Deacidification type organic silicone adhesive and preparation method thereof

A silicone adhesive, deacidification technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of difficult preservation, slow curing speed, erosion of plastics, etc., to achieve large heat absorption, reduce Combustion gas concentration, effect of reducing high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

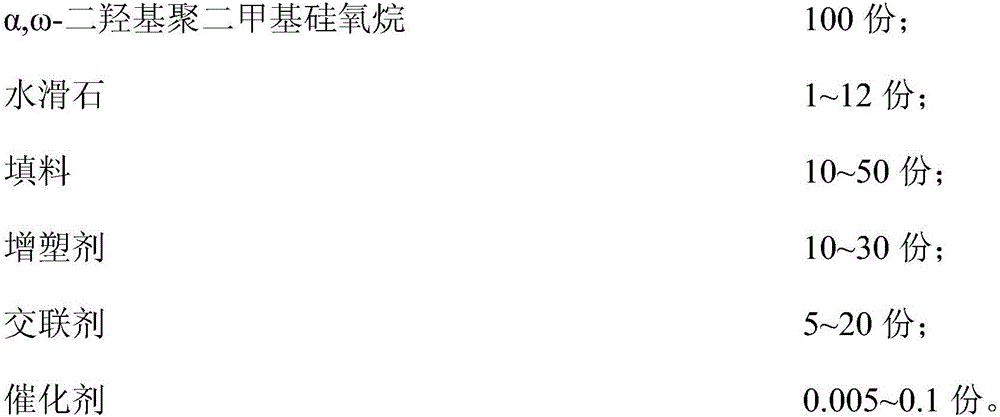

[0047]A deacidification type silicone adhesive, the raw materials of the deacidification type silicone adhesive include by weight:

[0048]

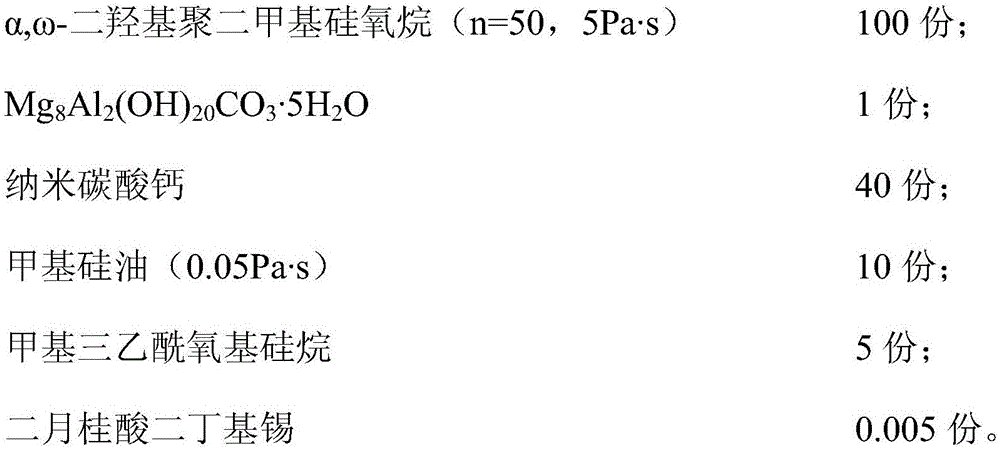

[0049] α,ω-Dihydroxypolydimethylsiloxane (n=50, 5Pa·s), Mg 8 al 2 (OH) 20 CO 3 ·5H 2 O and nano-calcium carbonate, at a temperature of 150 ° C, a vacuum of 0.085 MPa, dehydration, blending and kneading for 200 minutes, cooling to obtain the base material, and then adding methyl silicone oil (0.05Pa·s) to the base material, stirring at 200 rpm for 200 min, and then adding Methyltriacetoxysilane was stirred at 200 rpm for 200 min, and finally dibutyltin dilaurate was added and stirred at 200 rpm for 200 min.

Embodiment 2

[0051] A deacidification type silicone adhesive, the raw materials of the deacidification type silicone adhesive include by weight:

[0052]

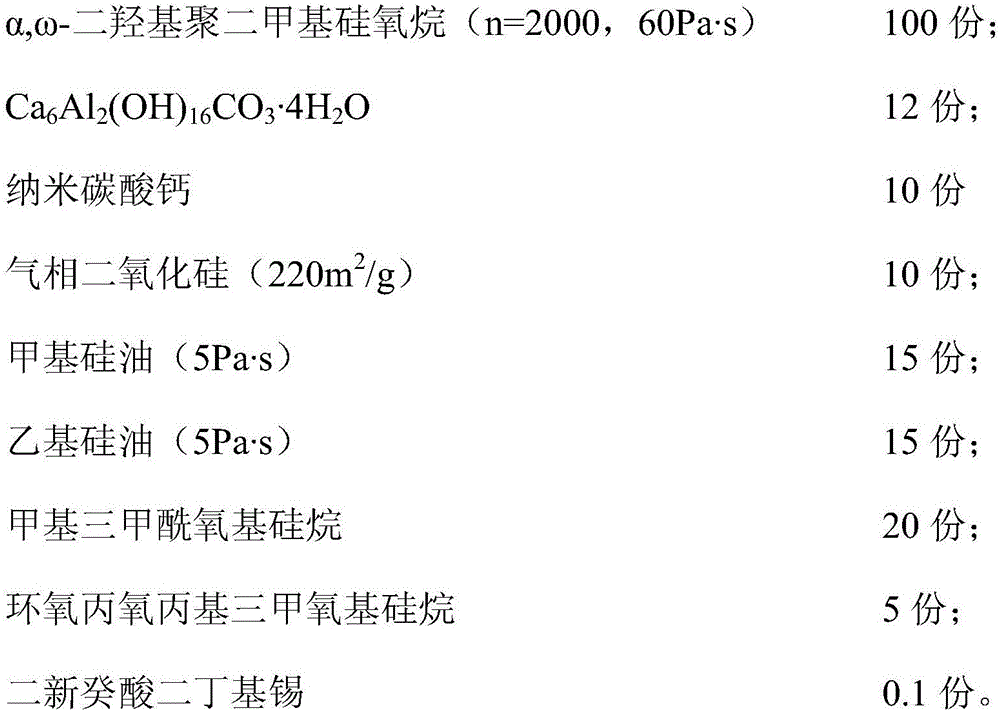

[0053] α,ω-Dihydroxypolydimethylsiloxane (n=2000, 60Pa·s), Ca 6 al 2 (OH) 16 CO 3 4H 2 O, nano calcium carbonate and fumed silica (220m 2 / g), at a temperature of 150°C, a vacuum of 0.098MPa, dehydration blending and kneading for 120min, cooling to obtain the base material, and then adding methyl silicone oil (5Pa·s) and ethyl silicone oil (5Pa·s) into the base material, 600rpm Stir at low temperature for 60min, then add methyltriformyloxysilane and glycidoxypropyltrimethoxysilane, stir at 600rpm for 60min, finally add dibutyltin dineodecanoate, and stir at 600rpm for 60min.

Embodiment 3

[0055] A deacidification type silicone adhesive, the raw materials of the deacidification type silicone adhesive include by weight:

[0056]

[0057]

[0058] α,ω-Dihydroxypolydimethylsiloxane (10Pa·s), Mg 4.5 al 2 (OH) 13 CO 3 3.5H 2 O and nano-calcium carbonate, at a temperature of 120 ° C, a vacuum of 0.09 MPa, dehydration, blending and kneading for 150 minutes, cooling to obtain the base material, then adding methyl silicone oil (0.1Pa·s) to the base material, stirring at 400 rpm for 120 min, and then adding Methyltriacetoxysilane and aminopropyltriethoxysilane were stirred at 400rpm for 120min, and finally dibutyltin dilaurate was added and stirred at 450rpm for 100min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com