Patents

Literature

152results about How to "Guaranteed thermal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

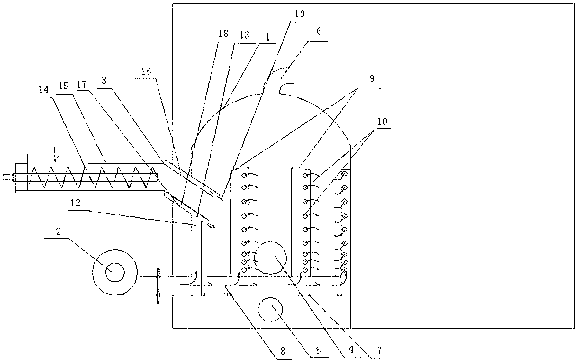

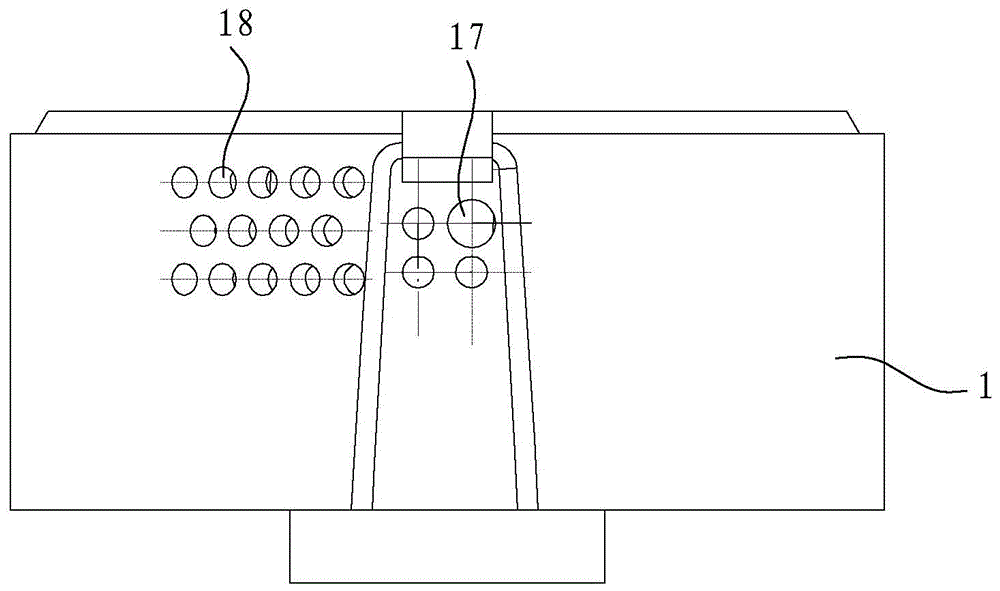

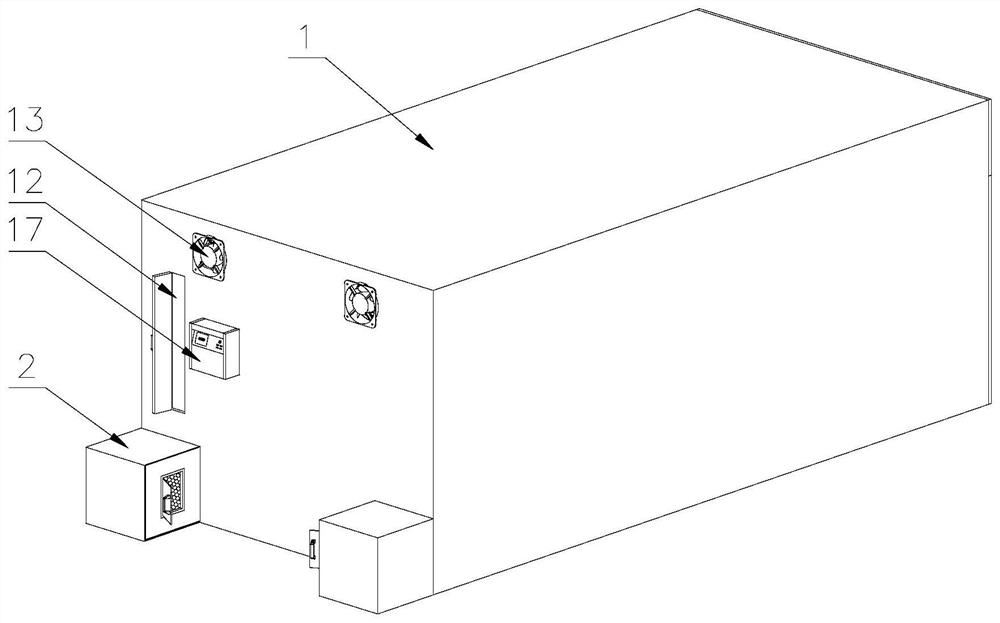

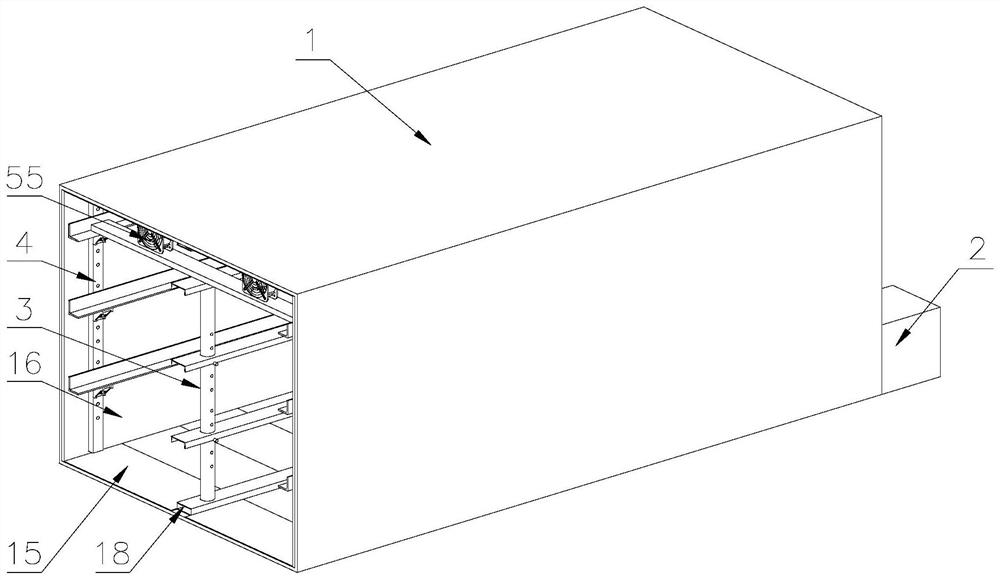

Process and apparatus for producing biomass gas

InactiveCN101294085ARepeated lysis eliminationSave energySpecial form destructive distillationWater vaporEngineering

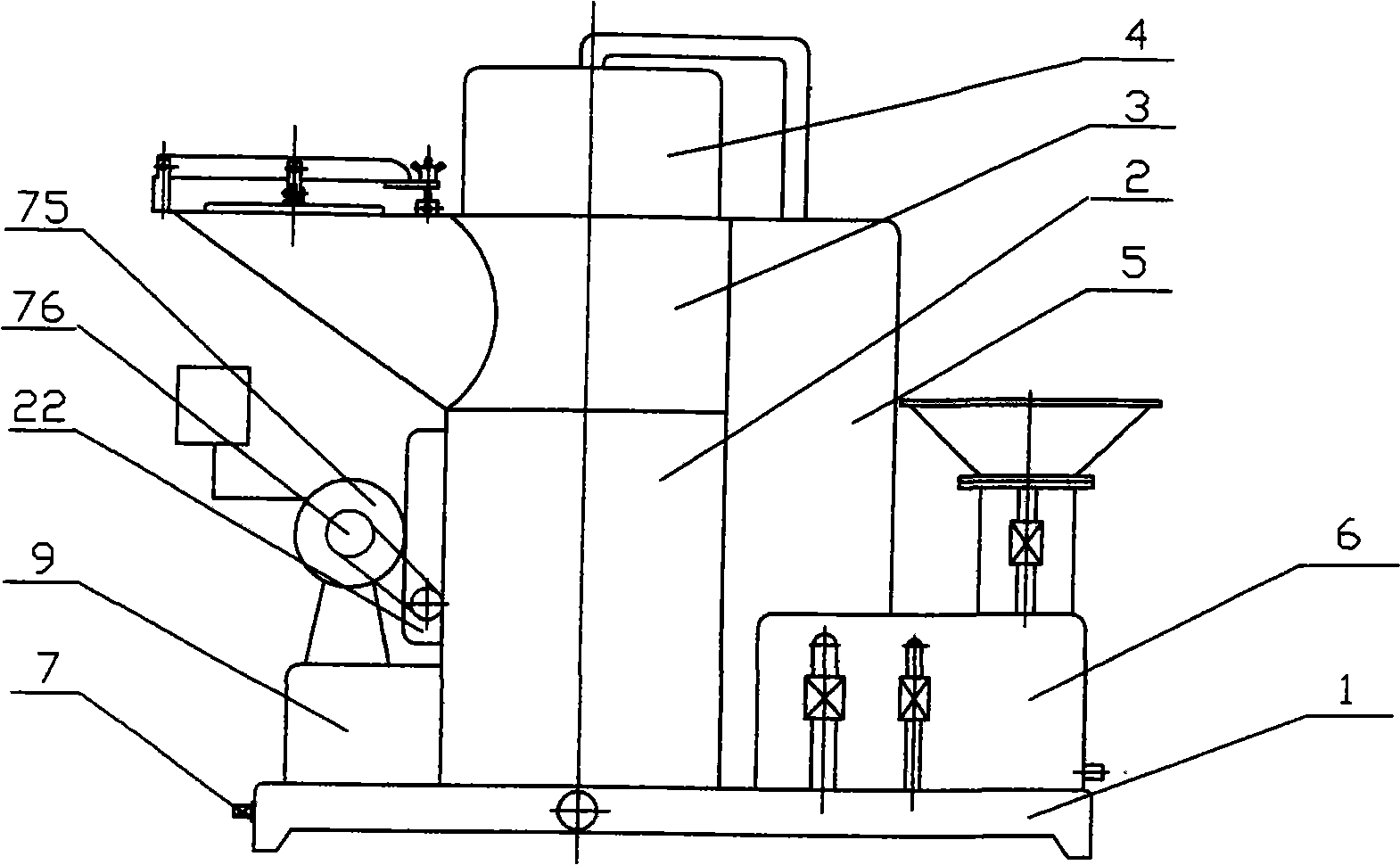

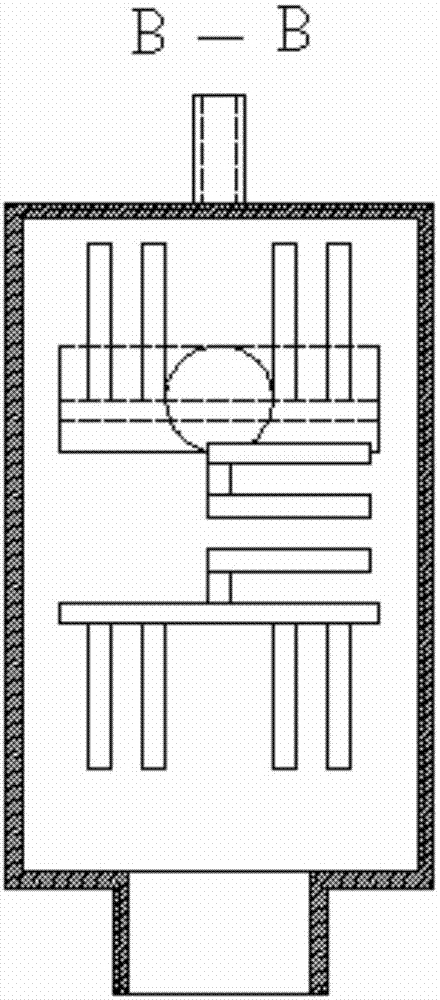

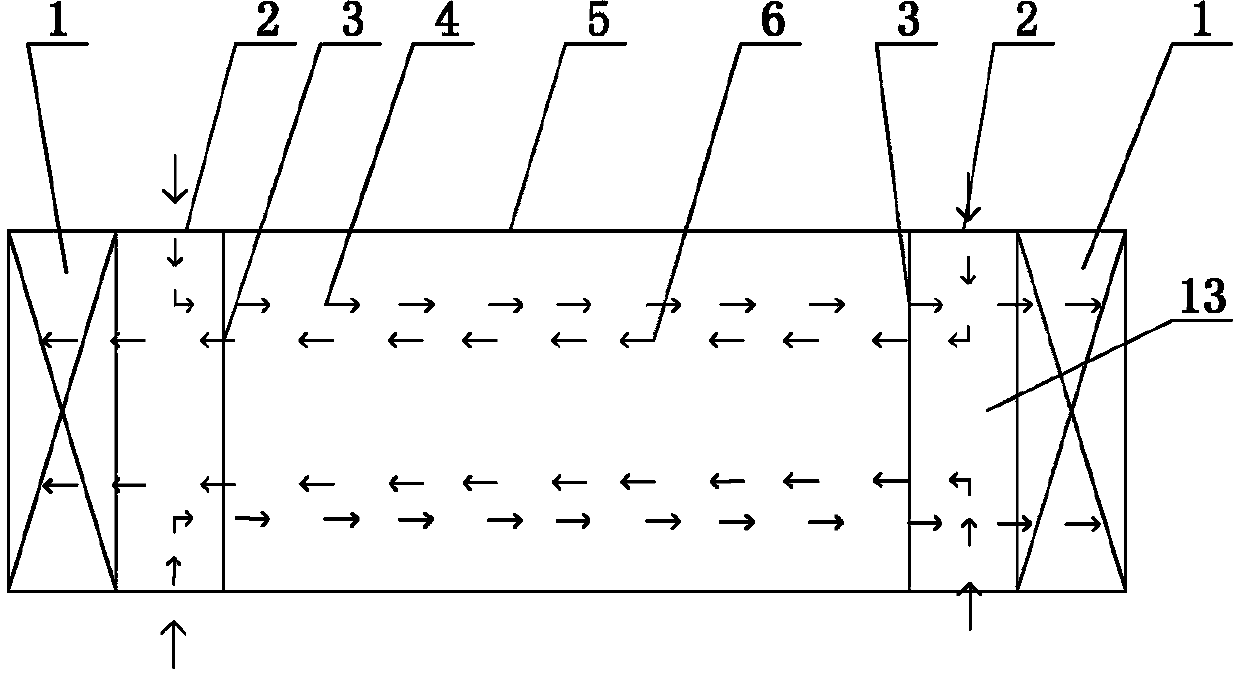

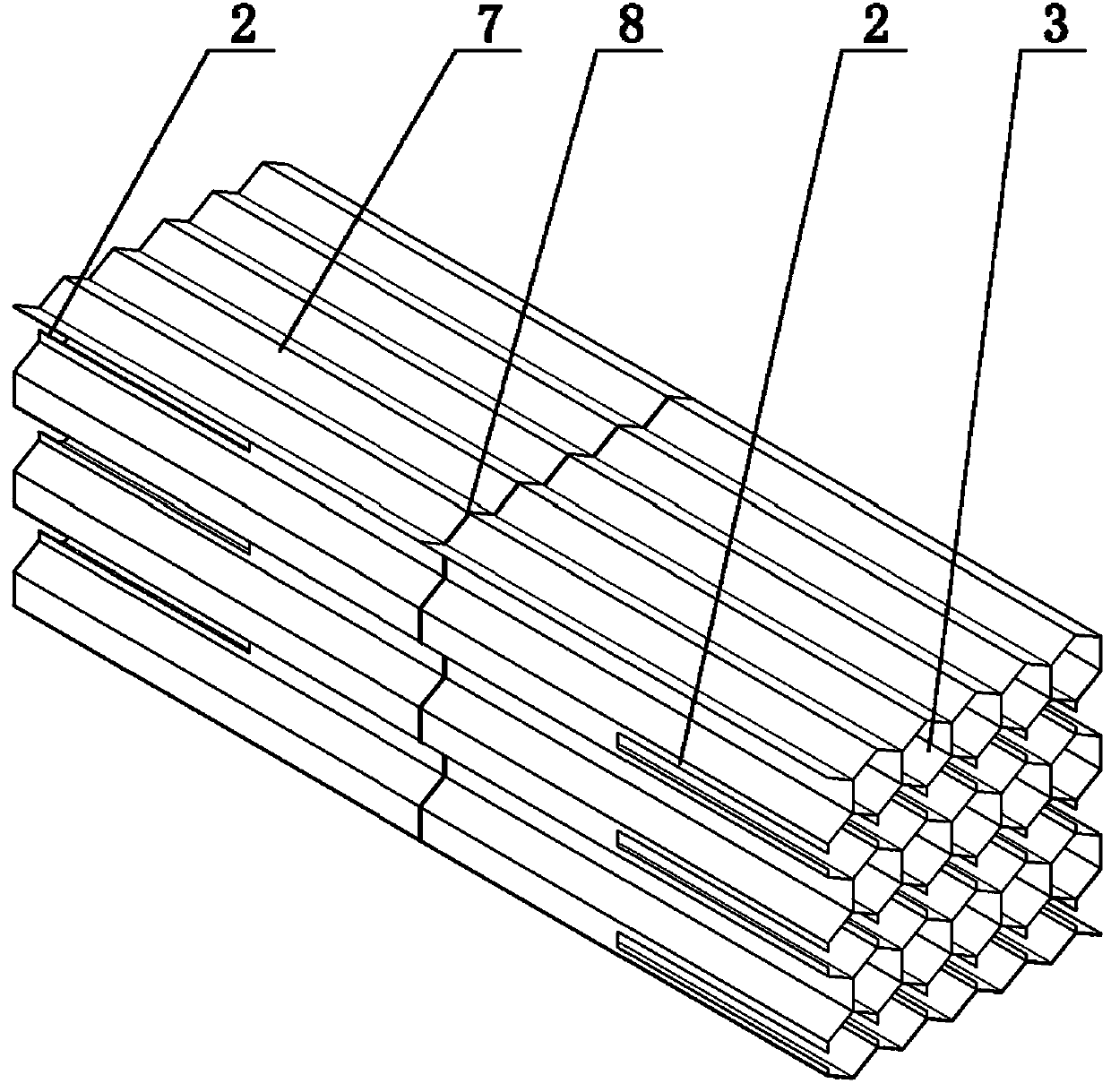

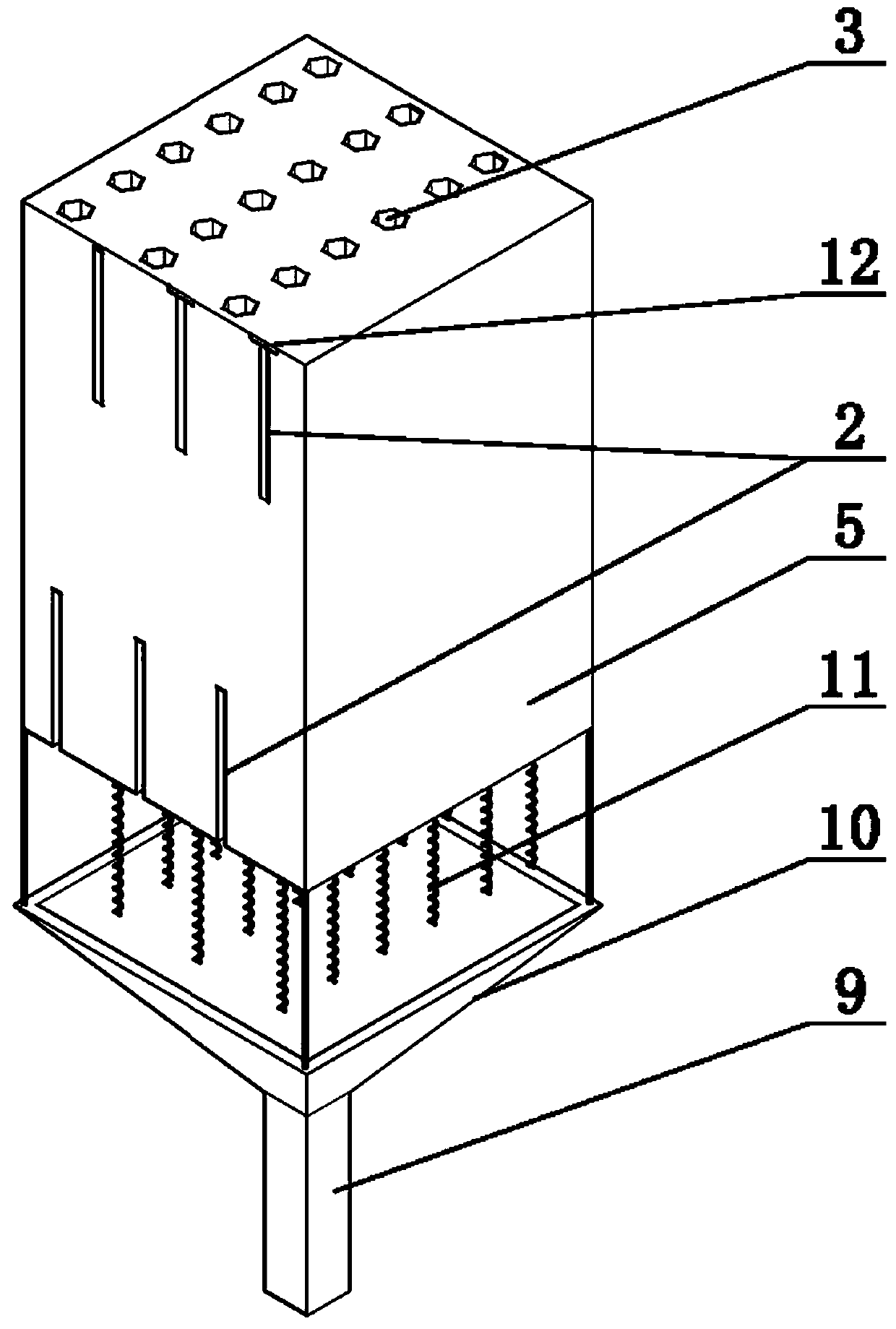

The invention relates to a method and a device for preparing biomass fuel from biomass materials. The method comprises the following steps: loading biomass materials in a gas generating chamber, and carrying out pyrolysis to generate mixed gas; cracking the tar to generate a combustible gas; filtering off fly-ash and residual tar in the combustible gas; carrying out gas-water separation to separate water; and deodorizing to obtain the biomass fuel. The device comprises the gas generating chamber (2) fixed on a pedestal (1), a material storage chamber (3) fixed on the upper side of the gas generating chamber (2), a cracking catalyst absorber (4) fixed on the upper side of the material storage chamber (3), a gas-water separator (5) communicated with the cracking catalyst absorber (4), and a deodorizing and gas storage box (6) communicated with the gas-water separator (5). The device and the method have the advantages that the device and the method can effectively remove tar, fly-ash, vapor, odor, etc. in the biomass fuel without contaminating the environment and can ensure the combustion heat efficiency of the biomass fuel, etc.

Owner:赵靖敏

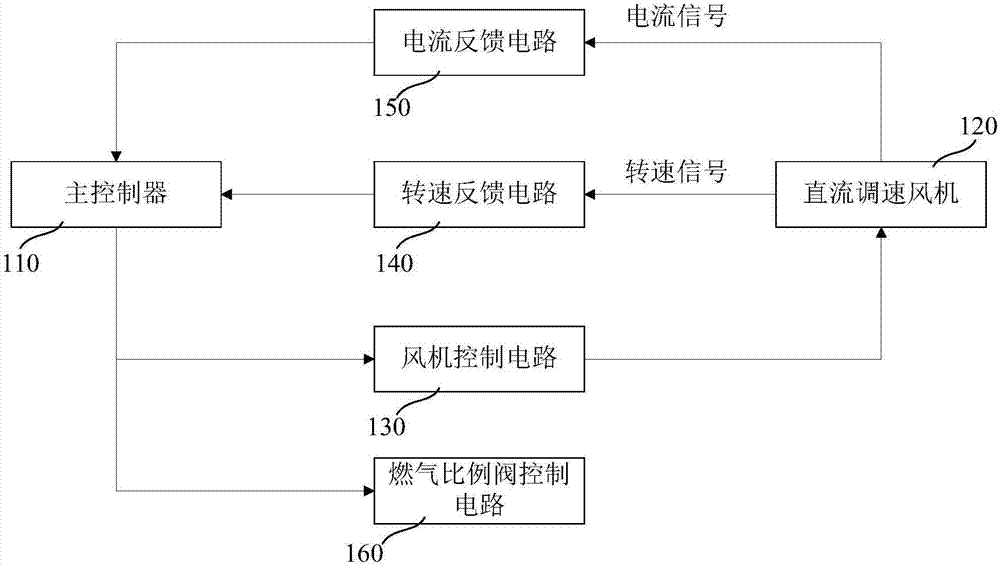

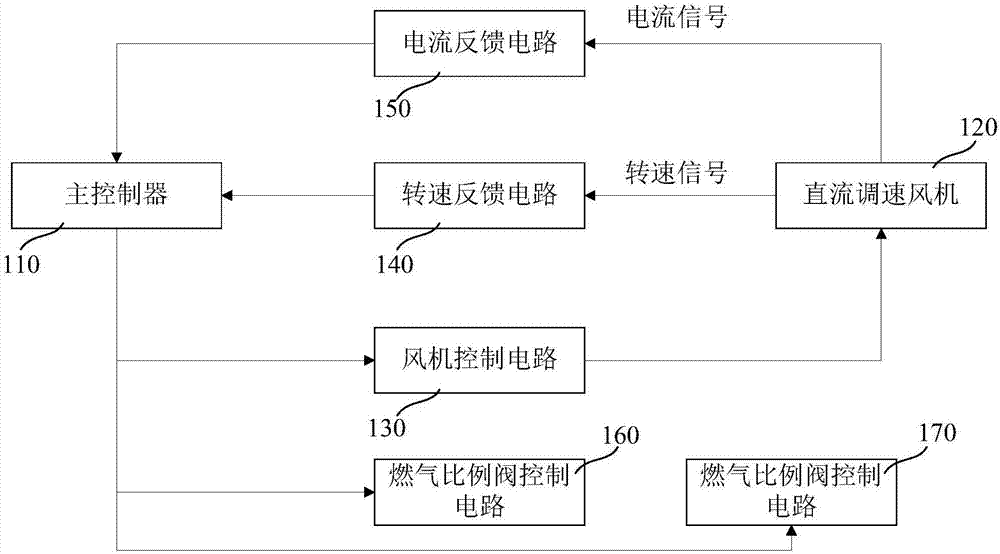

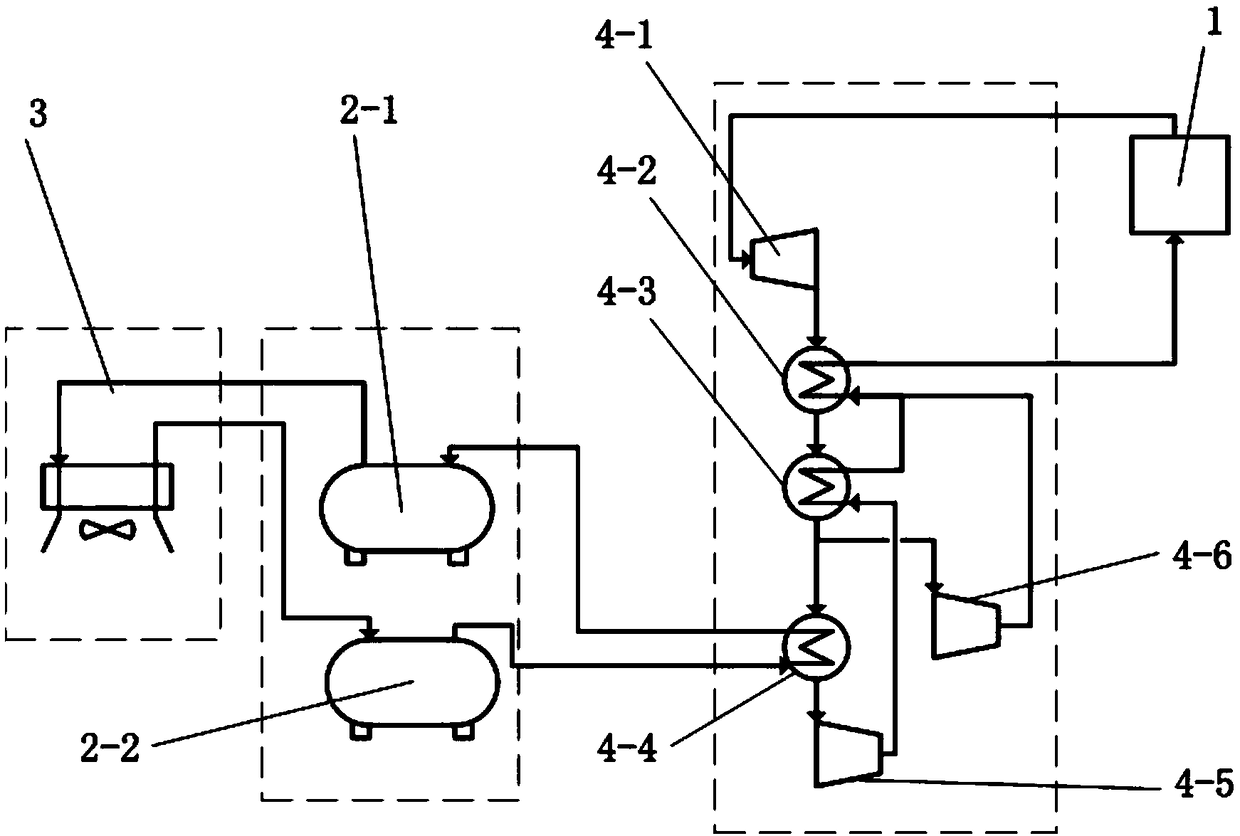

Gas water heater wind-pressure-resistance control system

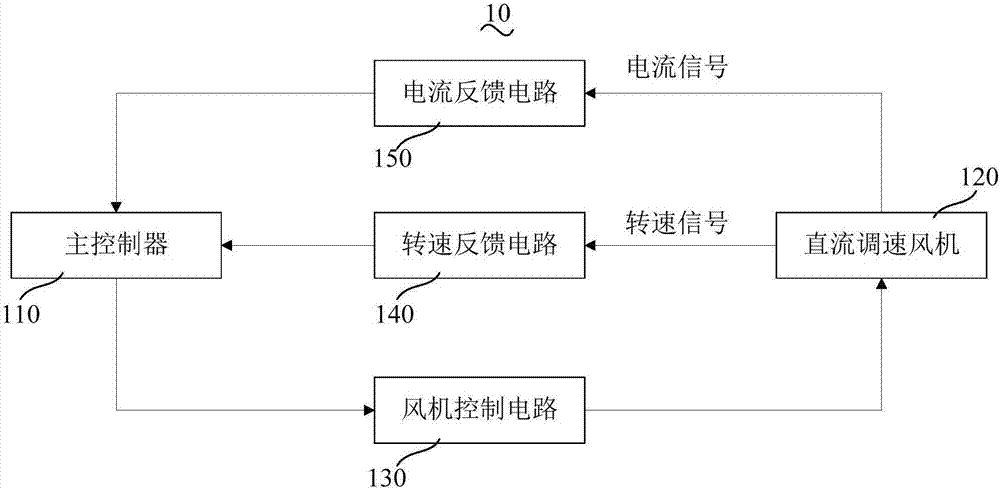

The invention discloses a gas water heater wind-pressure-resistance control system. The gas water heater wind-pressure-resistance control system comprises a main controller, a direct current speed governing fan, a fan control circuit, a rotating speed feedback circuit and a current feedback circuit; the control end of the main controller is connected with the input end of the fan control circuit, and the output end of the fan control circuit is connected with the control end of the direct current speed governing fan; the input end of the main controller is connected with the output end of the rotating speed feedback circuit and the output end of the current feedback circuit; and the input end of the rotating speed feedback circuit and the input end of the current feedback circuit are connected with the output end of the direct current speed governing fan. Through the gas water heater wind-pressure-resistance control system, backflow of a lot of waste gas and flame overflowing are effectively avoided, noise and electric leakage hidden danger are well controlled, accordingly, the product adaptation and comfort of a gas water heater are further improved, and the effect that combustion noise, fumes and heat efficiency reach the best state is ensured.

Owner:GUANGDONG VANWARD NEW ELECTRIC CO LTD

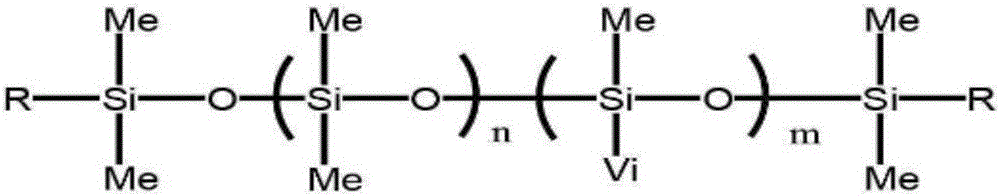

Heat-conducting silica gel and preparation method thereof

The invention discloses a heat-conducting silica gel and a preparation method thereof, wherein the heat-conducting silica gel comprises the following components in parts by weight: 100 parts of a basic polymer, 0.1-10 parts of a crosslinking agent, 500-1800 parts of a filler, and 0.1-15 parts of a silane coupling agent. The technical scheme of the invention can obtain a heat-conducting interface material which has higher heat-conducting stability compared with silicone grease, silicone cream and heat-conducting mud which are generally used on market at present, and solves the problem that the silicone grease, the silicone cream and the heat-conducting mud which are generally used on market at present will become dry when used at a high temperature for a long time, thereby ensuring the heat-conducting efficiency of long-term use of the heat-conducting interface material.

Owner:厦门安耐伟业新材料有限公司

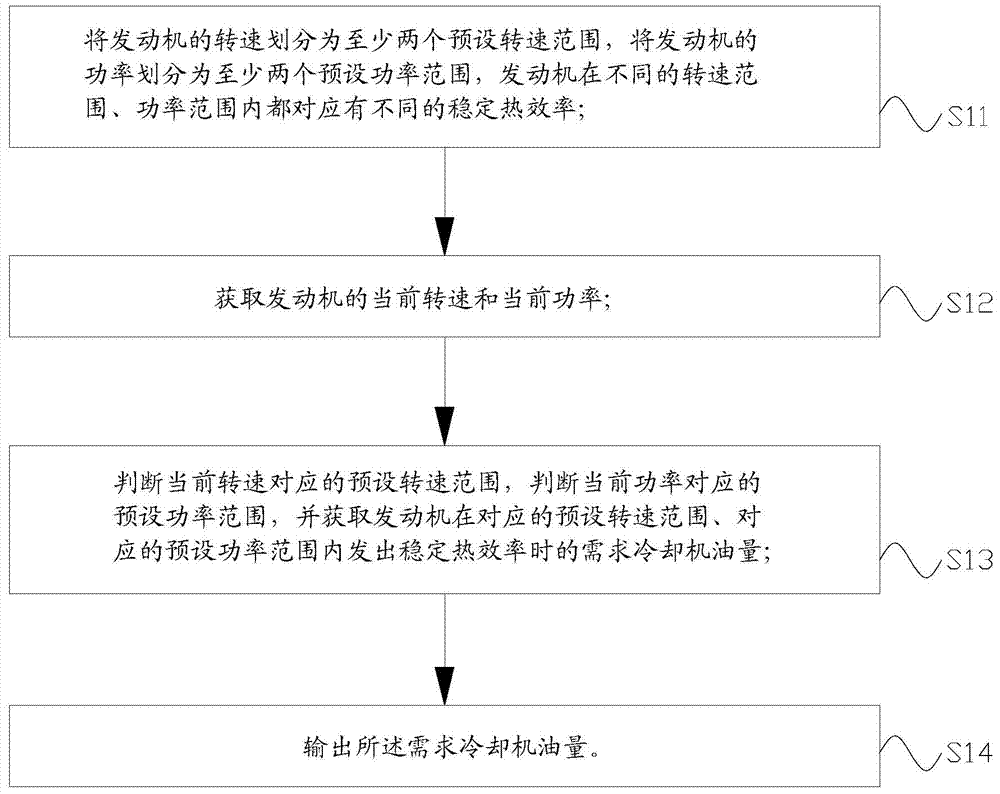

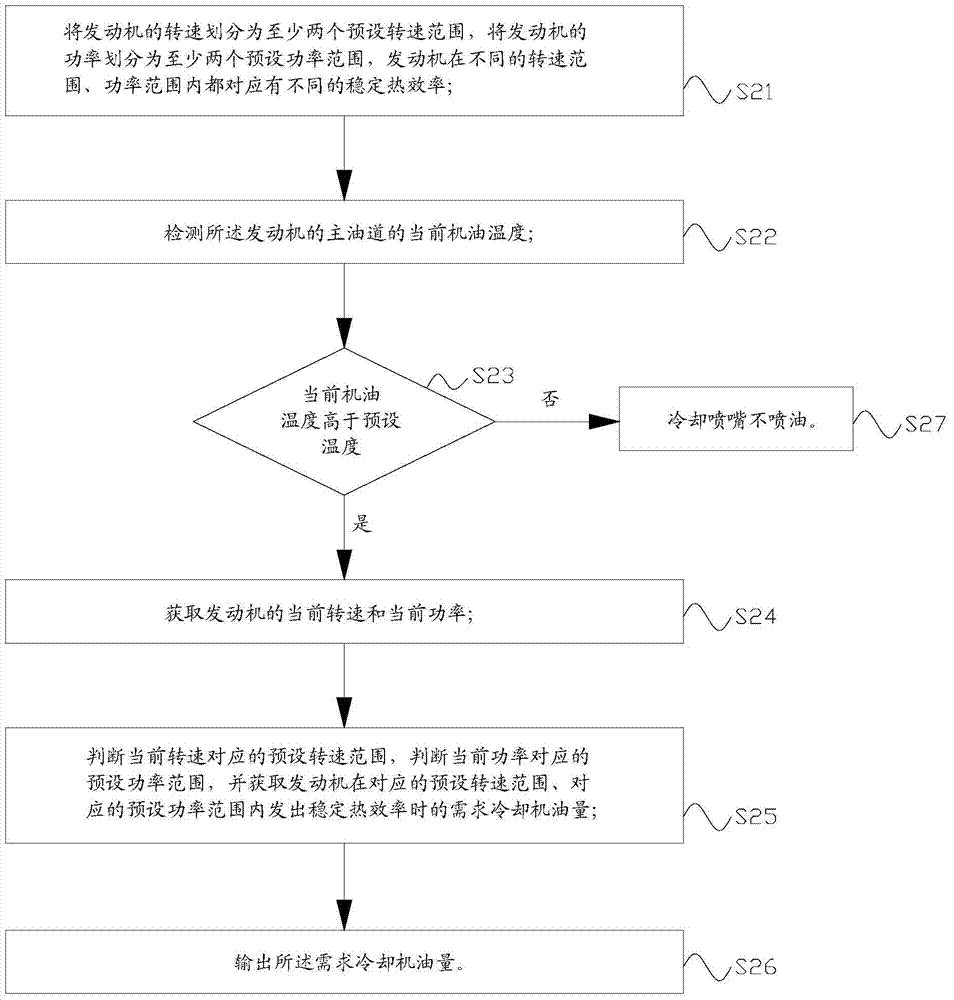

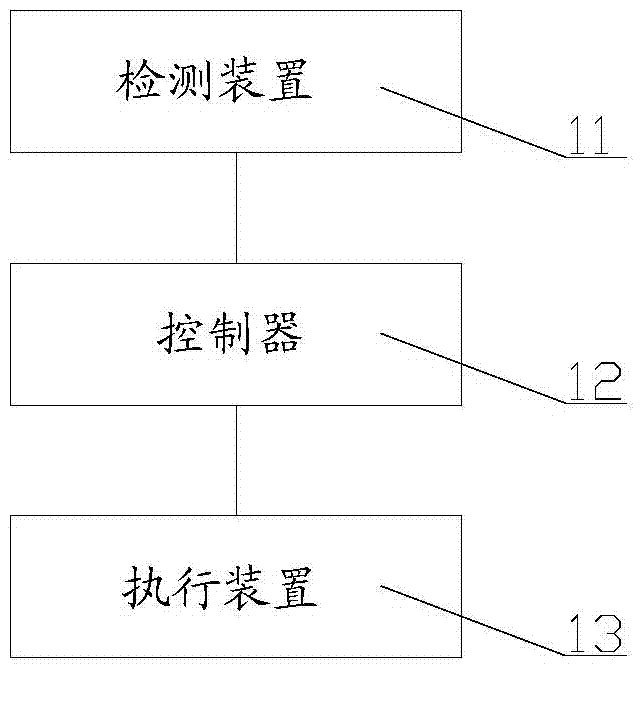

Engine and control method and system for cooling jet of engine

ActiveCN103790688APrevent sprayingGuaranteed thermal efficiencyLiquid coolingCoolant flow controlControl systemSpray nozzle

The invention discloses a control method for a cooling jet of an engine. The control method for the cooling jet of the engine comprises the following steps that the rotating speed of the engine is divided to be within at least two preset rotating speed ranges, the power of the engine is divided to be within at least two preset power ranges, and the engine has different levels of stable heat efficiency when the rotating speed of the engine is within different preset rotating speed ranges and the power of the engine is within different preset power ranges; the current rotating speed and the current power of the engine are obtained; the preset rotating speed range corresponding to the current rotating speed is judged, the preset power range corresponding to the current power is judged, and the quantity of cooling machine oil needed by the engine is obtained when the engine has the stable heat efficiency within the corresponding preset rotating speed range and the corresponding preset power range; the quantity of the needed cooling machine oil is output. According to the control method for the cooling jet of the engine, distribution of the quantity of the cooling machine oil according to the needs is achieved, the phenomenon that when an engine is in idling and is low in load, the quantity of output cooling machine oil is large is avoided, and heat efficiency of the engine is ensured. The invention further discloses a control system for the cooling jet of the engine, and the engine with the control system.

Owner:WEICHAI POWER CO LTD

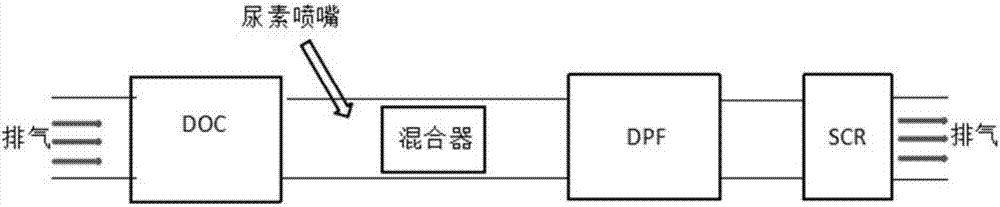

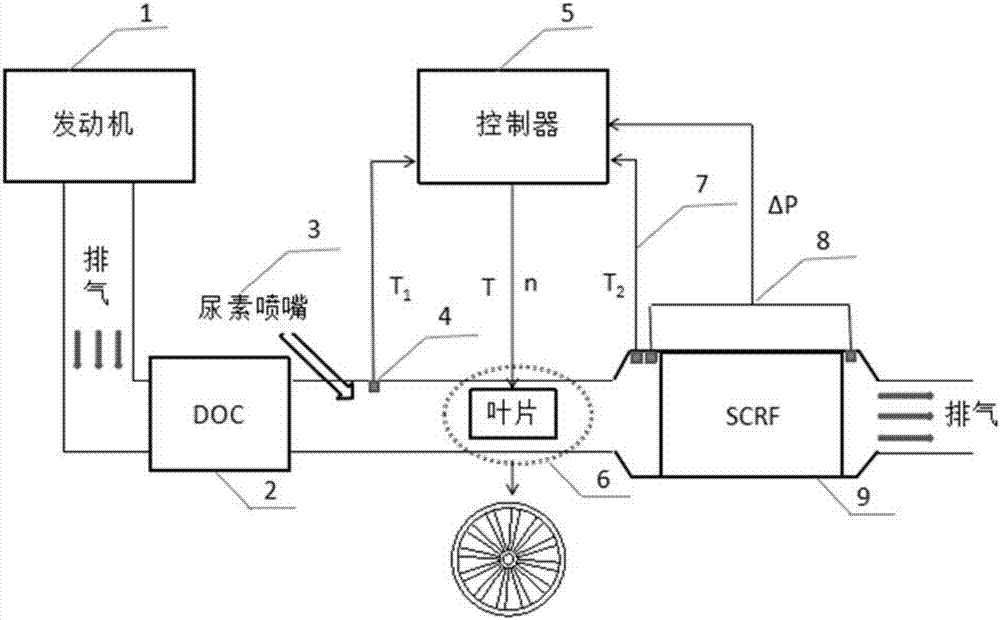

SCRF system capable of actively controlling catalytic environment

ActiveCN107514307AGuaranteed thermal efficiencyInternal combustion piston enginesExhaust apparatusDifferential pressurePulp and paper industry

The invention discloses an SCRF system capable of actively controlling a catalytic environment. The SCRF system comprises a DOC, a urea spraying device, blades, a controller and an SCRF; the DOC is used for oxidizing NO into NO2, and furthermore the efficiency of converting NOx by the SCRF can be improved, and the regeneration of the SCRF can be facilitated; the urea spraying device is used for spraying urea into an exhaust pipe; the blades are arranged at the front end of the SCRF of the exhaust pipe of a diesel engine and are used for heating the urea sprayed by the urea spraying device so that urea crystallization can be avoided, and NH3 and exhaust gas can be fully mixed; the controller determines the heating temperature and the rotating speed of the blades according to the exhaust gas temperature in the exhaust pipe of the diesel engine as well as the gas temperature and the differential pressure in the SCRF system and actively controls the catalytic environment of the SCRF system; and the SCRF (namely an SCR catalysts coated DPF) carries out treatment on the NOx and PM in the exhaust gas of the diesel engine. The SCRF system has the beneficial effects that the temperature and the rotating speed of the blades can be controlled, heating and forced stirring are carried out on the mixed gas so that the uniformity of a mixture can be improved, and therefore the catalytic environment can be controlled, the generation of the catalytic reaction can be facilitated, and the generation of urea crystal substances at low temperature can be reduced.

Owner:JIANGSU UNIV

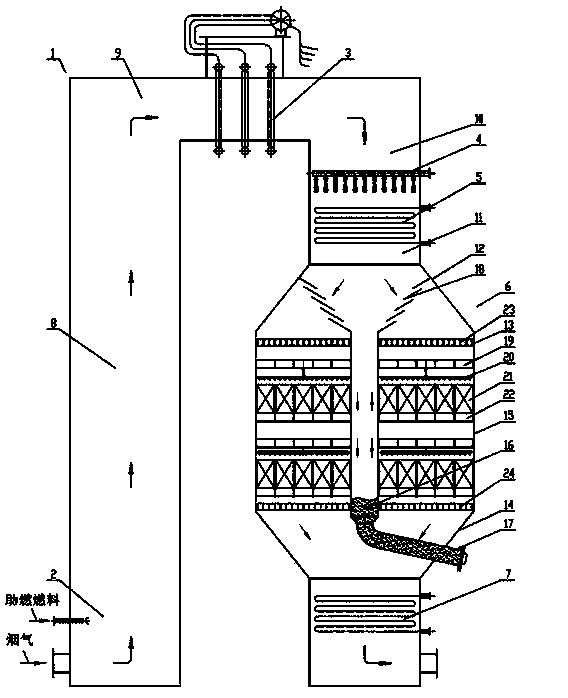

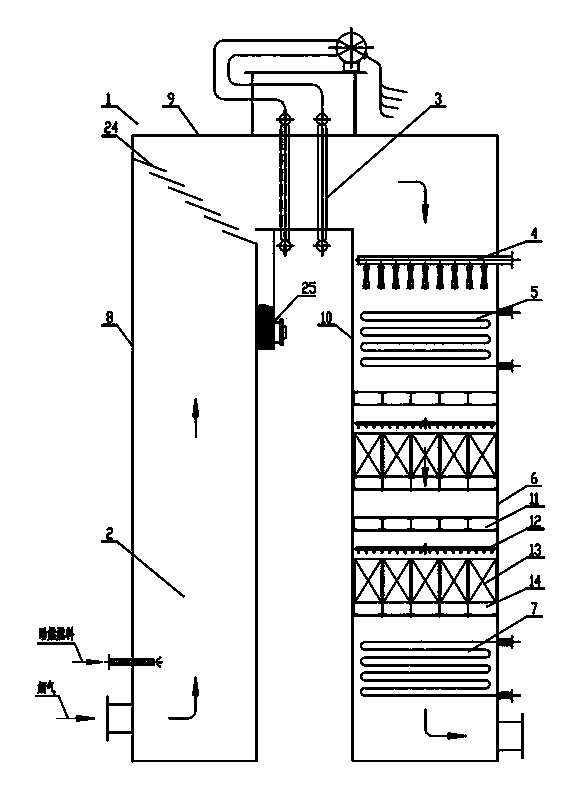

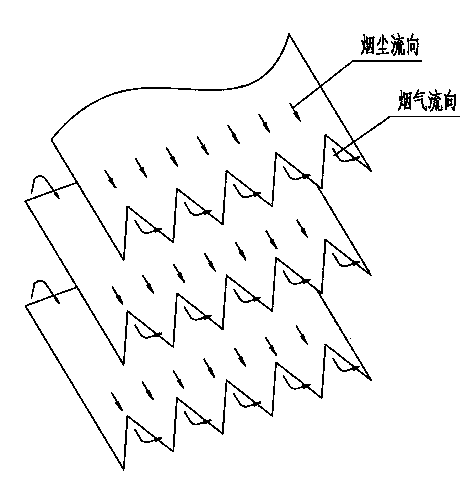

CO boiler having dustproof function and denitration function

ActiveCN103776042AImprove utilization efficiencyEfficient use ofCombination devicesLighting and heating apparatusFlueCoal

The invention relates to a CO boiler having the dustproof function and the denitration function. The CO boiler having the dustproof function and the denitration function comprises a flue, a combustion chamber, steam drums, an evaporation section and an economizer section. The CO boiler further comprises an ammonia spraying and mixing mechanism and a dustproof denitration reactor. The ammonia spraying and mixing mechanism is arranged above the evaporation section or between the evaporation section and the denitration reactor. The dustproof denitration reactor is arranged between the evaporation section and the economizer section and comprises a mixed-smoke inlet section, a denitration section and a purified-smoke discharging section, wherein an ash removal section is arranged between the mixed-smoke inlet section and the denitration section, ash baffles are arranged in the ash removal section, an ash bin is arranged in the denitration section, the center line of the ash bin and the center line of the reactor coincide, and the lower end of the ash bin is connected with an ash discharging pipeline. According to the CO boiler having the dustproof function and the denitration function, the denitration reactor is arranged in the CO boiler, so that the utilization rate of smoke heat is increased; due to the fact that the ash removal section is arranged in the reactor, smoke dust of mixed smoke can be removed before the mixed smoke enters denitration units, catalyst hole channels are prevented from being blocked, and the denitration efficiency and the denitration effect are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

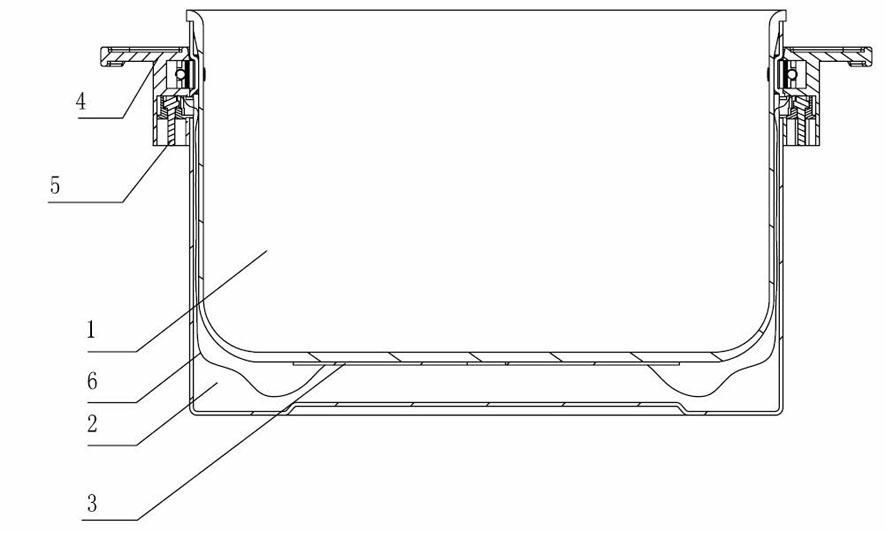

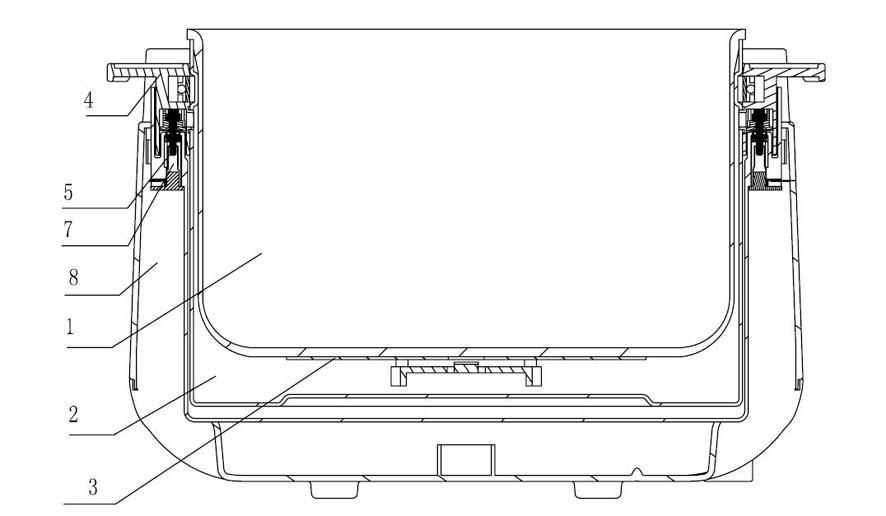

Composite cooking pot

ActiveCN102090838AEliminate concernsGuarantee the safety of usePressure-cookersWarming devicesElectricityElectrical connection

The invention discloses a composite cooking pot which comprises an inner pot body and an electric heating element, wherein the inner pot body is a container body with a pot wall and a pot bottom. The composite cooking pot is characterized in that a shielding protective cover is sleeved outside the inner pot body and is a concave container which is sealed and fastened on the inner pot body, the electric heating element is fixedly arranged in a closed cavity between the inner pot body and the shielding protective cover, the peripheral wall of the shielding protective cover of the pot body is provided with an electric connector used for realizing the electrical connection of the electric heating element with a mains supply, and the electrical connector is arranged at the upper-side part of the shielding protective cover of the pot body. The electric heating element of is fixedly arranged in the closed cavity between the inner pot body and the shielding protective cover, thus the composite cooking pot has a high heating efficiency; meanwhile, because the electric heating element and accessorial electric elements are hidden in the pot by using the shielding protective cover and the electrical connector is arranged at the upper-side part, the worry of a user is eliminated, and the pot is safer in cleaning and is low in processing and manufacturing cost; and the process is easier to realize, the shape of the pot is consistent with the shape of the traditional pot, and the whole pot is attractive and elegant in appearance.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

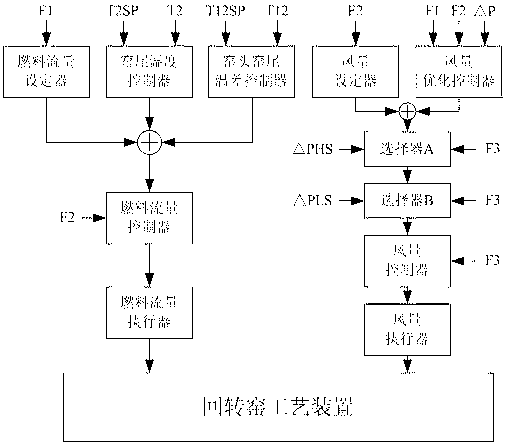

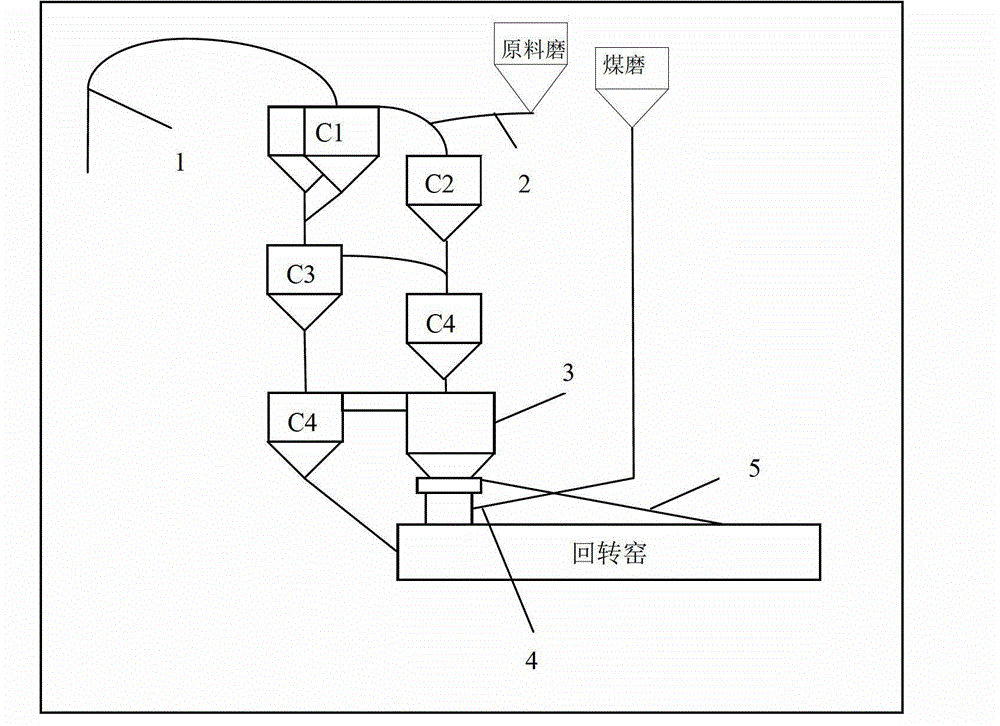

Method for optimizing and controlling rotary kiln air volume

ActiveCN103234347AGuaranteed thermal efficiencyRealize energy-saving controlFuel supply regulationRotary drum furnacesLoop controlAir volume

A method for optimizing and controlling rotary kiln air volume includes that closed-loop control is conducted on fuel flow according to load raw material flow, the kiln tail temperature and temperature difference between the kiln head and the kiln tail, optimal air volume is found according to the fuel flow, a back-to-back method and a self-optimization algorithm, and closed-loop control on the air volume is achieved. By means of the method, product quality problems caused by unreasonable temperature field distribution of the rotary kiln can be effectively solved, problems of insufficient burning of fuel, raw material flow abnormality in a preheater and low heat efficiency of the preheater due to unreasonable air volume can be solved effectively, and the purposes of reducing fuel consumption and stabilizing product quality are achieved.

Owner:北京和隆优化科技股份有限公司

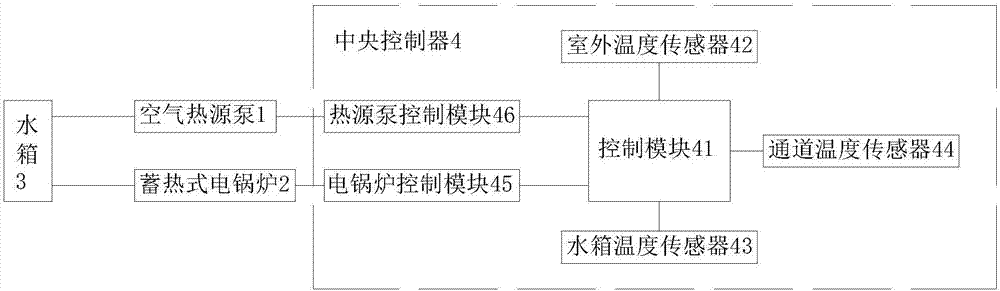

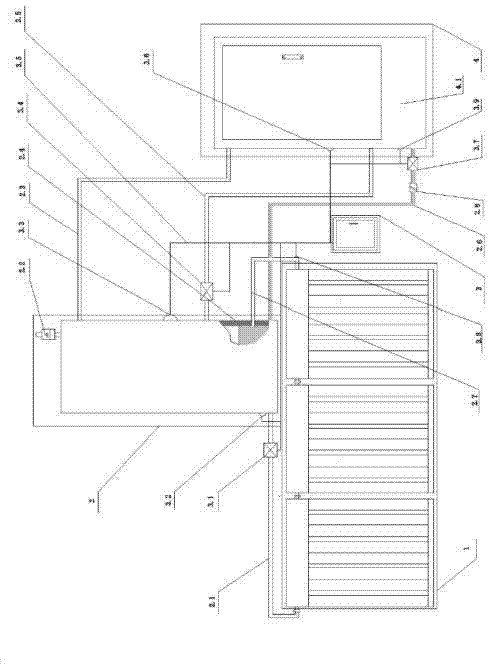

Combined heat supply device using heat storage electric boiler and air source heat pump and heat supply method thereof

ActiveCN107091494AHeating is economical and reasonableGuaranteed water temperatureHeating fuelLighting and heating apparatusEngineeringSystem combination

The invention discloses a combined heat supply device using a heat storage electric boiler and an air source heat pump and a heat supply method thereof. The combined heat supply device comprises the air source heat pump, the heat storage electric boiler, a water tank and a central control unit. The water tank communicates with the heat storage electric boiler and the air source heat pump. The heat storage electric boiler and the air source heat pump are further electrically connected with the central control unit. According to the combined heat supply device using the heat storage electric boiler and the air source heat pump and the heat supply method thereof, the central control unit is used for detecting the outdoor temperature of the air source heat pump and further judging and controlling whether the air source heat pump supplies heat to the water tank or the electric boiler supplies heat to the water tank, the air source heat pump is adopted when the outdoor temperature is high, and the heat storage electric boiler is adopted when the temperature is low; and the central control unit is provided with an environment and indoor temperature measuring device, the temperature of the water tank can be monitored to be used as judgment data, the defects are overcome by means of system combination, and therefore the overall heat supply is made more economical and reasonable, and the water outlet temperature can be guaranteed.

Owner:北京马六点科技有限公司

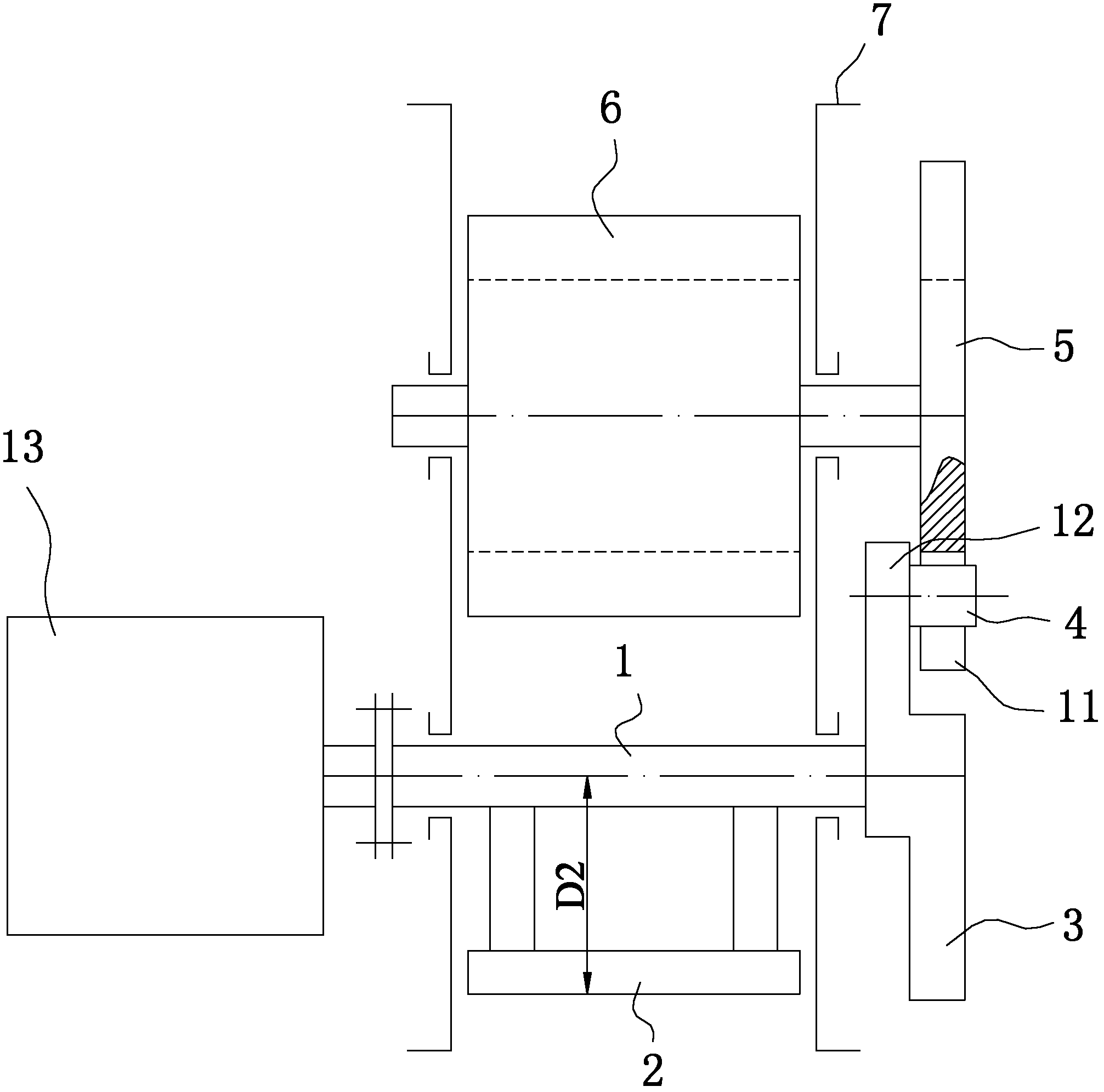

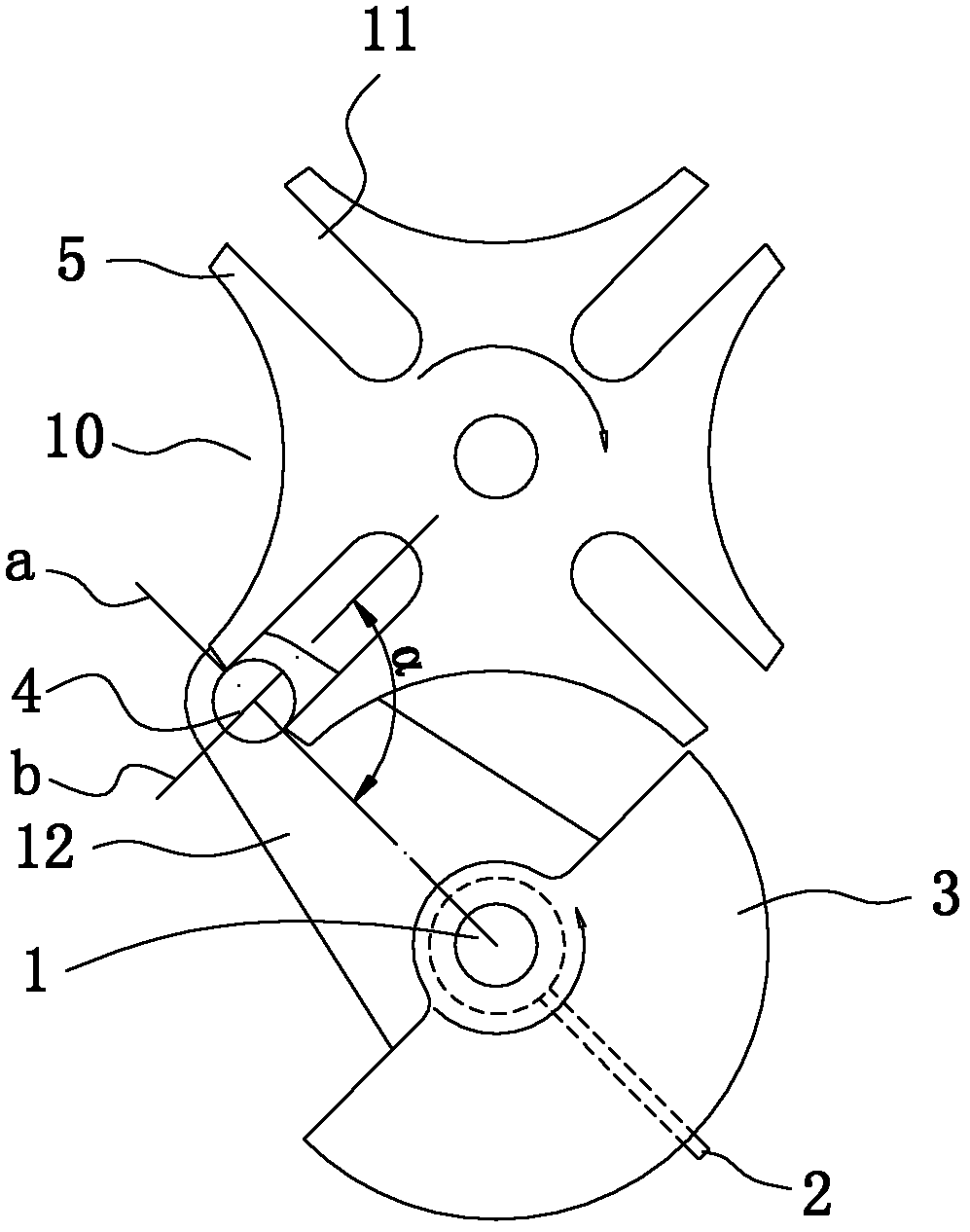

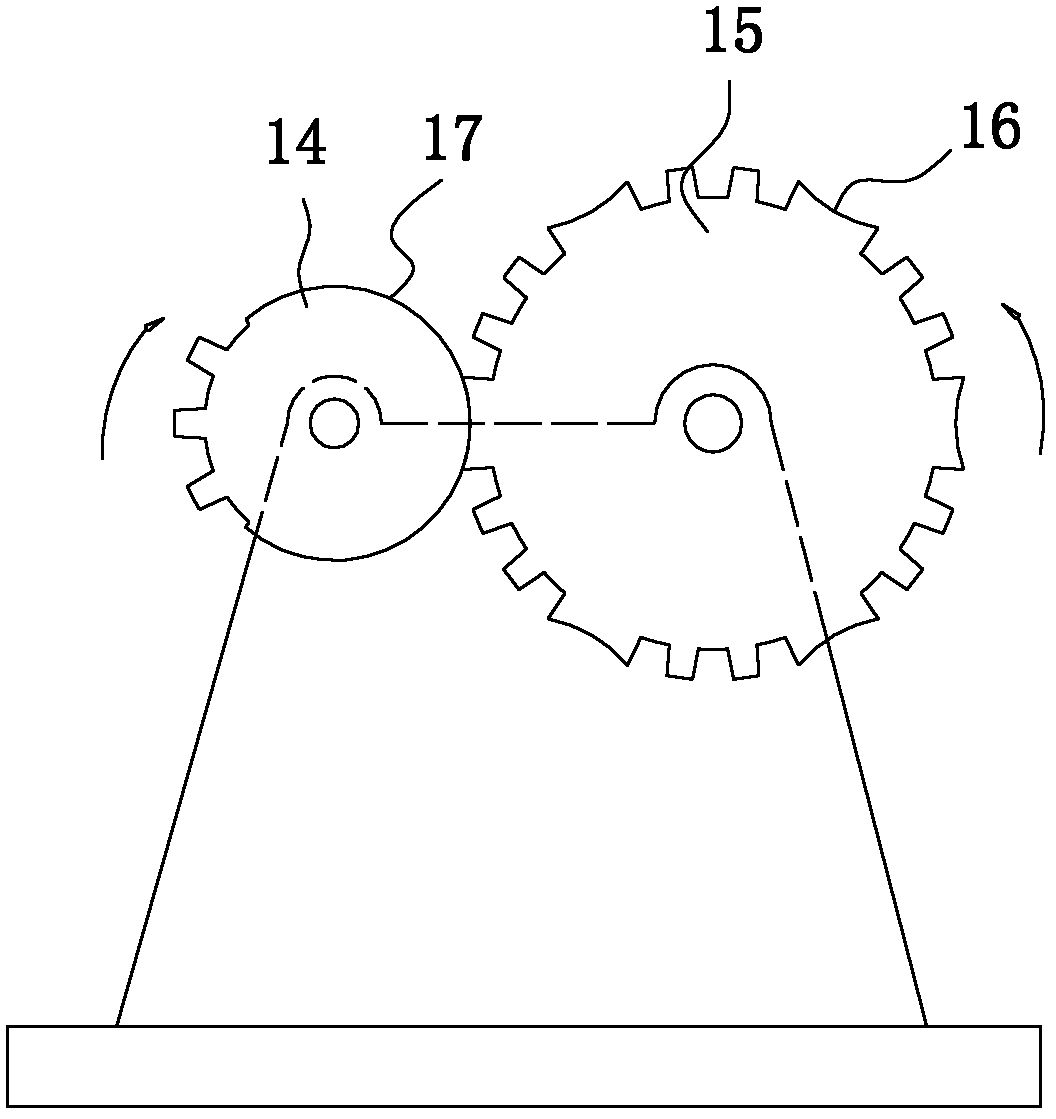

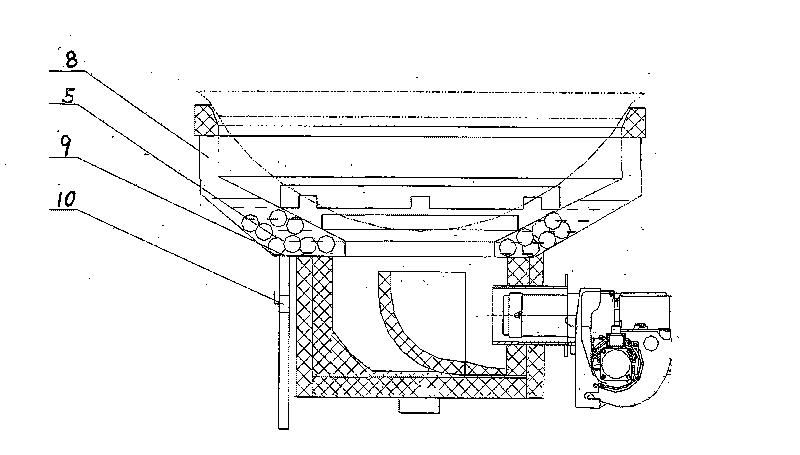

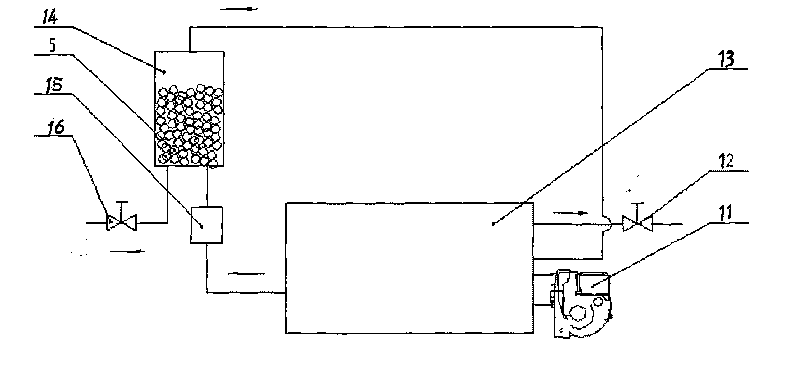

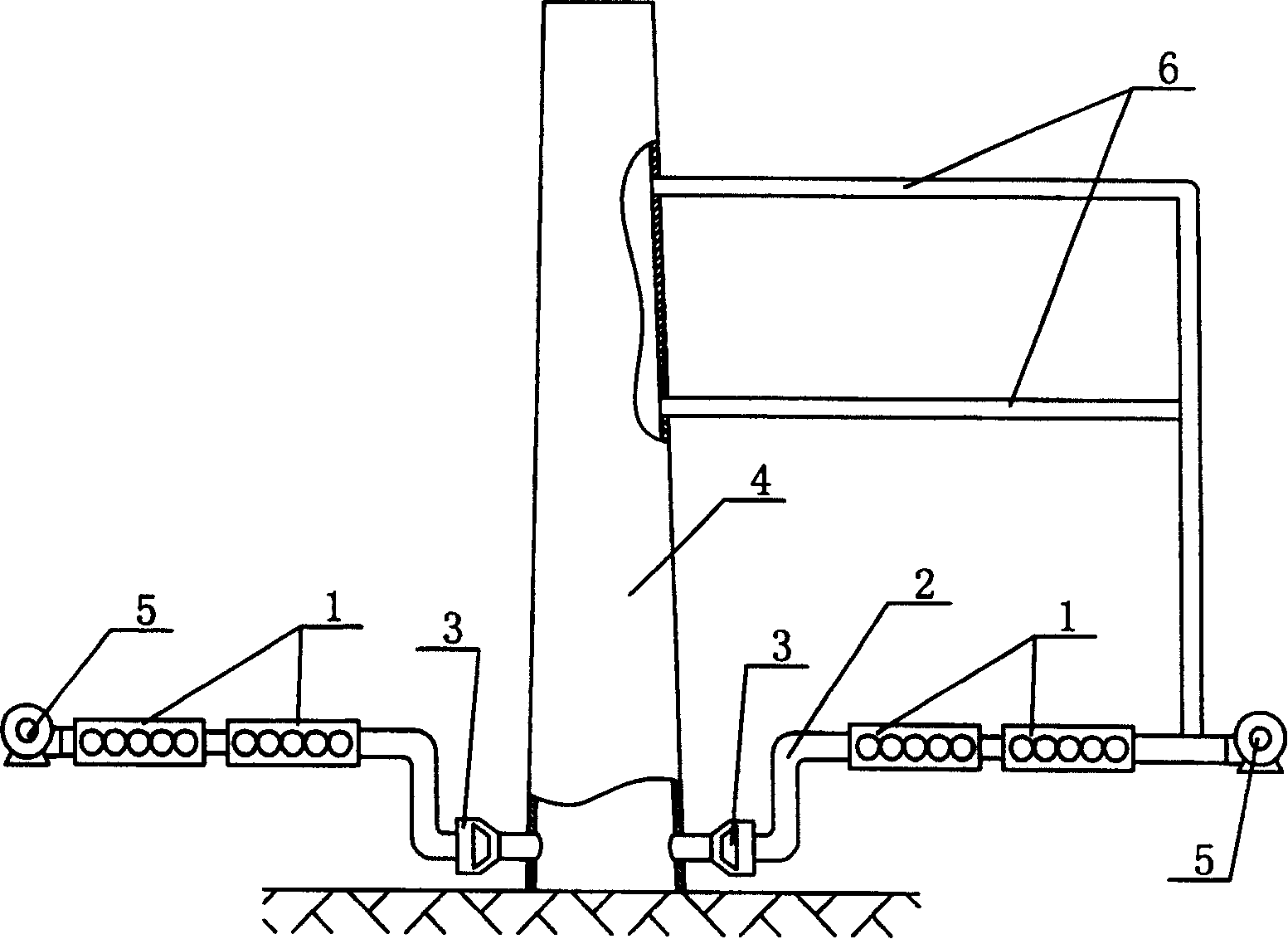

Air-locking feeder of moisture-containing raw material

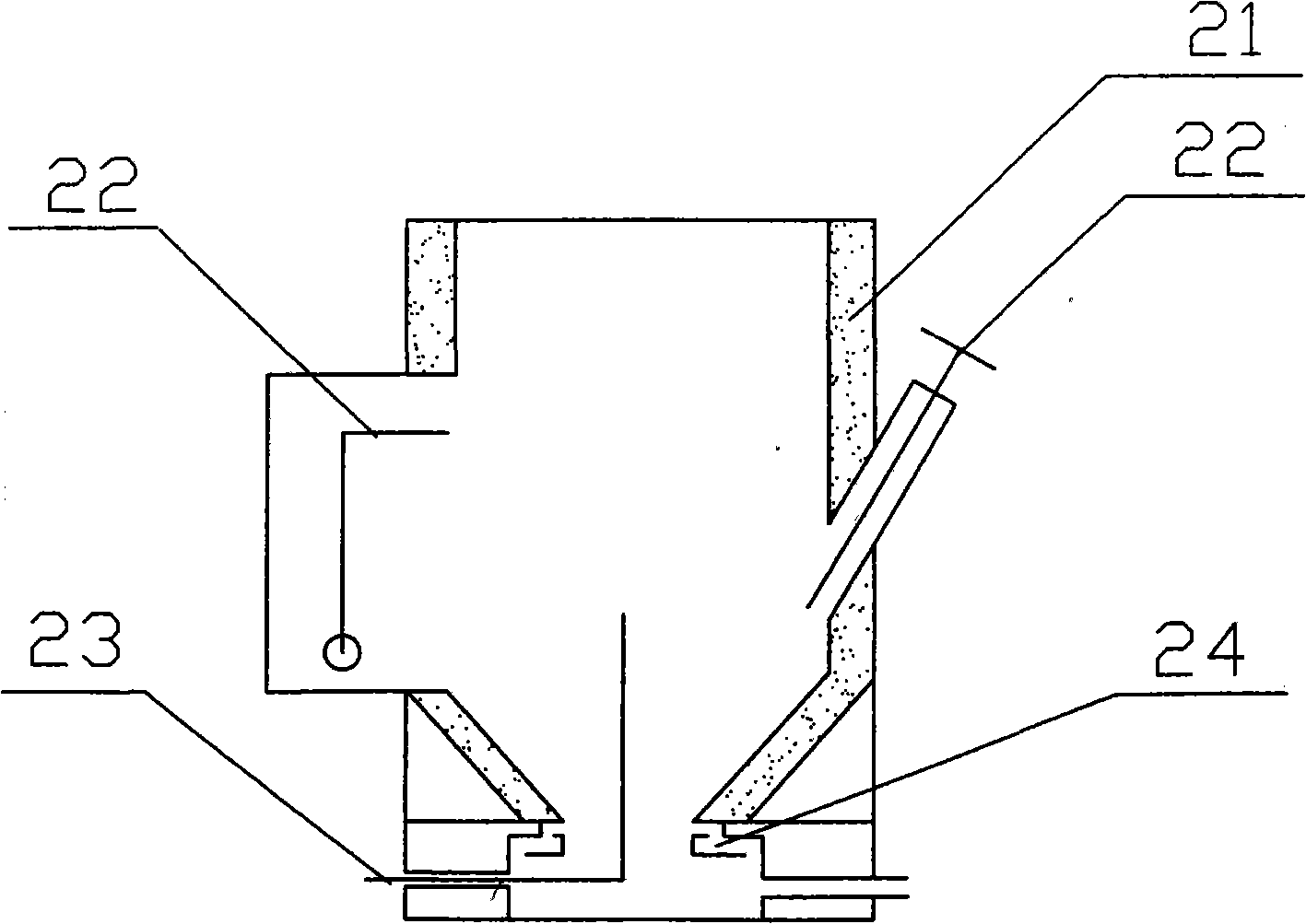

InactiveCN102602673AEliminate stickySolve the problem of air lock feedingCleaningRotary conveyorsImpellerEngineering

The invention discloses a moisture-containing raw material air-locking feeder with an air locking function, which both has the air locking function and a binding material cleaning function. The air-locking feeder of the moisture-containing raw material comprises a shell with a feed port and a discharge port, and a feeding impeller arranged in the shell, the feeding impeller is provided with a plurality of uniformly distributed concave feeding regions, the inner wall of the shell is provided with a circular arc surface structure, a circle centre of the circular arc surface structure is coincided with the axial lead of the feeding impeller, the distance between the outer circumferential surface of the feeding impeller and the centre of the feeding impeller is D1, the distance D1 is matched with the radius of the circular arc surface structure, the two sides of the feeding impeller are matched on the inner wall of the shell, a binding material cleaning device used for preventing the moisture-containing raw material from being adhered at the concave feeding regions is arranged in the shell, the feeding impeller is in transmission connection with a graduation locating mechanism situated at the outside of the shell, and the graduation locating mechanism is in transmission connection with a power driving mechanism. The air-locking feeder of the moisture-containing raw material, disclosed by the invention, can both guarantee the heat efficiency of a successive drying procedure and effectively prevent the feeding impeller from adhering materials.

Owner:SICHUAN FANGDA NEW BUILDING MATERIAL DEV CO LTD

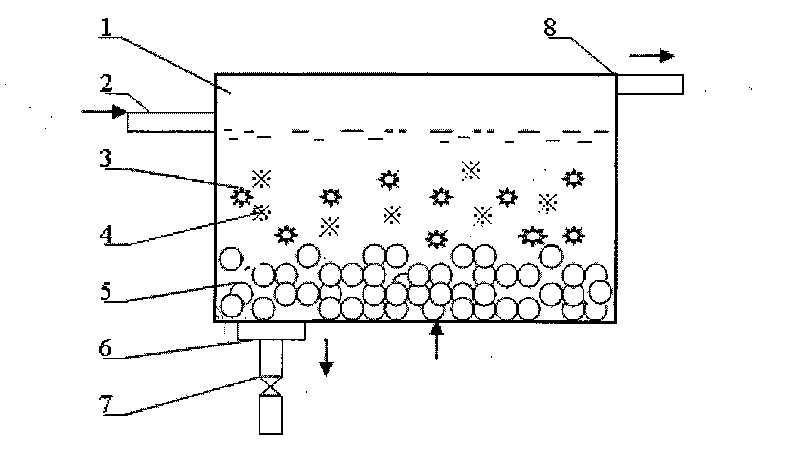

Antiscaling compound and method for preventing and removing scale

ActiveCN101691259APrevent and remove scalingAvoid churnBoiler cleaning apparatusTreatment using complexing/solubilising chemicalsVolume bodyAdditive ingredient

The invention relates to an antiscaling compound and a method for preventing and removing scales; the ingredients of the antiscaling compound comprises: 20-50 percent of natural zeolite, 25-20 percent of TiO, 10-40 percent of V2O5, 20-40 percent of SiO2, and 5-20 percent of NdFeB; the antiscaling compound is an ensemble of regular or irregular solid fine particles or an ensemble of solid porous particles; the average diameter of the fine particles of the antiscaling compound is 0.5-15mm; when the average diameter of the particles of the antiscaling compound is more than 15mm, porous particles are adopted, the pore diameter of the particle is more than 20mum and penetrates through the particle; the density of the antiscaling compound is 1.2-5g / cm<3>; the method for preventing and removing scales is that: the antiscaling compound is placed in water of a heating jacket of a water system freely for preventing and removing the scales in the water system, a filter screen is arranged at the outlet of the water jacket to prevent the antiscaling compound particles from being drained; or the antiscaling compound is placed in a volume body with meshes to form a water processor, the processor is placed nearby the heater and is arranged at the water charging port of the water system to processing charged water. The invention can process the scales efficiently for a long time without secondary pollution, the water treatment is safe, real-time on-line scale removal can be carried out, and the installation and usage are convenient and rapid.

Owner:昆明博远中菱科技有限公司

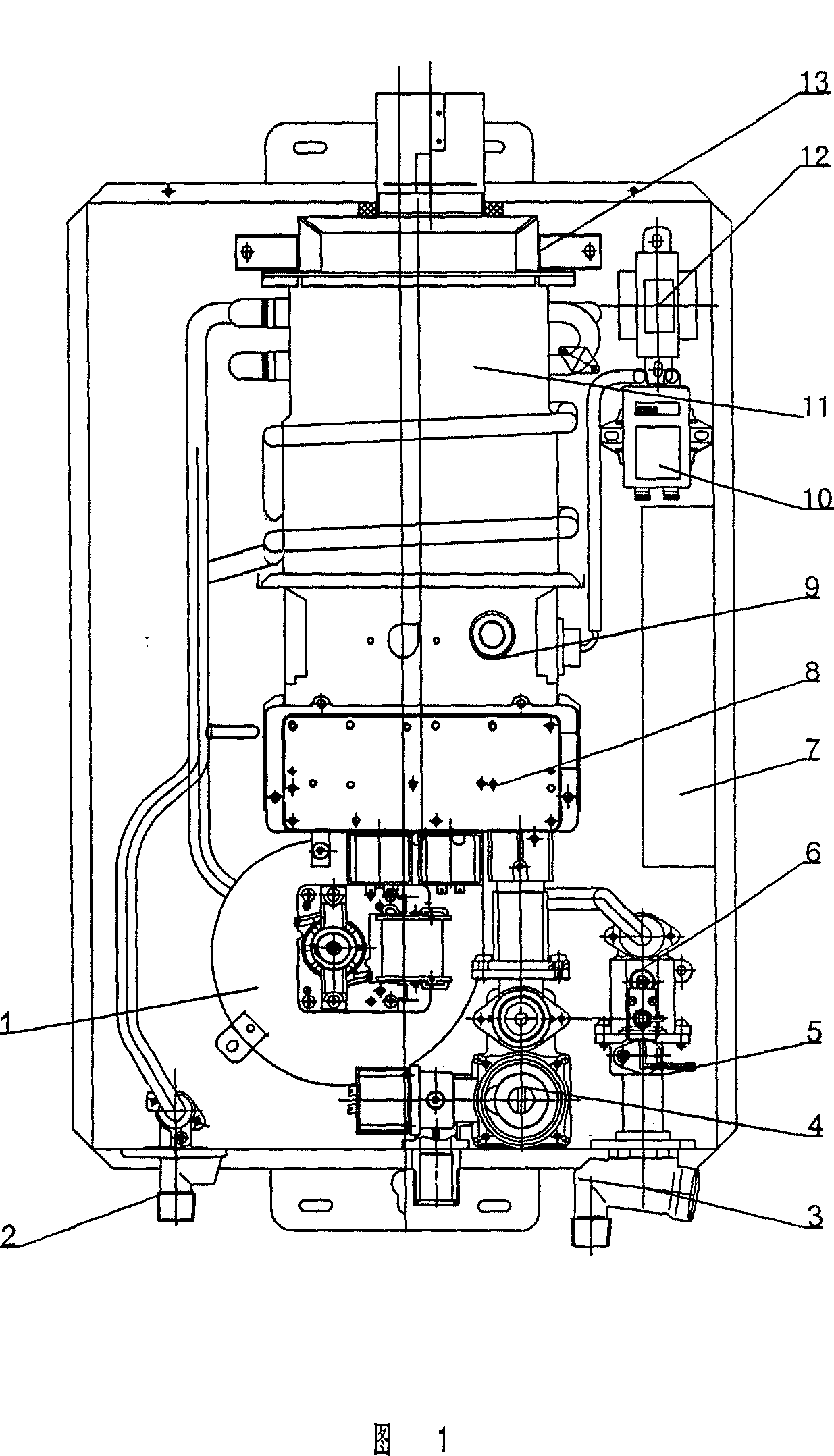

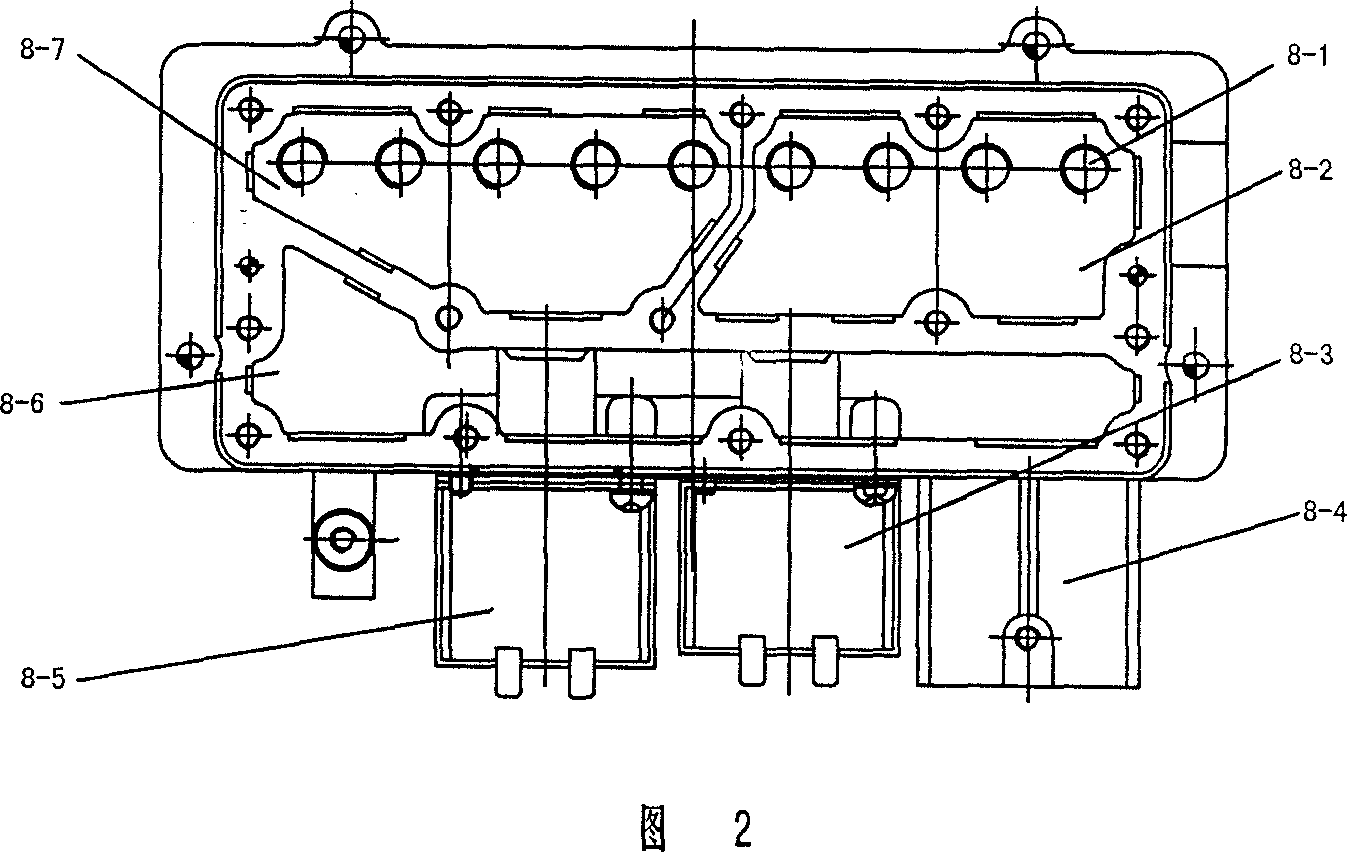

Fuel gas high efficiency water heater litre level changing method and variable litre level fuel gas high efficiency water heater

In the casing of the gas rapid water heater is mounted a heat-exchanger with a water intake and a discharge tube. Under the heat-exchanger is set a combustion chamber, in which is mounted a burner connected with gas-distributing nozzles separately. A variable-speed fan is mounted under the combustion chamber. The gas-distributing nozzles are divided into at least two group of the gas-distributing nozzles is connected with the gas source separately through the air intake distributing valve. When used, by switching the air intake distributing valve, it is at least realized that the group with a smaller number of combustion nozzles is independent gas-fed for burning and the group with a larger number of combustion nozzles is also independent gas-fed for burning.

Owner:A O SMITH CHINA WATER HEATER CO LTD

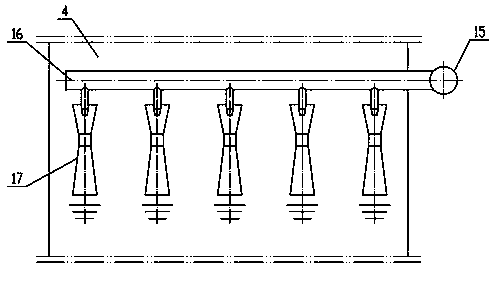

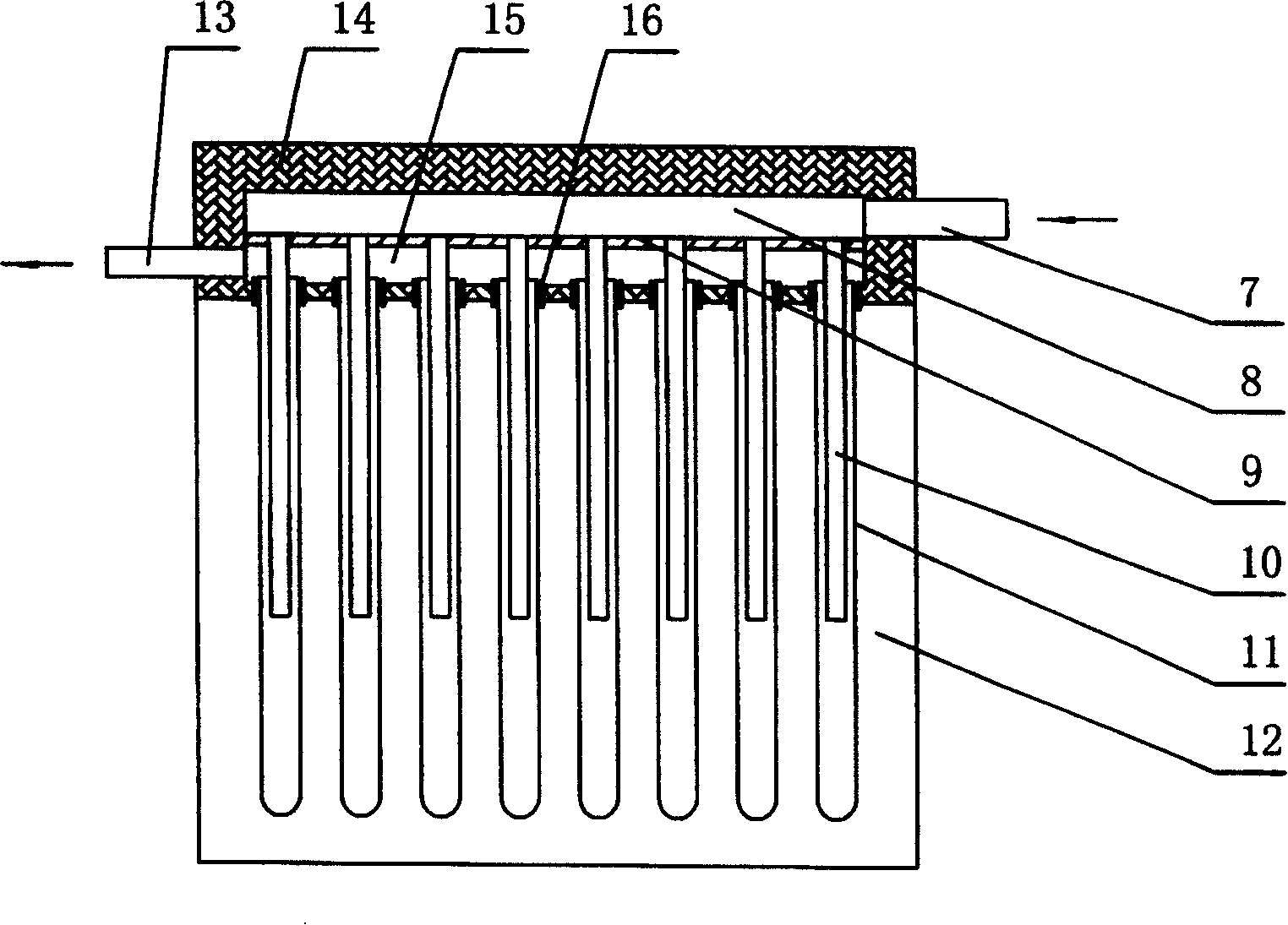

CO boiler having ash removal function

ActiveCN103776014AImprove heat transfer efficiencyReduce the frequency of soot blowingDispersed particle separationSteam boilersFlueEngineering

The invention discloses a CO boiler having the ash removal function. The CO boiler having the ash removal function comprises a first vertical flue, a horizontal flue and a second vertical flue, wherein ash baffles are arranged at the connection position between the first vertical flue and the horizontal flue, an ash storage bin is arranged at the position, flush with the lower edge of the lowest ash baffle, of the inner side of the first vertical flue, the ash baffles are of the structure that multiple layers of baffles are arranged in a staggered mode, each ash baffle is arranged in an inclined mode, and the outer end of each ash baffle is higher than the inner end of the ash baffle. According to the CO boiler having the ash removal function, the ash baffles arranged in the CO boiler can remove most of smoke dust contained in smoke and also play a role in rectifying the smoke, so that the smoke is rectified into the stable horizontal laminar flow state, the smoke evenly passes through steam drums, and the heat exchange efficiency of the boiler is high. The CO boiler having the ash removal function can solve the problem of equipment wear and abrasion caused by the smoke dust to the maximum extent, optimize the smoke processing technology, reduce energy consumption and reduce investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

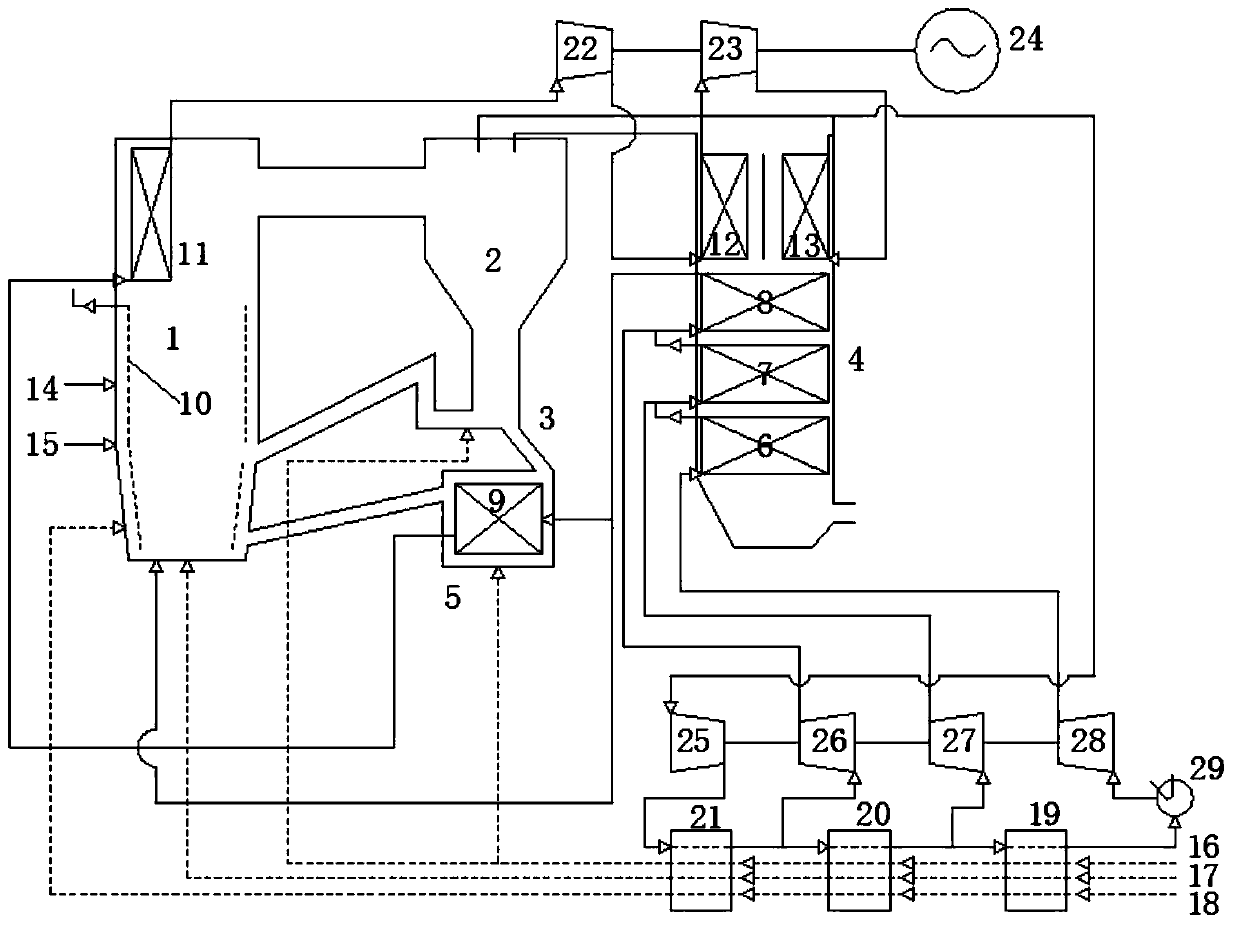

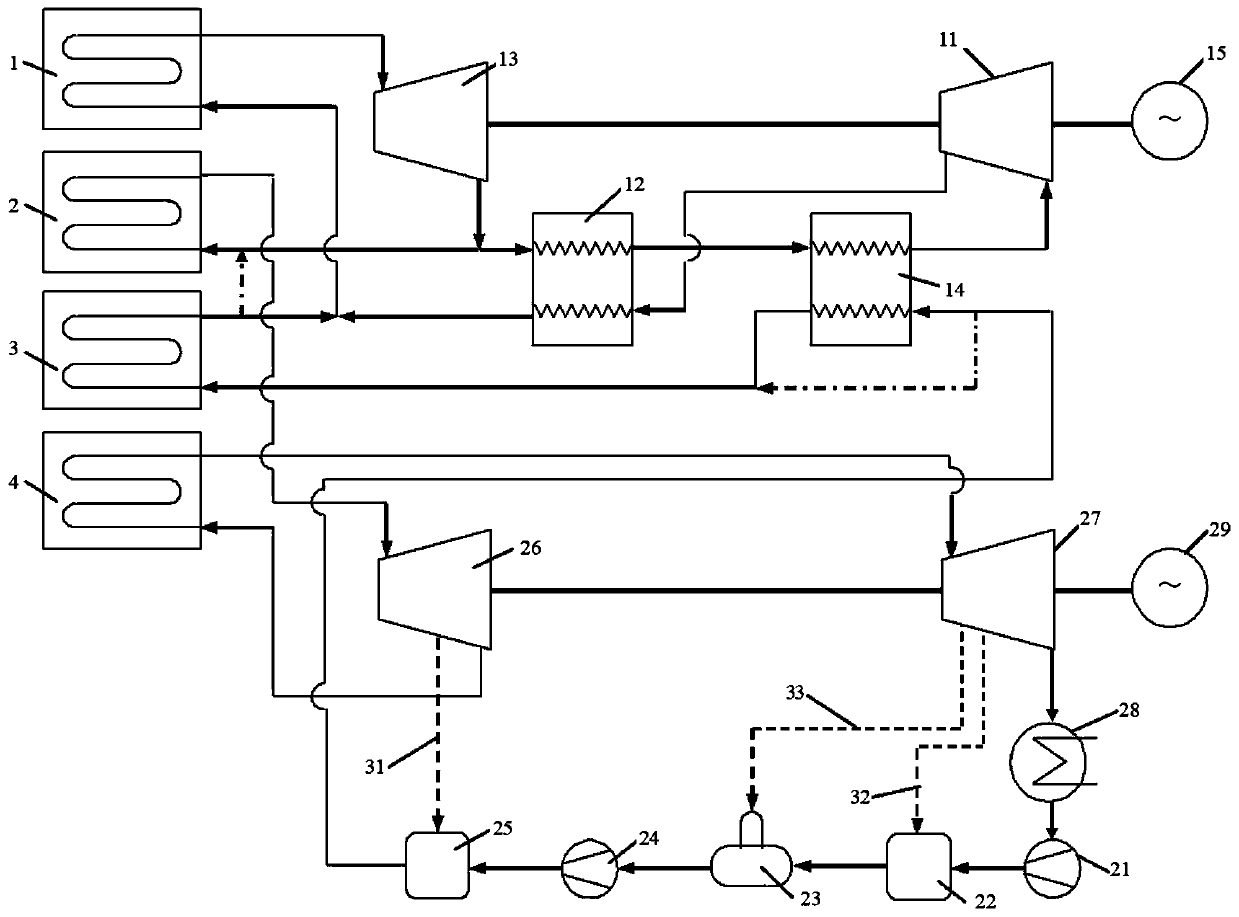

Cold accumulation type supercritical Brayton cycle power generation system and method

PendingCN108661731ASolve the cooling problemGuaranteed cold junction temperatureFrom solar energySteam engine plantsBrayton cycleEngineering

The invention discloses a cold accumulation type supercritical Brayton cycle power generation system and method. The system comprises a heat source, a supercritical Brayton cycle system, a cold accumulation system and a cooling system which sequentially communicate. According to the cold accumulation system and the adjusting method, the problem of heat dissipating of a thermal system under high temperature in the daytime in summer can be effectively solved; the temperature of the cold end of the system can be ensured; and the heat efficiency of the system can be ensured.

Owner:XIAN THERMAL POWER RES INST CO LTD

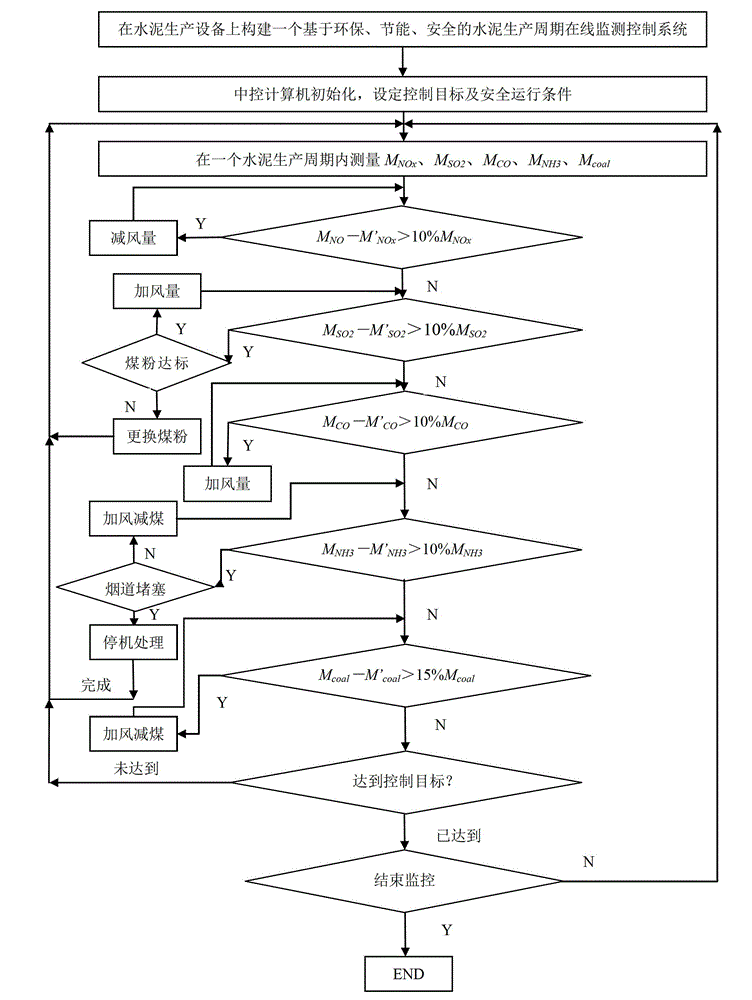

Online monitoring control method based on environment-friendly, energy-saving and safe cement production period

The invention provides an online monitoring control method based on an environment-friendly, energy-saving and safe cement production period, belonging to the field of cement production. The online monitoring control method is characterized in that an online monitoring control system based on computer online monitoring and manual command control is constructed on cement production equipment, the actual measuring quantity of NOx, NH3, CO and SO2 and the coal-burning amount of a decomposing furnace are sequentially adjusted within the cement production period including the raw material mixing process, the raw material grinding and waste gas treating process, the coal dust preparation process, the raw material homogenizing process, the process of transferring the raw material into a pre-heater, the process of sectional burning of the decomposing furnace, and the process of sintering to obtain clinker based on the implementation of sectional burning and low-nitrogen oxide burner technology, so that the emission such as NOx can be comprehensively controlled, factors such as smoke channel blocking, excessively high sulfur content in coal dust, and excessively high coal consumption of the decomposing furnace, which influence the safe running and energy consumption can be controlled, and as a result, the stability of the quality of the cement can be ensured, the safety in production can be ensured, the energy is saved, and the cost is reduced.

Owner:BEIJING UNIV OF TECH

Supercritical carbon dioxide circulating coal-fired power generation system

PendingCN110080848AEliminate manufacturing difficultiesReduce boiler exhaust gas temperatureCombustion processSteam useSuperheaterCirculating fluidized bed boiler

The invention relates to a supercritical carbon dioxide circulating coal-fired power generation system. The supercritical carbon dioxide circulating coal-fired power generation system comprises a hearth and a primary reheater, a membrane type wall is arranged on the inner wall of the hearth, a secondary superheater is arranged at the upper end of the hearth, a separator is connected to the outer end of the top of the hearth, the bottom end of the separator is connected with a return valve, one end of the bottom of the return valve is connected into the hearth, the other end of the bottom of the return valve is connected with an external heat exchanger, and an outlet of the external heat exchanger is connected to one end of the bottom of the hearth. The supercritical carbon dioxide circulating coal-fired power generation system has the beneficial effects that the supercritical carbon dioxide circulation is combined with a circulating fluidized bed boiler, the fuel flexibility of the circulating fluidized bed boiler is good, high-sulfur coal and low-calorific-value fuel can be efficiently utilized, the up-to-standard emission can be realized only through the desulfurization and low-temperature combustion nitrogen inhibiting in the furnace, the heat efficiency of the circulating fluidized bed boiler can achieve 90% or more, and compared with a pulverized coal fuel boiler, the circulating fluidized bed boiler has better economical advantages.

Owner:SHANGHAI POWER EQUIP RES INST

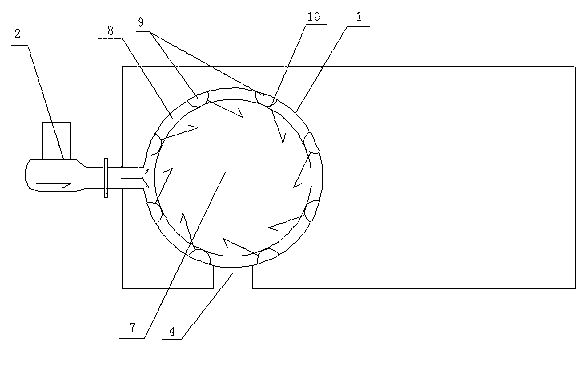

Cyclone boiler

ActiveCN102798118AGuaranteed thermal efficiencyNot easy to cokeSolid fuel combustionAir/fuel supply for combustionCycloneEngineering

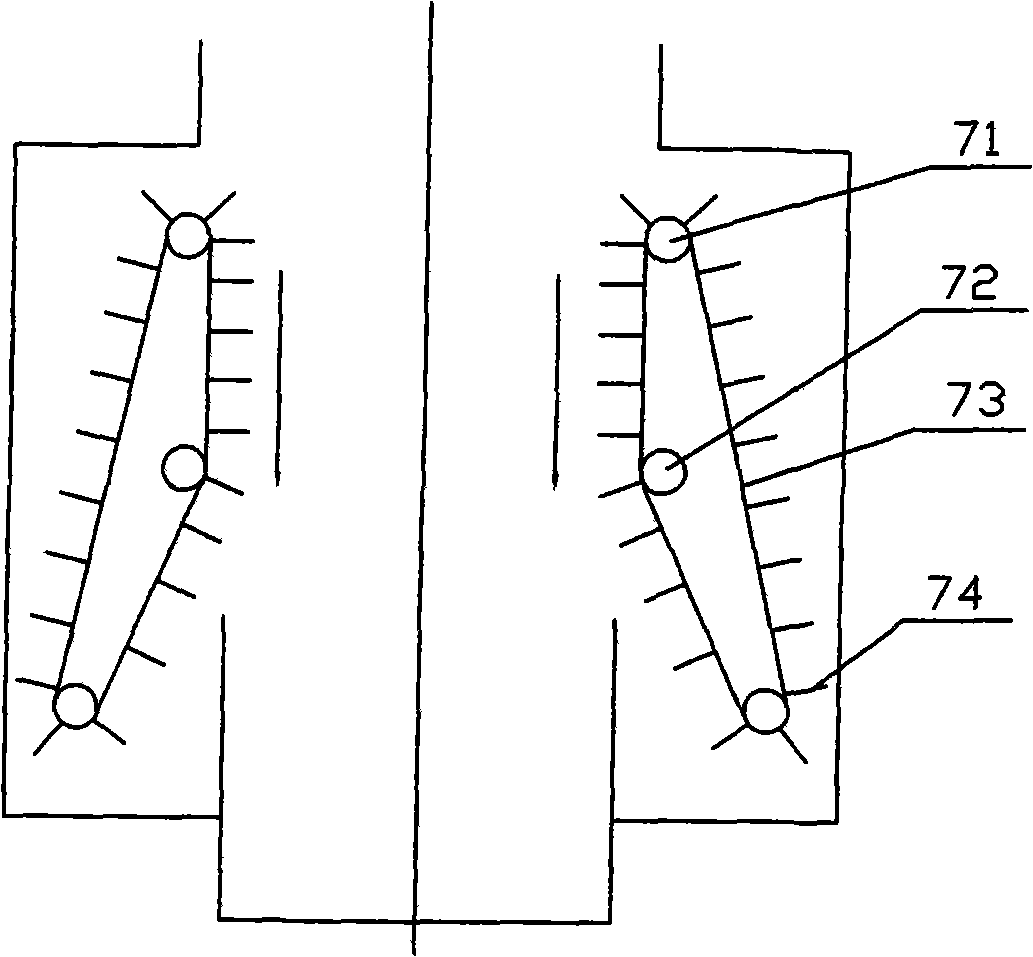

The technology discloses a cyclone boiler which comprises a furnace wall, a blast blower and a grain feeding auger, wherein the grain feeding auger is connected to the part above the middle part of the furnace wall; a furnace door and an ash outlet are arranged at the lower end of the furnace wall; a smoke discharge tube is connected with the top of the furnace wall; a fire grate is near the bottom part; a furnace wall air flue is arranged along the furnace wall; more than two blast pipes the tops of which are sealed and communicated with the furnace wall air flue are attached to the furnace wall above the furnace wall air flue; the blast pipes are vertically arranged; a ventilating hole is formed at the same side of axes of the blast pipes towards the direction of the furnace wall from the interior of the boiler, so eddy is formed inside a hearth by the air blown from the ventilating hole; the fire grate is arranged below the furnace wall air flue, and an air outlet is arranged at the inner side of the furnace wall air flue. The technology has the beneficial effects that the structure is simple; the operation is convenient; oxygen supply can be further reinforced; the ignition of particles inside the auger can be avoided at high temperature after feeding is stopped; thermal radiation of the hearth can be reduced to the maximal extent; oxygen of the hearth can be supplied for the second time; and the fuel burns more fully, and the thermal efficiency of the boiler is high.

Owner:胡光

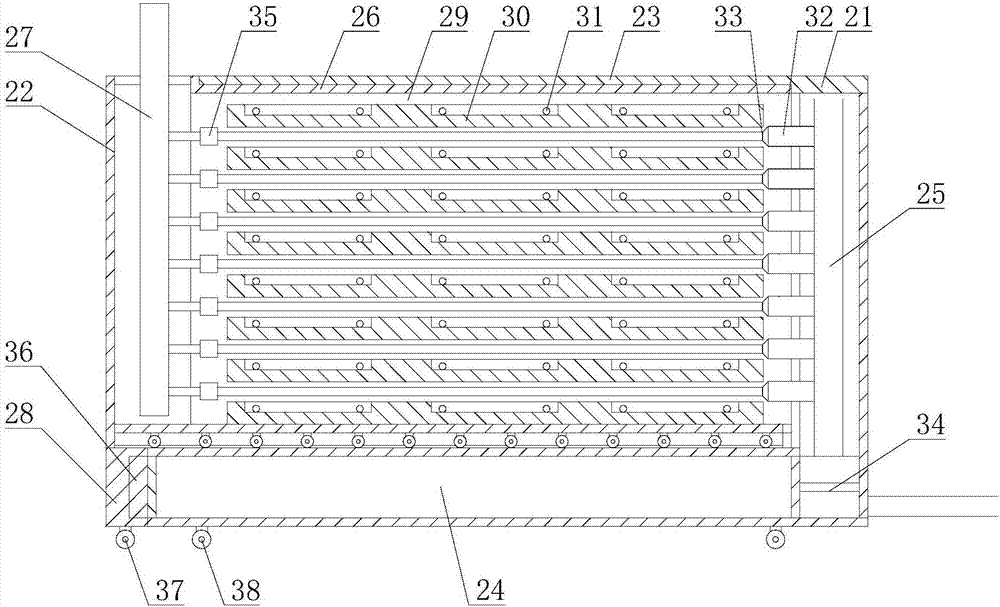

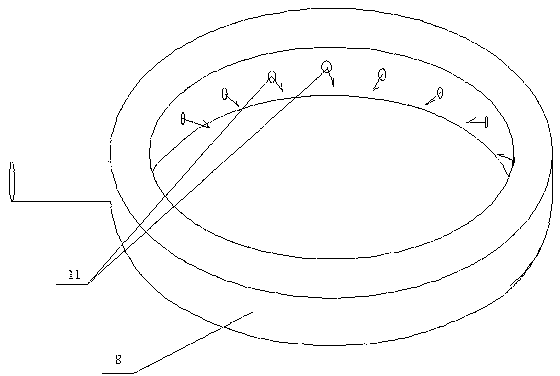

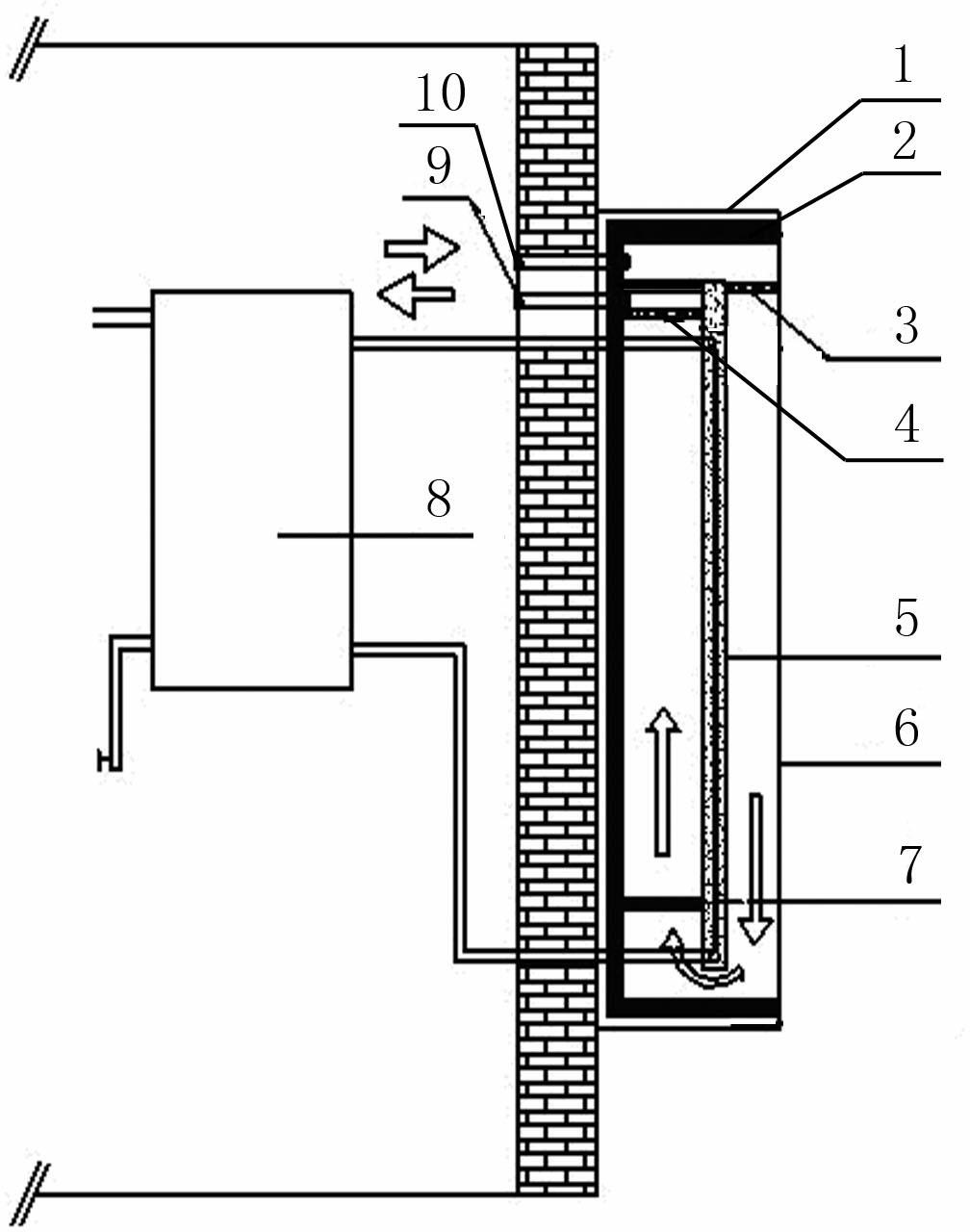

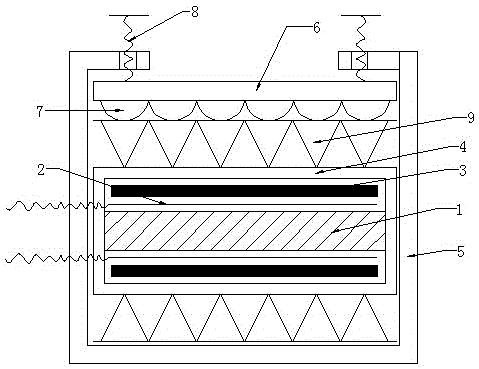

Low-cost double-effect solar air collector

ActiveCN102628617AReduce manufacturing costReduce heat lossSolar heating energySolar heat devicesThermodynamicsSolar air collector

The invention discloses a low-cost double-effect solar air collector, which comprises a light-transmitting cover plate, a water tank and a capillary net and is characterized in that a heat preservation layer matched with a casing is arranged on the inner side of the casing, one surface of the casing is provided with an opening and the other surfaces of the casing are sealed. The light-transmitting cover plate is arranged on the surface of the casing with the opening. An air supply port is arranged at the position where the casing is matched with the upper portion of the back wall of the heat preservation layer. A heat absorption device is arranged on the lower portion of the air supply port, fixed on the ball wall of the casing through a support and composed of the capillary net uniformly arranged in a concrete layer and a heat collection surface of a selective absorbing coating arranged on one surface of the concrete layer close to the light-transmitting cover plate. An air outlet is arranged at the position where the casing at the back of the heat absorption device is matched with the back wall of the heat preservation layer. An inlet and an outlet of the capillary net are respectively connected with the water tank through pipelines. The low-cost double-effect solar air collector is low in manufacture price and long in service life, meets requirements of users to the maximum limit, and has wide social benefit.

Owner:大连建大建筑节能科技发展有限责任公司

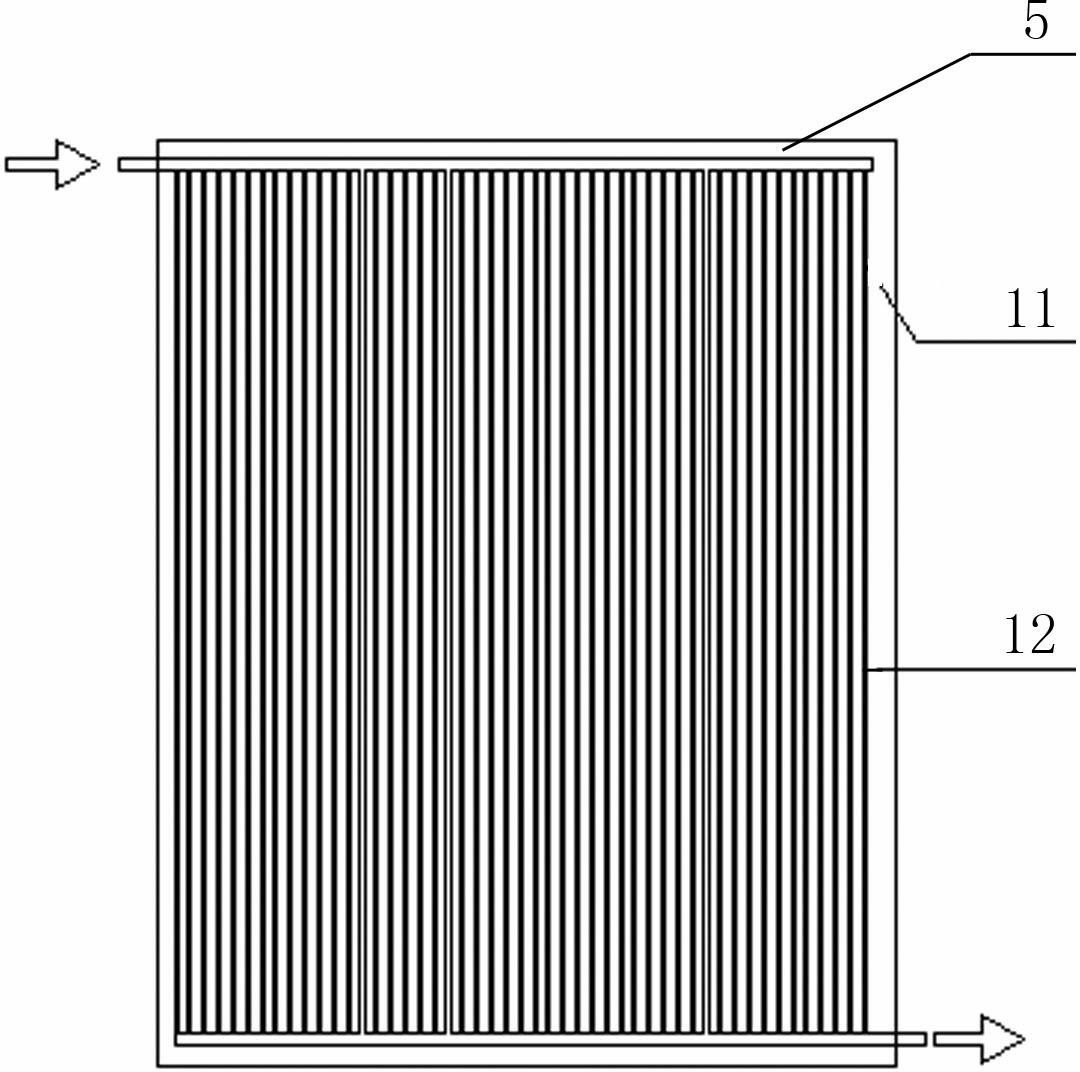

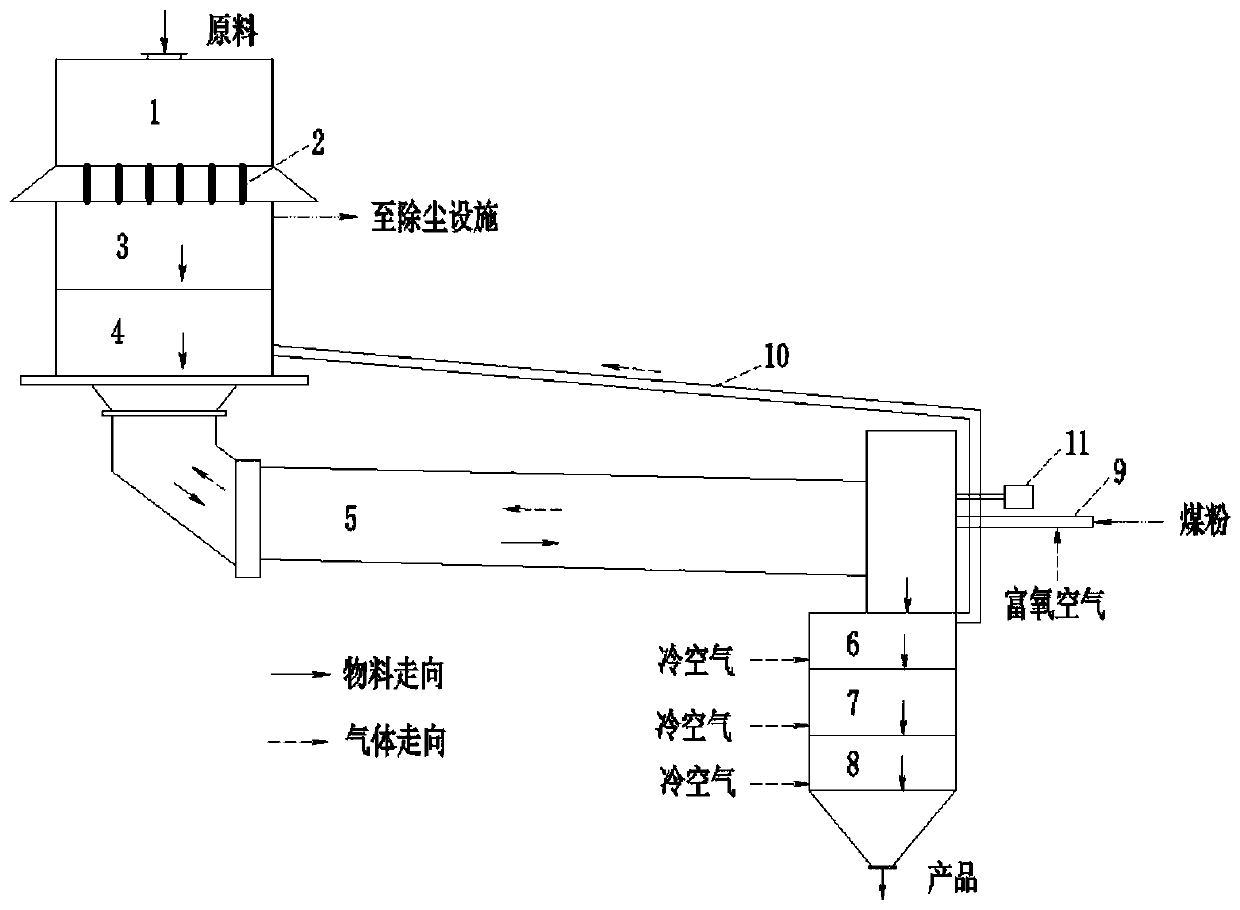

Process method for preparing active calcium oxide through oxygen-enriched calcination

InactiveCN110627384AHigh activityLow ignition pointCalcium/strontium/barium oxides/hydroxidesDecompositionHeat transfer efficiency

The invention discloses a process method for preparing active calcium oxide by oxygen-enriched calcination. The process method the following steps of firstly crushing and sieving raw limestone to enable the particle size of the raw limestone to be 10-55 mm, conveying the raw limestone into a stock bin with a circular cross section, wherein the stock bin is arranged at an upper part of a vertical preheater; then, uniformly conveying the raw materials in the stock bin into the vertical preheater through a blanking pipe, and preheating the raw materials by using high-temperature kiln gas and cooling gas of a vertical cooler; then, feeding the materials into a rotary kiln, and importing oxygen-enriched air from a kiln head to perform oxygen-enriched calcination; and then, feeding the calcium oxide obtained after calcination and decomposition into the vertical cooler to be cooled by air, namely, obtaining the active calcium oxide. According to the process method disclosed by the invention,through the integration of the processes of graded preheating, oxygen-enriched calcination, graded cooling, dynamic temperature monitoring and the like, and the raw materials are preheated by combining the high-temperature kiln gas and the high-temperature gas discharged from the cooler, the heat transfer efficiency of the system is greatly improved, the activity of calcium oxide is obviously improved, the energy consumption is reduced, and the energy conservation and emission reduction are realized.

Owner:HUBEI UNIV

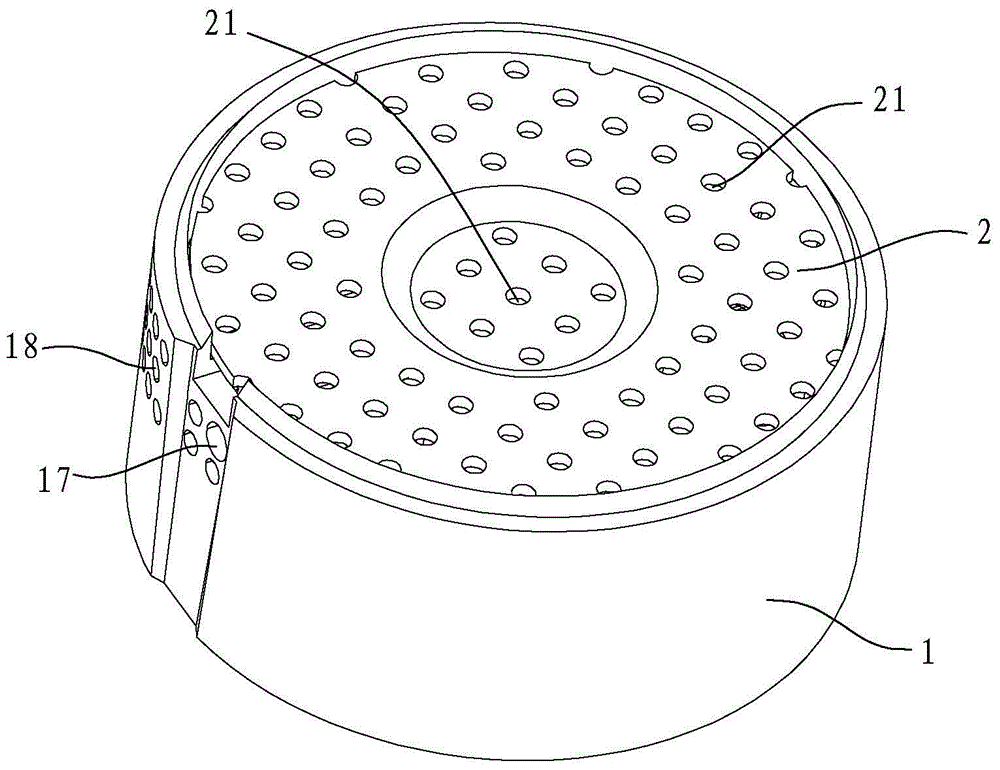

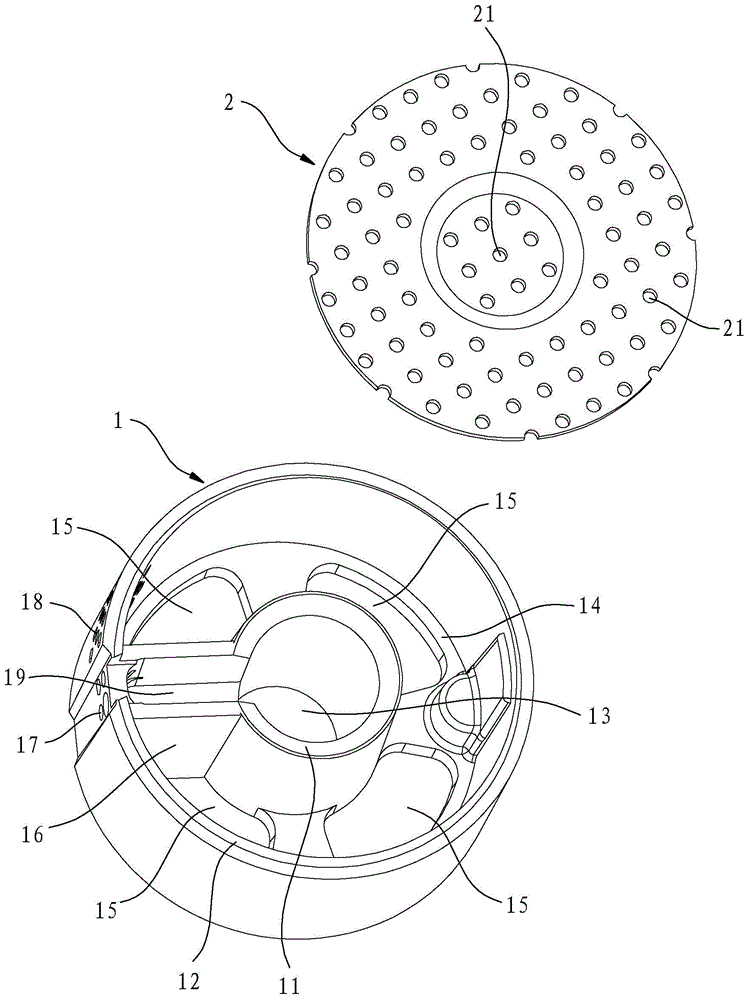

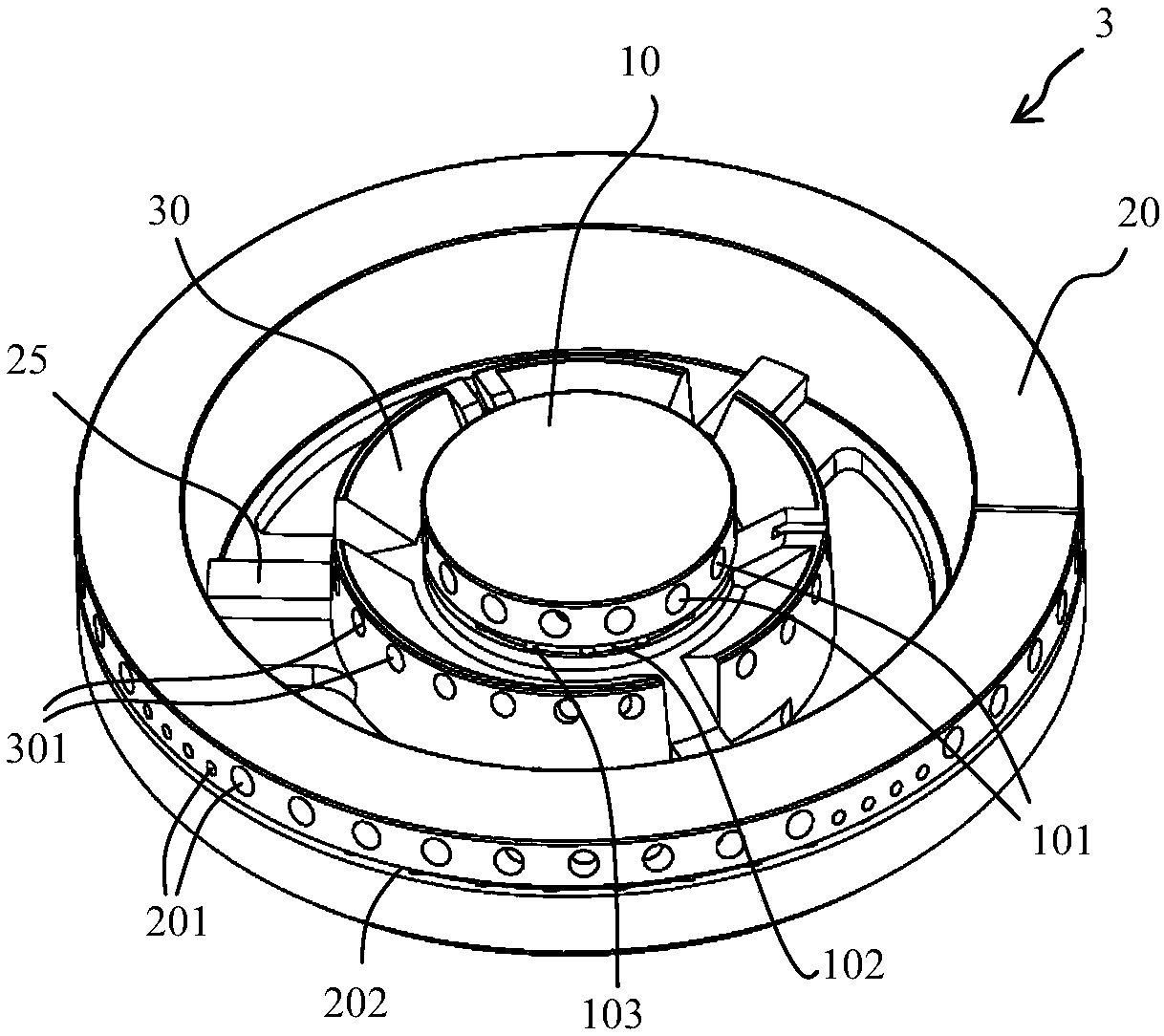

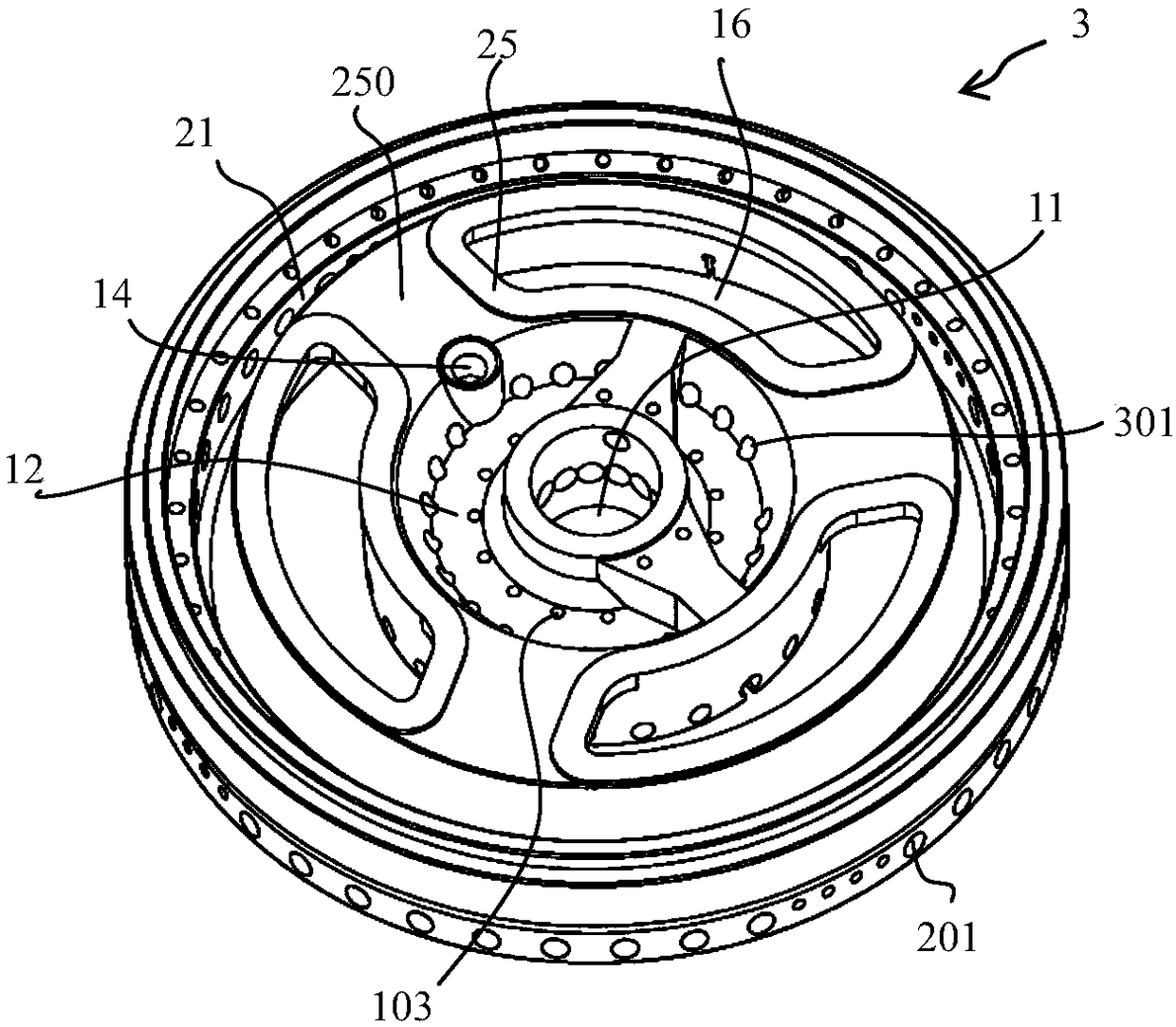

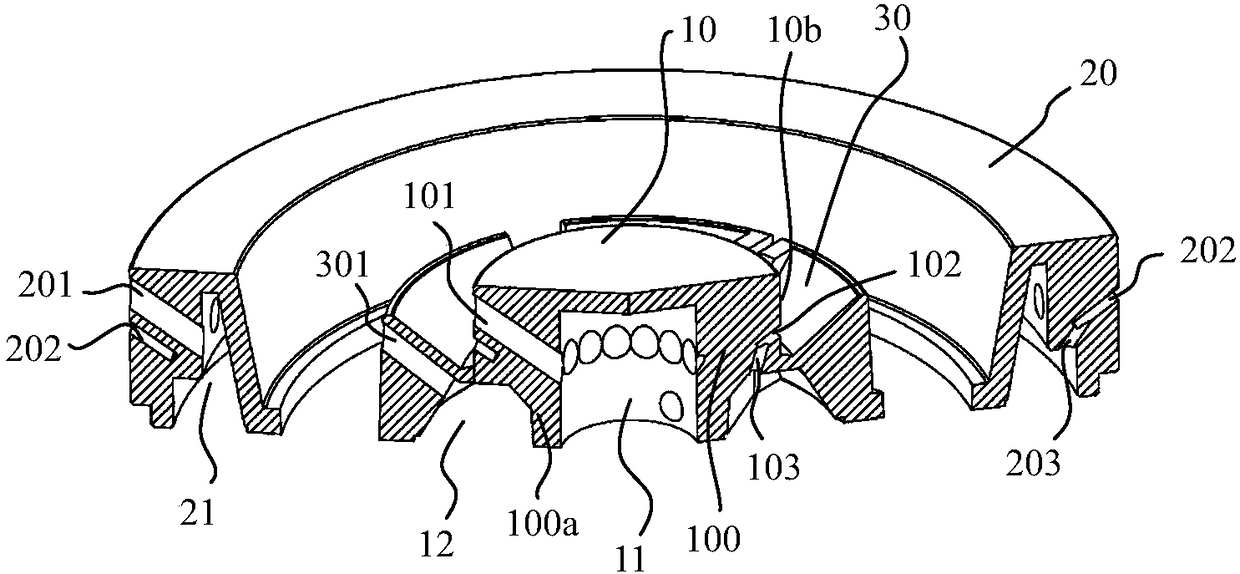

Fire cover for domestic gas stove and burner using the same

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Device for generation using hot gas flow

InactiveCN100408937CNo pollution in the processImprove thermal efficiencySolar heating energySolar heat devicesElectricitySolar generator

The present invention relates to solar generator, and is especially one solar generator utilizing solar energy to heat air and generating electricity with the hot airflow. The solar generator includes one heat collector comprising solar energy collecting vacuum tubes and one generator, and features the heat collector has air inlet with blower and air outlet connected through pipeline to chimney, the turbogenerator installed inside the pipeline, and the afterheat pipeline connected between the chimney and the air inlet of the heat collector. The present invention has no environmental pollution and low running cost.

Owner:银川瑞明太阳能有限公司

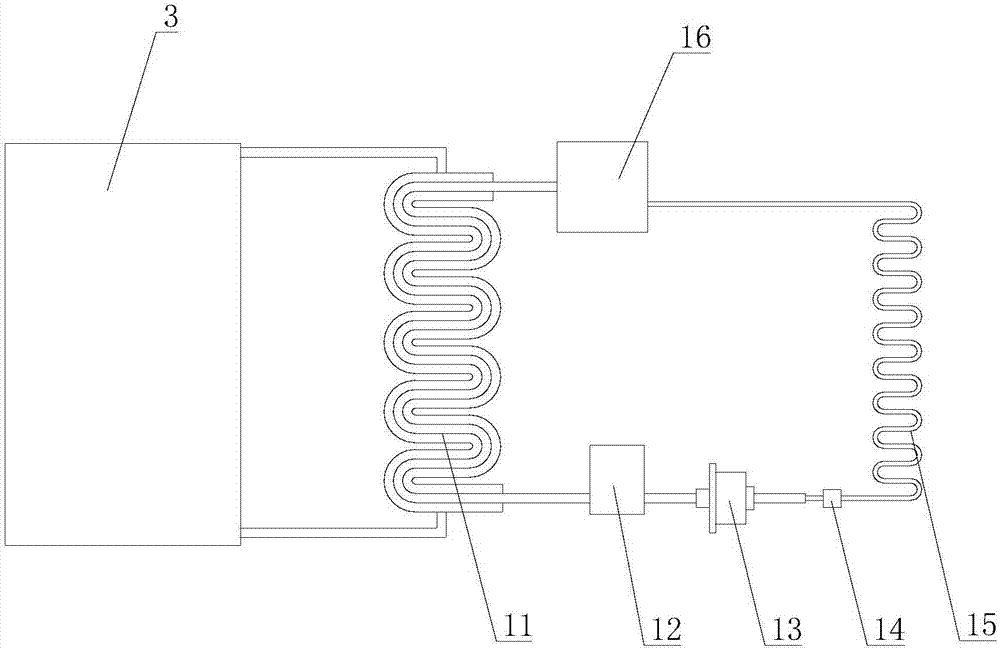

Solar steam boiler system

InactiveCN103672831ANo spillageReduce lossSteam generation heating methodsBoiler controlAutomatic controlThermal insulation

The invention discloses a solar steam boiler system, and belongs to solar heat collection implementation projects. The solar steam boiler system is composed of a solar heat collection area, a pressure-bearing steam thermal-insulation barrel, an automatic controller and a steam heat exchange cooling fin area. The main principle is that the solar heat collection area absorbs sunlight to generate heat and heats heat conduction working media, the heat conduction working media are utilized to activate water, and high-temperature steam is generated in the pressure-bearing steam thermal-insulation barrel; the high-temperature steam is utilized to carry out circulating radiation in the steam heat exchange cooling fin area under automatic control of the automatic controller, so that the heat carried by the high-temperature steam can be utilized, and water-steam separation and automatic reflux can be achieved. Solar thermal utilization is the primary, electric heat utilization is the secondary, and therefore the solar steam boiler system belongs to zero-emission boiler systems, and saves energy and protects the environment. The system is controlled automatically, the water-steam separation is achieved, and therefore the system is safe and efficient. The system operates in a sealed mode, overflowing of steam is avoided, and loss of energy and system scaling are reduced, and the heat efficiency of the system can be guaranteed because the system does not scale.

Owner:应县方圆炉业制造有限责任公司

Steam turbine set of power station and power generation method of steam turbine set

PendingCN110318961AHigh thermal efficiencyGuaranteed thermal efficiencyFrom solar energySteam engine plantsSuperheaterBrayton cycle

The technical scheme of the invention discloses a steam turbine set of a power station and a power generation method of the steam turbine set. The steam turbine set comprises a solar heat exchanger set, a steam brayton cycle and a steam rankine cycle, the solar heat exchanger set comprises a first superheater, a first reheater, a second superheater and a second reheater, the steam brayton cycle comprises a compressor, a heat regenerator, a high-pressure turbine, a middle heat exchanger and a first power generator, and the steam rankine cycle comprises a condensation water pump, a low-pressureheater, a deaerator, a water feeding pump, a high-pressure heater, a medium-pressure turbine, a low-pressure turbine, a condenser and a second generator. According to the steam turbine set, the steamturbine set organically combines the brayton cycle with the rankine cycle, on one hand, the heat efficiency of the rankine cycle can be remarkably improved, on the other hand, the working medium flowpassing through the high-pressure turbine is very large, the internal efficiency of the high-pressure turbine is improved, the heat efficiency of the brayton cycle is ensured, and finally the heat efficiency of the whole unit is remarkably improved.

Owner:SHANGHAI POWER EQUIP RES INST

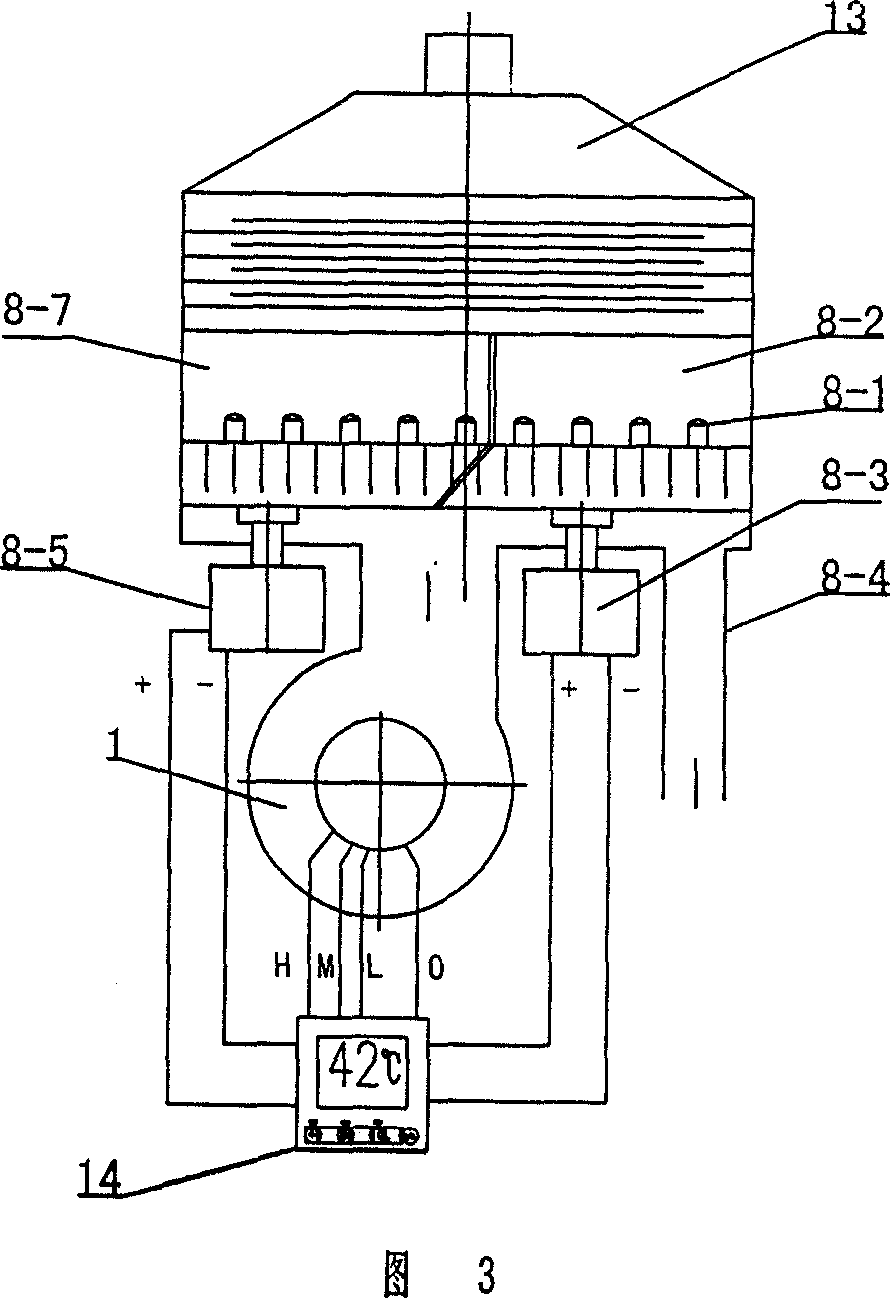

Pretightening force PTC electric heater

InactiveCN105072711AIncrease cooling areaHigh strengthOhmic-resistance heating detailsElectricityEngineering

Owner:JIANGSU YUANZHIYI ELECTRIC

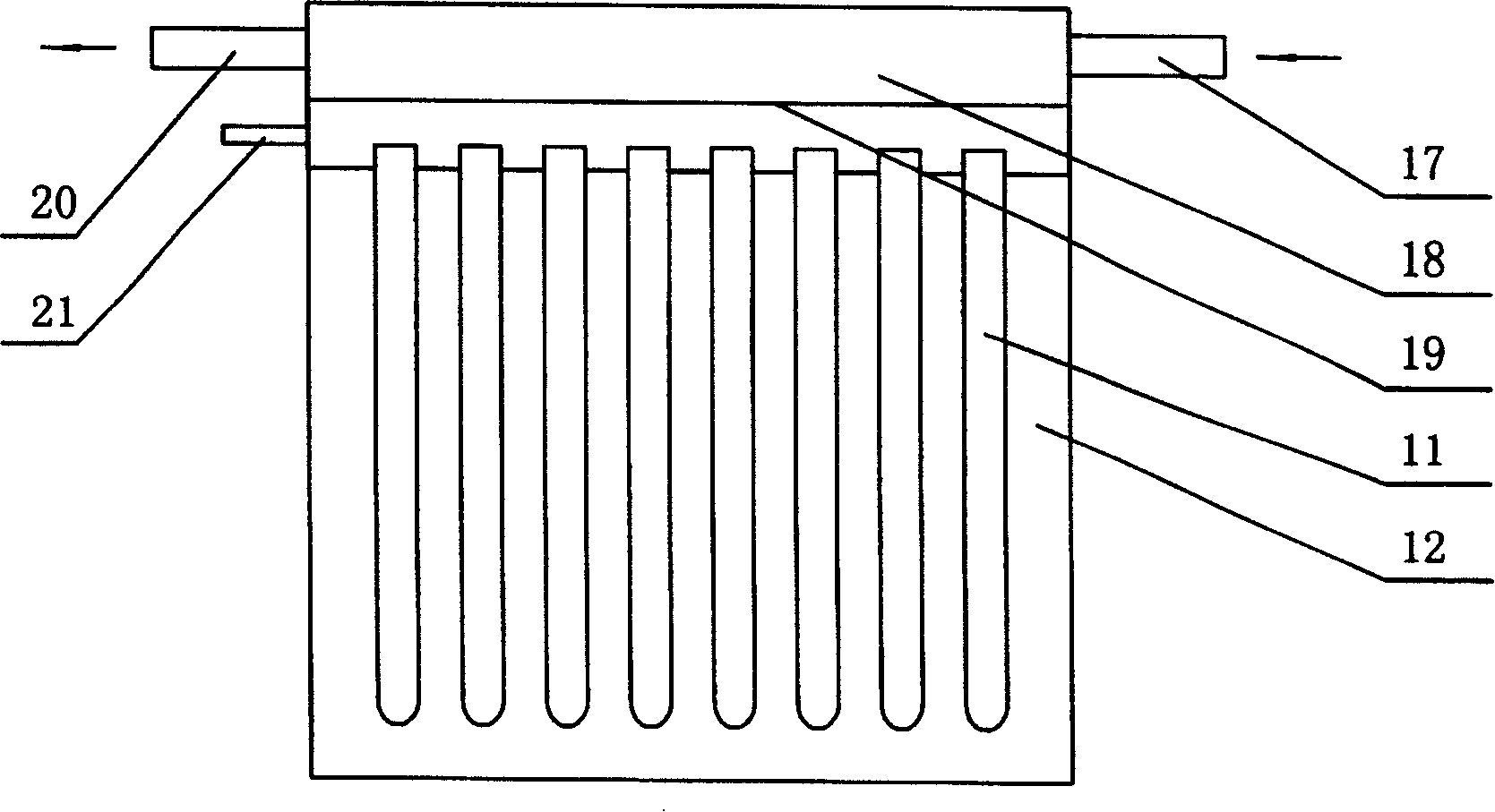

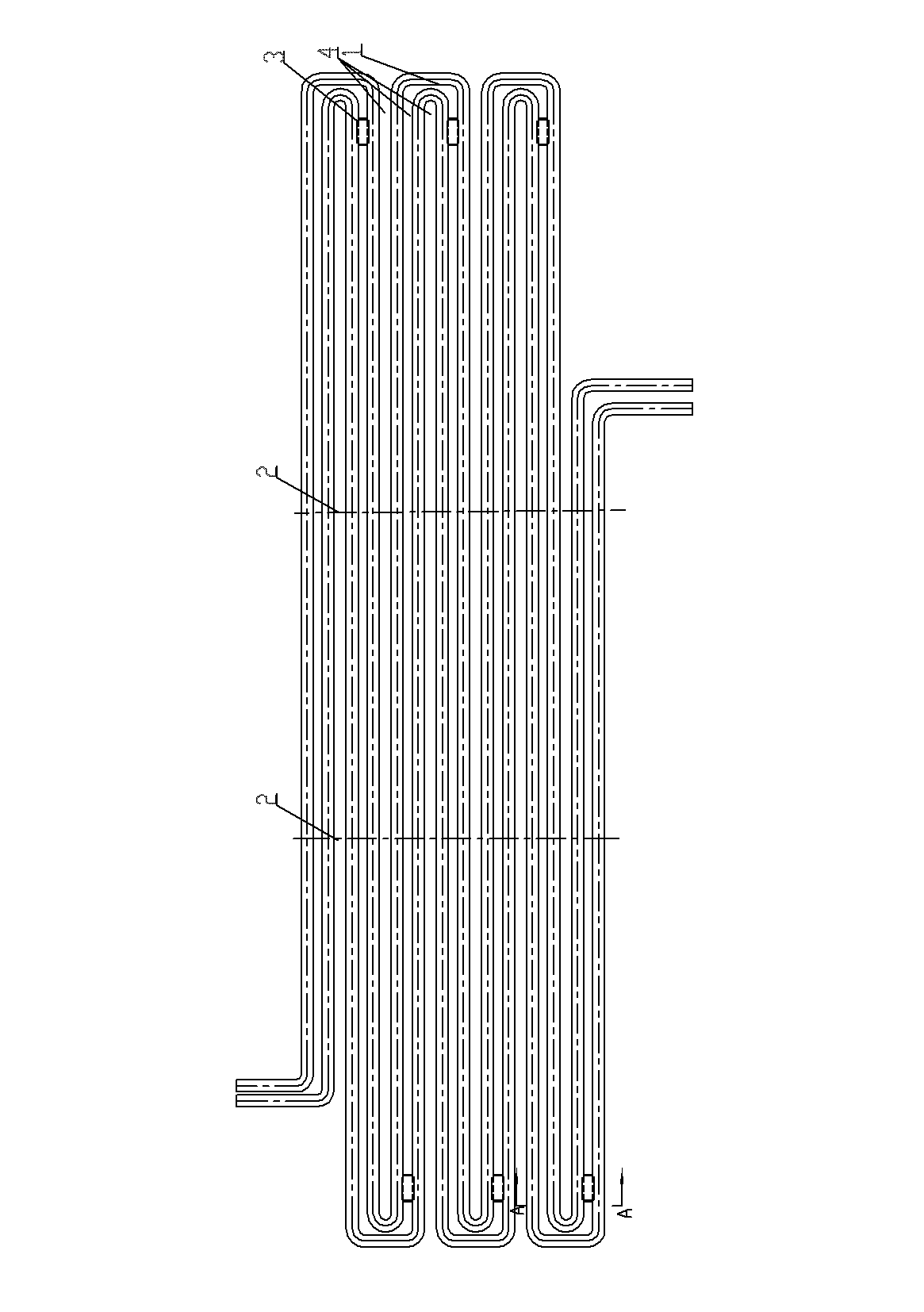

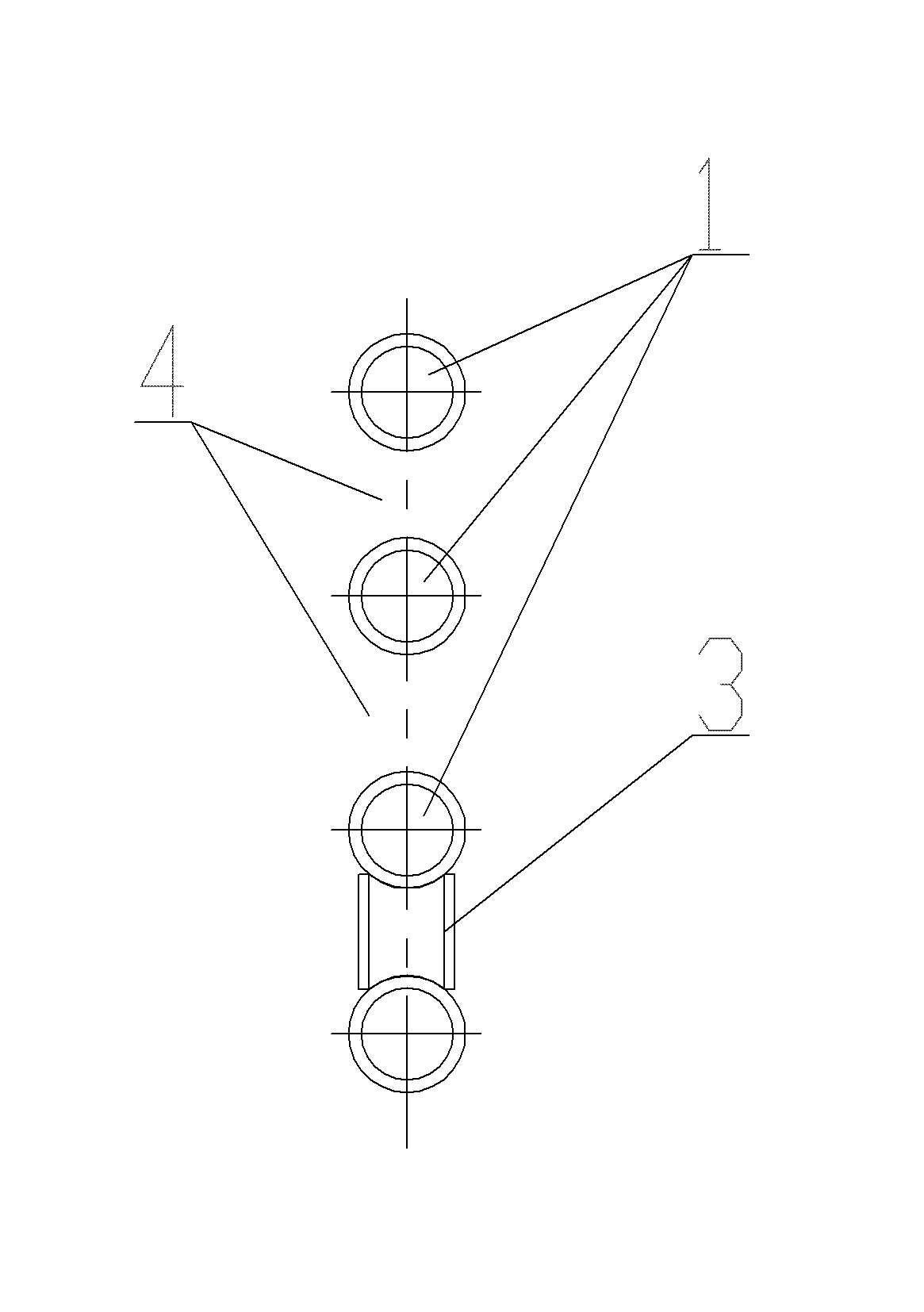

Limiting structure of S-shaped piping system

InactiveCN103216813AGuaranteed thermal efficiencyWill not deformHeat exchanger casingsSteam boilersThermal efficiencyElectrical and Electronics engineering

The invention provides a limiting structure for an S-shaped piping system, which is used for preventing pipes of the piping system from being deformed by longitudinal heating under the condition that S-shaped pipes are long in the horizontal direction, and ensuring the thermal efficiency of a boiler. The limiting structure comprises S-shaped pipes which are arranged horizontally, wherein the horizontal segments of the S-shaped pipes are long; the upper layers and the lower layers of the S-shaped pipes are hoisted on upper transverse beams through hoisting assemblies; and the hoisting assemblies are positioned at the middle positions of the horizontal segments of the S-shaped pipes. The limiting structure is characterized in that limiting blocks are arranged between the upper layers and the lower layers at the two ends of the horizontal segments of the S-shaped pipes at certain intervals; the upper sides of the limiting blocks are connected with upper layer S-shaped pipes by welding; and the lower sides of the limiting blocks are connected with lower layer S-shaped pipes by welding.

Owner:WUXI HUAGUANG BOILER

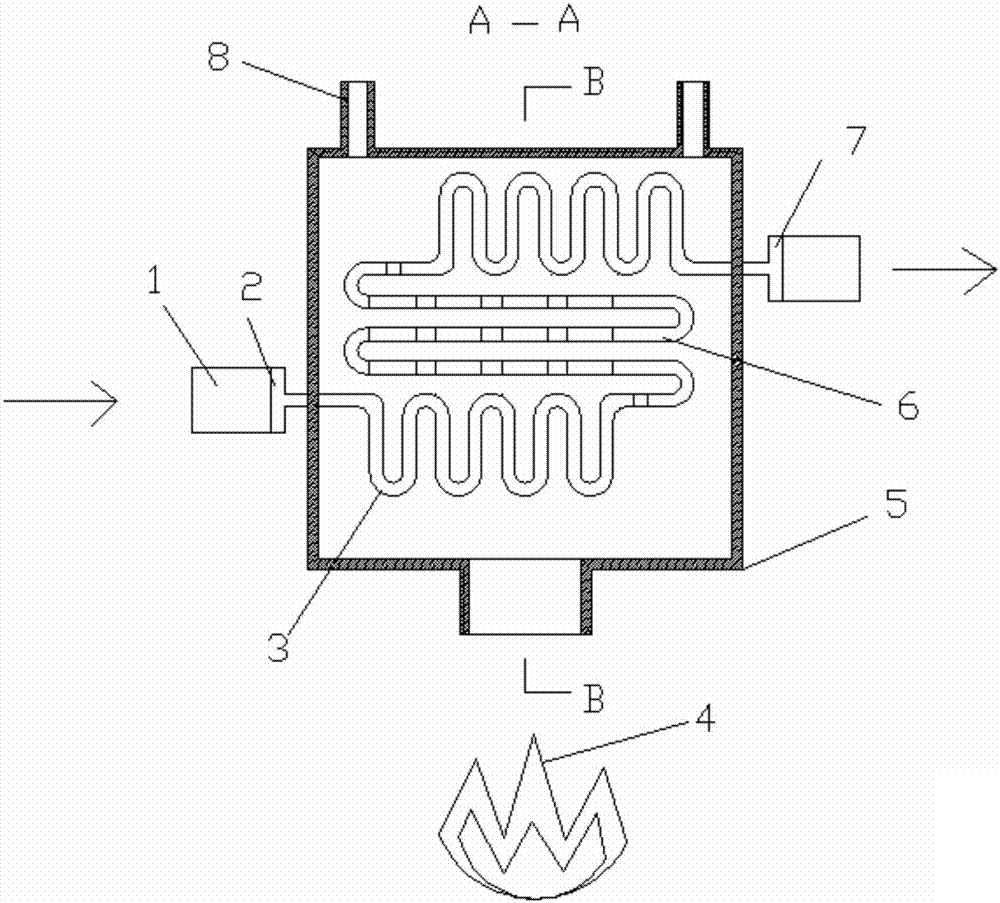

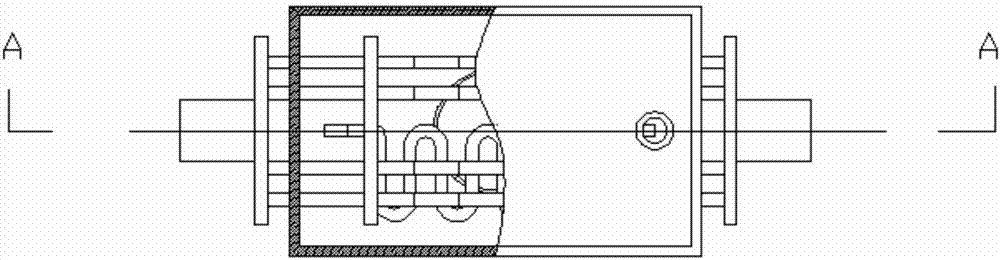

Combustion heat recovery device for combustible exhaust gas of carbonized oven

InactiveCN107270308AAvoid pollutionSave heating energyWater heatersIncinerator apparatusWaste heat recovery unitHeat conducting

The invention discloses a combustion heat recovery device for combustible exhaust gas of a carbonized oven. The device comprises a waste heat recovery cavity and a waste heat recovery pipe which passes through the waste heat recovery cavity. A combustion port and a combustion product exhaust port are formed in the waste heat recovery cavity. A heat-conducting medium flows in the waste heat recovery pipe. The combustion heat recovery device for combustible exhaust gas of the carbonized oven of the structure has the advantages of being simple to operate, convenient to use and good in heat recovery effect, and the comprehensive energy consumption in a production process is greatly reduced.

Owner:CENT SOUTH UNIV

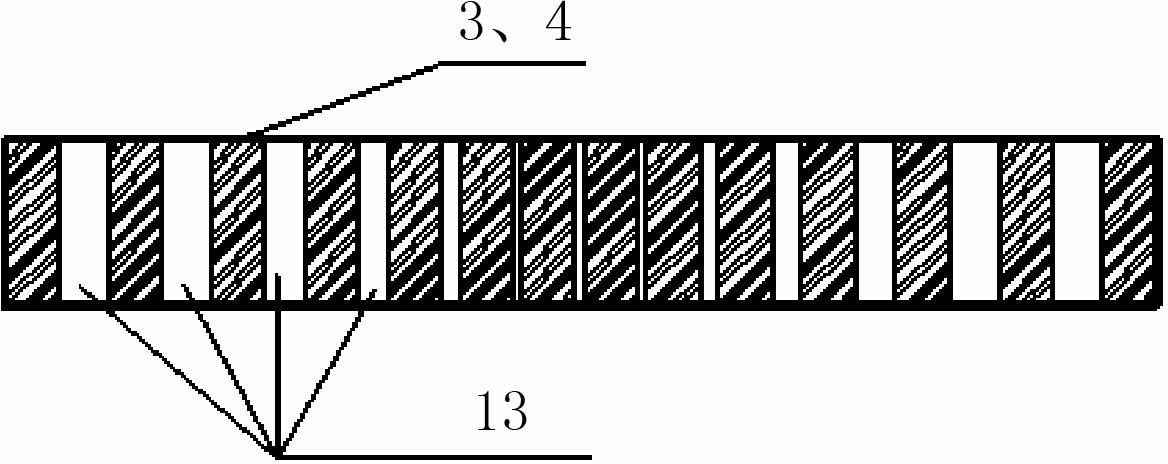

Temperature-retaining fresh air ventilator

ActiveCN103968491AIncrease the lengthShorten the lengthEnergy recovery in ventilation and heatingLighting and heating apparatusManufacturing technologyFresh air

The invention relates to a temperature-retaining fresh air ventilator, and relates to an improvement on a fresh air ventilator structure. The temperature-retaining fresh air ventilator is low in production cost, simple in manufacturing technology and high in heat exchange efficiency. The temperature-retaining fresh air ventilator comprises a housing, and has the structural features that a honeycomb integrally molded is arranged in the housing; fresh air channels and exhaust air channels are arranged in the honeycomb at intervals; air inlets of the fresh air channels and the exhaust air channels are respectively formed in sides at two ends of the honeycomb; air outlets of the fresh air channels and the exhaust air channels are respectively formed in end faces at the two ends of the honeycomb.

Owner:SHENZHEN ZPWTECHNOLOGY CO LTD

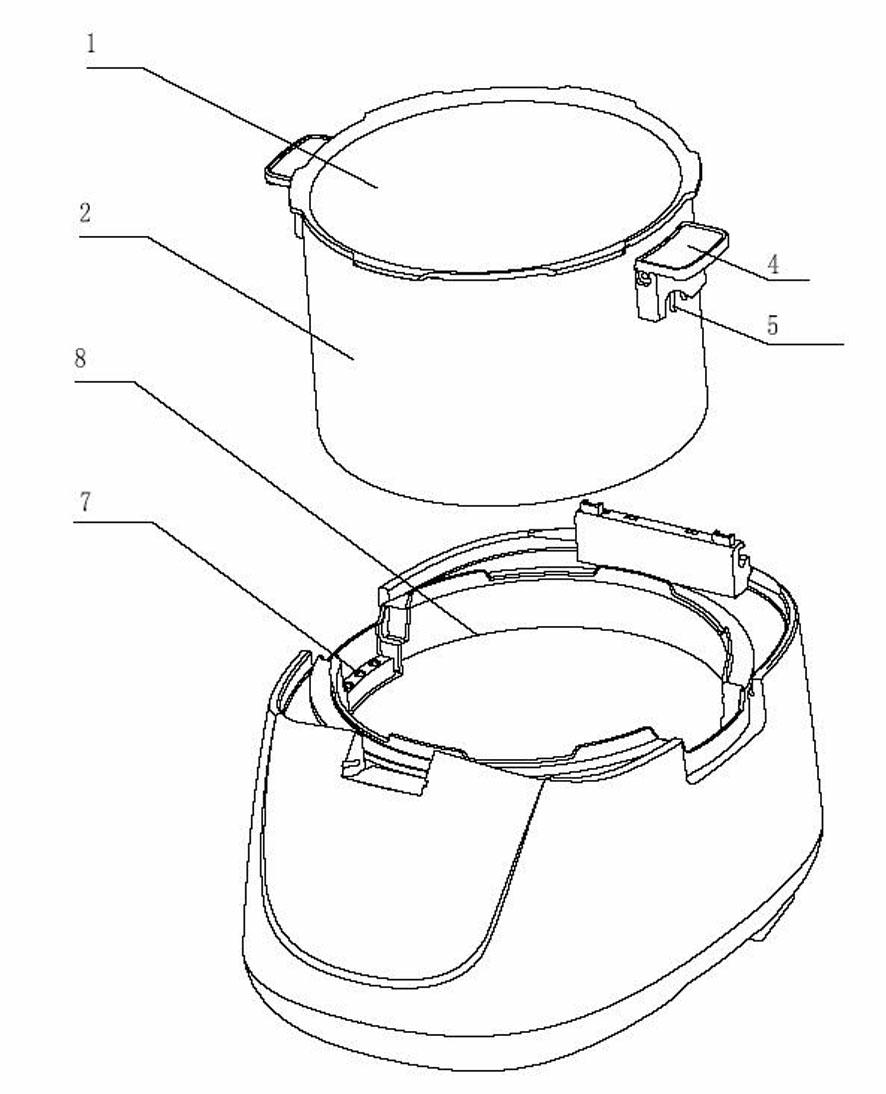

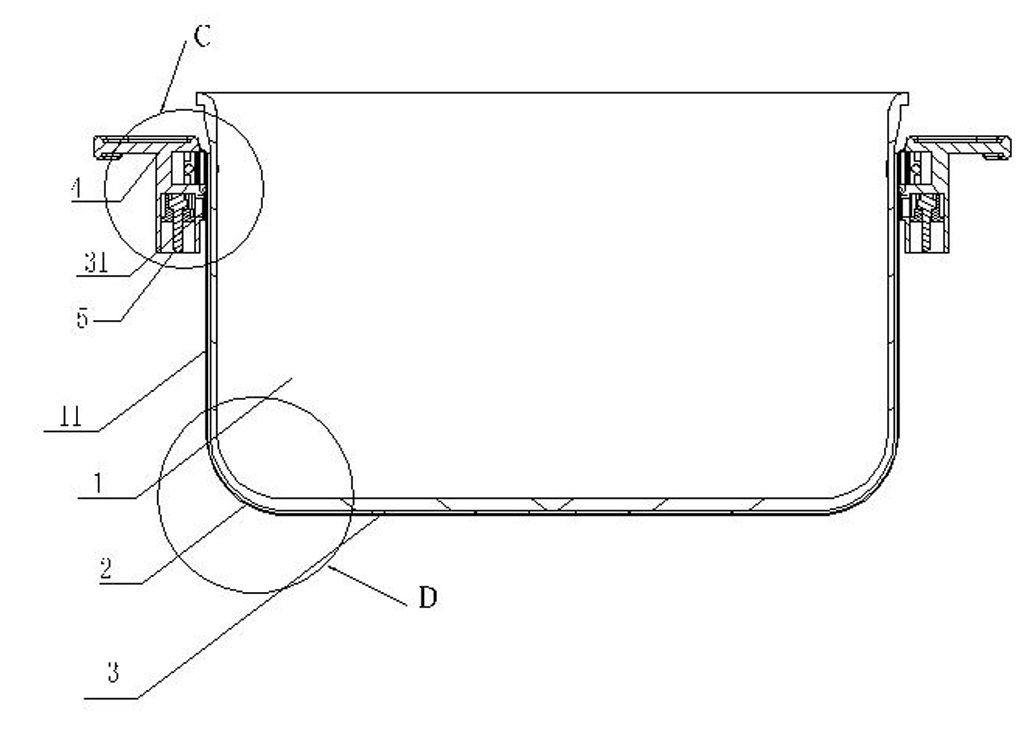

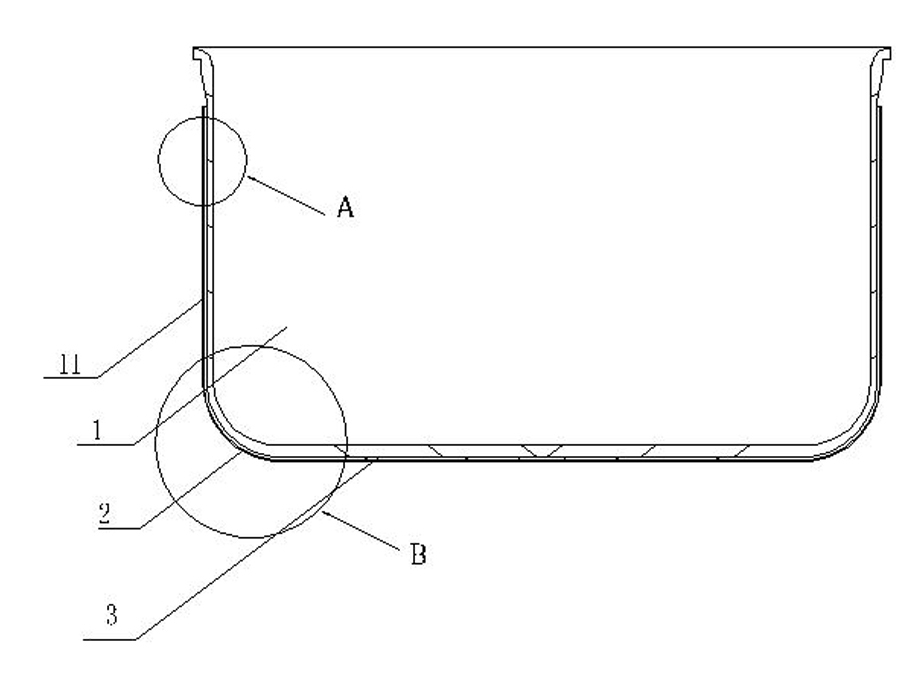

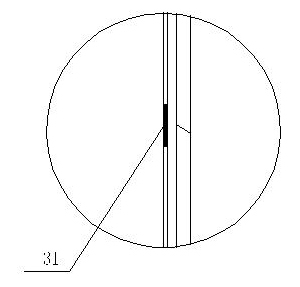

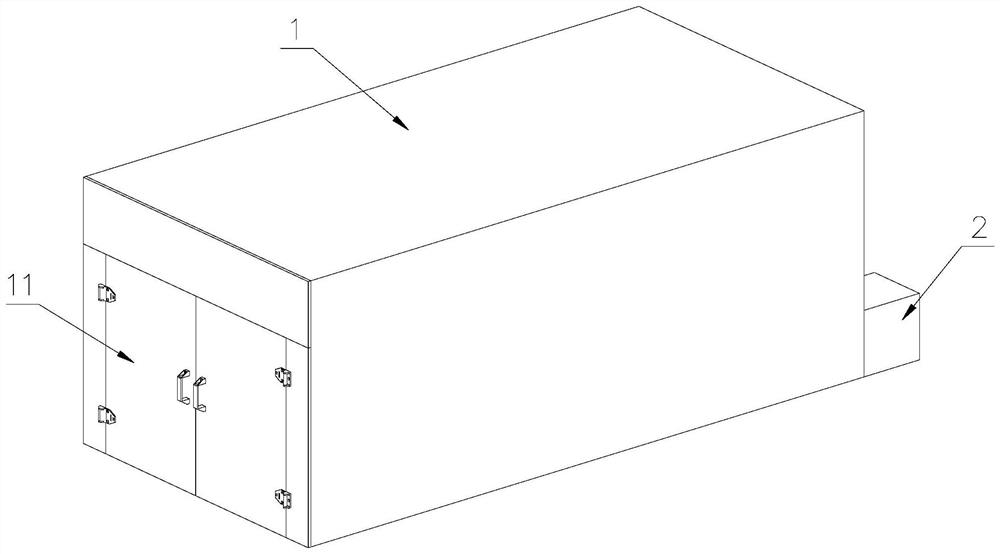

Electric heating film inner pot

ActiveCN101991347AGuarantee the safety of useEase of use guaranteedWarming devicesElectricityEngineering

The invention relates to an electric heating film inner pot, belonging to the technical field of electric cooking appliances, and comprising an open concave container formed by a pot wall and a pot bottom, which is characterized in that an electric heating film, an electrically connected electrode of the electric heating film connected with a power supply, and an insulation protecting layer on the external surface of the electric heating film are printed on the external surface of the concave container; and the electrically connected electrode of the electric heating film is arranged on the pot wall and connected with the power supply through an electric connector. In the electric heating film inner pot of the invention, the electric heating film is basically printed on the external surface of the whole pot body, thus the heating efficiency is high; the electrically connected electrode of the electric heating film is arranged on the side part and even the upper side part of the pot wall, so the worry of a user in cleaning is eliminated; and the complete machine has great advantages on the manufacturing cost and the appearance.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

Thermal distributed tobacco curing barn

PendingCN111920075AImprove baking efficiencyImprove roast qualityTobacco preparationCold airEnvironmental engineering

The invention discloses a thermal distributed tobacco curing barn. A plurality of groups of carbon crystal plates are arranged at the bottom and the top of a curing barn body; the upper side of the back surface of the curing barn body is provided with a number of dehumidifying fans, and a cold air door is arranged on the lower side of the back surface of the curing barn body; a first tobacco hanging frame is arranged in the middle of the curing barn body, a second tobacco hanging frame is arranged on the inner walls of the two sides of the curing barn body, and a temperature sensor, a humiditysensor and the carbon crystal plates are electrically connected with a control cabinet through wires. According to the invention, a traditional hot air chamber is cancelled; the plurality of groups of carbon crystal plates are arranged at the bottom and the top of the curing barn body; heat radiation and weak convection are transmitted to the outside; heat radiation is mainly carried out throughfar infrared radiation, after the far infrared radiation is absorbed by tobacco leaves, intense molecular resonance of moisture in the tobacco leaves is caused, the molecular resonance generates heat,the temperature in the tobacco leaves is promoted to rise, the purpose of synchronously drying the moisture in the tobacco leaves and surface moisture is achieved, the tobacco leaf baking efficiencyand quality are improved, and environmental pollution is avoided.

Owner:SHANDONG LINYI TOBACCO

Gas stove as well as burner cap and furnace end of burner for gas stove and burner

ActiveCN108870390AGuaranteed thermal efficiencyWide firepowerGaseous fuel burnerEngineeringGas stoves

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com