Electric heating film inner pot

An electric heating film and electrode technology, which is used in heating devices, cooking utensils, household appliances, etc., can solve the problems of consumers worrying about the sealing of sockets, the danger of electric shock, and foreign objects stuck in sockets, so as to ensure the safety and convenience of use. , The effect of ensuring safety and convenience, and eliminating concerns about use

Active Publication Date: 2011-03-30

ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

View PDF9 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

1. As in CN201418654, the exposure of the electric heating tube makes consumers question its cleaning and worry about the risk of electric shock. Moreover, if the electric heating element such as the electric heating tube or the electric heating film is exposed, once the pot body is hit, it is easy to cause the electric heating tube or the electric heating film to be damaged.

2. Self-heating pots such as CN1094934 are electrically connected at the bottom, and sockets must be installed at the bottom. The appearance is quite different from the inner pots of existing products. Consumers question its cleaning and worry about the risk of electric shock. For products such as electric rice cookers or electric pressure cookers, the lower part of the pot body of the electric rice cooker or electric pressure cooker sometimes needs to be immersed in water for cleaning, which causes consumers to worry about the sealing of the socket, and at the same time, they are also worried that foreign objects will get stuck in the socket and cause problems in use.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

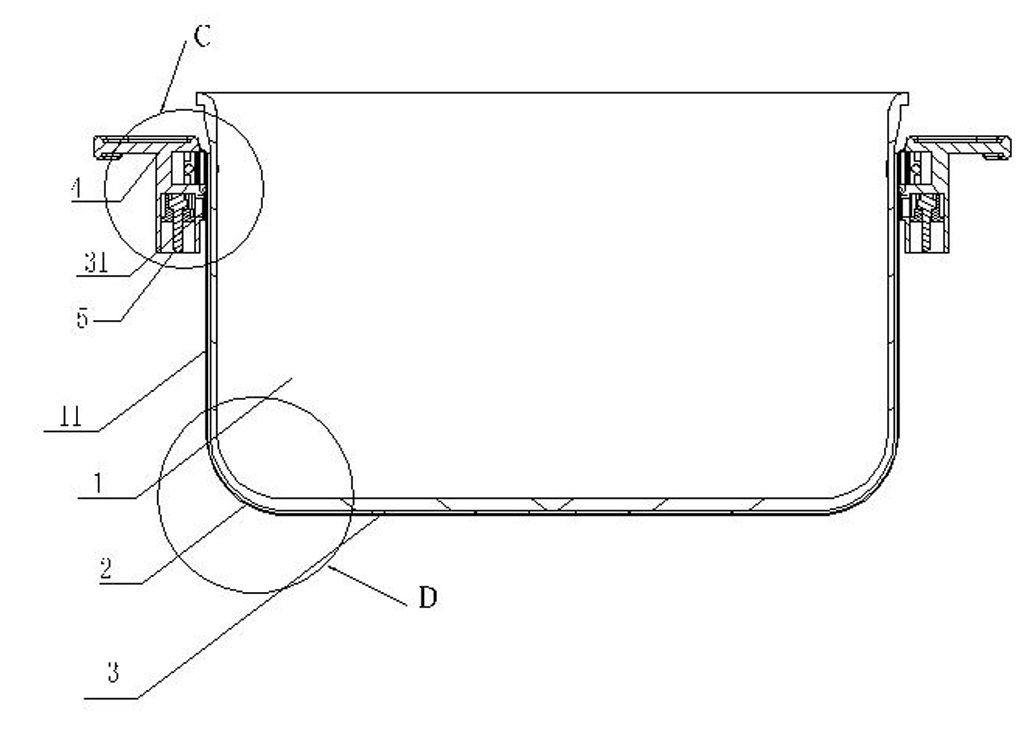

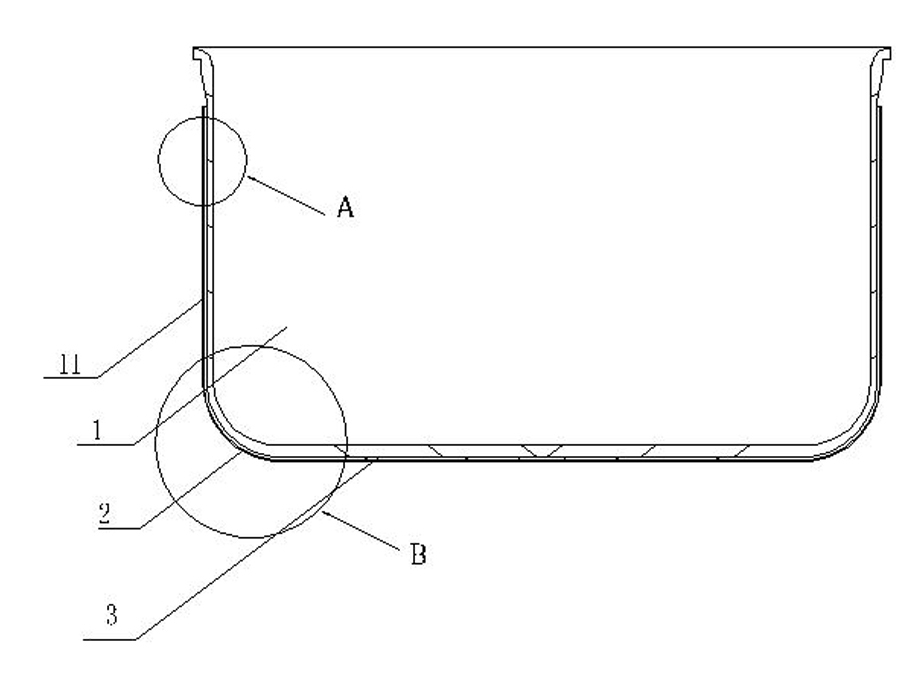

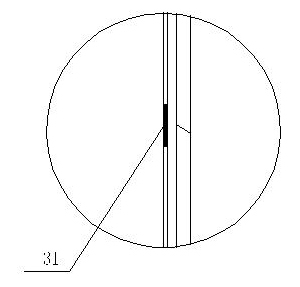

The invention relates to an electric heating film inner pot, belonging to the technical field of electric cooking appliances, and comprising an open concave container formed by a pot wall and a pot bottom, which is characterized in that an electric heating film, an electrically connected electrode of the electric heating film connected with a power supply, and an insulation protecting layer on the external surface of the electric heating film are printed on the external surface of the concave container; and the electrically connected electrode of the electric heating film is arranged on the pot wall and connected with the power supply through an electric connector. In the electric heating film inner pot of the invention, the electric heating film is basically printed on the external surface of the whole pot body, thus the heating efficiency is high; the electrically connected electrode of the electric heating film is arranged on the side part and even the upper side part of the pot wall, so the worry of a user in cleaning is eliminated; and the complete machine has great advantages on the manufacturing cost and the appearance.

Description

Electric heating film inner pot technical field The invention belongs to the technical field of electric heating cookers, and in particular relates to an electric heating film inner pot. Background technique In the existing electric cooking utensils, the pot is an ordinary pot body and a self-heating pot body made of stretched metal materials. The heat generation of the ordinary pot body is mainly through the electric heating device (electric heating plate or electric heating plate) at the bottom of the pot body. , The pot body transfers heat through contact with the electric heating device. Because the ordinary pot body relies on contact heat transfer, its thermal efficiency is not high, and the electric heating device has the problem of thermal upshoot after power off, it is difficult to achieve precise control in control, which affects the cooking effect. The self-heating pot body is welded with a heating tube or an electric heating film at the bottom of the ordinary po...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A47J27/00A47J36/24

Inventor 蔡才德高晖

Owner ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com