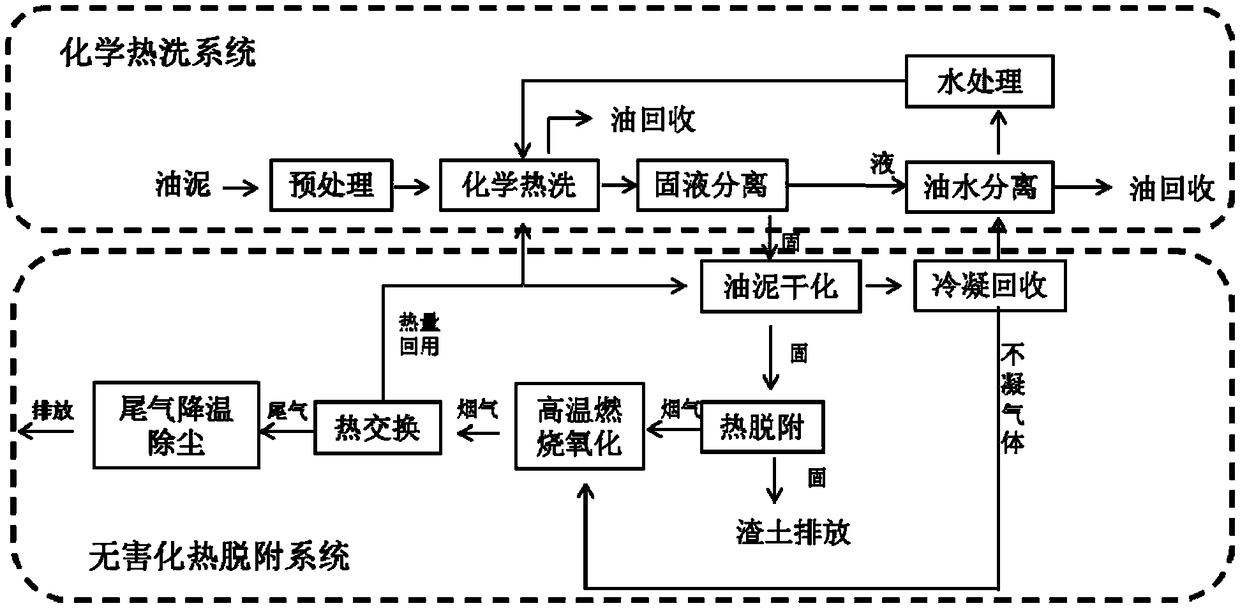

Green cleaning-thermal desorption integrated technology treatment method and treatment system for high-concentration petroleum sludge

A petroleum sludge, technical treatment technology, applied in sludge treatment, dehydration/drying/concentrated sludge treatment, water/sludge/sewage treatment, etc. Waste oil resources and other problems, to achieve the effect of operating temperature and residence time, high oil recovery rate and high desorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

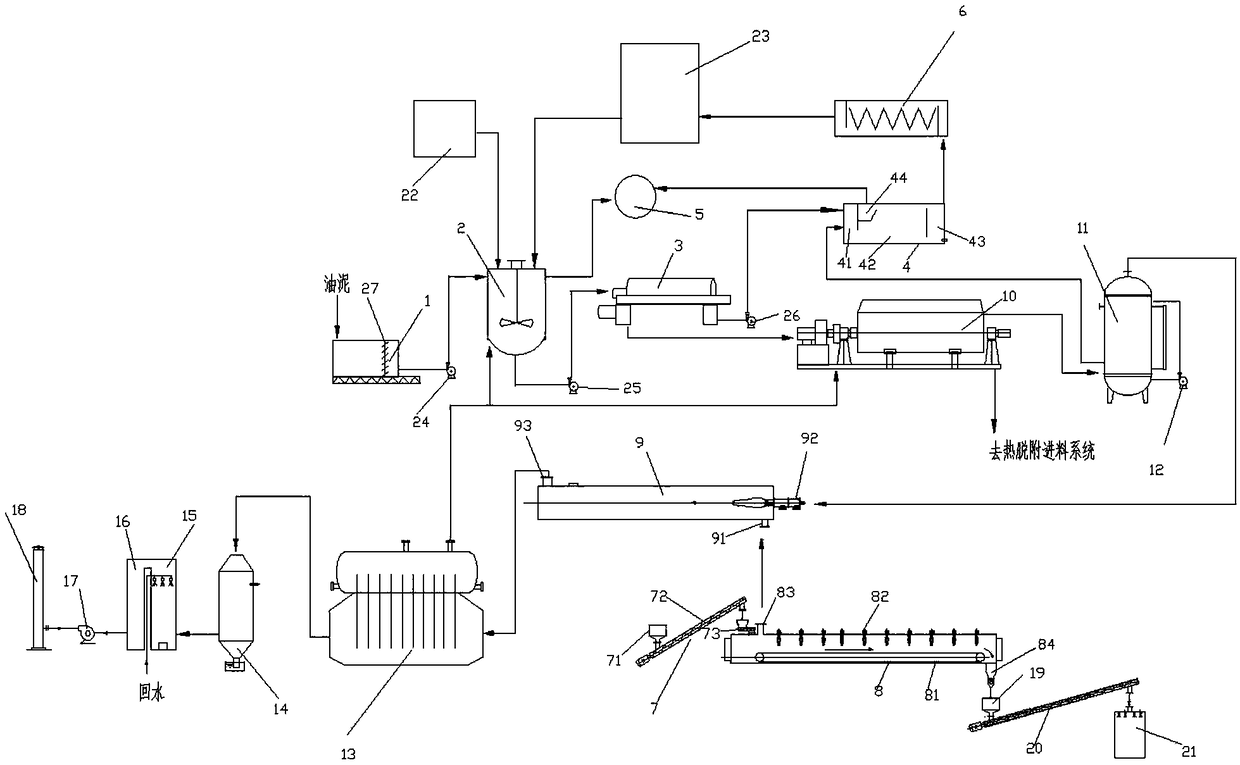

[0058] Taking the oil sludge at the bottom of an oilfield as the processing object, its moisture content is 50%, oil content is 18%, and the average particle size is less than 5mm. After being treated by the high-efficiency solid-liquid separator, the moisture content of the sludge is 65%, and the oil content of the sludge is reduced to 6%; after being dried, the moisture content of the sludge is reduced to 20%, and the dried sludge is sent by the feeding system to the metering hopper and fall onto the stainless steel track in the thermal desorption system. The temperature range of the oil sludge in the thermal desorption chamber is controlled to be 500-700°C, and the residence time is 20 minutes. The temperature of the high-temperature combustion chamber is controlled at 1100°C. 2s. The oil content of the slag after thermal desorption is 220mg / kg, and the removal rate reaches 99.69%. The dioxin content in the flue gas purified by thermal desorption tail gas is less than 0.1TE...

example 2

[0060] Taking the ground oil sludge from an oilfield as the processing object, its water content is 40%, oil content is 15%, and the average particle size is less than 10mm. After being treated by a high-efficiency solid-liquid separator, the moisture content of the sludge is 60% to 65%, and the oil content of the sludge is reduced to 3%; after drying, the moisture content of the sludge is reduced to 19%, and the dried sludge is sent to the Send it to the metering hopper and fall on the stainless steel track in the thermal desorption system. The temperature range of the oil sludge in the thermal desorption chamber is controlled at 300-500 °C, and the residence time is 18 minutes. The temperature of the high-temperature combustion chamber is controlled at 850 °C. Stay for 1.5s. The oil content of the slag after thermal desorption is 200mg / kg, and the removal rate reaches 99.62%. The dioxin content in the flue gas purified by thermal desorption tail gas is less than 0.1TEQng / Nm ...

example 3

[0062] Taking the oil mud sand in an oilfield as the processing object, its water content is 55%, oil content is 25%, and the average particle size is less than 10mm. After being treated by a high-efficiency solid-liquid separator, the moisture content of the sludge is 60% to 65%, and the oil content of the sludge is reduced to 5%; after drying, the moisture content of the sludge is reduced to 18%, and the dried sludge is sent to the Send it to the metering hopper and fall on the stainless steel track in the thermal desorption system. The temperature range of the oil sludge in the thermal desorption chamber is controlled at 400-550°C, and the residence time is 20min. The temperature of the high-temperature combustion chamber is controlled at 950°C. Stay for 1.8s. The oil content of the slag after thermal desorption is 180mg / kg, and the removal rate reaches 99.71%. The dioxin content in the flue gas purified by thermal desorption tail gas is less than 0.1TEQng / Nm after high-tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com