Nodular cast iron pipe production process information tracking method and system implementing the method

A ductile iron pipe and production process technology, applied in the field of metal casting, can solve problems such as manual marking, and achieve the effect of optimizing operating parameters and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

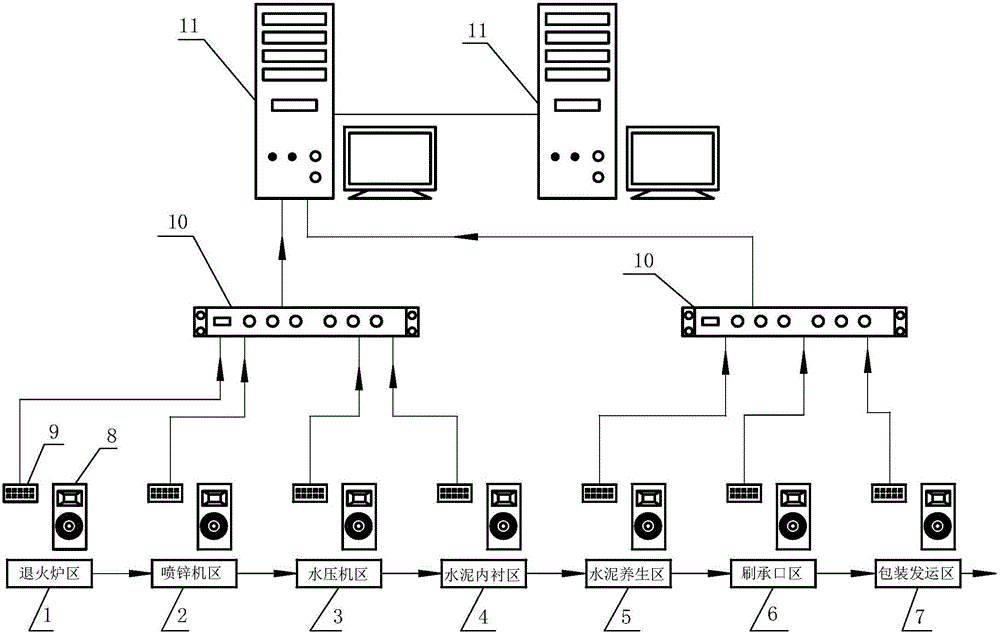

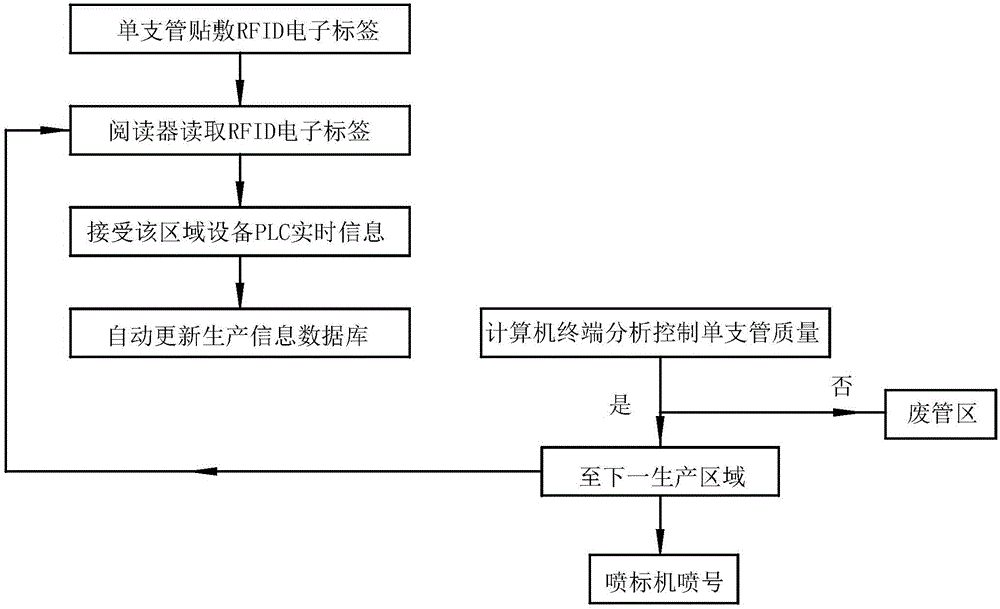

[0028] Such as figure 1 with figure 2 As shown, the information tracking method for the production process of ductile iron pipes of the present invention, each ductile iron pipe is pasted with an RFID electronic tag and then enters the production area. The writer 9 obtains information by reading the high-frequency signal of the RFID electronic tag. The production area includes: annealing furnace area 1, zinc spraying machine area 2, hydraulic machine area 3, cement lining area 4, cement health preservation area 5, brush bearing Port area 6 and packaging and shipping area 7; there is a Computer terminal 8 and a reader / writer 9, when the ductile iron pipe enters annealing furnace area 1, zinc spraying machine area 2, hydraulic machine area 3, cement lining area 4, cement health maintenance area 5, brush socket area 6 and packag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com