Limiting structure of S-shaped piping system

A technology of limiting structure and serpentine tube, which is applied in steam boiler components, steam boiler accessories, steam boilers, etc., can solve problems affecting boiler thermal efficiency and tube deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

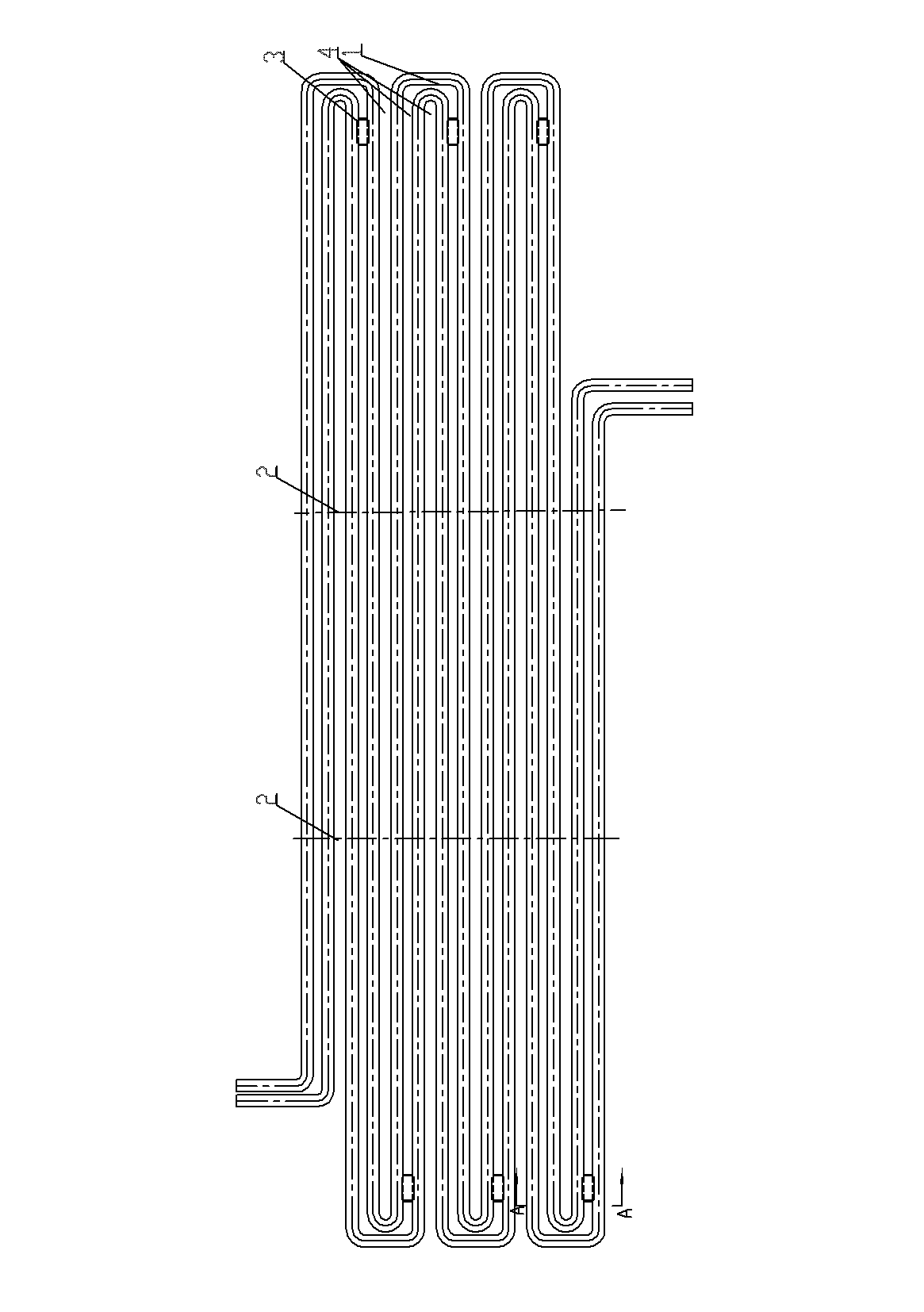

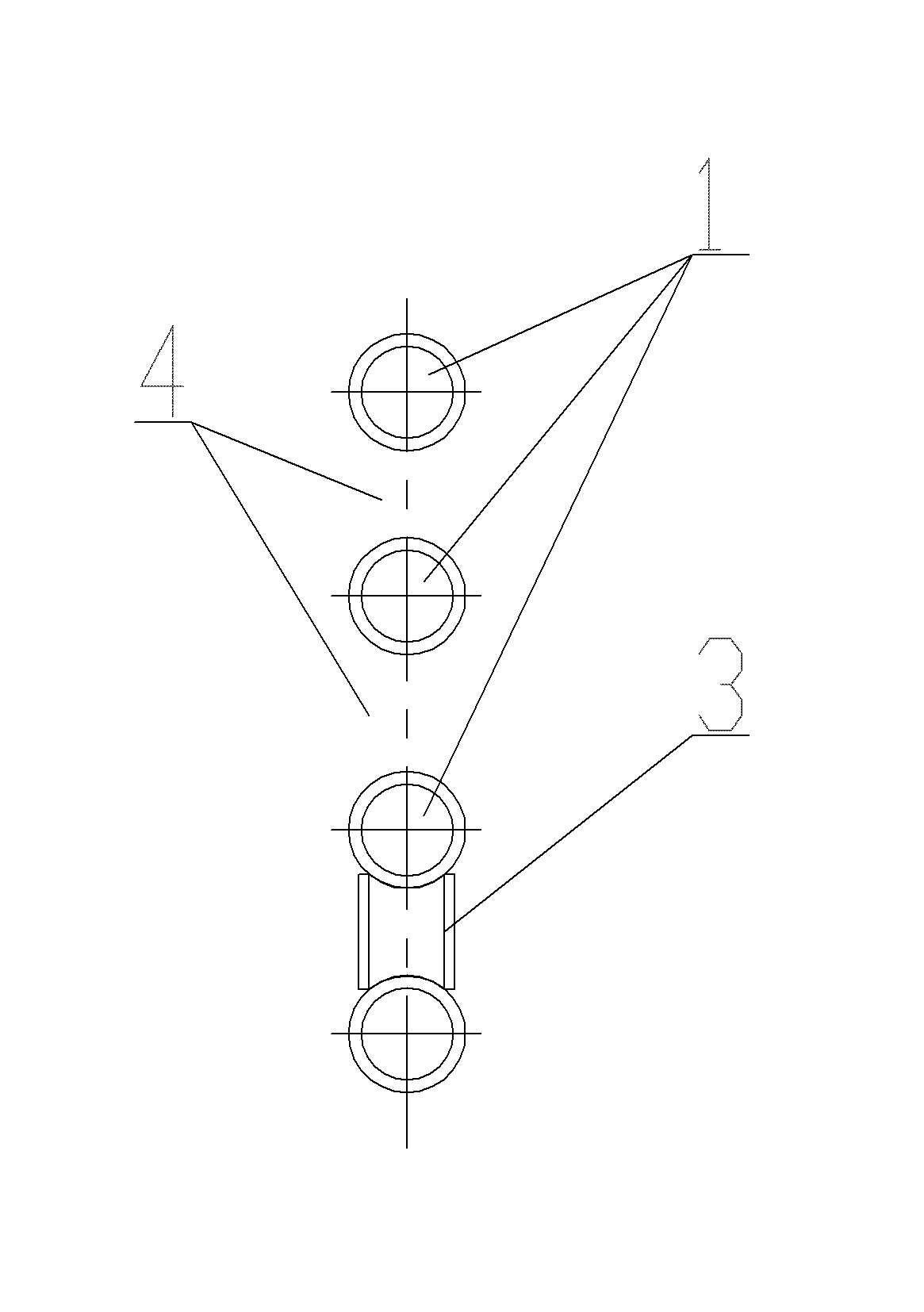

[0010] See figure 1 , figure 2 , which includes a horizontally arranged serpentine tube 1, the horizontal section of the serpentine tube 1 is relatively long, and the upper and lower layers of the serpentine tube 1 are hoisted on the upper beam by a hoisting assembly 2 (not shown in the figure, which belongs to the existing Mature technology), the hoisting assembly 2 is located in the middle of the horizontal section of the serpentine tube 1, and the upper and lower layers of the two ends of the horizontal section of the serpentine tube 1 are spaced with a limit block 3, and the upper side of the limit block 3 is welded. Its upper floor serpentine pipe, the lower side of the limit block 3 is welded to connect the serpentine pipe of its lower floor.

[0011] The specific interval setting method of the limit block 3 is as follows: the upper and lower layers of each end in the two ends of the horizontal section of the serpentine tube 1 are spaced after three vacancies, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com