Environment-friendly type carbonaceous press material for maintaining blast furnace hearth

An environmentally friendly blast furnace technology, applied in the field of ironmaking refractory materials, can solve environmental pollution and other problems, and achieve the effects of ensuring thermal conductivity, small linear expansion coefficient, and anti-erosion and penetration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] The above-mentioned various dry raw materials are weighed and batched according to the stated ratio, mixed evenly, then added with a liquid binder and stirred evenly, and can be applied at the production site after being sealed and packaged.

[0037]

Example 1

Example 2

Example 3

15

25

35

Flake graphite<0.074mm

32

26

20

11

8

4

Quartz<0.154mm

15

10

5

Boron carbide <0.044mm

3.0

2.0

1.0

Environmental modified tar 24~35

24

29

35

[0038] To analyze the performance of the pressed material, the material test method refers to the corresponding national standard or industry standard for refractory materials.

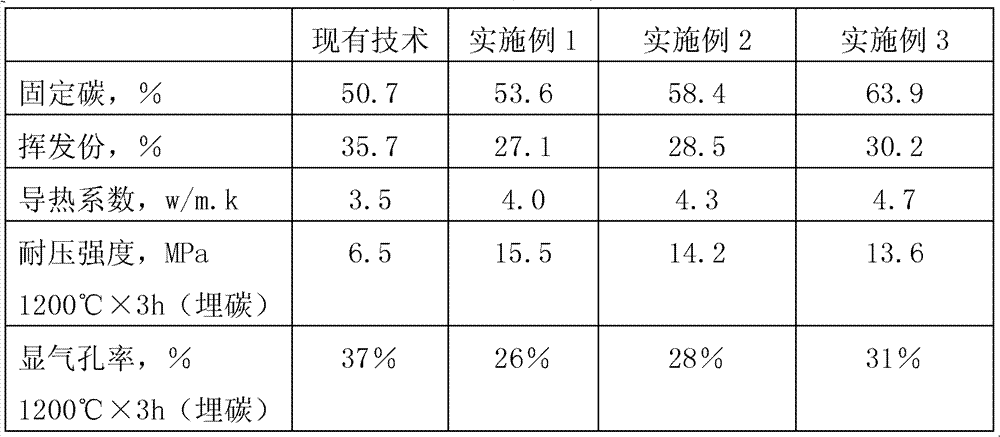

[0039] The measured value of the technical index of the press-feed material

[0040]

[0041] The environmentally friendly carbonaceous press-f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com