Fuel gas high efficiency water heater litre level changing method and variable litre level fuel gas high efficiency water heater

A water heater and gas technology, which is applied to the conversion of rated parameters of high-efficiency gas instant water heaters, and the field of gas-fired high-efficiency water heaters with variable elevation, to achieve the effect of avoiding waste of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

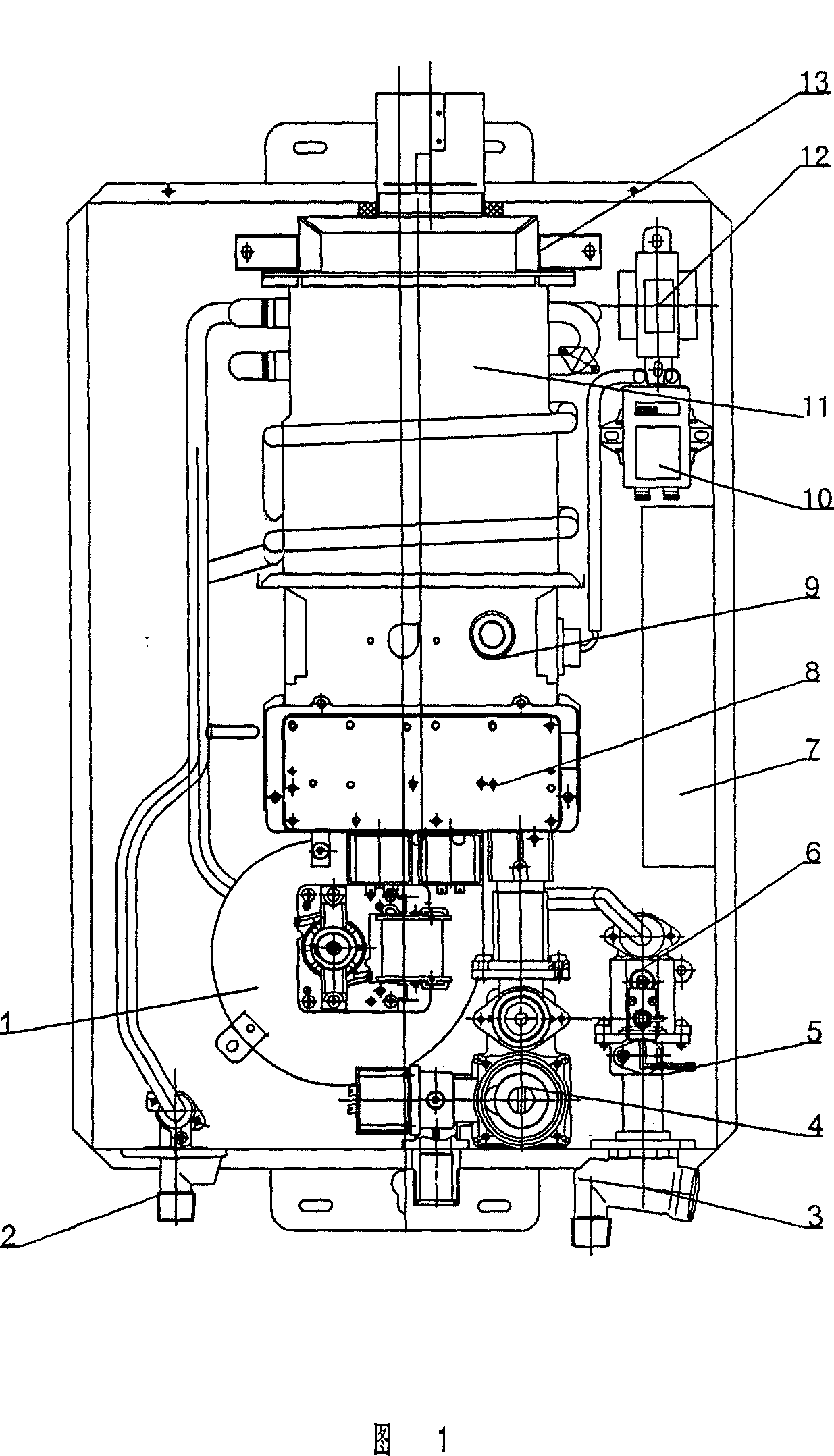

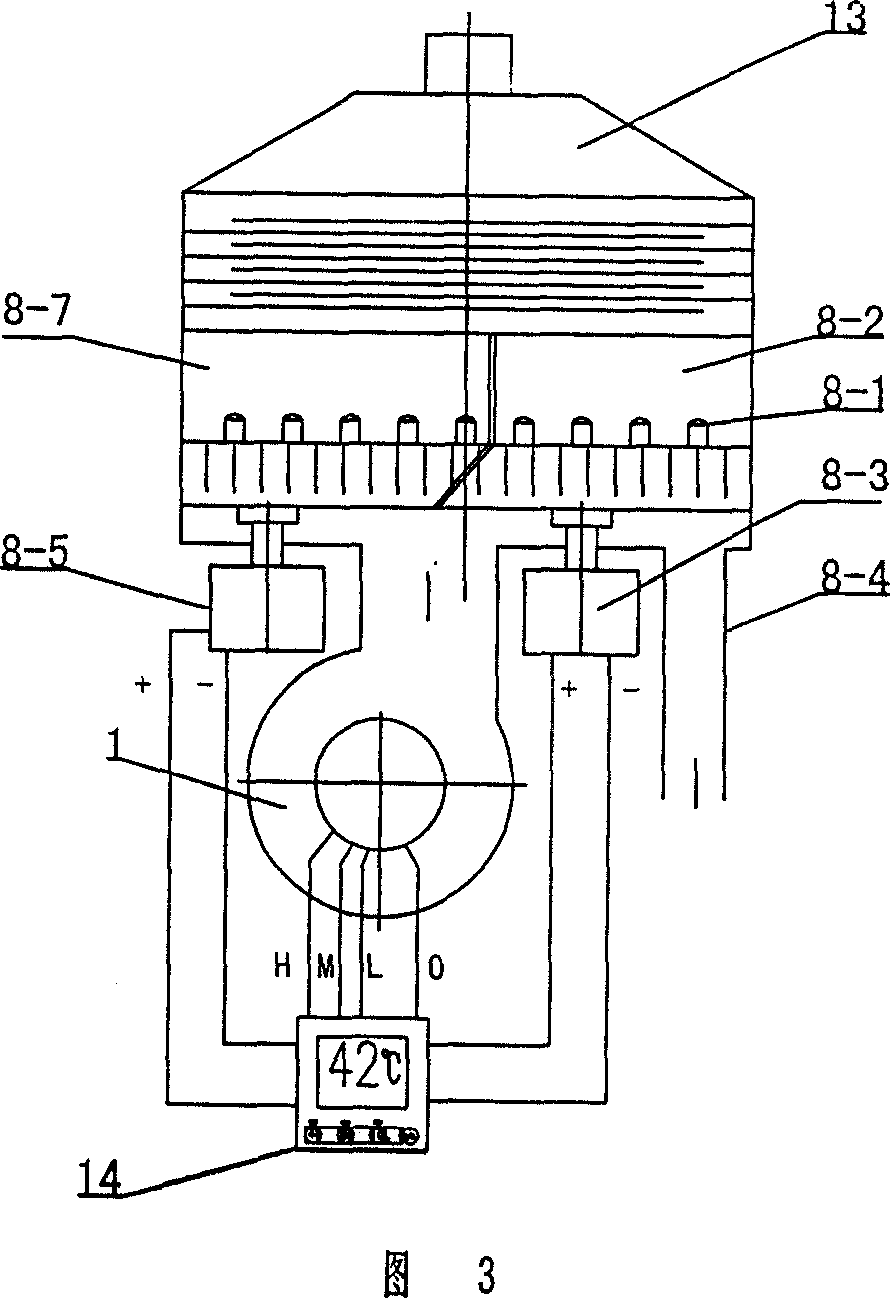

[0021] The gas-fired high-efficiency water heater with variable elevation in this embodiment is designed according to the above-mentioned variable elevation method. The structure is shown in FIG. A water flow sensor 5 and a water valve 6 are connected above the water inlet joint. A combustion chamber 9 is arranged below the heat exchanger, and an ignition head on one side of the combustion chamber 9 is electrically connected to an igniter 10 via a transformer 12 . A controller 7 is installed on one side of the housing. A row of combustion heads is housed in the combustion chamber 9. These structures are basically the same as the prior art.

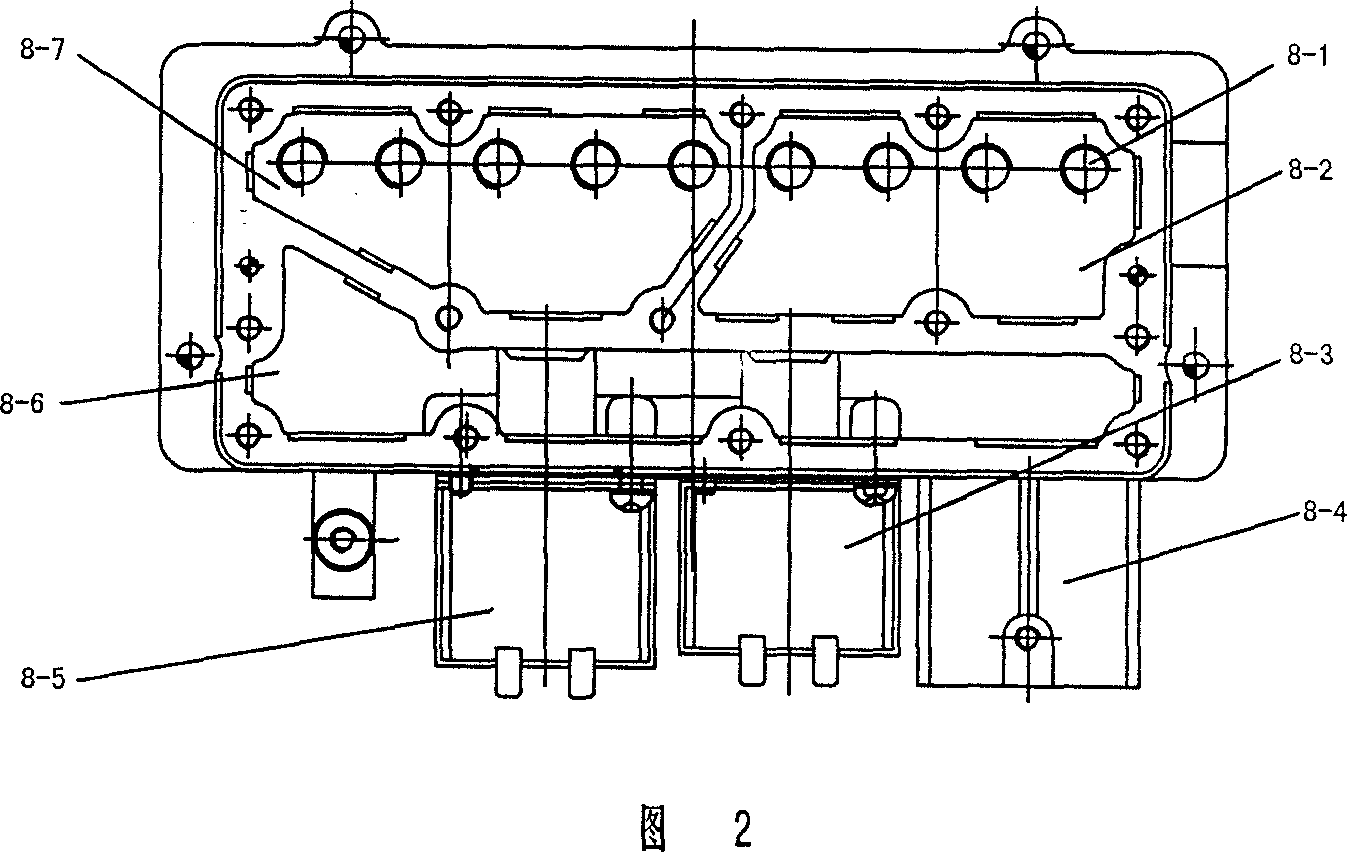

[0022] Each combustion head in the combustion chamber 9 is respectively connected to the corresponding gas distribution nozzle 8-1 in the gas distribution chamber 8. The structure of the distributing chamber is shown in Figure 2. It is divided into left and right air chambers and a uniform air chamber connected to the lower part. There ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com