Automatic control system and method for nodular cast iron pipe production process

An automatic control system and ductile iron pipe technology, applied in the field of metal casting, can solve the problems of mixed numbers of ductile iron pipes, unsatisfactory, difficult manual prevention, etc., to achieve the effect of optimizing operating parameters and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

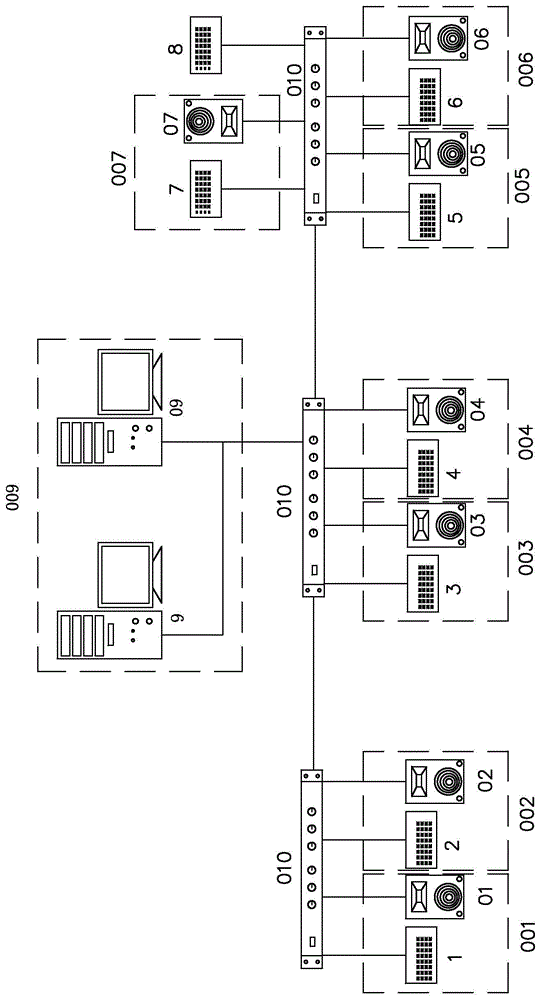

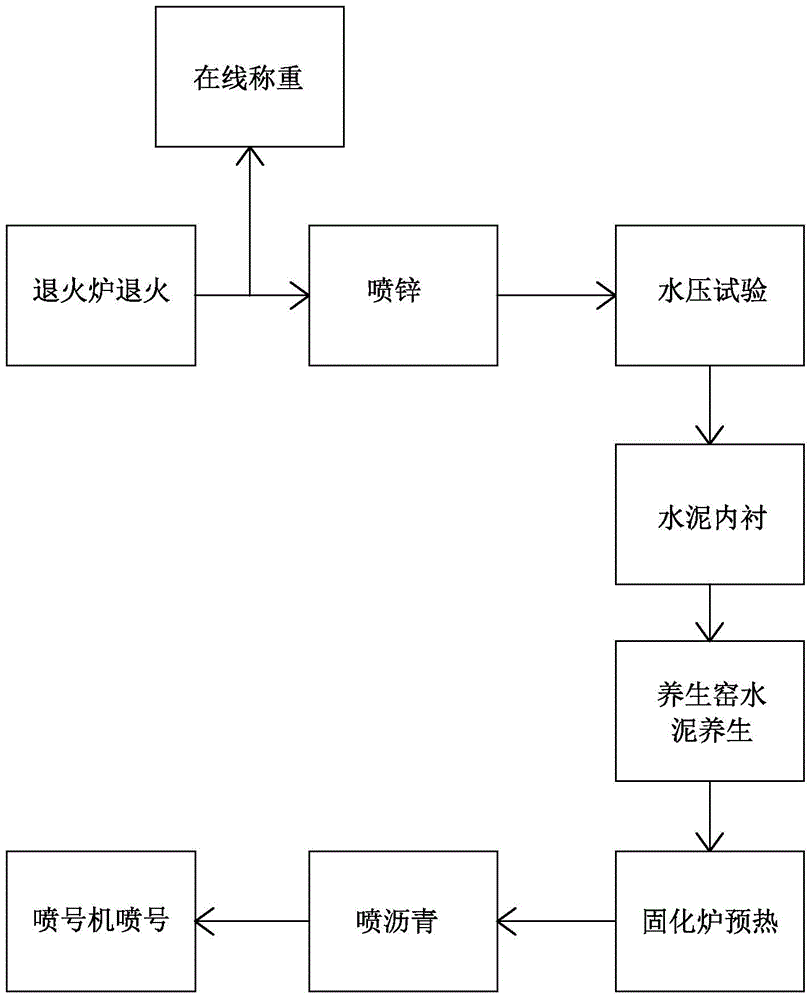

[0033] figure 1 It is an automatic control system for the production process of ductile iron pipes of the present invention, including an annealing furnace area 001, a zinc spraying area 002, a water pressure area 003, a cement lining area 004, a health kiln area 005, an asphalt spraying area 006, and a curing furnace area 007, It also includes tube RFID electronic tags, Ethernet interface 010, server 009; annealing furnace area 001, zinc spraying area 002, cement lining area 004, health kiln area 005, asphalt spraying area 006, and curing furnace area 007 through Ethernet The interface 010 is connected to the server 009, and the tube RFID electronic tag is installed on the tube for storing tube information;

[0034] When the ball tube passes through the annealing furnace area (001), the zinc spray area (002), and the water pressure area (003), the RFID electronic tag is placed in the straight pipe section near the socket side of the ball tube; the ball tube passes through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com