Patents

Literature

766 results about "Pumpjack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

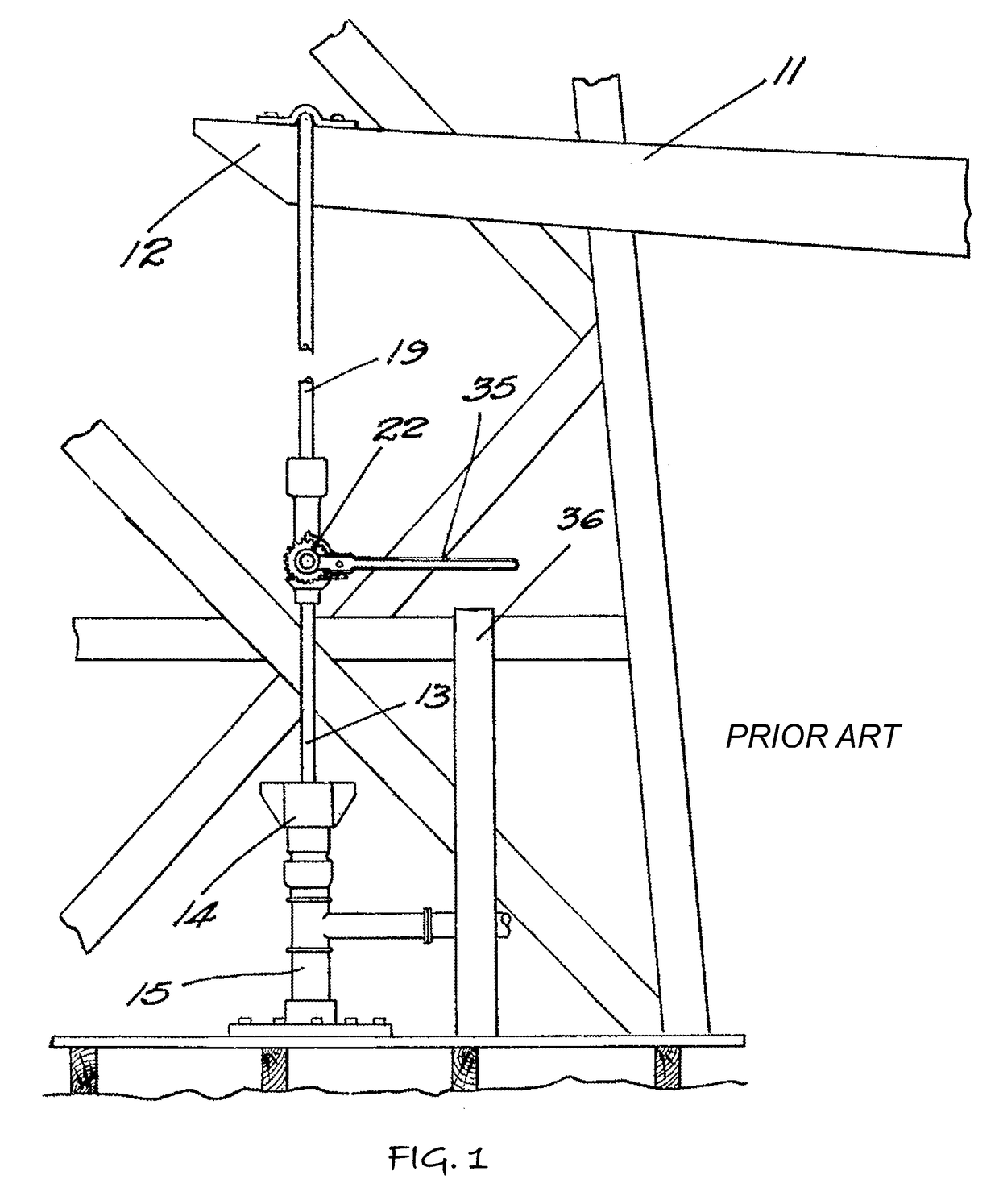

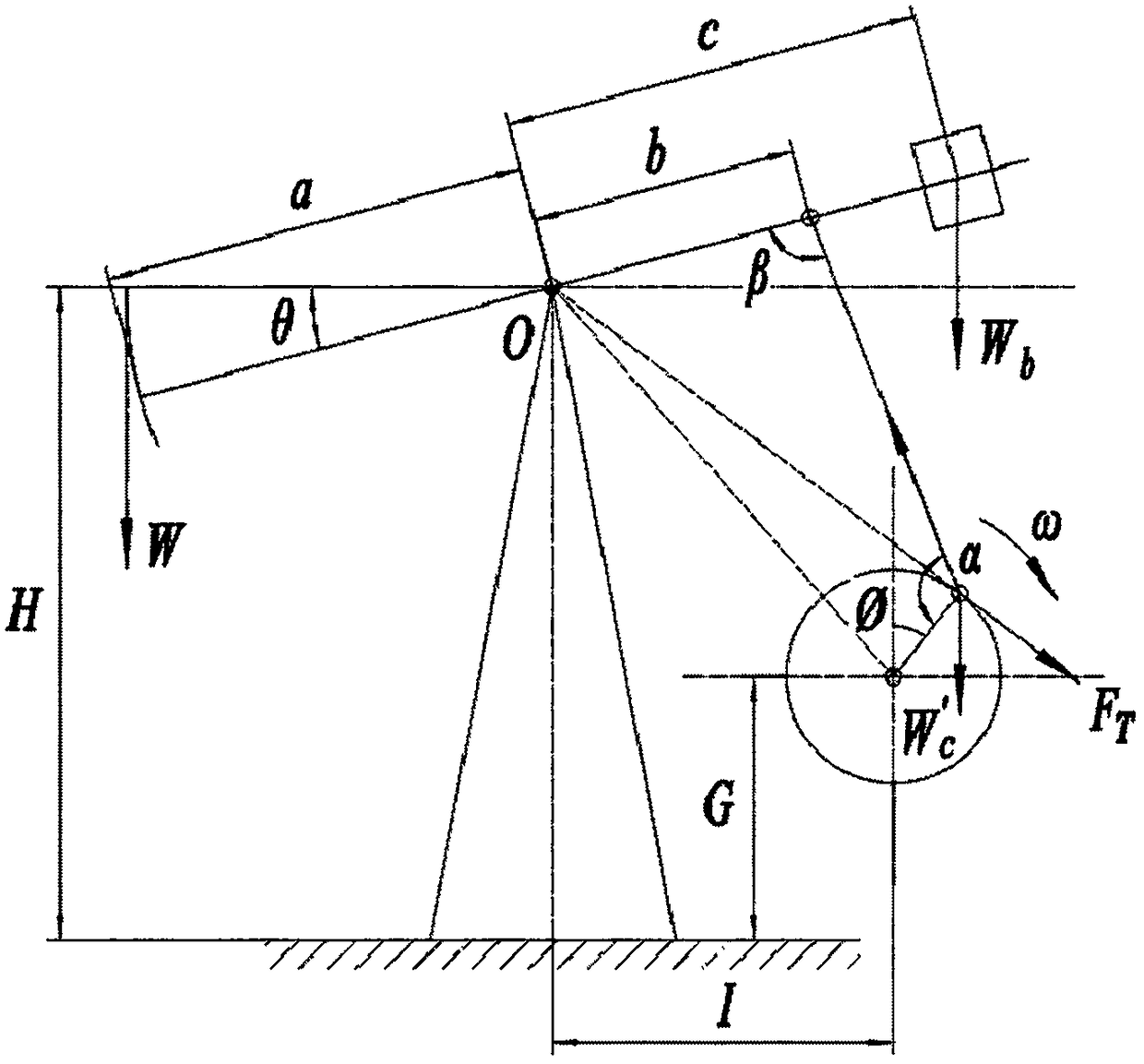

A pumpjack is the overground drive for a reciprocating piston pump in an oil well. It is used to mechanically lift liquid out of the well if not enough bottom hole pressure exists for the liquid to flow all the way to the surface. The arrangement is commonly used for onshore wells producing little oil. Pumpjacks are common in oil-rich areas.

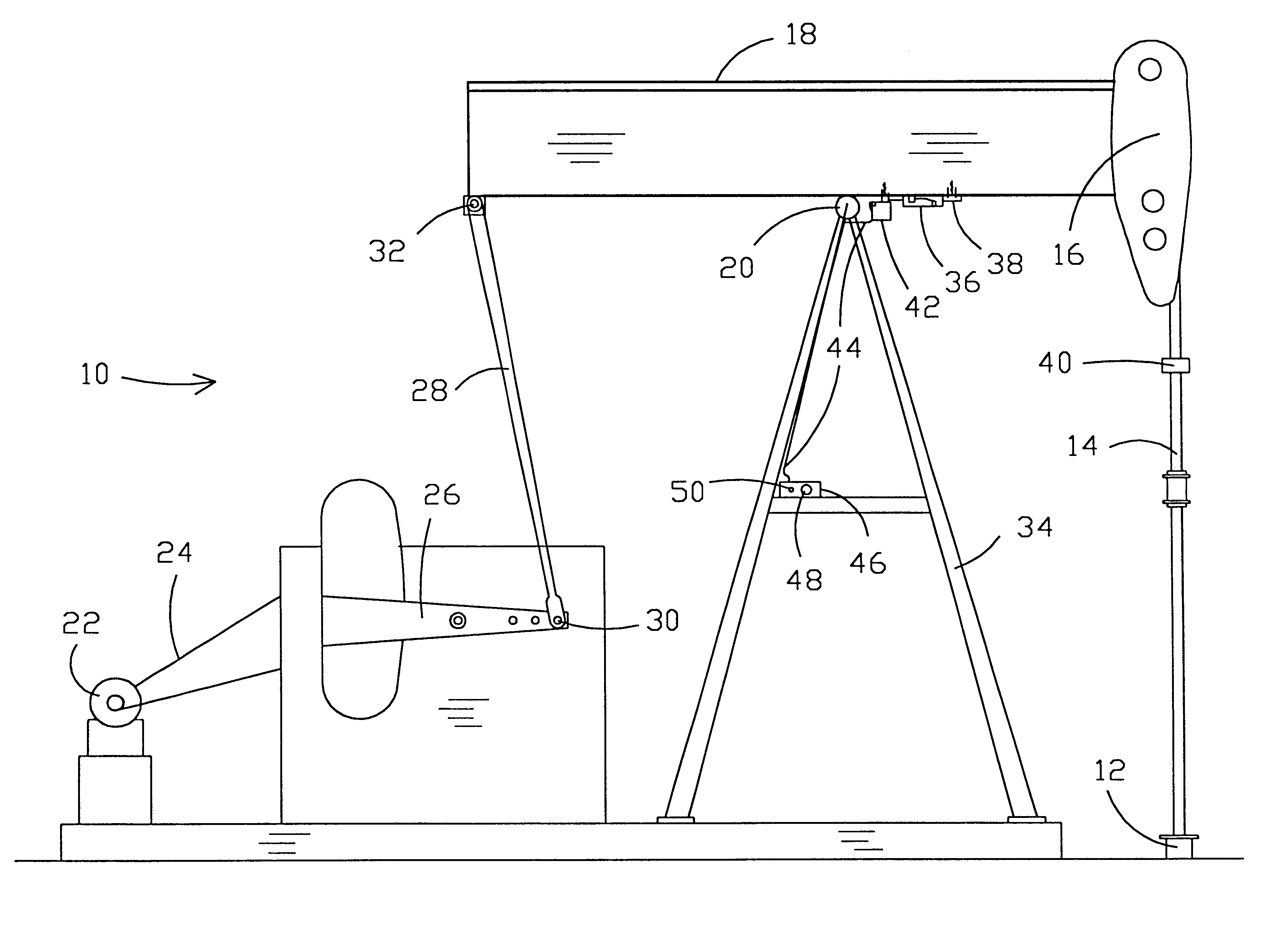

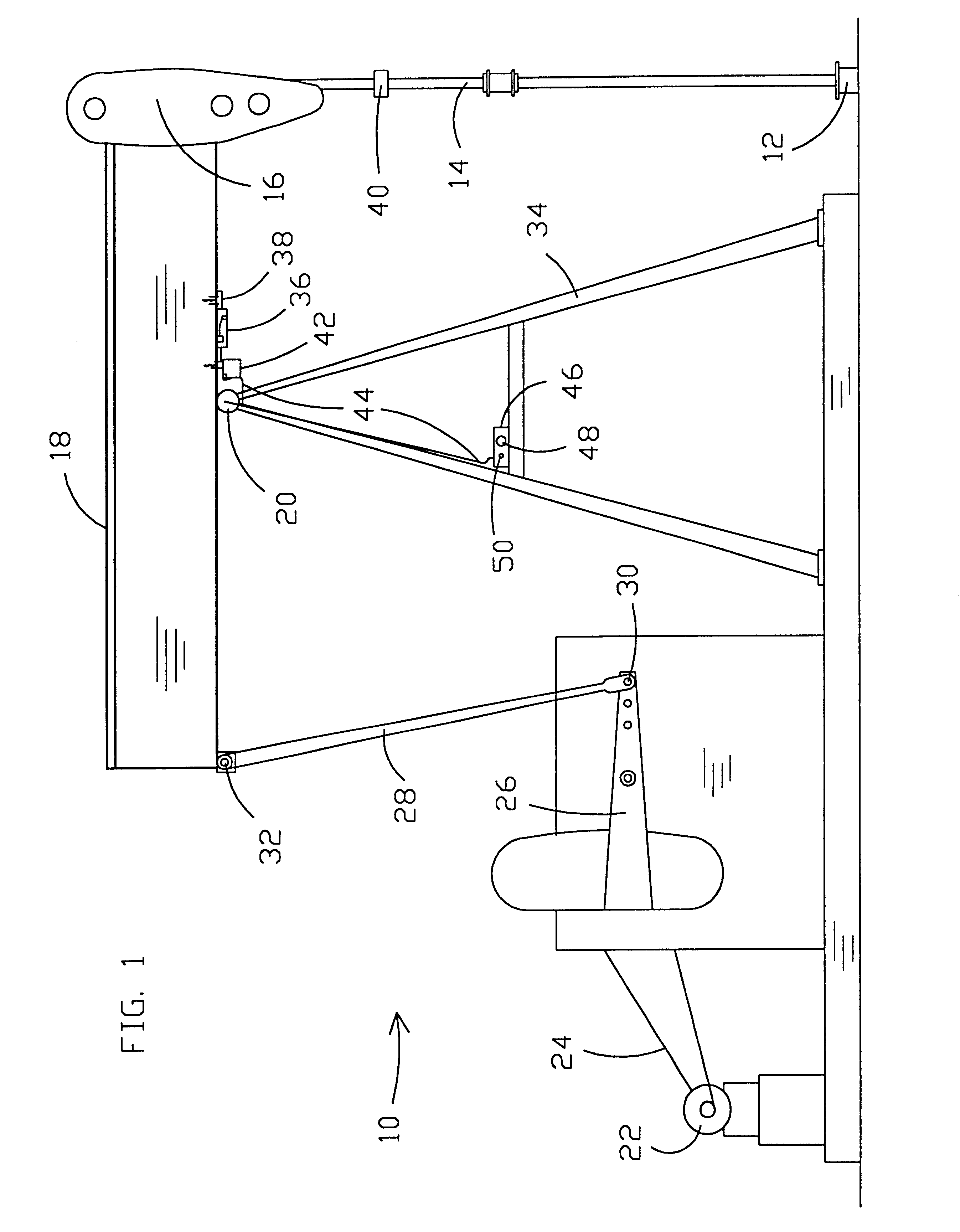

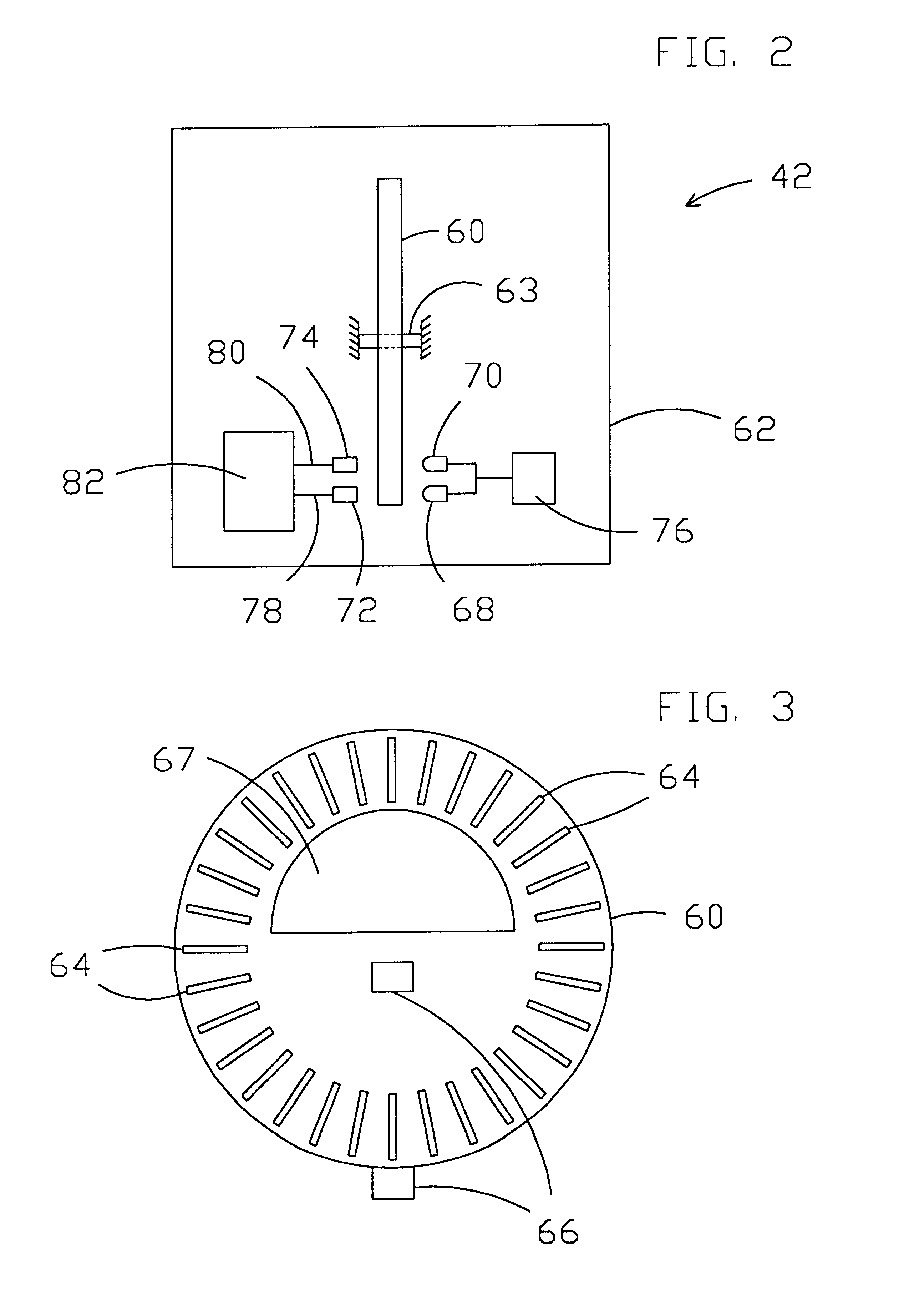

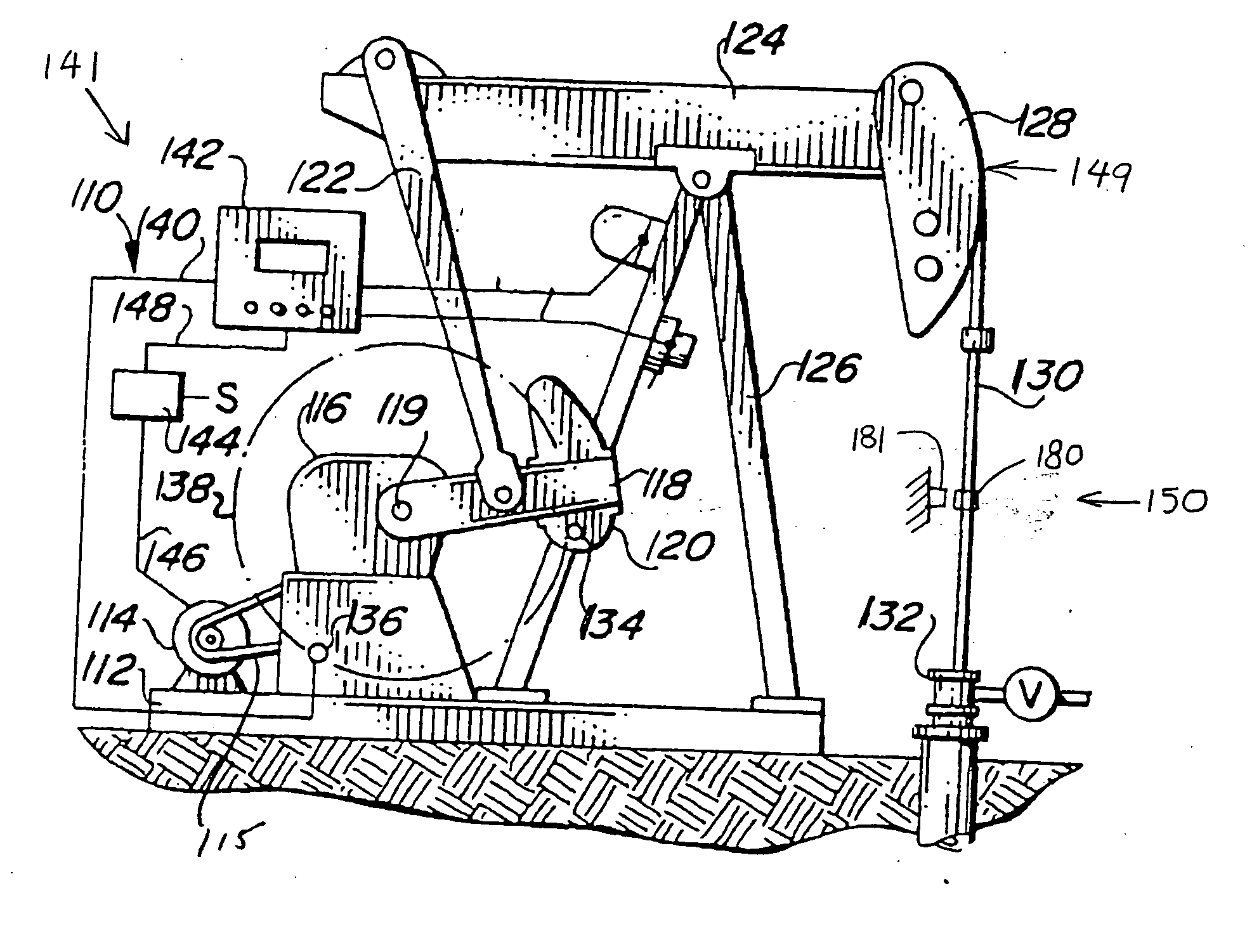

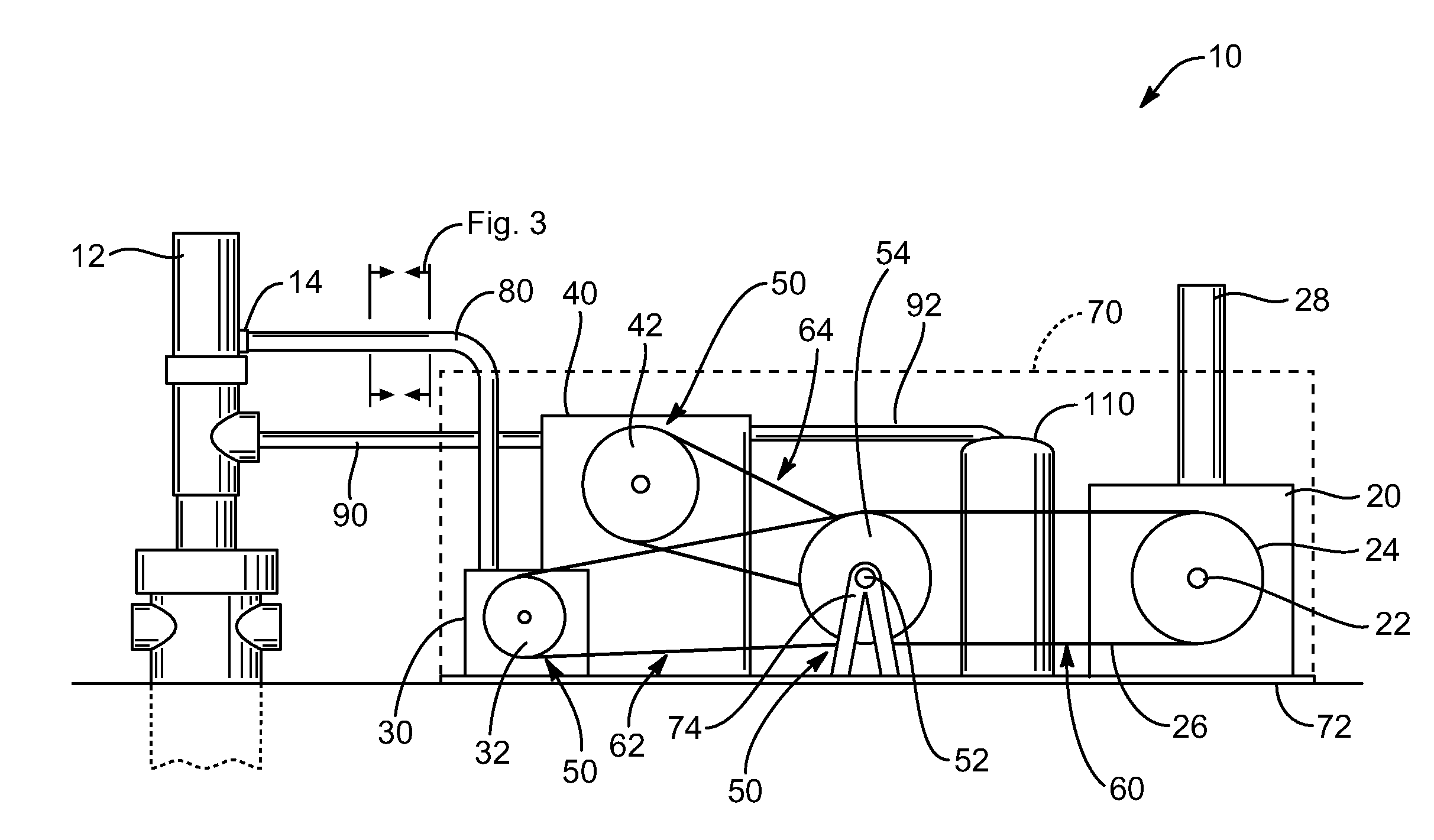

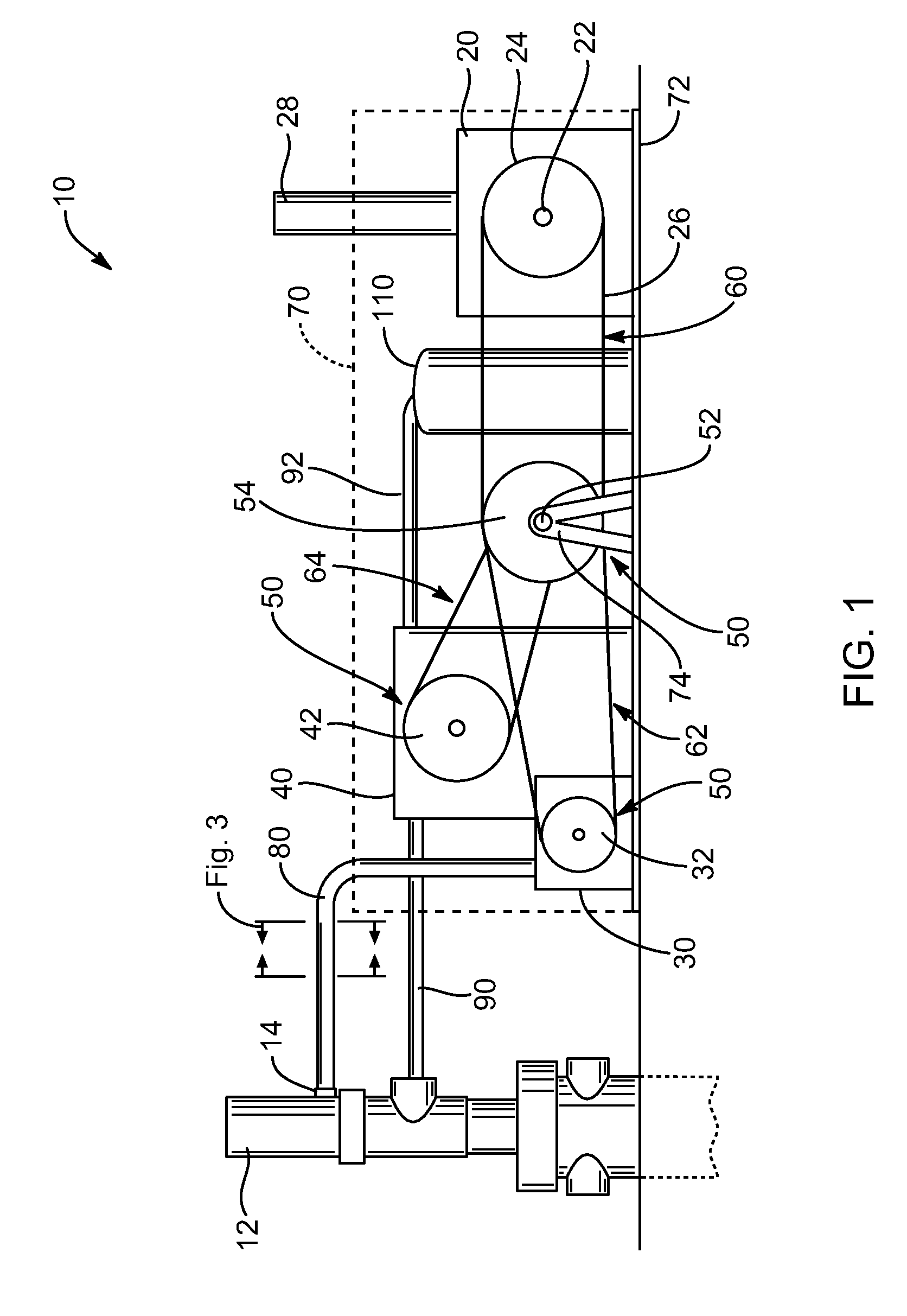

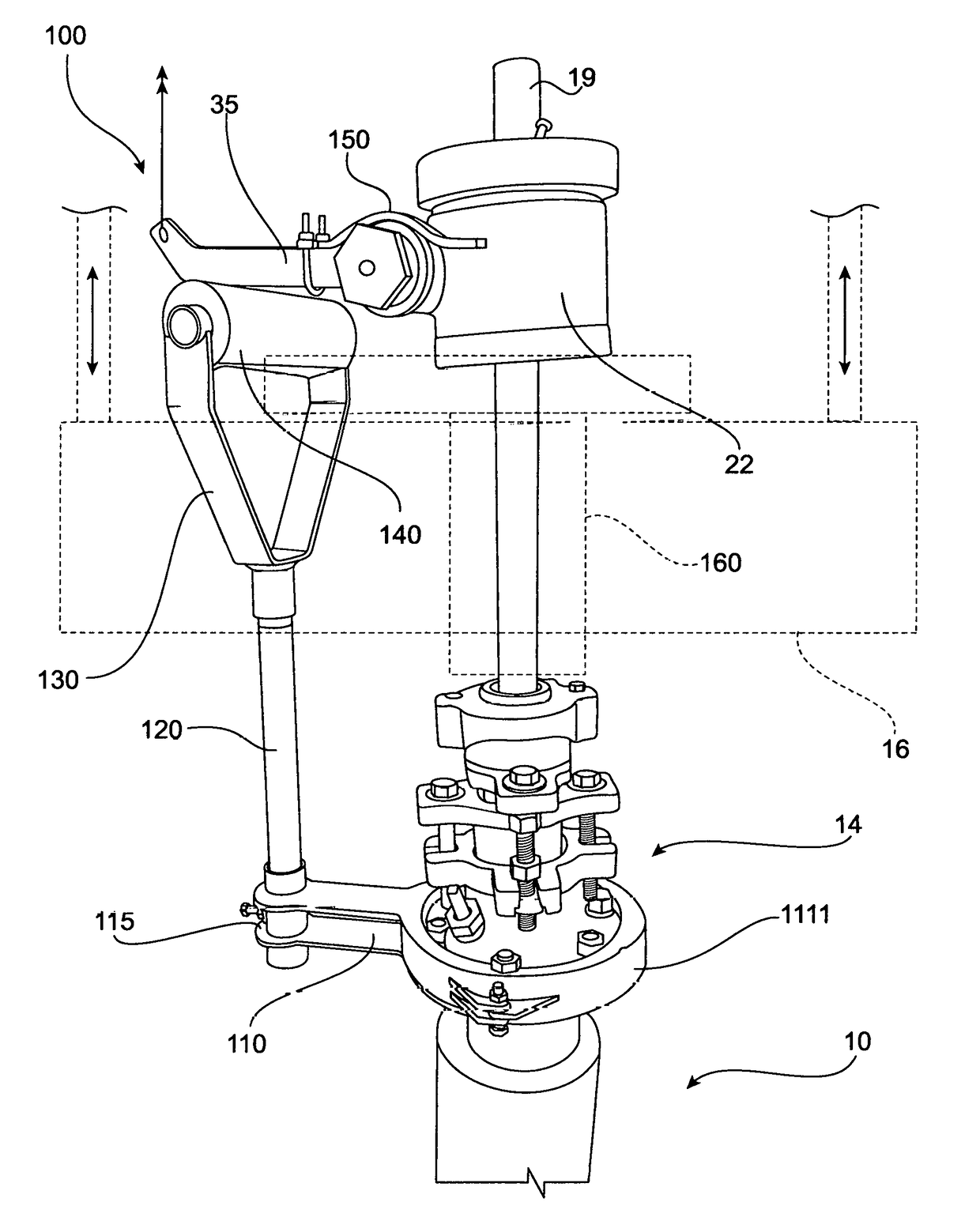

Pumpjack dynamometer and method

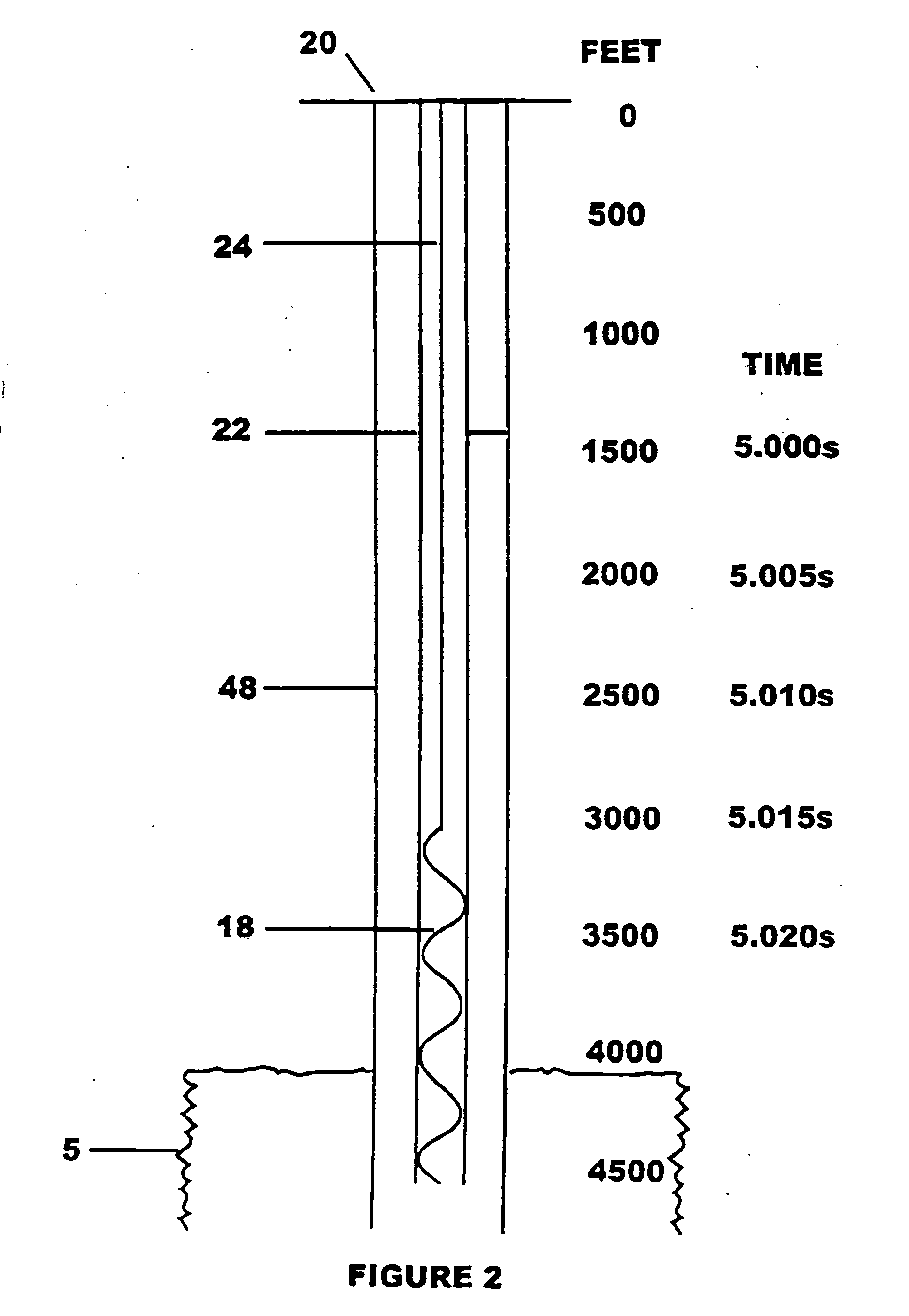

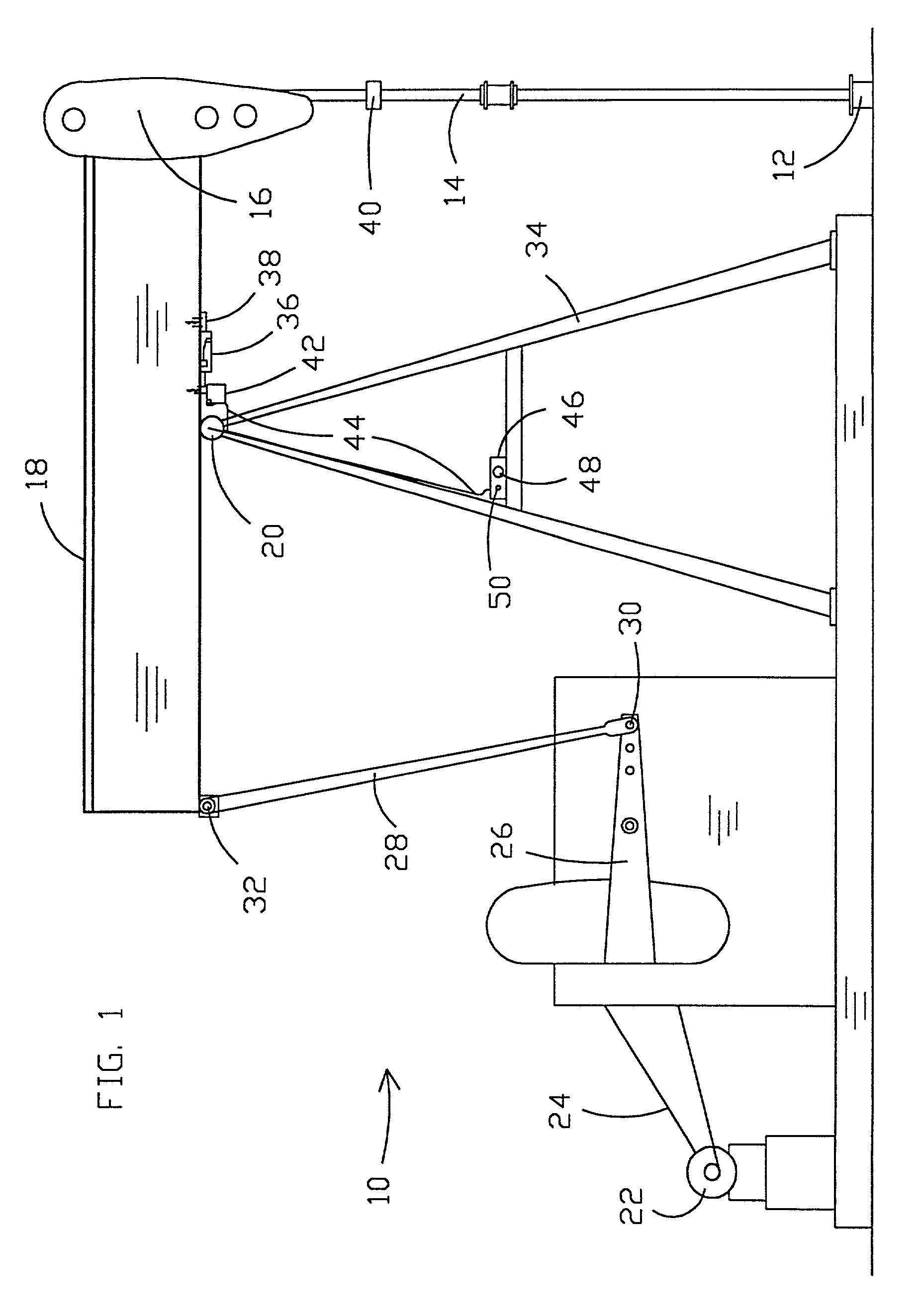

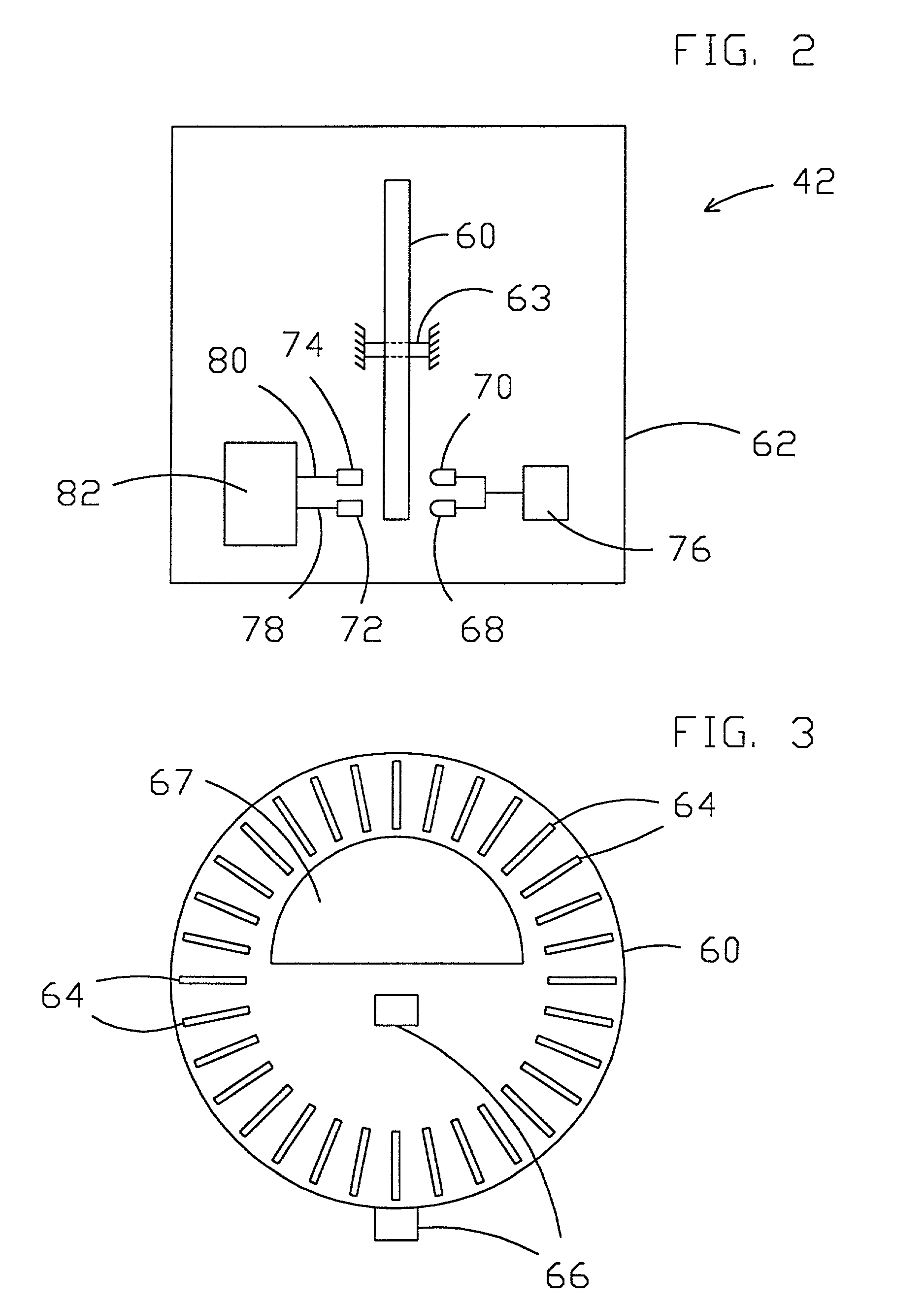

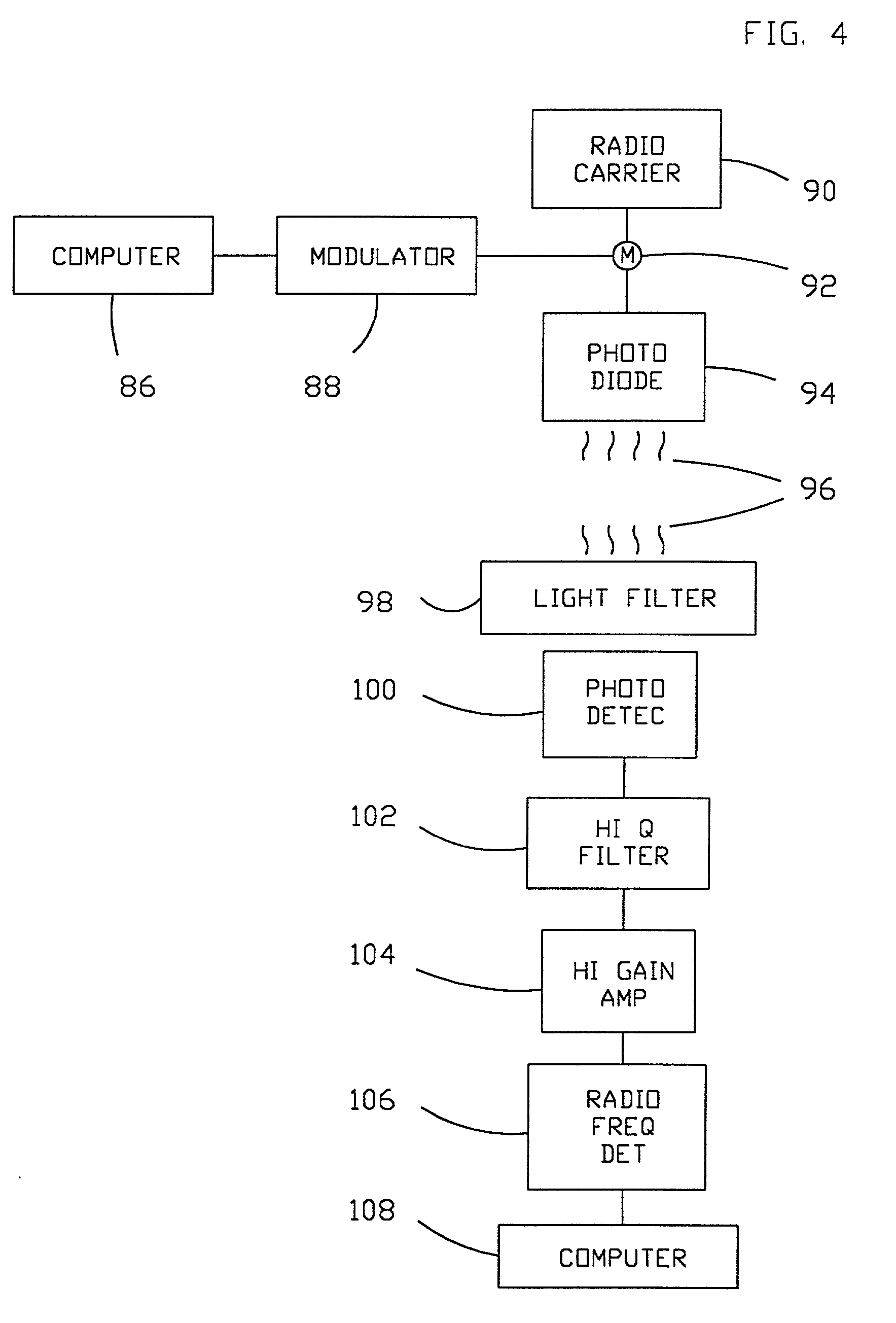

A dynamometer readout (42, 46) and method is disclosed for obtaining dynamometer information (110) related to pumpjacks (10). For this purpose, a change of pivotal direction of the walking beam (18) may be detected by processor (82) utilizing an encoder component (60) with spaced slots (64) therein and light signal devices (68, 70, 72, 74) positioned to have a spacing different from that of the spacing of the slots (64). Software techniques filter out effects of stray mechanical vibrations. An infrared transceiver (46, 50, 100) of a preferred embodiment includes a radio frequency carrier generator (90) and modulator (88) that produces an infrared signal receivable by a low cost consumer radio receiver. The radio frequency modulation technique for infrared signals (96) and related filtering (98, 102, 104) condition formatted infrared signals for utilization in daylight and through a car window for drive-by downloading of data to second computer (108). A sensor (163) may be substituted for the encoder. A sensor (163) may include a moveable light interrupter, such as a ball (160) or a bubble (260), moveably disposed within the sensor. The sensor may also provide one or more apertures (180) for transmitting light through the apertures.

Owner:MILLS MANUEL D

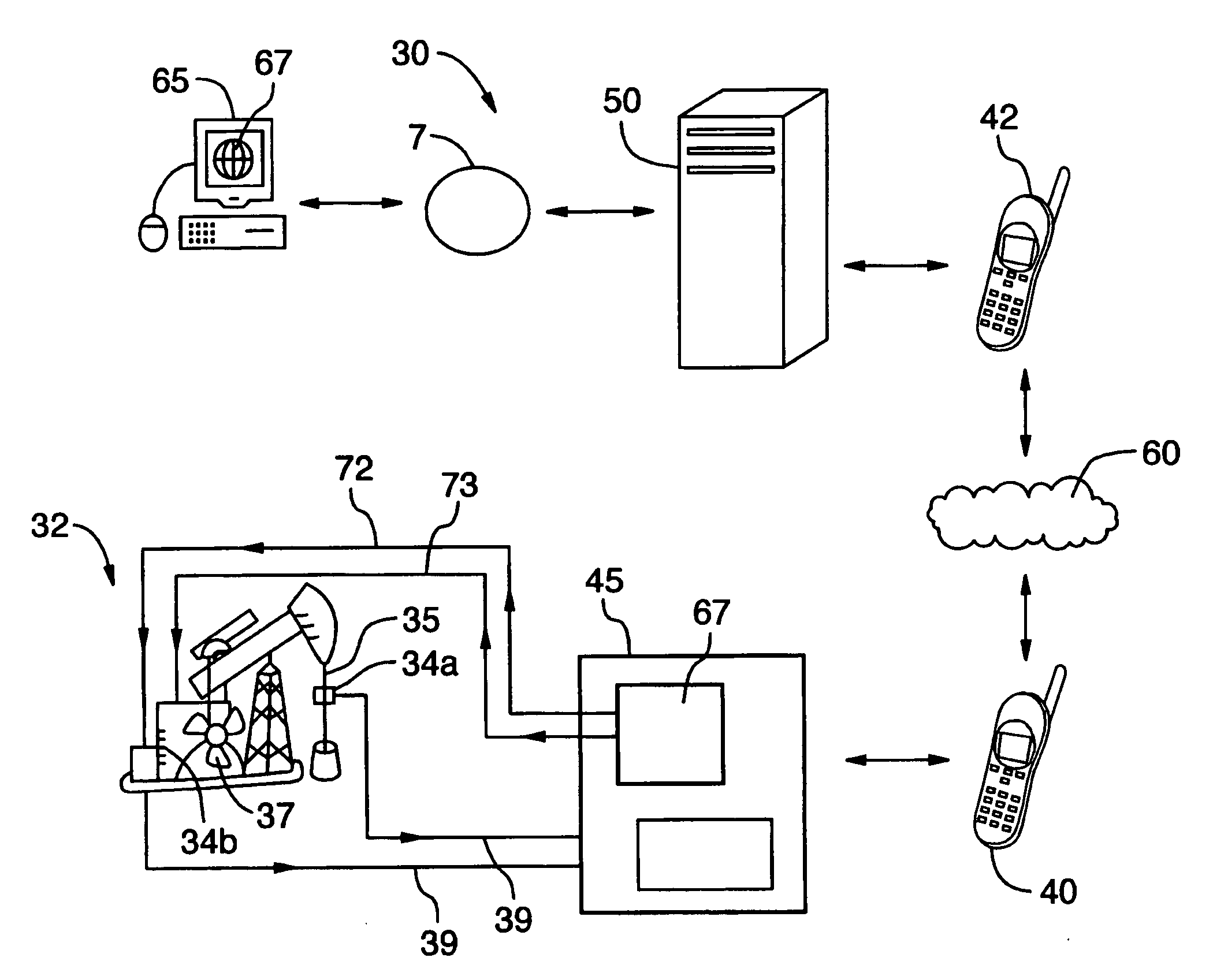

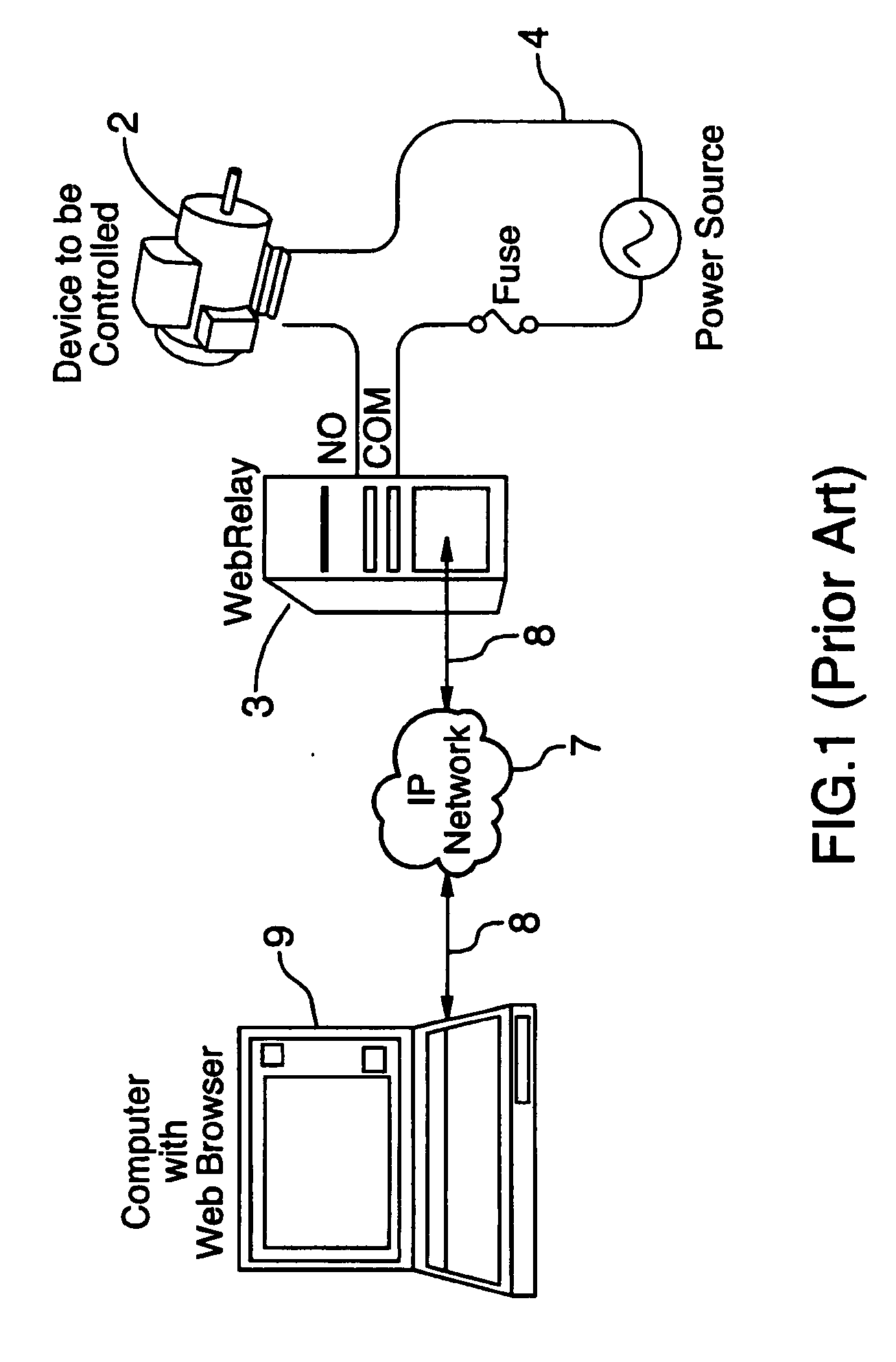

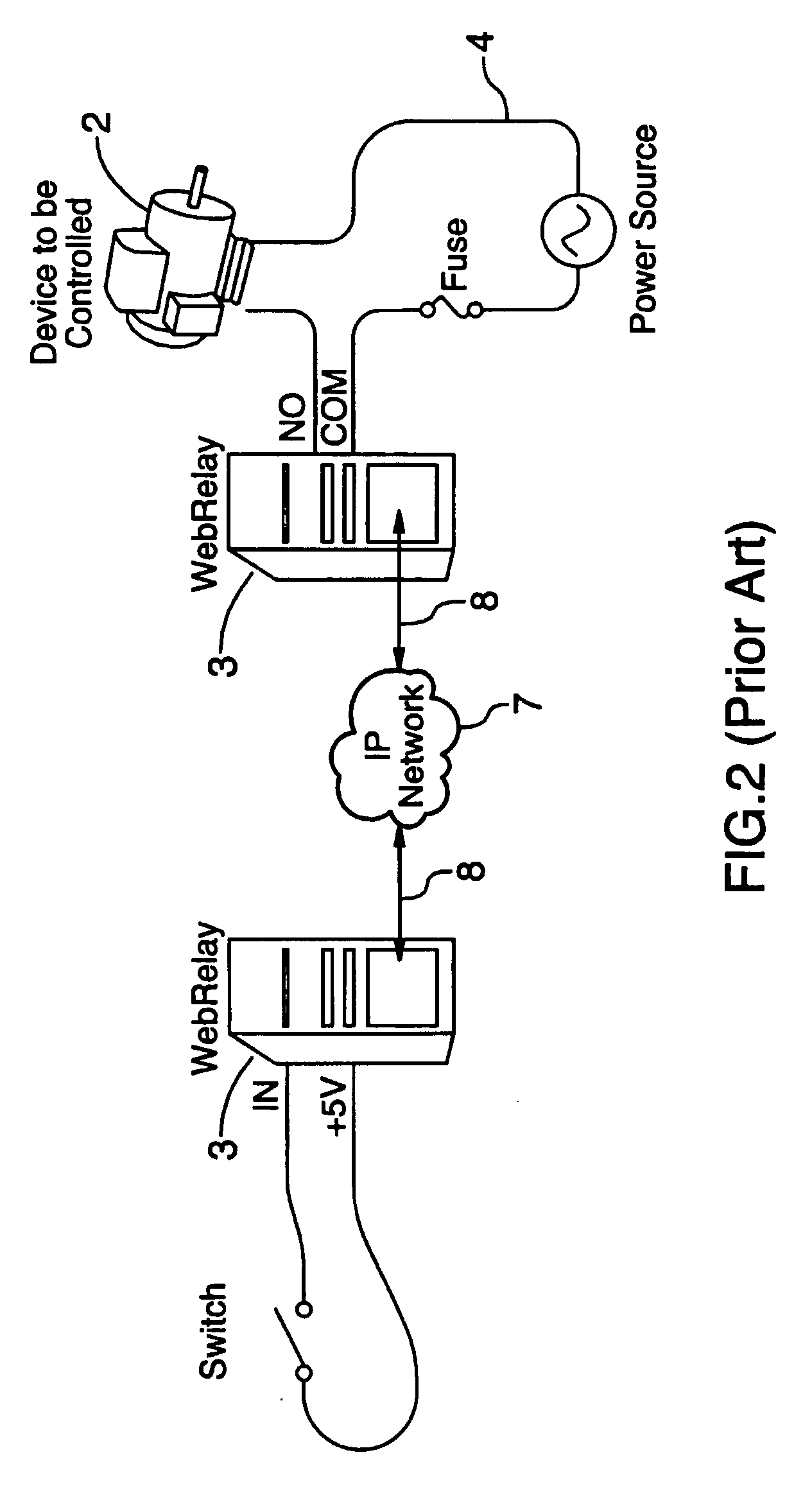

System and method for remotely monitoring and controlling pump jacks

InactiveUS20100228398A1The process is simple and effectiveError detection/correctionDigital data processing detailsDigital dataModem device

A simplified system and method for remotely monitoring and optionally further controlling pumpjack operating parameters of a pumpjack located at a distant site but within wireless cell phone station reception. Sensors situated on a pumpjack monitor and create analog output of operational conditions of the pumpjack. Digitizing means digitize the analog output of the sensors to digital data, and modem means transmit the digital data via a wireless cellular network to a network server. A user's computer communicates with the network server via the internet, and accesses the digital data to obtain information regarding the operational conditions of the pumpjack.

Owner:RIEMER POWERS CORP

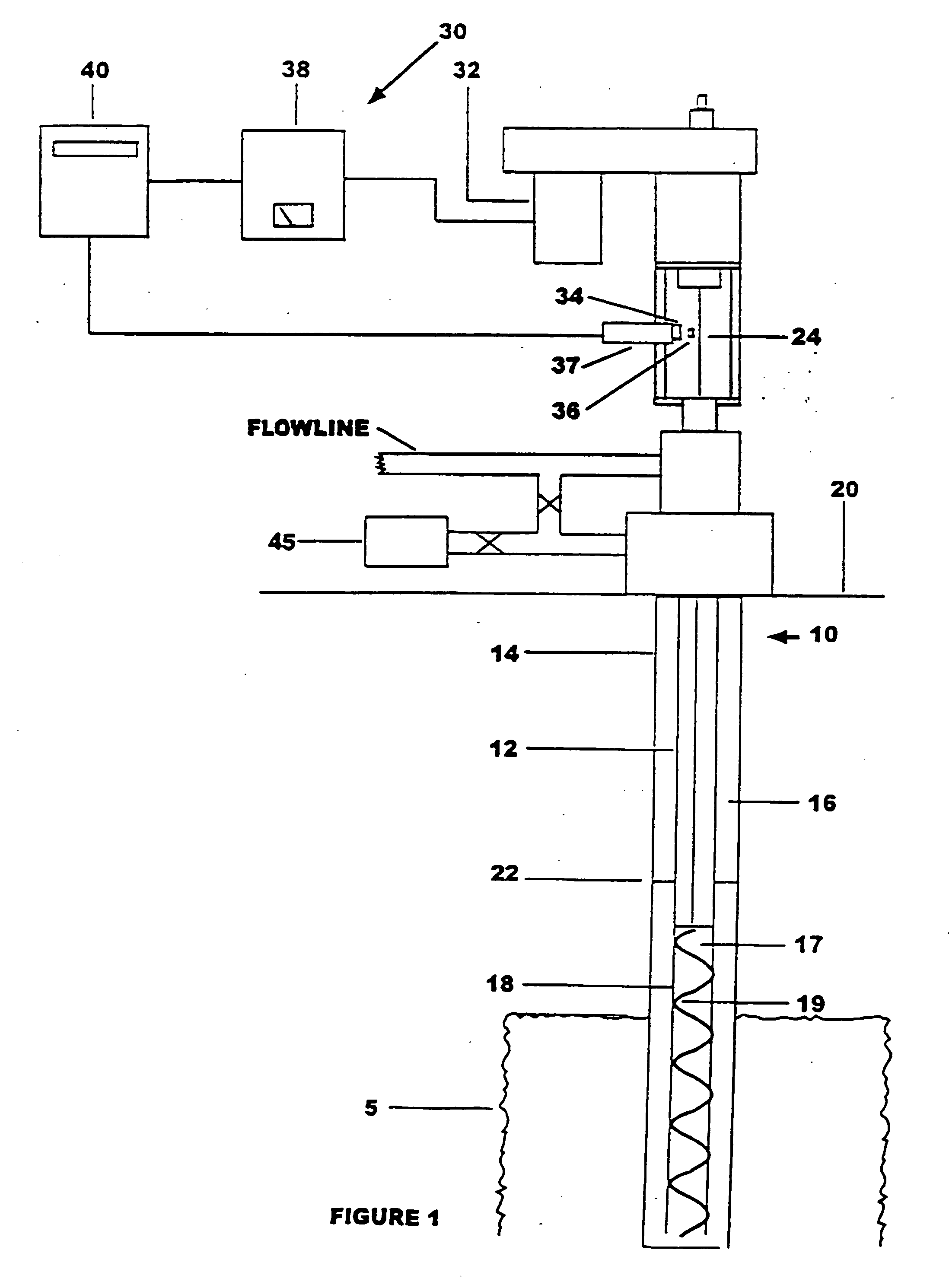

Fluid level control system

InactiveUS20050238496A1Reduce power outputHigh power outputConstructionsFlexible member pumpsControl systemReciprocating motion

A control system governs fluid level in a well system including a pump positioned downhole for pumping fluid upward through a tubular, a rod positioned within the tubular for driving the pump, a prime mover, and a pumpjack to transmit power from the prime mover to the rod to reciprocate the rod. A sensor senses a position of the rod or a member of the pumpjack and outputting signals in response thereto. A controller receives the signals and computes a plurality of time intervals, each time interval being between signals and occurring during at least a portion of an upstroke of the rod. The controller selectively decreases power output from the prime mover in response to an increase in the computed time interval.

Owner:DJAX CORP

Pumpjack dynamometer and method

A dynamometer readout (42, 46) and method is disclosed for obtaining dynamometer information (110) related to pumpjacks (10). For this purpose, a change of pivotal direction of the walking beam (18) may be detected by processor (82) utilizing an encoder component (60) with spaced slots (64) therein and light signal devices (68, 70, 72, 74) positioned to have a spacing different from that of the spacing of the slots (64). Software techniques filter out effects of stray mechanical vibrations. An infrared transceiver (46, 50, 100) of a preferred embodiment includes a radio frequency carrier generator (90) and modulator (88) that produces an infrared signal receivable by a low cost consumer radio receiver. The radio frequency modulation technique for infrared signals (96) and related filtering (98, 102, 104) condition formatted infrared signals for utilization in daylight and through a car window for drive-by downloading of data to second computer (108). A sensor (163) may be substituted for the encoder. A sensor (163) may include a moveable light interrupter, such as a ball (160) or a bubble (260), moveably disposed within the sensor. The sensor may also provide one or more apertures (180) for transmitting light through the apertures.

Owner:MILLS MANUEL D

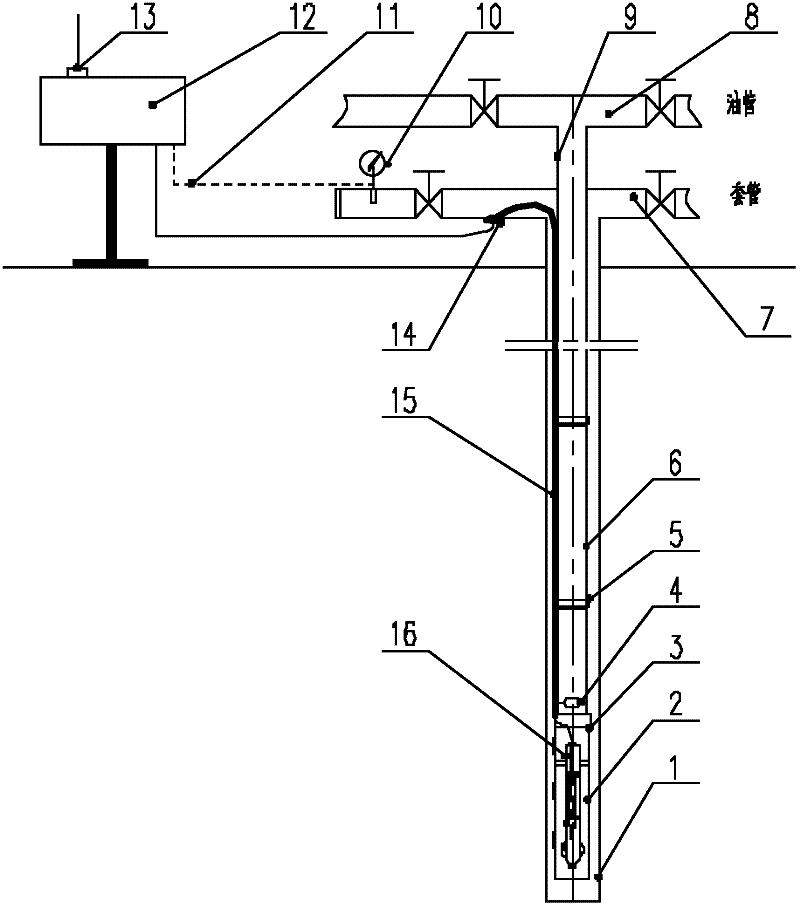

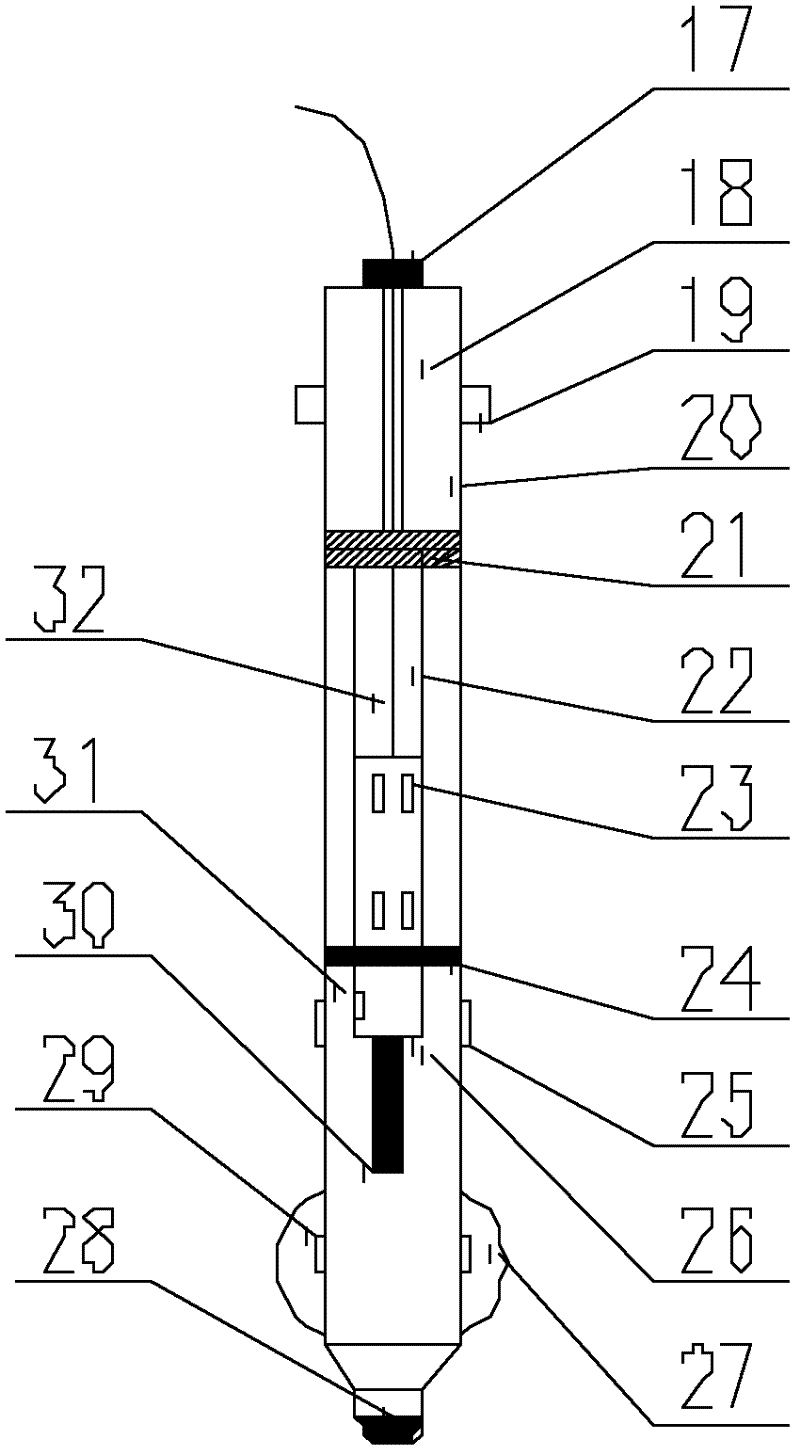

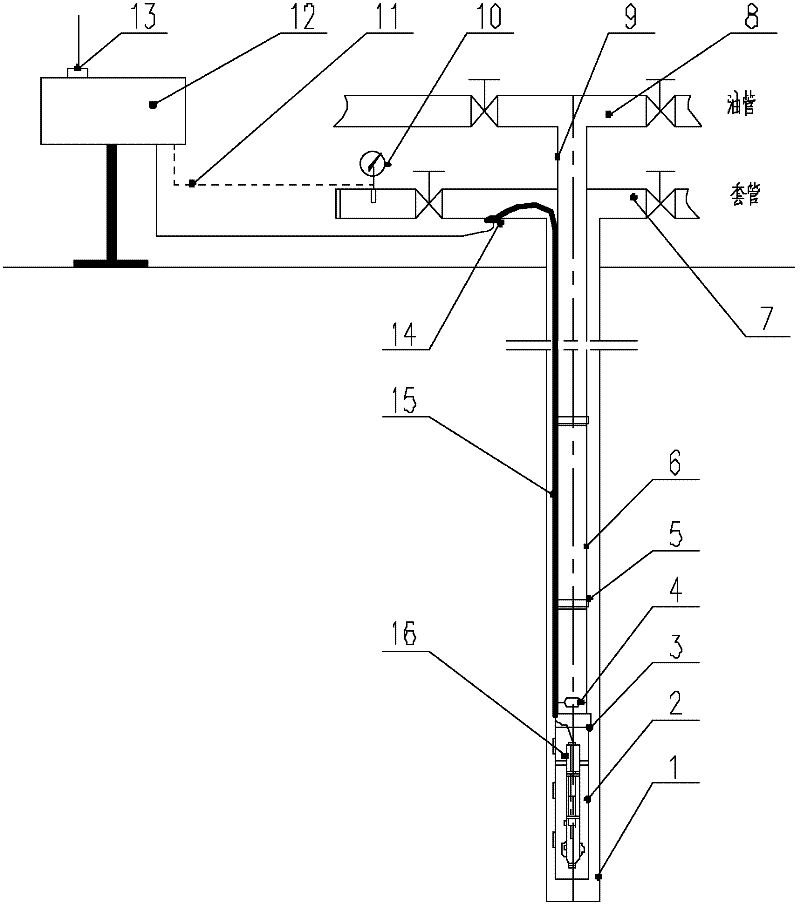

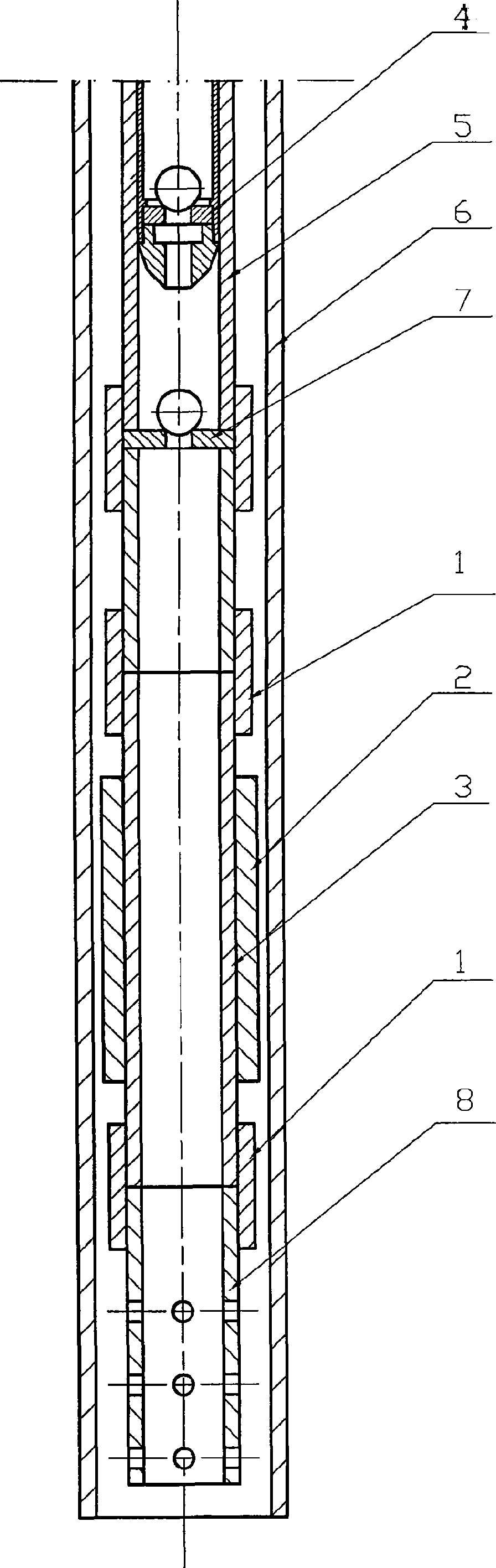

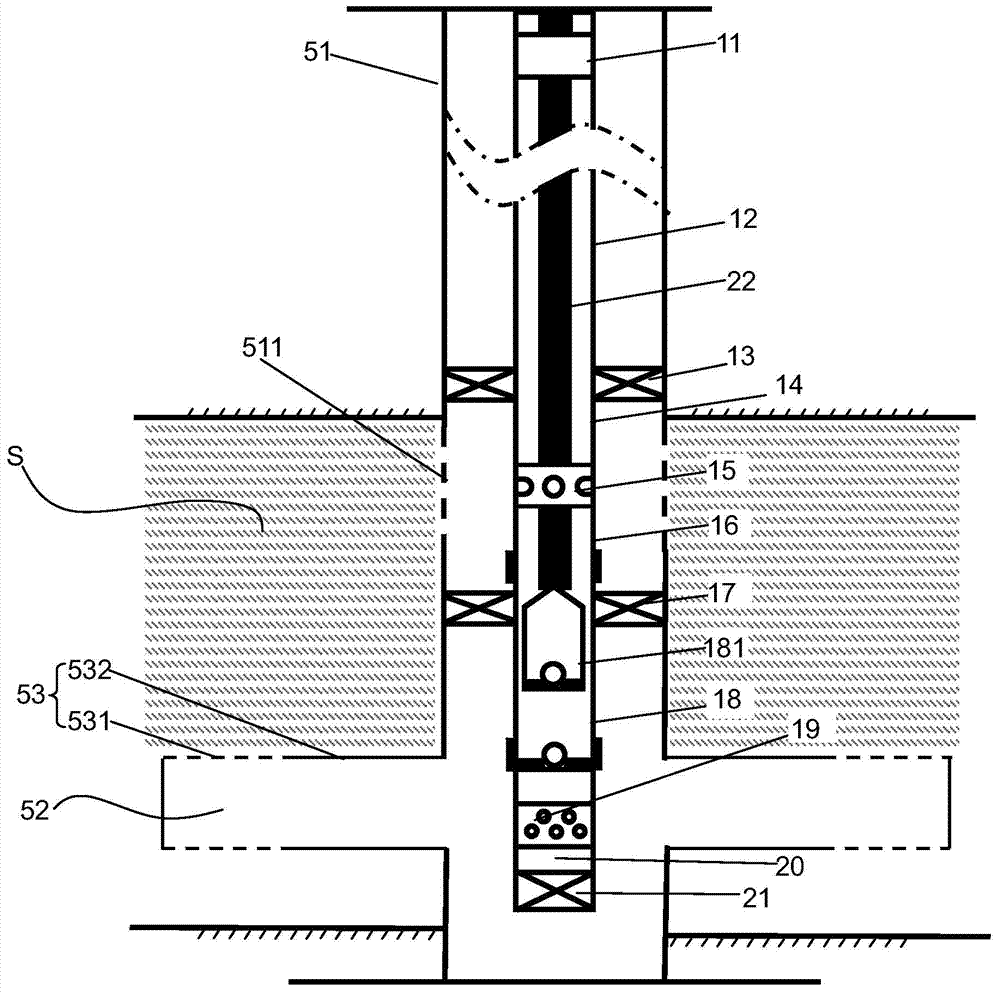

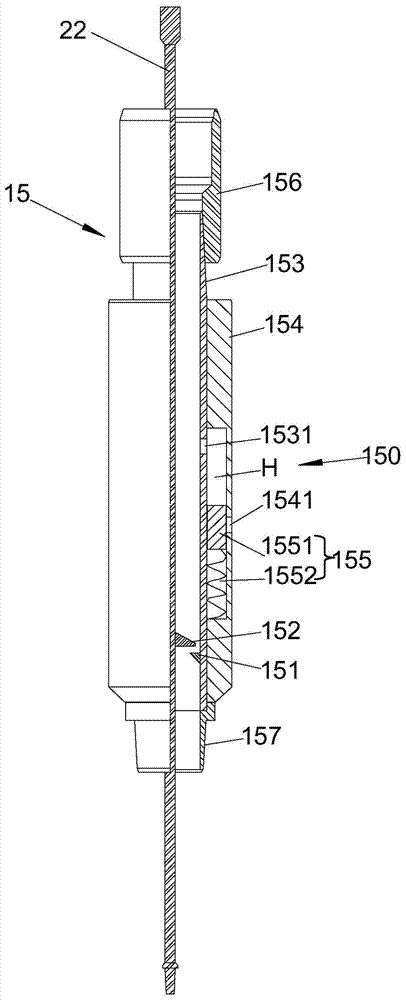

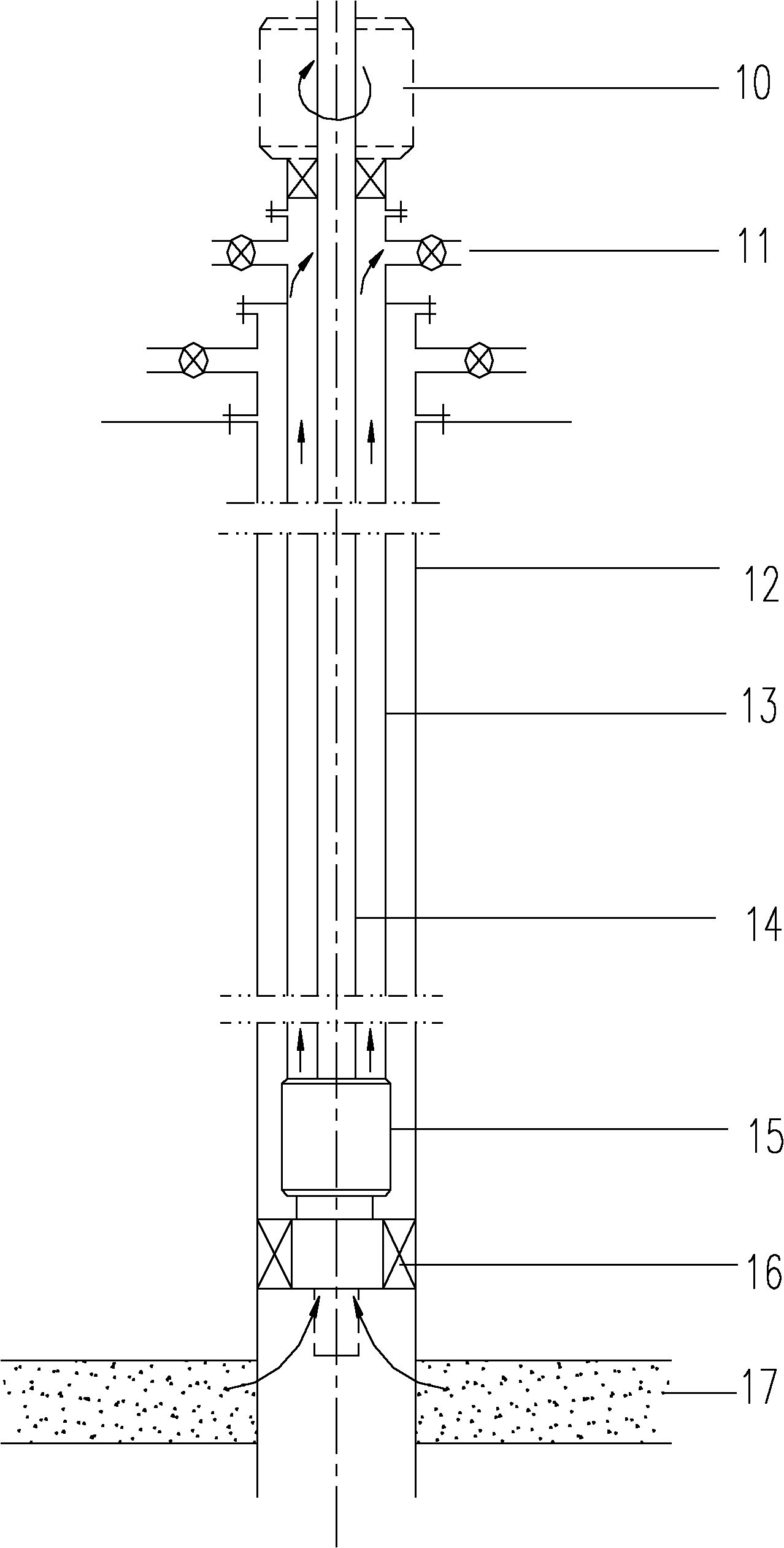

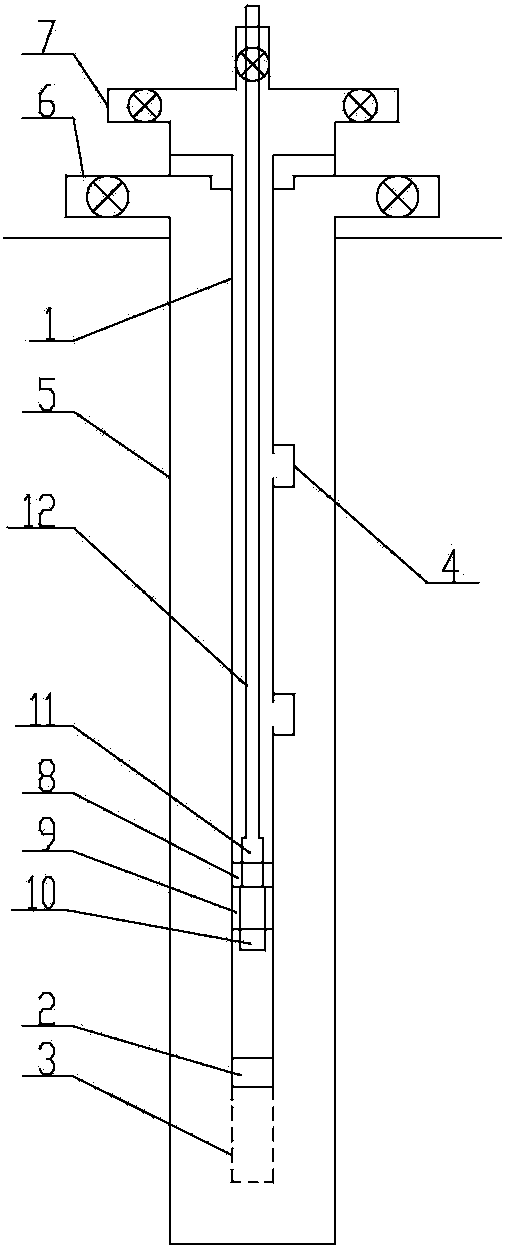

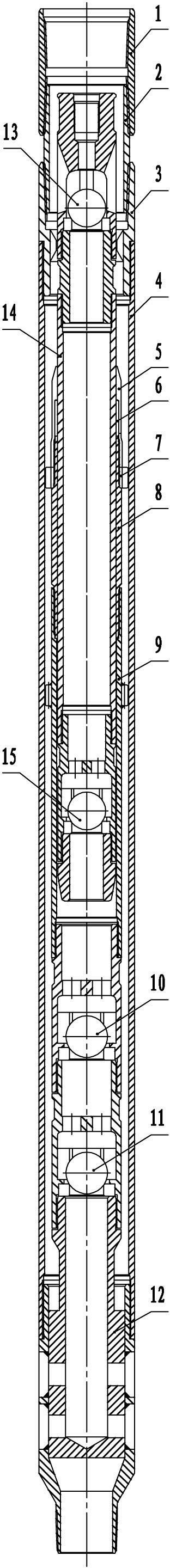

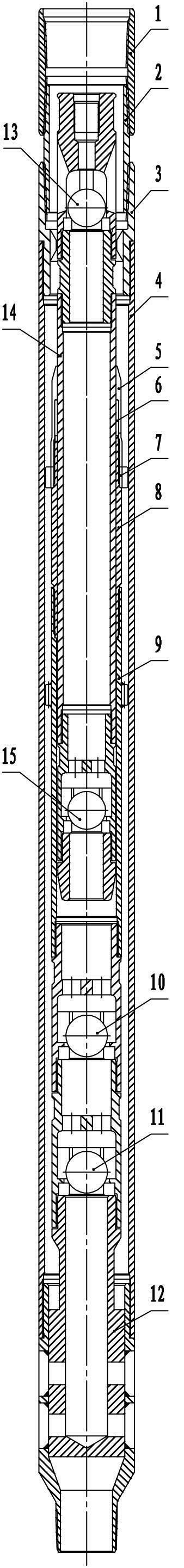

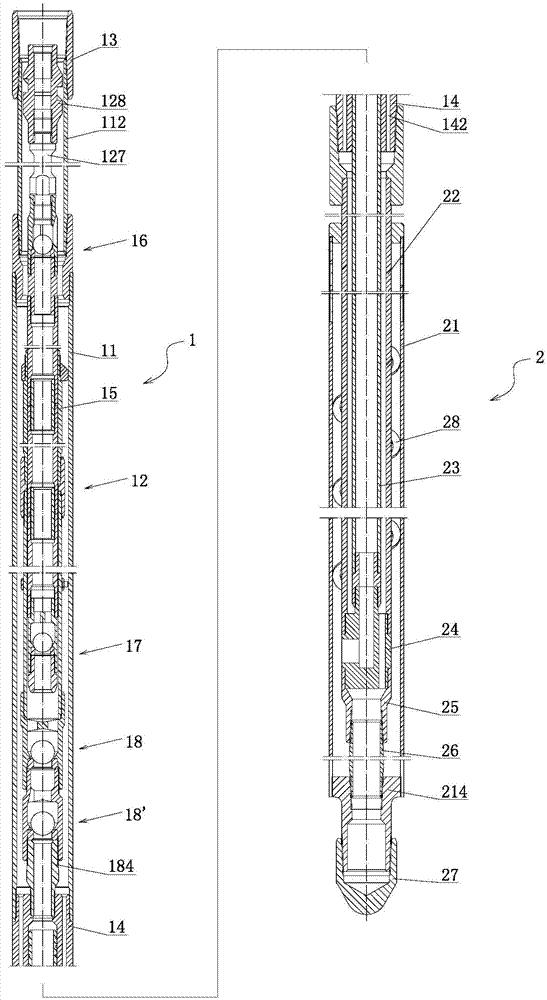

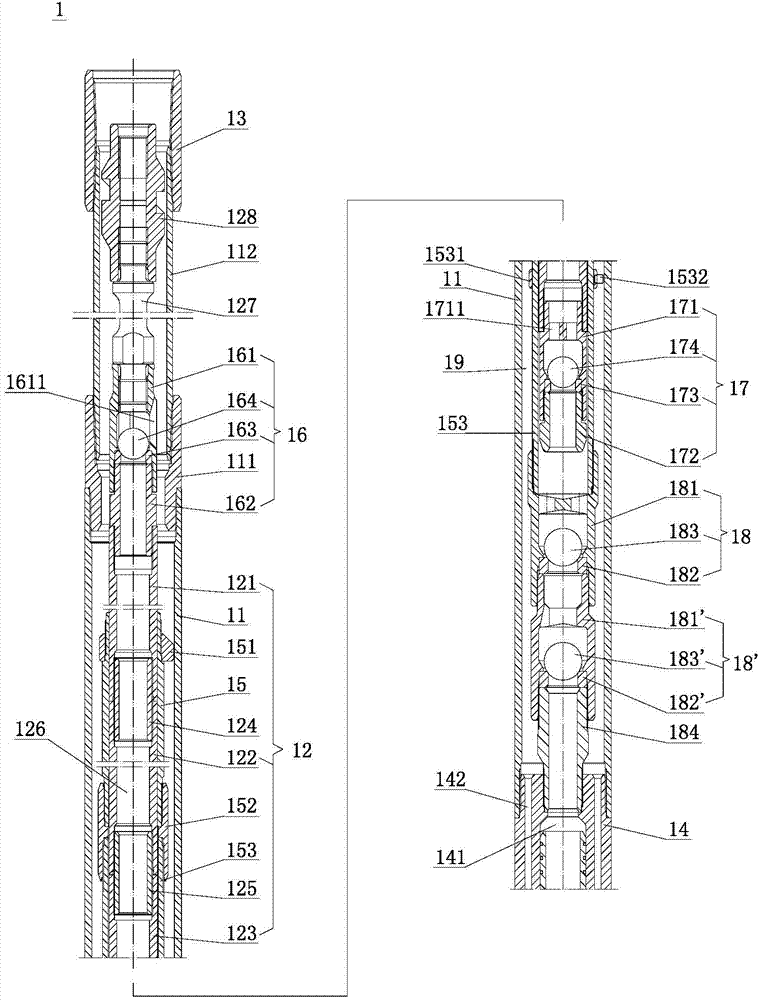

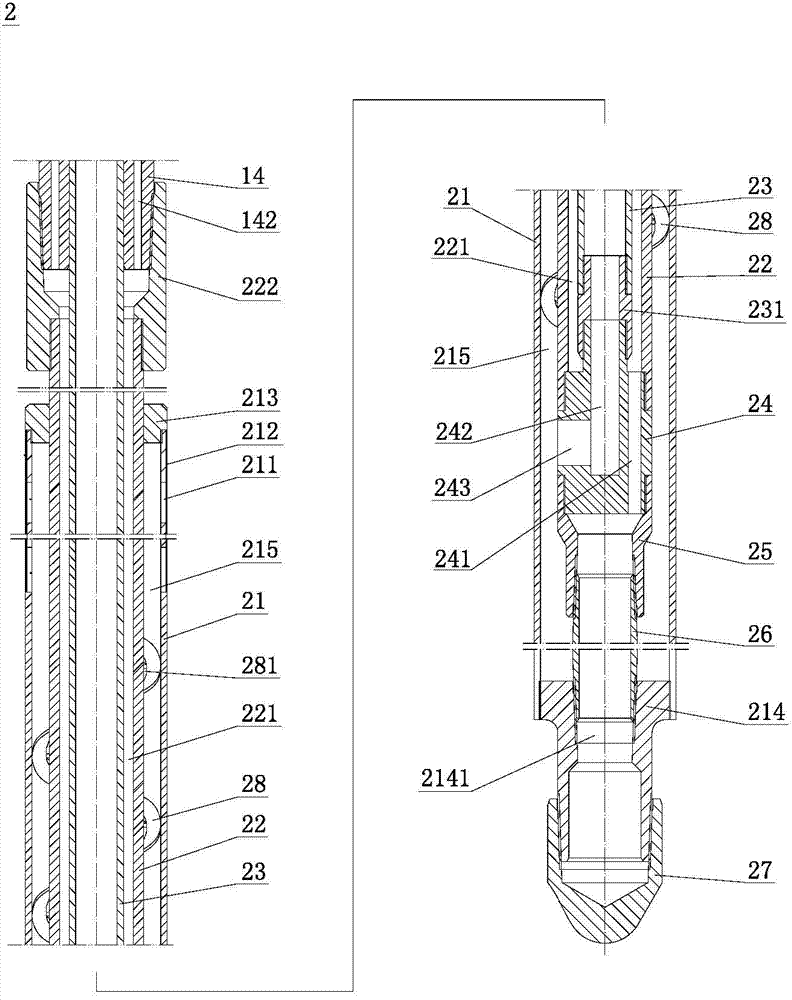

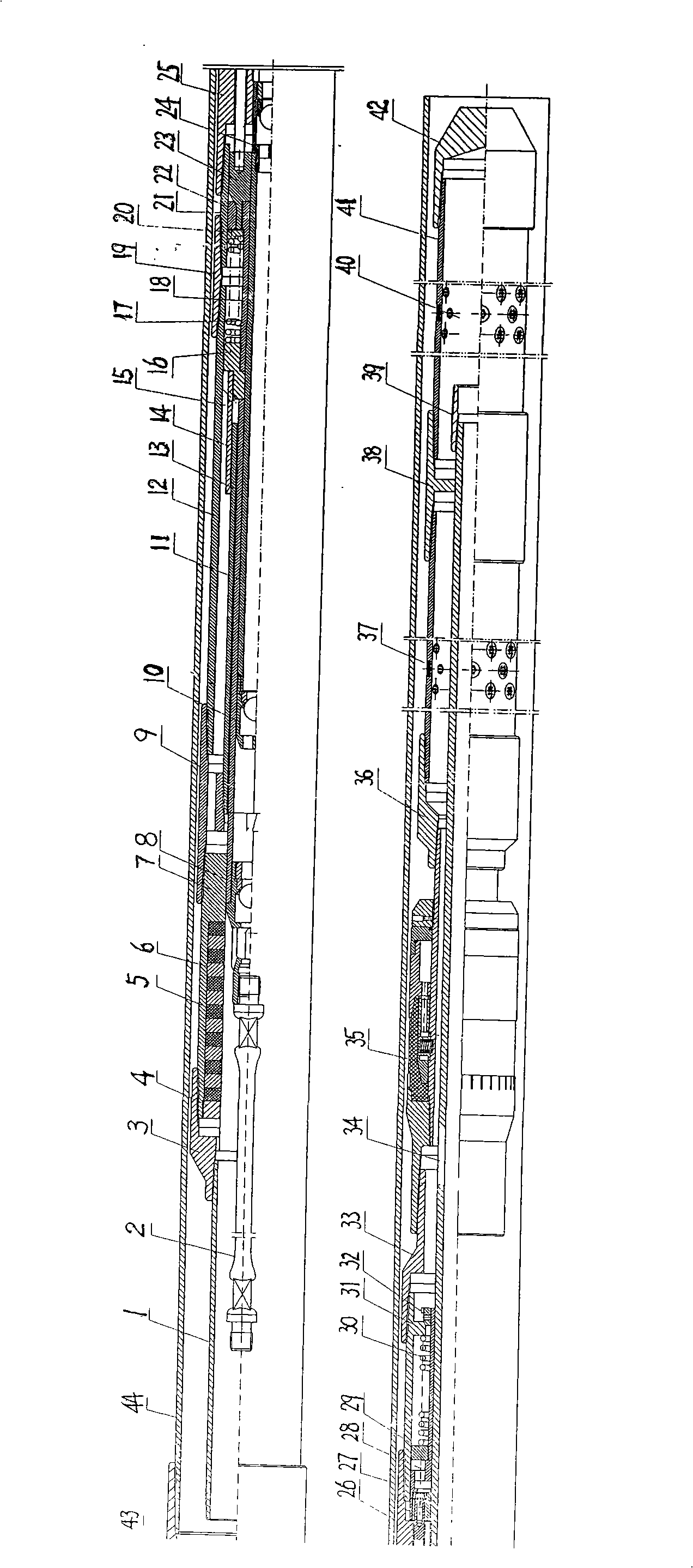

Multi-parameter monitoring device of oil well and working method thereof

The invention discloses a multi-parameter monitoring device of an oil well and a working method thereof, and the device comprises a supporting cylinder arranged in a sleeve, a supporting cylinder coupling, an oil pump, a cable protector and an oil pipe, wherein the supporting cylinder is connected below the oil pump through the supporting cylinder coupling, and a multi-parameter testing instrument of the oil well, which is used for testing the temperature, pressure, water content and working fluid level of the oil well, is suspended and fixed on the supporting cylinder; the oil pump is arranged at the lower end of the oil pipe; the cable protector is connected to the oil pipe, and a channel for crossunder and binding of a single-core logging cable is arranged on the cable protector; a ground sleeve manifold and an oil pipe manifold form a wellhead device; one end of the single-core logging cable is connected with the multi-parameter testing instrument of the oil well, and the other end of the single-core logging cable is connected to a ground data collection device through the sleeve manifold; a wellhead cable sealing device and a sleeve pressure testing sensor are arranged on thesleeve manifold, and the sleeve pressure testing sensor is connected to the data collection device through a sleeve pressure signal wire; and the data collection device is connected with a wireless transmitting device. By adopting the device, the real-time and online monitoring of parameters, such as the underground temperature, the pressure, the water content and the working fluid level can be realized.

Owner:PETROCHINA CO LTD

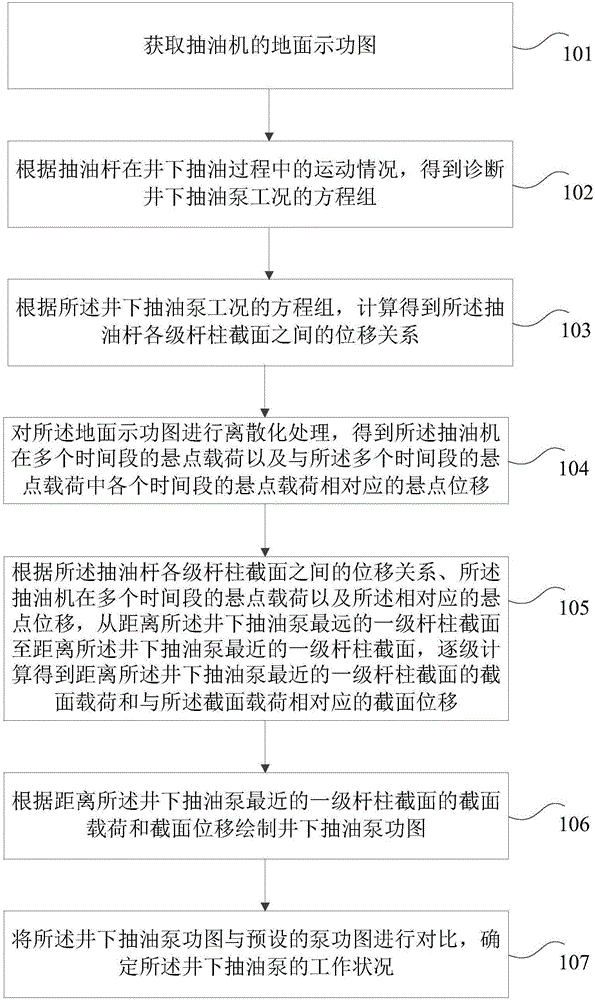

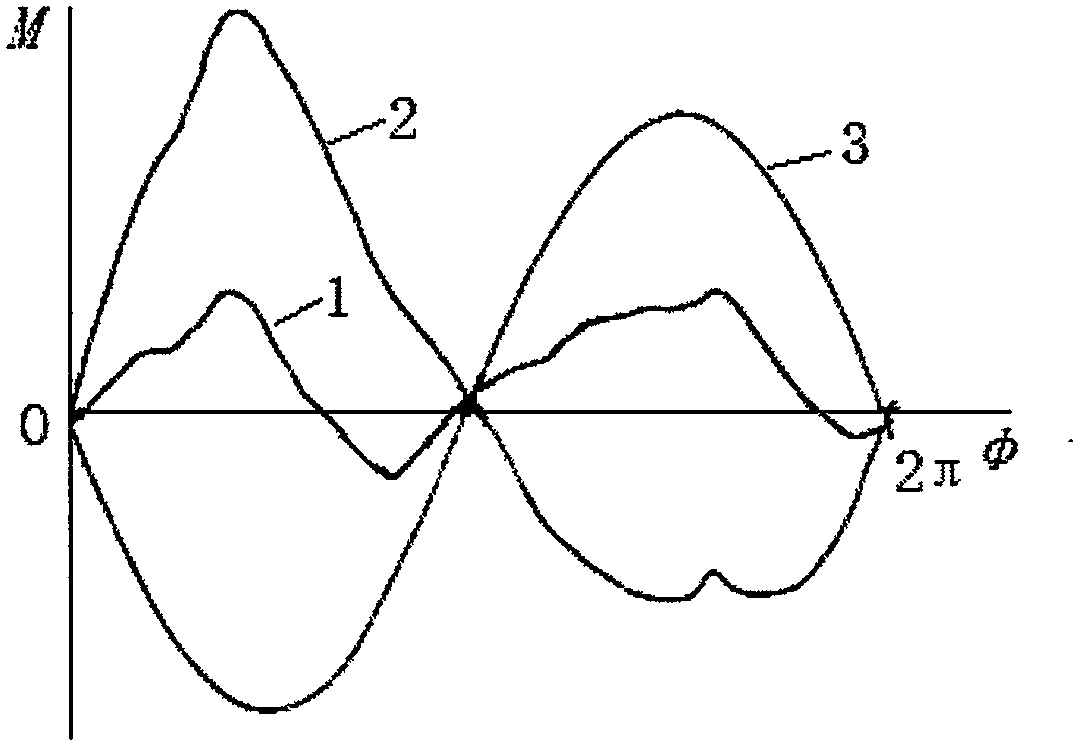

Method and device for diagnosing working conditions of underground oil well pump

ActiveCN106089184AImprove diagnostic accuracyGuaranteed accuracyConstructionsInformaticsIndicator diagramPumpjack

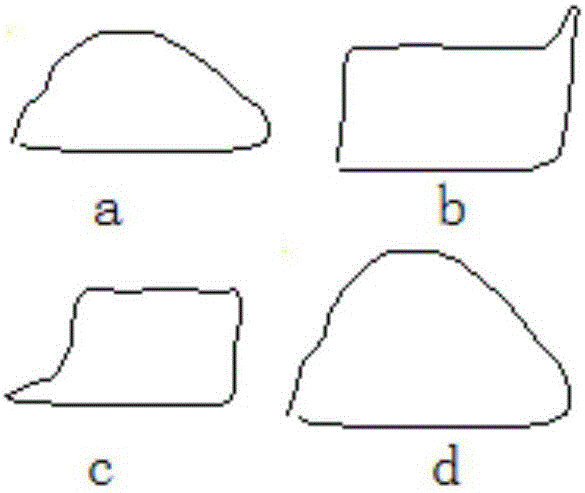

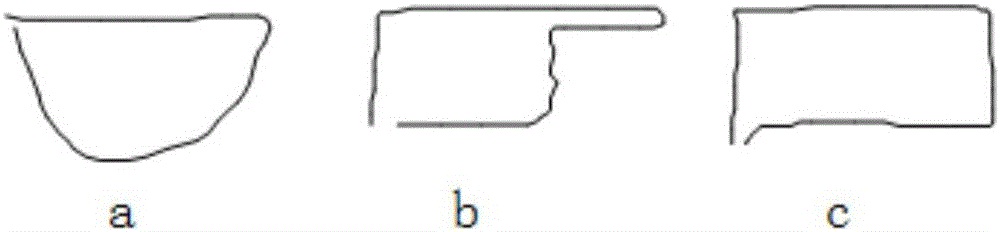

The invention provides a method and device for diagnosing the working conditions of an underground oil well pump. The method comprises the following steps: obtaining an equation set for diagnosing the working conditions of an oil well pump according to the movement conditions of a sucker rod, and calculating the displacement relationship between the cross section of the sucker rod on each level; discretizing a ground indicator diagram to obtain the polished rod load of a pumping unit in multiple time periods as well as the polished rod displacement corresponding to the polished rod load of each time period; stepwise calculating the cross section load of the bolt-support cross section on the level closest to the oil well pump as well as the cross section displacement corresponding to the cross section load from the bolt-support cross section on the level farthest from the oil well pump to the bolt-support cross section closest to the oil well pump, and drawing the indicator diagram of the oil well pump; and comparing the indicator diagram of the oil well pump with a preset pump indicator diagram to determine the working conditions of the underground oil well pump. In the embodiment of the invention, by adopting the method, the diagnosis precision of the working conditions of the underground oil well pump is effectively improved, and the accuracy of the diagnosis result of the working conditions of the underground oil well pump is guaranteed.

Owner:PETROCHINA CO LTD

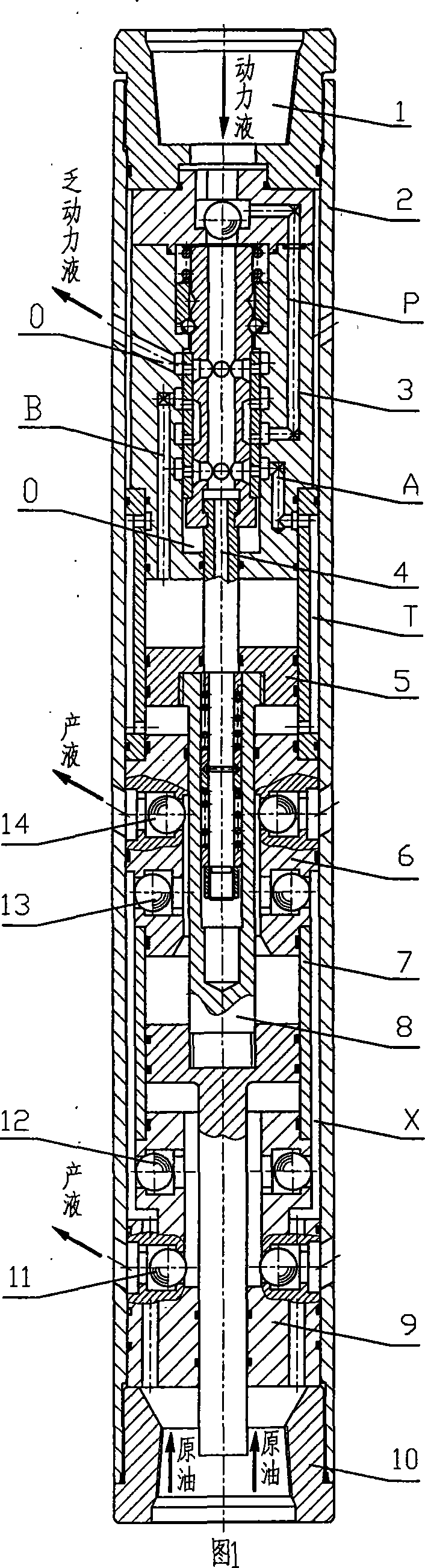

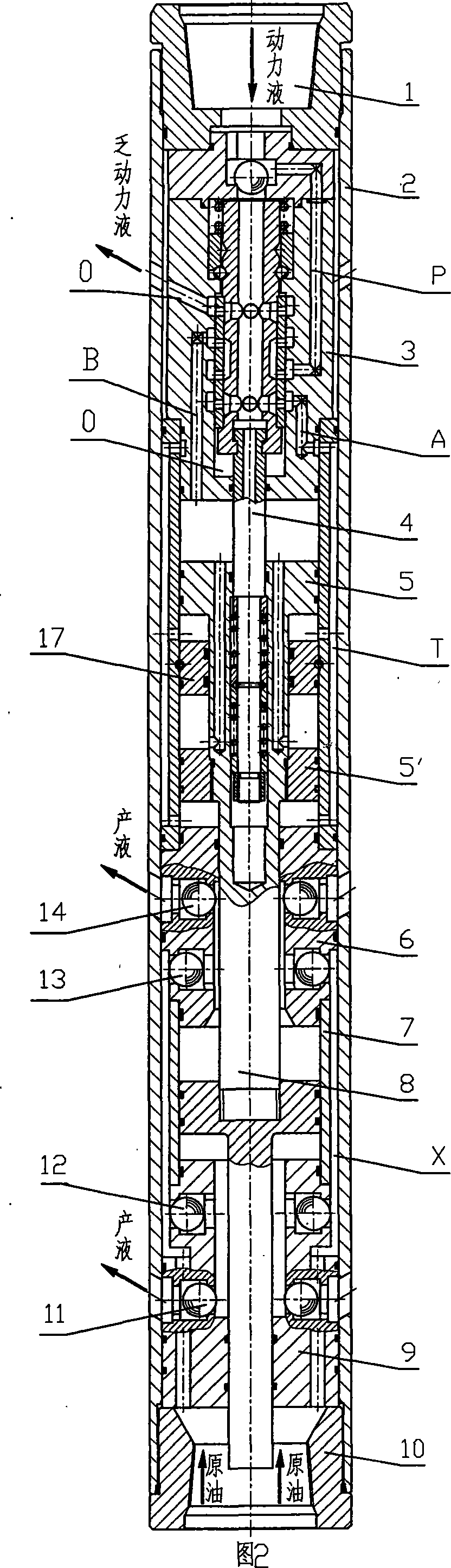

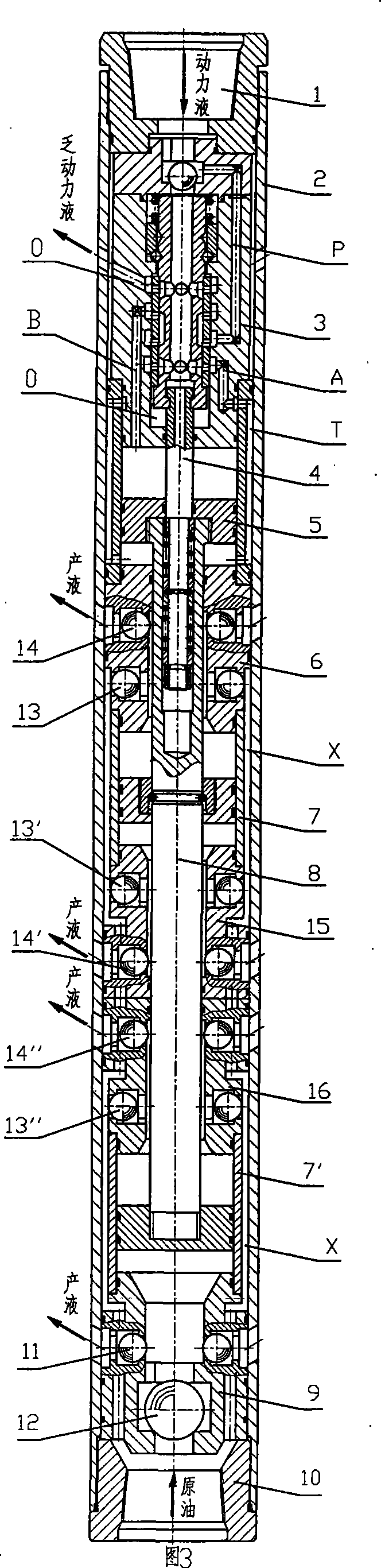

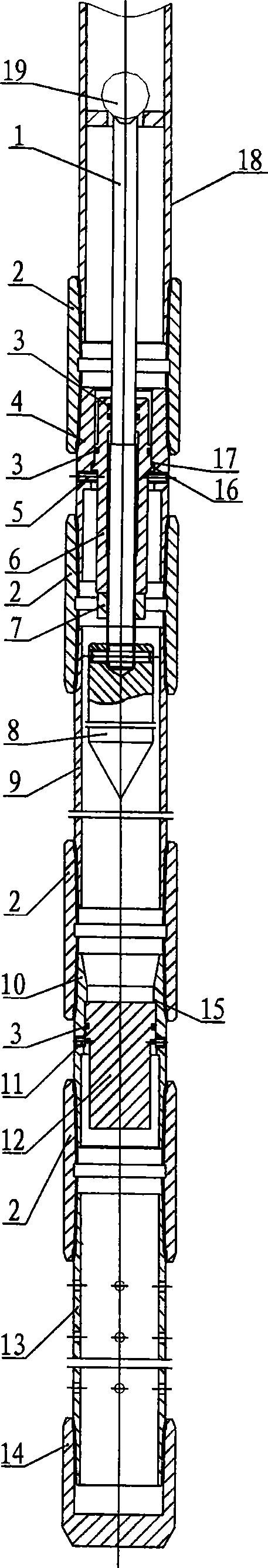

Hydraulic oil pump

ActiveCN101054968AUnrestricted pump hanging depthExtended service lifeFlexible member pumpsFluid removalControl mannerUpper joint

A hydraulic oil pump realizes automatic switch by depending the oil well liquid provided by ground pump station as power liquid. The pump includes an upper joint, a pump housing, a switch valve, a control mechanism, a drive cylinder, an upper discharge suck valve assembly, a hollow piston rod, a liquid discharging cylinder, a lower discharge suck valve assembly and a lower joint. Two different opening loops can be adopted according to different well conditions; each loop has four implementing schemes. The effect is that: the pump thoroughly changes the control mode that the switch valve and drive cylinder moves synchronously in conventional water power piston pump, the switch valve is at non-friction state in most time, and the sealing surface will not bearing erosion during switch process. Therefore, the pump has strong reliability and low requirement for power liquid quality, and has a power consumption which is only 25-30% of existing oil pump; thereby it is perfect equipment for oil extraction from inclined well, deep well and dense oil well.

Owner:ZHONGCHAO LIANHE ENERGY SCI & TECH BEIJING CO LTD

Sacrificial anode and protective cathode-oil-well pump anti-corrosive apparatus

InactiveCN101397672AReduce consumptionEliminate accidentsFlexible member pumpsPositive-displacement liquid enginesZinc metalThermal insulation

The invention relates to a corrosion resistant device for an oil well pump which utilizes a sacrificial anode to protect a cathode. The corrosion resistant device utilizes the principle of protecting the cathode by sacrificing the anode in electrochemistry and takes zinc, lead, magnesium and other active metals as the anode of the oil well pump. The production method is as follows: the nipple of the oil well pump is processed according to the technical specification of the oil well pump firstly and the length of the nipple is 400mm to 500mm; then the nipple is put into a specially designed rod cavity; magnesium or aluminium or zinc metal blocks are converted into liquid by heating and melting and then cast into the nipple cavity of a special oil well pump; and shaping, thermal insulation, slow cooling, mold unloading and mechanical processing are carried out, a coarse blank is processed into a smooth revolution body, thread at the two ends of the oil well pump is processed, and collars are installed, therefore, the anode assembly of the oil well pump is formed. The instillation method is as follows: during the process of putting down the oil well pump, the anode of the pumping rod is connected in series with the collar at the lower end of the oil well pump and collar is screwed.

Owner:HENAN XINYU PETROLEUM MACHINERY MFG

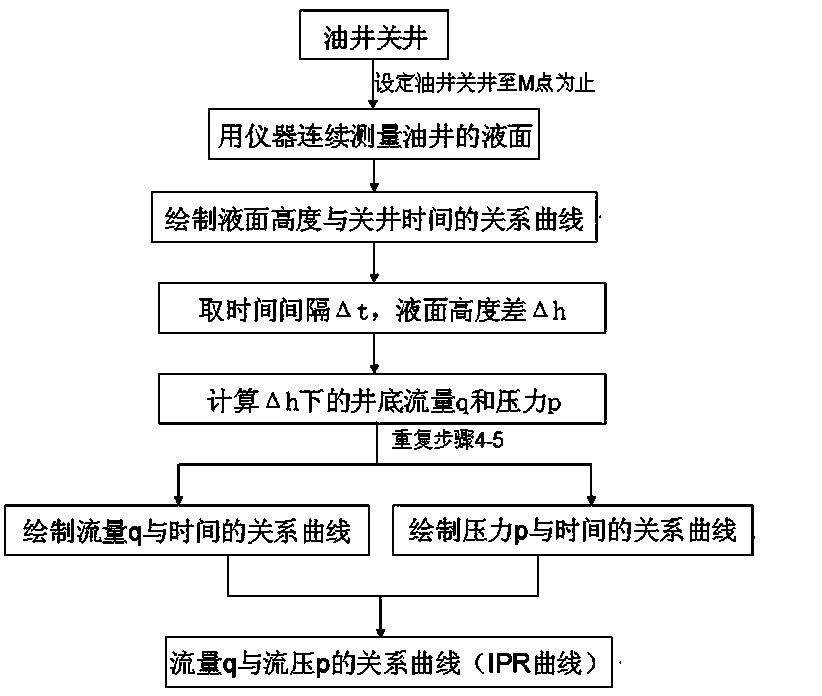

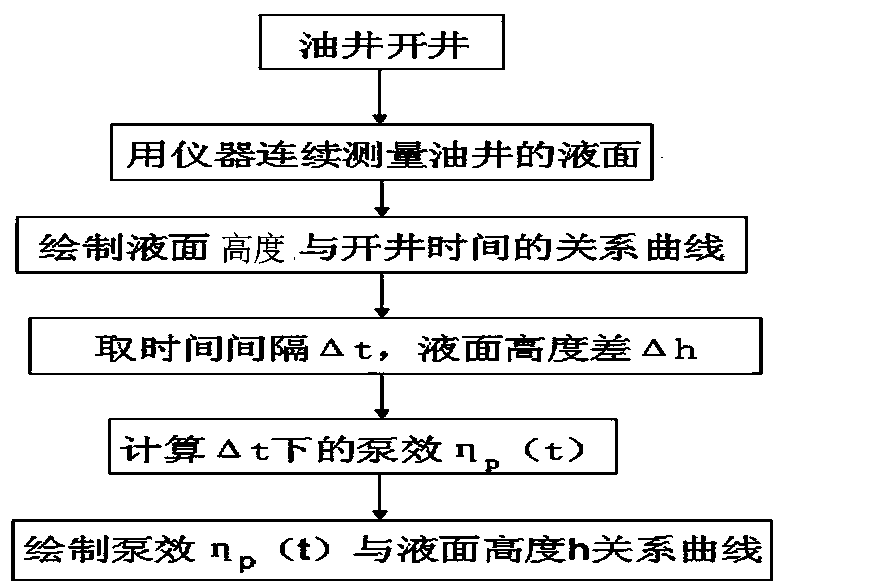

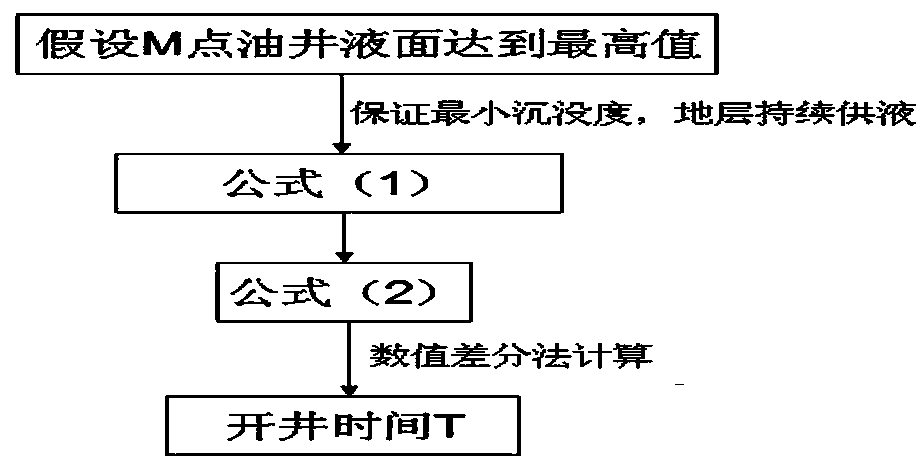

Method for determining reasonable intermittent pumping system for low-permeability oil well

The invention discloses a method for determining a reasonable intermittent pumping system for a low-permeability oil well and relates to the field of petrochemical industry, in particular to the method for determining the reasonable intermittent pumping system for the low-permeability oil well. The method for determining the reasonable intermittent pumping system for the low-permeability oil well includes steps that drawing an IPR curve; drawing a relationship curve between a pump efficiency eta and a fluid surface height h; determining a well opening time T; determining an oil well closing time T2; calculating an intermittent oil well pumping period T+T2; obtaining the intermittent pumping system for the low-permeability oil well and correcting the intermittent pumping period. The method for determining the reasonable intermittent pumping system for the low-permeability oil well finds out a fluid surface change rule through continuously monitoring the working fluid level; an oil well pump can run under a high fluid supply situation through determining the reasonable starting and stopping time of an oil pumping unit according to the method so as to dig the potential output, save energy and reduce consumption.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

Thermal oil production pipe column for injection-production in the same well for vertical well and oil production method thereof

ActiveCN104514535AIncrease profitImprove the effect of throughput miningFluid removalOil productionCheck valve

The invention discloses a thermal oil production pipe column for injection-production in the same well for a vertical well and an oil production method thereof. The oil production pipe column comprises a telescopic pipe, a first insulated pipe, an upper packer, a second insulated pipe, a steam injection check valve, an oil pipe, a lower packer, an oil well pump, a sieve pipe, a tail pipe and a screwed plug which are connected in sequence from the top to bottom, an oil pumping rod is placed in the oil production pipe column, and the lower end of the oil pumping rod is connected with a traveling valve in the oil well pump; a gas injection flow passage which connects the inside to the outside in one direction is formed in the side wall of the steam injection check valve, a fixed sealing ring plate and a movable sealing ring plate placed on the fixed sealing ring plate are arranged in the inner cavity of the lower side of the gas injection flow passage, the movable sealing ring plate sleeves the oil pumping rod, and the outer periphery thereof hermetically contacts with the upper surface of the inner periphery of the fixed sealing ring plate. The thermal oil production pipe column for the injection-production in the same well for the vertical well and the oil production method thereof are capable of effectively using the steam heat, improving the economical benefit and improving the cyclic steam stimulation effect for thickened oil.

Owner:PETROCHINA CO LTD

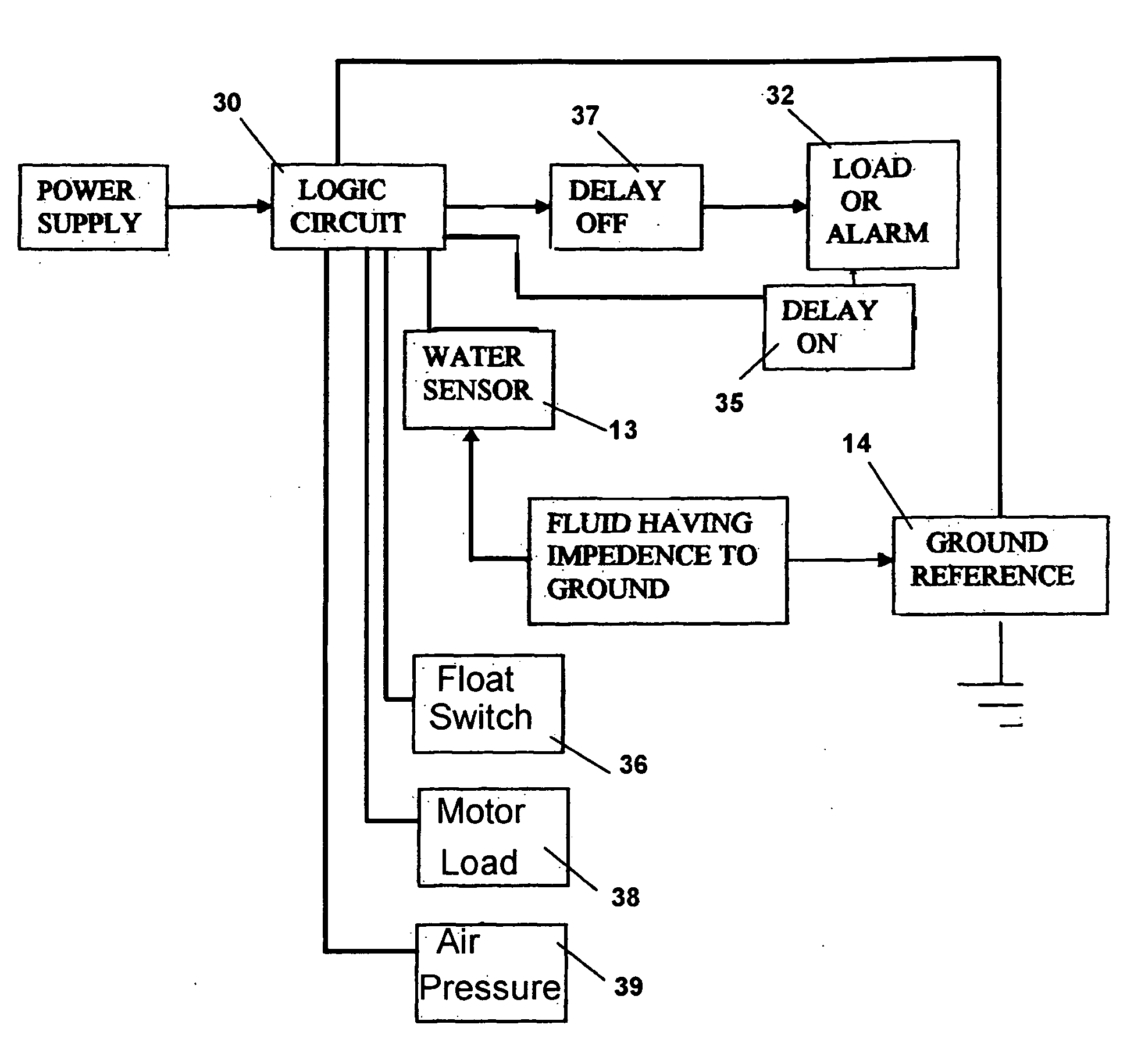

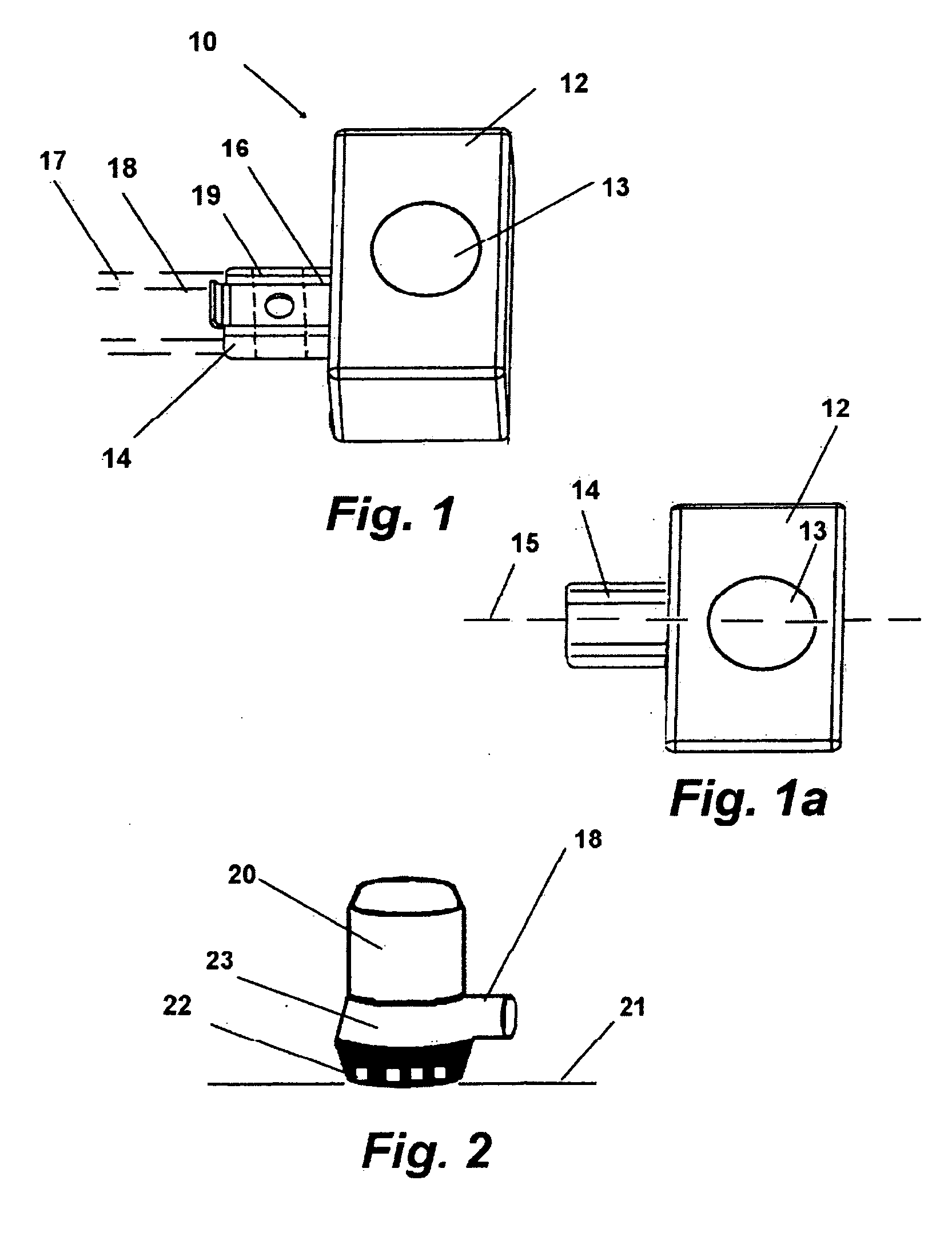

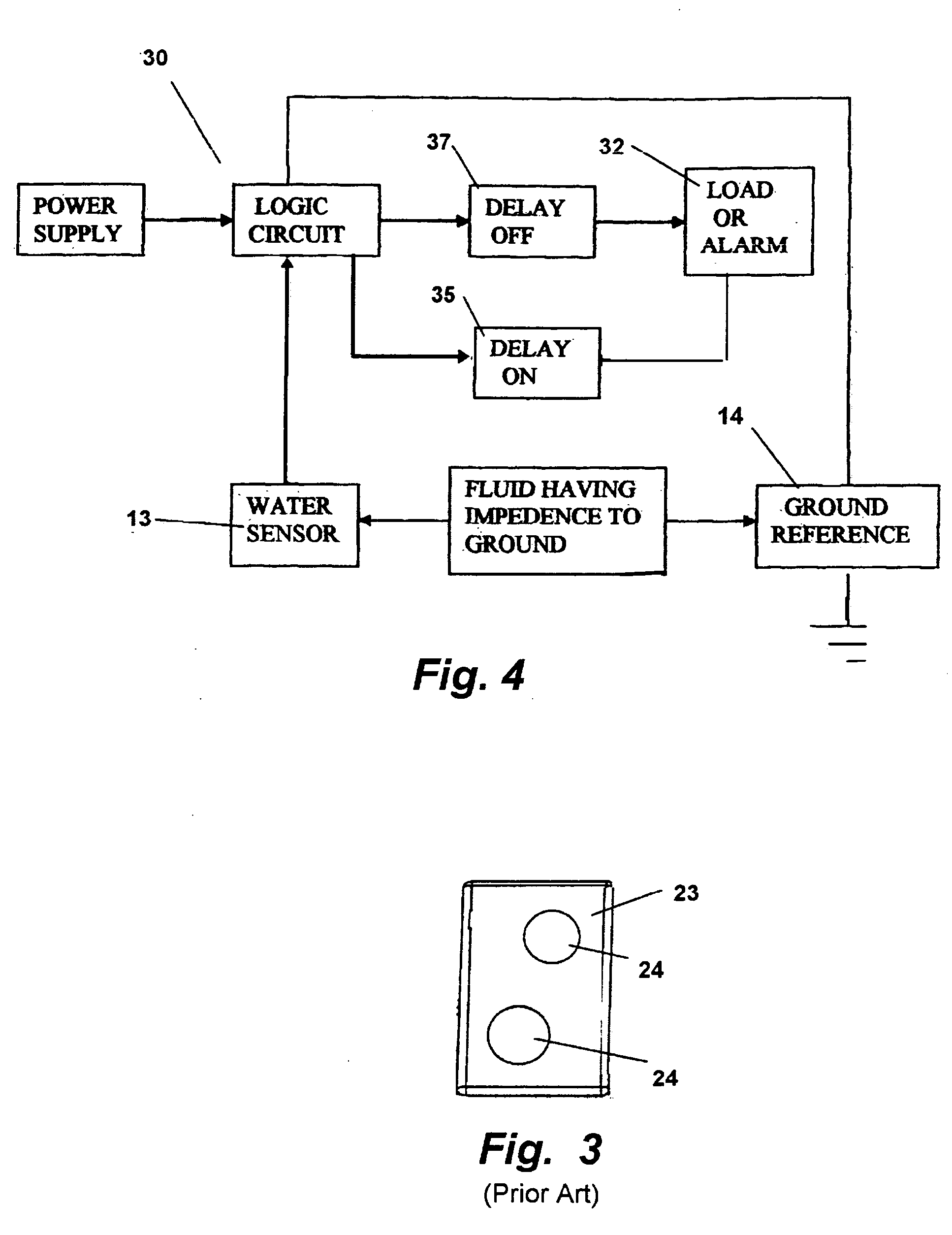

Sump pump activation switch

InactiveUS20090123295A1Improve performanceFor easy referencePump controlPositive-displacement liquid enginesFluid levelBiological activation

A switching device for submersed sump pump. The switching device employs an internal logic circuit inside a housing having a metallic member extending therefrom for mounting. The member is adapted to engage with the curved surface of a hose and hose clamp engaged to the sump pump. The member is engaged to the electrical ground to communicate a reference ground to the fluid in the sump to allow an impedance sensor to discern the fluid level and cause the logic circuit to energize or de-energize the sump pump.

Owner:ABBOTT BRYAN L

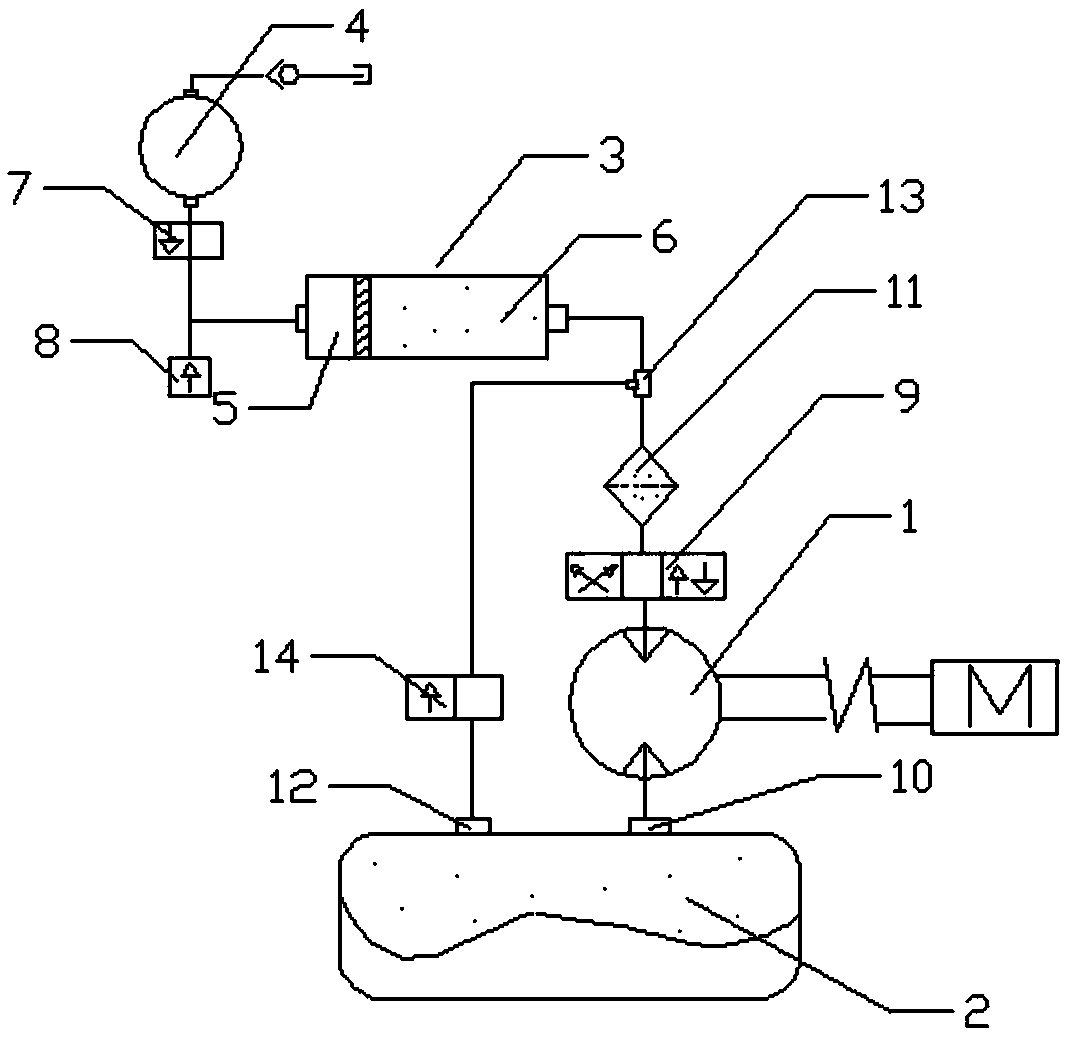

Underwater buoyancy force automatic adjustment device and using method thereof

ActiveCN109334929ABuoyancy adjustmentReduce consumptionUnderwater vesselsUnderwater equipmentAutomatic controlGas cylinder

The invention relates to an underwater buoyancy force automatic adjustment device and a using method thereof. According to the underwater buoyancy force automatic adjustment device and the using method thereof, the technical problems that an underwater buoyancy force driving device cannot automatically control and adjust the self buoyancy force in water and the operation energy consumption is highin the prior art are solved. The underwater buoyancy force automatic adjustment device comprises a main controller, a hydraulic pneumatic energy storage system, a bi-directional oil well pump and a first pressure sensor, wherein the hydraulic pneumatic energy storage system and the bi-directional oil well pump are correspondingly connected with the main controller, and the first pressure sensor is used for detecting external environmental pressure; the hydraulic pneumatic energy storage system comprises an inflatable type energy accumulator and a high-pressure gas cylinder, the inflatable type energy accumulator comprises a telescopic air bag cavity and a telescopic oil cavity, and the high-pressure gas cylinder is connected with an opening end of the air bag cavity through a first pipeline; the front end opening of the bi-directional oil well pump is connected with an opening end of the oil cavity through a second pipeline; and an oil filling opening is formed in the upper part of anelastic container in a penetrating mode, and the oil filling opening is connected with the rear end opening of the bi-directional oil well pump through a pipeline. The invention further provides theusing method of the underwater buoyancy force automatic adjustment device. The underwater buoyancy force automatic adjustment device and the using method of the underwater buoyancy force automatic adjustment device can be widely applied to the technical field of underwater buoyancy force driving devices.

Owner:HARBIN INST OF TECH AT WEIHAI

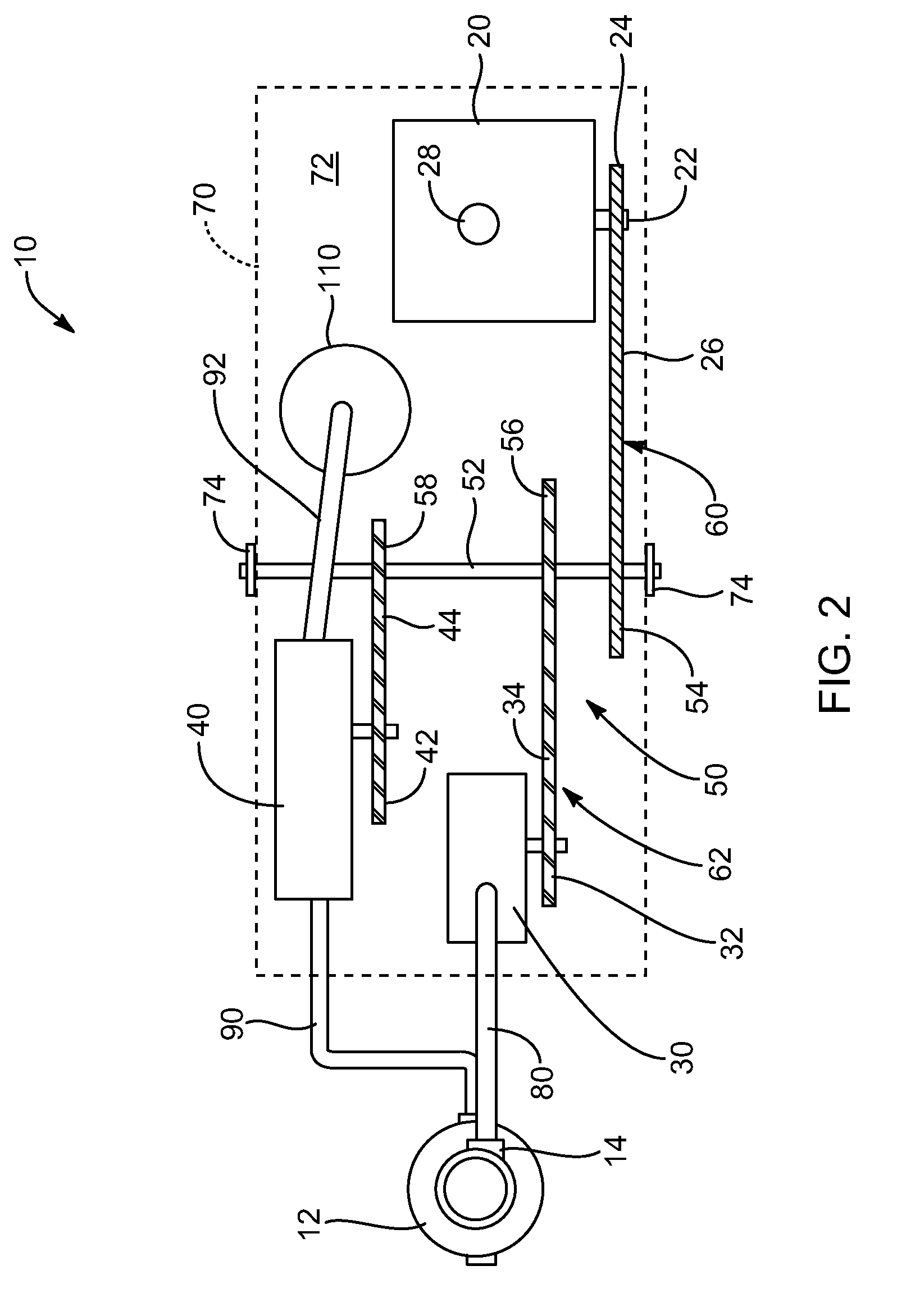

Systems and methods for driving a pumpjack

InactiveUS20100054959A1Efficient driveEliminate needFlexible member pumpsPump controlAbove groundEngineering

Systems and methods for providing a pump driving unit for driving an above ground pump. The pump driving unit utilizes a single prime mover and a drive train for actuating multiple components required to drive the above ground pump. Some implementations of the pump driving unit include phase separation devices, filtering units, and cooling units that may also be actuated by the drive train of the unit. Some implementations of the pump driving unit further include an enclosure and a platform for containing the unit and simplifying on-site installation.

Owner:SOONER B & B

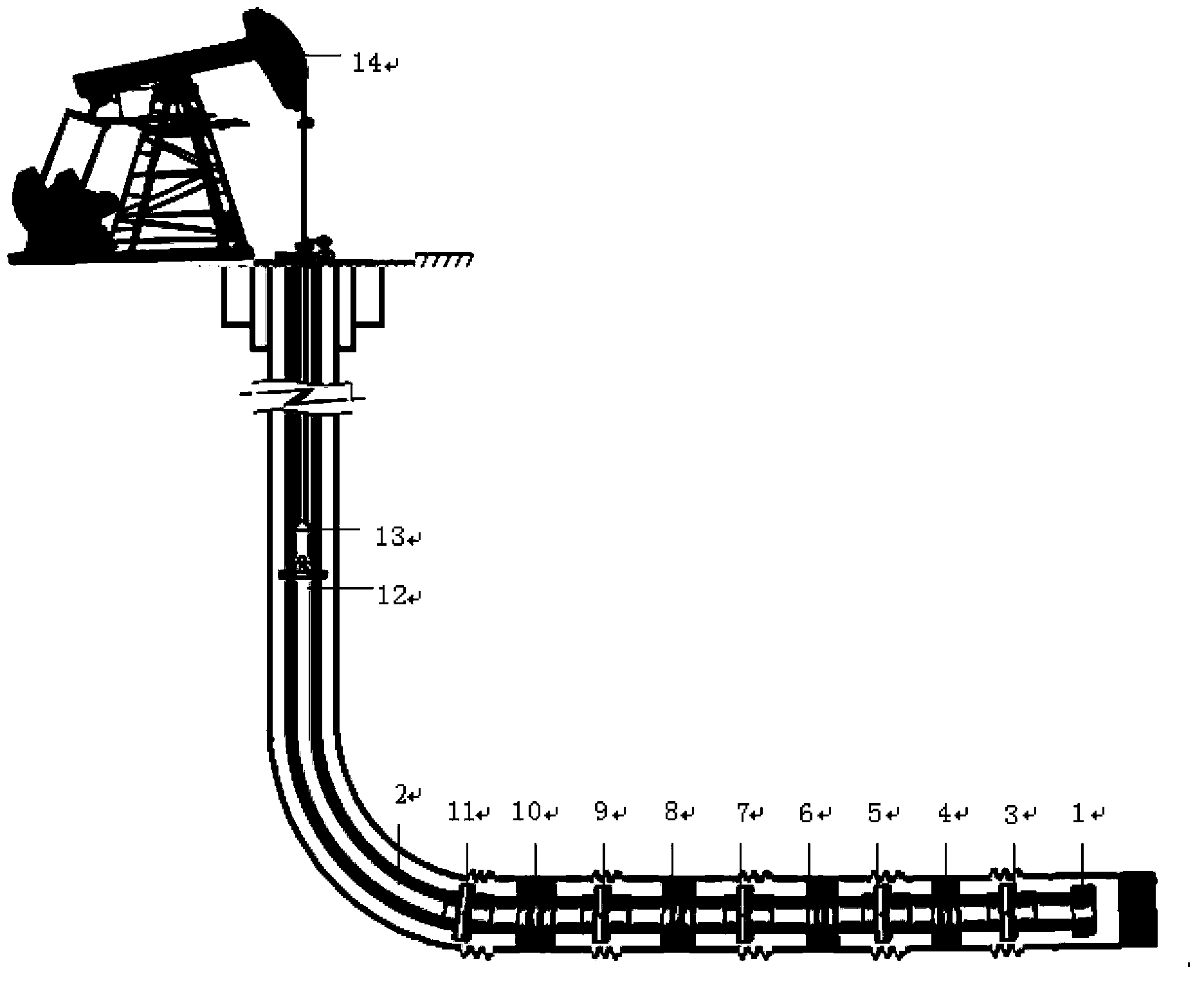

Sectional synchronous flow rate and water content monitoring and water exploration tubular column of multi-section fracturing horizontal well and working method thereof

InactiveCN104100254AShorten the water search cycleImprove water search efficiencySurveyWater dischargeOil production

The invention discloses a sectional synchronous flow rate and water content monitoring and water exploration tubular column of a multi-section fracturing horizontal well and a working method thereof, and the tubular column is designed for realizing synchronous monitoring and water exploration for all intervals of the horizontal well through one trip of the tubular column. The tubular column is arranged between a screwed plug and an oil well pump, multiple stages of connecting units consisting of underground storage flow rate and water content monitors and packers are connected through oil pipes, and each stage of connecting unit corresponds to one interval respectively; the upper end of the underground storage flow rate and water content monitor at the top stage is connected with the oil well pump through an oil pipe, the oil pipe is connected to a wellhead, and the oil well pump is connected to a ground pumping unit through a sucker rod. The tubular column adopts the underground storage flow rate and water content monitors, so that synchronous flow rate and water content monitoring and water exploration for multiple intervals through one trip of the tubular column can be realized, the original manner that production and water exploration for each interval are separated is converted into the manner of synchronous production and water exploration, the water exploration period can be significantly shortened, the water discharge interval and the water discharge rate can be determined, the water exploration efficiency is improved, and a reliable basis can be provided for water control and oil production enhancement measures for the horizontal well.

Owner:PETROCHINA CO LTD

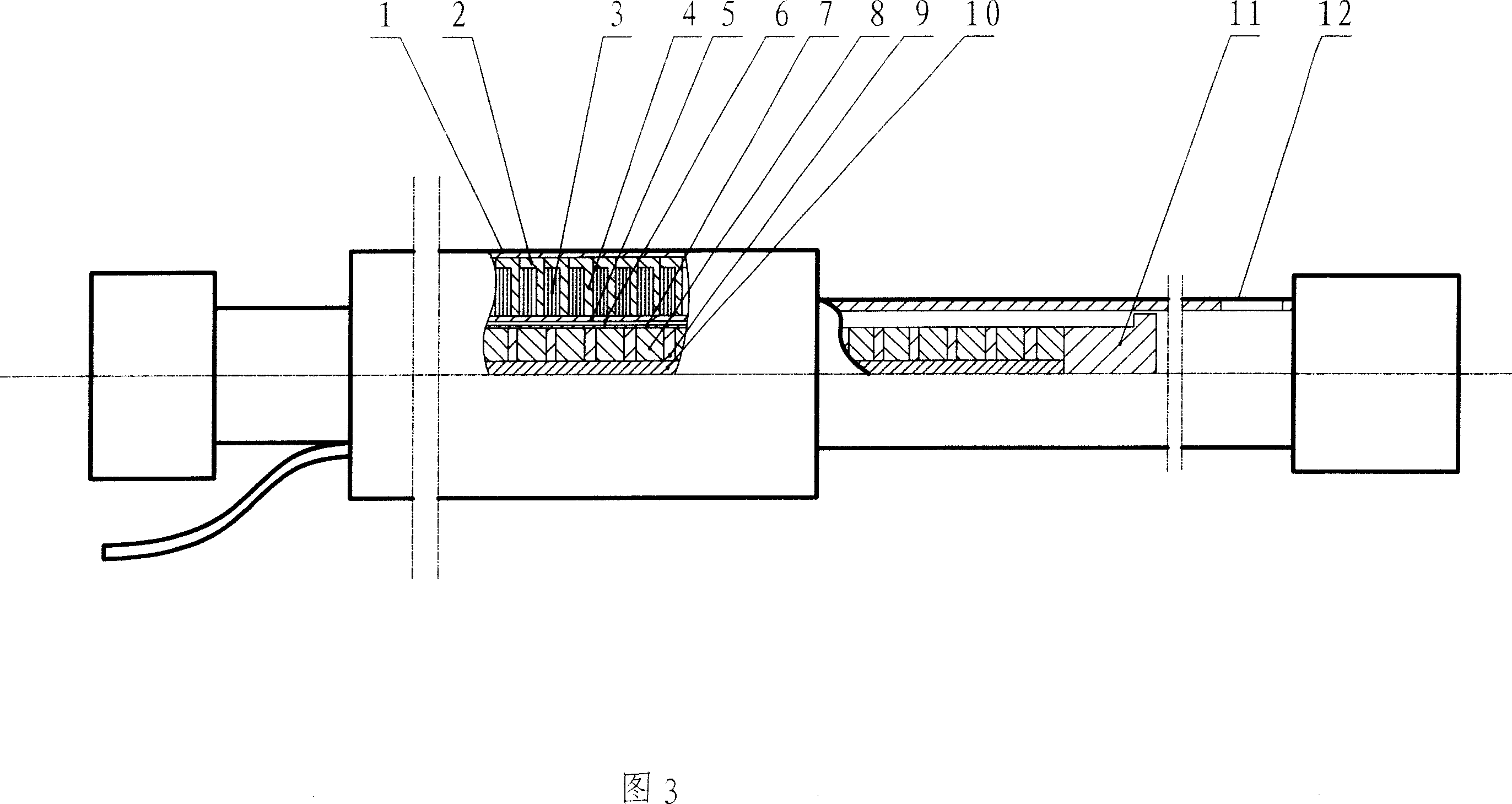

Lifting device of electric submersible piston pump in horizontal wells

ActiveCN101008380AAdjust displacementFlexible member pumpsFluid removalHorizontal wellsPermanent magnet linear motor

A horizontal well submersible electric plug pump lifter resolves the problems of prior horizontal well lifter as high cost and large discharge. The invention is characterized in that the device also comprise a small-diameter high-flexibility permanent-magnetic straight motor (44) and a horizontal lifting oil pump (43), wherein, the motor (44) is mainly formed by a stator and a rotor, and the oil pump (43) is mainly formed by a fixed flange, a pump cylinder (23), a plug (22), upper and lower movable flanges, and the stator is connected with the pump cylinder (23) and the rotor is connected with the plug (22). The invention has low cost and the application in low discharge, for resolving the deflected abrasion between rod and tube, to work at variable flow pressures.

Owner:DAQING OILFIELD CO LTD +1

Hydraulic auxiliary brake device of motor used for oil production

A hydraulic auxiliary brake device of a motor used for oil production is provided. A turning shaft and an oil extraction pump of the motor are provided with a brake disc. The motor is provided with a hydraulic brake. The hydraulic brake is connected with an oil pressure pipe, a one-way clutch gear, and an oil pump. The one-way clutch gear meshes with the brake disc. When the turning shaft and the oil extraction pump of the motor are turned normally for oil production, the one-way clutch idles so that the oil pump doesn't output oil pressure, and the hydraulic brake doesn't activate to brake the brake disc. In case of a power failure, the oil pump is opened to output oil pressure and the hydraulic brake is activated to brake the brake disc, such that the turning shaft and the oil extraction pump are stopped from turning.

Owner:WONG YEN HONG

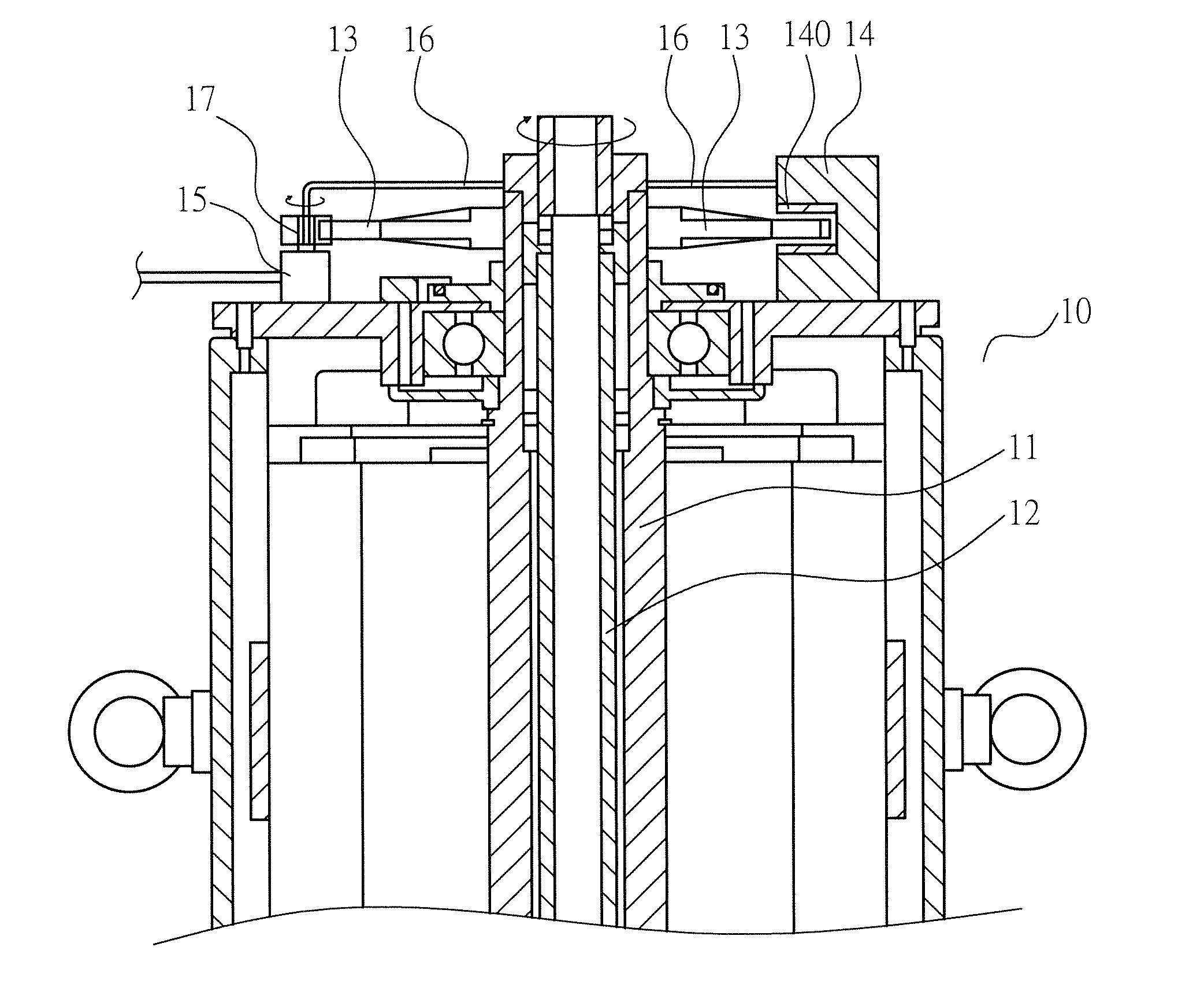

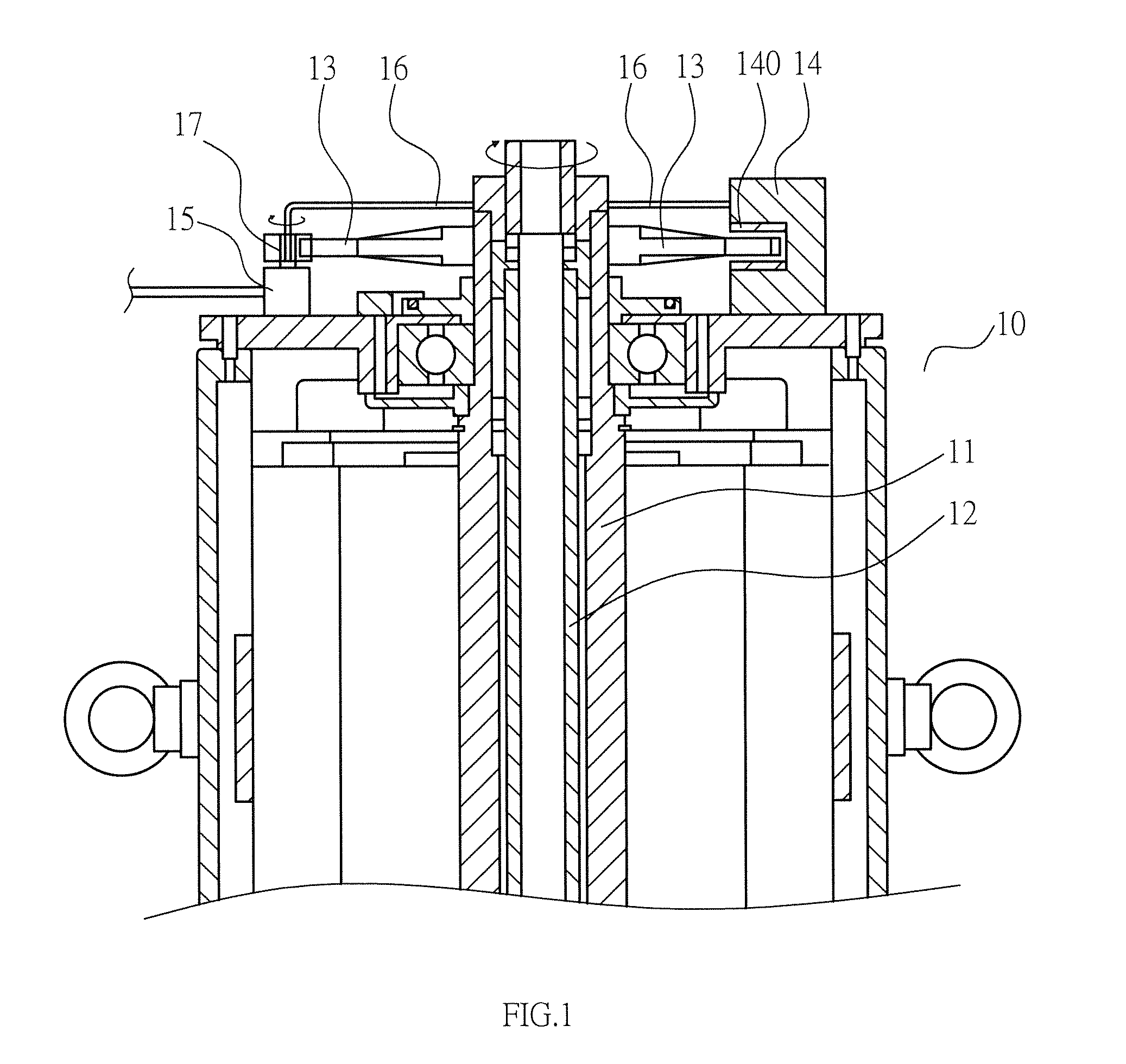

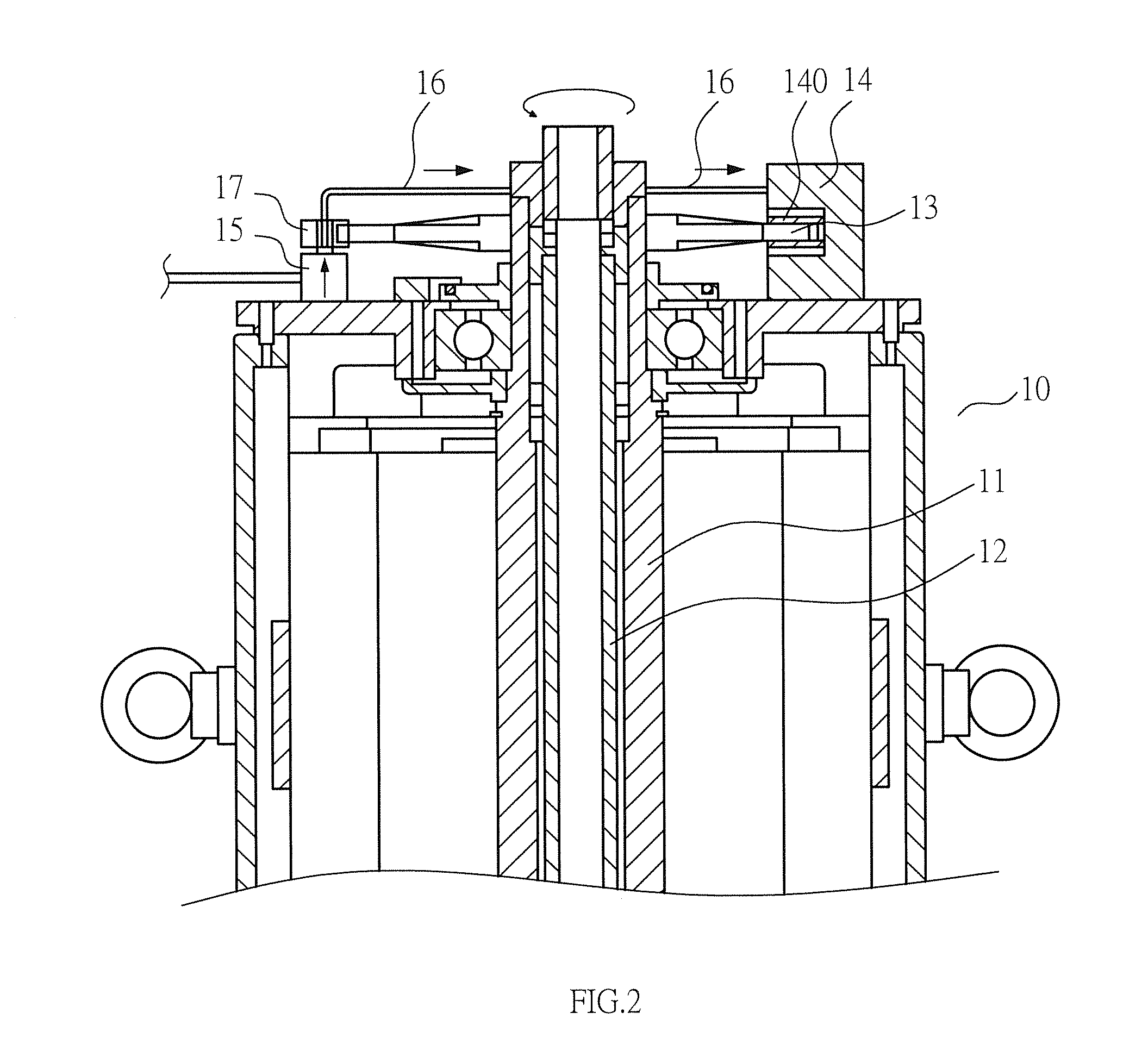

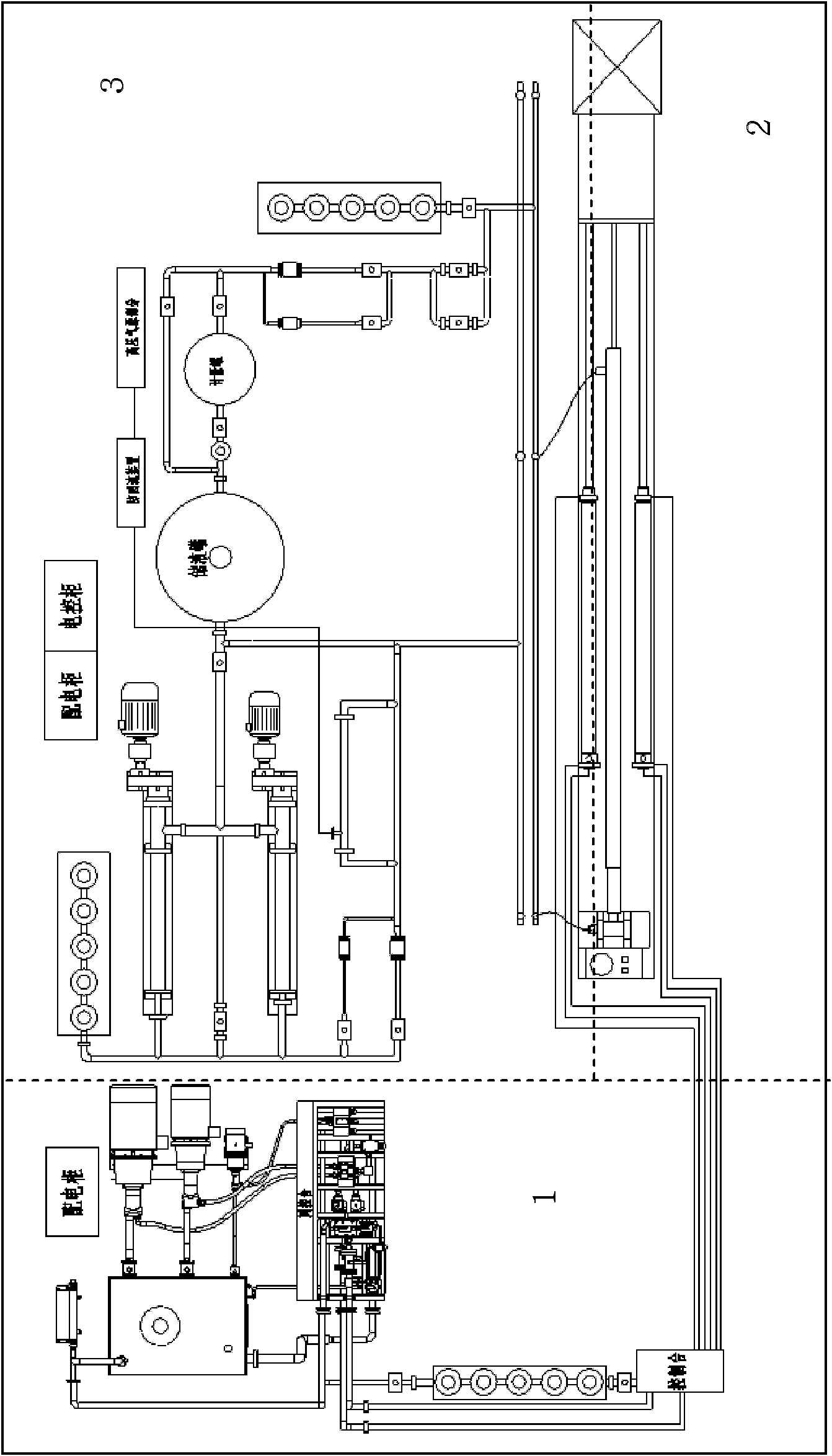

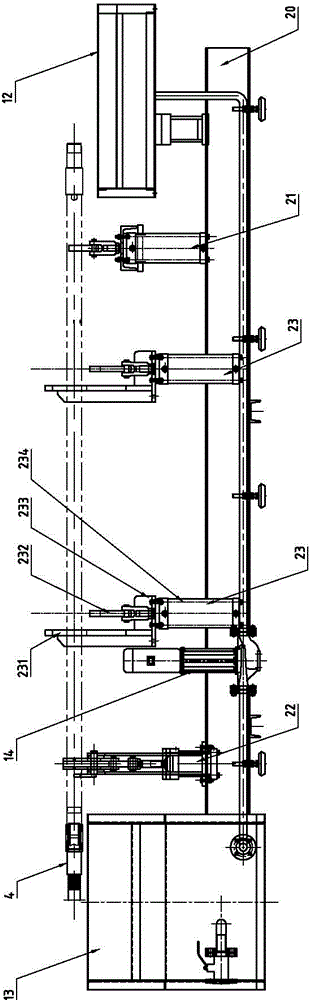

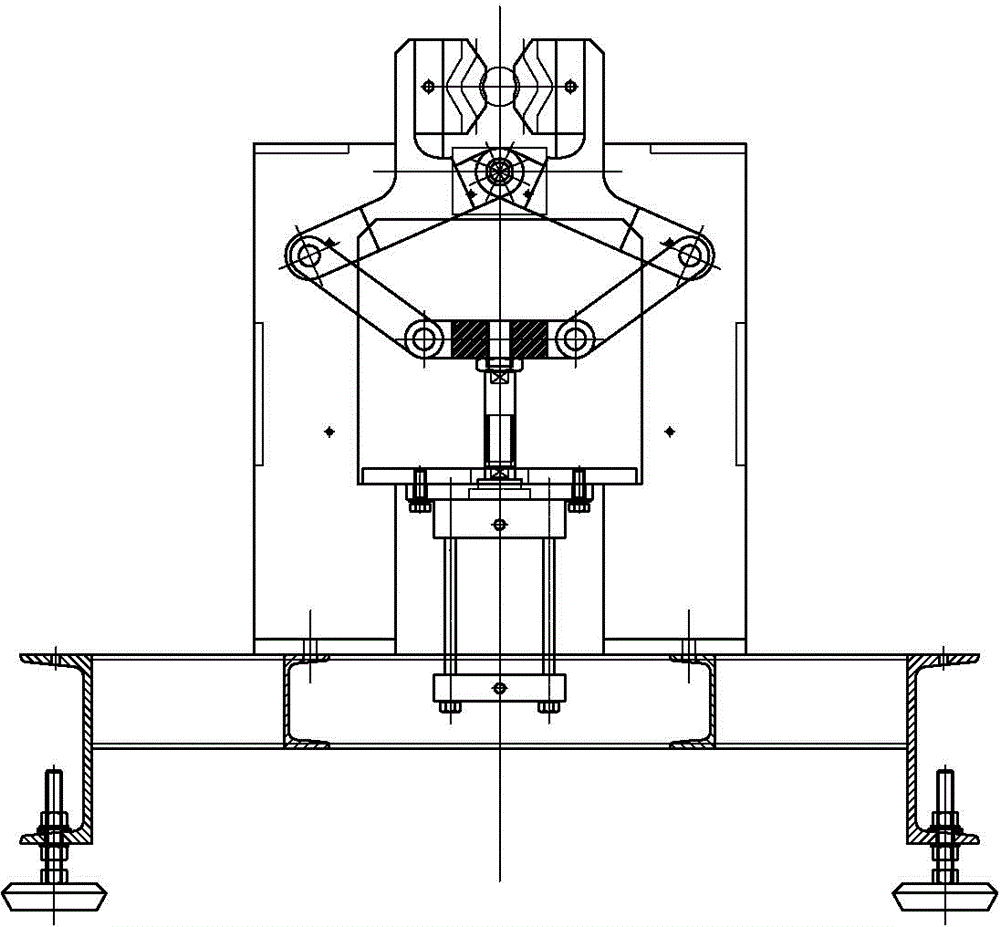

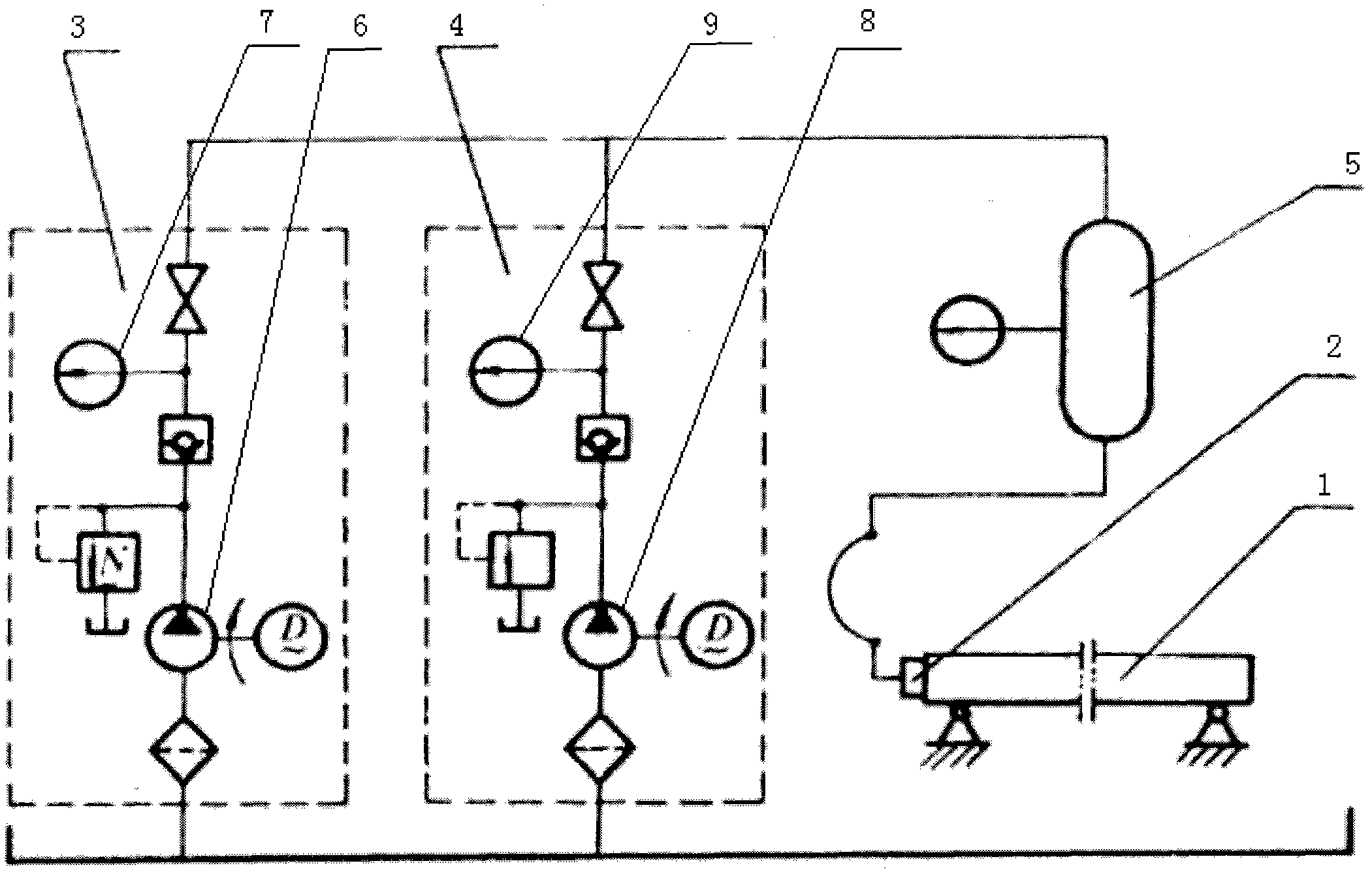

Multifunctional sucker-rod pump hoisting simulation test system

ActiveCN102094803AMeet performance testing needsScientific testing dataPump testingPositive-displacement liquid enginesProcess systemsDirectional well

The embodiment of the invention provides a multifunctional sucker-rod pump hoisting simulation test system which comprises an electro-hydraulic proportion hoisting drive control system, an inclination angle simulation system, a mechanical connecting system, a circulation process system, a data acquisition system and a data control system. According to the embodiment of the invention, the defects of the existing test system can be overcome, the performance test of sucker-rod oil well pumps of a straight well, a deviated well, a directional well and a horizontal well can be carried out, the performance test requirement of an oil field oil-well pump can be satisfied, and scientific detection data can be provided for novel oil-well pumps used under the well.

Owner:PETROCHINA CO LTD

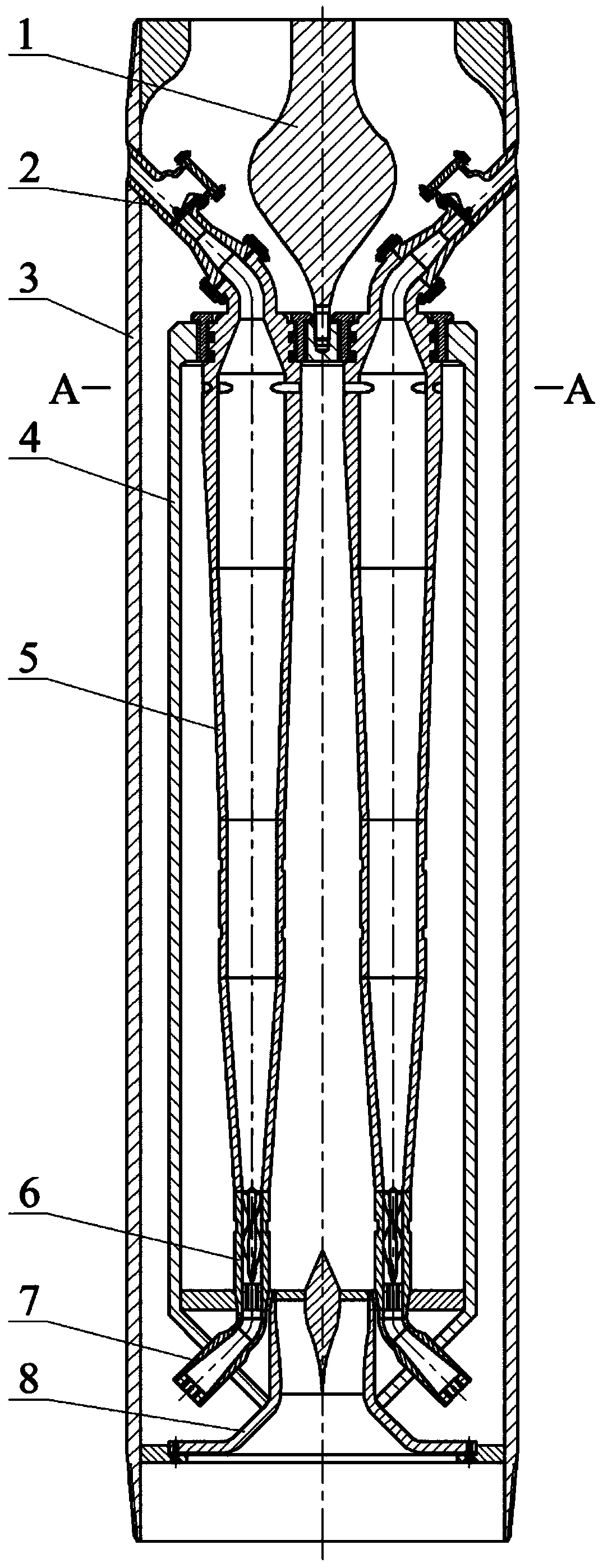

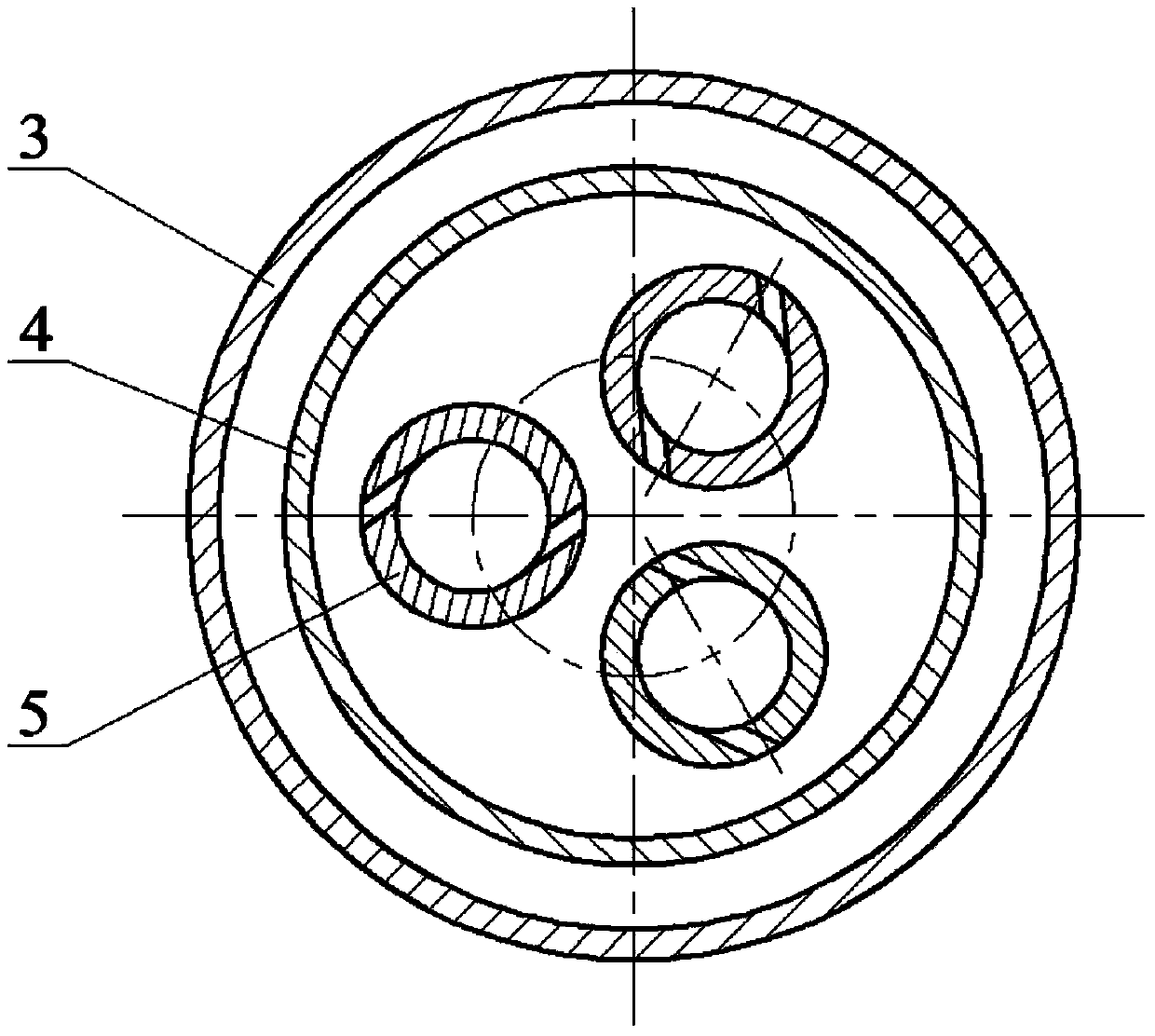

Double-barrel type two-stage axial flow downhole degassing device

The invention provides a double-barrel type two-stage axial flow downhole degassing device which is mounted between an oil pump and a sieve pipe and which is used for gas-liquid phase separation before the oil and gas well output fluid enters the pump for the first time. According to the degassing device, by means of the special double barrel type structure and the two stage axial flow technology, the output fluid gas-liquid phase separation is implemented, and the mechanical recovery system efficiency is improved; the sieve tube is communicated with an inner fluid barrel through a fluid feeding device, and the speed of the fluid being outputted by pumping is increased; an axial flow pipe assembly adopts two stage axial flow gas-liquid separation, axial flow pipes are designed in standardized and modular manners, and the output fluid can be degassed efficiently and thoroughly; the output fluid can be ejected into the axial flow pipes in the high initial velocity through the inner fluid barrel, the double-barrel annular space is formed by the inner fluid barrel and an outer fluid barrel and is used for delivering the fluid in the axial flow pipes after degassing; the degassed fluid is adjusted reversely to form the stabilized flow through a rectifier, is discharged into the outer fluid barrel and is delivered to the oil pump after being accelerated through a fluid director, and the gas is slowed and pressurized through an exhauster before being exhausted into the wellhole.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Oil well sucker rod pump oil pumping completion tubular pile plugging device with pressure

InactiveCN101144377AEasy to installHigh sealing pressureFlexible member pumpsPositive-displacement liquid enginesInlet channelCoupling

The invention relates to a rod pumping well completion string plugging device of an oil-well operating under pressure, and the rod pumping well completion string plugging device comprises an adjusting core axle, a coupling, an upper connector, an upper piston, a locking nut, a drop bar, an oil tube, a lower connector, a lower piston, a screen tube, a screwed plug and an oil well pump. The lower end of the oil well pump is connected with the coupling, the upper connector, the coupling, the oil tube, the coupling, the lower connector, the coupling, the screen tube and the screwed plug in sequence, the upper piston is fixed in the upper connector through an upper shear pin, the adjusting core axle is arranged in the upper piston, the upper end of the core axle is propped up the oil well pump to fix a valve ball, the lower end is connected with the drop bar through the locking nut, the drop bar is positioned in the oil tube, and the lower piston is fixed in the lower connected via a lower shear pin. The invention has the advantages that the installation is convenient, the sealing pressure is high, the success ratio of forming an oil inlet channel with pressure is high, the construction difficulty is reduced, and the invention is widely applied to the petroleum recovery as well as the rework operation process.

Owner:RES INST OF PETROLEUM ENG SHENGLI OIL FIELD SINOPEC

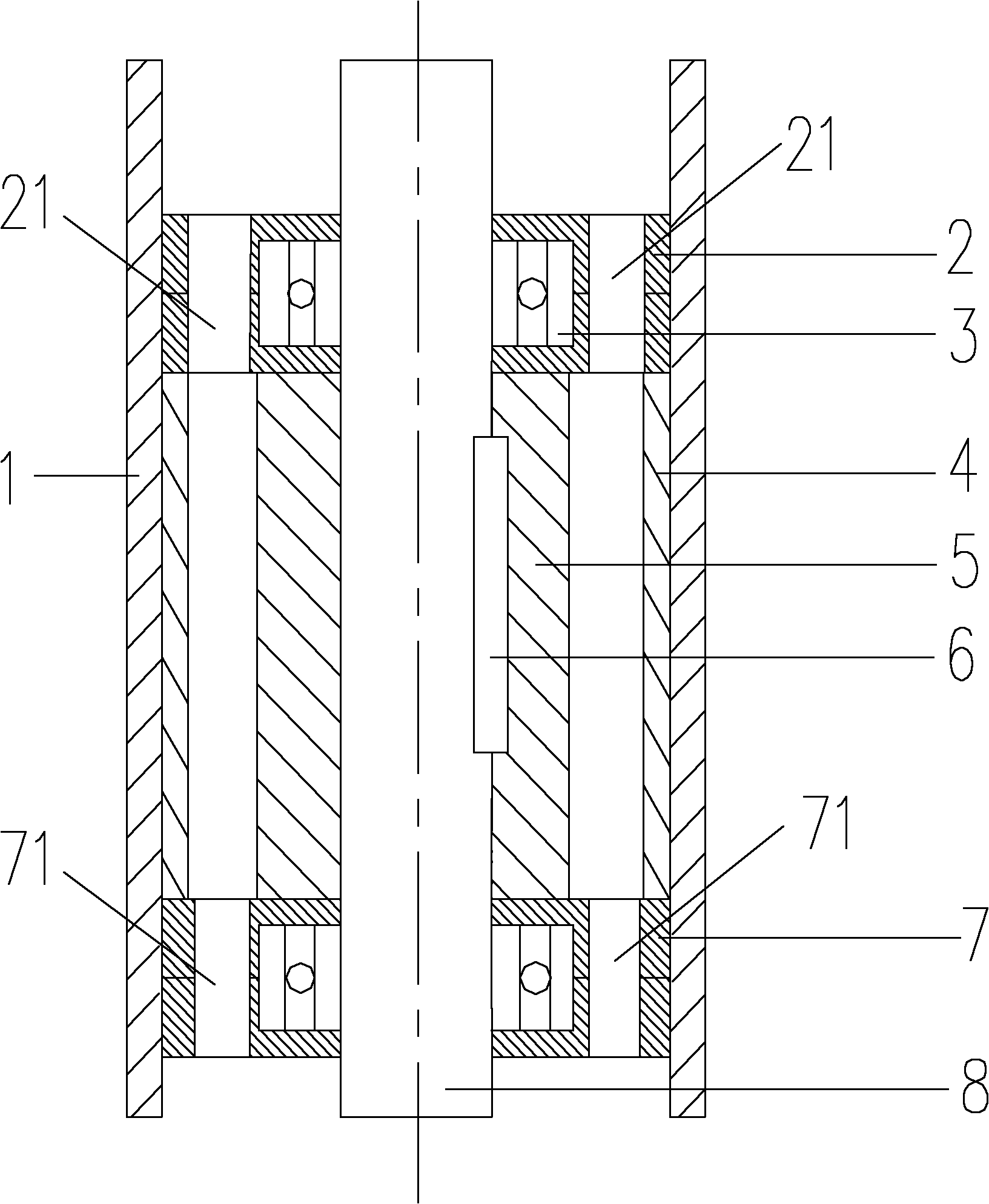

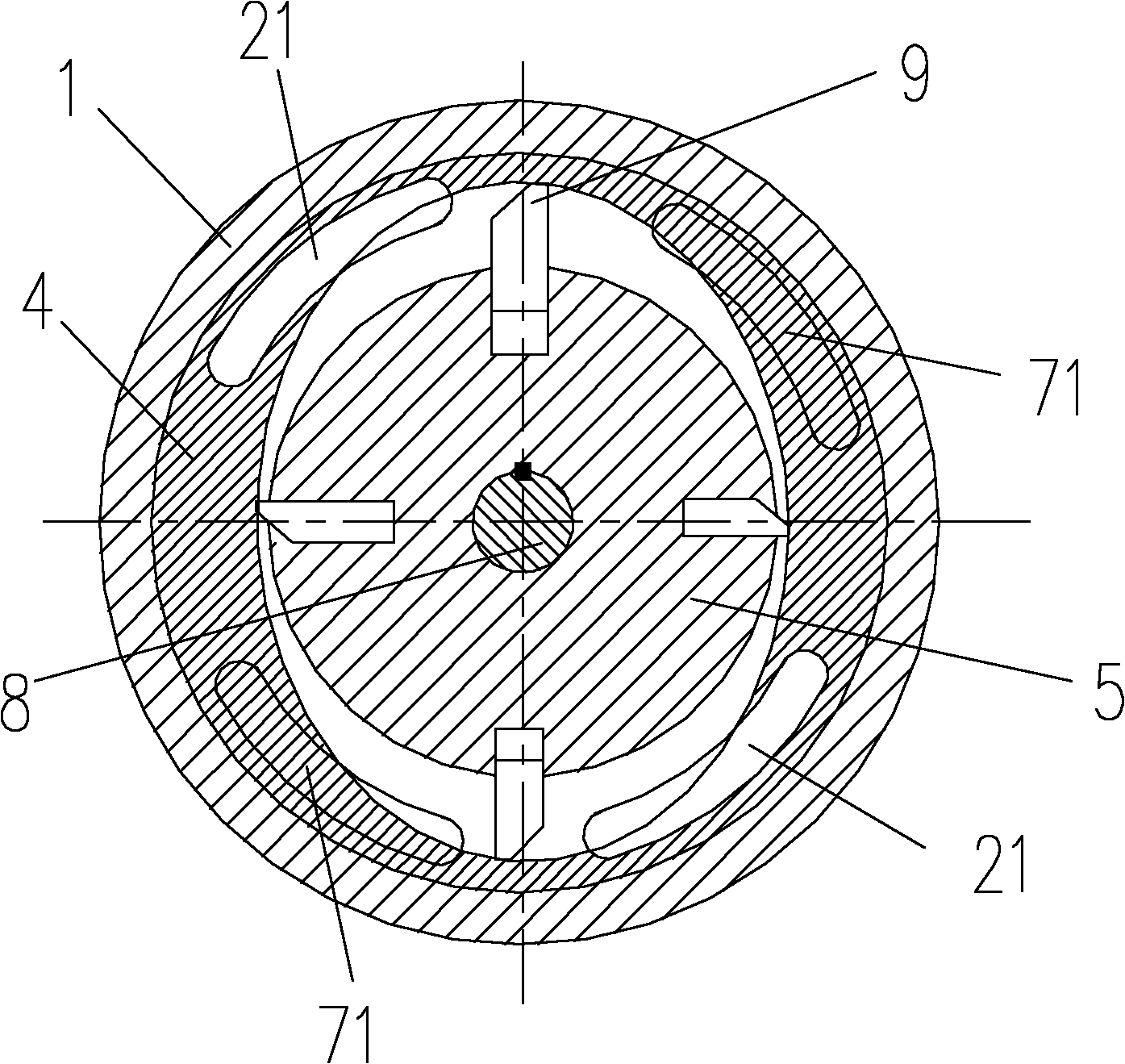

Raw oil lifting system and method for conveying fluid by utilizing sliding vane pump

The invention provides a raw oil lifting system and a method for conveying a fluid by utilizing a sliding vane pump. The raw oil lifting system comprises an oil pipe and an oil pump connected with the oil pipe, wherein the oil pump is the sliding vane pump; the sliding vane pump is provided with a barrel-shaped stator; a drive shaft arranged in the stator along a direction parallel to the length of the stator, and a rotor sleeved onto the drive shaft are arranged in the stator; the lower end of the stator is provided with a suction disk; the upper end of the stator is provided with an exhaustion disk; the suction disk, the exhaustion disk and the stator form a barrel-shaped inner cavity; the rotor is arranged between the suction disk and the exhaustion disk; the suction disk is provided with a suction hole for sucking raw oil; and the exhaustion disk is provided with an exhaustion hole for exhausting the raw oil. The method for conveying the fluid by utilizing the sliding vane pump comprises the steps of sucking and exhausting the fluid from the direction of the end part of the stator to perform a lifting process.

Owner:PETROCHINA CO LTD

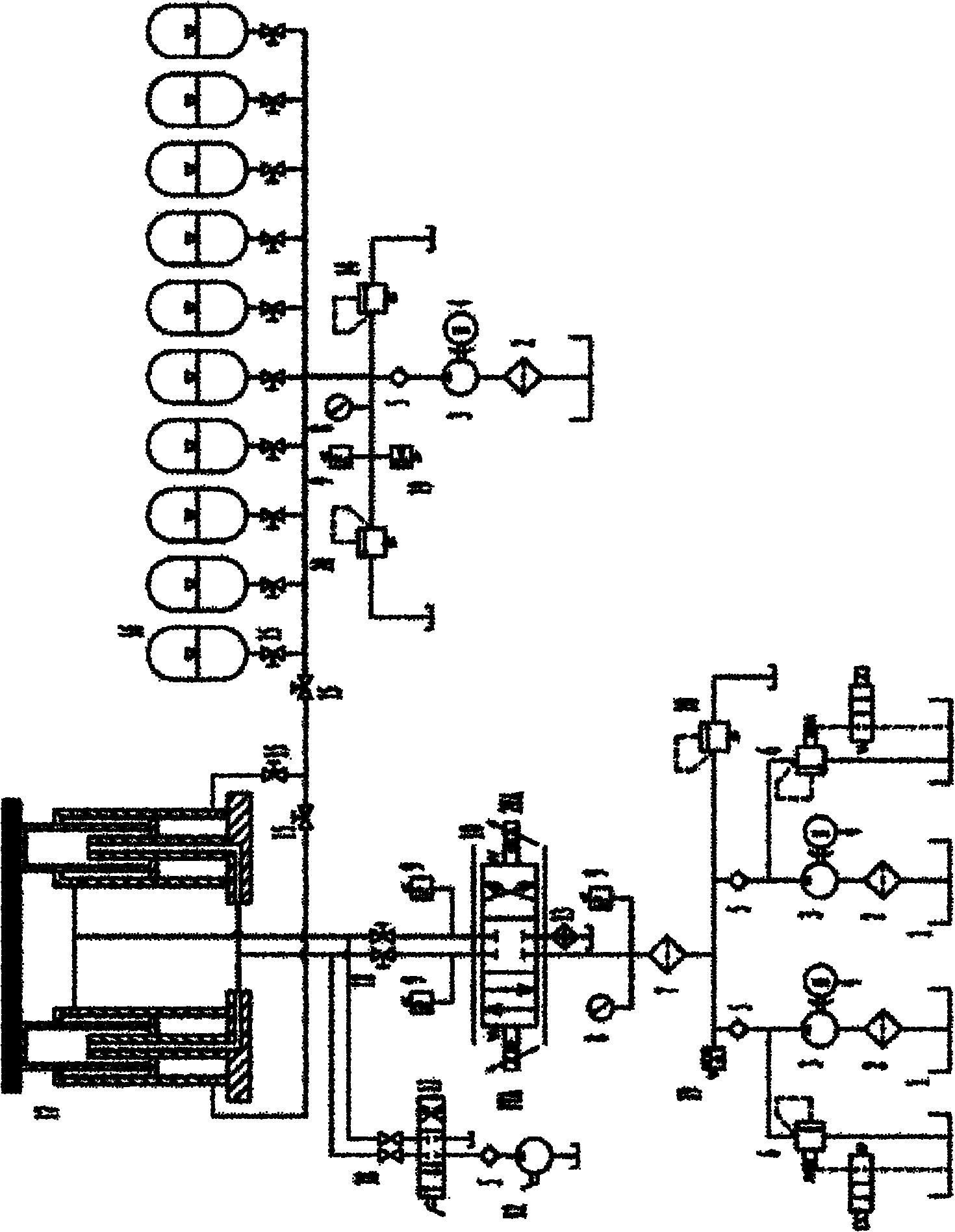

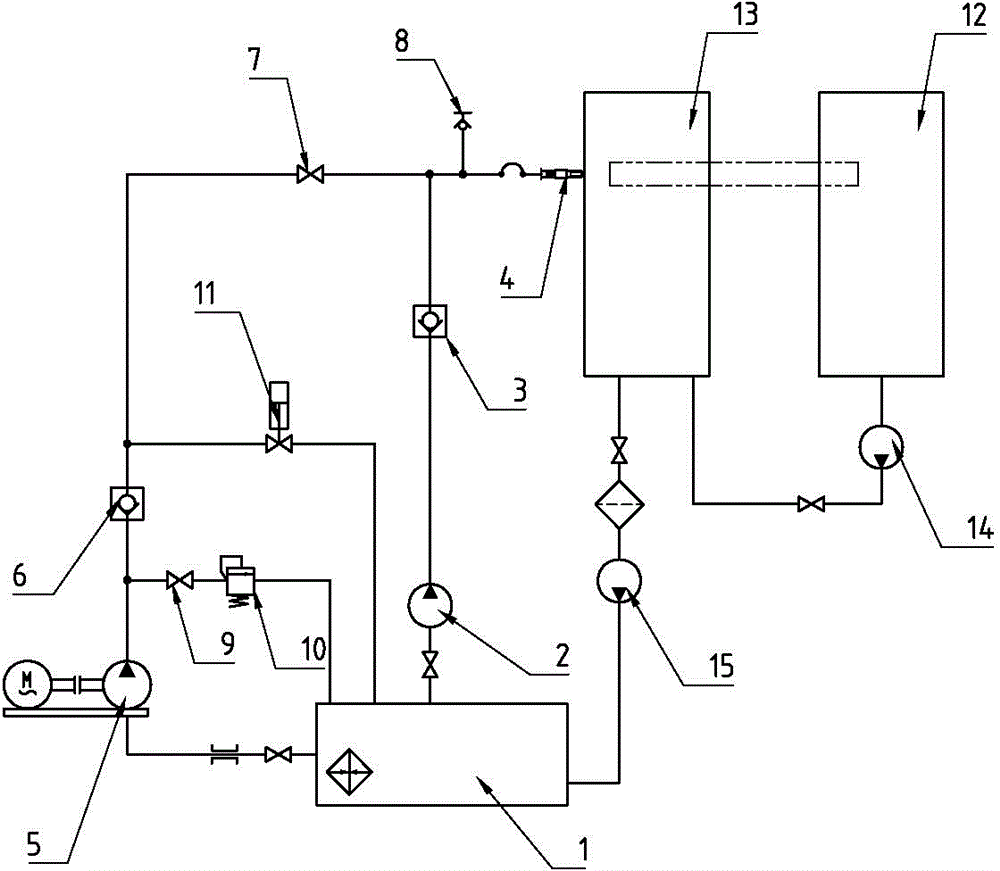

Oil pump tightness performance test and leakage loss detection system and test device

ActiveCN104792475AEasy to switchImprove adaptabilityPump testingMeasurement of fluid loss/gain rateControl engineeringSystem pressure

The invention aims to solve technical problems of providing an oil pump tightness performance test and leakage loss detection system and test device, the oil pump tightness performance test and leakage loss detection can be switched conveniently, the degree of mechanization is high, and multiple oil pumps can be detected simultaneously. Since an overflow valve is arranged, the leakage loss detection state can be switched without the adjustment of a high pressure pump, the adaptability of the system is improved, and the oil pump tightness performance test and leakage loss detection can be switched conveniently since the system matches with a first switch valve and a second switch valve. After testing, an unloading valve is adopted to relief pressure, impact caused by system pressure change can be reduced, and the system safety can be guaranteed.

Owner:QINGDAO ZHONGRUITAI MESNAC TECH CO LTD

Method for underbalanced tubing descending, non-well-killing gas lifting, rotary pumping, pump maintaining and tubing maintaining

ActiveCN103452531AGood productivity improvement effectShorten the working cycleFluid removalFlushingWell drillingGas lift

The invention relates to the technical field of underbalanced well completion and oil production, in particular to a method for underbalanced tubing descending, non-well-killing gas lifting, rotary pumping, pump maintaining and tubing maintaining. The method includes the steps: firstly, fixedly mounting an in-tubing blowout preventer and a lifting basket at the bottom end of a tubing string in sequence from top to bottom, and mounting a float valve in the in-tubing blowout preventer. The in-tubing blowout preventer is fixedly mounted at the bottom of the tubing string, so that tubing descending operation can be completed smoothly in the well completion phase, a gas lift liquid discharge or production passage can be established during gas-lift oil production, tubing descending, gas-lift oil production, oil pumping, oil-well pump maintenance and tubing maintenance can be closely integrated, operation cycle is shortened, operation of putting into production is simplified, reservoir protection effect of underbalanced well drilling is enhanced, oil-gas wells can be put into production timely to keep an excellent productivity increase effect, further competitiveness of the underbalanced technique is improved, and oil production cost is lowered.

Owner:CNPC XIBU DRILLING ENG

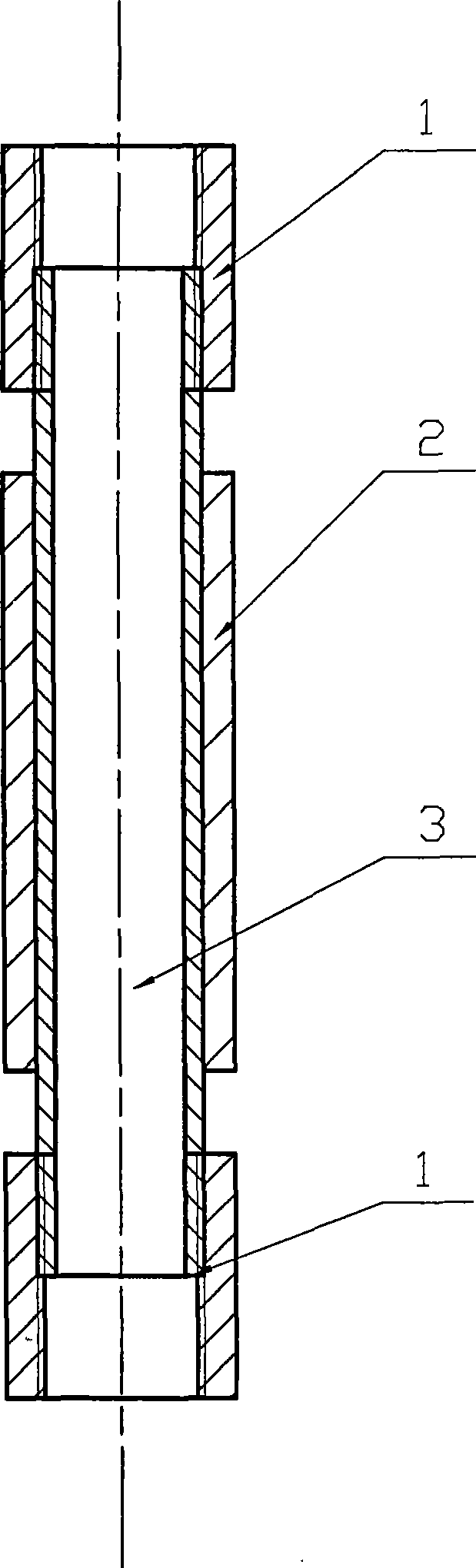

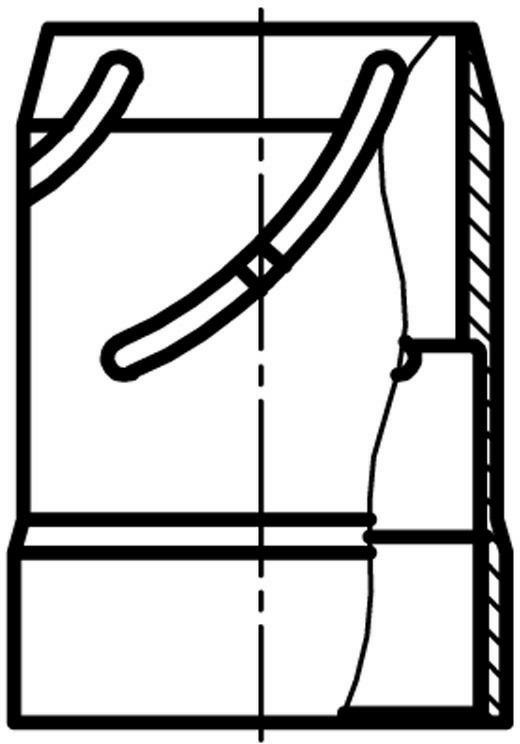

Sand-preventing scale-preventing oil well pump with long plunger piston

ActiveCN102562542AAvoid cloggingPrevent leakagePositive displacement pump componentsFlexible member pumpsCouplingPumpjack

Provided is a sand-preventing scale-preventing oil well pump with a long plunger piston. A short pump barrel is connected with a pump barrel lengthening barrel, the upper end of the short pump barrel is provided with a righting ring and a scale scraping ring, the long plunger piston is installed in the short pump barrel and the pump barrel lengthening barrel, a sand-settling pipe is further installed outside the short pump barrel and the pump barrel lengthening barrel, and the lower end of the pump barrel lengthening barrel is provided with at least one one-way valve. The upper end of the sand-settling pipe is connected with an oil pipe coupling through a righting coupling and a extension coupling, and the lower end of the sand-settling pipe is connected with a double-passage joint. Two ends of the long plunger piston are provided with a first traveling valve and a second traveling valve. The sand-preventing scale-preventing oil well pump with the long plunger piston can effectively prevent litter, sand grains and scale form clamping and burying the plunger piston and a plug fixing valve, achieve normal work in a sand-containing and scaled crude oil well, improve pump efficiency and prolong the pump inspection period.

Owner:CSIC ZHONGNAN EQUIP

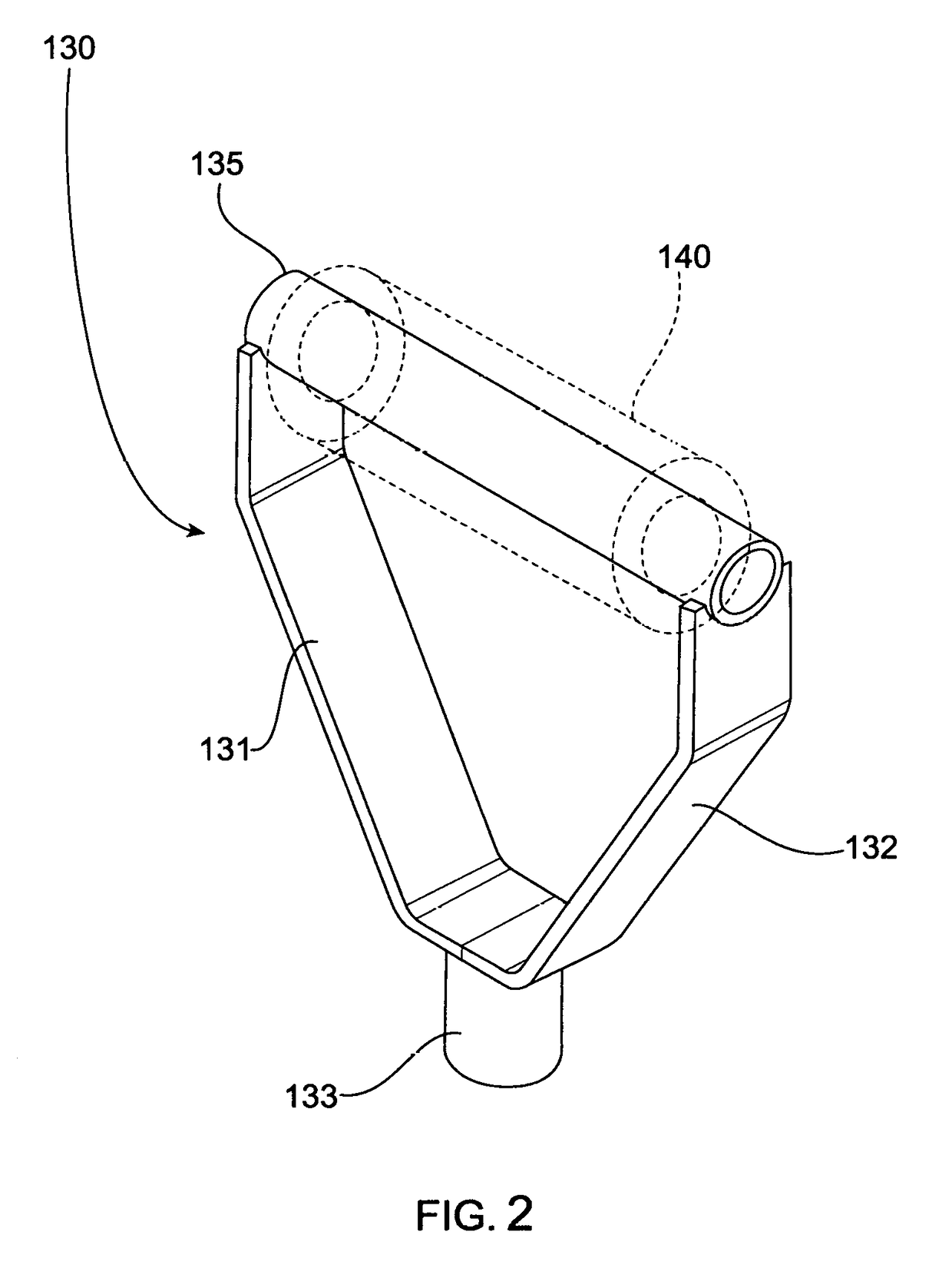

Rotator arm stop and roller assembly

A petroleum extraction pump deploying a sucker rod has an actuator for rotating the portion of the rod in the stuffing box on every stroke to minimize local wear. The rotor handle or arm of the actuator is triggered by an upright roller supported by a an upright rigid linear member, such as a post or tube, that is spaced apart from the well bore by a clamp attached to the main well pipe or stuffing box. The roller rotates with each stroke as it engages the rotator handle. The roller is supported by a Y-shaped saddle to avoid catching on the upstroke of the pumping unit should these member become laterally separated. The device is capable of retrofitting to an existing sucker rod actuator by eliminating a cable to the arm of the actuator and deploying an arm stop member to support the handle in a horizontal orientation until it contacts the roller.

Owner:JW JOHNSON EQUIP LEASING CO

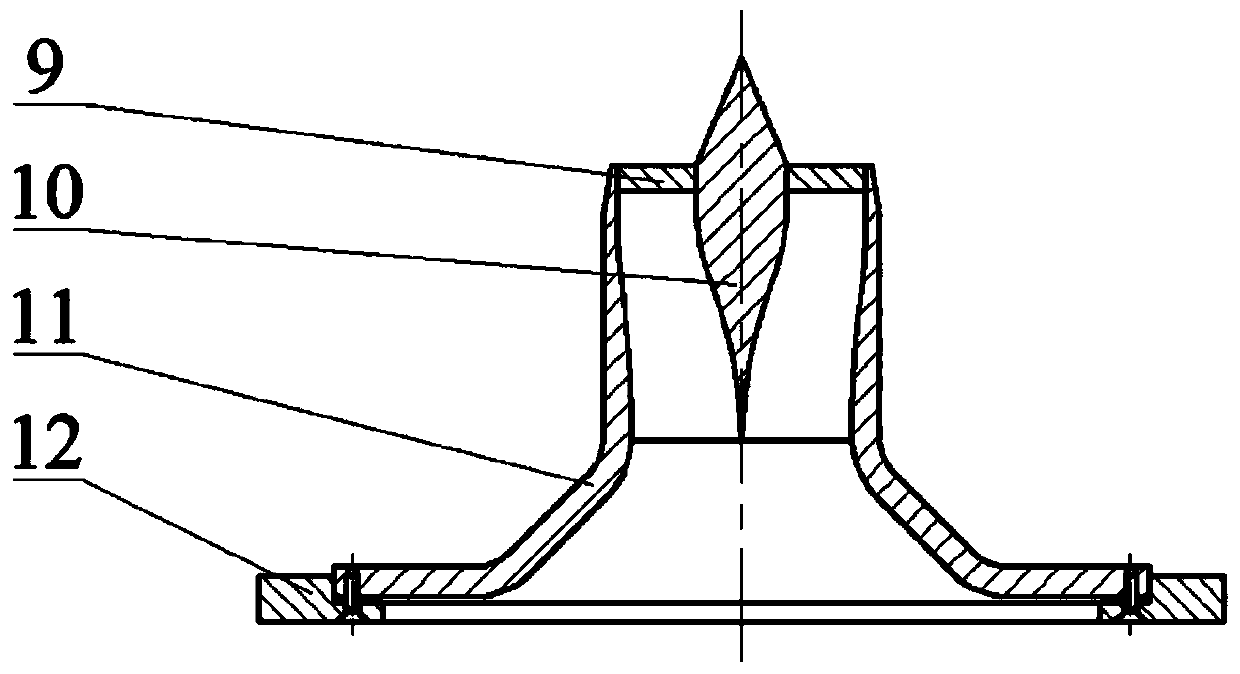

Sand-preventing gas-preventing integrated oil production device

ActiveCN103541887AReduce pump volumeImprove mining efficiencyPositive displacement pump componentsFlexible member pumpsInlet channelCoupling

A sand-preventing gas-preventing integrated oil production device comprises an oil pump and a gas anchor. The oil pump is provided with an outer tube and a plunger, the plunger is arranged in the outer tube in a penetrating mode, and the lower end of the outer tube is connected with a two-way coupling; the plunger is sleeved with a pump cylinder, the upper end of the plunger is connected with an upper traveling valve, the lower end of the plunger is connected with a lower traveling valve, the lower end of the pump cylinder is connected with a plurality of fixing valves, and the fixing valves are communicated with a center hole of the two-way coupling oppositely; the gas anchor is provided with an outer cylinder, an inner cylinder and a center tube, the upper end of the outer cylinder is provided with a liquid inlet hole, a screen is arranged outside the liquid inlet hole, the upper end of the outer cylinder is connected with a straightening ring, and the lower end of the outer cylinder is connected with a reducing coupling; the inner cylinder is located in the outer cylinder, the upper end of the inner cylinder is connected with the two-way coupling, and the lower end of the inner cylinder is connected with a two-way joint; the center tube is located in the inner cylinder, the upper end of the center tube is communicated with the center hole of the two-way coupling oppositely, and the lower end of the center tube is communicated with an oil inlet channel of the two-way joint oppositely. According to the sand-preventing gas-preventing integrated oil production device, in the oil production process, sand-preventing gas-preventing integration can be achieved, and oilfield exploitation benefits are improved.

Owner:PETROCHINA CO LTD

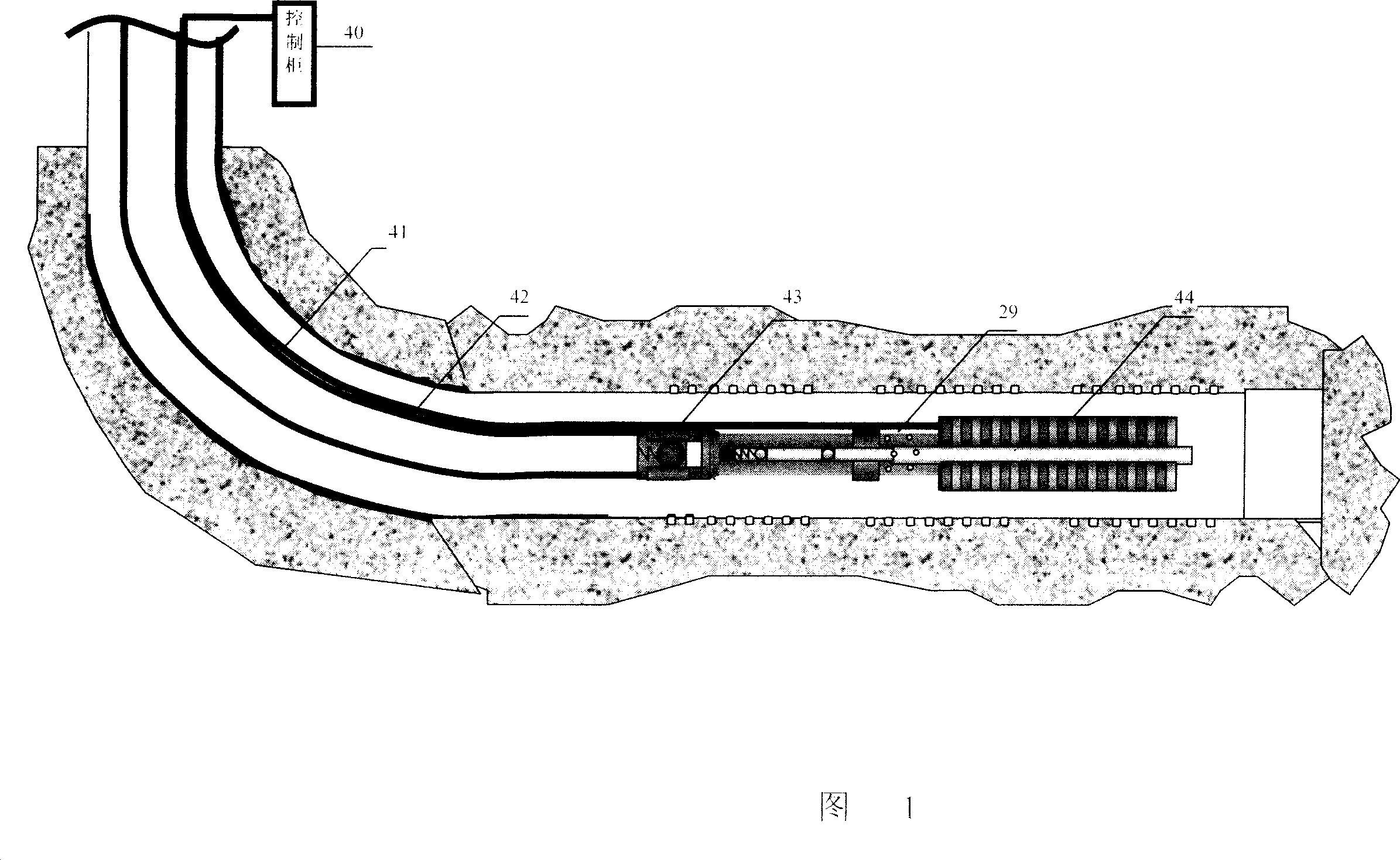

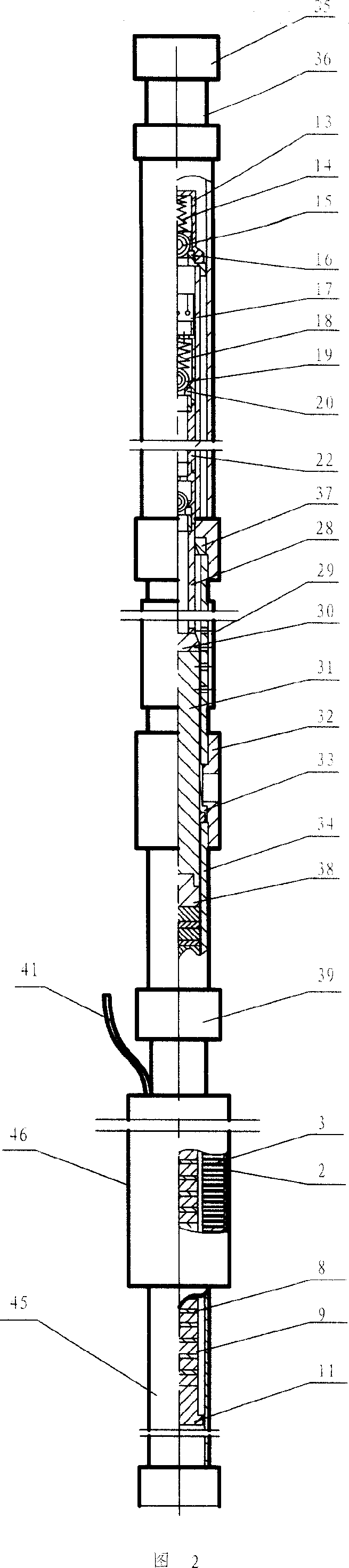

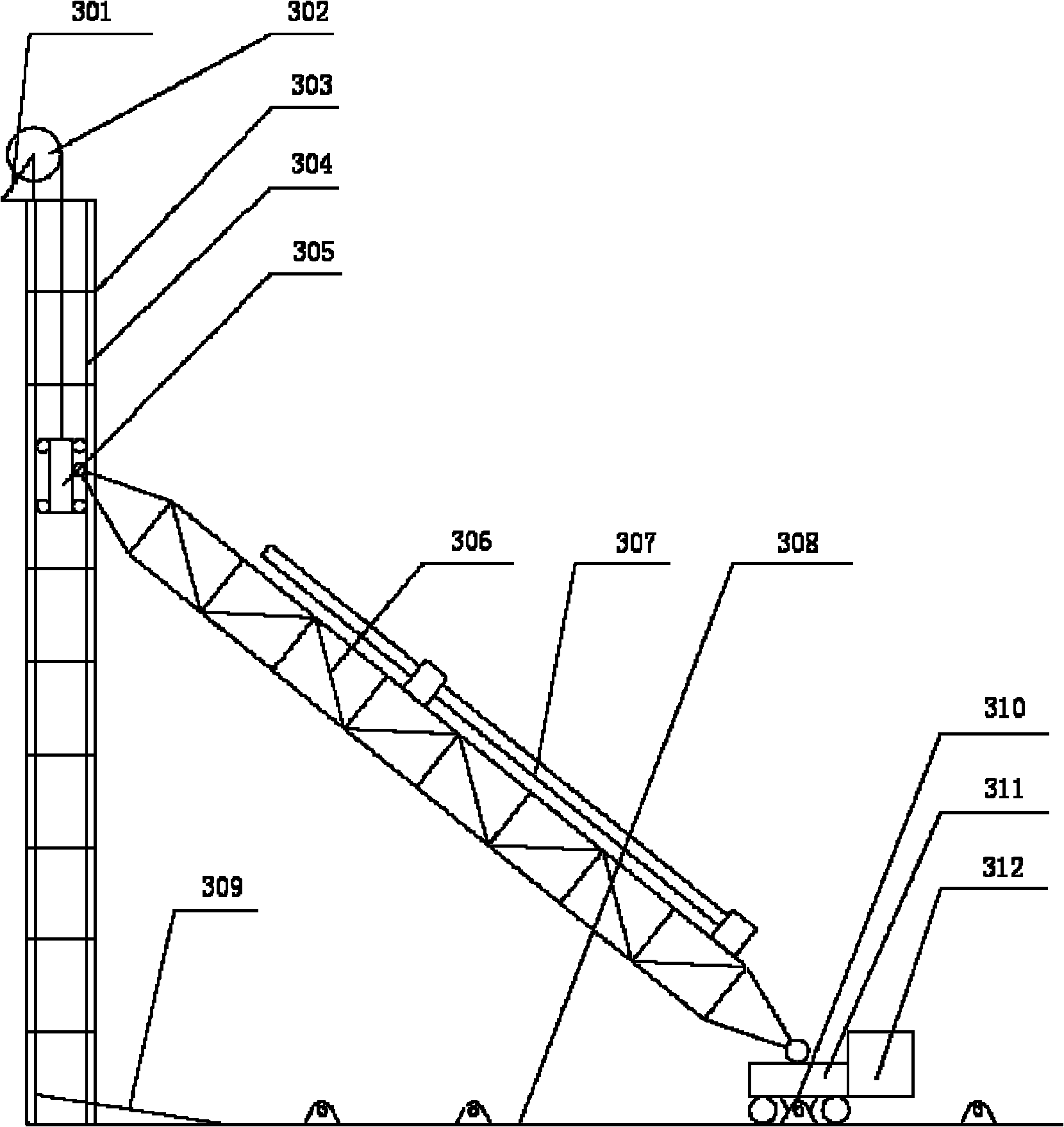

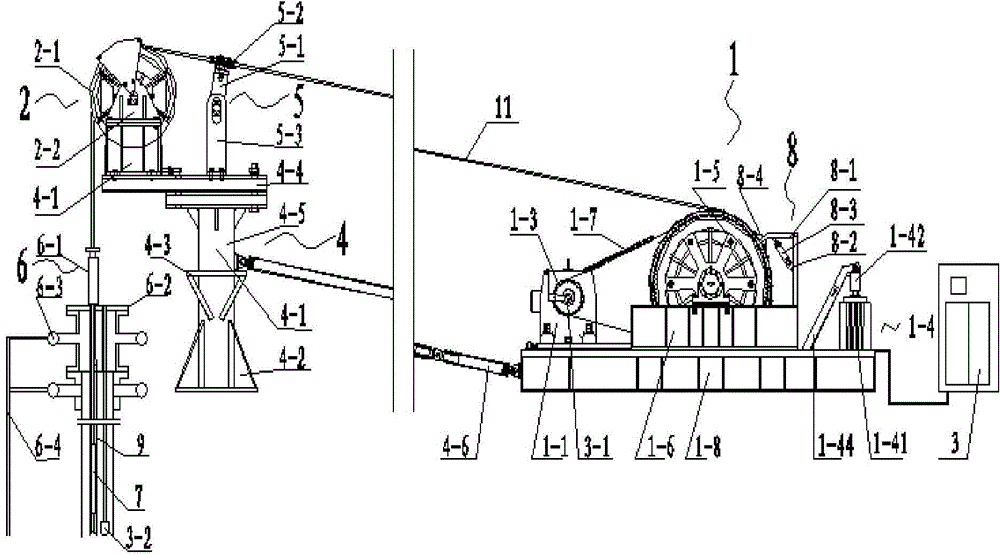

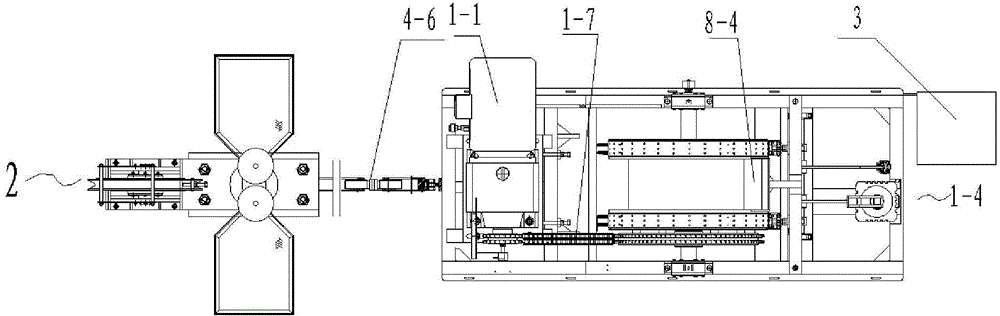

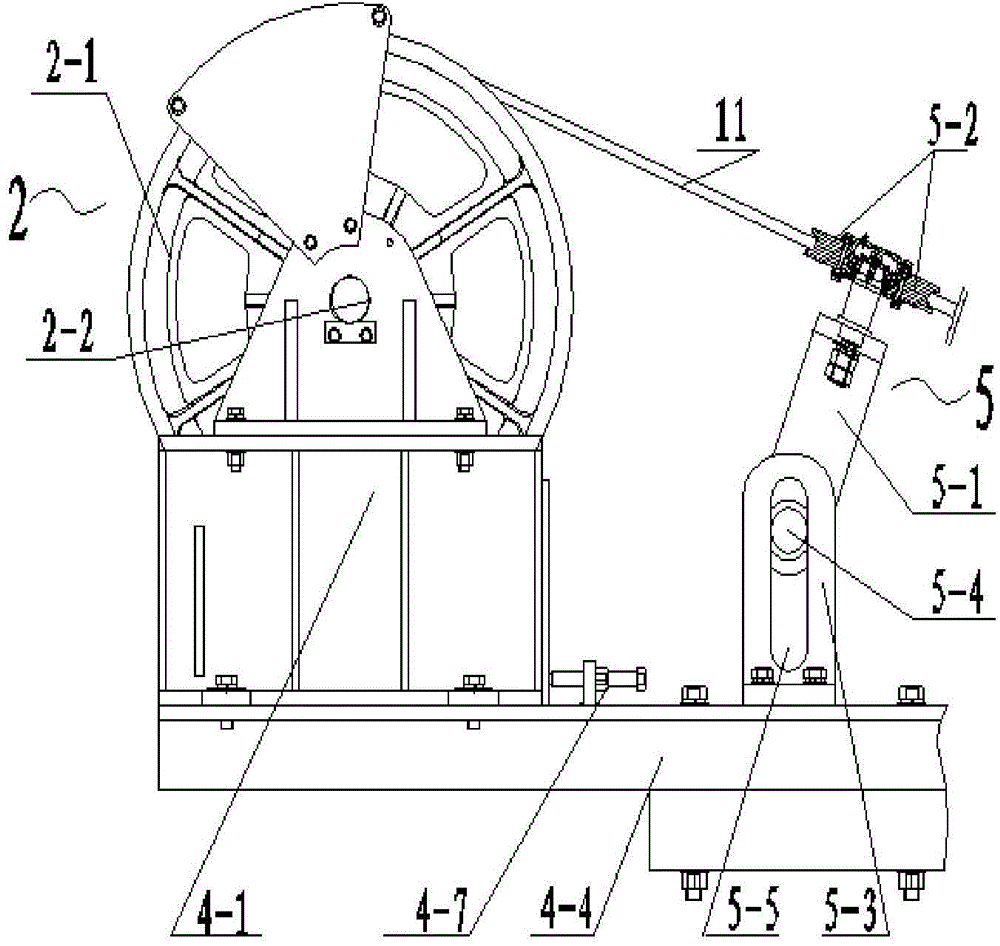

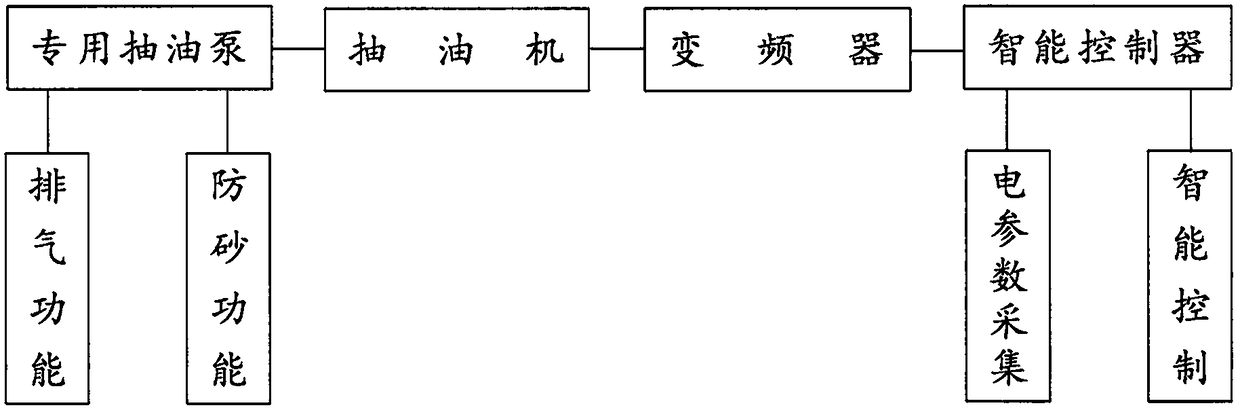

Low-rise super-long stroke intelligent control winding type pulling oil production system and working method

ActiveCN104033134ASolve obstaclesSave crafting materialsConstructionsFluid removalMaterial consumptionWorking set

The invention relates to a low-rise super-long stroke intelligent control winding type pulling oil production system. The low-rise super-long stroke intelligent control winding type pulling oil production system comprises a power drive assembly, a control assembly, a derrick assembly, a well mouth device, an underground tubular column and an underground multi-stage plunger super-long stroke oil well pump. A flexible oil pumping rope driven by the power drive assembly sequentially passes through a blowout prevention box of the well mouth device, an eccentric well mouth and the underground tubular column and is then connected with a steel wire rope in the tubular column or an oil pumping rod through a hoop, and therefore a full-well oil pumping rope is formed. The steel wire rope or the oil pumping rod is connected with the multi-stage plunger of the oil well pump. A fixed pulley assembly and a sliding and swinging device are arranged on the derrick assembly. The well mouth device is connected with the tubular column. The tubular column is connected with a super-long pump cylinder of the underground multi-stage plunger super-long stroke oil well pump. The low-rise super-long stroke intelligent control winding type pulling oil production system can overcome the defects that the stroke of a beam-pumping unit is limited, the beam-pumping unit is not suitable for low-yield oil wells, deep wells and gas-contained large wells, and can solve the problems that according to an existing winding type pulling oil production device, due to the full-well running mode, the size and the weight of the complete machine are large, material consumption is high, and transportation is not convenient.

Owner:瑞燕(上海)能源科技有限公司

Multifunctional oil-extraction and gas-injection integrated oil well pump for sanding heavy crude oil well

InactiveCN101526079AReduce workloadIncrease heatFlexible member pumpsFluid removalHeavy crude oilPumpjack

The invention relates to a multifunctional oil-extraction and gas-injection integrated oil well pump for a sanding heavy crude oil well, comprising a long pump cylinder, a long plunger, a valve group, a gas-injection device and a sand control device, wherein the long plunger and the valve group are arranged in the long pump cylinder, and the gas-injection device and the sand control device are connected with and mounted below the long pump cylinder. The oil well pump has reasonable design, novel structure and reliable operation and can enable the sanding heavy crude oil well to integrate sand washing, gas injection and oil extraction so as to lighten a great amount of downhole operation workload, effectively solve sanding problem and favorably improve the thermal recovery and stable yield effects of a pumping well.

Owner:潘昌德

Oil well pump gap leakage test method

InactiveCN103133326AImprove sealingReliable bearing strengthPump testingPositive-displacement liquid enginesInlet valveLeakage test

The invention discloses an oil well pump gap leakage test method which is mainly composed of pressure test joints (2), a lower-pressure charging pump system (3) and a high-pressure charging pump system (4), wherein the pressure test joints (2) are connected with an oil well pump (1), and the lower-pressure charging pump system (3) and the high-pressure charging pump system (4) are respectively communicated with the inside of the oil well pump (1) through the pressure test joints (2). The oil well pump gap leakage test method can test whether seal performance and pressure bearing strength of various cone pipe thread seal surfaces, various section seal surfaces, oil inlet valve seal surfaces and various pressure bearing parts of the oil well pump under underground liquid column pressure is reliable.

Owner:欧阳才伟

Swabbing parameter matching non-stop intermittent oil pumping and production system

InactiveCN109424337AGuaranteed reliabilityFit clearance is smallConstructionsFluid removalElectricityWorking fluid

The invention relates to a swabbing parameter matching non-stop intermittent oil pumping and production system. The system is characterized by being composed of an intelligent controller, a frequencyconverter and a special oil pump. An electric parameter test acquisition device is installed in the intelligent controller, embedded software is written in the intelligent controller, the active powerof a pumping unit is tested in real time, the working fluid level depth of an oil well is calculated according to the active power and structural parameters of the pumping unit, on this basis, when the working fluid level reaches a certain range, an intelligent program is started automatically, every time after the pumping unit reaches a top dead center, a crank is controlled to swing within a small angle range instead of immediate starting of a lower stroke, the time is provided for filling of the special oil pump, after the crank swings for a set time, an oil production program is started,and the operations are repeated; the oil pump is kept to always work under the optimal submergence condition while the high pumping efficiency is ensured; meanwhile, the pumping diameter of the oil pump is increased, the oil production stroke frequency of the pumping unit is greatly reduced under the condition of the same liquid yield, and the energy consumption of the system is reduced.

Owner:DAQING SENENPU MACHINERY MFG

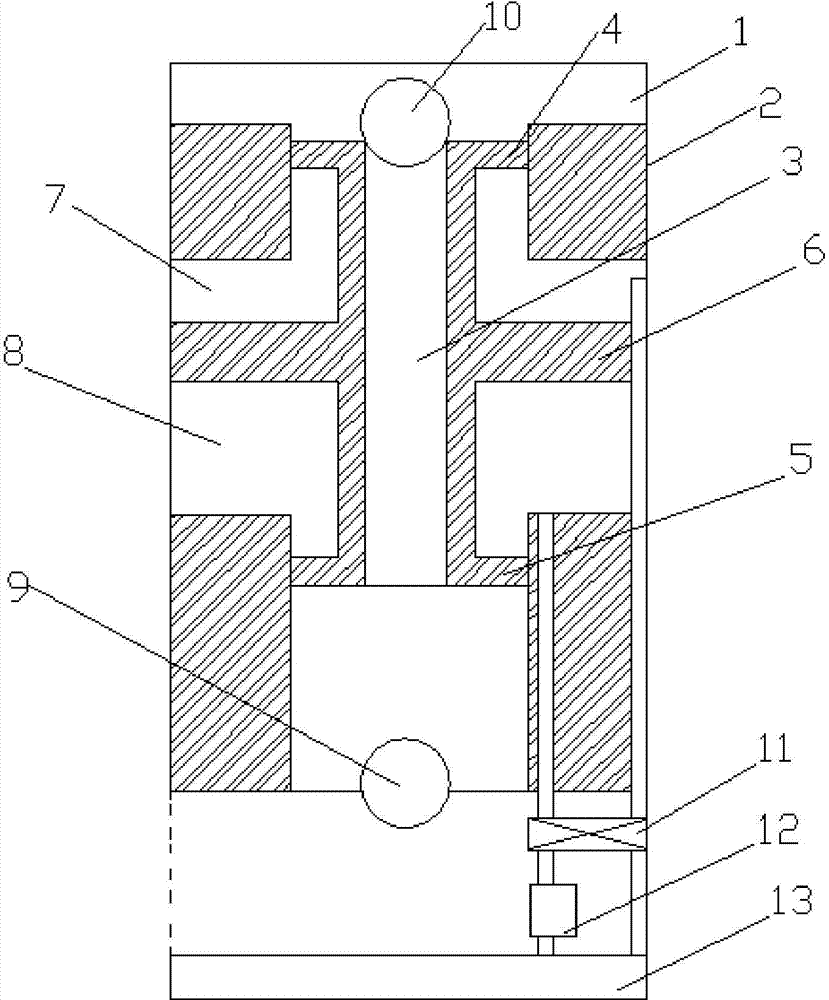

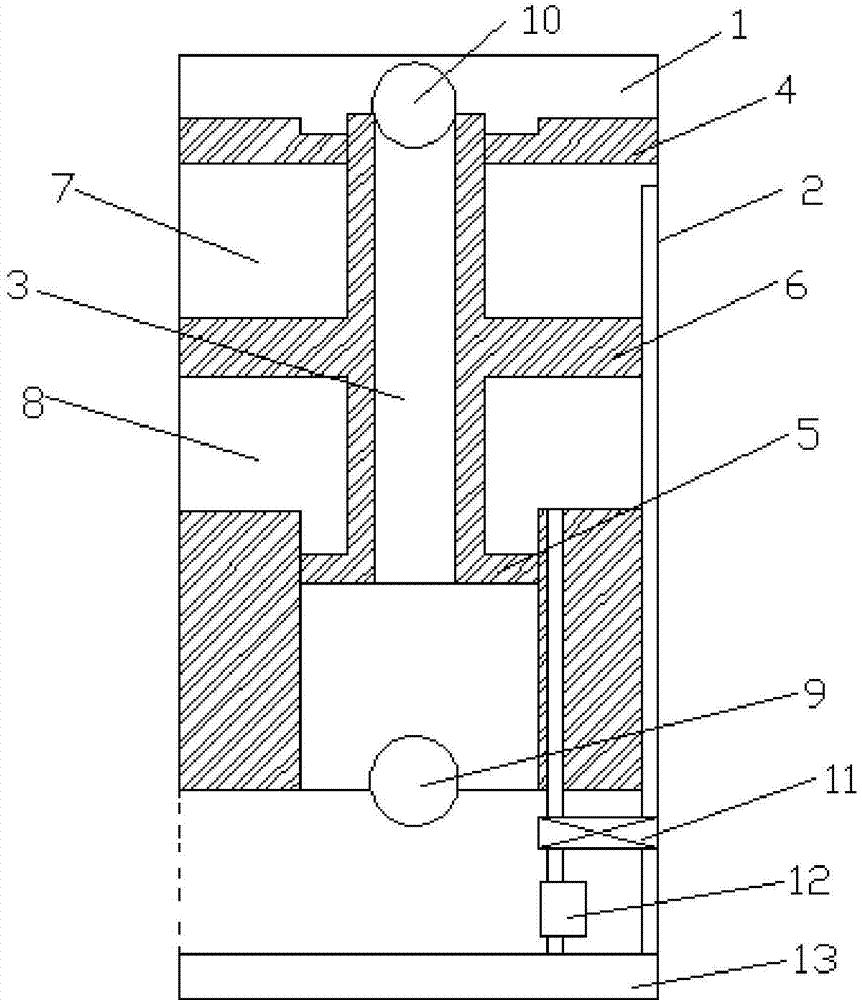

Oil production pump

InactiveCN103498786ATightly boundReduce oil outputFlexible member pumpsPositive-displacement liquid enginesInlet valveOil production

The invention discloses an oil production pump which comprises an oil-well pump and a hydraulic system. The oil production pump is characterized in that the oil-well pump comprises a pump body, the lower end portion of the pump body is a sealed face which is provided with an oil inlet, an oil inlet valve is arranged on the oil inlet, an oil pumping pipe is vertically arranged in the pump body above the oil inlet valve, an upper piston is arranged outside the upper end portion of the oil pumping pipe in a sleeved mode, a lower piston is fixedly arranged on the lower end portion of the oil pumping pipe in a sleeved mode, the upper piston, the lower piston, the oil pumping pipe and the pump body form a sealed hydraulic oil storage chamber, a middle piston is fixedly arranged in the middle of the oil pumping pipe in a sleeved mode, the middle piston divides the hydraulic oil storage chamber into an upper chamber and a lower chamber with changeable volumes, the upper chamber and the lower chamber are communicated with the hydraulic system through pipelines respectively, and an oil outlet valve is arranged at an upper end outlet of the oil pumping pipe.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com