Swabbing parameter matching non-stop intermittent oil pumping and production system

An oil production system and parameter matching technology, applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve problems such as damage to oil production system, increase the possibility of freezing wellhead and wax deposition, liquid hammer phenomenon, etc. Guaranteed effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

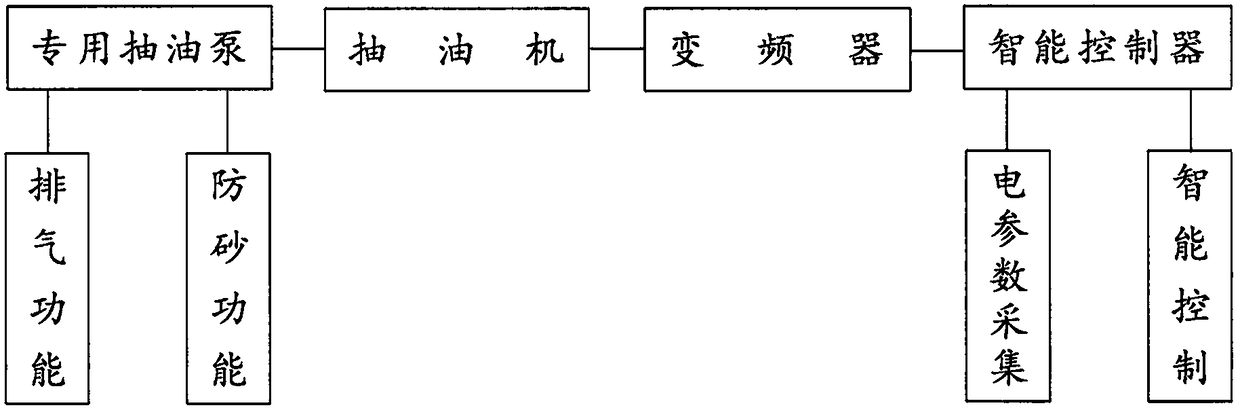

[0070] When working in oil wells, the special oil pump for the intelligent oil production system is lowered to the design depth, and a special intelligent controller and frequency converter are installed in the original control cabinet. The intelligent controller is designed with an electrical parameter acquisition device to test and collect the running time of the motor in real time. The active power of the intelligent controller is written with embedded software, which calculates the power map and the depth of the dynamic liquid surface of the pumping unit through the software, and based on the depth of the dynamic liquid surface, when the submergence of the oil well reaches a reasonable range, the intelligent The program controls the forward and reverse rotation of the motor at low speed through the frequency converter to realize the swing of the crankshaft and provide waiting time for the oil pump to be fully charged. At the same time, it realizes the remote transmission and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com