Air knife pressure real-time optimization control method and system in galvanizing process

A technology of optimized control and air knife pressure, applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problems of slow correction of coating thickness deviation, difficulty in establishing a system model, overshoot of control quantity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example. The meaning of each symbol among the present invention is referring to the following table:

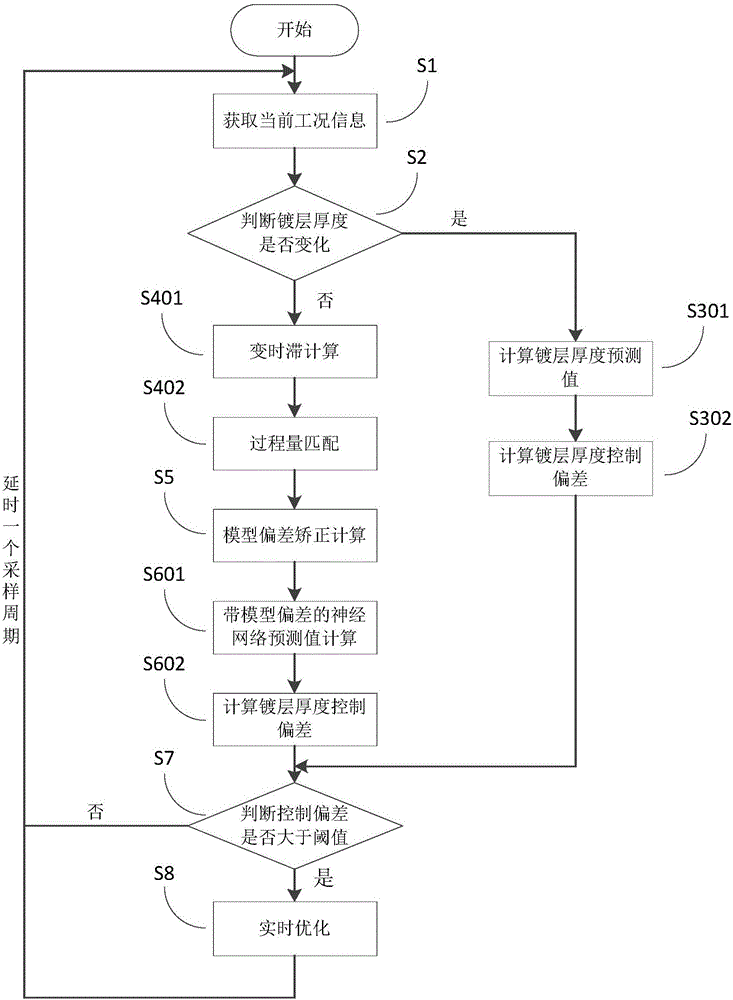

[0090] The embodiment of the present application provides a method for real-time optimal control of air knife pressure in the galvanizing process, such as figure 1 shown, including the following steps:

[0091] S1. Obtain the working condition information at the current moment, including air knife distance D(t), air knife pressure P(t), production line speed S(t), coating thickness measurement value CW_act(t) and coating thickness setting value CW_set( t);

[0092] S2, determine whether formula (1) is established, if yes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com