Patents

Literature

32results about How to "Increase fullness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

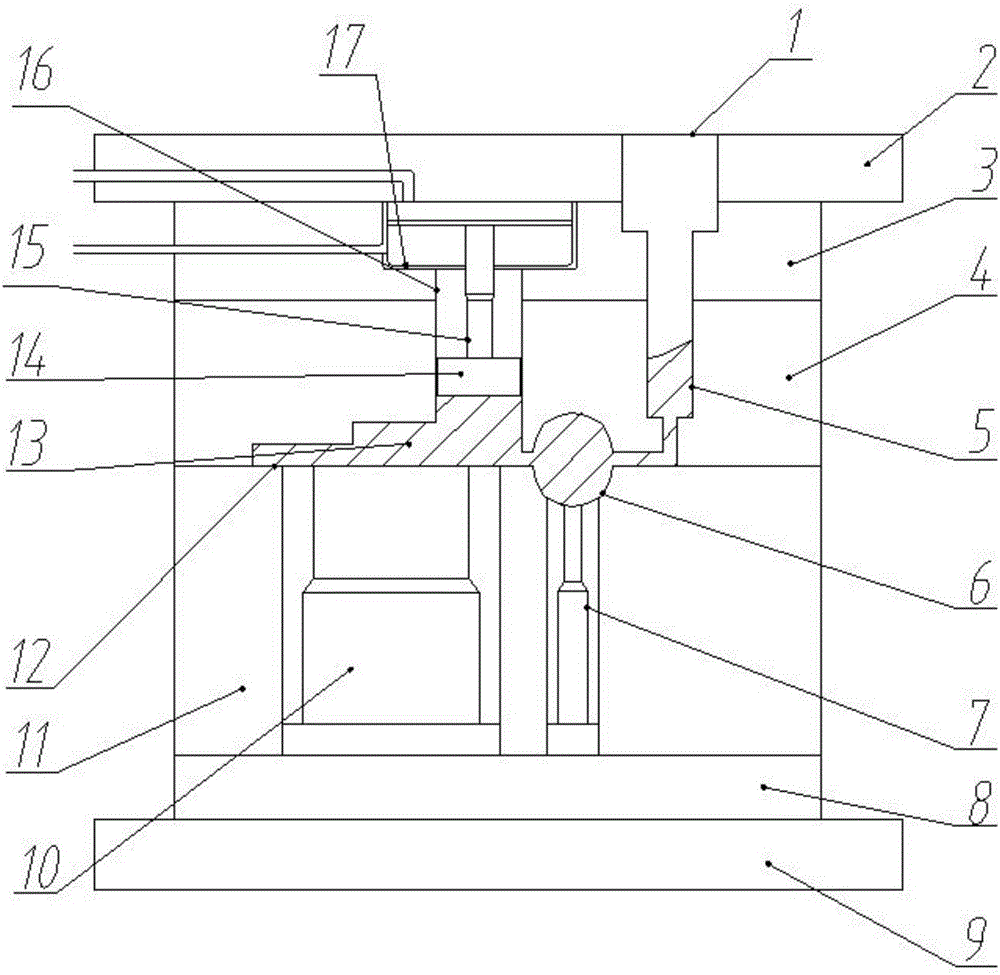

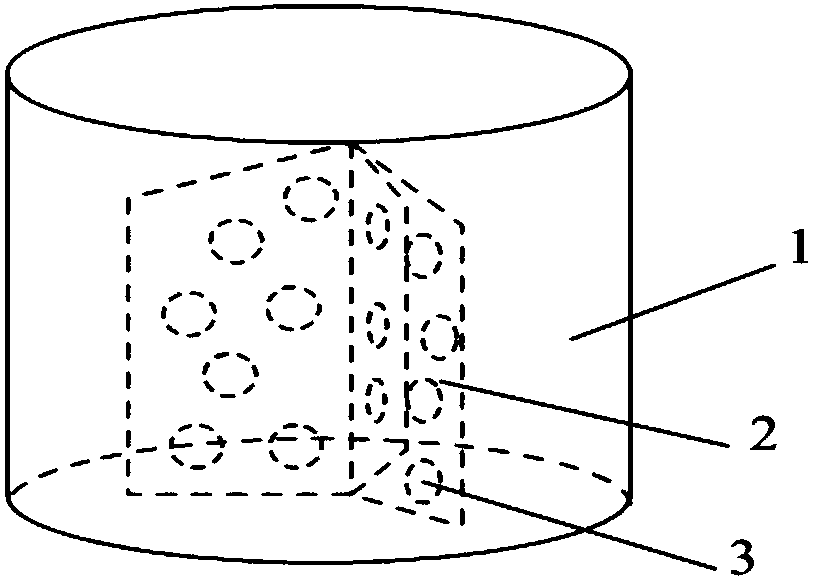

Die casting technology for shrinkage-prevention die casting

InactiveCN105817599AIncrease fullnessSolve shrinkage cavity, shrinkage porosityPush outShrinkage porosity

The invention discloses a die-casting process for anti-shrinkage cavity die-casting parts. The die-casting method comprises the following steps: starting the die-casting machine → installing the mold → debugging the mold → cleaning the preheated mold → spraying paint → closing the movable mold and the fixed mold → pouring →holding pressure→feeding and compaction→pressurization→separation of movable mold and fixed mold→push out the die casting→cut off the riser and gate on the die casting→saturate the die casting→surface the die casting. The die-casting process of this kind of anti-shrinkage cavity die-casting effectively solves the problems of product shrinkage and porosity, and finally obtains dense and intact parts, reducing the defective rate.

Owner:安徽纯启动力科技有限公司

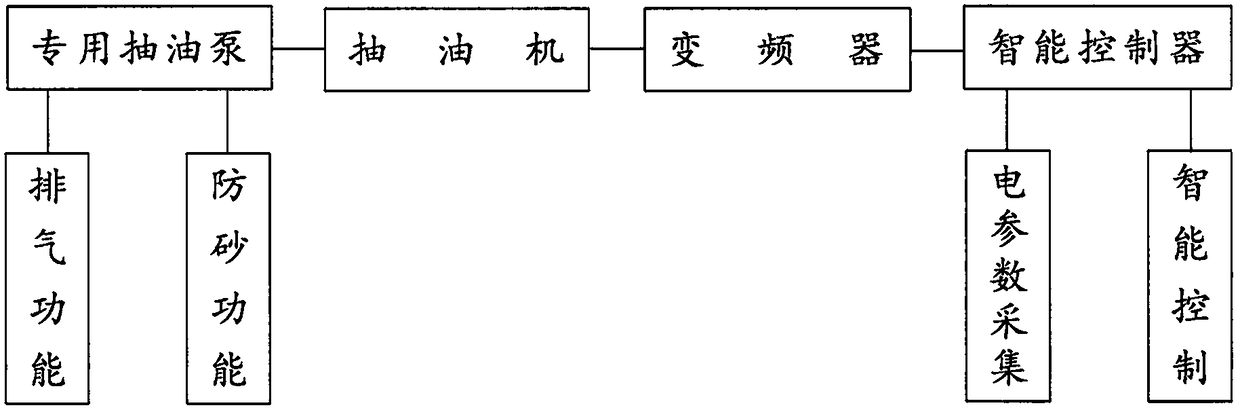

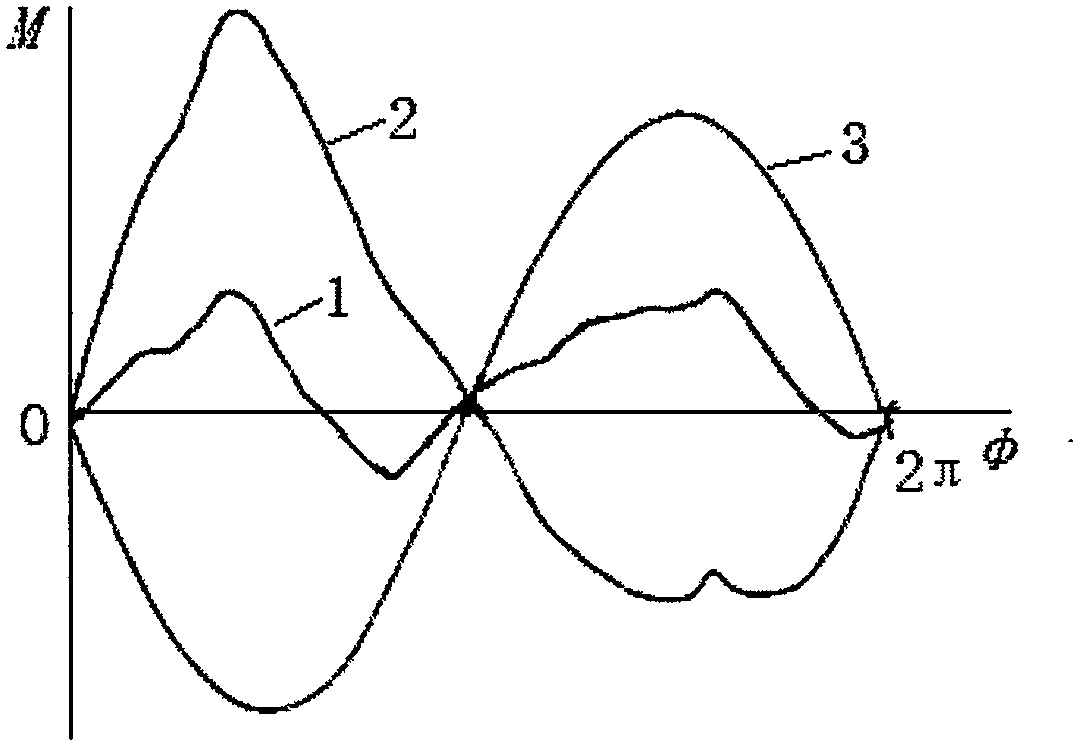

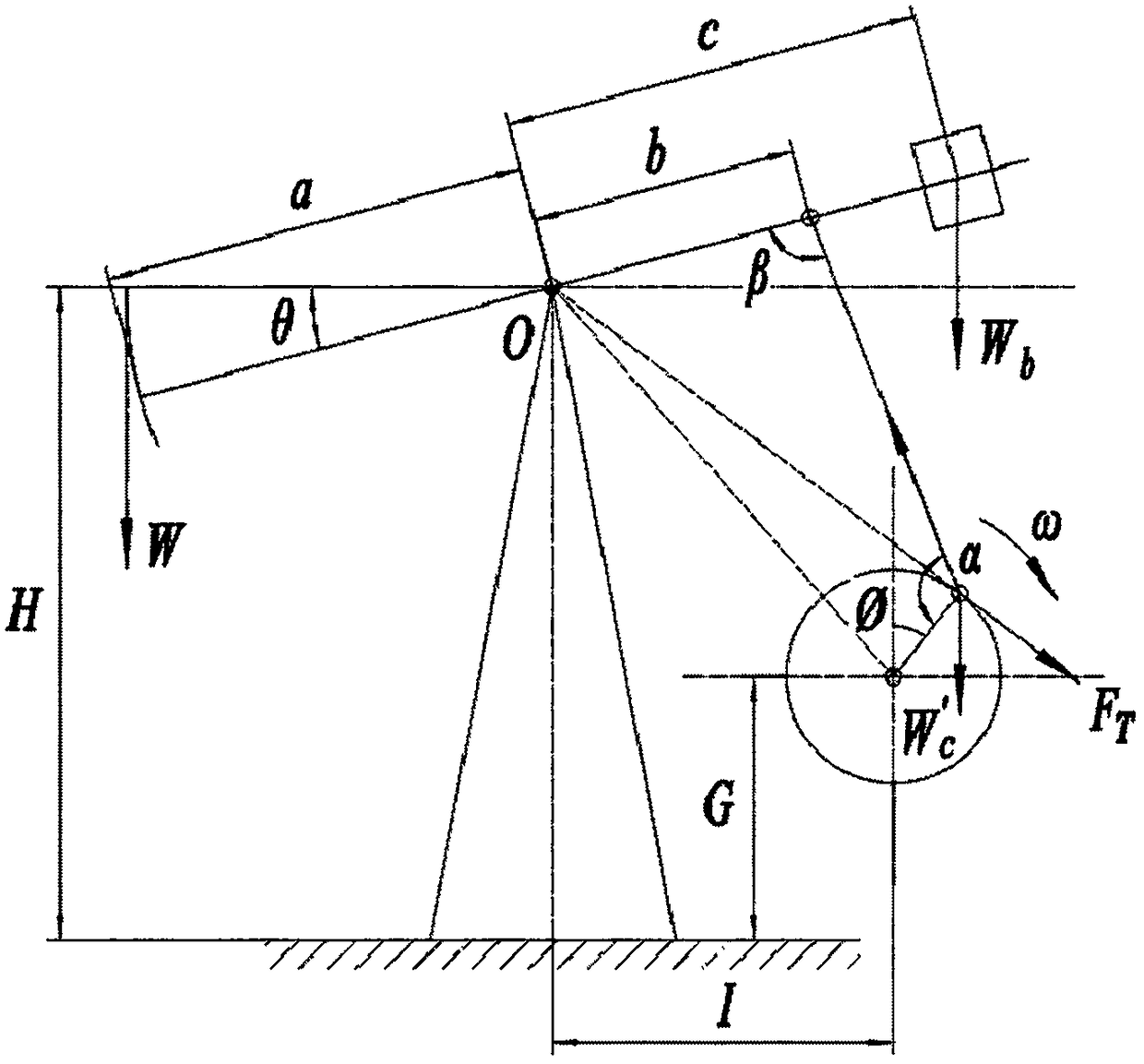

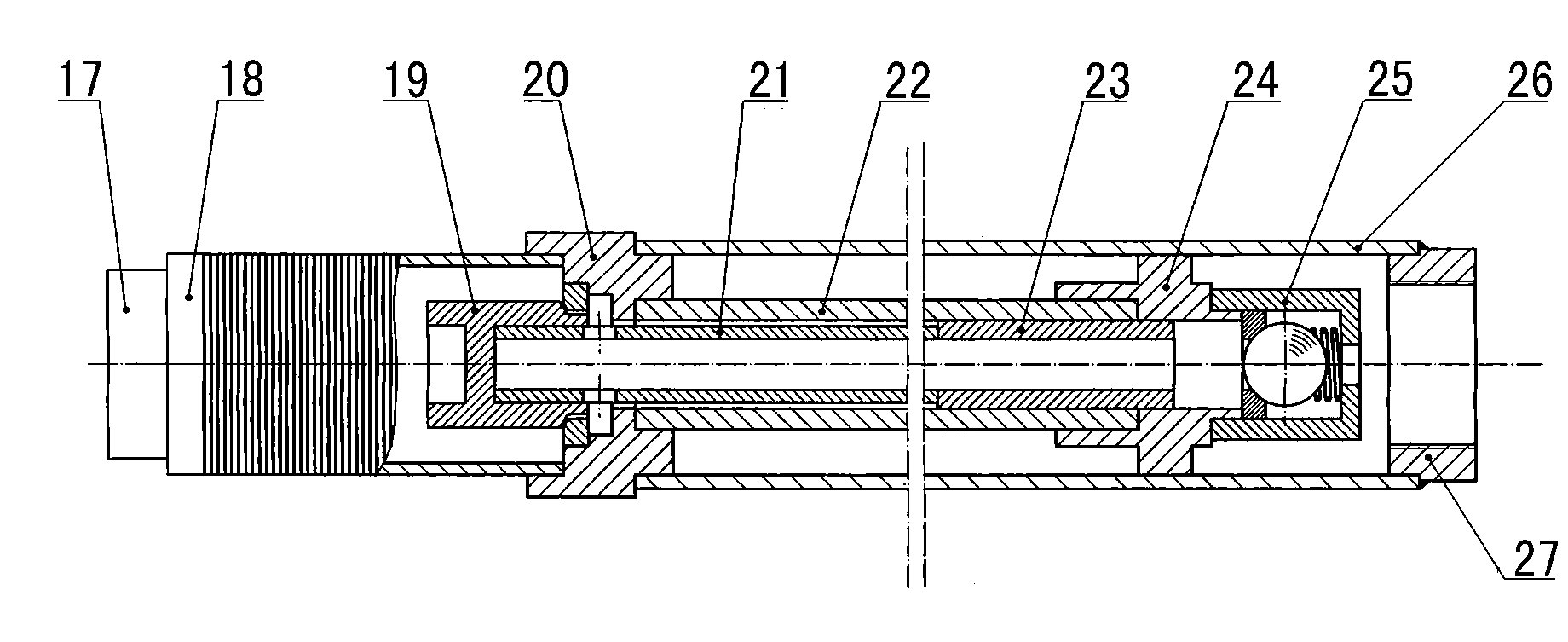

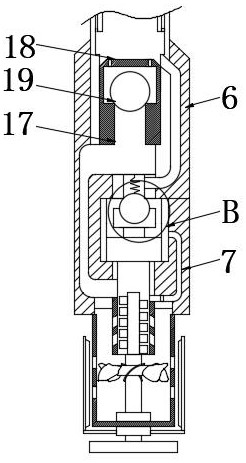

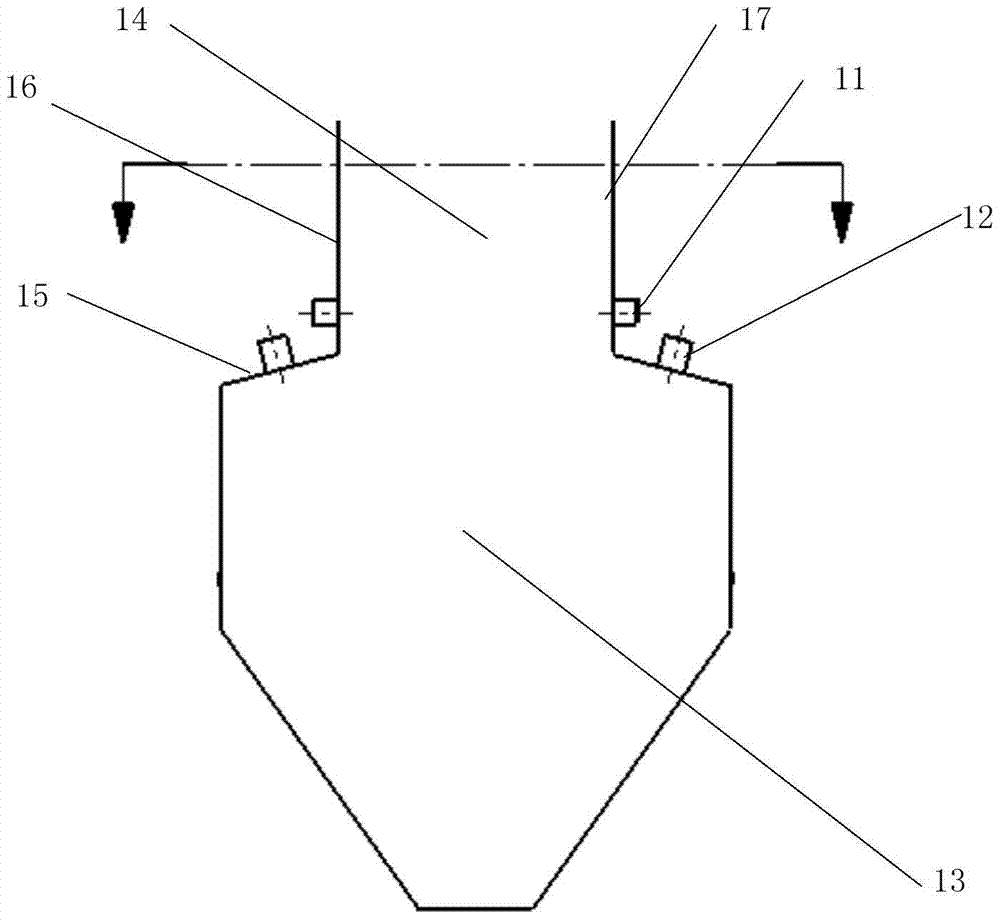

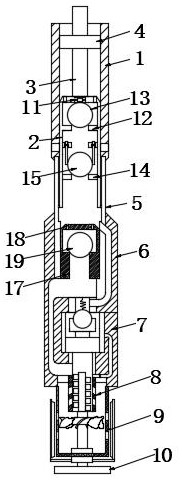

Swabbing parameter matching non-stop intermittent oil pumping and production system

InactiveCN109424337AGuaranteed reliabilityFit clearance is smallConstructionsFluid removalElectricityWorking fluid

The invention relates to a swabbing parameter matching non-stop intermittent oil pumping and production system. The system is characterized by being composed of an intelligent controller, a frequencyconverter and a special oil pump. An electric parameter test acquisition device is installed in the intelligent controller, embedded software is written in the intelligent controller, the active powerof a pumping unit is tested in real time, the working fluid level depth of an oil well is calculated according to the active power and structural parameters of the pumping unit, on this basis, when the working fluid level reaches a certain range, an intelligent program is started automatically, every time after the pumping unit reaches a top dead center, a crank is controlled to swing within a small angle range instead of immediate starting of a lower stroke, the time is provided for filling of the special oil pump, after the crank swings for a set time, an oil production program is started,and the operations are repeated; the oil pump is kept to always work under the optimal submergence condition while the high pumping efficiency is ensured; meanwhile, the pumping diameter of the oil pump is increased, the oil production stroke frequency of the pumping unit is greatly reduced under the condition of the same liquid yield, and the energy consumption of the system is reduced.

Owner:DAQING SENENPU MACHINERY MFG

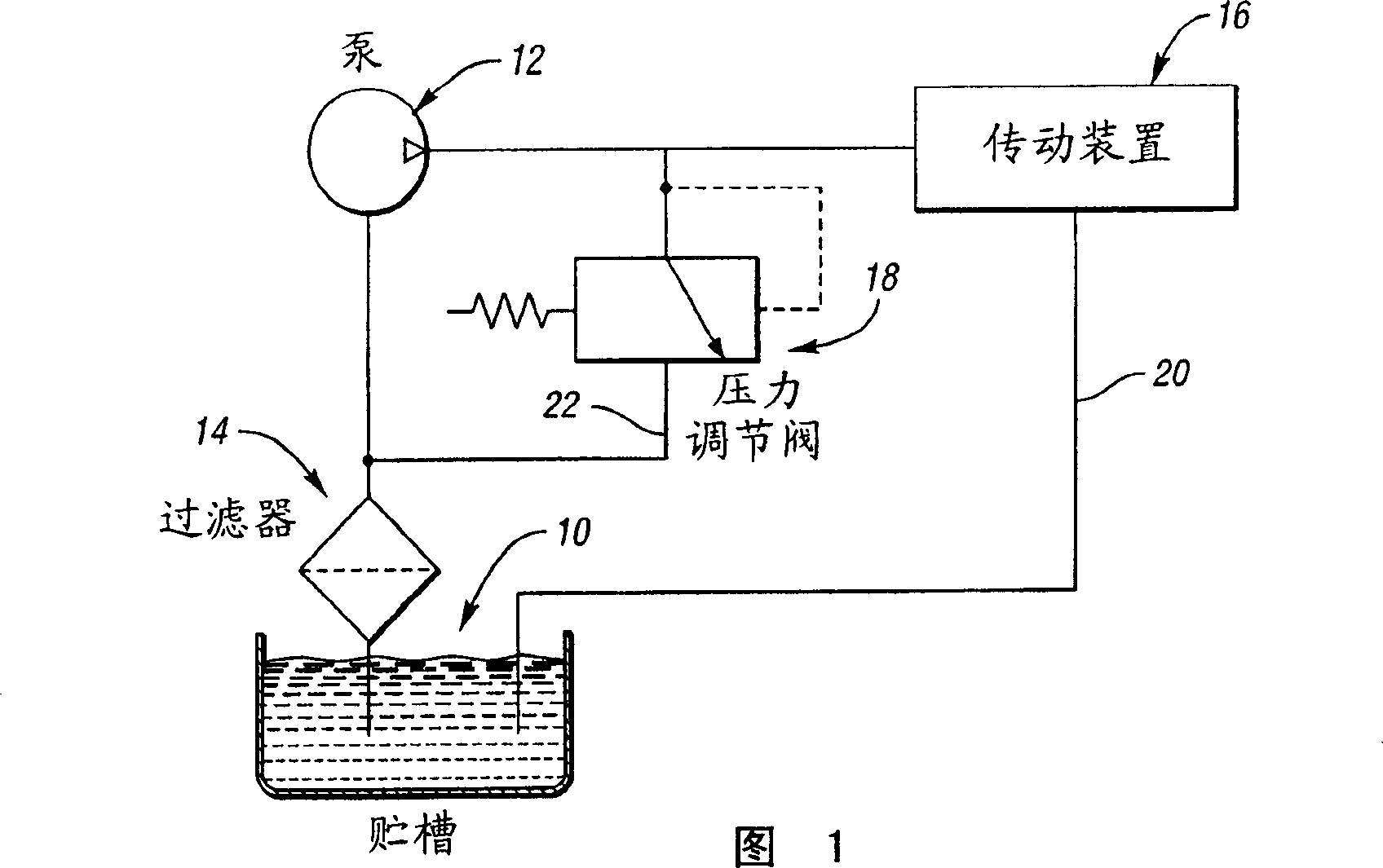

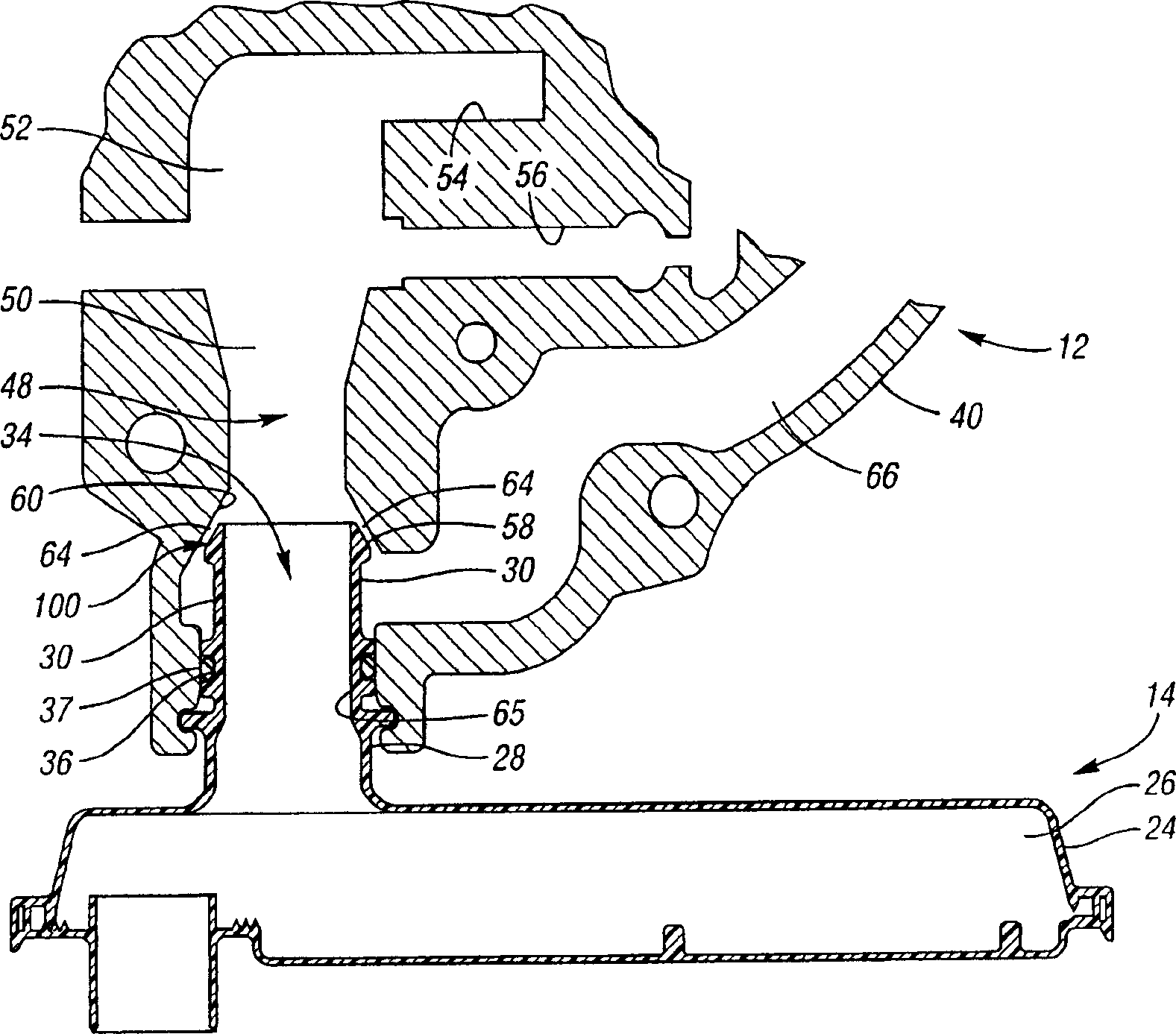

Transmission pump and filter

The filter housing has a filter outlet portion with a central filter outlet passage. The outlet portion includes a terminal end portion defining a filter nozzle. The filter nozzle forms a nozzle passage between the filter nozzle and the pump housing. The nozzle passage communicates with an annular recess formed in the filter outlet portion. The annular recess receives return bypassed hydraulic fluid from a regulator valve for distribution into an inlet stream of fluid flowing through the filter outlet passage. The inlet stream velocity is increased which increases the pressure at the pump inlet. The increased pressure at the pump inlet allows the pump to operate at higher speeds without cavitation.

Owner:GENERAL MOTORS COMPANY

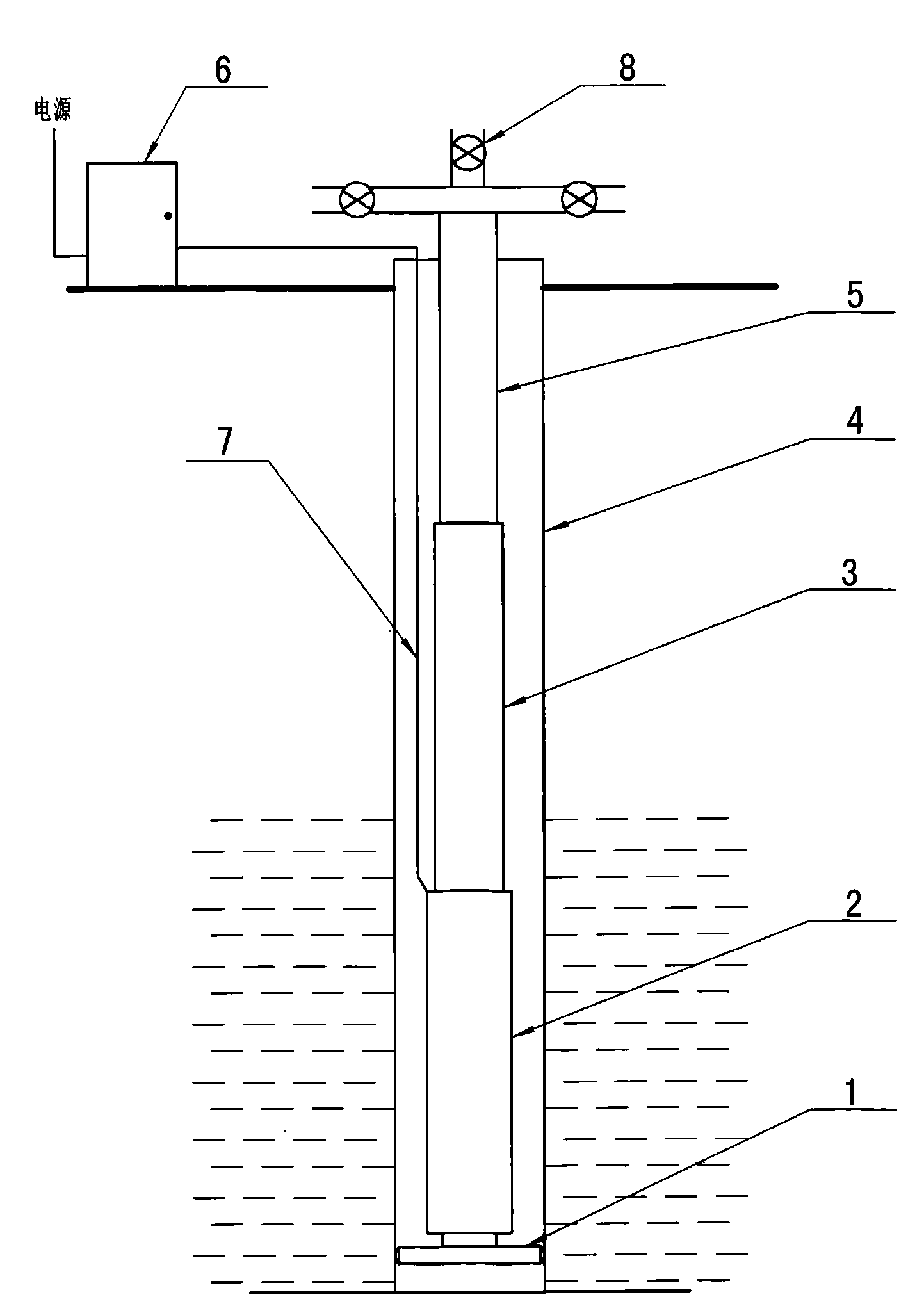

Intelligent linear-motor oil production system

InactiveCN103062023AReduce reactive power lossReduce maintenance time and costsAC motor controlFlexible member pumpsOil productionPlunger pump

The invention discloses an intelligent linear-motor oil production system. The intelligent linear-motor oil production system comprises an underground linear motor and is connected with a plunger pump through the linear motor, wherein the linear motor is also connected with a control part. According to the intelligent linear-motor oil production system, a cylindrical synchronizing linear motor, a plunger oil pump and a ground high-performance frequency conversion control part are adopted, thereby mechanical-electrical integration can be realized, and complicated speed reducing devices can be omitted; a frequency conversion control system is adopted, so that the intelligent linear-motor oil production system has an automatic voltage boosting and maintaining function, therefore, the harmonic pollution to a power grid can be avoided, the equipment can be remotely controlled, and running parameters can be adjusted; once underground oil is in an insufficient state, the frequency of stroke can be automatically reduced, so that high degree of filling of a chamber of the pump can be realized, and over 50% of energy can be saved for the system; in addition, the intelligent linear-motor oil production system is convenient and quick to transport, install and maintain, about 85% of floor area can be saved, and a pumping rod mechanism is omitted, so that the pumping period is greatly prolonged, and the continuous working time is increased.

Owner:杨超

Rayon fabric dyeing and finishing method

InactiveCN108193520AIncrease fullnessFeel goodGrip property fibresDyeing processSteam pressureEngineering

The invention relates to a rayon fabric dyeing and finishing method. The rayon fabric dyeing and finishing method comprises the following steps: conducting dyeing pretreatment and antistatic and crease-resistant finishing on a primary woven rayon fabric, conducting dye discharge print on the cooked and formed primary woven rayon fabric, immersing in a staining fluid, wherein the staining fluid comprises 1 ml / L of a dye and 1 ml / L of a chelating agent; raising the temperature to 40-50 DEG C, steaming with vapor for 20-30 minutes in a rapid steamer at the steam pressure of 2 kg, raising the temperature of a curve to 50-60 DEG C, preserving the heat for 10 minutes, adding salt and sodium carbonate, wherein the masses of both the salt and the sodium carbonate are the same and are both 3-5 g / L;raising the temperature of the curve to 60-70 DEG C, preserving the heat for 10 minutes, adding a dye fixing agent, and post-processing. The third-dimensional effect of a discharge print pattern obtained through the method is strong, the fastness of a dye is high, the effects of moisture permeation and UV resistance meet satisfaction, and the dyeing effect is good.

Owner:宁波高新区州致科技有限公司

Dyeing and finishing technology of rayon fabric

InactiveCN108221376AIncrease fullnessFeel goodWrinkle resistant fibresDyeing processSteam pressureUltraviolet

The invention relates to a dyeing and finishing technology of a rayon fabric. The dyeing and finishing technology comprises the following steps: dyeing and pre-treating a primary high-grade woven rayon fabric; carrying out antistatic and anti-crease finishing; carrying out dyestuff discharge printing on the steamed and sized primary high-grade woven rayon fabric and immersing into a dyeing solution, wherein the dyeing solution is prepared from 1ml / L of a dyeing agent and 1ml / L of a chelating agent; raising the temperature to 40 to 50 DEG C; steaming for 20 to 30min by utilizing a steaming machine with the steam pressure of 2kg to raise the temperature to 50 to 60 DEG C along a curve; carrying out heat preservation for 10min; then adding table salt and sodium carbonate, wherein the mass ofthe table salt is the same as that of the sodium carbonate and is 3 to 5g / L; then raising the temperature to 60 to 70 DEG C along the curve and carrying out the heat preservation for 10min; adding a color fixing agent and then carrying out post-treatment. According to the method provided by the invention, an obtained discharge printing dyed pattern has strong stereoscopic impression and a dyestuffis firm; the moisture-permeable and anti-ultraviolet effects reach satisfied degrees and the dyeing effect is good.

Owner:宁波高新区州致科技有限公司

Dyeing and finishing process of rayon fabric containing acrylic yarn

InactiveCN107956117AIncrease fullnessFeel goodWrinkle resistant fibresGrip property fibresYarnUltraviolet

The invention relates to a dyeing and finishing process of a rayon fabric containing acrylic yarn, which includes dyeing and pretreatment of the primary woven rayon fabric, antistatic and anti-wrinkle finishing, and cooking and finalizing the primary woven rayon fabric Perform dye discharge printing, that is, immerse in the dyeing solution, the dyeing solution includes 1ml / L dyeing agent, 1ml / L chelating agent; heat up to 40-50°C, and steam for 20 minutes in a steamer with a steam pressure of 2kg ‑30min, the curve rises to 50‑60°C, keep warm for 10min, then add salt and soda ash. Fixative, followed by post-processing. The method of the invention obtains a strong three-dimensional effect of the discharge-printed dyed flower, the dye is firm, the moisture-permeable anti-ultraviolet effect reaches a satisfactory level, and the dyeing effect is good.

Owner:NINGBO DUNHE TECH CO LTD

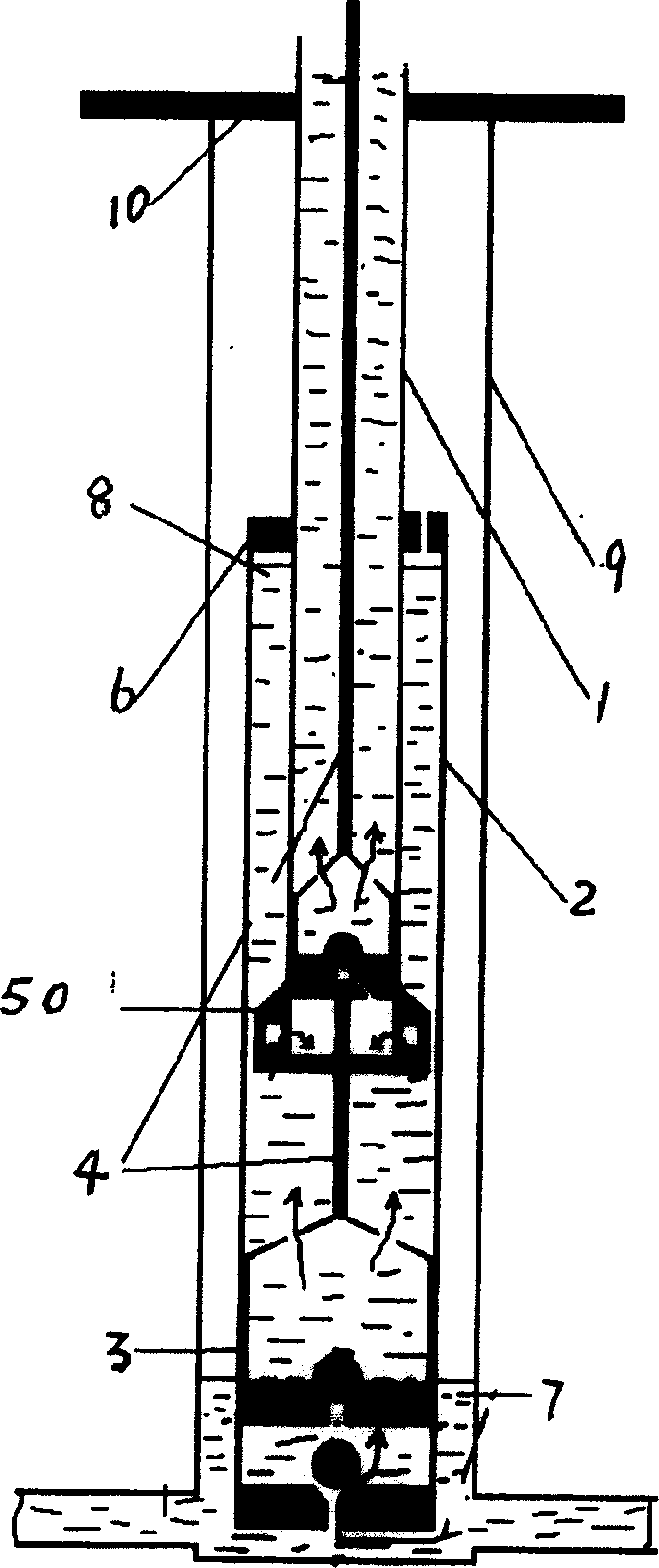

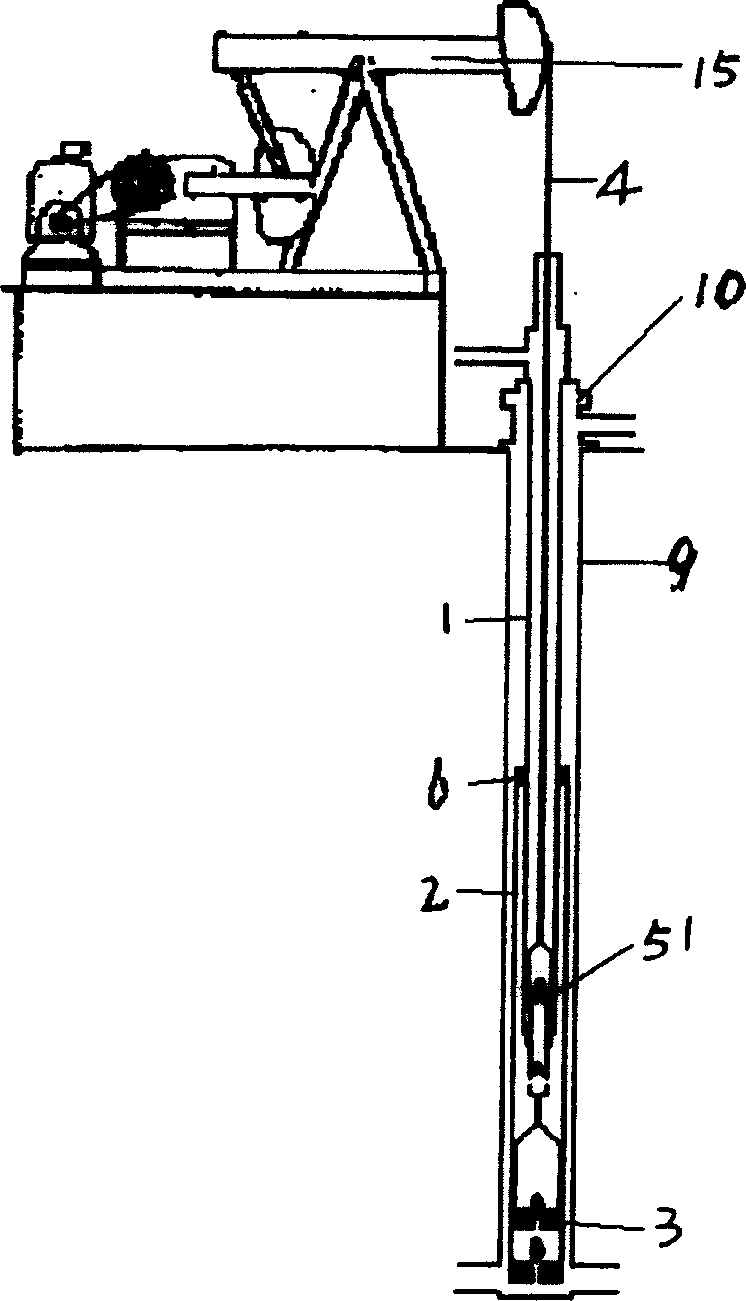

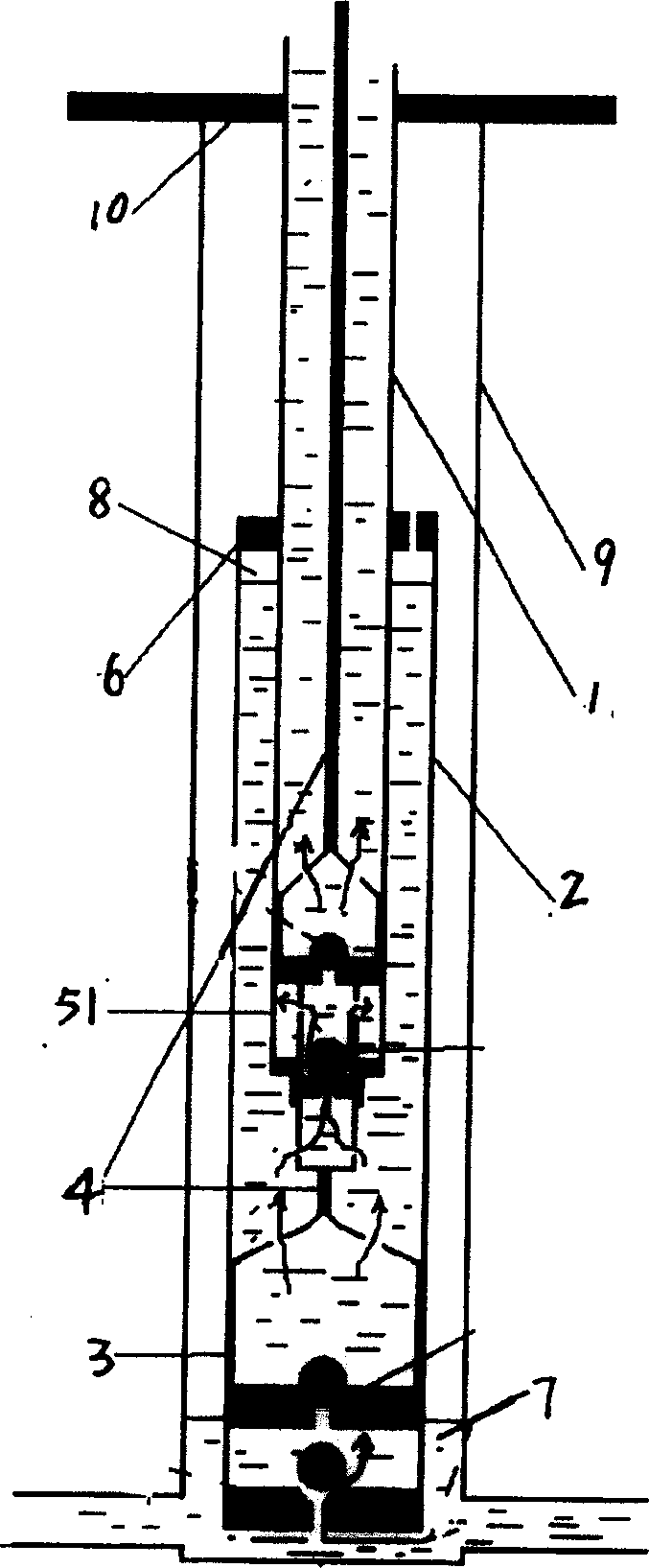

High-inclination horizontal well oil pump

InactiveCN101205900AIncrease fullnessIncrease displacementFlexible member pumpsFluid removalWellheadOil well

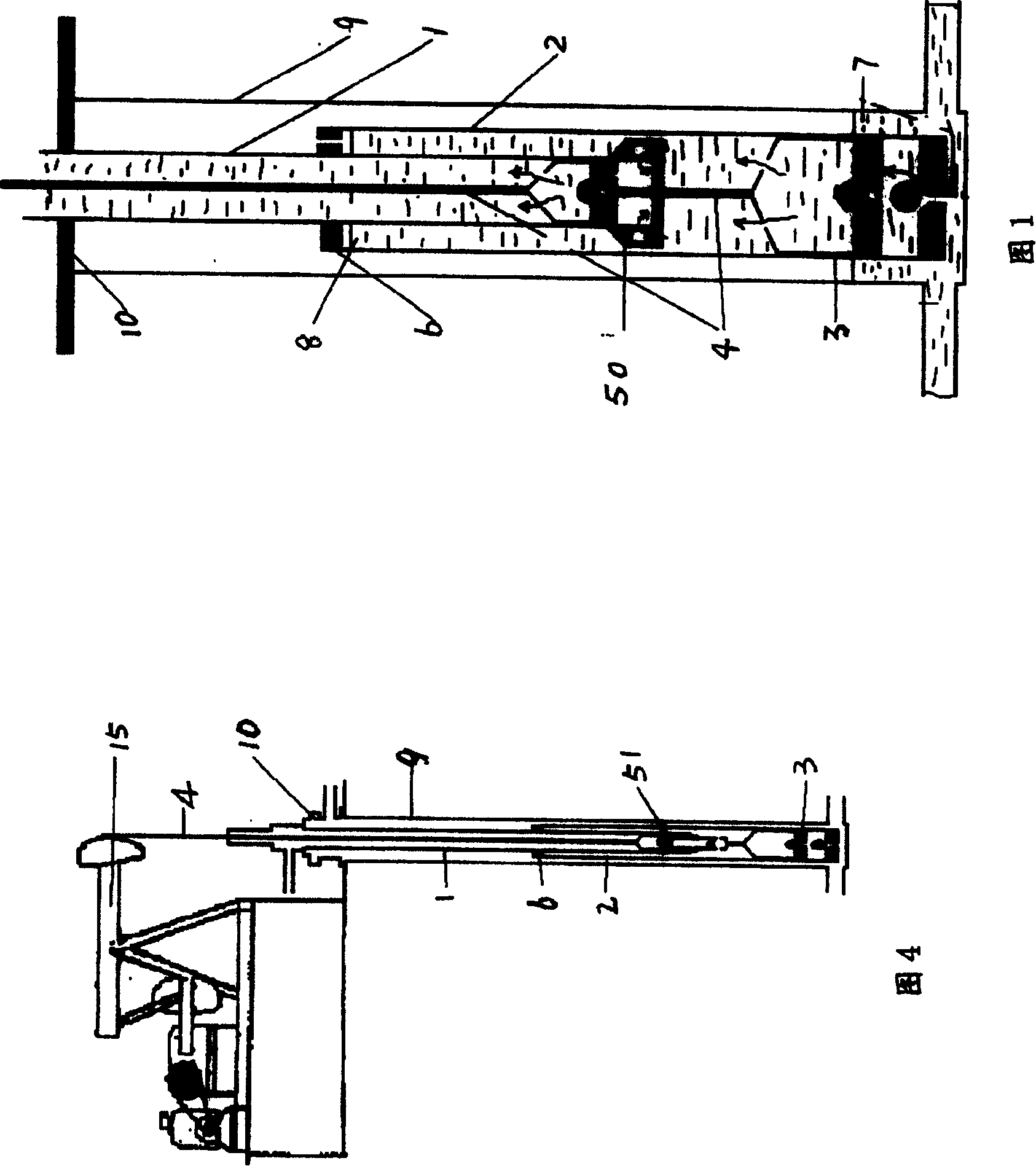

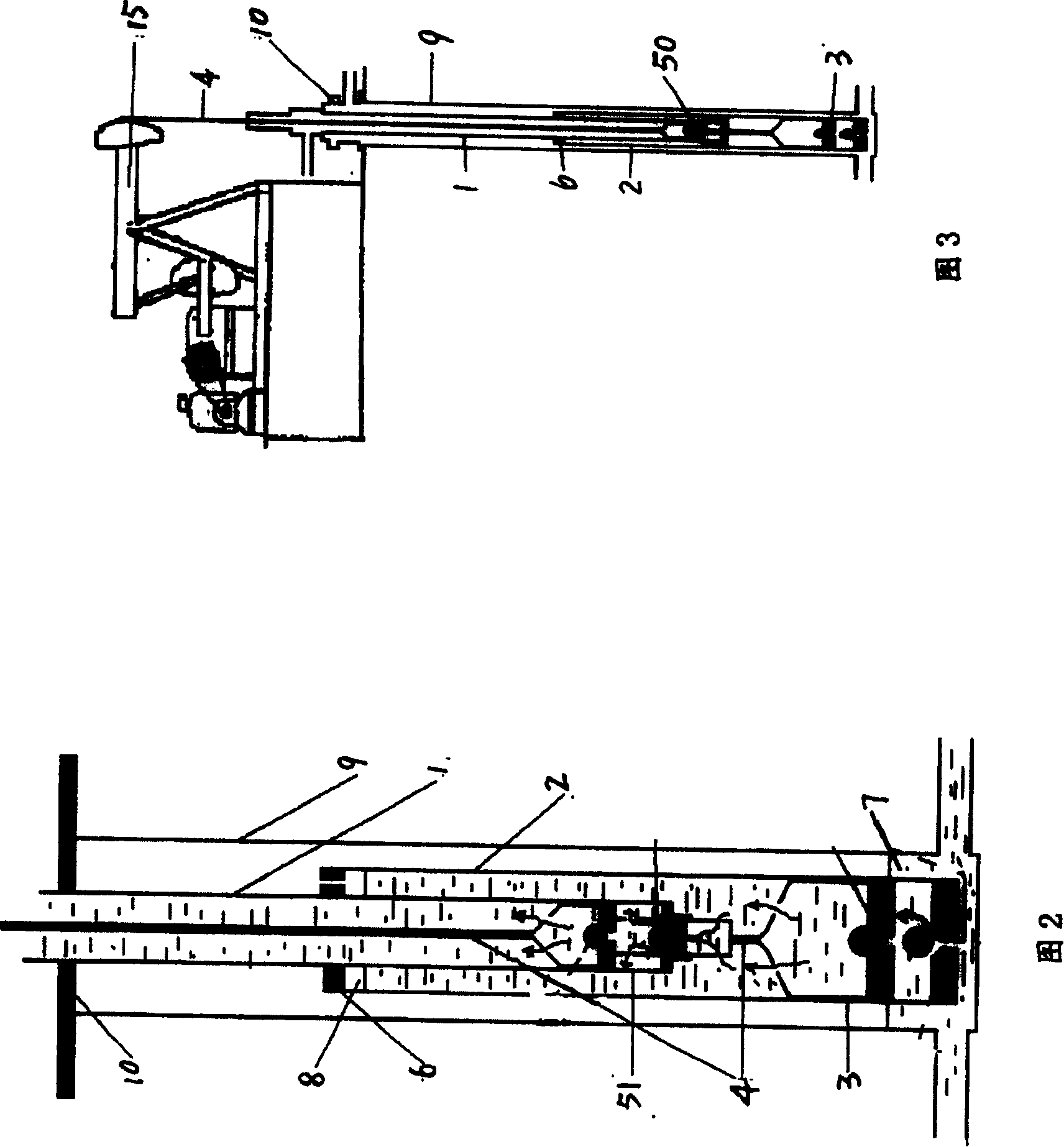

The invention relates to a high deviated horizontal well oil well pump. The high deviated horizontal well oil well pump comprises a major diameter oil well pump(3), a minor diameter ring valve oil well pump(50), a small oil pipe(1), a big oil pipe(2), an oil pipe fixer(6), a sleeve(9), a well head(10), a sucker rod(4), a pumping unit(15), wherein, the sleeve(9), the well head(10), the sucker rod(4) and the pumping unit(15) are characterized in that: the big oil pipe(2) is arranged inside the sleeve(9), the top of the big oil pipe(2) is fixed on the middle part of the small oil pipe(1) by the oil pipe fixer(6), the major diameter oil well pump(3) is arranged inside the sleeve(9) and fixed on the bottom of the big oil pipe(2), the minor diameter ring valve oil well pump(50) is fixed on the bottom of the small oil pipe(1), the small oil pipe(1) is inserted in the big oil pipe(2) from the oil pipe fixer(6) on the top of the big oil pipe(2) and extends downward and is connected with the upper part of the minor diameter ring valve oil well pump(50); in the minor diameter ring valve oil well pump(50), the lower end of the sucker rod(4) and a plunger top of the minor diameter ring valve oil well pump(50) are connected, the plunger bottom of the minor diameter ring valve oil well pump(50) is fixedly provided with the short sucker rod(4).

Owner:金昌昊

Nutrient agent for planting full peanuts and preparation method of nutrient agent

The invention provides a kind of nutrient agent for plumping peanut granules and a preparation method thereof, comprising the following raw materials: 80-95 parts of leaves of Dajibis fern, 150-170 parts of petals of Oxytropis axie, and leaves of philodendron philodendron 160‑180 parts, 300 parts of water. The nutrient agent of the present invention undergoes a series of treatments, and the soaked peanuts are sown, which effectively increases the diameter of the peanuts, greatly improves the plumpness of the peanuts, and thus greatly increases the yield and oil yield of the peanuts.

Owner:龚春华

Vegetable growth quality enhancer and preparation method thereof

InactiveCN108658676AHigh nutritional valueImprove qualityMagnesium fertilisersOrganic fertilisersChinese ChiveP-chlorophenoxyacetic acid

The invention discloses a vegetable growth quality enhancer and a preparation method thereof. The vegetable growth quality enhancer is prepared from the following raw materials in parts by weight: 5-10 parts of magnesium carbonate, 6-12 parts of potassium sulfate, 0.5-0.8 part of citric acid, 3-6 parts of potassium acetate, 0.002-0.004 part of p-chlorophenoxyacetic acid, 0.003-0.006 part of sodiumnitrophenolate, 3-9 parts of wood chips, 0.4-0.7 part of Chinese chive extract, 0.1-0.4 part of tomato extract and 30-50 parts of deionized water. The vegetable growth quality enhancer disclosed by the invention is simple in preparation method and lower in raw material cost, can obviously improve the strength of vegetable stems and leaves, and enables fruits to be full, thus improving vegetable quality and economic value and increasing returns; therefore, the vegetable growth quality enhancer is suitable for being widely popularized.

Owner:王兴民

Preparation method of prepackaged pseudo-ginseng steam pot chicken

The invention discloses a preparation method of prepackaged pseudo-ginseng steam pot chicken. The preparation method comprises the steps of cutting off hind leg meat and chicken chest meat of a spayed hen, washing, precooking in a saucepan for 8-12min with water which is twice of the hind leg meat and the chicken chest meat in amount, carrying out vacuum knead-salting, adding pseudo-ginseng powder and a seasoner with specific formula, adding precooking fluid which is 60-65wt% of the chicken meat subjected to vacuum knead-salting, performing vacuum packaging, and sterilizing at high temperature and under high pressure, thereby preparing the prepackaged pseudo-ginseng steam pot chicken. The precooking and seasoning process is adopted to achieve the prepackaged pseudo-ginseng steam pot chicken with excellent flavor; the vacuum packaging and the high temperature sterilization processes are adopted, the shelf life of the prepackaged pseudo-ginseng steam pot chicken is greatly prolonged, the prepackaged pseudo-ginseng steam pot chicken can be transported and sold conveniently, and the traditional prepackaged pseudo-ginseng steam pot chicken in restaurants can be consumed favorably by ordinary families.

Owner:曲靖市沾益区贵火卢食品厂 +1

Step continuous pressure reduction synergistic oil pumping device and method

ActiveCN110185420AIncrease flow rateRealize step-by-step continuous step-downFluid removalPressure reductionScrew thread

The invention discloses a step continuous pressure reduction synergistic oil pumping device and method. The device comprises at least three pressure reduction devices which are sequentially connectedin series from bottom to top; the flow speed in the bottommost pressure reduction device is minimal, and the flow speed in the uppermost pressure reduction device is maximal, that is, the flow speedsin the pressure reduction devices which are connected in series together are gradually and sequentially increased from bottom to top; the upper end outlet of the uppermost pressure reduction device isin screw threaded connection with the lower port of a pump cylinder of the pump; and the lower end inlet of the bottommost pressure reduction device is connected with a fixed valve of an oil pipe. The device and the method have the advantages that the step continuous pressure reduction is realized, the liquid phase content is increased, and the pump efficiency is improved; and the pressure reduction devices are connected in series, and the flow speeds in the pressure reduction devices are sequentially increased from bottom to top.

Owner:CHINA PETROLEUM & CHEM CORP +1

Dyeing and finishing process for high-grade cotton fabric

The invention relates to a dyeing and finishing process for high-grade cotton fabric. The dyeing and finishing process comprises the following steps: performing dyeing pre-treatment on primary high-grade cotton fabric, performing antistatic and crease-resistant finishing, performing dye discharge print on cooked and formed primary high-grade cotton fabric, soaking the primary high-grade cotton fabric into a dyeing solution which comprises 1ml / L of a dyeing agent and 1ml / L of a chelating agent; heating to a temperature of 40-50 DEG C, performing steaming for 20-30 minutes through a rapid steamer with steam pressure of 2 kg, heating up to a temperature of 50-60 DEG C in a curved mode, preserving the heat for 10 minutes, adding salt and sodium carbonate which are equal in mass of 3-5g / L, heating up to a temperature of 60-70 DEG C in the curved mode, preserving the heat for 10 minutes, adding a dye-fixing agent, and performing after-treatment. The high-grade cotton fabric obtained by the method is high in three-dimensional feeling of discharge-printed and dyed patterns, is firm in dye, has moisture permeability and ultraviolet ray resistance which reach satisfying degree, and is good in dyeing effect.

Owner:NINGBO DUNHE TECH CO LTD

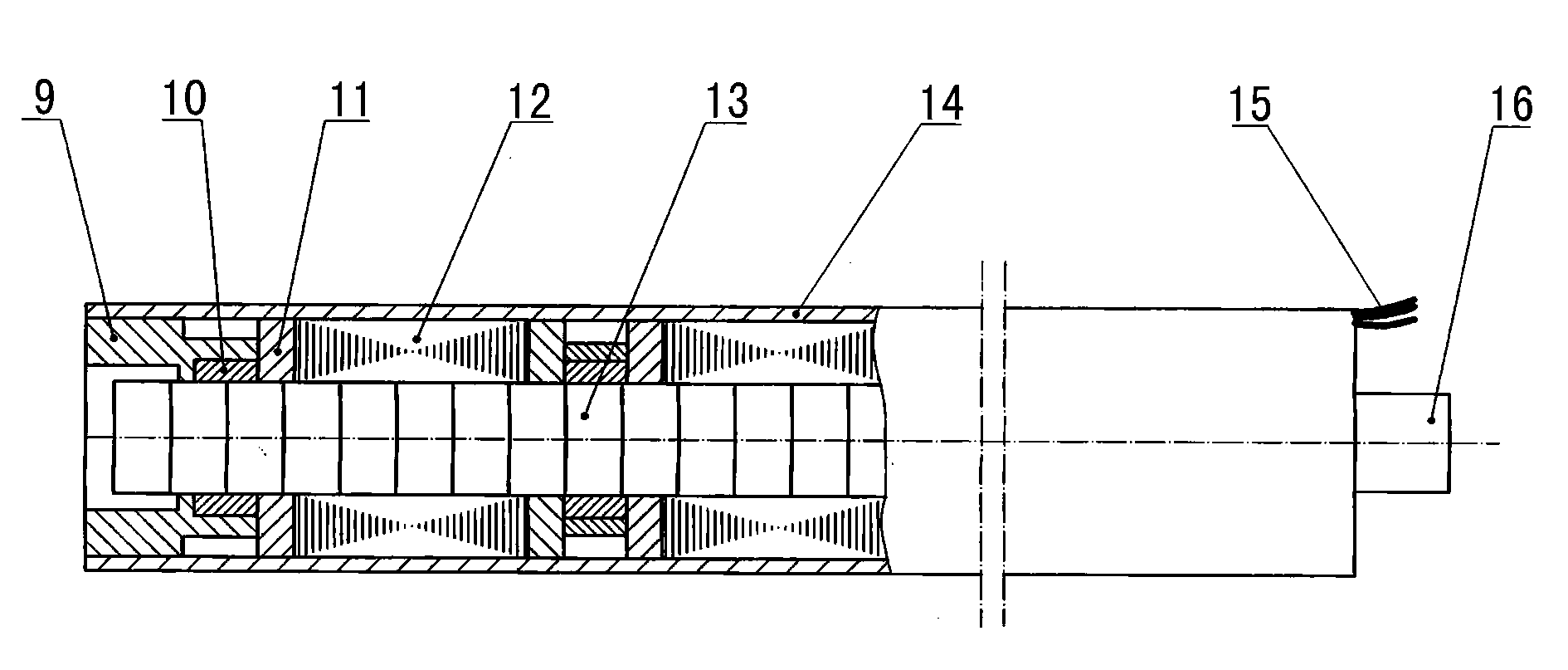

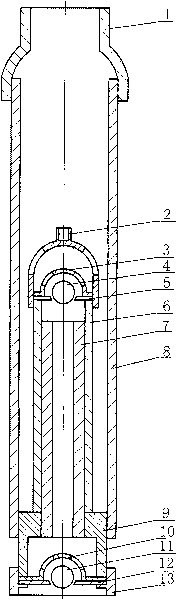

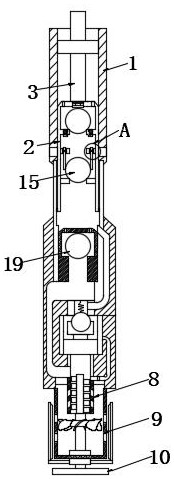

Moving cylinder efficient tubular oil pump

InactiveCN101709696AIncrease fullnessIncrease the effective strokeFlexible member pumpsFluid removalUpper jointInlet valve

The invention relates to a moving cylinder efficient tubular oil pump which belongs to the technical field of petroleum machinery. The moving cylinder efficient tubular oil pump is characterized in that one or a plurality of oil charging valves which are connected in series are arranged at the lower end of a plunger seat and are fixedly connected with an oil inlet valve seat joint through threads, one or a plurality of oil outlet valves in series connection are arranged at the upper end of a pump cylinder, an outer pipe is connected with the plunger seat and a plunger through the threads and then the lower end of the outer pipe forms a sealing cavity, and the plunger is fixed, and the pump cylinder is connected with an oil pumping rod through a cylinder pump upper joint and is also matched with the plunger in a sliding sealing way. The diameter of an oil inlet is larger than that of an inner hole of the plunger, therefore, the oil inlet resistance is little, and the oil filling degree of a pump cavity is high. Especially, the oil outlet valve is arranged on the pump cylinder, the oil outlet valve seat of the pump is not limited by the diameter of the pump cylinder, the diameter can be enlarged, the oil outlet resistance is little, the descending bending of the oil pumping rod is reduced, the effective stroke of the pump cylinder of the oil pump is increased, and the efficiency of the oil pump is improved.

Owner:王志杰

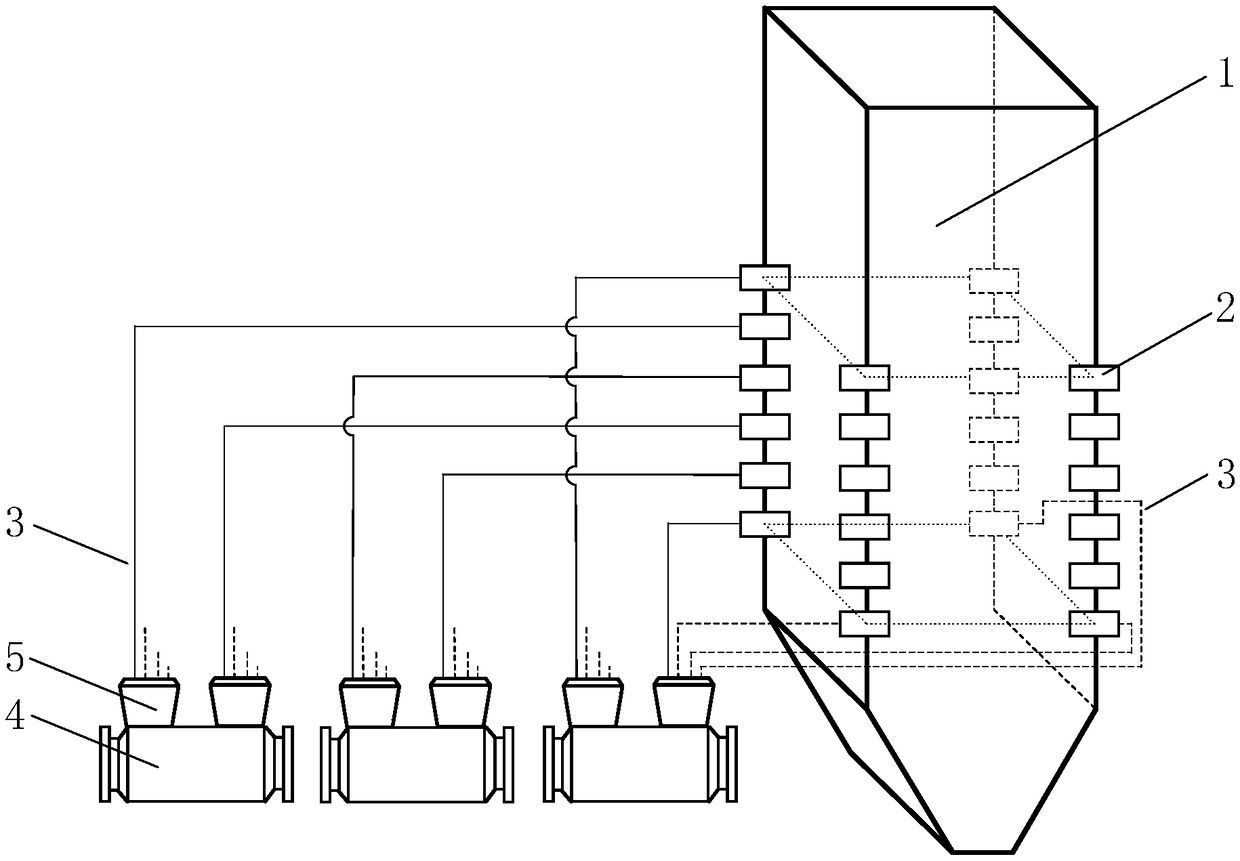

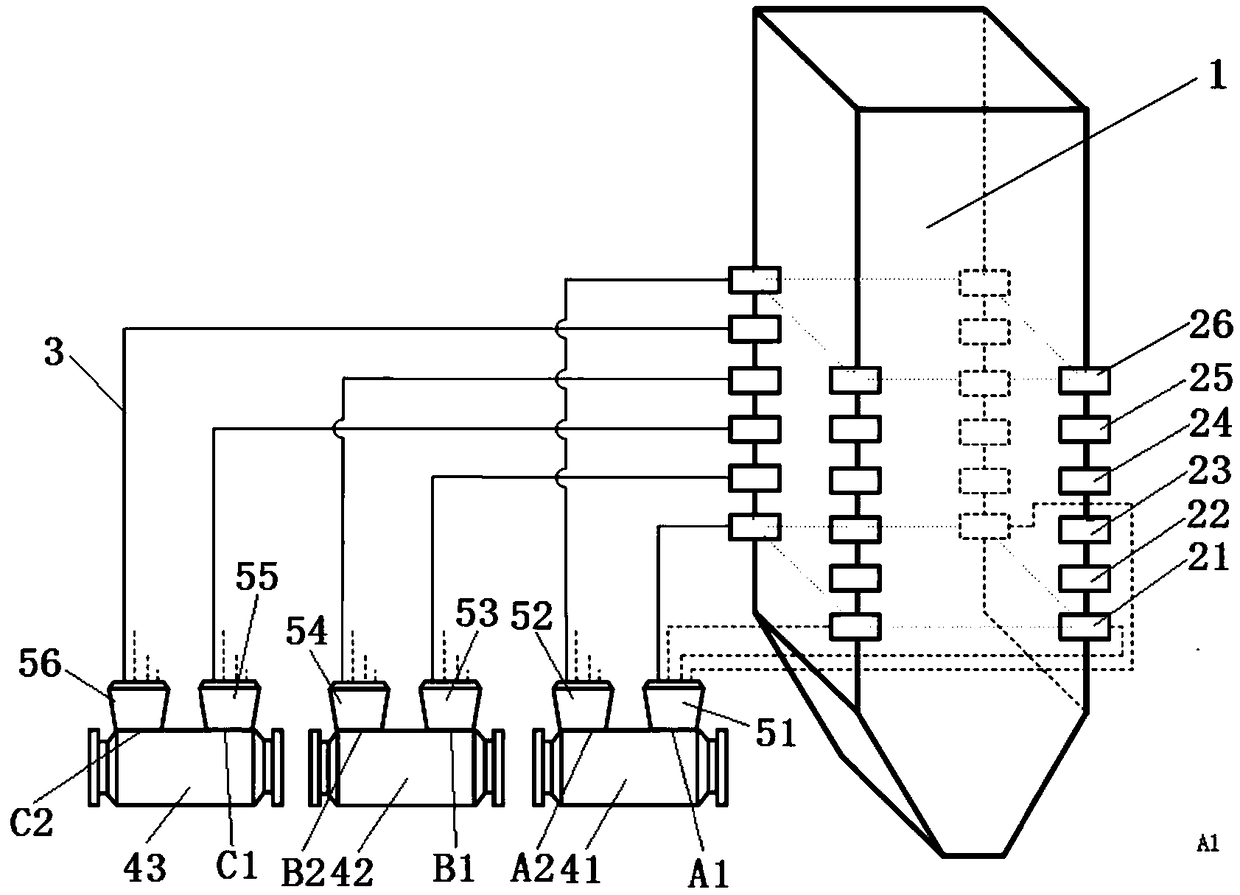

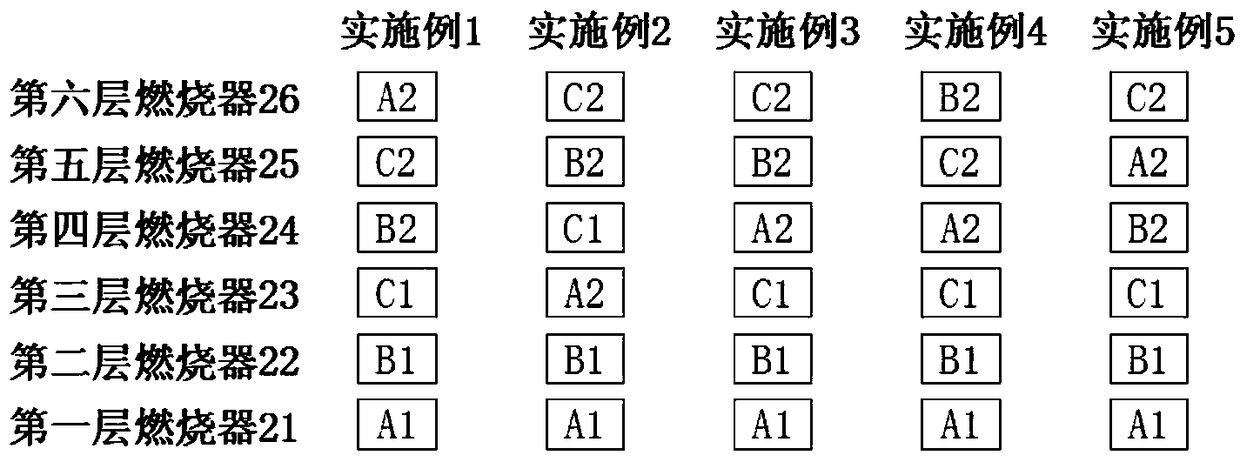

Flame center controllable coal pulverizing system mill dislocation pulverized coal pipeline arrangement structure

PendingCN109268870AIncrease fullnessStable combustionFuel feeding arrangementsSolid fuel pretreatmentDislocationCoal pipeline

The invention discloses a flame center controllable coal pulverizing system mill dislocation pulverized coal pipeline arrangement structure which comprises a plurality of double-inlet and double-outlet coal mills, pulverized coal pipelines and a tangential boiler. Pulverized coal burners are arranged at corner areas of the tangential boiler along the height direction in a layered manner, each double-inlet and double-outlet coal mill is provided with a first discharging port and a second discharging port, the first discharging ports are connected with the pulverized coal burners at the corner areas of the tangential boiler at the same height through the pulverized coal pipelines, the second discharging ports are connected with the pulverized coal burners at the corner areas of the tangential boiler at the same height through the pulverized coal pipelines, and the first discharging port and the second discharging port of at least one double-inlet and double-outlet coal mill are connectedwith two layers of non-adjacent pulverized coal burners in the height direction of the corner areas of the tangential boiler through the pulverized coal pipelines. According to the structure, a flamecenter in the boiler cannot deflect some corner of a hearth when any coal mill is started and stopped, the elevation of the flame center of the tangential boiler is basically changed, flexible dispatching requirements of a rapid lifting load are met, and the fullness degree of a flame in the hearth is improved.

Owner:苏州吉杰电力科技有限公司

Nutritional agent for increasing peanut yield and preparation method thereof

InactiveCN107698282ALarge diameterIncrease fullnessOrganic fertilisersLiquid fertilisersSaussureaPetal

The invention provides a nutritional agent for increasing peanut yield and a preparation method thereof. The nutritional agent comprises the following raw materials: 80-95 parts of Hypolepis giganteanleaf, 150-170 parts of Oxytropis assiensis petal, 160-180 parts of Saussurea stricta leaf, and 300 parts of water. The nutritional agent provided by the invention is subjected to a series of treatments, soaked peanuts are sowed, the peanut diameter is effectively increased, and the fullness of peanuts can be greatly enhanced, thus greatly increasing the output and oil yield of peanuts.

Owner:龚春华

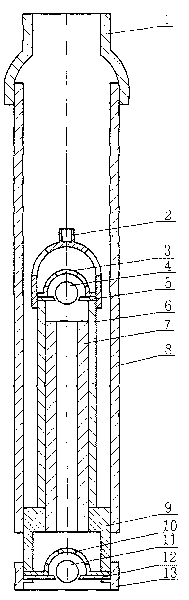

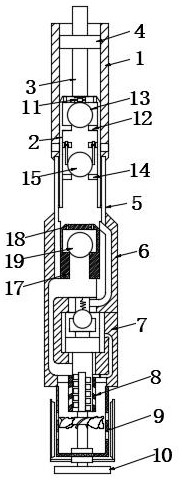

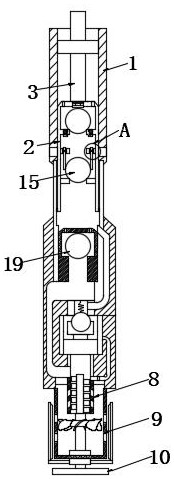

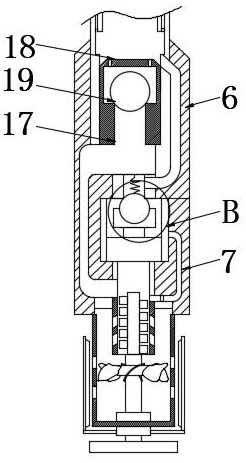

An oil pump for well cleaning

ActiveCN114412763BIncrease fullnessImprove oil intake efficiencyPositive displacement pump componentsFlexible member pumpsUpper jointDrive shaft

The invention relates to the technical field of oil well pump equipment, in particular to an oil well pump for well cleaning, which includes a pump barrel, an extended plunger is slidably connected to the inside of the pump barrel, and an oil pulling rod is fixedly connected to the upper surface of the extended plunger. The inside is located on the outside of the oil rod and a guide mechanism is installed. The lower end of the pump cylinder is fixedly connected with an upper joint, and the lower end of the upper joint is fixedly connected with a thick tube. The lower end is fixedly connected with an oil inlet cylinder; in the present invention, the driven fan outside the driven shaft is driven to rotate by the crude oil in the process of flowing, so that the support rod drives the cleaning plate on the vertical rod to clean the outer surface of the sand control cylinder , improve the oil inlet efficiency of the equipment, and also stir the crude oil through the spoiler to mix the crude oil and gas, so it can not only achieve the effect of sand prevention and self-cleaning of the equipment, but also help to improve the oil pumping capacity of the equipment degree.

Owner:DONGYING BAIHUA GASOLINEEUM TECH DEV

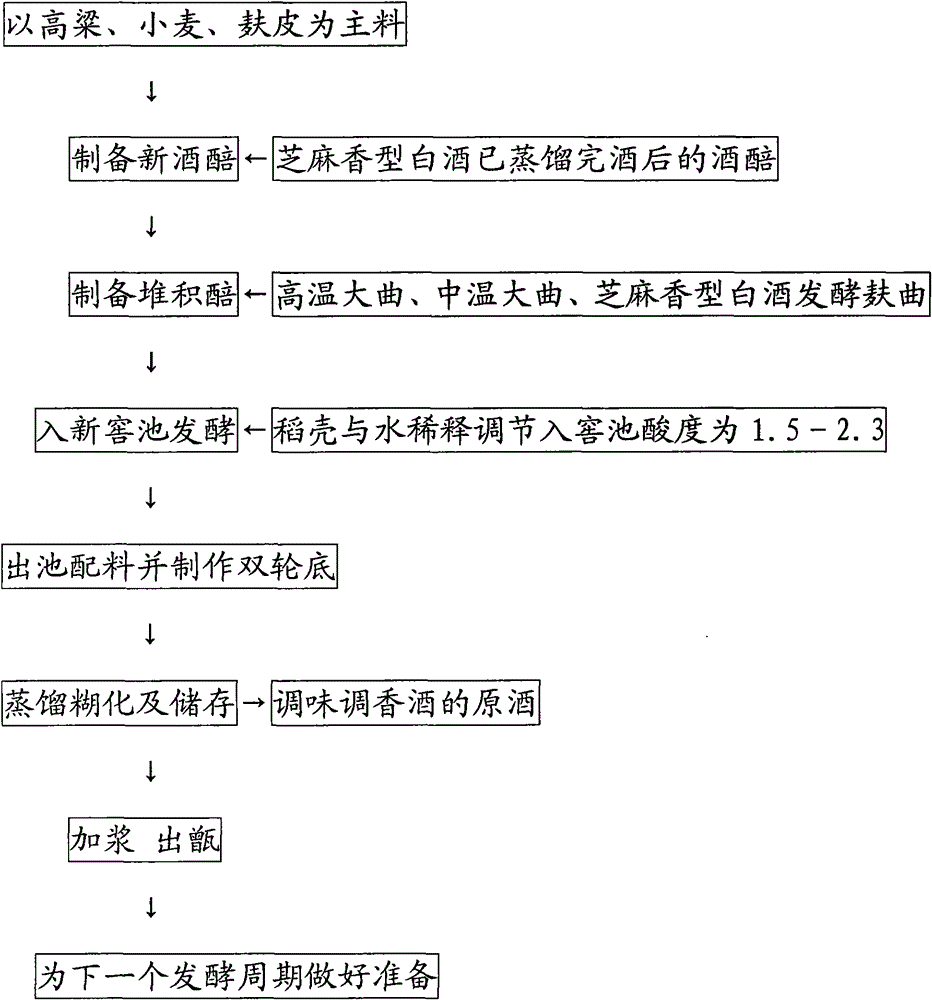

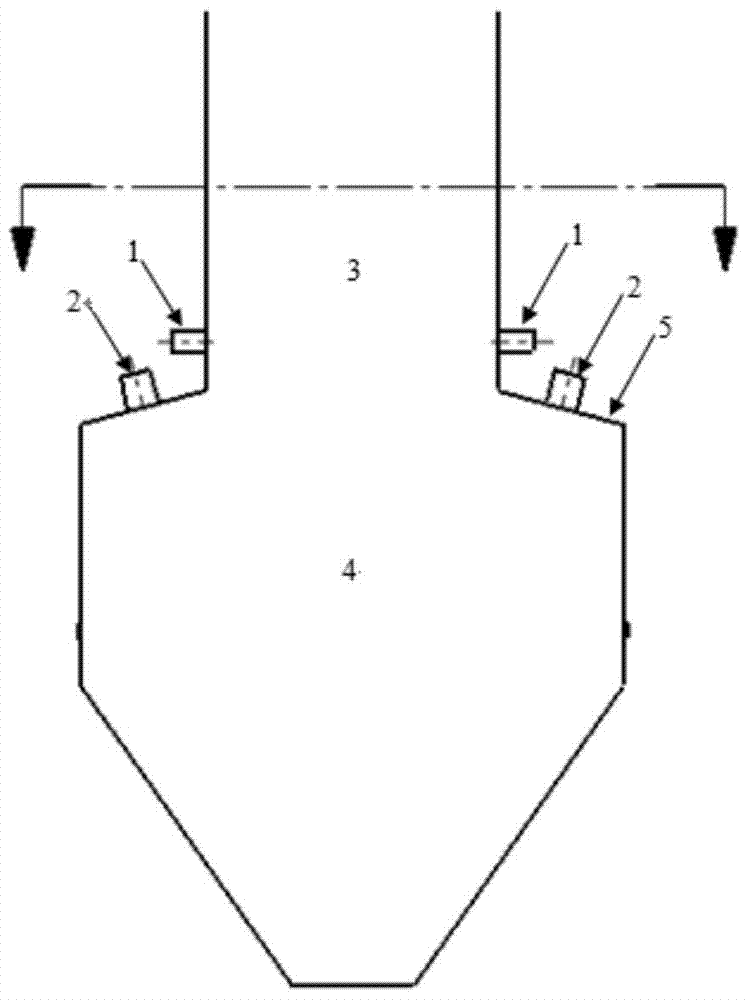

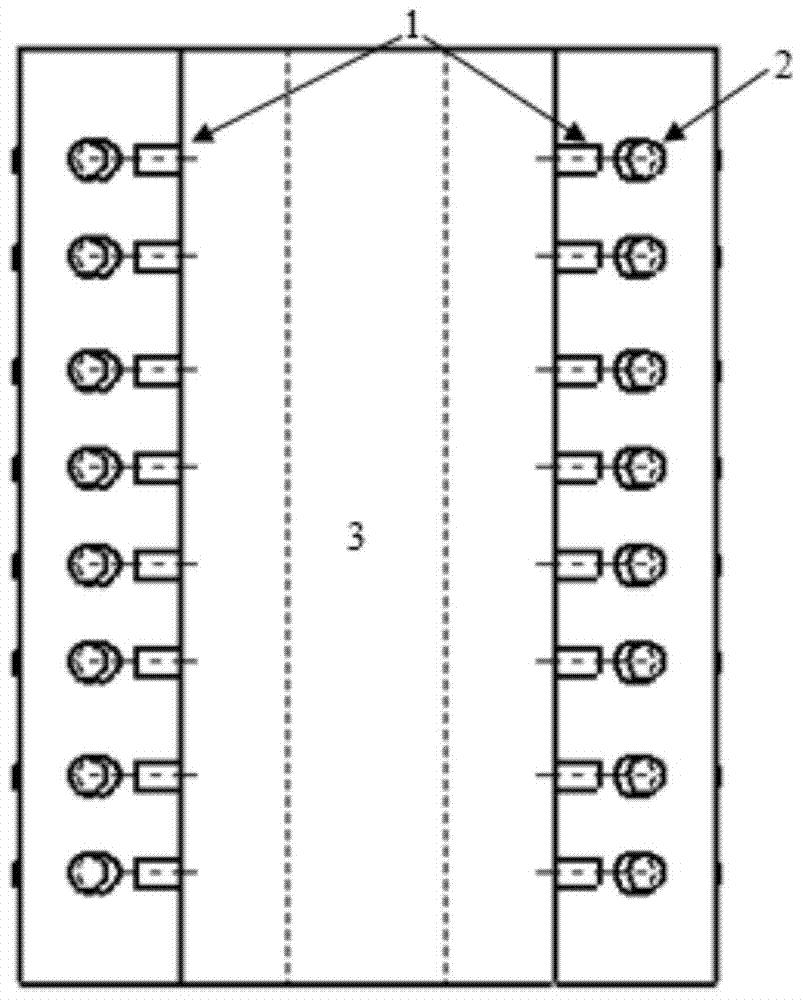

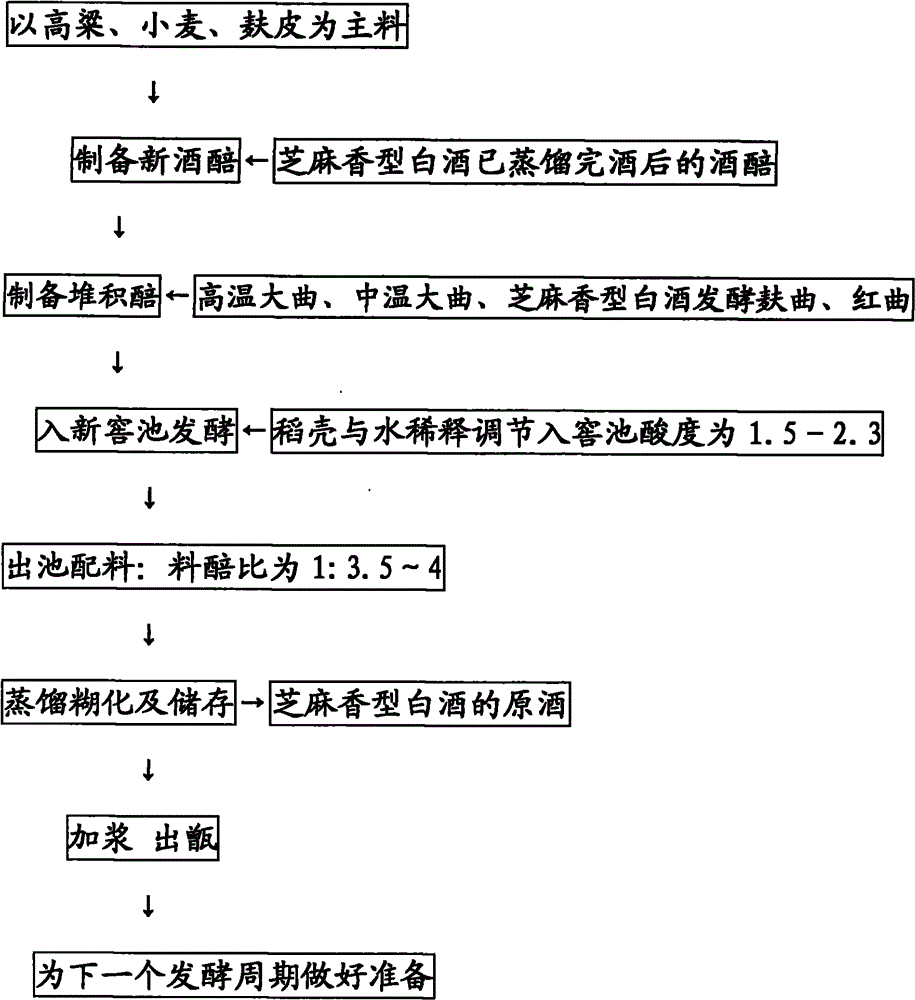

Method for producing strong aroma flavoring liquor by improving production process of sesame fragrant liquor

ActiveCN102311903BEasy to operateGood effectAlcoholic beverage preparationMicroorganism based processesWine cellarBrewing

The invention provides a method for producing strong aroma flavoring wine by improving production process of sesame fragrant wine, which relates to the technical field of wine brewing. A key technology of producing strong aroma flavoring wine based on the improvement of a fermentation cellar and a sesame fragrant wine process is emplyed, a building of strong aroma wine cellar is employed at a wall of the cellar at 50cm upward to the connecting place of the bottom of sesame fragrant wine cellar and the cellar wall and the bottom of the cellar to produce a novel fermentation cellar. According to the improved processes of preparing novel fermented grain, accumulating fermented grain, putting into a novel cellar for fermentation, taking out of the cellar and producing a double wheel bottom, distilling and gelatinizing and storing, the strong aroma flavoring original wine is produced. The method is used for producing the flavoring wine. The invention is characterized in that the novel cellar is built, novel strains can be selected, the raw material can be fully used, flavoring substance is fully formed, the wine product has compatible fragrance and the production is standardization.

Owner:SICHUAN CHUNZHIYUAN WINE

A w-flame boiler with multiple sets of burn-off air nozzles

ActiveCN104696950BGuaranteed thermal efficiencyThermal efficiency does not decreaseCombustion apparatusFlue gasFly ash

The invention discloses a W-flame boiler with multiple groups of burnout air nozzles. A plurality of burnout air nozzle groups are arranged at the lower part of the upper furnace, and the multiple burnout air nozzle groups in each burnout air nozzle group are respectively arranged in The front wall and rear wall of the upper furnace, and the wind blown out by the multiple burn-up air vents in each burn-up air vent group forms an imaginary tangent circle in the center of the upper furnace; each burn-up air vent group The number of the plurality of burnout air vents is 3 or more. The W-flame boiler with multiple groups of burn-out air nozzles of the present invention can strengthen the mixing of the air in the upper furnace area with the unburned pulverized coal, enhance the filling degree of the flue gas in the upper furnace area, and improve the burn-out rate of the pulverized coal in the later stage. Reducing the carbon content and carbon monoxide content of fly ash, especially in the case of large deviation of the primary air powder of the boiler, can achieve the purpose of reducing the NOx emission of the boiler on the premise of ensuring the normal boiler steam-water parameters and the boiler thermal efficiency not reducing.

Owner:YANTAI LONGYUAN POWER TECH

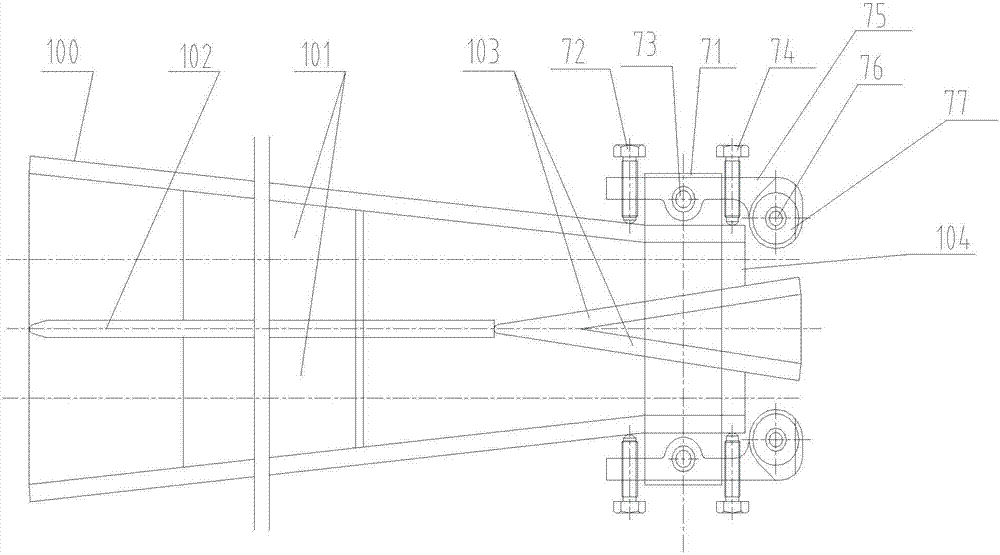

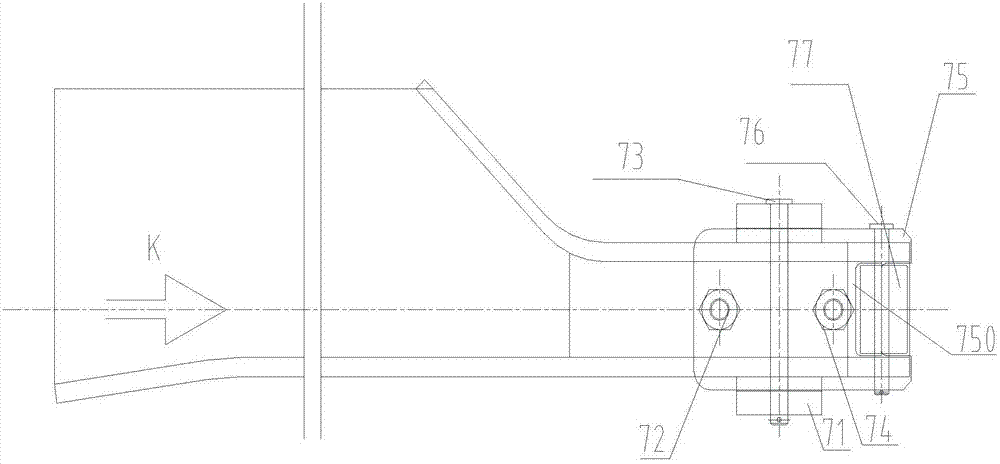

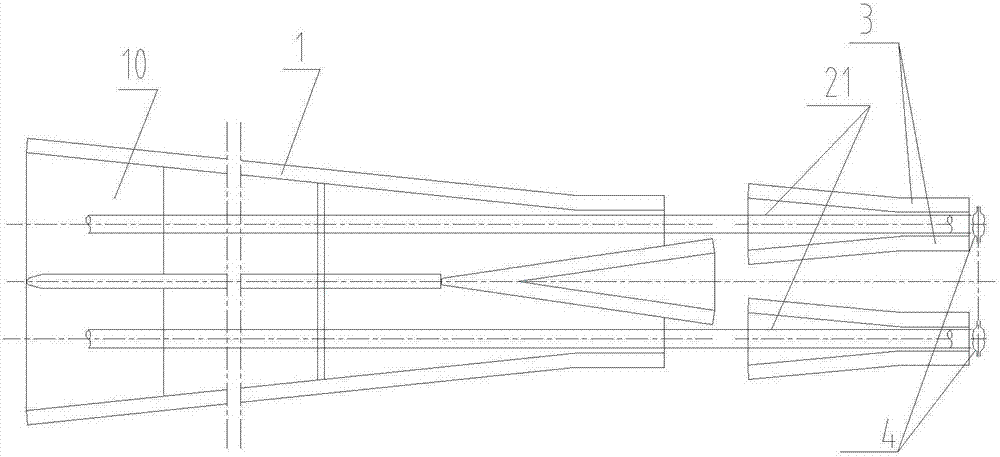

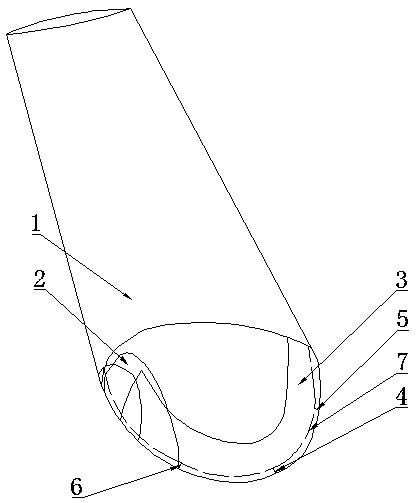

Guide trough for slitting and rolling rebar and restraint device installed on side plate for guide

ActiveCN105964706BSimple structureEasy to operateGuiding/positioning/aligning arrangementsSatiationsEngineering

The invention provides a guide groove for screw-thread steel slitting and rolling. The guide groove comprises two side plates and a partition plate located between the two side plates, and a piece rolling channel is formed between the corresponding side plate and the partition plate; the guide groove further comprises a restraint device arranged on the side plates, and the restraint device comprises guide wheels and supporting arms; the guide wheels are rotatably arranged and located at outlets of the piece rolling channels, the axes are in the vertical direction, and the circumferential faces of the guide wheels protrude inwards the piece rolling channels and are at least flush with the inner surfaces of the side plates; the supporting arms are arranged at the outlets of the piece rolling channels, and the guide wheels are rotatably arranged on the supporting arms. The restraint device with an adjustable function is preferably provided, the restraint device is adjusted according to the filling degree of actual screw-thread steel cross ribs at a production scene, accordingly the ideal size and satiation degree of reinforced cross ribs are obtained, and the quality control level is stabilized.

Owner:SHANDONG IRON & STEEL CO LTD

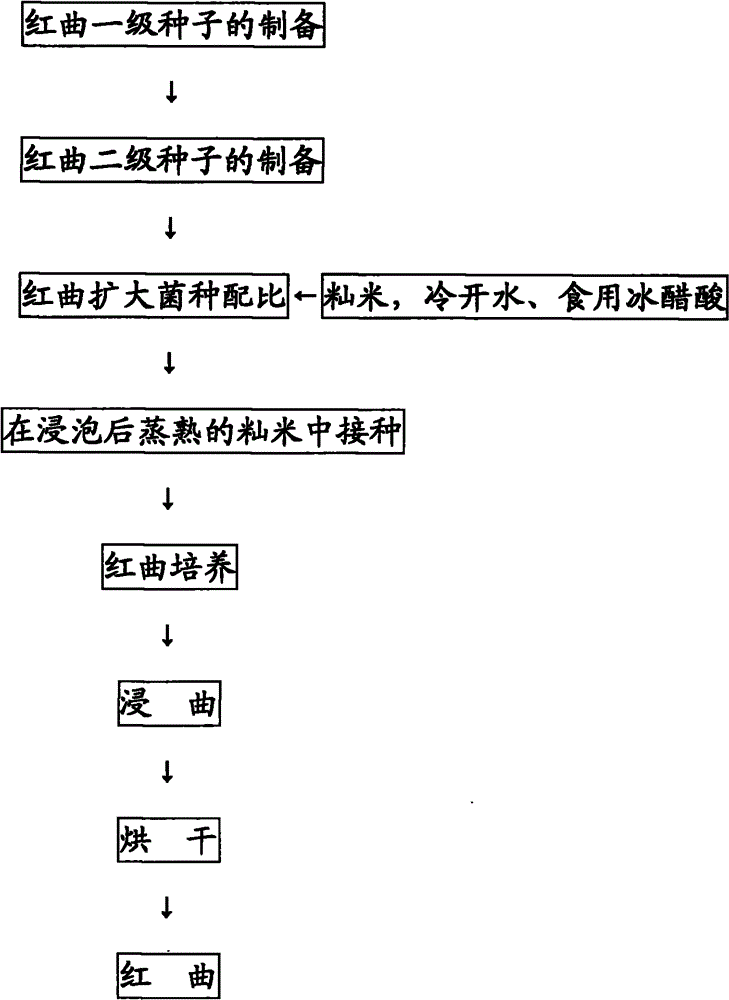

Use method of monascus in sesame-flavor liquor processing

ActiveCN102311904BHigh acid protease activityHigh yield esterase activityMicroorganism based processesAlcoholic beverage preparationBiotechnologySteeping

The invention discloses a use method of monascus in sesame-flavor liquor processing, and relates to the technical field of liquor brewing. Monascus first-order seeds and monascus second-order seeds are subjected to re-expanding culture, yeast steeping and drying in an oven to form monascus through adopting a key technology that a production process is regulated scientifically based on monascus addition. In the invention, sorghum, wheat and bran are utilized as main materials and rice husks are utilized as an auxiliary material. The main materials and fermented grains obtained by distillation of liquor are mixed into novel fermented grains. The novel fermented grains are steamed, spread for cooling and mixed with high-temperature and middle-temperature yeast for making hard liquor, fermentation bran koji and the prepared monascus to form accumulated fermented grains. After culture, the accumulated fermented grains are adjusted to acidity of 1.5 to 2.3 by rice husks and water and are putted into a fermentation pit for fermentation. After the fermentation, fermentation products are taken out from the fermentation pit and are subjected to preparation, distillation and gelatinization to form sesame-flavor raw liquor. The sesame-flavor raw liquor is stored hierarchically. The use method is utilized for production of sesame-flavor liquor. An acid protease added with monascus has highactivity. High temperature-resistant bacterial yeast and composite flavor-producing yeast are not added in process standardization. Fermentation pit performs fully its effects. A utilization rate of raw materials is high. The quality of produced liquor is high. The cost is low.

Owner:SICHUAN CHUNZHIYUAN WINE

A kind of sewing method of sleeve and armband lining for preventing cuff lock

ActiveCN107307492BEnsure fullness without cuffsIncrease fullnessGarmentsClothes making applicancesIndustrial engineering

Owner:SHANDONG RUYI WOOLEN GARMENT GRP CO LTD +1

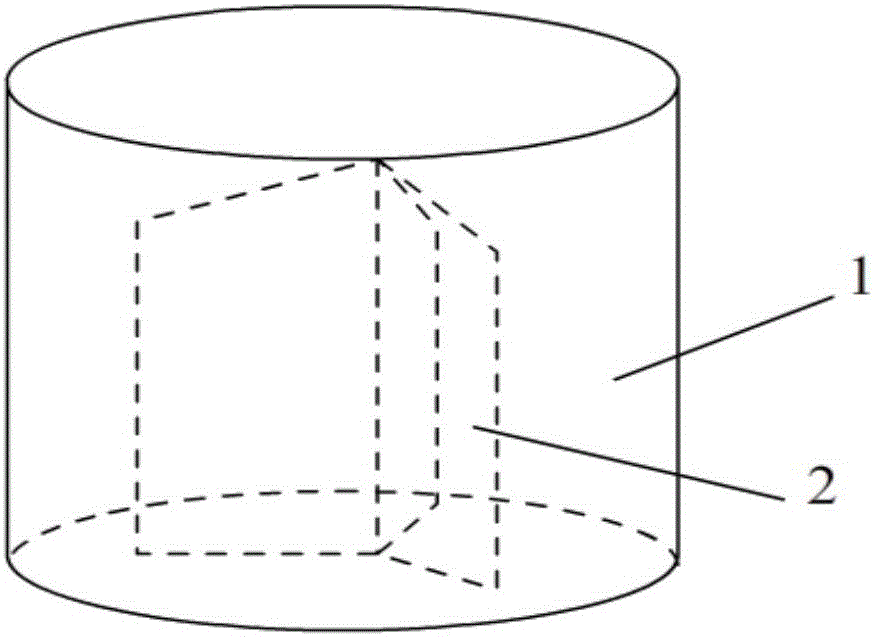

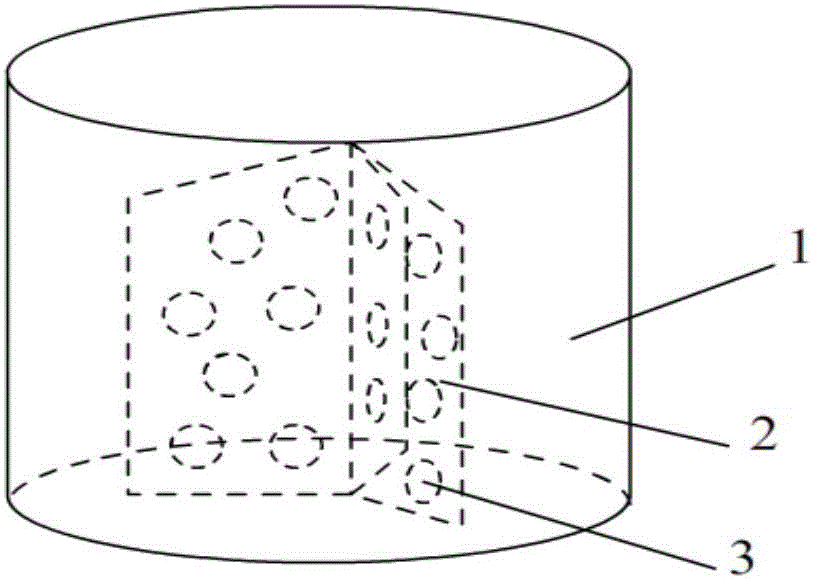

Combination oil-well pump

InactiveCN1239825CIncrease fullnessIncrease displacementFlexible member pumpsFluid removalLiquid surfacesOil well

The combined oil pump for extracting oil includes large diameter oil pump, small-diameter annular valve type oil pump, oil pipe fixer, oil pumping rod, etc. The small-diameter annular valve type oil pump is connected with small oil pipe and its plunger is connected to the oil pumping rod, and the other end of the oil pumping rod is connected to the plunger of the large diameter oil pump. The liquid is pumped with the large oil pump to the annular space between the large and the oil pipes to form the second liquid surface, and the second surface has greater submergence depth than the natural oil deposit. The small pump has sucking port submerged inside the great submergence depth to pump the liquid to ground. The oil pumping rod and the oil pumping machine can bear the force produced by the small pump in raising the plunger, and the present invention can raise the liquid pumping amount in relatively low submergence depth.

Owner:PETROCHINA CO LTD

A kind of dyeing method of yarn-dyed wool-like fabric

ActiveCN103726350BImprove crispnessIncrease drapeDyeing processLiquid/gas/vapor textile treatmentDisperse dyeYarn

The invention relates to a dyeing method for a yarn-dyed wool-like fabric. The dyeing method comprises the following steps: (1) adding an industrial liquid alkaline into a fabric to carry out alkaline decrement treatment; (2) adding a chelating agent GD-108, industrial glacial acetic acid and a disperse dye into the fabric subjected to the alkaline decrement treatment in the step (1) so as to dye the fabric; (3) adding industrial liquid alkaline and industrial sodium hydrosulfite for carrying out aftertreatment on the fabric dyed in the step (2); (4) shaping the fabric subjected to aftertreatment in the step (3); (5) adding an antistatic finishing agent and a soft anti-crease finishing agent for carrying out rolling liquid treatment on the fabric shaped in the step (4); and (6) decating the fabric subjected to rolling liquid treatment in the step (5) to obtain the yarn-dyed wool-like fabric. The dyeing method can be used for effectively improving the comprehensive color fastness of the yarn-dyed wool-like fabric, increasing the saturation degree of color and luster of the fabric, keeping the luster deep, enhancing the hand feeling of the fabric and better keeping the wool-like effect of the fabric; the fabric is bright in luster, flexible and fine in hand feeling; and the problem that a cloth surface is monotonous in color and has no luster because of decrement can be avoided.

Owner:浙江新建纺织有限公司

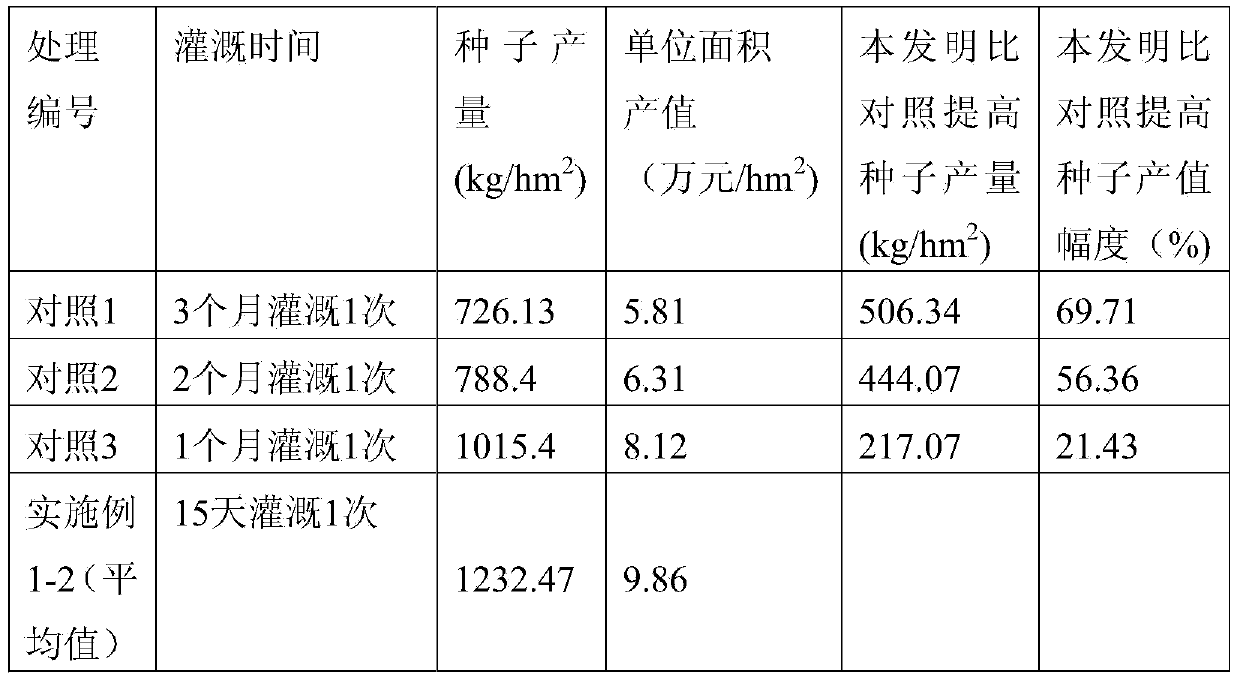

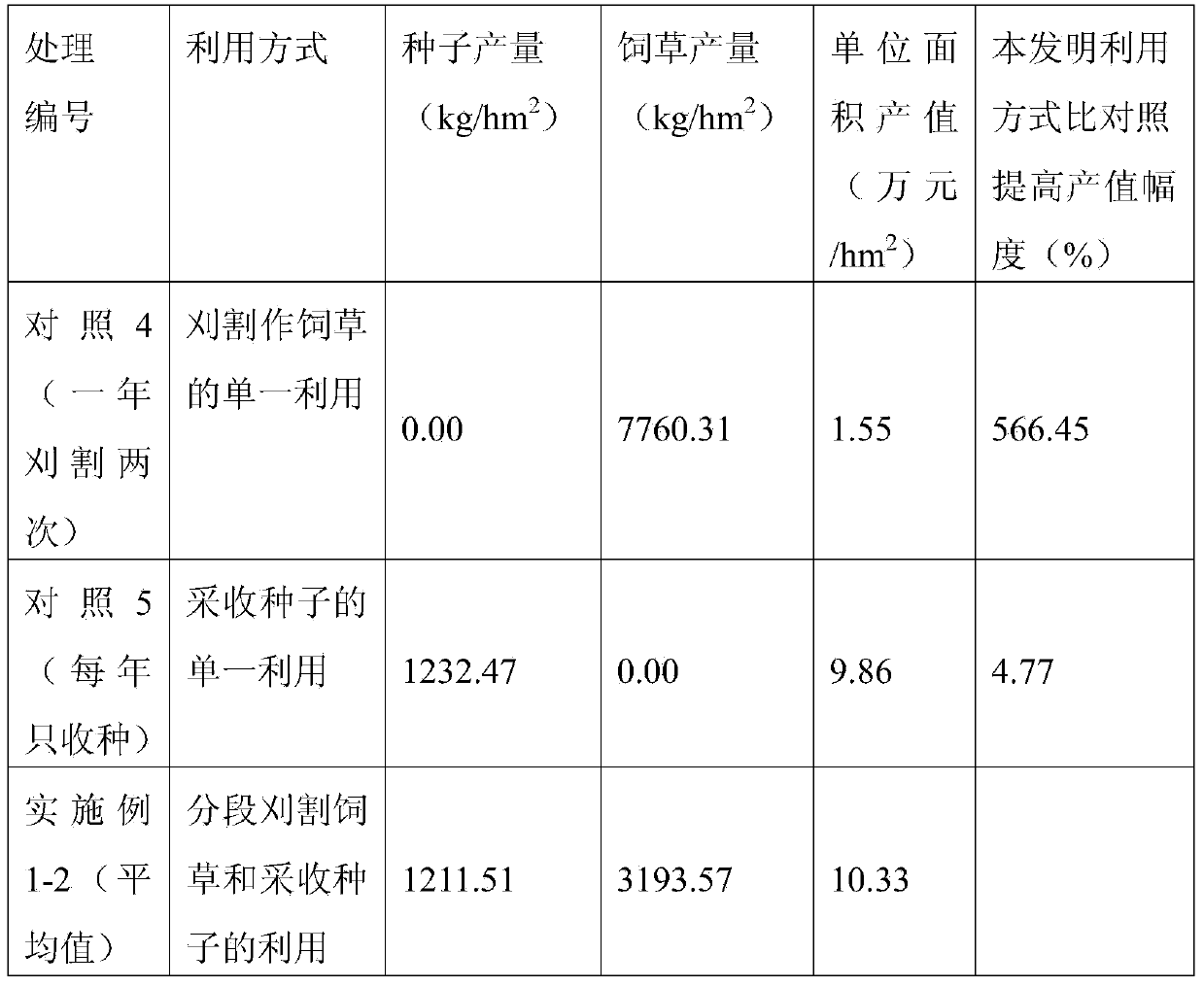

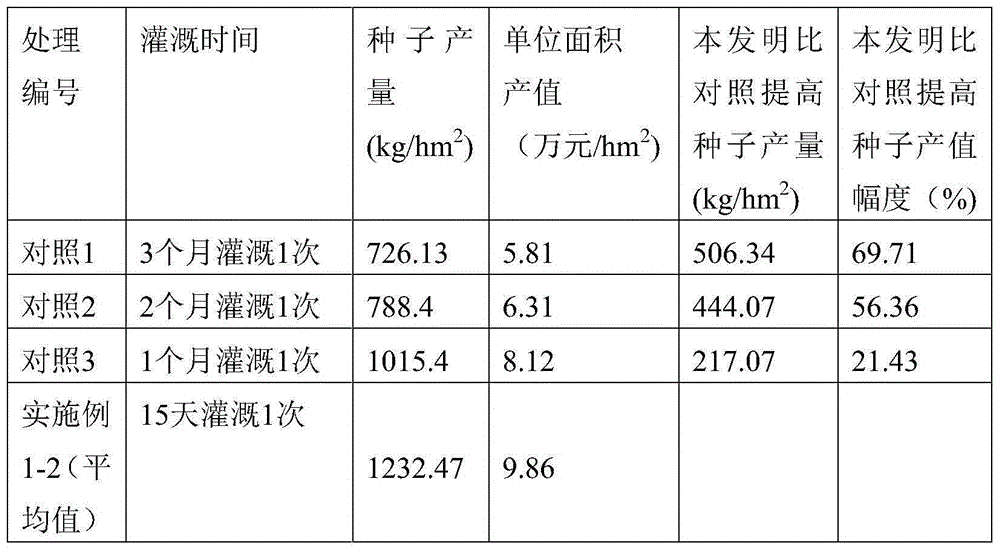

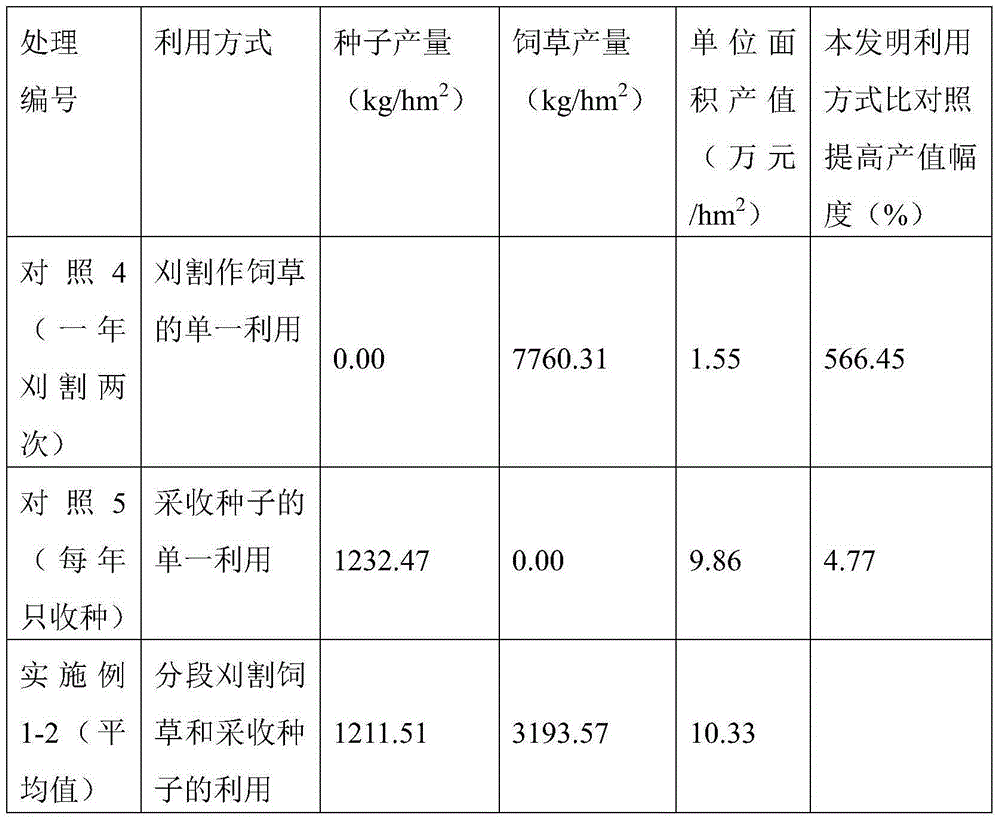

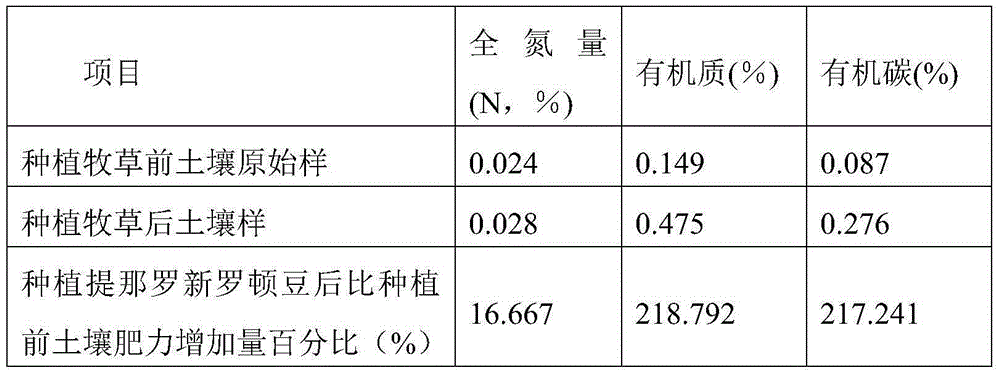

Method for mowing Neonotonia Wightii (Wight&Arn.) Lackey cv. Tinaroo stage by stage and cultivating and utilizing harvested seeds

ActiveCN104186142AGuarantee vigorous growthIncrease productionSeed and root treatmentWatering devicesBiotechnologySoil fertility

A method for mowing Neonotonia Wightii (Wight&Arn.) Lackey cv. Tinaroo stage by stage and cultivating and utilizing harvested seeds includes the steps that area selection is performed; seedlings are grown; cultivation and utilization are performed in the current planting year; Neonotonia Wightii (Wight&Arn.) Lackey cv. Tinaroo is mown stage by stage and harvested seeds are cultivated and utilized since the second year; according to the stage-by-stage mowing of Neonotonia Wightii (Wight&Arn.) Lackey cv. Tinaroo and cultivation and utilization of the harvested seeds, since the second planting year, the Neonotonia Wightii (Wight&Arn.) Lackey cv. Tinaroo is mown once in July or August every year as forage grass, seeds are harvested from January to February every year since the third planting year, from the time when pods appear to the time before harvesting of the seeds, watering is performed once every 14 days to 16 days, and from the time after harvesting of the seeds to the time when the dry season is over, watering is performed once a month. With the method, the benefits of unit area of cultivation field are effectively increased, and the benefits of the unit area are increased by 566.45% annually compared with the situation that Neonotonia Wightii (Wight&Arn.) Lackey cv. Tinaroo is merely used as forage grass, two agricultural products including forage grass and seeds can be obtained in one growth cycle, and meanwhile soil fertility is improved.

Owner:RES INST OF TROPICAL ECO AGRI SCI YUNAN ACAD OF AGRI SCI

Cultivation and Utilization Method of Segmental Cutting and Harvesting Seeds of Tinara New Roton Beans

ActiveCN104186142BGuarantee vigorous growthIncrease productionSeed and root treatmentWatering devicesDry seasonSoil fertility

A method for mowing Neonotonia Wightii (Wight&Arn.) Lackey cv. Tinaroo stage by stage and cultivating and utilizing harvested seeds includes the steps that area selection is performed; seedlings are grown; cultivation and utilization are performed in the current planting year; Neonotonia Wightii (Wight&Arn.) Lackey cv. Tinaroo is mown stage by stage and harvested seeds are cultivated and utilized since the second year; according to the stage-by-stage mowing of Neonotonia Wightii (Wight&Arn.) Lackey cv. Tinaroo and cultivation and utilization of the harvested seeds, since the second planting year, the Neonotonia Wightii (Wight&Arn.) Lackey cv. Tinaroo is mown once in July or August every year as forage grass, seeds are harvested from January to February every year since the third planting year, from the time when pods appear to the time before harvesting of the seeds, watering is performed once every 14 days to 16 days, and from the time after harvesting of the seeds to the time when the dry season is over, watering is performed once a month. With the method, the benefits of unit area of cultivation field are effectively increased, and the benefits of the unit area are increased by 566.45% annually compared with the situation that Neonotonia Wightii (Wight&Arn.) Lackey cv. Tinaroo is merely used as forage grass, two agricultural products including forage grass and seeds can be obtained in one growth cycle, and meanwhile soil fertility is improved.

Owner:RES INST OF TROPICAL ECO AGRI SCI YUNAN ACAD OF AGRI SCI

Oil well pump for well washing

ActiveCN114412763AImprove oil intake efficiencyIncrease fullnessPositive displacement pump componentsFlexible member pumpsOil wellCrude oil

The invention relates to the technical field of oil well pump equipment, in particular to an oil well pump for well washing, which comprises a pump cylinder, a lengthened plunger is slidably connected in the pump cylinder, an oil pull rod is fixedly connected to the upper surface of the lengthened plunger, a guide mechanism is arranged outside the oil pull rod in the pump cylinder, and an upper joint is fixedly connected to the lower end of the pump cylinder. The lower end of the upper connector is fixedly connected with a thick cylinder, one end, away from the upper connector, of the thick cylinder is fixedly connected with an oil drainage mechanism, and the lower end of the oil drainage mechanism is fixedly connected with an oil inlet cylinder. Crude oil drives a driven fan outside a driven rotating shaft to rotate in the flowing process, a supporting rod drives a cleaning plate on a vertical rod to clean the outer surface of a sand prevention cylinder, the oil inlet efficiency of the equipment is improved, the crude oil is stirred through a spoiler, the crude oil and gas are mixed, and the oil inlet efficiency of the equipment is improved. Therefore, the sand prevention and self-cleaning effects on the equipment can be achieved, and the oil pumping filling degree of the equipment can be improved.

Owner:DONGYING BAIHUA GASOLINEEUM TECH DEV

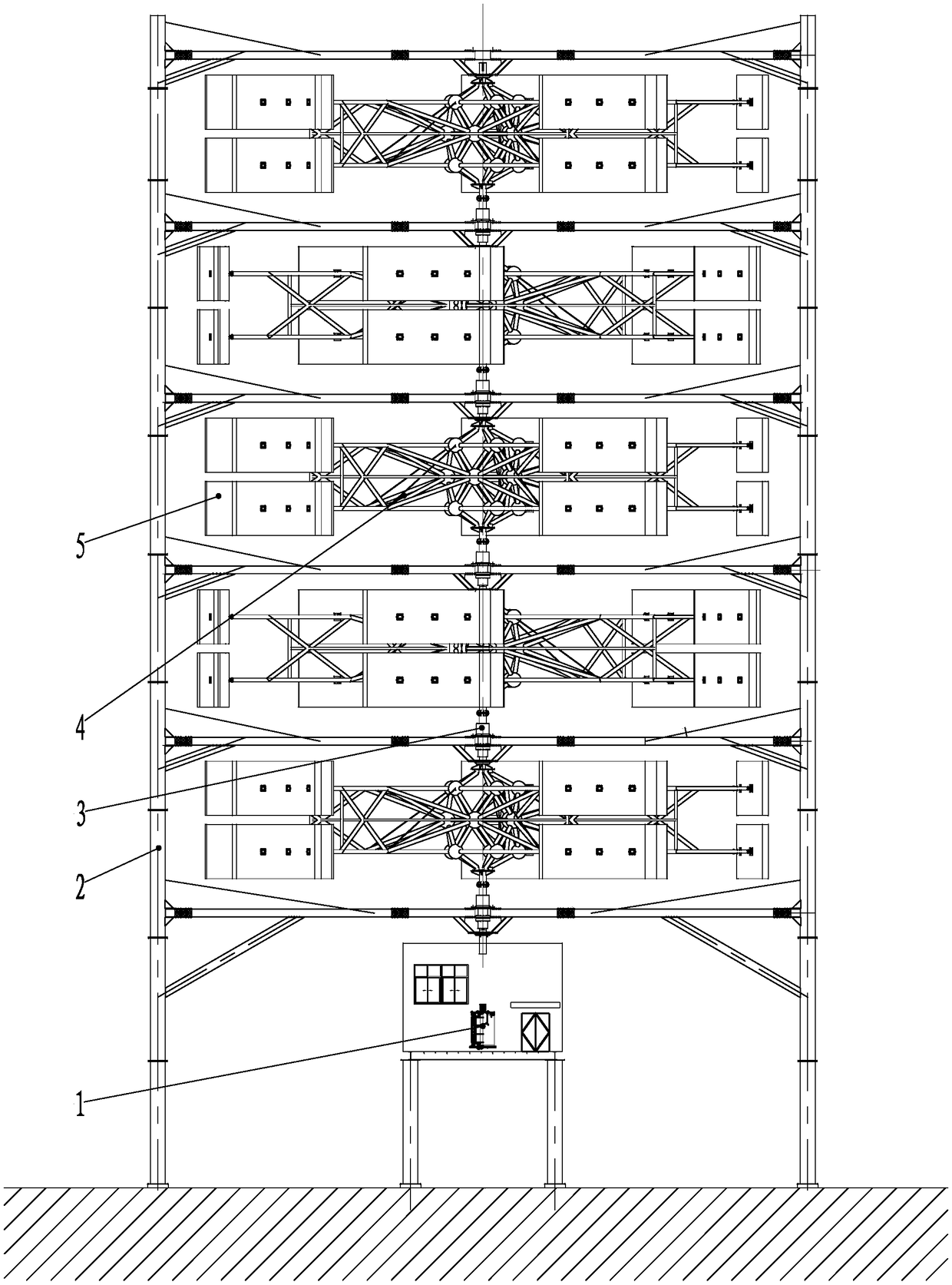

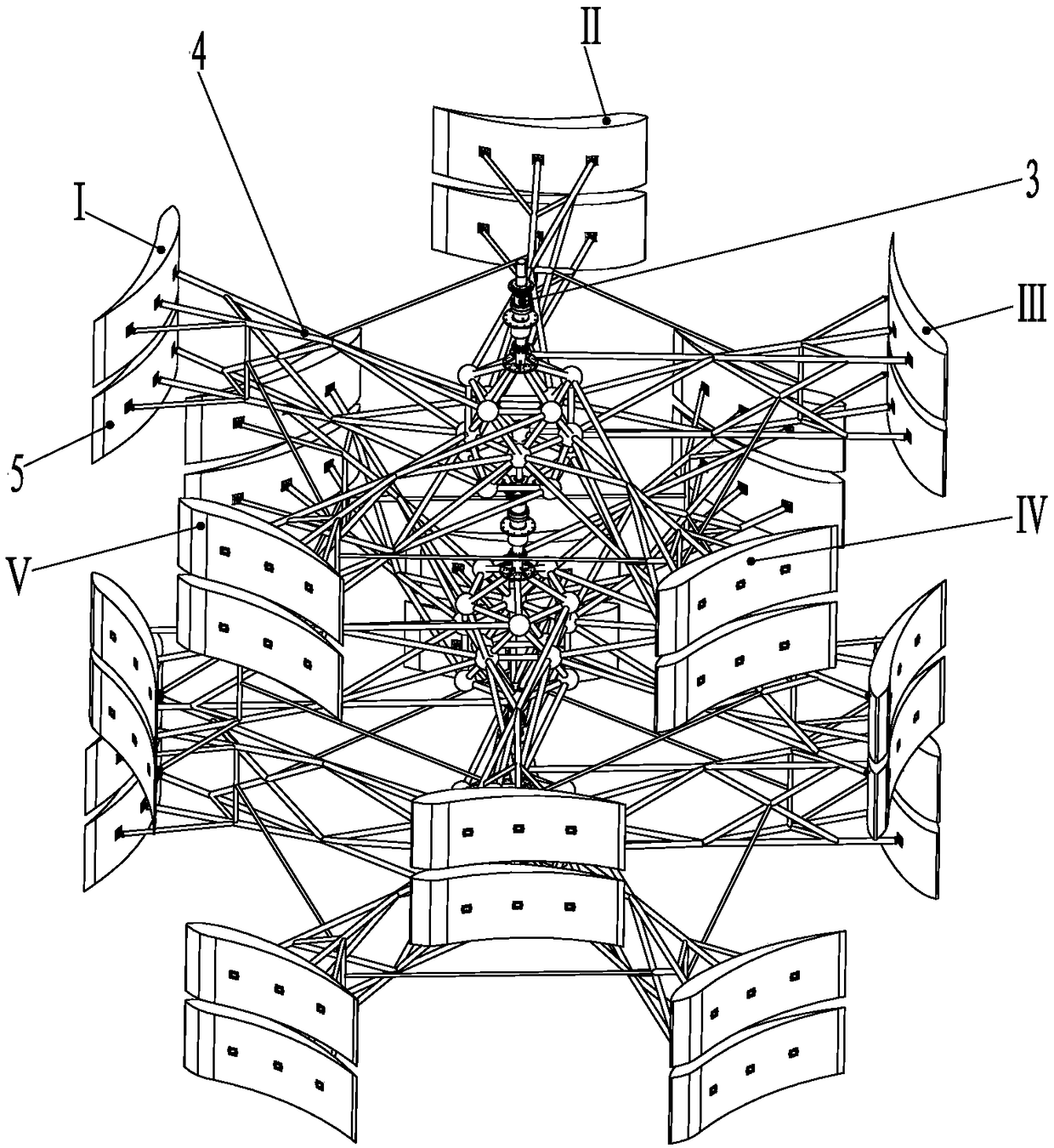

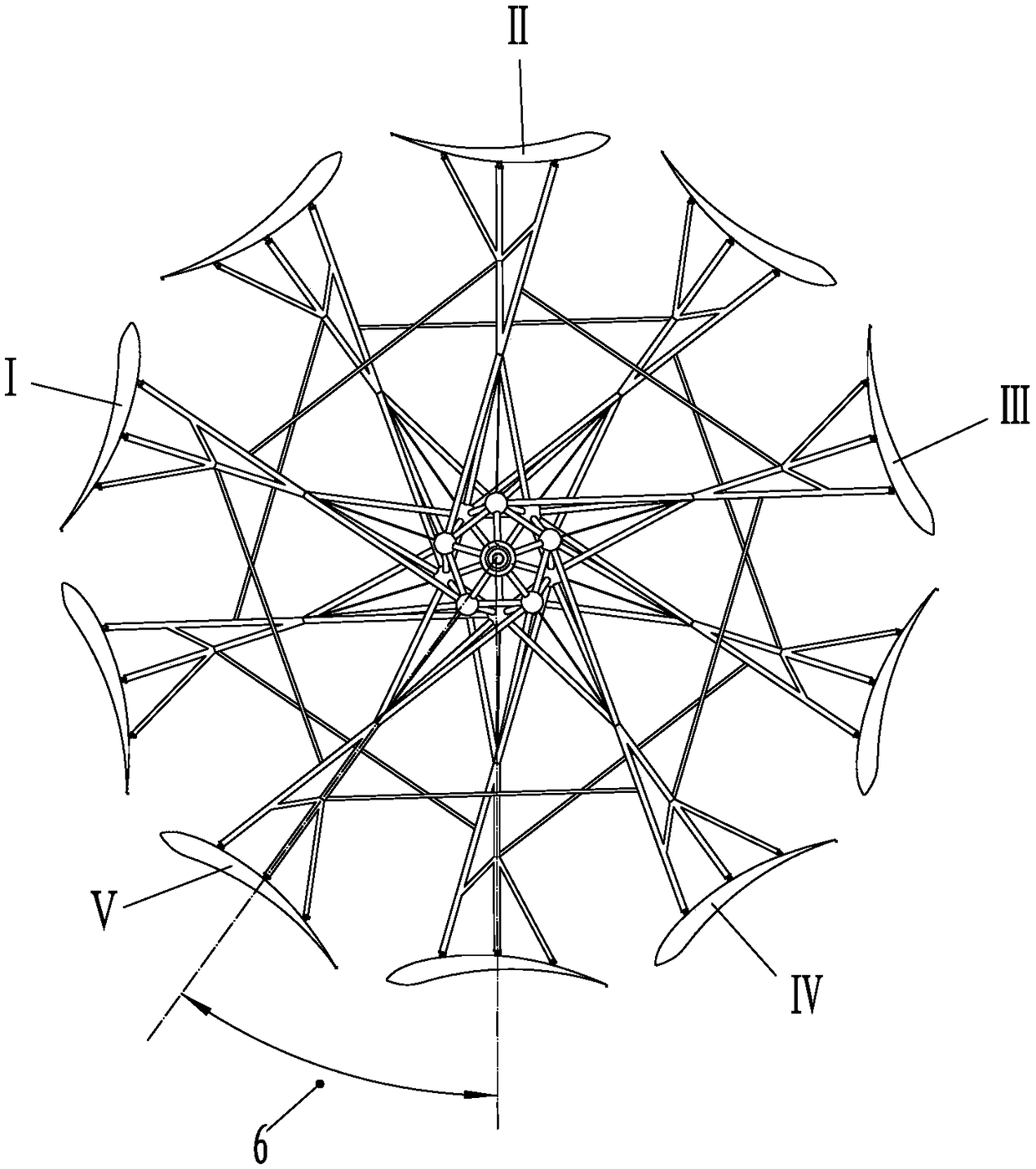

Fan blades on vertical axis wind power generation equipment

InactiveCN109372688AReduce vertical plane sizeReduce the difficulty of startingRenewable energy generationMachines/enginesVertical planeDrive shaft

The invention discloses fan blades on vertical axis wind power generation equipment. Each fan blade comprises a supporting frame, a transmission shaft fixed to the supporting frame, a fan blade supporting arm hinged to the transmission shaft and a fan blade fixed to the end of the fan blade supporting arm. Multiple fan blade supporting arms are arranged. The rotating centers of the fan blade supporting arms are connected in series through concentric rotary shafts. Multiple fan blades are uniformly distributed on the rotating circumference, and the adjacent to fan blades are staggered uniformlyin the vertical direction. The fan blades on the vertical axis wind power generation equipment reduce vertical planes of gaps among the fan blades, so that when air blows the blades, the starting difficulty of a fan is reduced and a power generator is smoothly started. Meanwhile, the stationarity of the power generator equipment in operation is also increased, and the full degree of a power generation power curve is increased.

Owner:渭南风云海新能源科技有限公司

Soil mixture for cultivating wheat

The invention relates to a soil mixture for cultivating wheat, which mainly comprises the following components in parts by mass: 30-40 parts of straw, 60-80 parts of garden soil, 3-5 parts of pomelo peel, 3-5 parts of eggshell powder, 8-10 parts of a cake fertilizer, 4-6 parts of rice husk charcoal, 2-3 parts of jujube pits, 4-6 parts of pig manure, 5-8 parts of Japanese banana leaves and 2-4 parts of brans. The soil mixture for cultivating wheat provided by the invention is particularly suitable for the cultivation of wheat, and can greatly increase the fullness of wheat granules and increasethe yield per mu.

Owner:丹阳市珥陵镇小潘园土地股份专业合作社

Nutritional agent for increasing peanut oil yield and preparation method of nutritional agent

The invention provides a nutritional agent for increasing a peanut oil yield and a preparation method of the nutritional agent. The nutritional agent comprises the following raw materials: 80-95 partsof hypolepis gigantea leaves, 150-170 parts of oxytropis assiensis vass petal, 160-180 parts of saussurea stricta leaves and 300 parts of water. After a series of treatment by the nutritional agent,soaked peanuts are sowed, diameters of the peanuts are effectively increased, and the plump degrees of the peanuts are raised greatly, so that the output and oil yield of the peanuts are greatly increased.

Owner:龚春华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com