Indicator diagram-based oil pumping machine regulating and controlling method

A technology for pumping units and pumping unit wells, which is applied in the field of intelligent automatic control of pumping units, can solve problems such as limitation and inability to realize closed-loop control, and achieve the effects of reducing power consumption, optimizing operating parameters, and improving system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

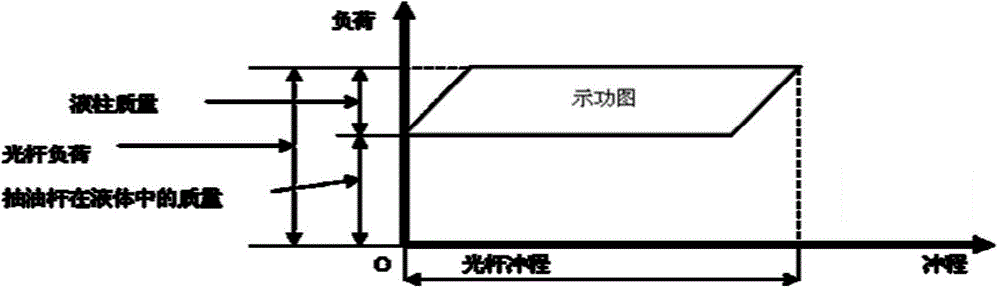

[0014] like figure 1 As shown, the uphole stroke of the pumping unit is due to the closing of the floating valve and the opening of the fixed valve. The static load of the suspension point mainly includes the mass of the sucker rod in the fluid, the mass of the liquid column above the piston, and the force of the tubing pressure on the piston, minus the sinking The reaction force of the liquid on the piston, minus the reaction force of the casing pressure on the piston. On the downstroke, since the floating valve is opened and the fixed valve is closed, the static load on the suspension point is only the mass of the sucker rod string in the fluid.

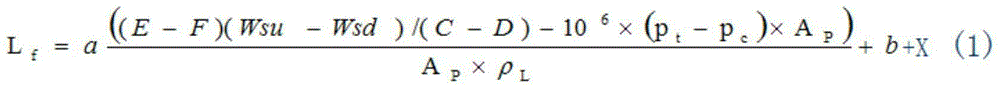

[0015] From this, it can be concluded that the difference between the upper and lower static loads is the force of the mass of the liquid column above the piston and the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com