Excavating tooth component, tooth holder and bucket teeth

A technology of excavating teeth and bucket teeth is applied in the field of fixed connection structure of bucket teeth and tooth bases, which can solve the problems of inconvenient installation, need for strong percussion, large size interference, etc., and achieve the effect of reducing the possibility of wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

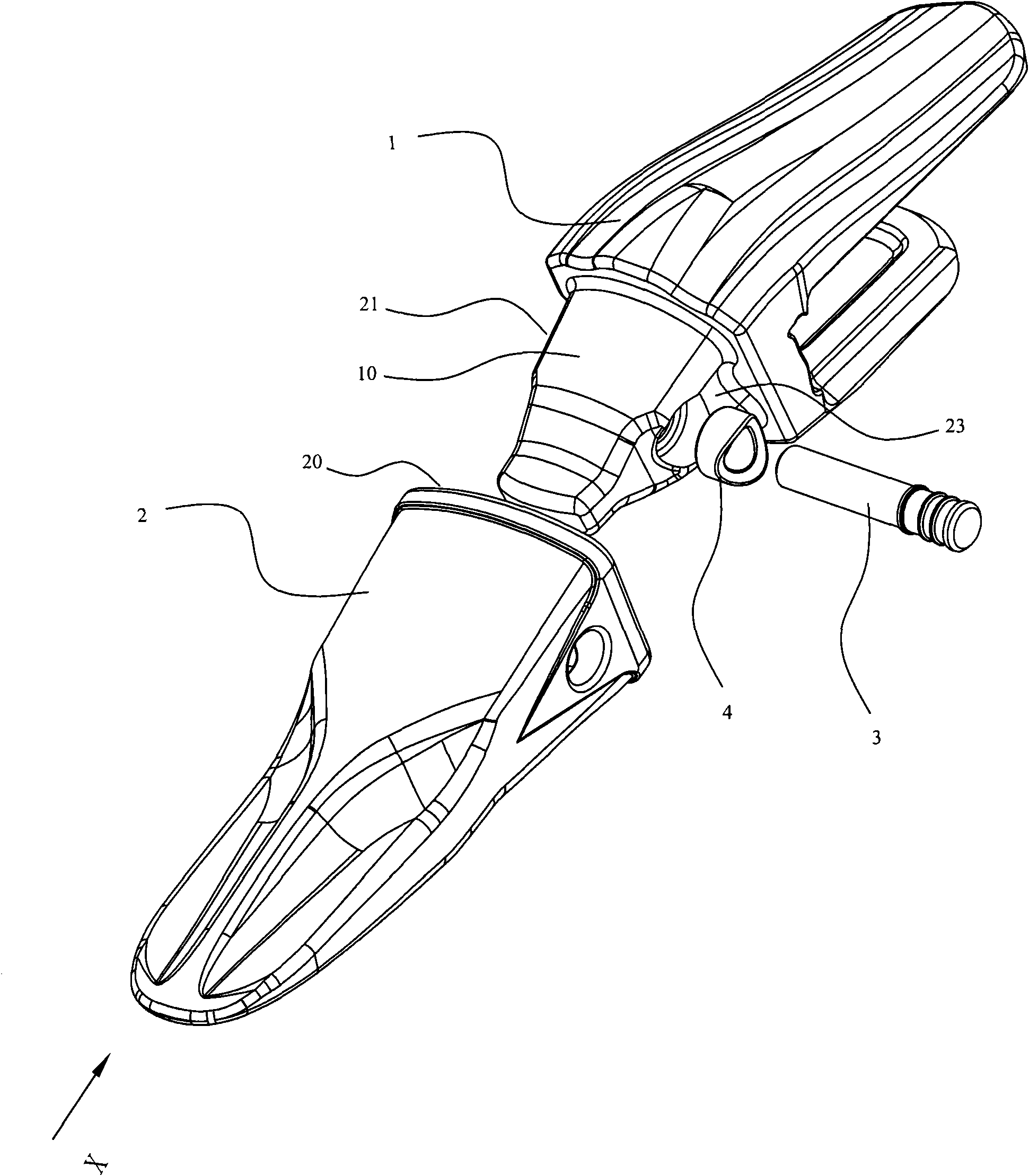

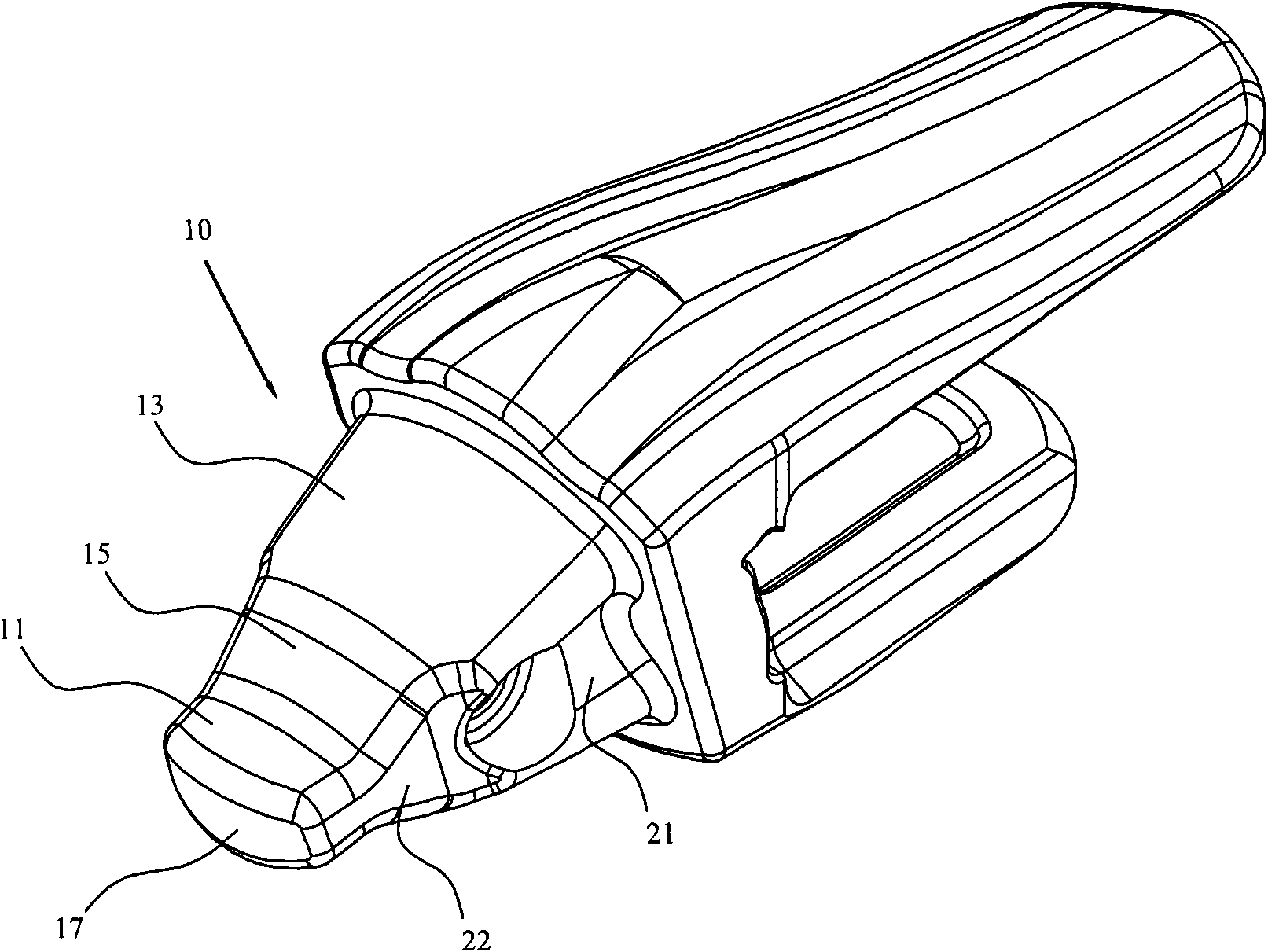

[0035] Such as figure 1 , figure 2 and Figure 4As shown, an embodiment of the excavating tooth assembly includes a tooth holder 1, a bucket tooth 2, a pin 3 and a rubber ring 4. The front end of the tooth holder 1 is provided with a tooth holder head 10, and the rear end of the bucket tooth 2 is provided with a cavity 20. , cavity 20. Another example Figure 5 As shown, the tooth holder head 10 is accommodated in the cavity 20, and the cavity 20 of the bucket tooth 2 and the tooth holder head 10 are firmly combined together through the locking member.

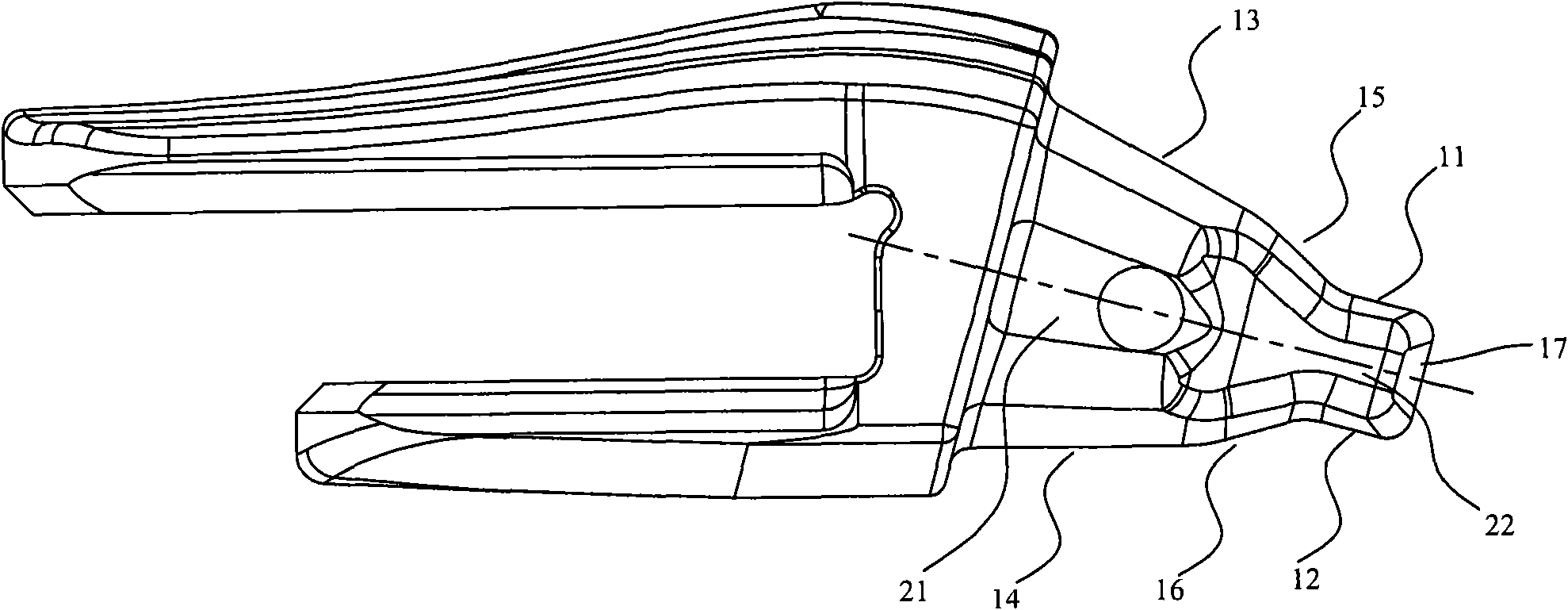

[0036] Such as figure 2 and image 3 As shown, the upper part of the tooth seat head 10 is provided with a first mating surface 13, a first transitional connection surface 15 and a third mating surface 11, and the lower part of the tooth seat head 10 is provided with a second transitional connection surface 16 and a second mating surface 14. and the fourth mating surface 12, the first mating surface 13 and the third ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com