System for monitoring running of oil extractor in oil field

A monitoring system and pumping unit technology, applied in the direction of total factory control, comprehensive factory control, electrical program control, etc., can solve the abnormal "light/no-load" fault of the drive motor without pumping unit, which is simple and easy, and once High investment costs, underutilization of monitoring devices and other issues, to achieve the effect of strengthening scientific management and efficient production, less workload of operation management/maintenance, and quick recovery of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

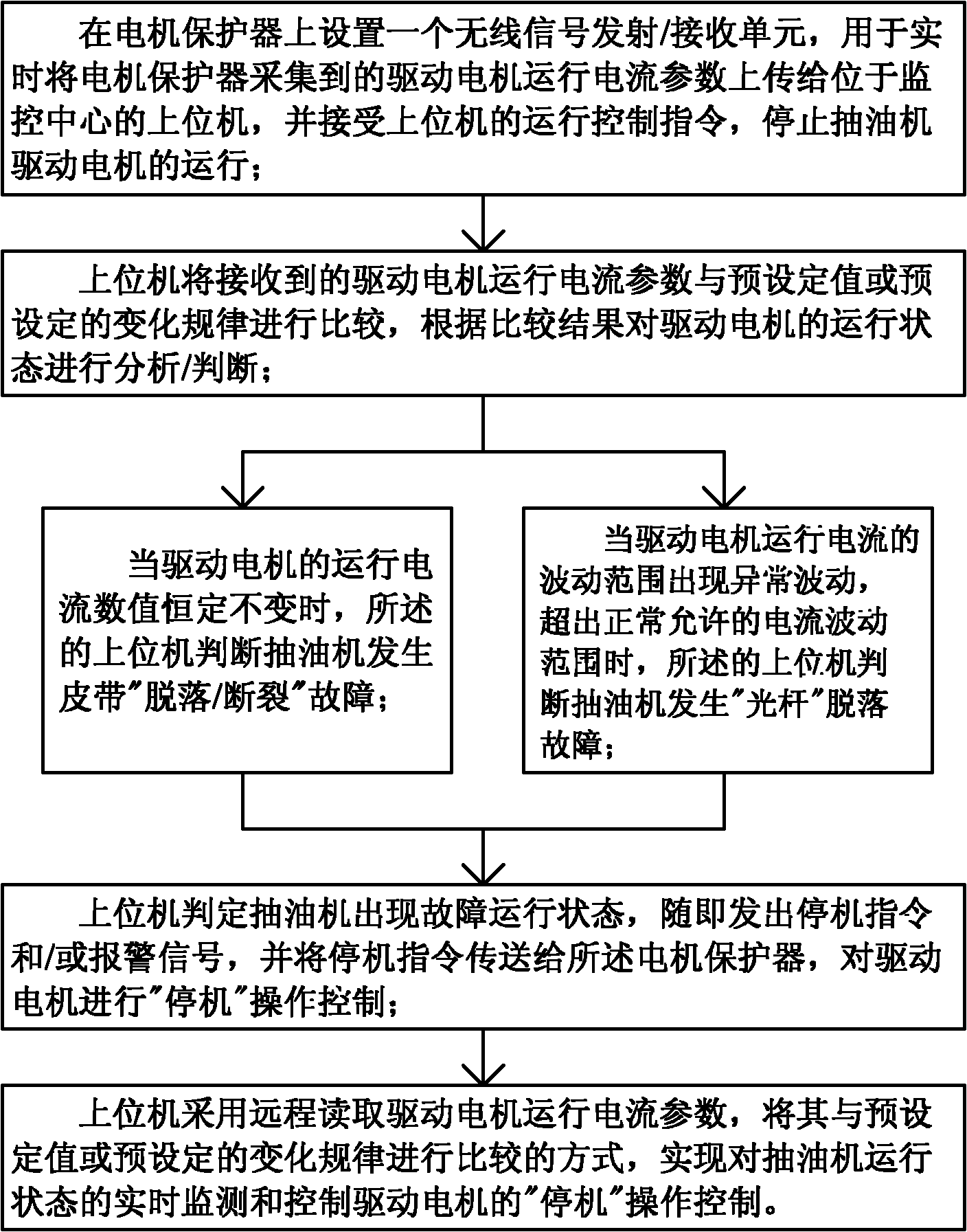

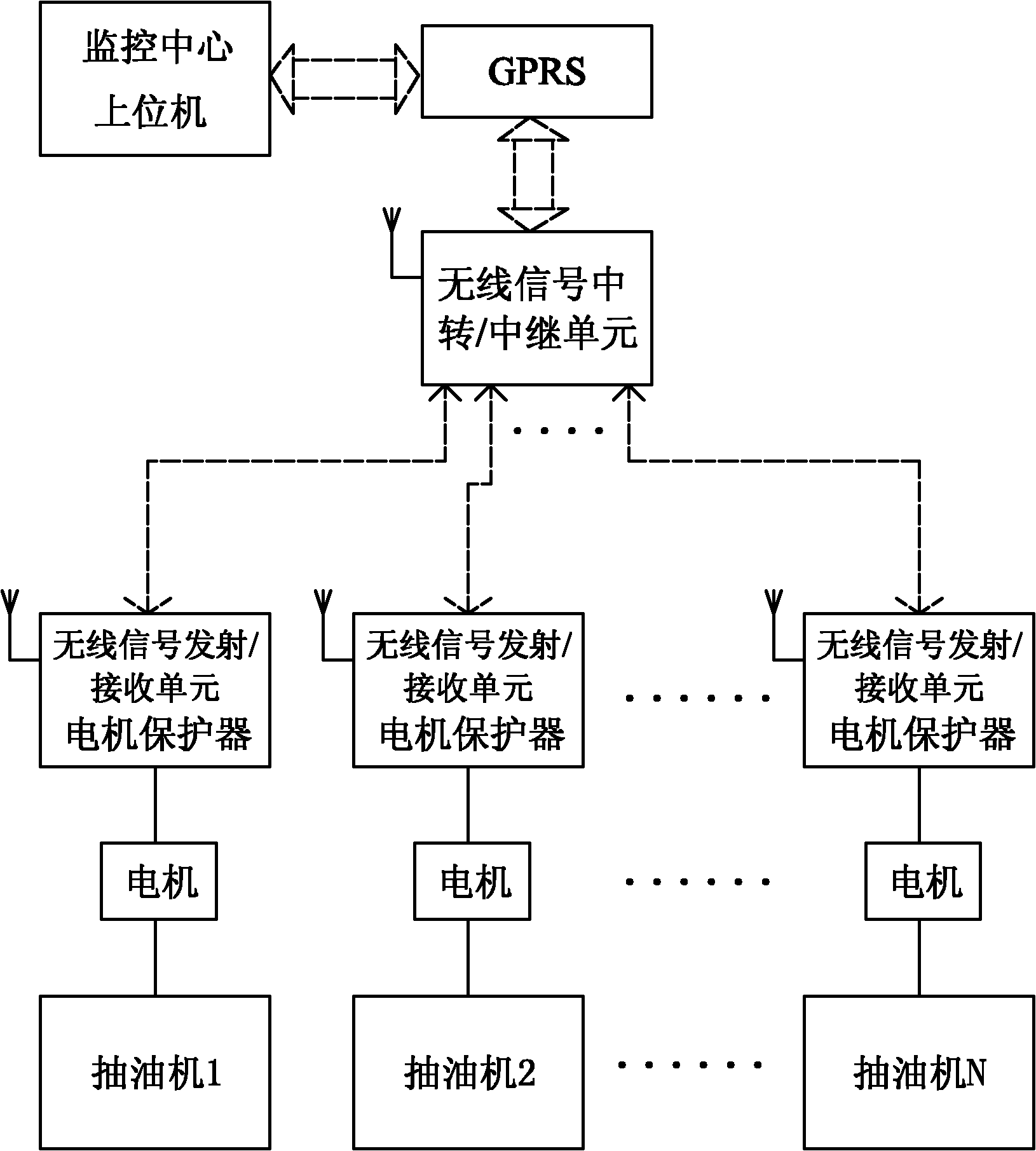

[0032] figure 1 Among them, this monitoring method includes setting a motor protector at the drive motor of the pumping unit and setting a host computer at the centralized monitoring center. The specific monitoring method is:

[0033] A. Set a wireless signal transmitting / receiving unit on the motor protector, which is used to upload the operating current parameters of the driving motor collected by the motor protector to the upper computer located in the monitoring center in real time, and accept the operation control command of the upper computer to stop The operation of the drive motor of the pumping unit;

[0034] B. The upper computer compares the received operating current parameters of the driving motor with the preset value or the preset change rule, and analyzes / judgments the operating state of the driving motor according to the comparison result;

[0035] C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com