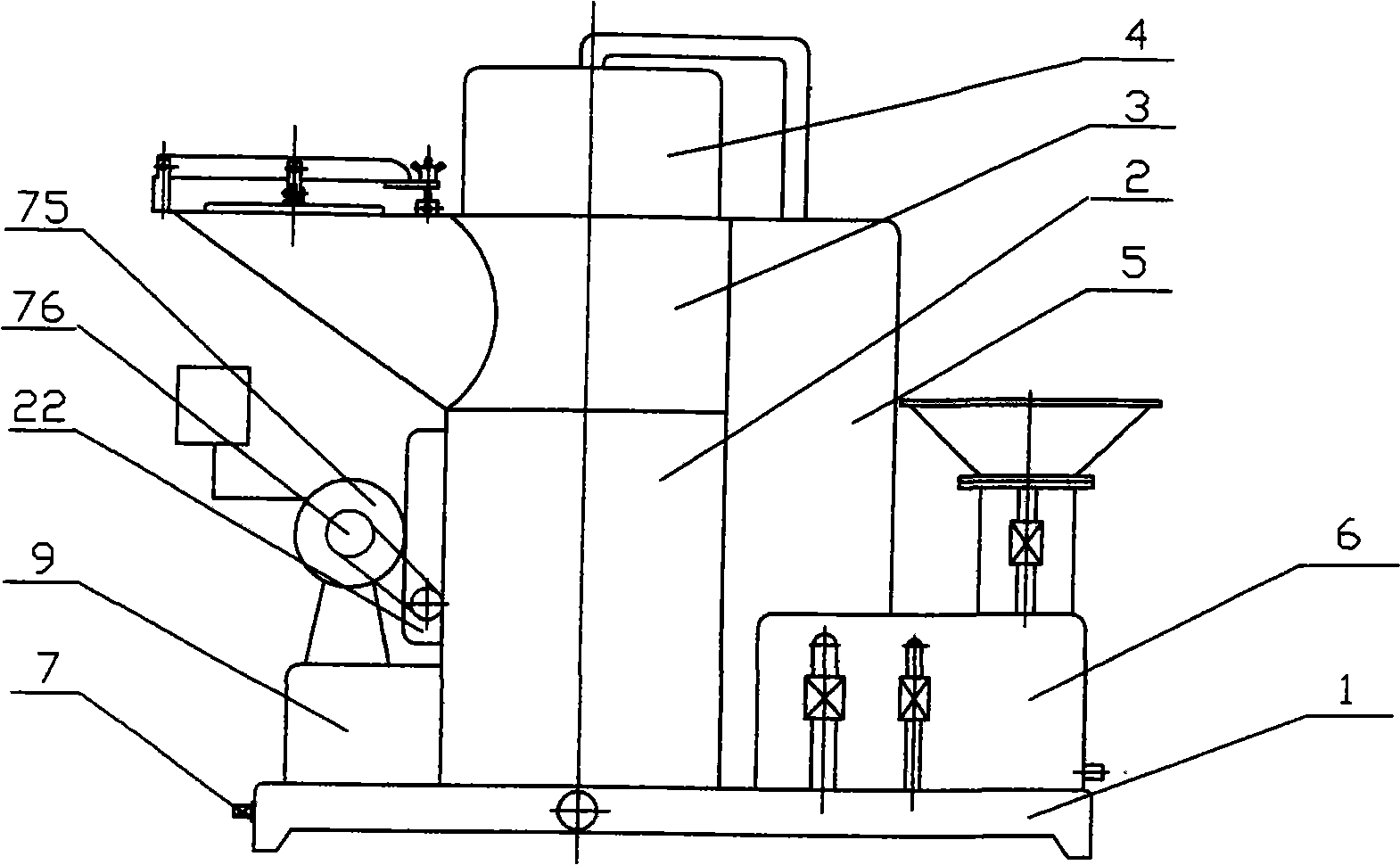

Process and apparatus for producing biomass gas

A technology for biomass gas and preparation equipment, which is applied in special forms of dry distillation, petroleum industry, coking oven, etc. It can solve problems such as excessive water vapor, blockage of gas equipment, pipelines, and stoves, and large amount of tar in gas, so as to achieve gas production Good effect, guaranteed thermal efficiency, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

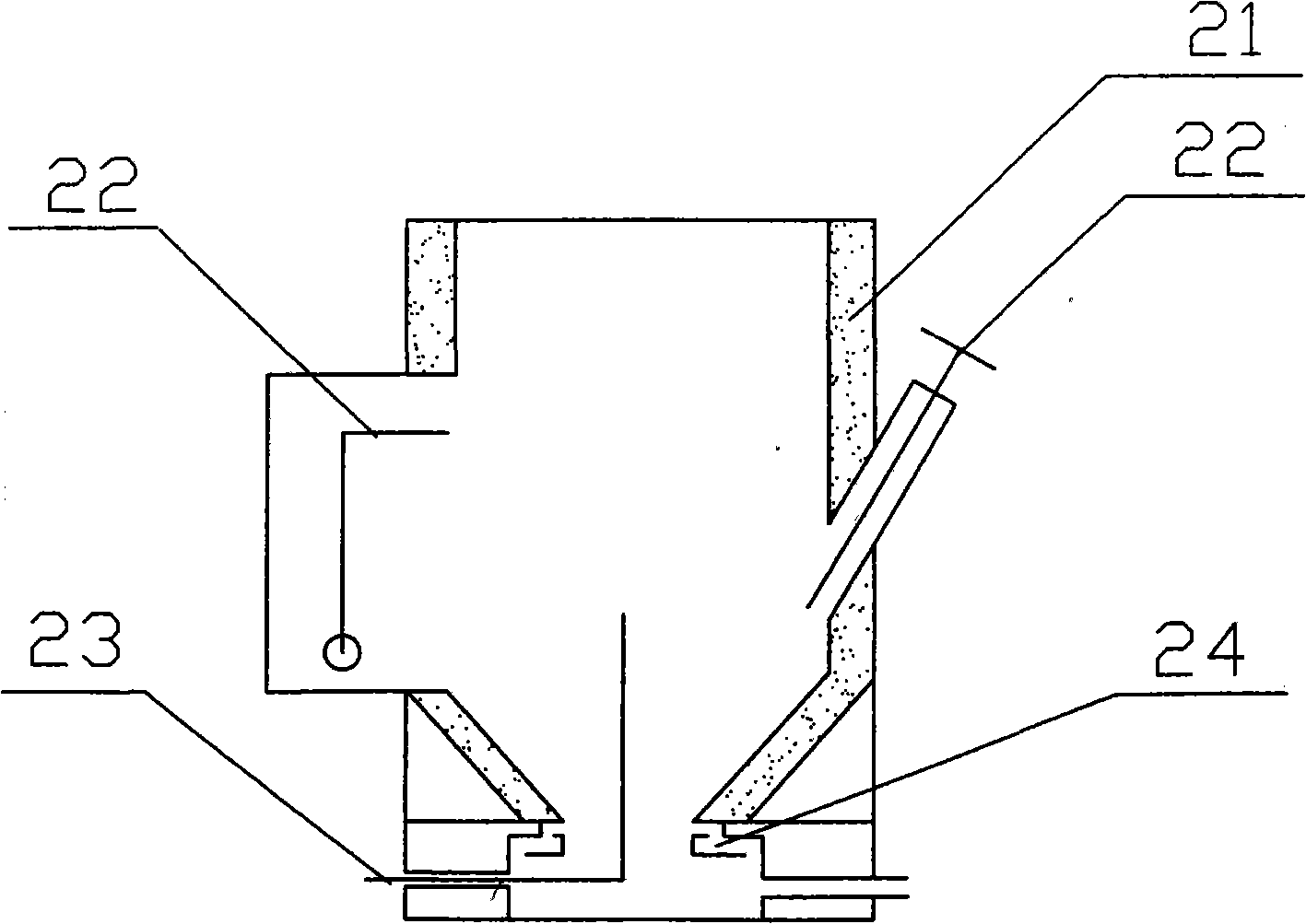

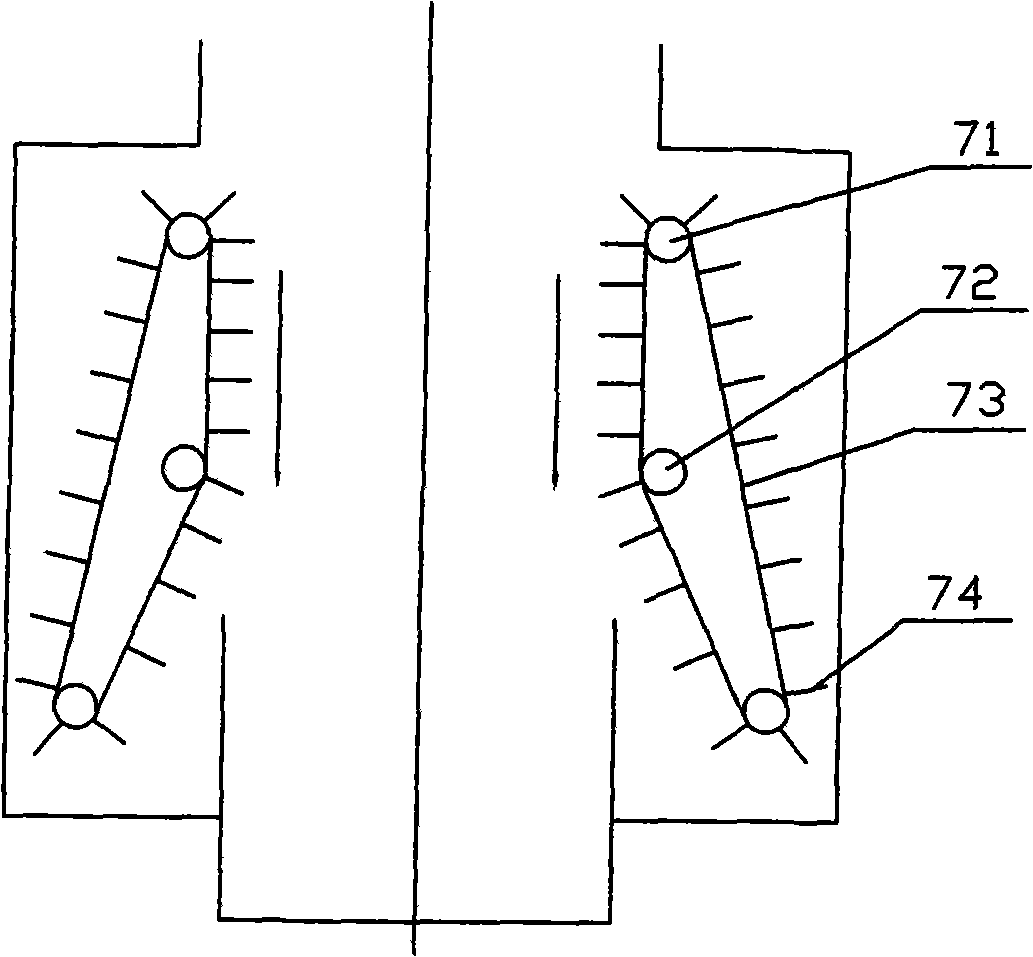

[0030] Put the biomass raw material into the gas production chamber for pyrolysis to generate mixed gas; the raw material of biomass can be various crop straws, firewood, firewood, sawdust, leaves, livestock manure produced by professional breeding households, and waste materials from professional breeding households , Chinese herbal medicine residue, waste plastic products, household garbage, etc.; the mixed gas generated after pyrolysis is filtered to remove tar and fly ash; at the same time, the tar is cracked to generate combustible gas; the combustible gas is separated from water and separated Moisture in the combustible gas; the combustible gas separated from the moisture is deodorized, and the deodorized combustible gas is available for use.

[0031] Its technological process is:

[0032] Step 1, pyrolysis-→step 2, tar cracking-→step 3, water removal-→step 4, odor removal.

[0033] Step 1. Pyrolysis: Send the raw materials into the gas production chamber for pyrolysis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com