Process method for preparing active calcium oxide through oxygen-enriched calcination

A technology of activated calcium oxide and process method, which is applied in the field of oxygen-enriched calcination to prepare activated calcium oxide, which can solve the problems of not reaching high-end products, low calcium oxide activity, and poor quality, and achieve reduced heat loss, uniform combustion temperature, and lower The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

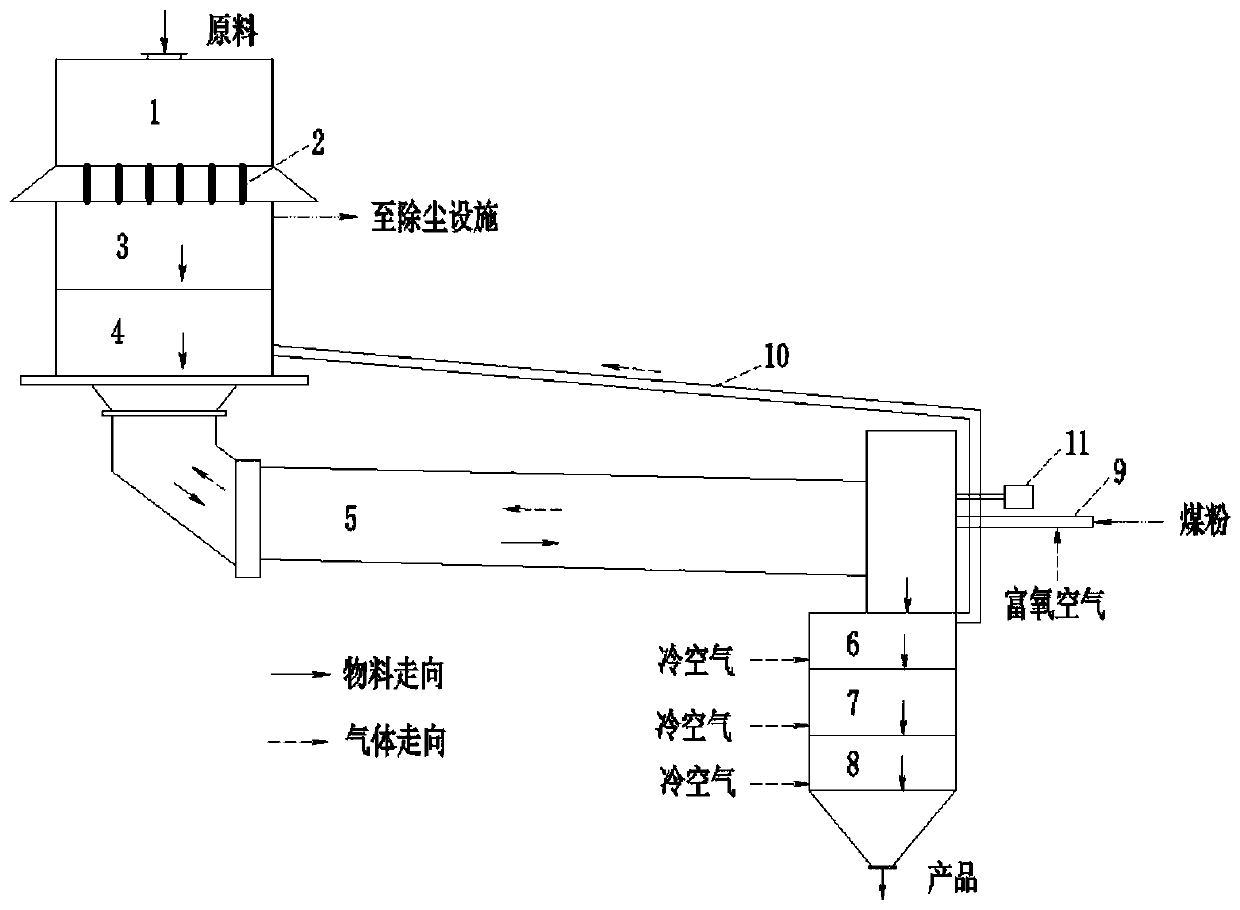

[0030] This embodiment provides a process for preparing activated calcium oxide by oxygen-enriched calcination, specifically, including the following steps:

[0031] (1) Crush the raw limestone, screen out three particle sizes of 10-25mm, 25-40mm, and 40-55mm, and transport them to the silo 1 with a circular cross section. The silo 1 is set in a vertical pre- The upper part of the heater is composed of 3 hopper chambers whose sections are all 120° fan-shaped.

[0032] (2) The raw materials in the above-mentioned silo 1 are evenly transported to the upper preheater 3 of the vertical preheater through six feeding pipes 2, and the raw materials pass through the upper preheater 3 and the lower preheater from top to bottom 4 Conduct relative motion heat exchange with hot gas to raise temperature, where hot gas is a mixed gas from kiln tail kiln gas and kiln head cooling air.

[0033] (3) Transport the heated raw material into the rotary kiln 5 for oxygen-enriched calcination and d...

Embodiment 2

[0036] This embodiment provides a process for preparing activated calcium oxide by oxygen-enriched calcination, specifically, including the following steps:

[0037] (1) Crush the raw limestone, screen out three particle sizes of 10-25mm, 25-40mm, and 40-55mm, and transport them to the silo 1 with a circular cross section. The silo 1 is set in a vertical pre- The upper part of the heater is composed of 3 hopper chambers whose sections are all 120° fan-shaped.

[0038] (2) The raw materials in the above-mentioned silo 1 are evenly transported to the upper preheater 3 of the vertical preheater through three feeding pipes 2, and the raw materials pass through the upper preheater 3 and the lower preheater from top to bottom 4 Conduct relative motion heat exchange with hot gas to raise temperature, where hot gas is a mixed gas from kiln tail kiln gas and kiln head cooling air.

[0039](3) Transport the heated raw material into the rotary kiln 5 for oxygen-enriched calcination and ...

Embodiment 3

[0042] This embodiment provides a process for preparing activated calcium oxide by oxygen-enriched calcination, specifically, including the following steps:

[0043] (1) Crush the raw limestone, screen out three particle sizes of 10-25mm, 25-40mm, and 40-55mm, and transport them to the silo 1 with a circular cross section. The silo 1 is set in a vertical pre- The upper part of the heater is composed of 3 hopper chambers whose sections are all 120° fan-shaped.

[0044] (2) The raw materials in the above-mentioned silo 1 are evenly transported to the upper preheater 3 of the vertical preheater through nine feeding pipes 2, and the raw materials pass through the upper preheater 3 and the lower preheater from top to bottom 4 Conduct relative motion heat exchange with hot gas to raise temperature, where hot gas is a mixed gas from kiln tail kiln gas and kiln head cooling air.

[0045] (3) Transport the heated raw material into the rotary kiln 5 for oxygen-enriched calcination and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com