High-inclination horizontal well oil pump

A technology for oil well pumps and horizontal wells, applied in the field of oil well pumps for highly deviated horizontal wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

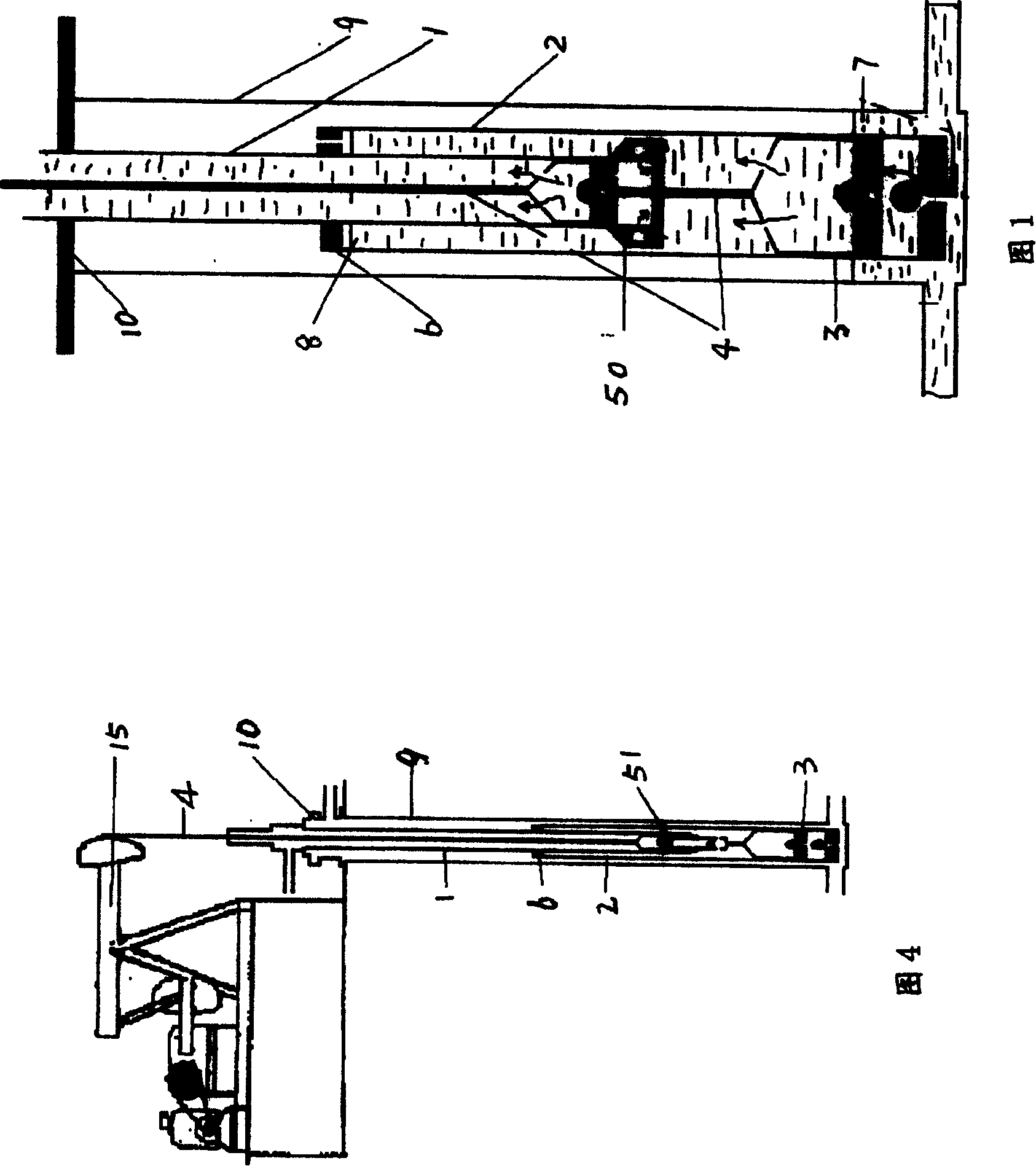

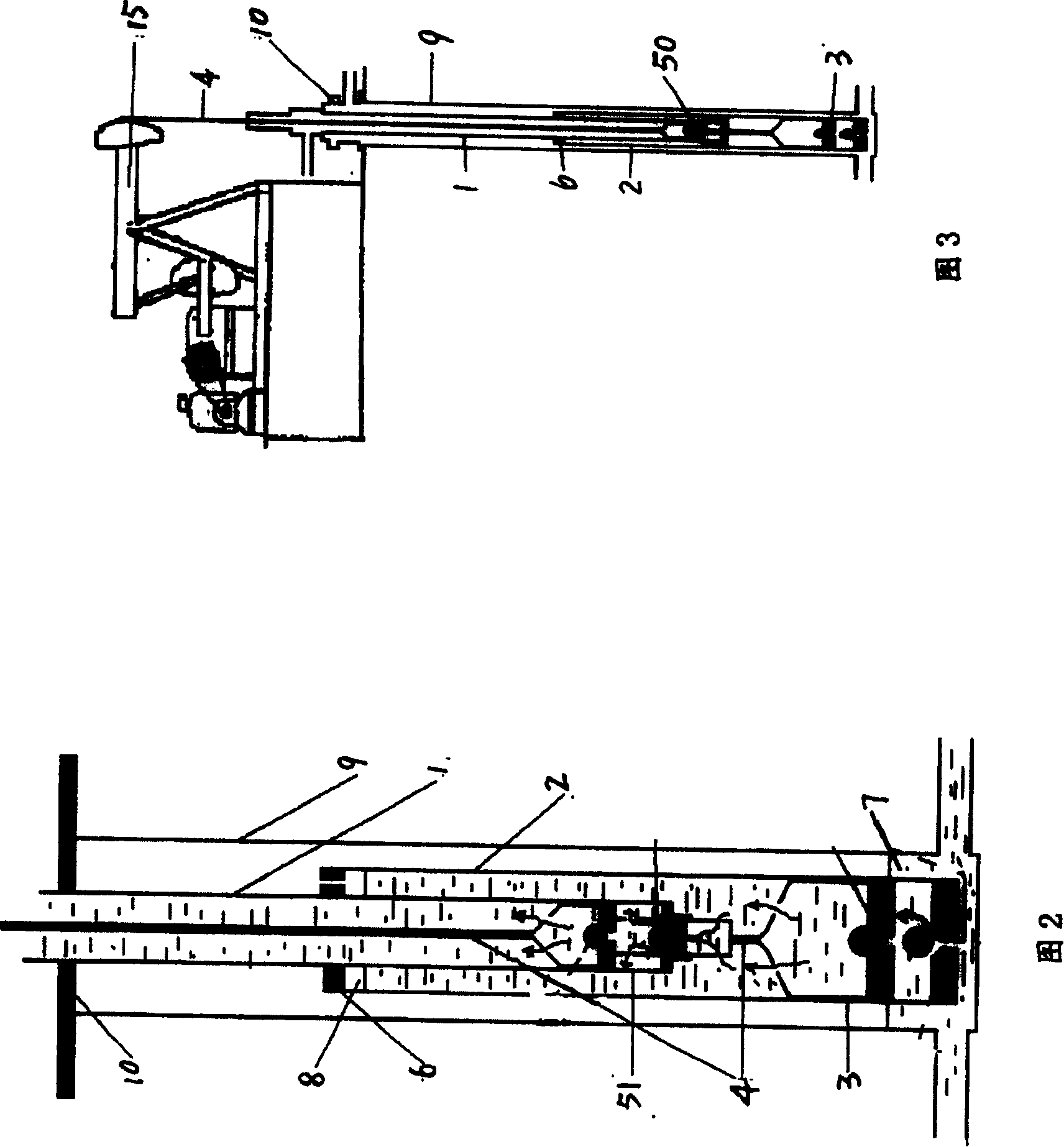

[0012] It includes a large-diameter oil pump 3, a small-diameter annular valve oil pump 50, a small oil pipe 1, a large oil pipe 2, an oil pipe holder 6, a casing 9, a wellhead 10, a sucker rod 4, and a pumping unit 15. Casing pipe 9, wellhead 10, sucker rod 4, and pumping unit 15 belong to the necessary equipment of oil well, and do not belong to the content of the present invention. Large oil pipe 2 is arranged in casing pipe 9. Through the oil pipe fixer 6, the top of the large oil pipe 2 is fixed on the middle part of the small oil pipe 1. The large-diameter oil well pump 3 is inserted into the casing 9 and fixed on the bottom of the large oil pipe 2, and the small-diameter ring valve oil well pump 50 is fixed on the bottom of the small oil pipe 1. The small oil pipe 1 is inserted into the large oil pipe 2 from the oil pipe holder 6 on the top of the large oil pipe 2, and extends downward to connect with the upper part of the small diameter ring valve oil well pump 50. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com