Hybrid nozzle guide vane made of ceramic matrix composite materials

A technology for turbine guides and composite materials, which is applied in the direction of machines/engines, stators, engine components, etc., can solve problems such as complex flow paths, which are difficult to manufacture, achieve high combustion temperatures, reduce weight, simplify cooling flow paths and The effect of additional structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

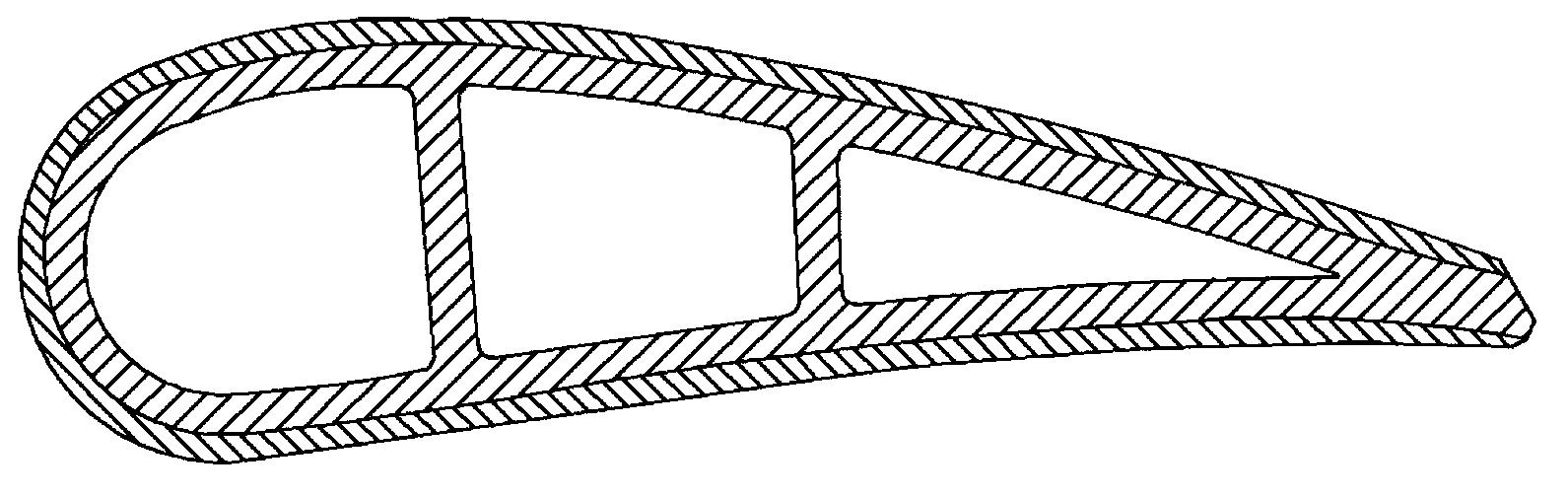

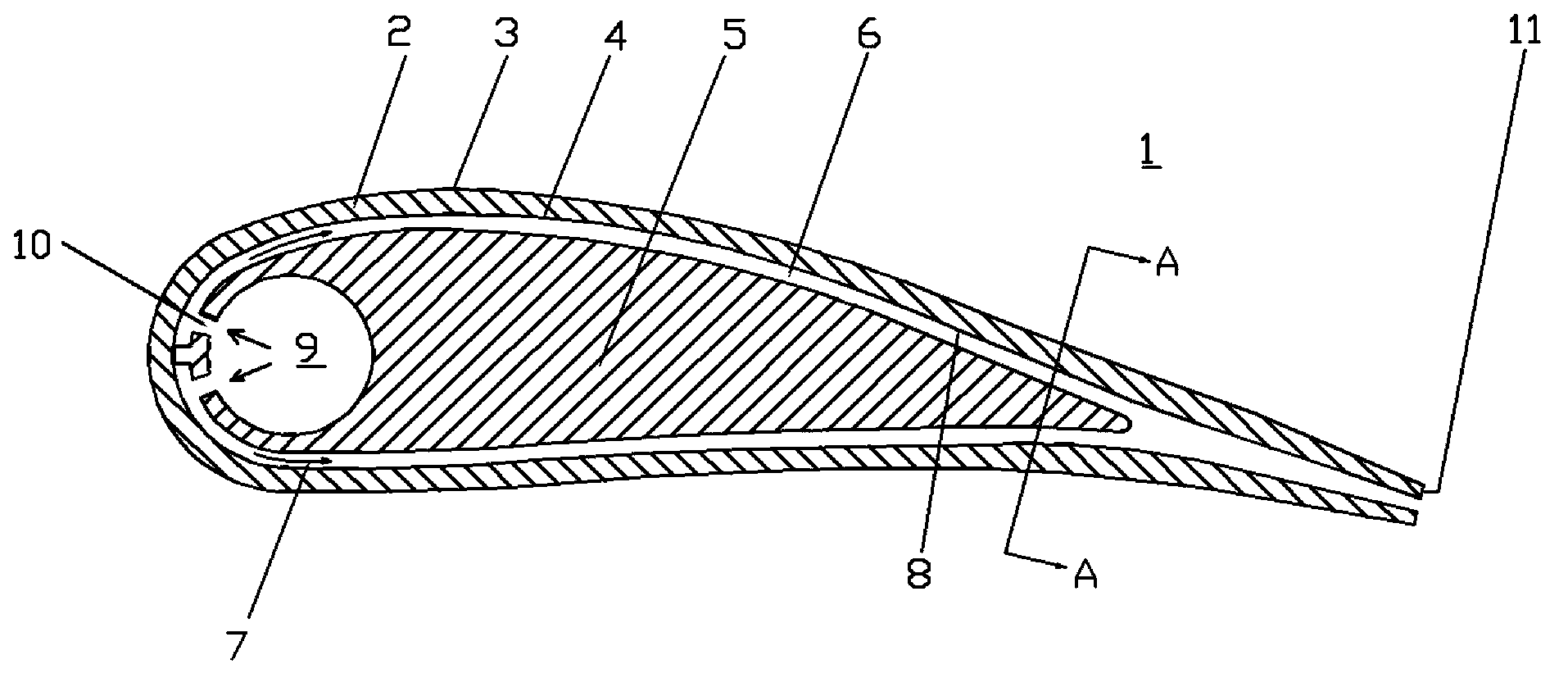

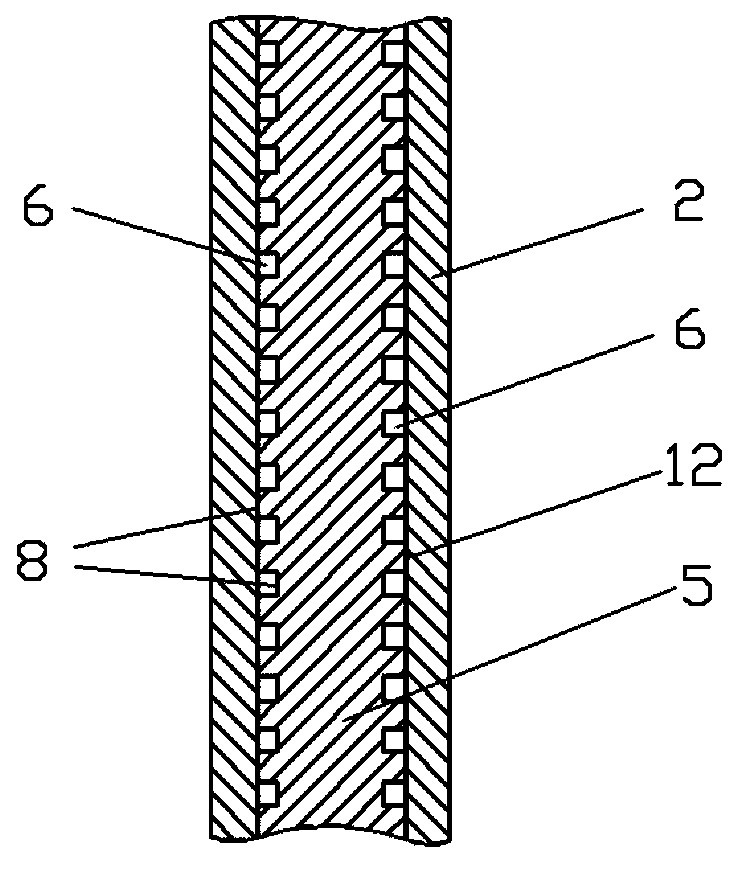

[0037] See Figure 1-Figure 4 , the present invention is a hybrid ceramic matrix composite material turbine guide blade (1), which includes an airfoil part (2) and a core part (5), and the core part (5) is installed inside the airfoil part (2) . The airfoil part (2) is composed of fiber-reinforced ceramic matrix composite material CMC, and the shape of the outer surface (3) of the airfoil part is a cubic spline surface, which determines the aerodynamic shape of the blade, and the shape of the inner surface (4) of the airfoil part Also a cubic spline surface, defining the interior area. The outer surface of the airfoil part (2) is attached with a thermal barrier coating TBC - mullite (2Al 2 o 3 -3SiO 2 ). The shape of the core part (5) corresponds to the inner surface of the airfoil part (2), and the core part (5) is installed inside the airfoil part (2). The inner core part (5) is made of metal material, and a plurality of cooling flow channels (6) are arranged on it, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com