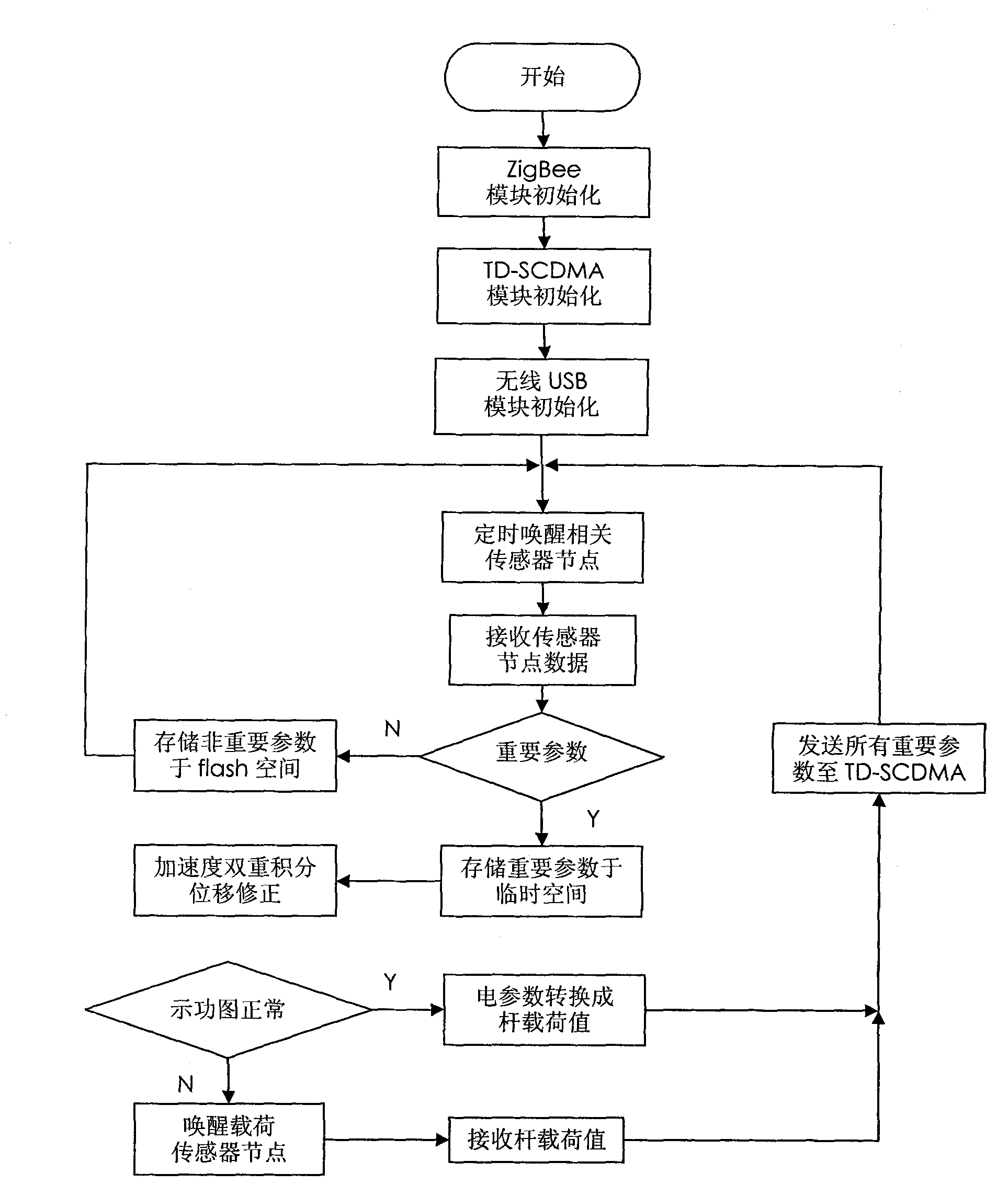

[0033] The remote monitoring method of pumping unit based on wireless sensor network and TD-SCDMA is as follows: the wireless sensor network adopts ZigBee wireless sensor network, the pumping unit monitoring center sends on-site collection instructions, and each sensor node in the ZigBee wireless sensor network collects oil pumping data. The working condition parameters of the machine, and send the collected working condition parameters to the only coordinator node in the ZigBee wireless sensor network. The coordinator node judges whether the received data is an important parameter. If the data is an important working condition parameter, The protocol conversion is performed on the received data, and the converted TD-SCDMA data packet is sent to the TD-SCDMA public network, and the GGSN gateway in the TD-SCDMA public network performs protocol conversion on the data packet again, and the converted TCP The / IP data packet is sent to the pumping unit monitoring center via the Inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com