Heat-conducting silica gel and preparation method thereof

A heat-conducting silicon and gel technology, which is applied in the field of heat-conducting silicon gel and its preparation, can solve the problems of drying out and achieve the effects of simple use, guaranteed heat conduction efficiency, and outstanding durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

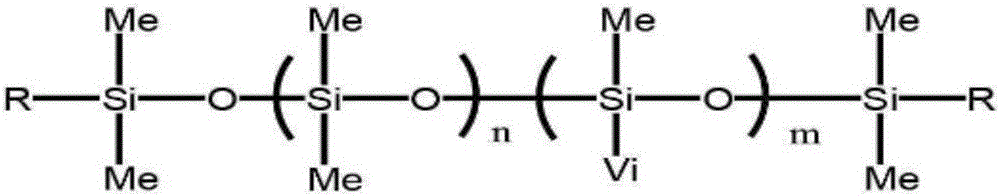

Method used

Image

Examples

preparation example Construction

[0051] The present invention also proposes a preparation method of the aforementioned thermally conductive silicone gel, the preparation method comprising the following steps:

[0052] mixing the base polymer, filler, silane coupling agent, and plasticizer to obtain a mixture;

[0053] heating the mixture to 120-160° C. for dehydration for 1-3 hours under vacuum to obtain the base material;

[0054] cooling the base to room temperature;

[0055] Adding inhibitor, crosslinking agent and catalyst to the base material in turn, and stirring evenly under vacuum condition;

[0056] Keeping it under vacuum condition at 80-150° C. for 30-60 minutes can obtain the thermally conductive silicone gel of the present invention.

[0057] The selection of vacuum conditions in the preparation method of the thermally conductive silicone gel of the present invention can make small molecular components such as water in the preparation process of the thermally conductive silicone gel more easily...

Embodiment 1

[0061] Mix 100 parts of base polymer vinylpolymethylvinylsiloxane with a dynamic viscosity of 100mPa·s at 25°C and a vinyl content of 5%, 850 parts of aluminum oxide, 250 parts of zinc oxide, 28 parts of Layer graphene powder, 0.2 parts of polydimethylsiloxane with a dynamic viscosity of 500mPa·s at 25°C, and 2 parts of (3-acryloyloxypropyl) trimethoxysilane were added to a kneader and mixed in a vacuum Heating to 130°C for 3 hours to dehydrate under the same conditions to obtain the base material;

[0062] Cool the base material prepared in the above steps to room temperature, add 0.01 parts of dimethylhexynol, 1 part of methyl hydrogen polysiloxane with a hydrogen content of 0.10%, and 10 parts of polysiloxane with a hydrogen content of 0.10% Terminal hydrogen-containing polysiloxane, 0.1 part of platinum catalyst with a concentration of 2000 ppm, after vacuum stirring evenly, keep at 150° C. under vacuum condition for 30 minutes to obtain thermally conductive silicone gel. ...

Embodiment 2

[0064] 100 parts of base polymer vinylpolymethylvinylsiloxane with a dynamic viscosity of 400mPa·s at 25°C and a vinyl content of 2%, 700 parts of aluminum oxide, 150 parts of zinc oxide, and more than 16 parts layer graphene powder, 1 part of hydrophilic fumed silica, 0.5 part of MDT polysiloxane with a dynamic viscosity of 400 mPa·s at 25 °C, 10 parts of (3-glycidoxypropyl) trimethoxy Add the silane to the kneader and mix, then heat to 150°C for 2 hours under vacuum to dehydrate to obtain the base material;

[0065] Cool the base material prepared in the above steps to room temperature, add 0.05 parts of acetylene cyclohexanol, 3 parts of methyl hydrogen polysiloxane with a hydrogen content of 0.18%, and 3 parts of end-containing polysiloxane with a hydrogen content of 0.08% Hydrogen polysiloxane, 2 parts of platinum catalyst with a concentration of 2000ppm, after vacuum stirring evenly, keep at 100°C under vacuum condition for 40min to obtain thermally conductive silicone g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com