Sectional coke and its production method and pressure forming equipment

A technology of molding equipment and coke preforming, which is applied in the field of coke, can solve the problems such as unresolved difficulties in demoulding molded products and molds, the inability to add spacers, and adhesion of spherical coke, so as to solve the problems of adhesion and deformation and improve The effect of temperature and density improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

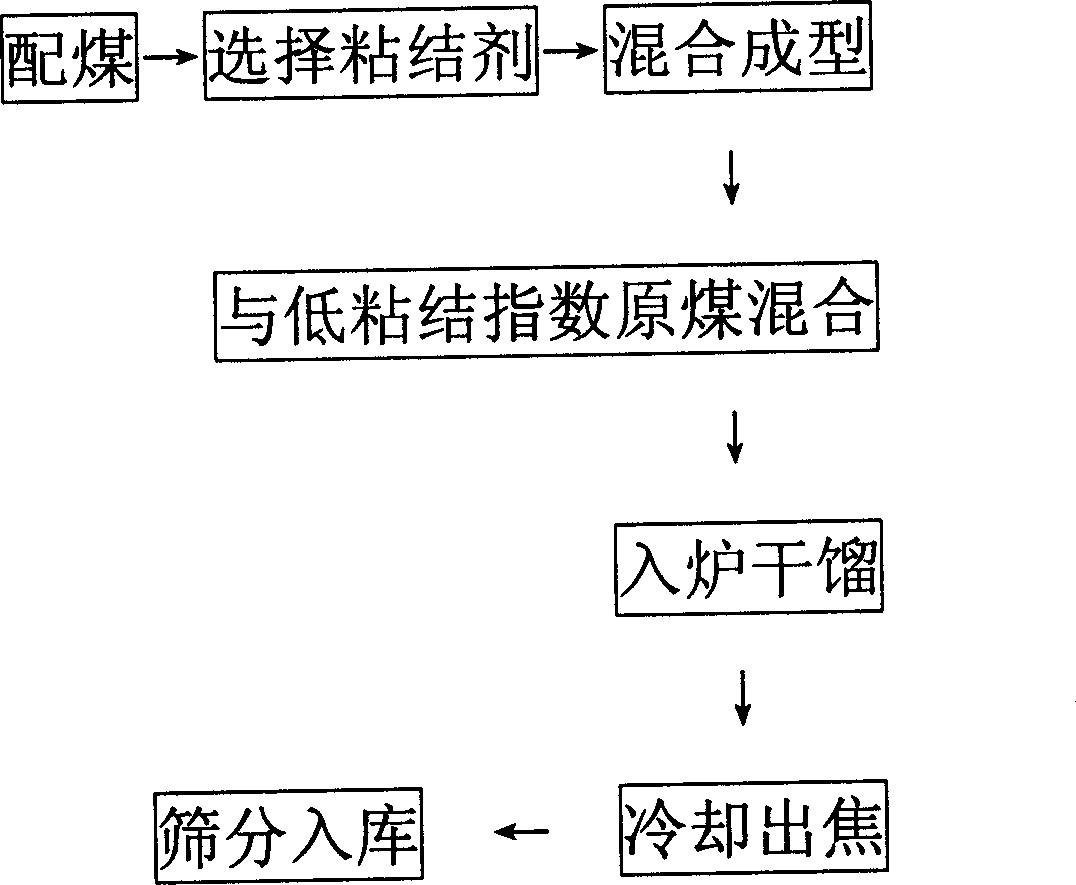

[0037] Example 1 selects 20 tons of No. 2 main coking coal from Guxian County, Shanxi Province with a caking index of 84, 25% volatile content and 8% ash; 60 tons of calcined anthracite with a caking index of 0, 1.5% volatile content and 10% ash. tons; 20 tons of calcined pitch coke with a cohesive index of 0, a volatile content of 1.3%, and an ash content of 0.5% were mixed and pulverized until the particle size was less than 10 mm, and 100 tons of shaped coke raw materials were obtained.

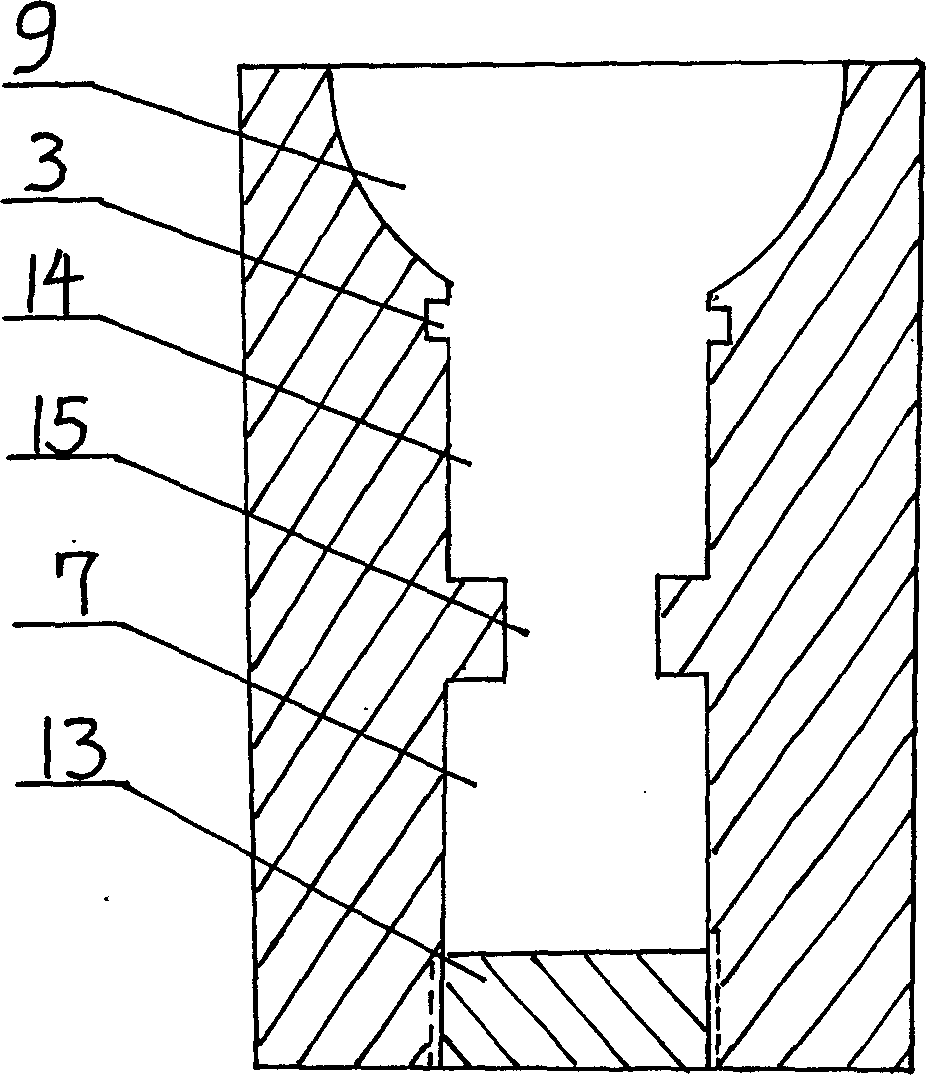

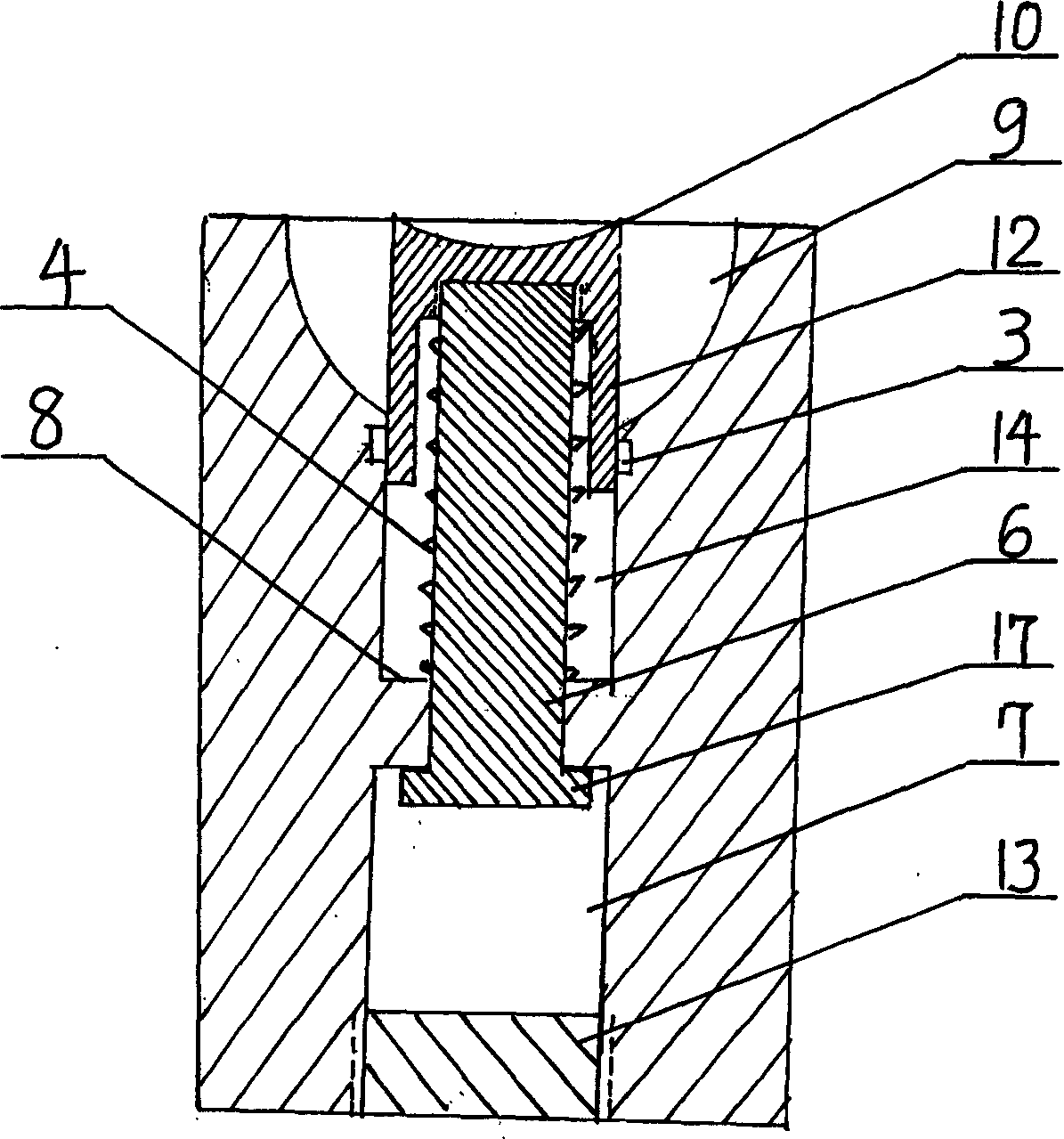

[0038] The above raw materials plus 8 tons of pitch coke were heated to 120°C and mixed. Pressurize to 50kg / cm with a pressure forming machine 2 Molding under the conditions, the mold is spherical, with a diameter of 100mm, and 100 tons of coke preformed products are obtained after all molding. The preformed product is mixed with 30 tons of anthracite coal with a cohesive index of 10 and a particle size of less than 15mm, and is charged into a coke oven at a temperature of 850°C for carbo...

Embodiment 2

[0039] Example 2 Take 200 tons of coke powder with a particle size of less than 20mm, add 14 tons of tar, mix at a temperature of 100°C, and pressurize to a pressure of 350kg / cm in a pressure molding machine 2 , Model selection oval, long diameter 250mm, short diameter 200mm. 214 tons of molded coke preforms and 130 tons of Shanxi Shouyang lean coal with a caking index of 15 and a particle size of 5mm were mixed into the furnace for carbonization. 210 tons of molded coke and 118 tons of coke powder were obtained.

Embodiment 3

[0040] Embodiment 3 The molding pressure of the coke preformed product of this example is 250kg / cm 2 , the shape is olive-shaped, the length of both ends is 150mm, and the middle diameter is 100mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com