Fan blades on vertical axis wind power generation equipment

A technology of wind power generation equipment and vertical axis, applied in the field of wind blades, can solve the problems of inability to rotate the main shaft and increase the difficulty of starting, and achieve the effects of increasing the stability, reducing the difficulty of starting, and increasing the degree of fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The wind blades on the vertical axis wind power generation equipment of the present invention will be further described below in conjunction with the drawings and specific embodiments:

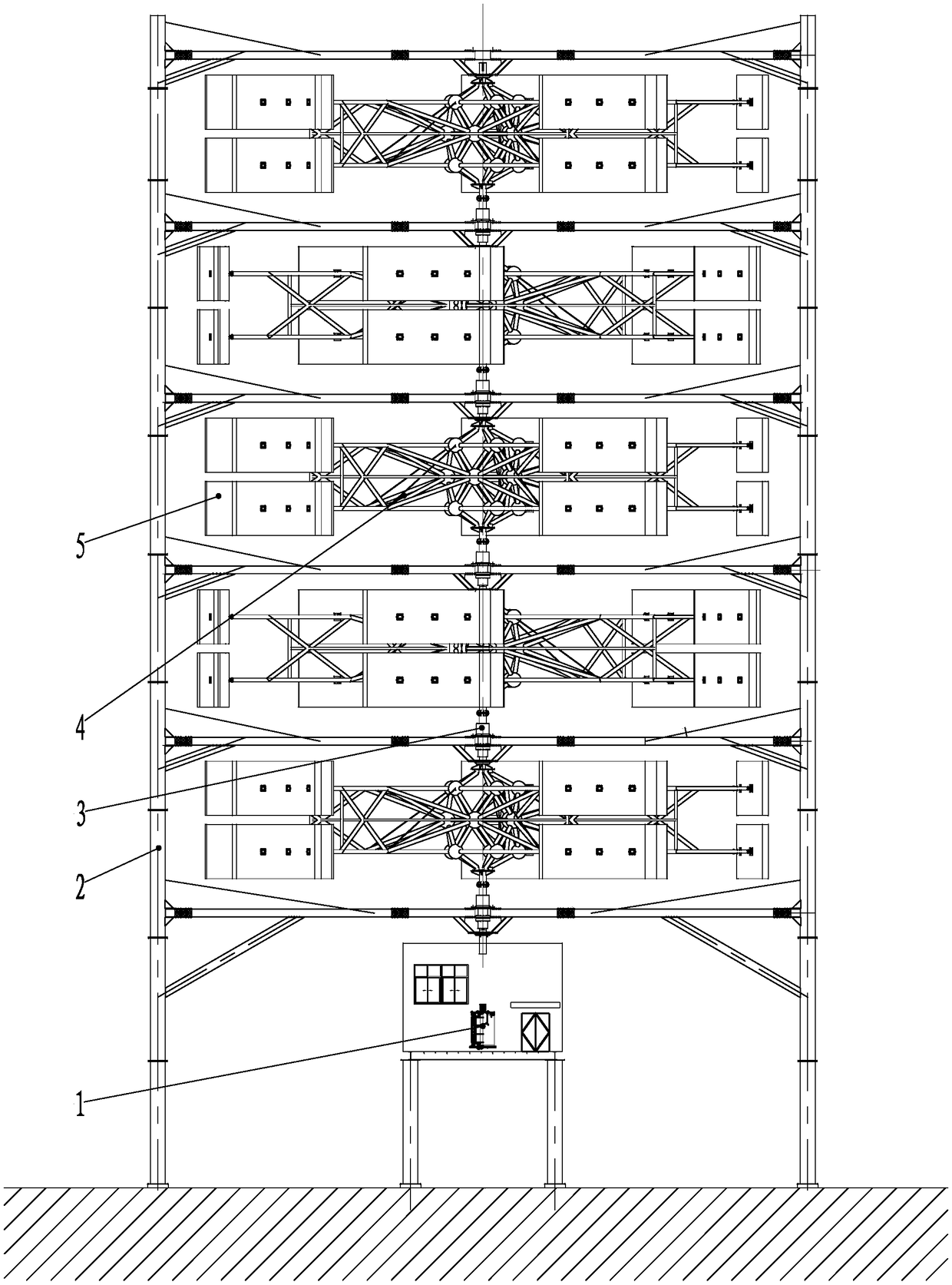

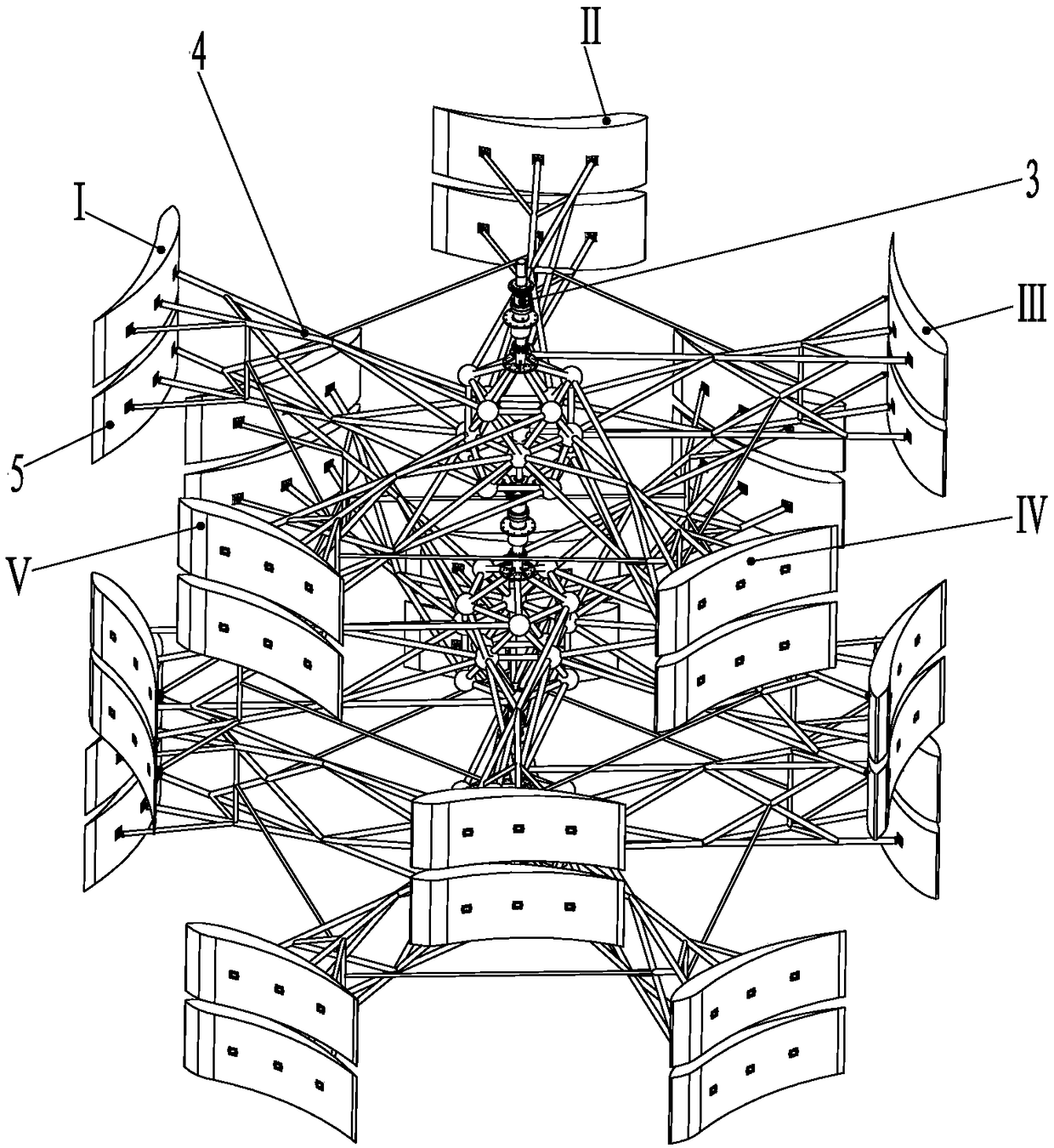

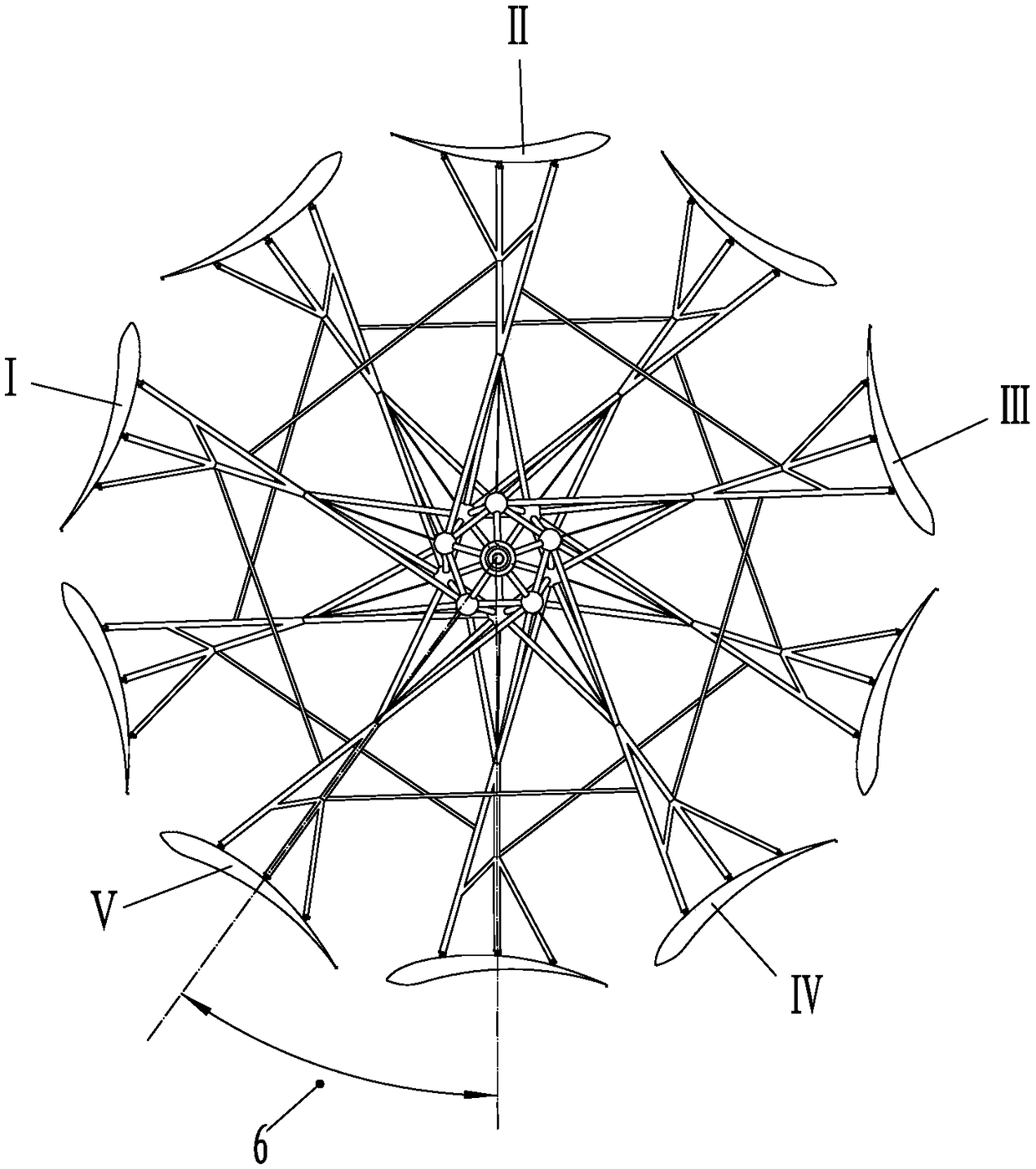

[0018] figure 1 It is a schematic diagram of the structure of a vertical axis wind power generation equipment of the present invention, figure 2 It is the structural position diagram of the wind blades on the power generation equipment, image 3 Yes figure 2 Top view. In the figure, the vertical axis wind power generation equipment includes a support frame 2, a drive shaft 3 fixed on the support frame, a fan blade support arm 4 hinged on the drive shaft, and a wind blade 5 fixed on the end of the fan support arm. , The support frame 2 is supported on the bottom surface through the uprights, and in the middle of the support frame is each group of fan blade support arms 4 connected in series by the drive shaft 3. The lower end of the drive shaft is connected to the generator 1, and the fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com