A transmission method based on belt conveying

A belt conveying and driving wheel technology, applied in conveyors, electric components, transportation and packaging, etc., can solve the problems of waste of resources, increase capital investment, unfavorable production, etc., achieve good control, reduce start-up difficulty, and large friction force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

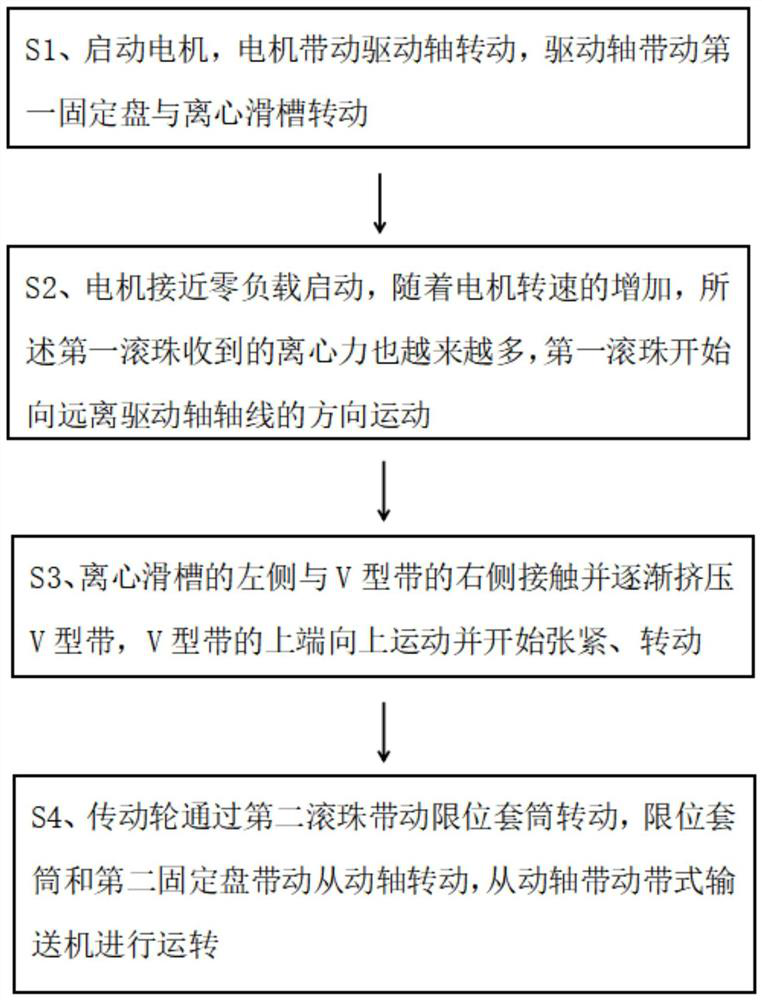

[0030] Such as figure 1 Described, a kind of transmission method based on belt conveying, this transmission method comprises the following steps:

[0031] S1, start the motor, the motor drives the drive shaft 14 to rotate, and the drive shaft 14 drives the first fixed disk 7 and the centrifugal chute 10 to rotate, because there is a large distance between the first fixed disk 7 and the centrifugal chute 1, so it cannot drive The V-belt 1 rotates, so the motor does not drive the belt conveyor to run at this moment.

[0032] S2. The motor is started with close to zero load. As the motor speed increases, the first ball 11 receives more and more centrifugal force, and the first ball 11 starts to move away from the axis of the drive shaft 14, and squeezes the centrifugal force. On the right side of the chute 10, the centrifugal chute 10 overcomes the elastic force of the first spring 9 and moves to the left.

[0033] S3. The left side of the centrifugal chute 10 is in contact wit...

Embodiment 2

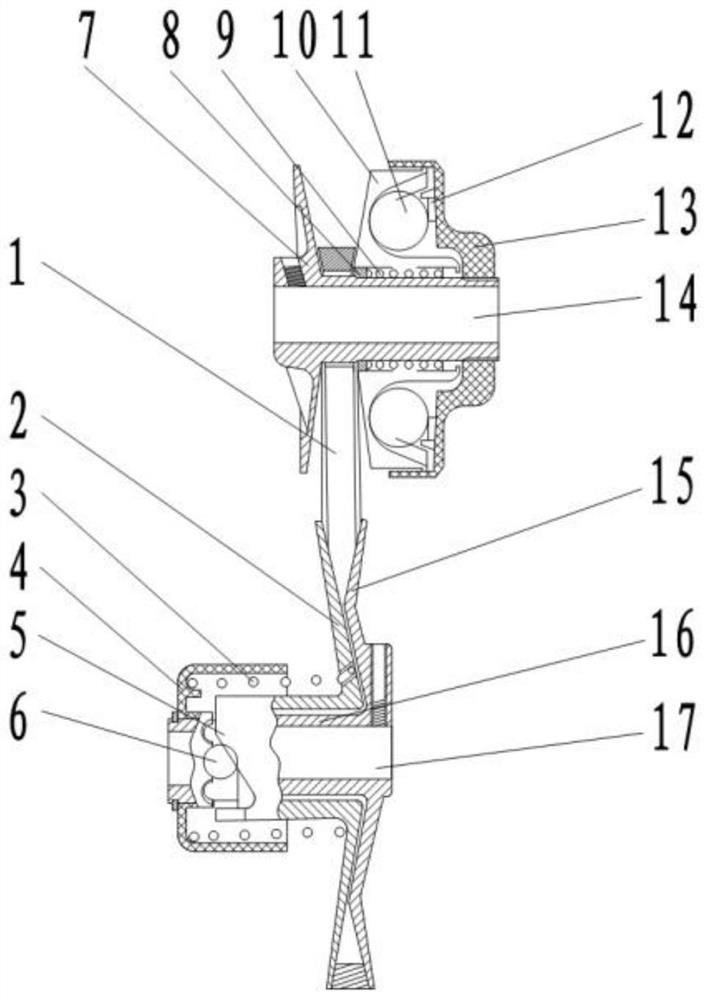

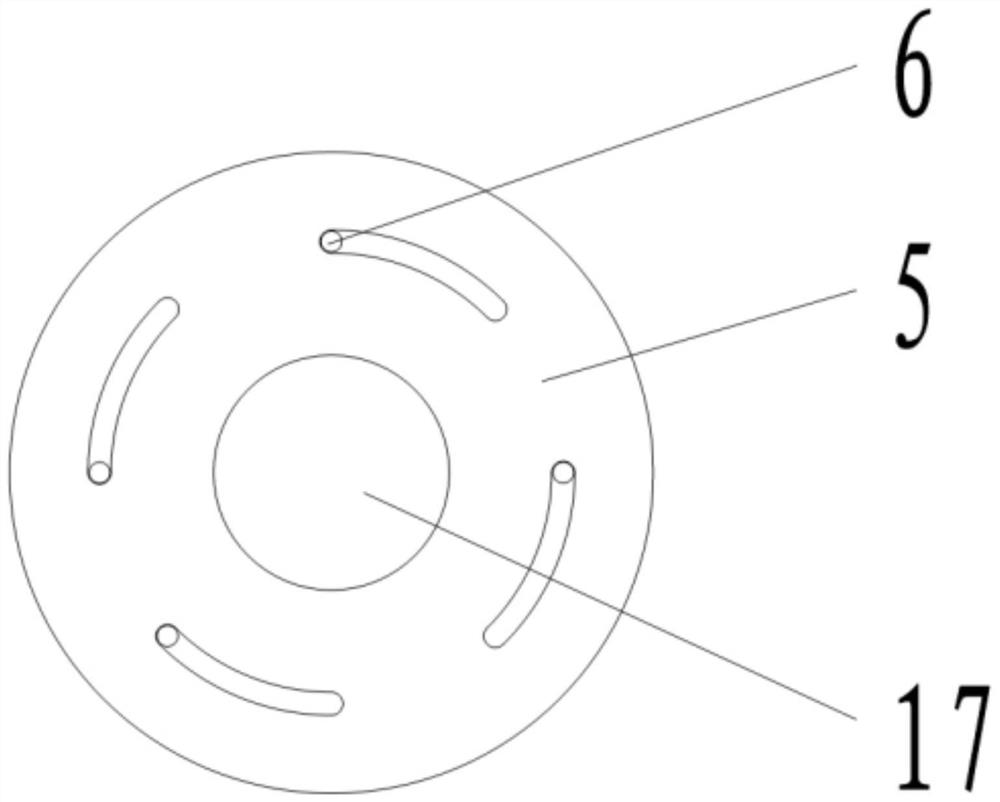

[0044] Such as figure 2 , 4 As shown in -5, a transmission mechanism for a belt conveyor includes: a drive shaft 14, used to drive the V-belt 1, and then drives a driven shaft 17, and the driven shaft 17 is used to drive the belt conveyor The transmission mechanism is used to transmit the driving force of the drive shaft 14 to the driven shaft 14 when the drive shaft 14 reaches a certain speed.

[0045] The transmission mechanism includes a driving end transmission mechanism and a driven end transmission mechanism, the driving end transmission mechanism is used to gradually tension the V-belt 1 when the drive shaft 14 reaches a certain speed, and the driven end transmission mechanism is used for The V-belt 1 that is gradually tensioned is connected with the driven shaft 17 in transmission. During the process of the V-belt 1 being gradually tensioned, the drive shaft 14 and the driven shaft 17 have a gradually smaller transmission ratio.

[0046] The driving end transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com